hose CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 495 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 495

Again, rotate the engine, this time

to position the number one cylinder bore

(head surface) up. Turn the crankshaft until the number one piston is at the

bottom of its travel, this should allow t he maximum access to its connecting rod.

Remove the number one co nnecting rods fasteners and cap and place two

lengths of rubber hose over the rod bolts/studs to protect the crankshaft from

damage. Using a sturdy wooden dowel and a hammer, push the connecting rod

up about 1 in. (25mm) from the cranks haft and remove the upper bearing insert.

Continue pushing or tapping the connecti ng rod up until the piston rings are out

of the cylinder bore. Remove the piston and rod by hand, put the upper half of

the bearing insert back into the rod, in stall the cap with its bearing insert

installed, and hand-tighten the cap fasteners. If the parts are kept in order in this

manner, they will not get lost and you wil l be able to tell which bearings came

form what cylinder if any problems are discovered and diagnosis is necessary.

Remove all the other piston assemblie s in the same manner. On V-style

engines, remove all of the pistons from one bank, then reposition the engine

with the other cylinder bank head surface up, and remo ve that banks piston

assemblies.

The only remaining component in the engine block should now be the

crankshaft. Loosen the main bearing ca ps evenly until the fasteners can be

turned by hand, then remove them and the caps. Remove the crankshaft fro\

m

the engine block. Thoroughly clea n all of the components.

INSPECTION

Now that the engine block and all of its components ar e clean, it's time to

inspect them for wear and/or damage. To accurately inspect them, you will need

some specialized tools:

• Two or three separate micromet ers to measure the pistons and

crankshaft journals

• A dial indicator

• Telescoping gauges for the cylinder bores

• A rod alignment fixture to check for bent connecting rods

If you do not have access to the proper tools, you may want to bring the

components to a shop that does.

Generally, you shouldn't expect cracks in the engine block or its components

unless it was known to leak, consume or mix engine fluids, it was severely

overheated, or there was ev idence of bad bearings and/or crankshaft damage.

A visual inspection should be performed on all of the components, but just

because you don't see a crack does not mean it is not there. Some more

reliable methods for inspecting for cracks include Magnaflux, a magnetic

process or Zyglo, a dye penetrant. M agnaflux is used only on ferrous metal

(cast iron). Zyglo uses a spray on fluoresce nt mixture along with a black light to

reveal the cracks. It is strongly recommended to have your engine block

checked professionally for cracks, especia lly if the engine was known to have

overheated and/or leaked or consumed coolant. Contact a local shop for

availability and pricing of these services.

Page 509 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 509

1. Before installing the

piston/connecting rod assembly, oil the pistons,

piston rings and the cylinder walls with light engine oil. Install connecting

rod bolt protectors or rubber hose onto the connecting rod bolts/studs.

Also perform the following: a. Select the proper ring set for the size cylinder bore.

b. Position the ring in the bore in which it is going to be used.

c. Push the ring down into the bor e area where normal ring wear is

not encountered.

d. Use the head of the piston to posi tion the ring in the bore so that

the ring is square with the cyli nder wall. Use caution to avoid

damage to the ring or cylinder bore.

e. Measure the gap betw een the ends of the ring with a feeler gauge.

Ring gap in a worn cylinder is normally greater than specification.

If the ring gap is greater than the specified limits, try an oversize

ring set.

Fig. 13: Checking the piston ring-to-ri ng groove side clearance using the ring

and a feeler gauge

Page 512 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 512

5. Make sure the ring gaps are pr

operly spaced around the circumference

of the piston. Fit a piston ring co mpressor around the piston and slide the

piston and connecting rod assembly do wn into the cylinder bore, pushing

it in with the wooden hammer handle. Pu sh the piston down until it is only

slightly below the top of the cylinder bore. Guide the connecting rod onto

the crankshaft bearing journal carefully, to avoid damaging the

crankshaft.

6. Check the bearing clearance of all the rod bearings, fitting them to the

crankshaft bearing journals. Follow the procedure in the crankshaft

installation above.

7. After the bearings have been fitted, apply a light coating of assembly oil

to the journals and bearings.

8. Turn the crankshaft until the appropria te bearing journal is at the bottom

of its stroke, then push the piston a ssembly all the way down until the

connecting rod bearing seat s on the crankshaft journal. Be careful not to

allow the bearing cap screws to stri ke the crankshaft bearing journals

and damage them.

9. After the piston and connecting rod assemblies have been installed, check the connecting rod side clearance on each crankshaft journal.

10. Prime and install t he oil pump and the oil pump intake tube.

CAMSHAFT, LIFTERS AND TIMING ASSEMBLY 1. Install the camshaft.

2. Install the lifters/followers into their bores.

3. Install the timing gears/chain assembly.

CYLINDER HEAD(S) 1. Install the cylinder head(s) using new gaskets.

2. Assemble the rest of the valve tr ain (pushrods and rocker arms and/or

shafts).

ENGINE COVERS AND COMPONENTS

Install the timing cover(s) and oil pan. Re fer to your notes and drawings made

prior to disassembly and install all of the components that were removed. Install

the engine into the vehicle.

ENGINE START-UP AND BREAK-IN

STARTING THE ENGINE

Now that the engine is inst alled and every wire and hose is properly connected,

go back and double check that all cool ant and vacuum hoses are connected.

Check that you oil drain plug is instal led and properly tightened. If not already

done, install a new oil filt er onto the engine. Fill the crankcase with the proper

amount and grade of engine oil. Fill the cooling system with a 50/50 mixture of

coolant/water.

Page 513 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 513

1. Connect the vehicle battery.

2. Start the engine. Keep y

our eye on your oil pressure indicator; if it does

not indicate oil pressure within 10 se conds of starting, turn the vehicle

off.

WARNING - Damage to the engine can result if it is allowed to run with no oil

pressure. Check the engine oil level to make sure that it is full. Check for any

leaks and if found, repair the leaks be fore continuing. If there is still no

indication of oil pressure, y ou may need to prime the system.

3. Confirm that there are no fluid leaks (oil or other).

4. Allow the engine to reach nor mal operating temperature (the upper

radiator hose will be hot to the touch).

5. If necessary, set the ignition timing.

6. Install any remaining components such as the air cleaner (if removed for

ignition timing) or body panels which were removed.

BREAKING IT IN

Make the first miles on the new engine , easy ones. Vary the speed but do not

accelerate hard. Most importantly, do not lug the engine, and avoid sustained

high speeds until at least 100 miles. Ch eck the engine oil and coolant levels

frequently. Expect the engine to use a littl e oil until the rings seat. Change the

oil and filter at 500 miles, 1500 mile s, then every 3000 miles past that.

KEEP IT MAINTAINED

Now that you have just gone through all of that hard work, keep yourself from

doing it all over again by thoroughly maintaining it. Not that you may not have

maintained it before, heck you c ould have had one to two hundred thousand

miles on it before doing this. However, you may have bought the vehicle used,

and the previous owner did not keep up on maintenance. Which is why you just

went through all of that hard work. See?

Page 537 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 537

ENGINE CONTROLS

EMISSION CONTROLS

CRANKCASE VENTILATION SYSTEM

OPERATION

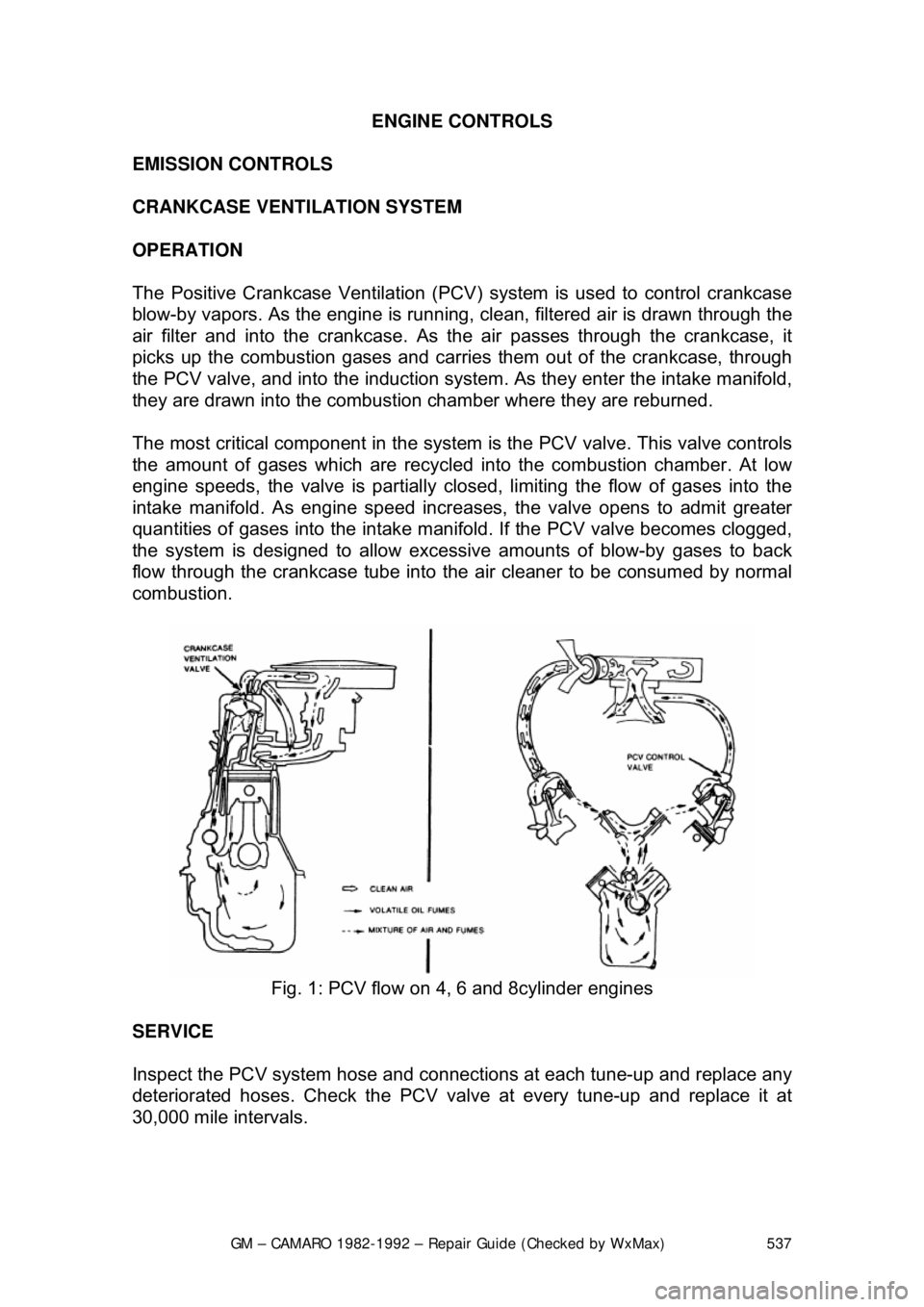

The Positive Crankcase Ventilation (PCV ) system is used to control crankcase

blow-by vapors. As the engine is running, clean, filtered air is drawn through the

air filter and into the crankcase. As the air passes through the crankca\

se, it

picks up the combustion gases and carries them out of the crankcase, through

the PCV valve, and into the induction system . As they enter the intake manifold,

they are drawn into the combustion chamber where they are reburned.

The most critical component in the system is the PCV valve. This valve controls

the amount of gases which are recycled into the combustion chamber. At low

engine speeds, the valve is partially clos ed, limiting the flow of gases into the

intake manifold. As engine speed incr eases, the valve opens to admit greater

quantities of gases into the intake manifold. If the PCV valve becomes clogged,

the system is designed to allow excessive amounts of blow-by gases to back

flow through the crankcase tube into the air cleaner to be consumed by normal

combustion.

Fig. 1: PCV flow on 4, 6 and 8cylinder engines

SERVICE

Inspect the PCV system hose and connecti ons at each tune-up and replace any

deteriorated hoses. Check the PCV valve at every tune-up and replace it at

30,000 mile intervals.

Page 538 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 538

TESTING

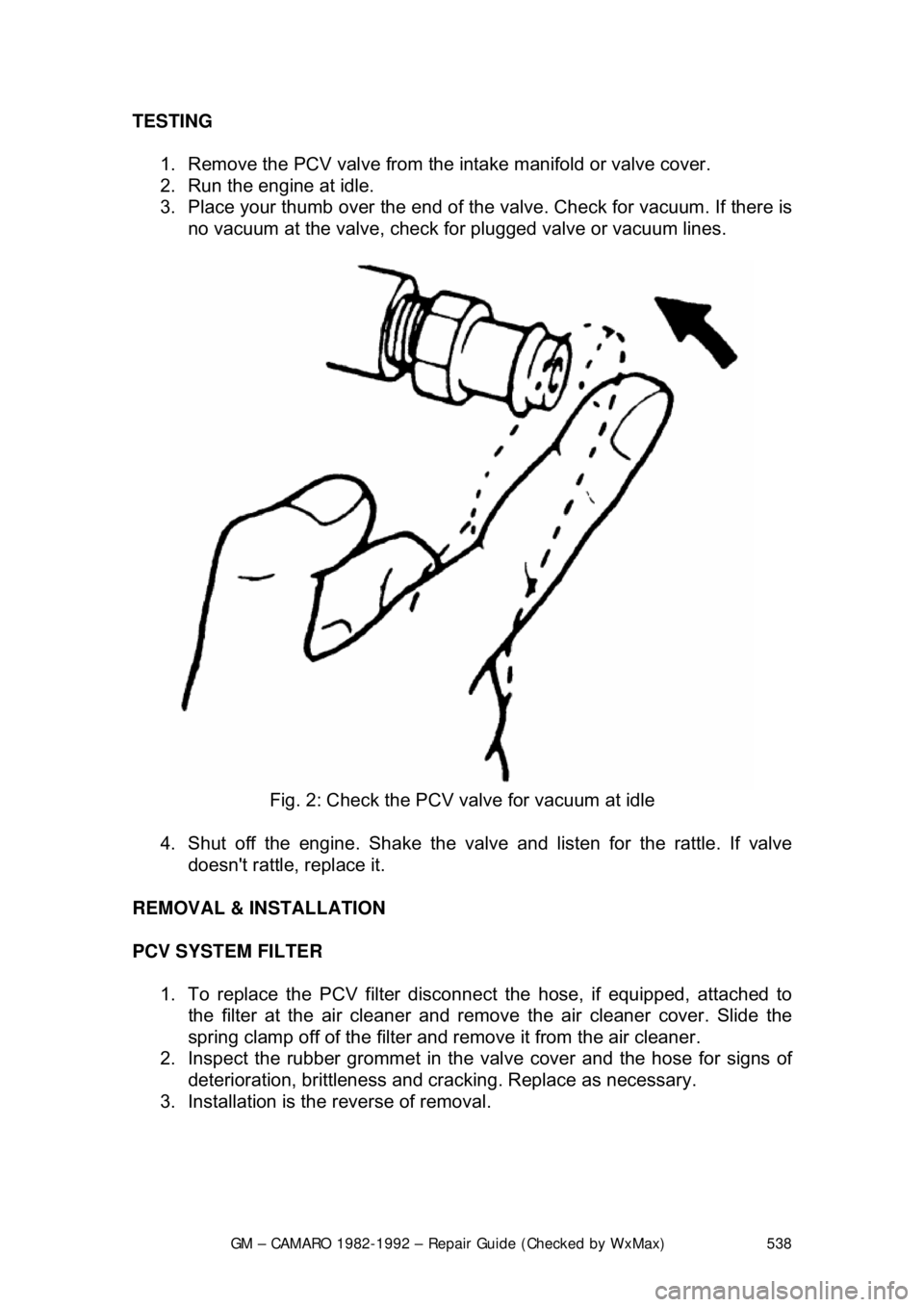

1. Remove the PCV valve from the intake manifold or valve cover.

2. Run the engine at idle.

3. Place your thumb over the end of the valve. Check for vacuum. If there is

no vacuum at the valve, check fo r plugged valve or vacuum lines.

Fig. 2: Check the PCV valve for vacuum at idle

4. Shut off the engine. Shake the valv e and listen for the rattle. If valve

doesn't rattle, replace it.

REMOVAL & INSTALLATION

PCV SYSTEM FILTER

1. To replace the PCV filter discon nect the hose, if equipped, attached to

the filter at the air cl eaner and remove the air cleaner cover. Slide the

spring clamp off of the filter and re move it from the air cleaner.

2. Inspect the rubber grommet in the valve cover and the hose for signs of \

deterioration, brittleness and cracking. Replace as necessary.

3. Installation is the reverse of removal.

Page 539 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 539

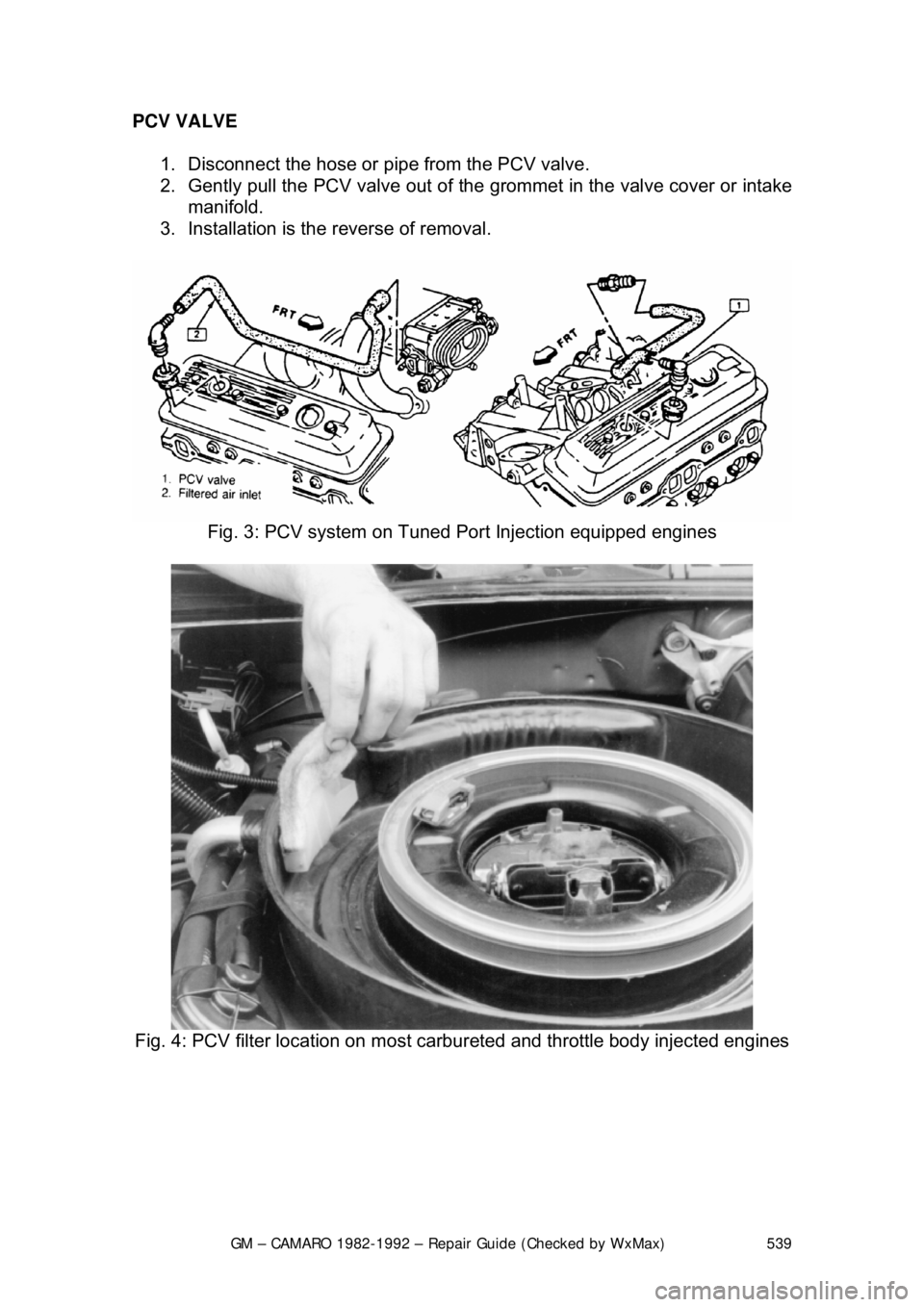

PCV VALVE

1. Disconnect the hose or pi pe from the PCV valve.

2. Gently pull the PCV valv e out of the grommet in the valve cover or intake

manifold.

3. Installation is the reverse of removal.

Fig. 3: PCV system on Tuned Port Injection equipped engines

Fig. 4: PCV filter location on most carbureted and throttle body injected engines

Page 540 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 540

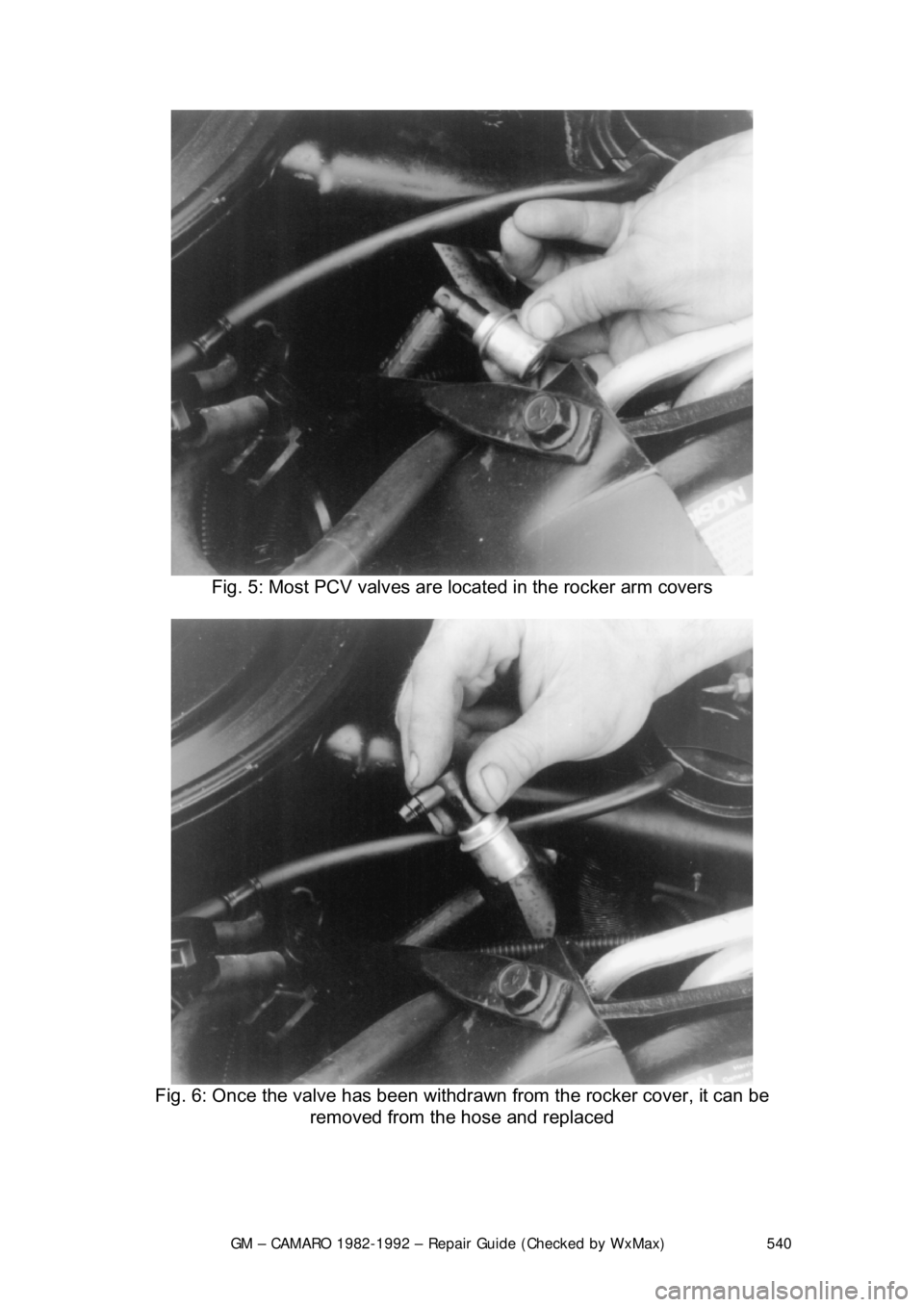

Fig. 5: Most PCV valves are lo cated in the rocker arm covers

Fig. 6: Once the valve has been withdraw n from the rocker cover, it can be

removed from the hose and replaced

Page 544 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 544

TESTING

TANK PRESSURE CONTROL VALVE

1. Using a hand-held vacuum pump, apply a vacuum of 15 in. Hg. (51 kPa)

through the control vacuum signal tube to the purge valve diaphragm. If

the diaphragm does not hold 5 in. Hg . at least for 10 seconds, the

diaphragm is leaking. Repl ace the control valve.

2. With the vacuum still applied to t he control vacuum tube, attach a short

piece of hose to the valve's tank tube side and blow into the hose. Air \

should pass through the valve. If it does not, replace the control valve.

REMOVAL & INSTALLATION

CANISTER 1. Disconnect the negative battery cable.

2. Loosen the screw holding the c anister retaining bracket.

3. Remove the canister.

4. Tag and disconnect the hoses leading from the canister.

To install: 5. Connect the hoses to the cani ster according to the tags.

6. Install the canister into the retaining bracket.

7. Tighten the screw holding the c anister retaining bracket.

8. Reconnect the negative battery cable.

Fig. 5: A common EEC canister location

Page 545 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 545

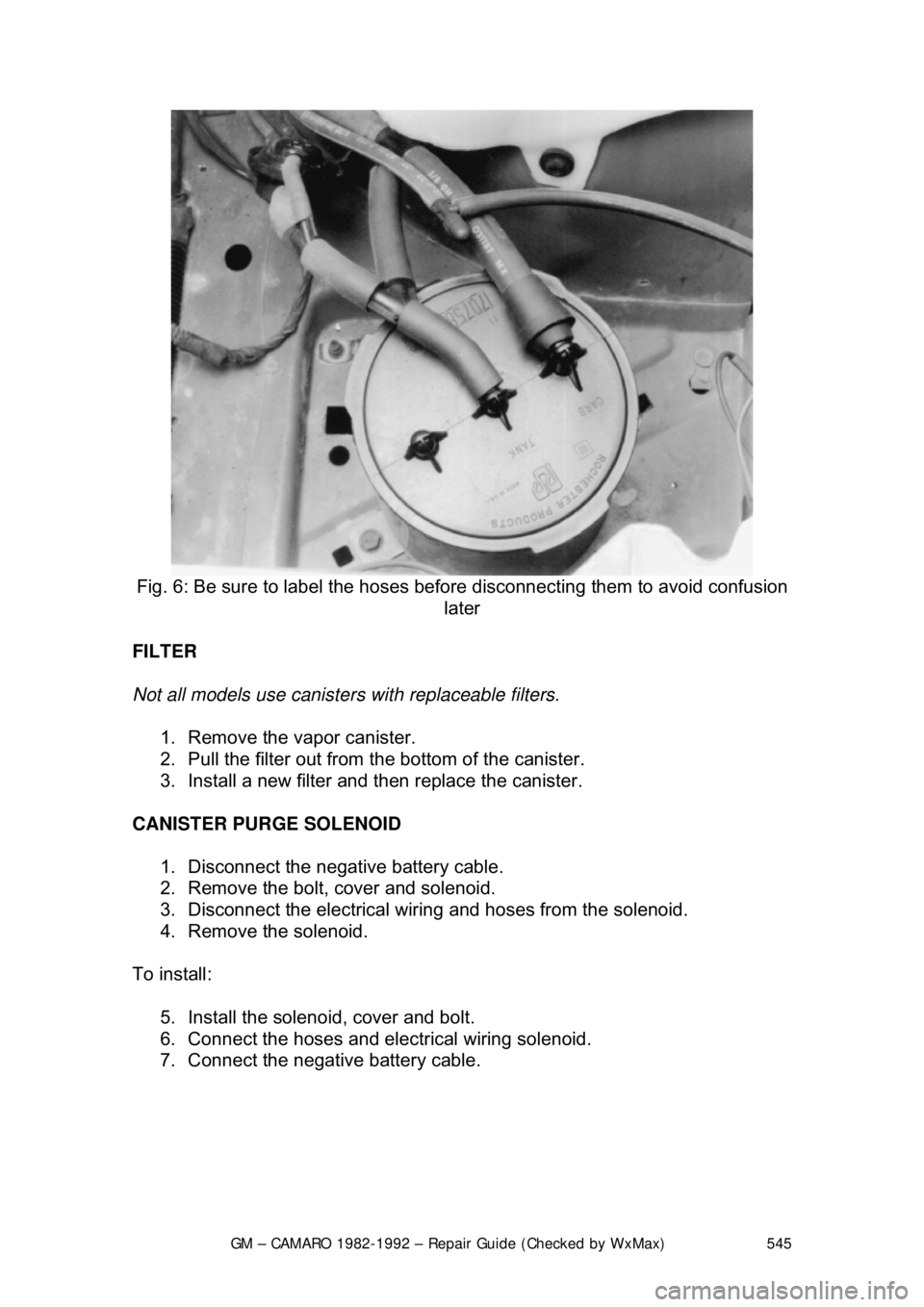

Fig. 6: Be sure to label the hoses bef ore disconnecting them to avoid confusion

later

FILTER

Not all models use canister s with replaceable filters.

1. Remove the vapor canister.

2. Pull the filter out from the bottom of the canister.

3. Install a new filter and then replace the canister.

CANISTER PURGE SOLENOID 1. Disconnect the negative battery cable.

2. Remove the bolt, cover and solenoid.

3. Disconnect the electrical wirin g and hoses from the solenoid.

4. Remove the solenoid.

To install: 5. Install the solenoid, cover and bolt.

6. Connect the hoses and elec trical wiring solenoid.

7. Connect the negative battery cable.