air condition CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 73 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 73

To install:

9. Install the new line or hose, starti

ng with the end farthest from the master

cylinder. Connect the other end, then confirm that both fittings are correctly

threaded and turn smoothly using finger pressure. Make sure the new line

will not rub against any ot her part. Brake lines must be at least 1/2 in.

(13mm) from the steering column and other moving parts. Any protective

shielding or insulators must be rein stalled in the original location.

WARNING - Make sure the hose is NO T kinked or touching any part of the

frame or suspension after installation. These conditions may cause the hose to

fail prematurely.

10. Using two wrenches as bef ore, tighten each fitting.

11. Install any retaining clips or brackets on the lines.

12. If removed, install the wheel and tire assemblies, then carefully lower the

vehicle to the ground.

13. Refill the brake master cylinder re servoir with clean, fresh brake fluid,

meeting DOT 3 specifications. Pr operly bleed the brake system.

14. Connect the negative battery cable.

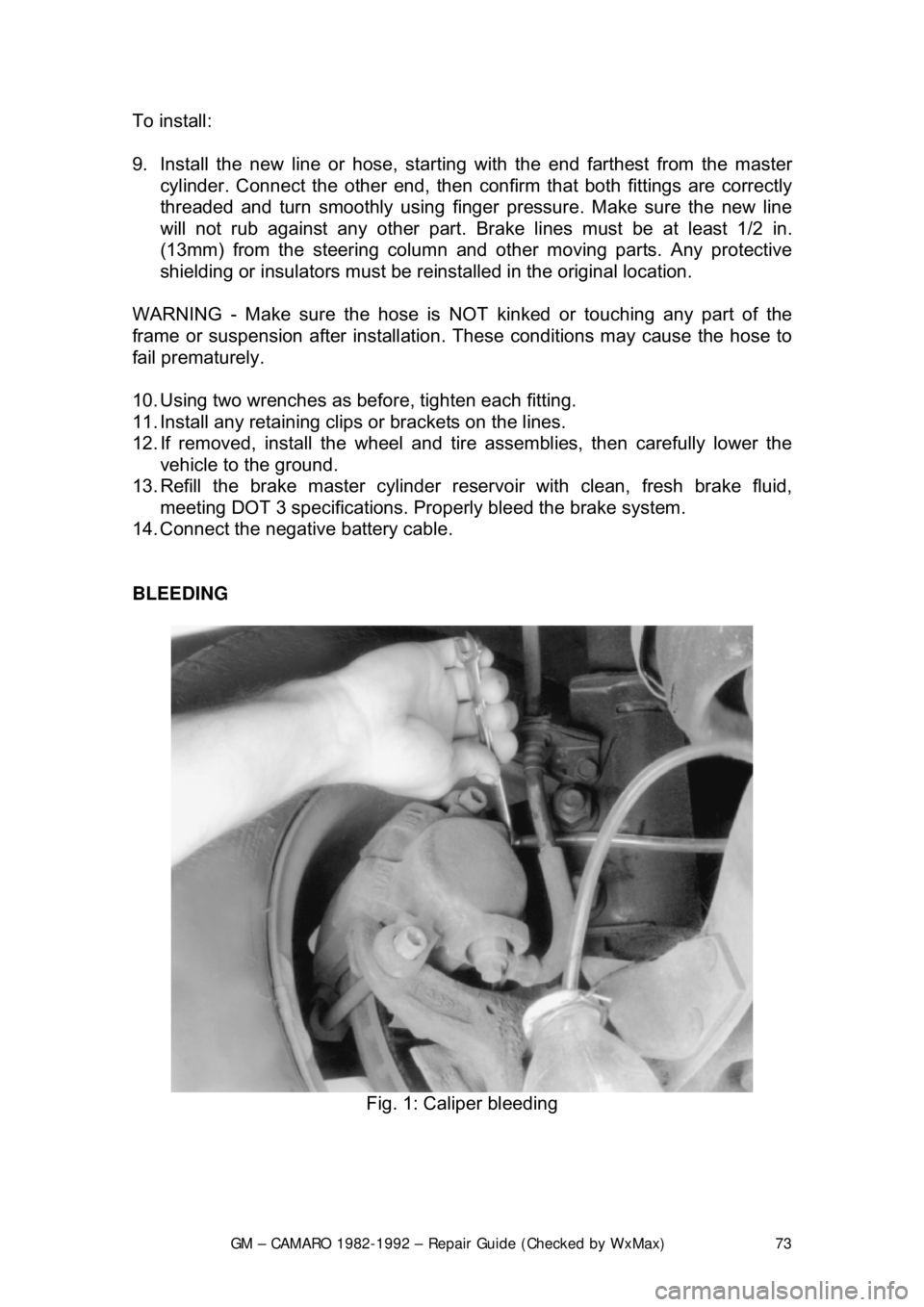

BLEEDING

Fig. 1: Caliper bleeding

Page 82 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 82

Avoid inhaling any dust from

any brake surface! When cleaning brake surfaces,

use a commercially available brake cleaning fluid.

1. Remove

2/3 of the brake fluid from the mast er cylinder. Raise the vehicle and

remove the wheel.

2. Place a C-clamp across the caliper, positioned on the brake pads. Tighten it

until the piston is forced into its bore.

3. Remove the C-clamp. Remove the bolt holding the brake hose to the caliper.

4. Remove the Allen head caliper mounting bolts. Inspect them for corrosion

and replace them if necessary. Remove the caliper.

To install:

5. Position the caliper with the brake pad installed and install Allen head caliper

mounting bolts. Mounting bo lt torque is 21-35 ft. lbs. (28-47 Nm.) for the

caliper.

6. Install the bolt holding the brake hos e to the caliper and tighten to 18-30 ft.

lbs. (24-40 Nm.).

7. Fill the master cylinder with brake fluid.

8. Install the wheels and lower the vehicle.

CAUTION - Before moving the vehicle, pump the brakes several times to seat

the brake pad against the rotor

OVERHAUL

Some vehicles may be equipped dual piston calipers. The procedure to

overhaul the caliper is e ssentially the same with t he exception of multiple

pistons, O-rings and dust boots.

1. Remove the caliper from the ve hicle and place on a clean workbench.

CAUTION - NEVER place your finger s in front of the pistons in an attempt to

catch or protect the pistons when applying compressed air. This could result in

personal injury!

Depending upon the vehicle, there are two different ways to remove the piston

from the caliper. Refer to the brake pad replacement procedure to make sure

you have the correct procedure for your vehicle.

2. The first method is as follows: a. Stuff a shop towel or a block of wood into the caliper to catch the piston.

b. Remove the caliper piston using co mpressed air applied into the caliper

inlet hole. Inspect the piston for scor ing, nicks, corrosion and/or worn or

damaged chrome plating. The piston mu st be replaced if any of these

conditions are found.

Page 93 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 93

2. Remove the wheel or wheels.

3. Pull the brake drum off. It may be nec

essary to gently tap the rear edges of

the drum to start it off the studs.

4. If extreme resistance to removal is encountered, it will be necessary to

retract the adjusting screw. Knock out the access hole in the backing plate

and turn the adjuster to retract th e linings away from the drum.

5. Install a replacement hole co ver before reinstalling drum.

6. Install the drums in the same position on the hub as removed.

DRUM INSPECTION

1. Check the drums for any cracks, scores, grooves, or an out-of-round

condition. Replace if cracked. Slight scores can be removed with fine emery

cloth while extensive scoring requires turning the drum on a lathe.

2. Never have a drum turned mo re than 0.060 in. (1.524mm).

BRAKE SHOES

ADJUSTMENT

Rotate the star wheel adjuster until a sl ight drag is felt between the shoes and

drum, then back off 12 clicks on the adjusting wheel. Put the car in reverse and,

while backing up, apply the brakes seve ral times. This will allow the self-

adjusters to complete the adjustment.

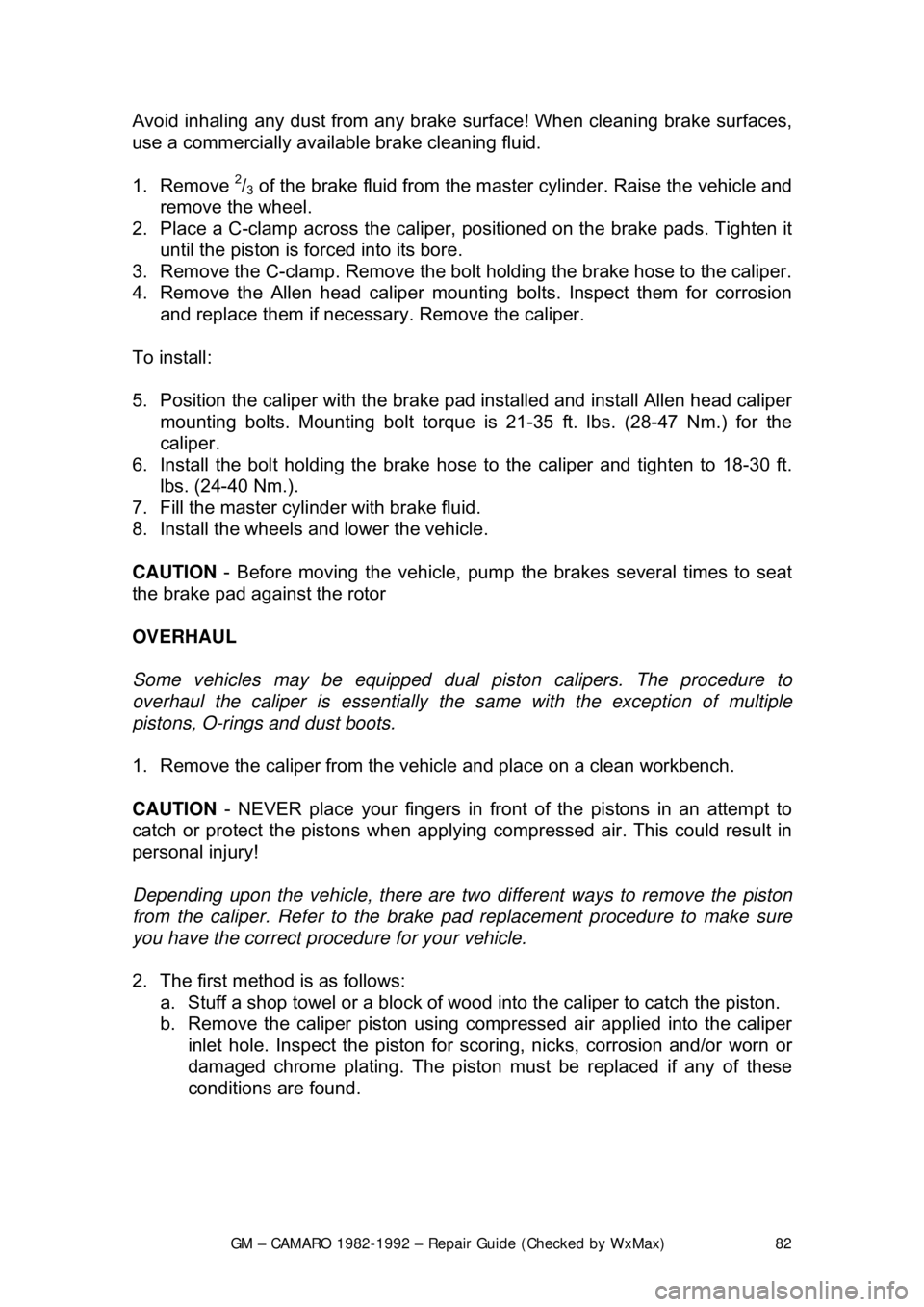

REMOVAL & INSTALLATION

Fig. 1: Drum brake assembly

Page 102 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 102

CAUTION

- Brake shoes may contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

1. Raise and support the car. Remove t he wheel. Remove the brake shoes by

following the Brake Shoe R eplacement procedure.

2. Remove dirt from ar ound the wheel cylinder inle t and pilot. Disconnect the

inlet tube.

3. Using 2 awls,

1/8 in. (3mm) in diameter, or J29839, remove the wheel

cylinder retainer. Insert the awls in to the access slots between the wheel

cylinder pilot and retainer. Simultaneous ly, bend both tabs away from each

other. Remove the wheel cylinder.

To install:

4. Place wheel cylinder into position and place a block of wood between it and

the axle flange. Install a new retainer over the end of the wheel cylinder.

Using a 1

1/8 in. 12-point socket with an extensi on, drive the new retainer into

position.

5. Connect the inlet tube and torque 120-280 inch lbs. (13.6-20 Nm). Complete

installation by reversing the remova l procedure. Bleed the brakes.

OVERHAUL

Wheel cylinder overhaul kits may be available, but often at little or no savings

over a reconditioned wheel cylinder. It often makes sense with these

components to substitute a new or re conditioned part instead of attempting an

overhaul.

If no replacement is availabl e, or you would prefer to overhaul your wheel

cylinders, the following procedure may be used. When rebuilding and installing

wheel cylinders, avoid getting any cont aminants into the system. Always use

clean, new, high quality brake fluid. If di rty or improper fluid has been used, it

will be necessary to drain the entire syst em, flush the system with proper brake

fluid, replace all rubber components , then refill and bleed the system.

1. Remove the wheel cylinder from the vehicle and place on a clean

workbench.

2. First remove and discard the old r ubber boots, then withdraw the pistons.

Piston cylinders are equipped with seals and a spring assembly, all located

behind the pistons in the cylinder bore.

Page 119 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 119

1. Raise and support the car. Remove the wheel.

2. Remove the caliper by referring to

the Rear Caliper Removal procedure. Pull

the brake disc from the axle.

3. To install, place the rotor ont o the spindle and install caliper.

4. Install the wheel and lower the car.

INSPECTION

1. Raise and support the car. Remove the wheel. Replace wheel nuts to hold rotor in place.

2. Check the rotor surface for wear, sco ring, grooves or rust pitting. Rotor

damage can be corrected by refacing, cons ult your local garage or machine

shop. If the damage exceeds the minimu m thickness, which is stamped on

the rotor, replace the rotor.

3. Using a dial indicator, check the ro tor parallelism at several points around

the circumference. The difference must not vary more than 0.0005 in.

(0.013mm). Make all measur ements at the same distance in from the edge

of the rotor.

4. Using the same dial indicator, meas ure the rotor runout. The runout should

not exceed 0.004 in. (0.10mm).

5. If any of these conditions are not me t, reface or replace the rotor.

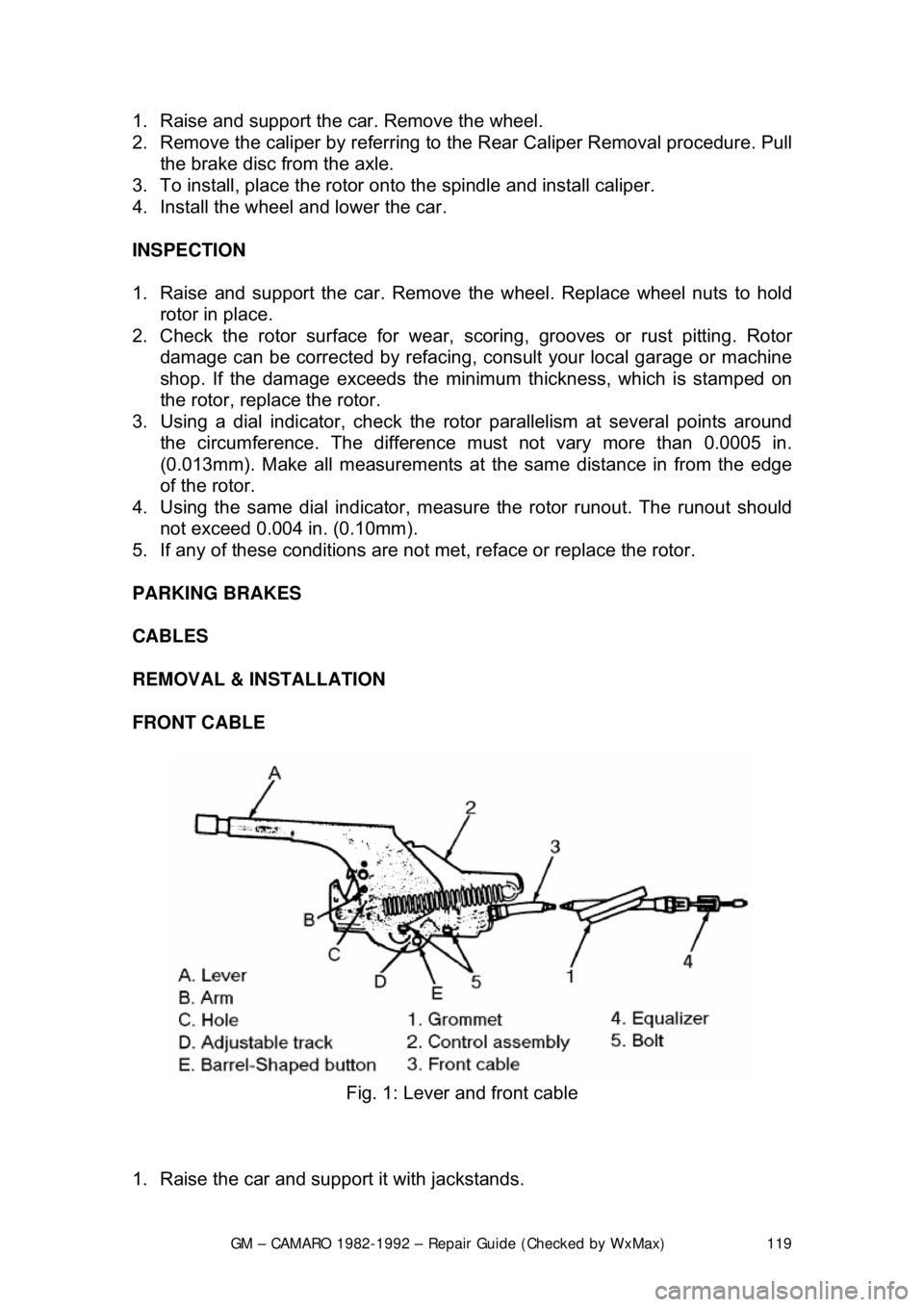

PARKING BRAKES

CABLES

REMOVAL & INSTALLATION

FRONT CABLE

Fig. 1: Lever and front cable

1. Raise the car and support it with jackstands.

Page 123 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 123

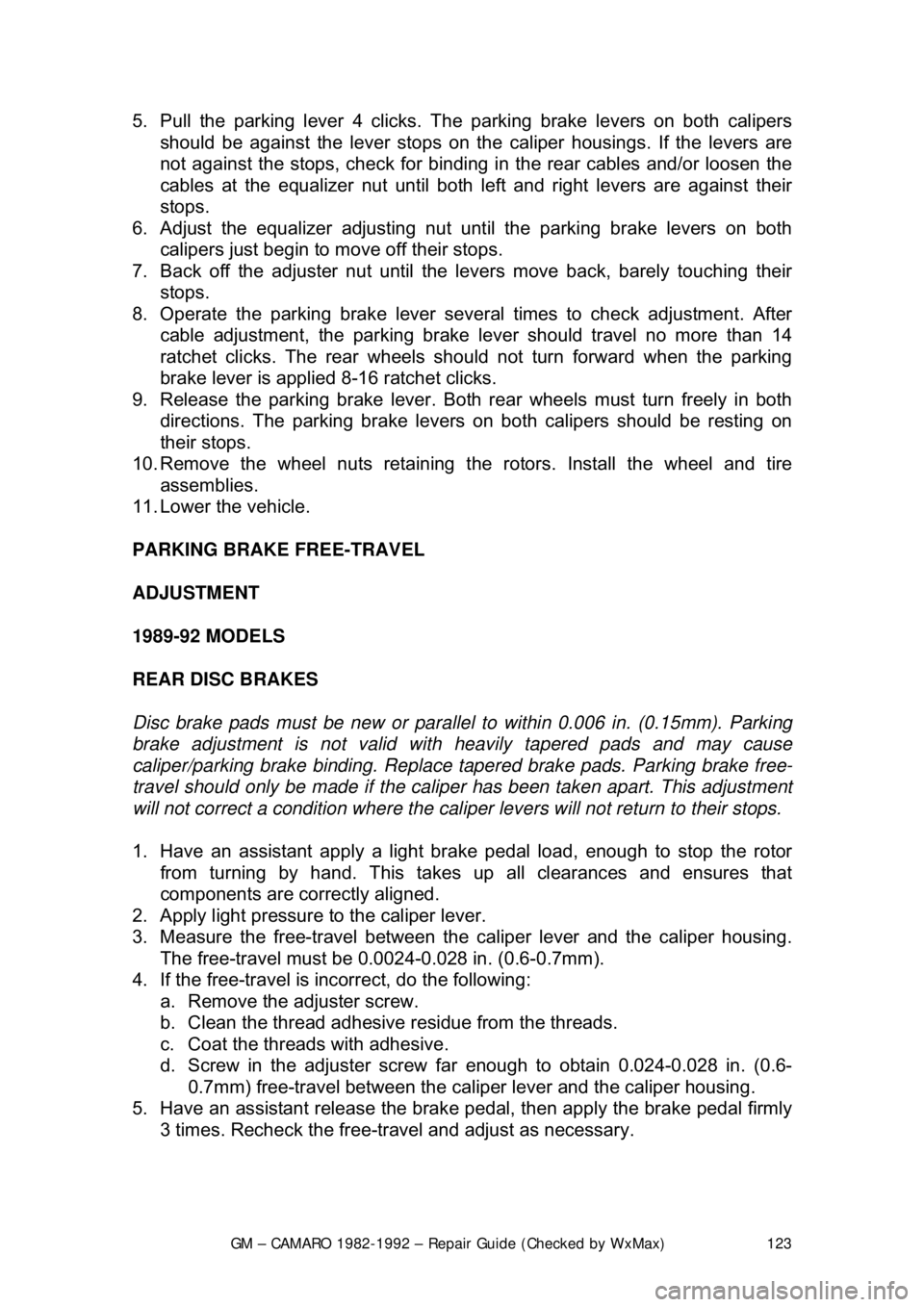

5. Pull the parking lever 4 clicks. T

he parking brake levers on both calipers

should be against the lever stops on the caliper housings. If the levers are

not against the stops, check for binding in the rear cables and/or loosen the

cables at the equalizer nut until both left and right levers are against their

stops.

6. Adjust the equalizer adjusting nut unt il the parking brake levers on both

calipers just begin to mo ve off their stops.

7. Back off the adjuster nut until the le vers move back, barely touching their

stops.

8. Operate the parking brak e lever several times to check adjustment. After

cable adjustment, the parking brake le ver should travel no more than 14

ratchet clicks. The rear wheels shoul d not turn forward when the parking

brake lever is applied 8-16 ratchet clicks.

9. Release the parking brake lever. Both rear whee ls must turn freely in both

directions. The parking brake levers on both calipers should be resting on

their stops.

10. Remove the wheel nuts retaining t he rotors. Install the wheel and tire

assemblies.

11. Lower the vehicle.

PARKING BRAKE FREE-TRAVEL

ADJUSTMENT

1989-92 MODELS

REAR DISC BRAKES

Disc brake pads must be new or parallel to within 0.006 in. (0.15mm). Parking

brake adjustment is not valid wit h heavily tapered pads and may cause

caliper/parking brake binding. Replace tapered brak e pads. Parking brake free-

travel should only be made if the caliper has been taken apart. This adjustment

will not correct a condition where the caliper levers will not return to their stops.

1. Have an assistant apply a light brake pedal load, enough to stop the rotor

from turning by hand. This takes up all clearances and ensures that

components are correctly aligned.

2. Apply light pressure to the caliper lever.

3. Measure the free-travel between t he caliper lever and the caliper housing.

The free-travel must be 0.0024-0.028 in. (0.6-0.7mm).

4. If the free-travel is incorrect, do the following: a. Remove the adjuster screw.

b. Clean the thread adhesive re sidue from the threads.

c. Coat the threads with adhesive.

d. Screw in the adjuster screw far enough to obtain 0.024-0.028 in. (0.6-

0.7mm) free-travel between the caliper lever and the caliper housing.

5. Have an assistant release the brak e pedal, then apply the brake pedal firmly

3 times. Recheck the free-travel and adjust as necessary.

Page 132 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 132

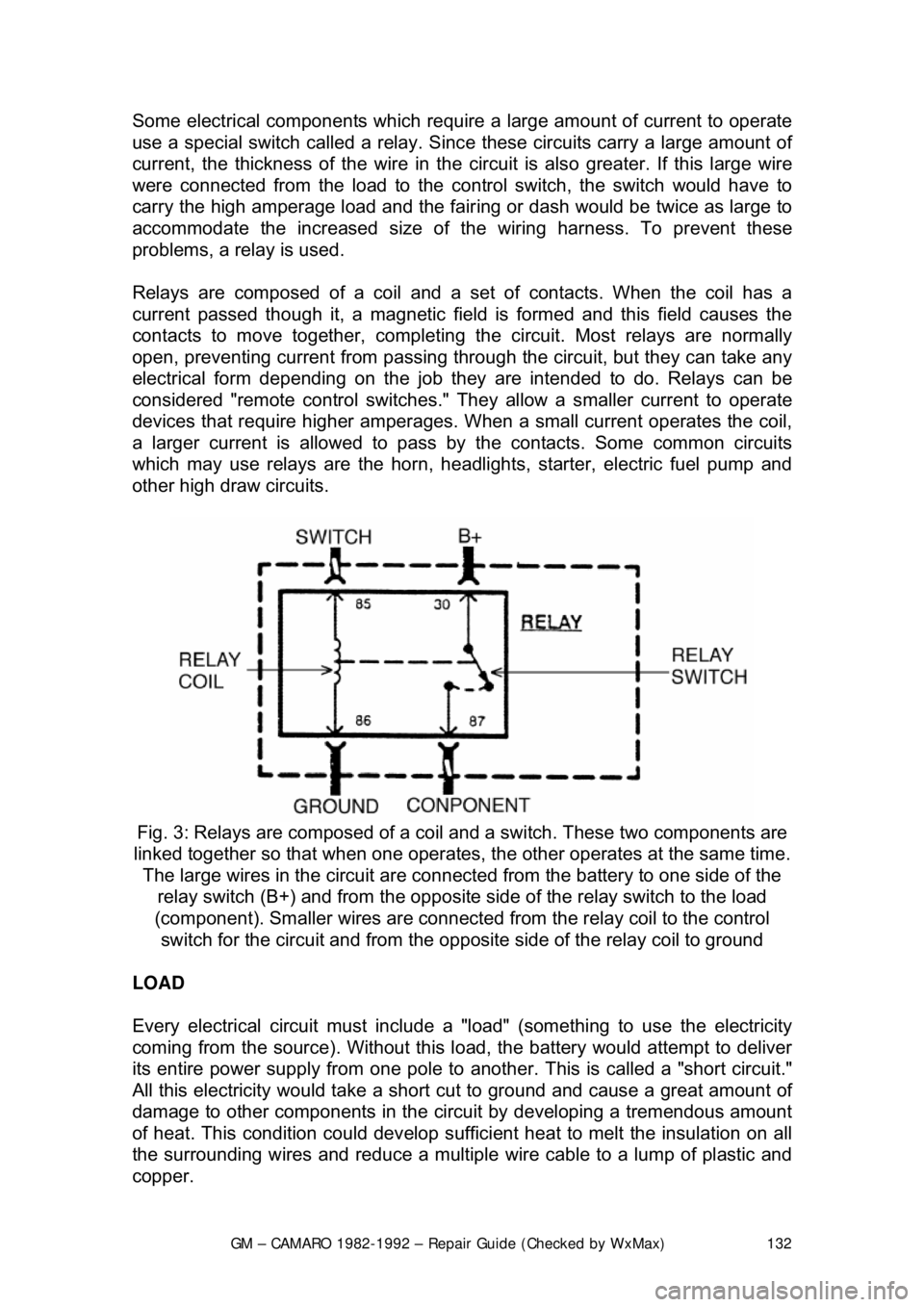

Some electrical components which require

a large amount of current to operate

use a special switch called a relay. Sinc e these circuits carry a large amount of

current, the thickness of the wire in the ci rcuit is also greater. If this large wire

were connected from the load to the c ontrol switch, the switch would have to

carry the high amperage load and the fair ing or dash would be twice as large to

accommodate the increased size of t he wiring harness. To prevent these

problems, a relay is used.

Relays are composed of a coil and a se t of contacts. When the coil has a

current passed though it, a magnetic fiel d is formed and this field causes the

contacts to move together, completing the circuit. Most relays are normally

open, preventing current from passing thr ough the circuit, but they can take any

electrical form depending on th e job they are intended to do. Relays can be

considered "remote control switches." They allow a smaller current to operate

devices that require higher amperages. W hen a small current operates the coil,

a larger current is allo wed to pass by the contacts. Some common circuits

which may use relays are the horn, headlight s, starter, electric fuel pump and

other high draw circuits.

Fig. 3: Relays are composed of a coil and a switch. These two components are

linked together so that w hen one operates, the other operat es at the same time.

The large wires in the circuit are connect ed from the battery to one side of the

relay switch (B+) and from the opposite side of the re lay switch to the load

(component). Smaller wires are connected from the relay coil to the control

switch for the circuit and from the opposite side of the relay coil to ground

LOAD

Every electrical circuit must include a "load" (something to use the electricity

coming from the source). Without this l oad, the battery would attempt to deliver

its entire power supply from one pole to another. This is called a "short circuit."

All this electricity would take a short cut to ground and cause a great amount of

damage to other components in the circui t by developing a tremendous amount

of heat. This condition could develop suffici ent heat to melt the insulation on all

the surrounding wires and reduce a multiple wire cable to a lump of plastic and

copper.

Page 139 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 139

TROUBLESHOOTING ELECTRICAL SYSTEMS

When diagnosing a specific problem, or

ganized troubleshooting is a must. The

complexity of a modern automotive v ehicle demands that you approach any

problem in a logical, organized m anner. There are certain troubleshooting

techniques, however, which are standard:

• Establish when the problem occurs. D oes the problem appear only under

certain conditions? Were there any noises, odors or other unusual

symptoms? Isolate the problem area. To do this, make some simple tests

and observations, then eliminate the syst ems that are working properly.

Check for obvious problems, such as broken wires and loose or dirty

connections. Always check the obvious before assuming something

complicated is the cause.

• Test for problems systematically to determine the cause once the

problem area is isolated. Are all t he components functioning properly? Is

there power going to electrical switc hes and motors. Performing careful,

systematic checks will often turn up mo st causes on the first inspection,

without wasting time checking co mponents that have little or no

relationship to the problem.

• Test all repairs after the work is done to make sure that the problem is

fixed. Some causes can be traced to more than one component, so a

careful verification of repair work is important in order to pick up

additional malfunctions that may cause a problem to reappear or a

different problem to arise. A blown fu se, for example, is a simple problem

that may require more than another fuse to repair. If you don't look for a

problem that caused a fuse to blow, a shorted wire (for example) may go

undetected.

Experience has shown that most problem s tend to be the result of a fairly

simple and obvious cause, such as loose or corroded connectors, bad grounds

or damaged wire insulation which causes a short. This makes careful visual

inspection of components during testing essential to quick and accurate

troubleshooting.

Page 151 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 151

ARMING THE SYSTEM

1. Turn the ignition key to the LO CK position and remove the key.

2. On vehicles with a passenger side ai r bag, reconnect the yellow two-way

connector assembly located near the yellow 24-way DERM harness

connector. Install the glov e box door assembly.

3. Connect the yellow two-way connector assembly at the base of the

steering column.

Always be sure to reinstall the Connec tor Position Assurance (CPA) device.

4. Install the left side trim panel and rein stall the fuse in the fuse block.

5. Turn the ignition key to the RUN posit ion and verify that the warning lamp

flashes seven to nine times and then turn s OFF. If it does not operate as

described, have the system repair ed by a qualified technician.

HEATING AND AIR CONDITIONING

BLOWER MOTOR

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable. If necessary, remove the diagonal

fender brace at the right rear corner of the engine compartment to gain

access to the blower motor.

2. Disconnect the electrical wiring fr om the blower motor. If equipped with

air conditioning, remove the blower relay and bracket as an assembly

and swing them aside.

3. Remove the blower motor cooling tube.

4. Remove the blower mo tor retaining screws.

5. Remove the blower motor and fan as an assembly from the case.

To install: 6. Position the blower motor into pl ace and install the retaining screws.

7. Install the blower motor cooling tube.

8. Connect all the electrical connections.

9. Connect the negative battery cable.

Page 159 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 159

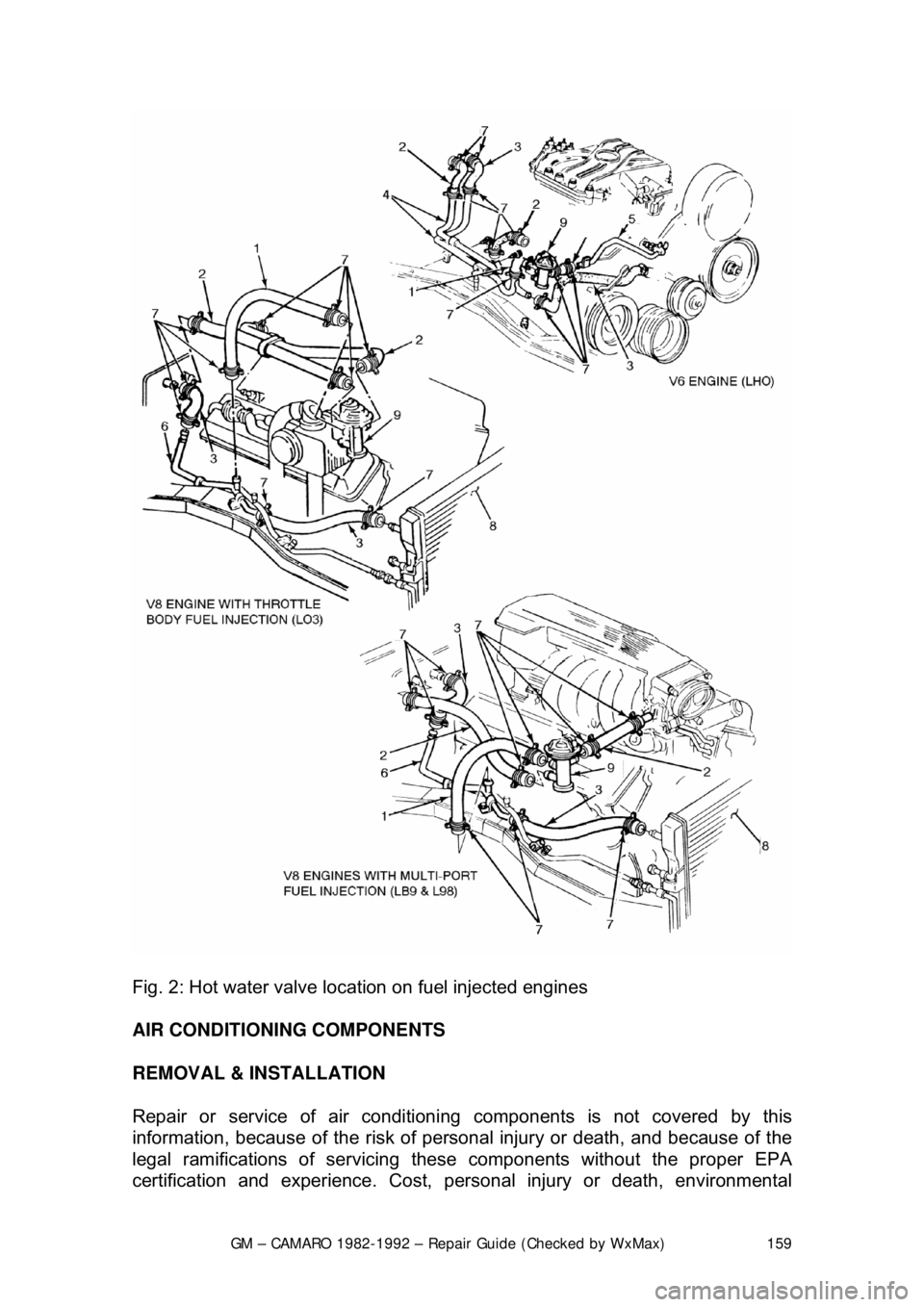

Fig. 2: Hot water valve location on fuel injected engines

AIR CONDITIONING COMPONENTS

REMOVAL & INSTALLATION

Repair or service of air conditioni ng components is not covered by this

information, because of the risk of personal injury or death, and because of the

legal ramifications of servicing these components without the proper EPA

certification and experience. Cost, perso nal injury or death, environmental