air condition CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 160 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 160

damage, and legal considerations (such as t

he fact that it is a federal crime to

vent refrigerant into the atmosphere), dictate that the A/C components on your

vehicle should be serviced only by a Motor Vehicle Air Conditioning (MVAC)

trained, and EPA certified aut omotive technician.

If your vehicle's A/C system uses R-12 re frigerant and is in need of recharging,

the A/C system can be c onverted over to R-134a refrigerant (less

environmentally harmful and expensive). Refer to General Information &

Maintenance for additional information on R- 12 to R-134a conversions, and for

additional considerations dealing with your vehicle's A/C system.

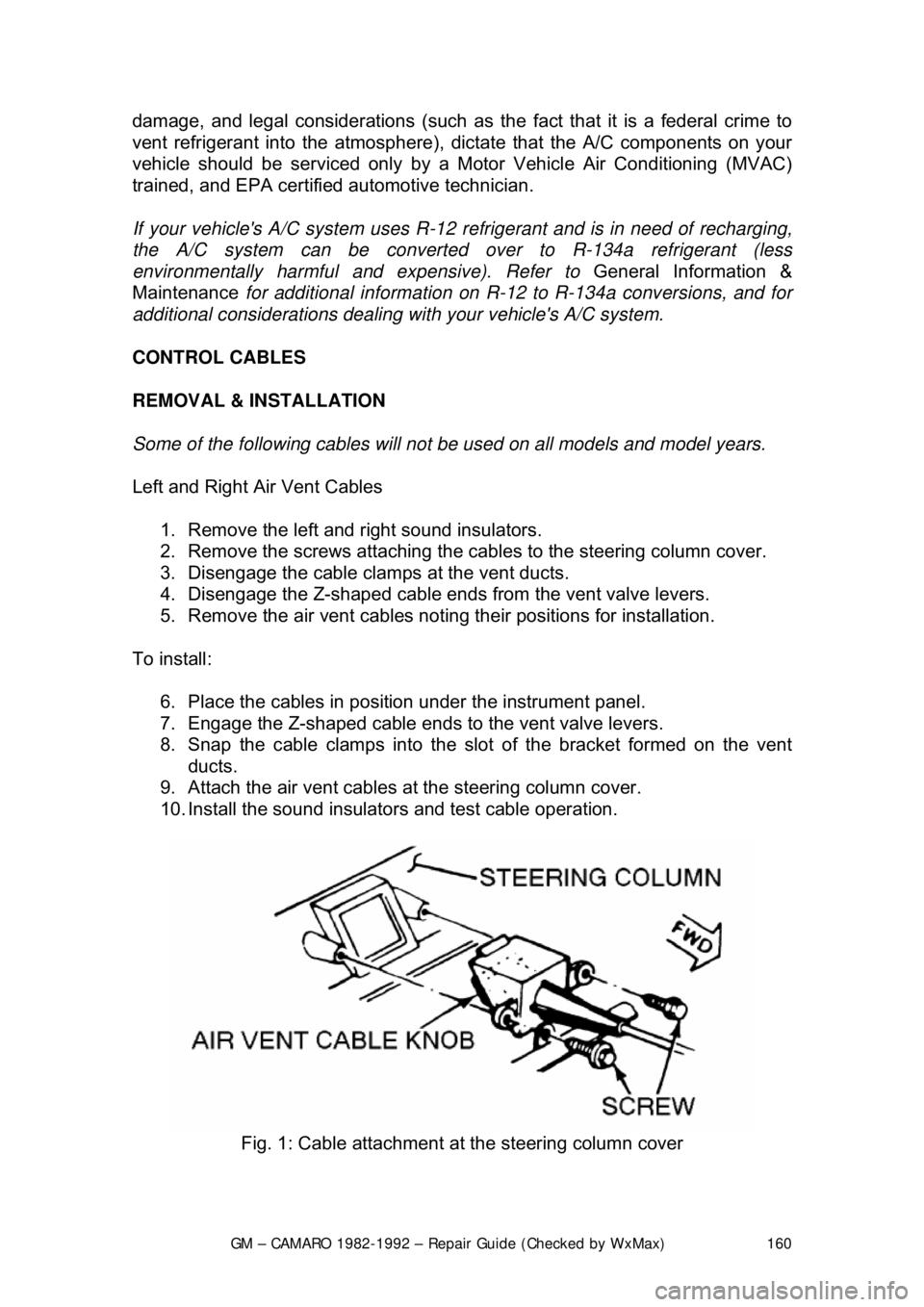

CONTROL CABLES

REMOVAL & INSTALLATION

Some of the following cables will not be used on all models and model years.

Left and Right Air Vent Cables 1. Remove the left and right sound insulators.

2. Remove the screws attaching the cabl es to the steering column cover.

3. Disengage the cable clamps at the vent ducts.

4. Disengage the Z-shaped c able ends from the vent valve levers.

5. Remove the air vent cables notin g their positions for installation.

To install: 6. Place the cables in posi tion under the instrument panel.

7. Engage the Z-shaped cable ends to the vent valve levers.

8. Snap the cable clamps into the slot of the bracket formed on the vent

ducts.

9. Attach the air vent cables at the steering column cover.

10. Install the sound insulators and test cable operation.

Fig. 1: Cable attachment at the steering column cover

Page 165 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 165

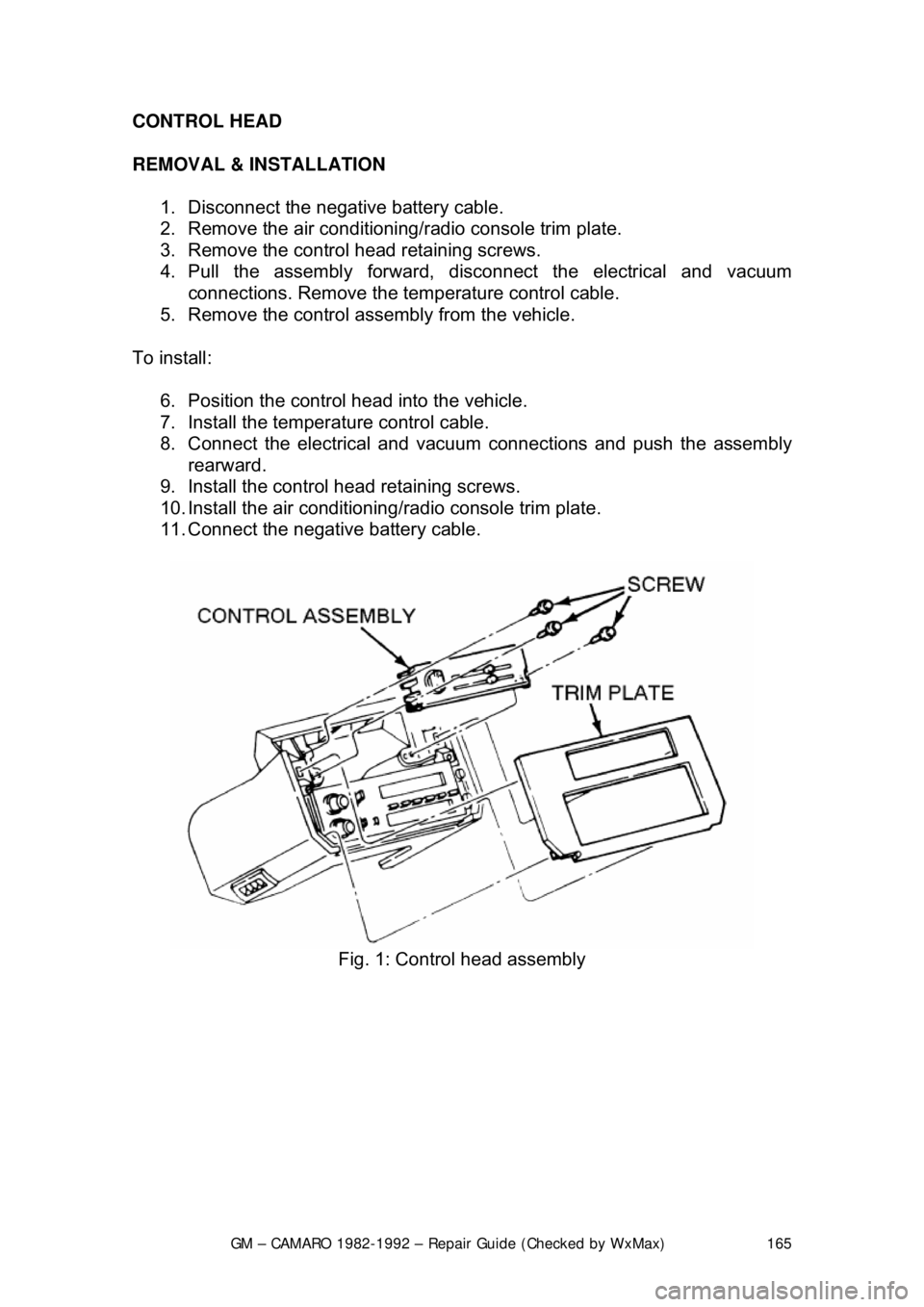

CONTROL HEAD

REMOVAL & INSTALLATION

1. Disconnect the negative battery cable.

2. Remove the air conditioning/ radio console trim plate.

3. Remove the control head retaining screws.

4. Pull the assembly forward, di sconnect the electrical and vacuum

connections. Remove the tem perature control cable.

5. Remove the control assembly from the vehicle.

To install: 6. Position the control head into the vehicle.

7. Install the temperat ure control cable.

8. Connect the electrical and vacuum connections and push the assembly rearward.

9. Install the control head retaining screws.

10. Install the air conditioning/ radio console trim plate.

11. Connect the negative battery cable.

Fig. 1: Control head assembly

Page 167 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 167

BLOWER SWITCH

With the control head removed from t

he vehicle, the blower switch may be

removed by pulling the blower switch knob off and removing the retaining clip or

retaining screws.

VACUUM MOTORS

OPERATION

Used on certain heating and air condition ing systems, the vacuum actuators

operate the air doors determining the differ ent modes. The actuator consists of

a spring loaded diaphragm connec ted to a lever. When vacuum is applied to the

diaphragm, the lever moves t he control door to its appropriate position. When

the lever on the control panel is moved to another position, vacuum is cut off

and the spring returns the actuator lever to its normal position.

TESTING 1. Disconnect the vacuum line from the actuator.

2. Attach a hand held vacuum pump to the actuator.

3. Apply vacuum to the actuator.

4. The actuator lever should move to its engaged position and remain there

while vacuum is applied.

5. When vacuum is released it should move back to its normal position.

6. The lever should operat e smoothly and not bind.

REMOVAL & INSTALLATION 1. Remove the vacuum li nes from the actuator.

2. Disconnect the linkage from the actuator.

3. Remove the hardware attaching the actuator.

4. Remove the actuator.

To install: 5. Install the actuator and attaching hardware.

6. Connect the linkage to the actuator.

7. Connect the vacuum lines to the actuator.

8. Test system to confirm proper functioning of the actuator.

Page 200 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 200

9. Lubricate the speedometer cable

with an appropriate lubricant, being

sure to cover the lower thirds of the cable.

10. Insert the cable into the casi ng, then connect the cable and casing

assembly to the speedometer.

11. Install the instrument cluster, then install the cluster attaching screws.

12. Install the instrument cluster trim plate.

13. On models without cruise control, connect the speedometer cable strap

at the power brake booste r. On models with cruise control, connect the

speedometer cable at the cr uise control transducer.

14. Connect the negative battery cable at the battery.

WIPER SWITCH

REMOVAL & INSTALLATION

The wiper switch is part of the multi-function lever, located on the steering

wheel column.

1. Disconnect the electrical connector of the multi-function lever, located

under the instrument panel.

2. Remove the protective cover from the wire.

3. Grasp the lever firmly, twist and pull (the tang on the lever must align

with the socket) the lever straight out.

4. Pull the wire through the steering column.

To install: 5. Slide a music wire tool through the steering column and connect the

lever wire to the tool wire; pull t he wire through the steering column.

6. Push the control lever into the sp ring loaded socket (be sure to align the

tang).

7. Install the protective cover to the wire.

8. Connect the electrical connector of the multi-function lever.

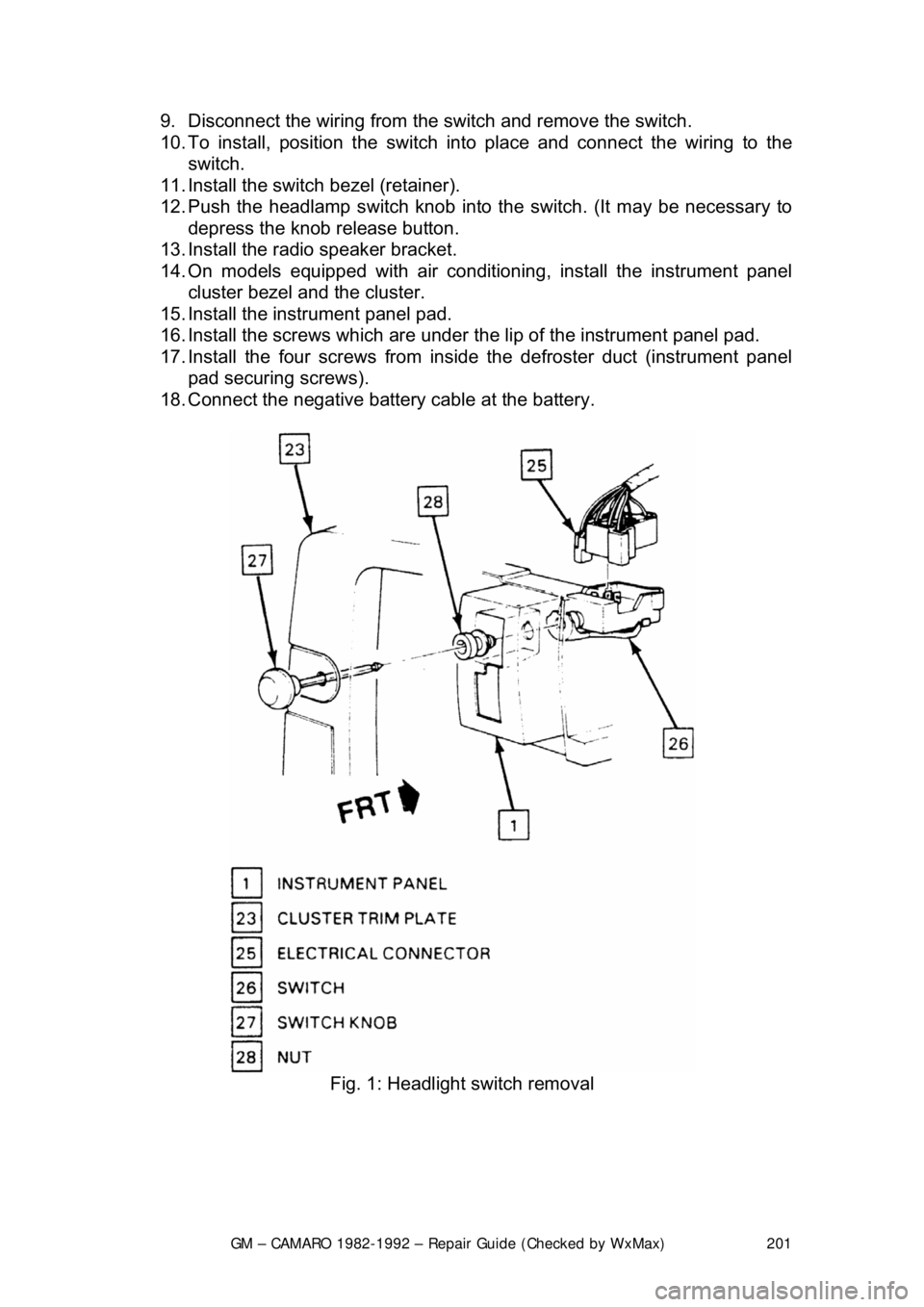

HEADLIGHT SWITCH

REMOVAL & INSTALLATION 1. Disconnect the negative batte ry cable at the battery.

2. Remove the four screws from insi de the defroster duct (instrument panel

pad securing screws).

3. Remove the screws which are under the lip of the instrument panel pad.

4. Remove the instrument panel pad.

5. On models equipped with air condition ing, remove the instrument panel

cluster bezel and the cluster.

6. Remove the radio speaker bracket.

7. Pull the headlamp switch knob to the ON position, depress the locking

button for the knob and shaft (locat ed on the switch), and remove the

knob and shaft.

8. Remove the switch bezel (retainer).

Page 201 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 201

9. Disconnect the wiring from the

switch and remove the switch.

10. To install, position t he switch into place and connect the wiring to the

switch.

11. Install the switch bezel (retainer).

12. Push the headlamp switch knob into the switch. (It may be necessary to

depress the knob release button.

13. Install the radio speaker bracket.

14. On models equipped with air conditioni ng, install the instrument panel

cluster bezel and the cluster.

15. Install the inst rument panel pad.

16. Install the screws which are under t he lip of the instrument panel pad.

17. Install the four screw s from inside the defroster duct (instrument panel

pad securing screws).

18. Connect the negative battery cable at the battery.

Fig. 1: Headlight switch removal

Page 302 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 302

7. To install, reverse the removal

procedures. Torque the master cylinder-

to-cowl brace nuts to 10-15 ft. lbs. (14-20 Nm). Fill master cylinder with

new hydraulic fluid conforming to DO T 3 specifications. Bleed and check

the hydraulic clutch system for leaks.

OVERHAUL 1. Remove the filler cap and drain fl uid from the master cylinder.

2. Remove the reservoir and seal from the master cylinder. Pull back the

dust cover and remove the snapring.

3. Remove the push rod assembly. Usi ng a block of wood, tap the master

cylinder on it to eject the plunger a ssembly from the cylinder bore.

4. Remove the seal (carefully) from the front of the plunger assembly,

ensuring no damage occurs to the plunger surfaces.

5. From the rear of t he plunger assembly, remove the spring, the support,

the seal and the shim.

6. Using clean brake fluid, clean all of the parts.

7. Inspect the cylinder bore and t he plunger for ridges, pitting and/or

scratches, the dust cover for wear and cracking; replace the parts if any

of the conditions exist.

To assemble: 8. Use new seals, lubric ate all of the parts in clean brake fluid, fit the

plunger seal to the plunger and reve rse the disassembly procedures.

9. Insert the plunger assembly, va lve end leading into the cylinder bore

(easing the entrance of the plunger seal).

10. Position the push rod assembly into the cylinder bore, then install a new

snapring to retain the push rod. Install dust cover onto the master

cylinder. Lubricate the inside of t he dust cover with Girling® Rubber

Grease or equivalent.

Be careful not to use any lubricant that will deteriorate rubber dust covers or

seals.

SLAVE CYLINDER

On vehicles equipped with a hydraulic clutch release mechanism, the slave

cylinder is located on the left side of the bellhousing and controls the clutch

release fork operation.

REMOVAL & INSTALLATION

1. Disconnect the negative battery cable.

2. Raise and safely support the front of the vehicle on jackstands.

3. Disconnect the hydraulic line from clutch master cylinder. Remove the

line-to-chassis screw and the c lip from the chassis.

Be sure to plug the line opening to k eep dirt and moisture out of the system.

Page 303 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 303

4. Remove the slave cyli

nder-to-bellhousing nuts.

5. Remove the push rod and the slav e cylinder from the vehicle, then

overhaul it (if necessary).

6. To install, reverse the removal pr ocedures. Lubricate leading end of the

slave cylinder with Girli ng® Rubber Lube or equiva lent. Torque the slave

cylinder-to-bellhousing nuts to 10-15 ft. lbs. (14-20 Nm). Fill the master

cylinder with new brake fluid conformi ng to DOT 3 specifications. Bleed

the hydraulic system.

OVERHAUL 1. Remove the shield, the pushrod and the dust cover from the slave cylinder, then inspect the cover for damage or deterioration.

2. Remove the snapring form t he end of the cylinder bore.

3. Using a block of wood, tap the slave cylinder on it to eject the plunger,

then remove the seal and the spring.

4. Using clean brake fluid, clean all of the parts.

5. Inspect the cylinder bore and the plunger for ridges, pitting and/or

scratches, the dust cover for wear and cracking; replace the parts if any

of the conditions exist.

To assemble: 6. Use new seals and lubricat e all of the parts in clean brake fluid. Install

the spring, the plunger seal and the plunger into the cylinder bore, then

install anew snapring.

7. Lubricate the inside of the dust co ver with Girling® Rubber Grease or

equivalent, then install it into the slave cylinder.

Be careful not to use any lubricant that will deteriorate rubber dust covers or

seals.

BLEEDING THE HYDRAULIC CLUTCH

Bleeding air from the hydrau lic clutch system is necessary whenever any part of

the system has been disconnect ed or the fluid level (in the reservoir) has been

allowed to fall so low that air has been drawn into the master cylinder.

1. Fill master cylinder reservoir wit h new brake fluid conforming to DOT 3

specifications.

2. Raise and safely support the front of the vehicle on jackstands.

3. Remove the slave cylinder attaching bolts.

4. Hold slave cylinder at approximatel y 45 degrees with the bleeder at

highest point. Fully depress clutch pedal and open the bleeder screw.

5. Close the bleeder screw and release clutch pedal.

6. Repeat the procedure until all of t he air is evacuated from the system.

Check and refill master cylinder reserv oir as required to prevent air from

being drawn through the master cylinder.

Page 306 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 306

As the speed of the turbine increases, th

e fluid spins faster and faster in the

direction of engine rotation. As a result, t he ability of the stator to redirect the

fluid flow is reduced. Under cruising conditions, the stator is eventually forced to

rotate on its one-way clutch in the dire ction of engine rotation. Under these

conditions, the torque converter begins to behave almost like a solid shaft, with

the torus and turbine speeds being almost equal.

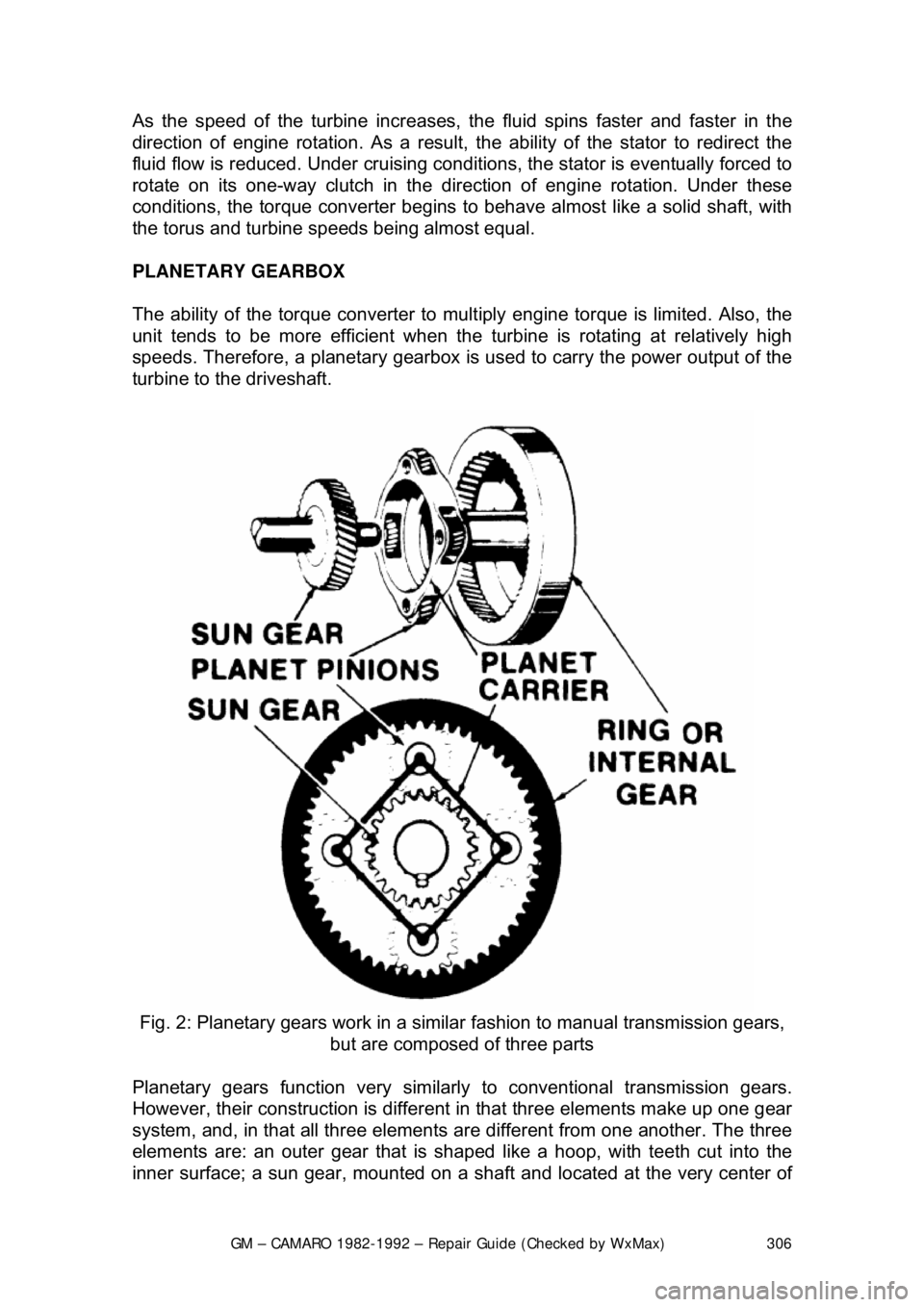

PLANETARY GEARBOX

The ability of the torque converter to mult iply engine torque is limited. Also, the

unit tends to be more efficient when the turbine is rotating at relatively high

speeds. Therefore, a planetar y gearbox is used to carry the power output of the

turbine to the driveshaft.

Fig. 2: Planetary gears work in a sim ilar fashion to manual transmission gears,

but are composed of three parts

Planetary gears function very similarly to conventional transmission gears.

However, their construction is different in that three elements make up one gear

system, and, in that all three elements ar e different from one another. The three

elements are: an outer gear that is shaped like a hoop, with teeth cut into the

inner surface; a sun gear, mounted on a sha ft and located at the very center of

Page 344 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 344

ENGINE & ENGINE OVERHAUL

ENGINE ELECTRICAL

ENGINE ELECTRICAL

The engine electrical system can be brok en down into three inter-related, but

distinct systems:

1. The starting system.

2. The charging system.

3. The ignition system.

BATTERY AND STARTING SYSTEM

The battery is the first link in the chai n of mechanisms which work together to

provide cranking of the autom obile engine. In most modern cars, the battery is a

lead-acid electrochemical device consis ting of six two-volt (2V) subsections

connected in series so the unit is c apable of producing approximately 12V of

electrical pressure. Each subsection, or ce ll, consists of a series of positive and

negative plates held a short distance apart in a solution of sulfuric acid and

water. The two types of plates are of di ssimilar metals. This causes a chemical

reaction to be set up, and it is this reacti on which produces current flow from the

battery when its positive and negative te rminals are connected to an electrical

appliance such as a lamp or motor.

The continued transfer of electrons would ev entually convert the sulfuric acid in

the electrolyte to water and make t he two plates identical in chemical

composition. As electrical energy is removed from the battery, its voltage output

tends to drop. Thus, measuring batte ry voltage and battery electrolyte

composition are two ways of checking the ability of the unit to supply power.

During the starting of the eng ine, electrical energy is removed from the battery.

However, if the charging circuit is in good condition and the operating conditions

are normal, the power removed from the battery will be replaced by the

generator (or alternator) which will forc e electrons back through the battery,

reversing the normal flow, and restoring the ba ttery to its original chemical state.

The battery and starting motor are linked by very heavy electrical cable\

s

designed to minimize resistance to the flow of current. Generally, the major

power supply cable that leaves the batte ry goes directly to the starter, while

other electrical system needs are supplied by a smaller cable. During the starter

operation, power flows from the battery to the starter and is grounded through

the car's frame and the batte ry's negative ground strap.

The starting motor is a specially designed, direct current electric motor capable

of producing a very great am ount of power for its size. One thing that allows the

motor to produce a great deal of power is its tremendous rotating speed. It

drives the engine through a ti ny pinion gear (attached to the starter's armature),

which drives the very large flywheel ring gear at a greatly reduced speed.

Another factor allowing it to produce so much power is that only intermittent

Page 352 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 352

To prevent serious damage to the alte

rnator and the rest of the charging

system, the following precauti ons must be observed:

• Never reverse the battery connections.

• Booster batteries for starting must be connected properly: positive-to-

positive and negative-to-ground.

• Disconnect the battery cables before using a fast charger; the charger

has a tendency to force current through the diodes in the opposite

direction for which they were designed. This burns out the diodes.

• Never use a fast charger as a booster for starting the vehicle.

• Never disconnect the voltage regulator while the engine is running.

• Avoid long soldering times when replacing diodes or transistors.

Prolonged heat is damaging to AC alternators.

• Do not use test lamps of more t han 12 volts (V) for checking diode

continuity.

• Do not short across or ground any of the terminals on the AC alternator.

• The polarity of the battery, alter nator, and regulator must be matched

and considered before making any elec trical connections within the

system.

• Never operate the alternator on an open circuit. make sure that all

connections within the circ uit are clean and tight.

• Disconnect the battery terminals when performing any service on the

electrical system. This wil l eliminate the possibility of accidental reversal

of polarity.

• Disconnect the battery ground cable if arc welding is to be done on any

part of the car.

CHARGING SYSTEM TROUBLESHOOTING

There are many possible ways in whic h the charging system can malfunction.

Often the source of a problem is diffi cult to diagnose, requiring special

equipment and a good deal of experience. However, when the charging system

fails completely and causes the dash boar d warning light to come on or the

battery to become dead the following items may be checked:

1. The battery is known to be good and fully charged.

2. The alternator belt is in good condition and adjusted to the proper

tension.

3. All connections in t he system are clean and tight.

REMOVAL & INSTALLATION