warning CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 559 of 2438

VEHICLE SPEED SENSOR TEST

For testing of the vehicle speed sensor and related

components using DRB II, refer to the appropriate

Powertrain Diagnostics Test Procedure Manual.

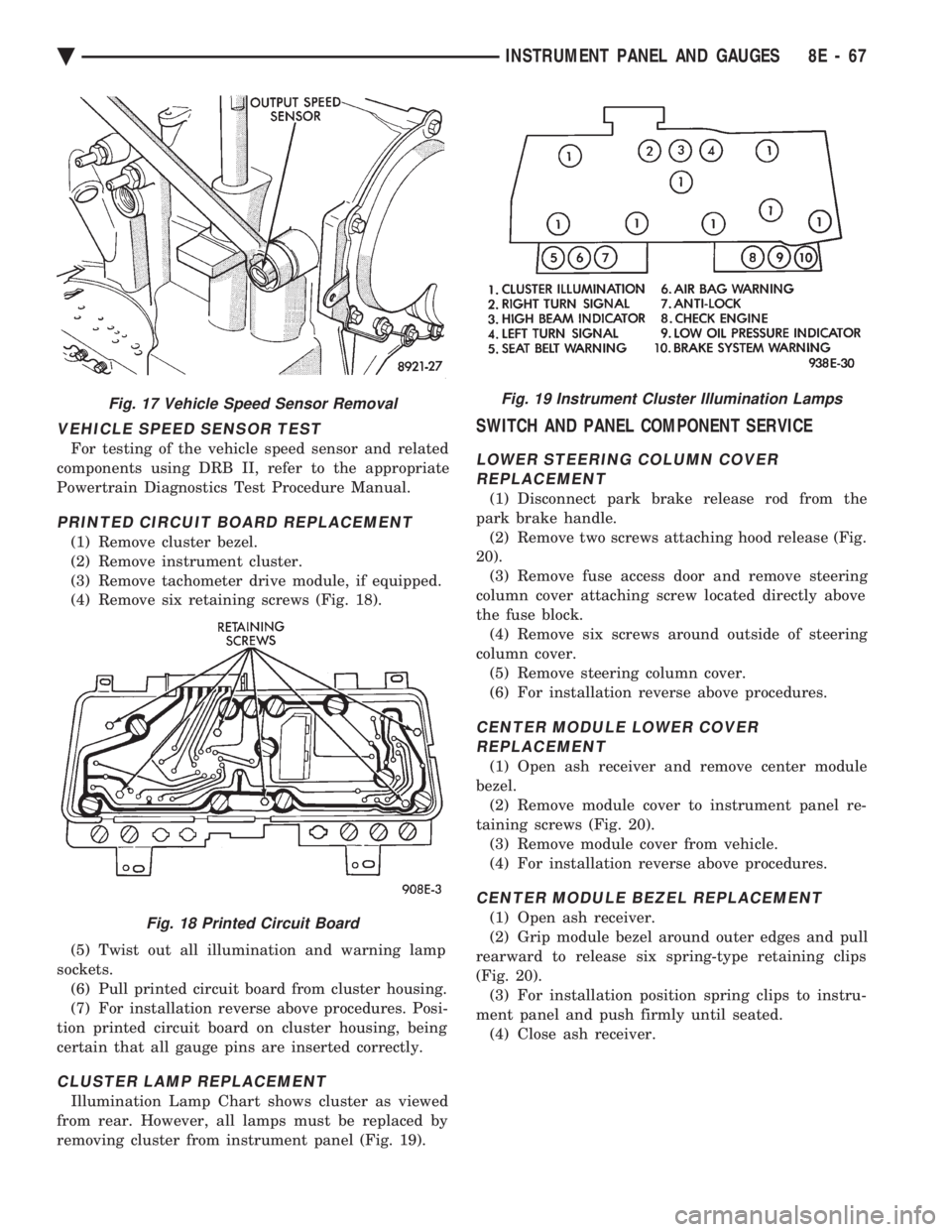

PRINTED CIRCUIT BOARD REPLACEMENT

(1) Remove cluster bezel.

(2) Remove instrument cluster.

(3) Remove tachometer drive module, if equipped.

(4) Remove six retaining screws (Fig. 18).

(5) Twist out all illumination and warning lamp

sockets. (6) Pull printed circuit board from cluster housing.

(7) For installation reverse above procedures. Posi-

tion printed circuit board on cluster housing, being

certain that all gauge pins are inserted correctly.

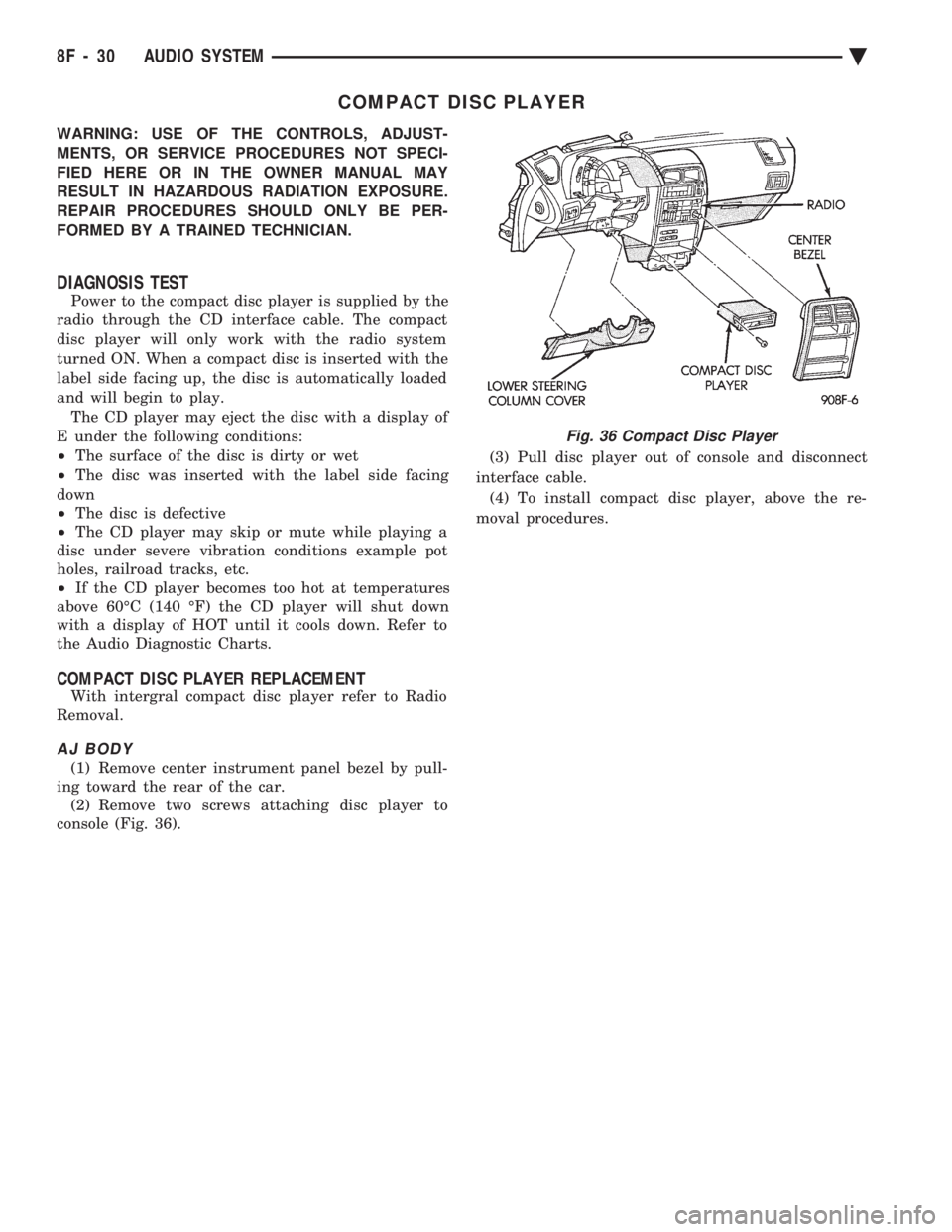

CLUSTER LAMP REPLACEMENT

Illumination Lamp Chart shows cluster as viewed

from rear. However, all lamps must be replaced by

removing cluster from instrument panel (Fig. 19).

SWITCH AND PANEL COMPONENT SERVICE

LOWER STEERING COLUMN COVER REPLACEMENT

(1) Disconnect park brake release rod from the

park brake handle. (2) Remove two screws attaching hood release (Fig.

20). (3) Remove fuse access door and remove steering

column cover attaching screw located directly above

the fuse block. (4) Remove six screws around outside of steering

column cover. (5) Remove steering column cover.

(6) For installation reverse above procedures.

CENTER MODULE LOWER COVER REPLACEMENT

(1) Open ash receiver and remove center module

bezel. (2) Remove module cover to instrument panel re-

taining screws (Fig. 20). (3) Remove module cover from vehicle.

(4) For installation reverse above procedures.

CENTER MODULE BEZEL REPLACEMENT

(1) Open ash receiver.

(2) Grip module bezel around outer edges and pull

rearward to release six spring-type retaining clips

(Fig. 20). (3) For installation position spring clips to instru-

ment panel and push firmly until seated. (4) Close ash receiver.

Fig. 17 Vehicle Speed Sensor Removal

Fig. 18 Printed Circuit Board

Fig. 19 Instrument Cluster Illumination Lamps

Ä INSTRUMENT PANEL AND GAUGES 8E - 67

Page 596 of 2438

COMPACT DISC PLAYER

WARNING: USE OF THE CONTROLS, ADJUST-

MENTS, OR SERVICE PROCEDURES NOT SPECI-

FIED HERE OR IN THE OWNER MANUAL MAY

RESULT IN HAZARDOUS RADIATION EXPOSURE.

REPAIR PROCEDURES SHOULD ONLY BE PER-

FORMED BY A TRAINED TECHNICIAN.

DIAGNOSIS TEST

Power to the compact disc player is supplied by the

radio through the CD interface cable. The compact

disc player will only work with the radio system

turned ON. When a compact disc is inserted with the

label side facing up, the disc is automatically loaded

and will begin to play. The CD player may eject the disc with a display of

E under the following conditions:

² The surface of the disc is dirty or wet

² The disc was inserted with the label side facing

down

² The disc is defective

² The CD player may skip or mute while playing a

disc under severe vibration conditions example pot

holes, railroad tracks, etc.

² If the CD player becomes too hot at temperatures

above 60ÉC (140 ÉF) the CD player will shut down

with a display of HOT until it cools down. Refer to

the Audio Diagnostic Charts.

COMPACT DISC PLAYER REPLACEMENT

With intergral compact disc player refer to Radio

Removal.

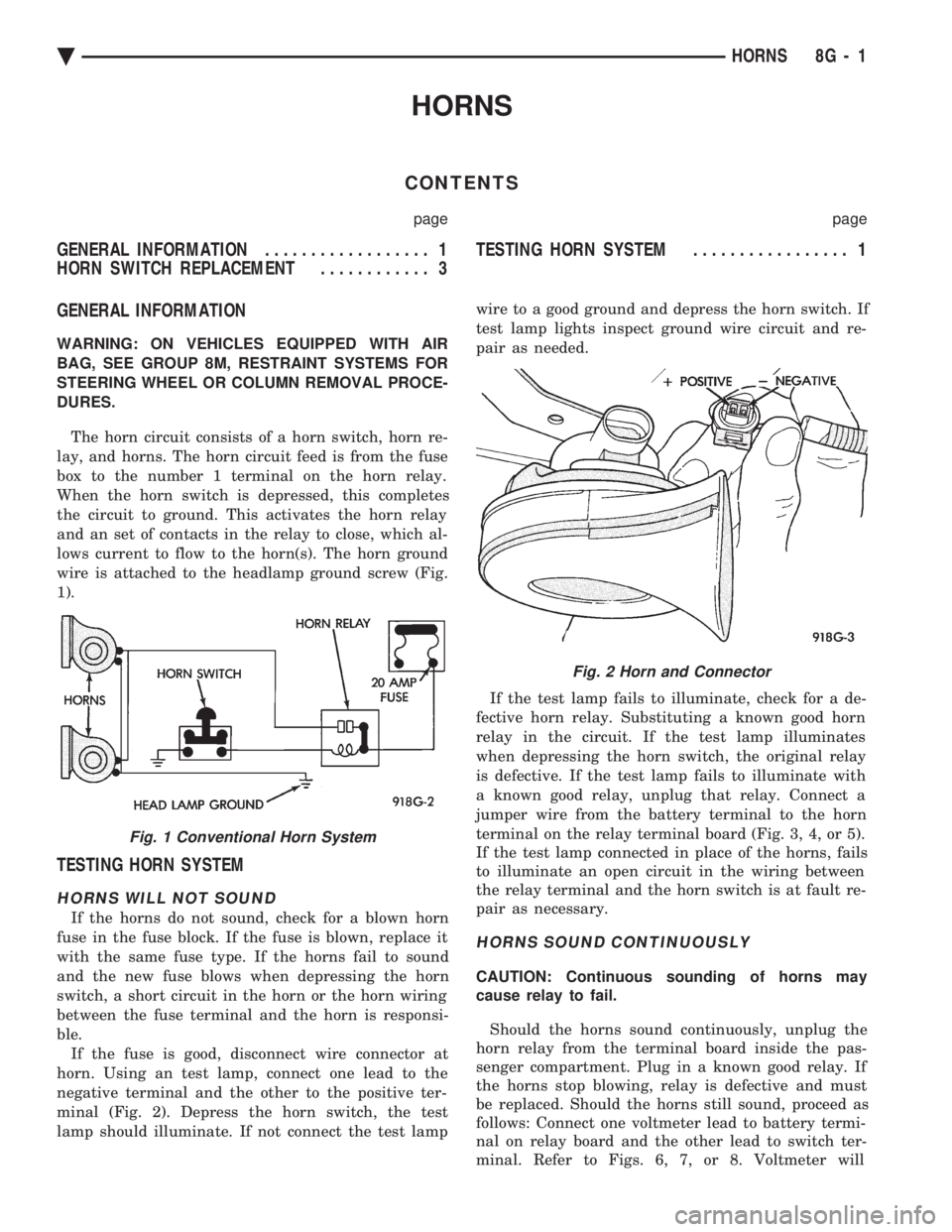

AJ BODY

(1) Remove center instrument panel bezel by pull-

ing toward the rear of the car. (2) Remove two screws attaching disc player to

console (Fig. 36). (3) Pull disc player out of console and disconnect

interface cable. (4) To install compact disc player, above the re-

moval procedures.

Fig. 36 Compact Disc Player

8F - 30 AUDIO SYSTEM Ä

Page 597 of 2438

HORNS

CONTENTS

page page

GENERAL INFORMATION .................. 1

HORN SWITCH REPLACEMENT ............ 3 TESTING HORN SYSTEM

................. 1

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AIR

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The horn circuit consists of a horn switch, horn re-

lay, and horns. The horn circuit feed is from the fuse

box to the number 1 terminal on the horn relay.

When the horn switch is depressed, this completes

the circuit to ground. This activates the horn relay

and an set of contacts in the relay to close, which al-

lows current to flow to the horn(s). The horn ground

wire is attached to the headlamp ground screw (Fig.

1).

TESTING HORN SYSTEM

HORNS WILL NOT SOUND

If the horns do not sound, check for a blown horn

fuse in the fuse block. If the fuse is blown, replace it

with the same fuse type. If the horns fail to sound

and the new fuse blows when depressing the horn

switch, a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble. If the fuse is good, disconnect wire connector at

horn. Using an test lamp, connect one lead to the

negative terminal and the other to the positive ter-

minal (Fig. 2). Depress the horn switch, the test

lamp should illuminate. If not connect the test lamp wire to a good ground and depress the horn switch. If

test lamp lights inspect ground wire circuit and re-

pair as needed.

If the test lamp fails to illuminate, check for a de-

fective horn relay. Substituting a known good horn

relay in the circuit. If the test lamp illuminates

when depressing the horn switch, the original relay

is defective. If the test lamp fails to illuminate with

a known good relay, unplug that relay. Connect a

jumper wire from the battery terminal to the horn

terminal on the relay terminal board (Fig. 3, 4, or 5).

If the test lamp connected in place of the horns, fails

to illuminate an open circuit in the wiring between

the relay terminal and the horn switch is at fault re-

pair as necessary.

HORNS SOUND CONTINUOUSLY

CAUTION: Continuous sounding of horns may

cause relay to fail.

Should the horns sound continuously, unplug the

horn relay from the terminal board inside the pas-

senger compartment. Plug in a known good relay. If

the horns stop blowing, relay is defective and must

be replaced. Should the horns still sound, proceed as

follows: Connect one voltmeter lead to battery termi-

nal on relay board and the other lead to switch ter-

minal. Refer to Figs. 6, 7, or 8. Voltmeter will

Fig. 1 Conventional Horn System

Fig. 2 Horn and Connector

Ä HORNS 8G - 1

Page 599 of 2438

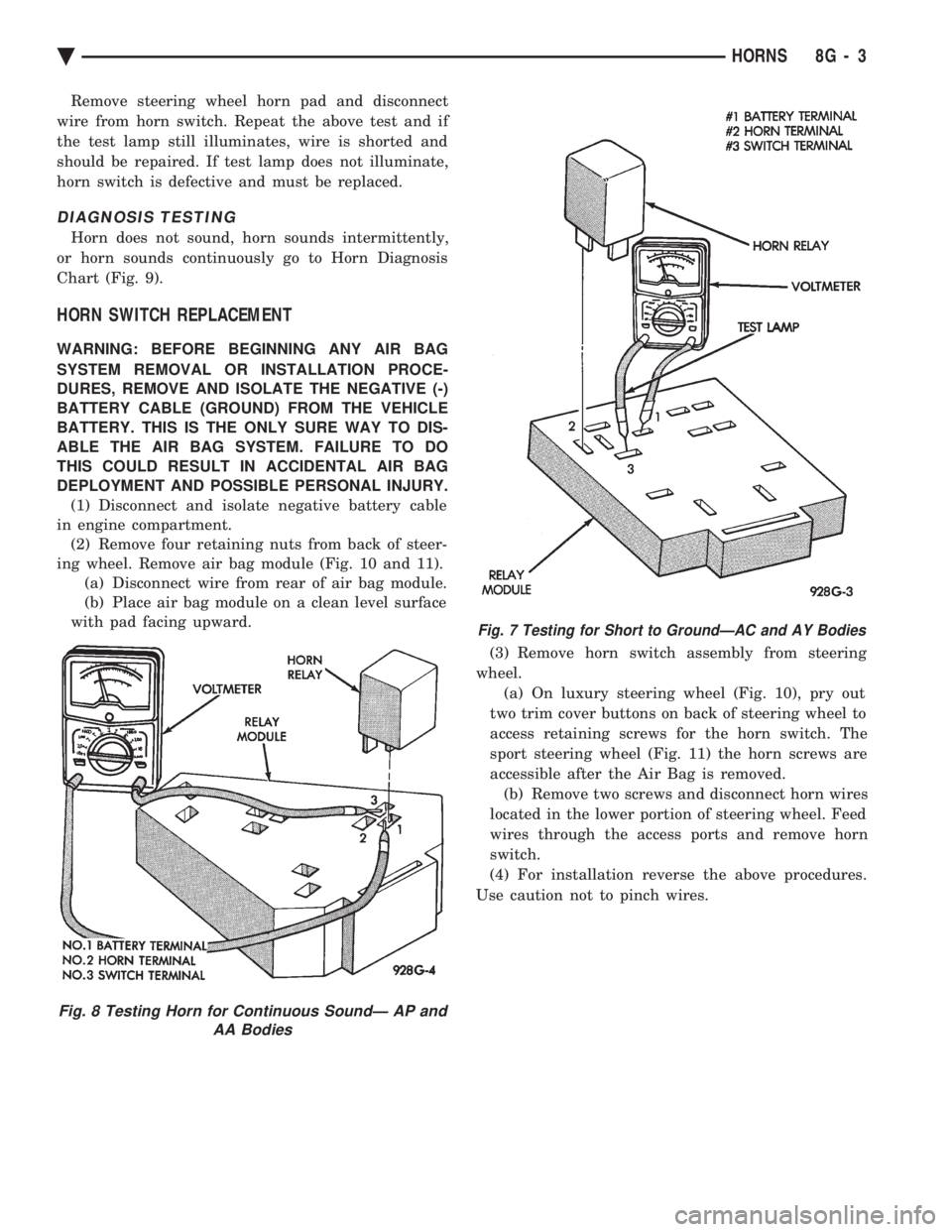

Remove steering wheel horn pad and disconnect

wire from horn switch. Repeat the above test and if

the test lamp still illuminates, wire is shorted and

should be repaired. If test lamp does not illuminate,

horn switch is defective and must be replaced.

DIAGNOSIS TESTING

Horn does not sound, horn sounds intermittently,

or horn sounds continuously go to Horn Diagnosis

Chart (Fig. 9).

HORN SWITCH REPLACEMENT

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE NEGATIVE (-)

BATTERY CABLE (GROUND) FROM THE VEHICLE

BATTERY. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. (1) Disconnect and isolate negative battery cable

in engine compartment. (2) Remove four retaining nuts from back of steer-

ing wheel. Remove air bag module (Fig. 10 and 11). (a) Disconnect wire from rear of air bag module.

(b) Place air bag module on a clean level surface

with pad facing upward.

(3) Remove horn switch assembly from steering

wheel. (a) On luxury steering wheel (Fig. 10), pry out

two trim cover buttons on back of steering wheel to

access retaining screws for the horn switch. The

sport steering wheel (Fig. 11) the horn screws are

accessible after the Air Bag is removed. (b) Remove two screws and disconnect horn wires

located in the lower portion of steering wheel. Feed

wires through the access ports and remove horn

switch.

(4) For installation reverse the above procedures.

Use caution not to pinch wires.

Fig. 8 Testing Horn for Continuous SoundÐ AP and AA Bodies

Fig. 7 Testing for Short to GroundÐAC and AY Bodies

Ä HORNS 8G - 3

Page 603 of 2438

VEHICLE SPEED CONTROL

CONTENTS

page page

CHECKING FOR FAULT CODE .............. 3

DIAGNOSIS PROCEDURES ................ 2

GENERAL INFORMATION .................. 1

INOPERATIVE SYSTEM ................... 3

POWERTRAIN CONTROL MODULE ELECTRICAL TEST ................................ 5

ROAD TEST ............................ 2

SERVO ELECTRICAL TESTS ............... 4

SERVO UNIT ............................ 9 SERVO VACUUM TEST

................... 9

STOP LAMP VEHICLE SPEED CONTROL SWITCH TEST ......................... 8

VACUUM SUPPLY TEST .................. 9

VEHICLE SPEED CONTROL SWITCH REMOVAL ........................... 10

VEHICLE SPEED CONTROL SWITCH TEST . . . 8

VEHICLE SPEED CONTROL ELECTRICAL TESTS ............................... 3

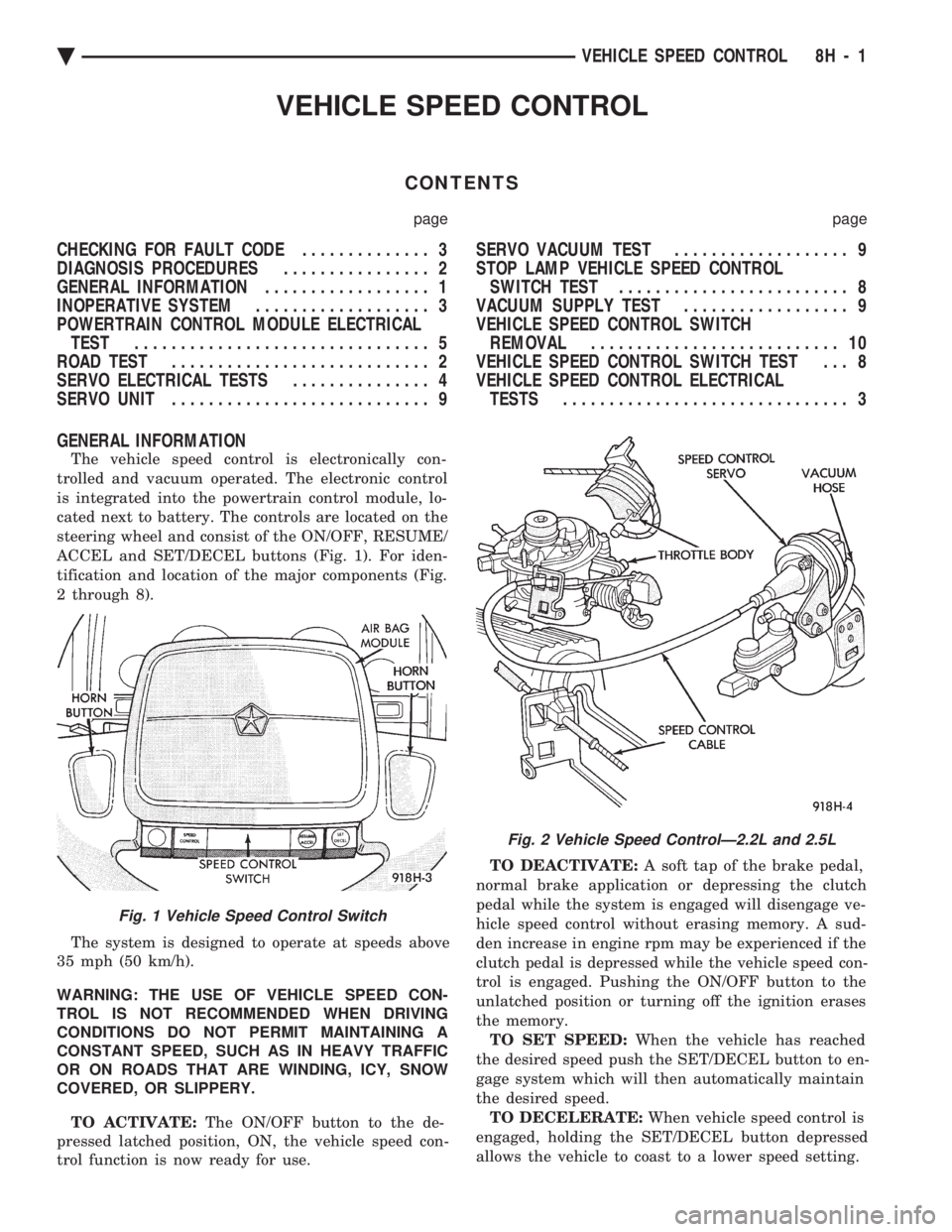

GENERAL INFORMATION

The vehicle speed control is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the powertrain control module, lo-

cated next to battery. The controls are located on the

steering wheel and consist of the ON/OFF, RESUME/

ACCEL and SET/DECEL buttons (Fig. 1). For iden-

tification and location of the major components (Fig.

2 through 8).

The system is designed to operate at speeds above

35 mph (50 km/h).

WARNING: THE USE OF VEHICLE SPEED CON-

TROL IS NOT RECOMMENDED WHEN DRIVING

CONDITIONS DO NOT PERMIT MAINTAINING A

CONSTANT SPEED, SUCH AS IN HEAVY TRAFFIC

OR ON ROADS THAT ARE WINDING, ICY, SNOW

COVERED, OR SLIPPERY.

TO ACTIVATE: The ON/OFF button to the de-

pressed latched position, ON, the vehicle speed con-

trol function is now ready for use. TO DEACTIVATE:

A soft tap of the brake pedal,

normal brake application or depressing the clutch

pedal while the system is engaged will disengage ve-

hicle speed control without erasing memory. A sud-

den increase in engine rpm may be experienced if the

clutch pedal is depressed while the vehicle speed con-

trol is engaged. Pushing the ON/OFF button to the

unlatched position or turning off the ignition erases

the memory. TO SET SPEED: When the vehicle has reached

the desired speed push the SET/DECEL button to en-

gage system which will then automatically maintain

the desired speed. TO DECELERATE: When vehicle speed control is

engaged, holding the SET/DECEL button depressed

allows the vehicle to coast to a lower speed setting.

Fig. 1 Vehicle Speed Control Switch

Fig. 2 Vehicle Speed ControlÐ2.2L and 2.5L

Ä VEHICLE SPEED CONTROL 8H - 1

Page 605 of 2438

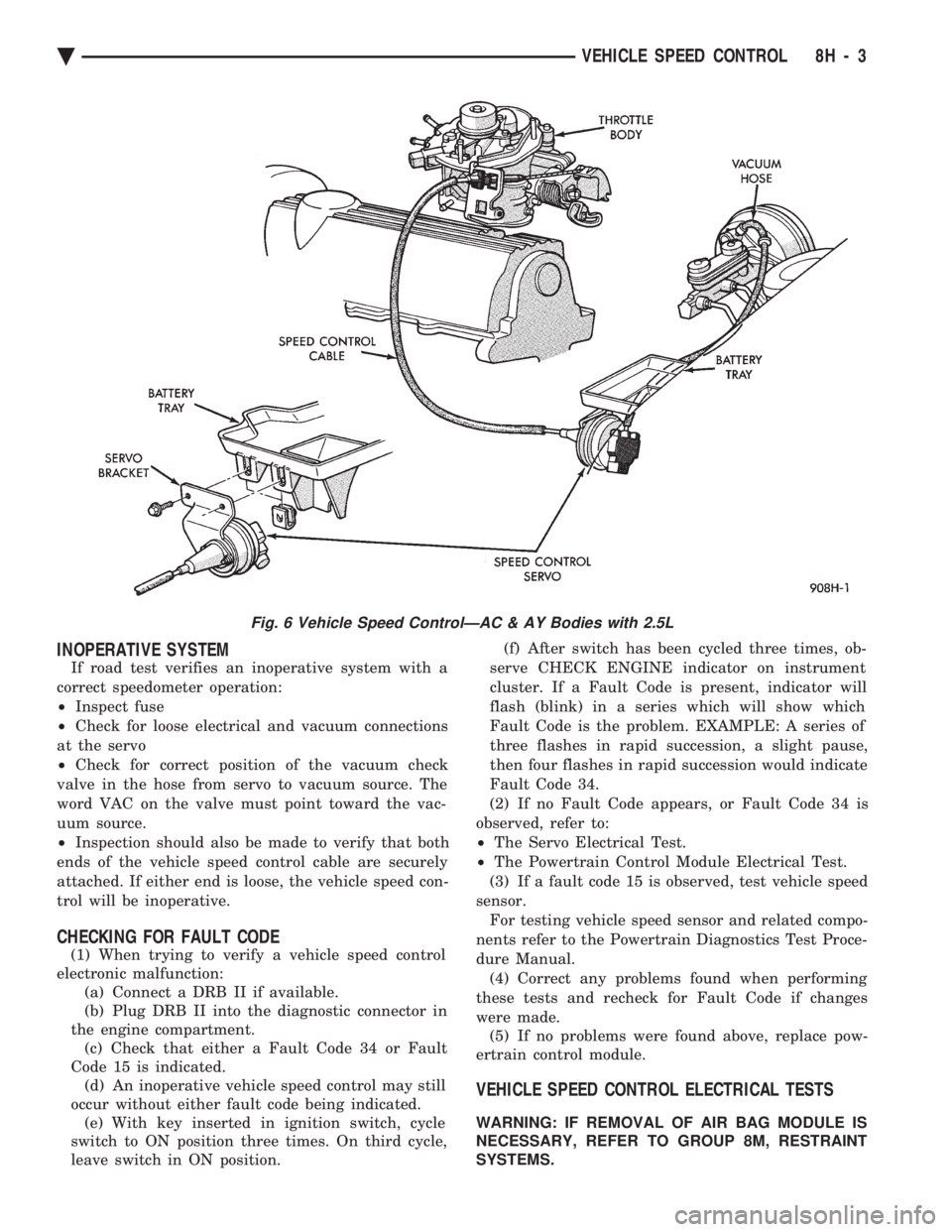

INOPERATIVE SYSTEM

If road test verifies an inoperative system with a

correct speedometer operation:

² Inspect fuse

² Check for loose electrical and vacuum connections

at the servo

² Check for correct position of the vacuum check

valve in the hose from servo to vacuum source. The

word VAC on the valve must point toward the vac-

uum source.

² Inspection should also be made to verify that both

ends of the vehicle speed control cable are securely

attached. If either end is loose, the vehicle speed con-

trol will be inoperative.

CHECKING FOR FAULT CODE

(1) When trying to verify a vehicle speed control

electronic malfunction: (a) Connect a DRB II if available.

(b) Plug DRB II into the diagnostic connector in

the engine compartment. (c) Check that either a Fault Code 34 or Fault

Code 15 is indicated. (d) An inoperative vehicle speed control may still

occur without either fault code being indicated. (e) With key inserted in ignition switch, cycle

switch to ON position three times. On third cycle,

leave switch in ON position. (f) After switch has been cycled three times, ob-

serve CHECK ENGINE indicator on instrument

cluster. If a Fault Code is present, indicator will

flash (blink) in a series which will show which

Fault Code is the problem. EXAMPLE: A series of

three flashes in rapid succession, a slight pause,

then four flashes in rapid succession would indicate

Fault Code 34.

(2) If no Fault Code appears, or Fault Code 34 is

observed, refer to:

² The Servo Electrical Test.

² The Powertrain Control Module Electrical Test.

(3) If a fault code 15 is observed, test vehicle speed

sensor. For testing vehicle speed sensor and related compo-

nents refer to the Powertrain Diagnostics Test Proce-

dure Manual. (4) Correct any problems found when performing

these tests and recheck for Fault Code if changes

were made. (5) If no problems were found above, replace pow-

ertrain control module.

VEHICLE SPEED CONTROL ELECTRICAL TESTS

WARNING: IF REMOVAL OF AIR BAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

Fig. 6 Vehicle Speed ControlÐAC & AY Bodies with 2.5L

Ä VEHICLE SPEED CONTROL 8H - 3

Page 606 of 2438

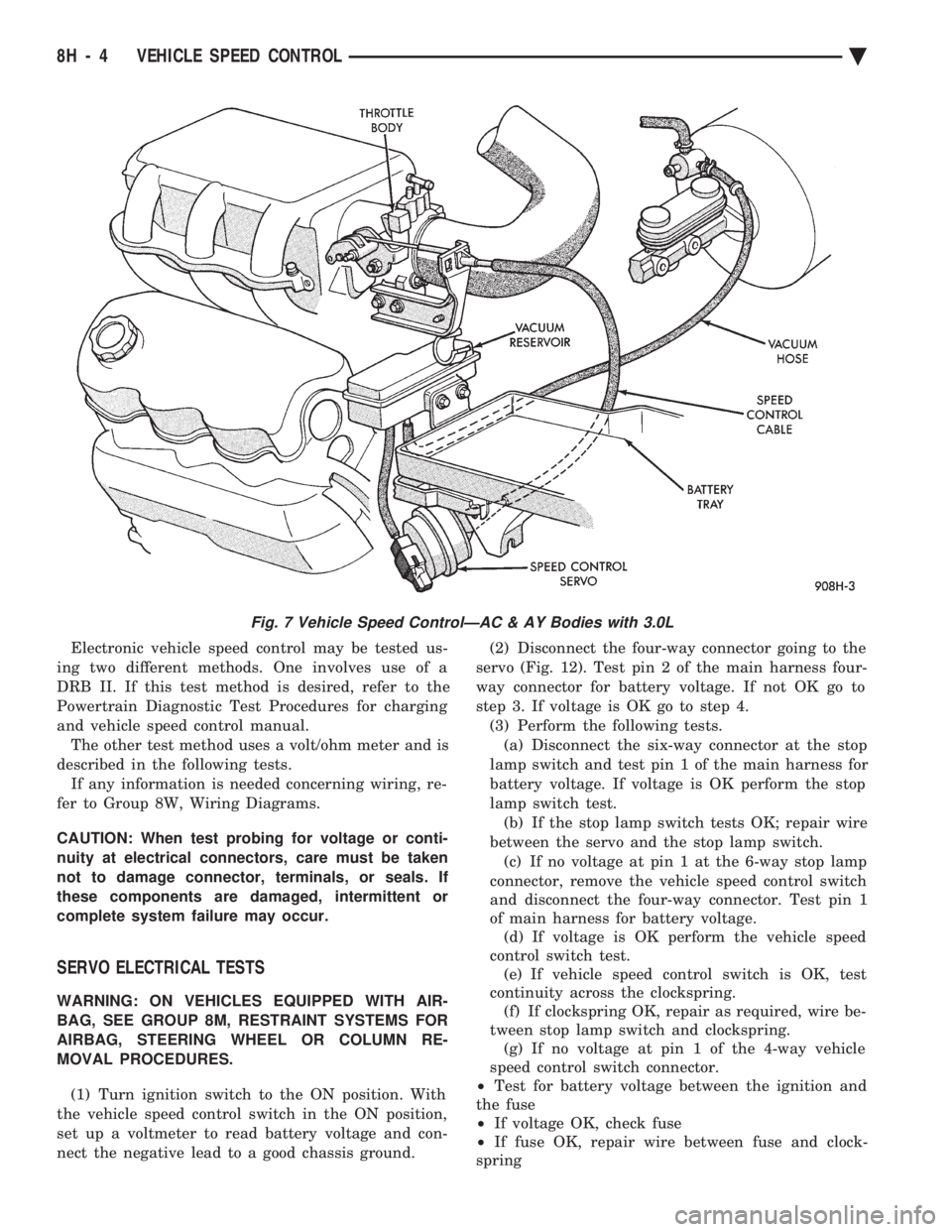

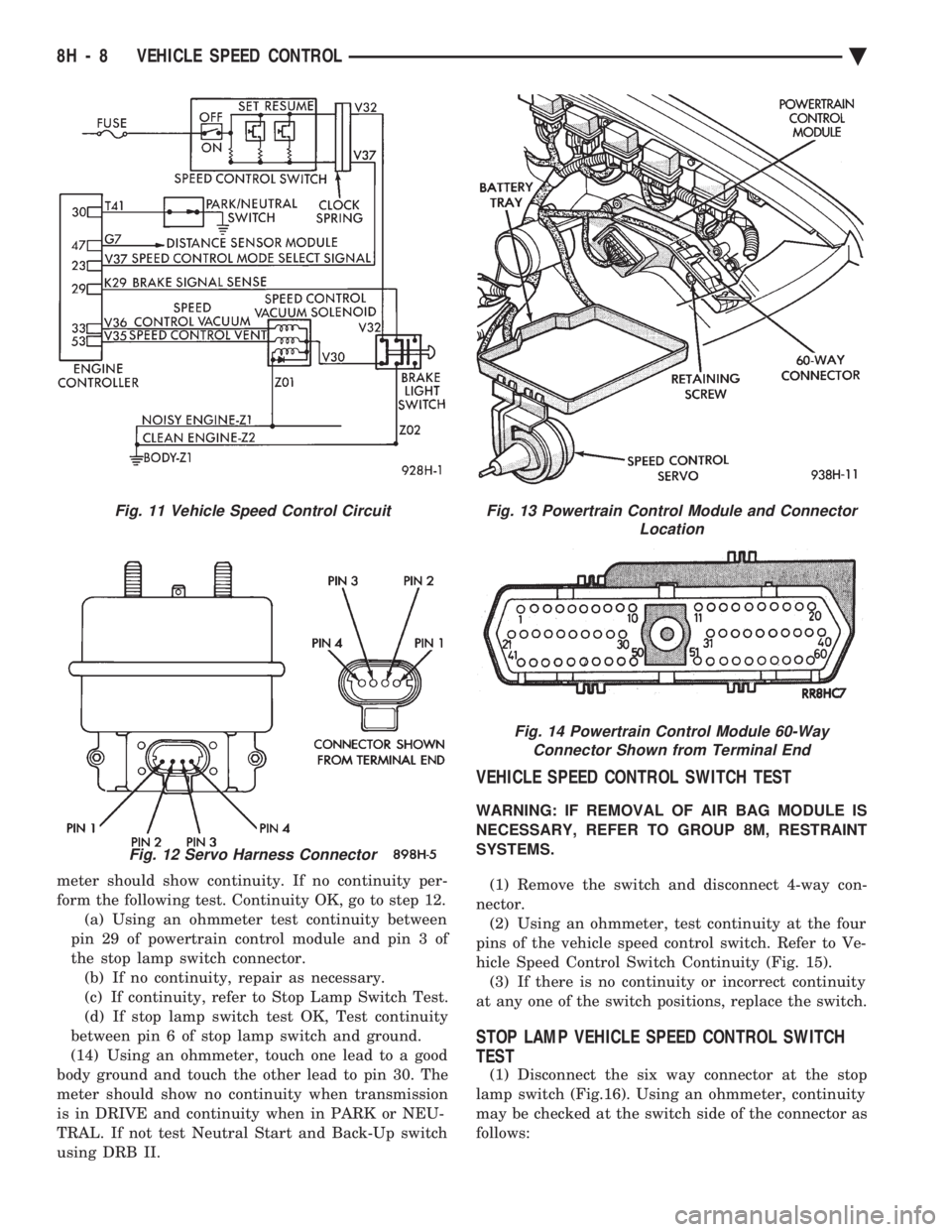

Electronic vehicle speed control may be tested us-

ing two different methods. One involves use of a

DRB II. If this test method is desired, refer to the

Powertrain Diagnostic Test Procedures for charging

and vehicle speed control manual. The other test method uses a volt/ohm meter and is

described in the following tests. If any information is needed concerning wiring, re-

fer to Group 8W, Wiring Diagrams.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SERVO ELECTRICAL TESTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG, STEERING WHEEL OR COLUMN RE-

MOVAL PROCEDURES.

(1) Turn ignition switch to the ON position. With

the vehicle speed control switch in the ON position,

set up a voltmeter to read battery voltage and con-

nect the negative lead to a good chassis ground. (2) Disconnect the four-way connector going to the

servo (Fig. 12). Test pin 2 of the main harness four-

way connector for battery voltage. If not OK go to

step 3. If voltage is OK go to step 4. (3) Perform the following tests.(a) Disconnect the six-way connector at the stop

lamp switch and test pin 1 of the main harness for

battery voltage. If voltage is OK perform the stop

lamp switch test. (b) If the stop lamp switch tests OK; repair wire

between the servo and the stop lamp switch. (c) If no voltage at pin 1 at the 6-way stop lamp

connector, remove the vehicle speed control switch

and disconnect the four-way connector. Test pin 1

of main harness for battery voltage. (d) If voltage is OK perform the vehicle speed

control switch test. (e) If vehicle speed control switch is OK, test

continuity across the clockspring. (f) If clockspring OK, repair as required, wire be-

tween stop lamp switch and clockspring. (g) If no voltage at pin 1 of the 4-way vehicle

speed control switch connector.

² Test for battery voltage between the ignition and

the fuse

² If voltage OK, check fuse

² If fuse OK, repair wire between fuse and clock-

spring

Fig. 7 Vehicle Speed ControlÐAC & AY Bodies with 3.0L

8H - 4 VEHICLE SPEED CONTROL Ä

Page 607 of 2438

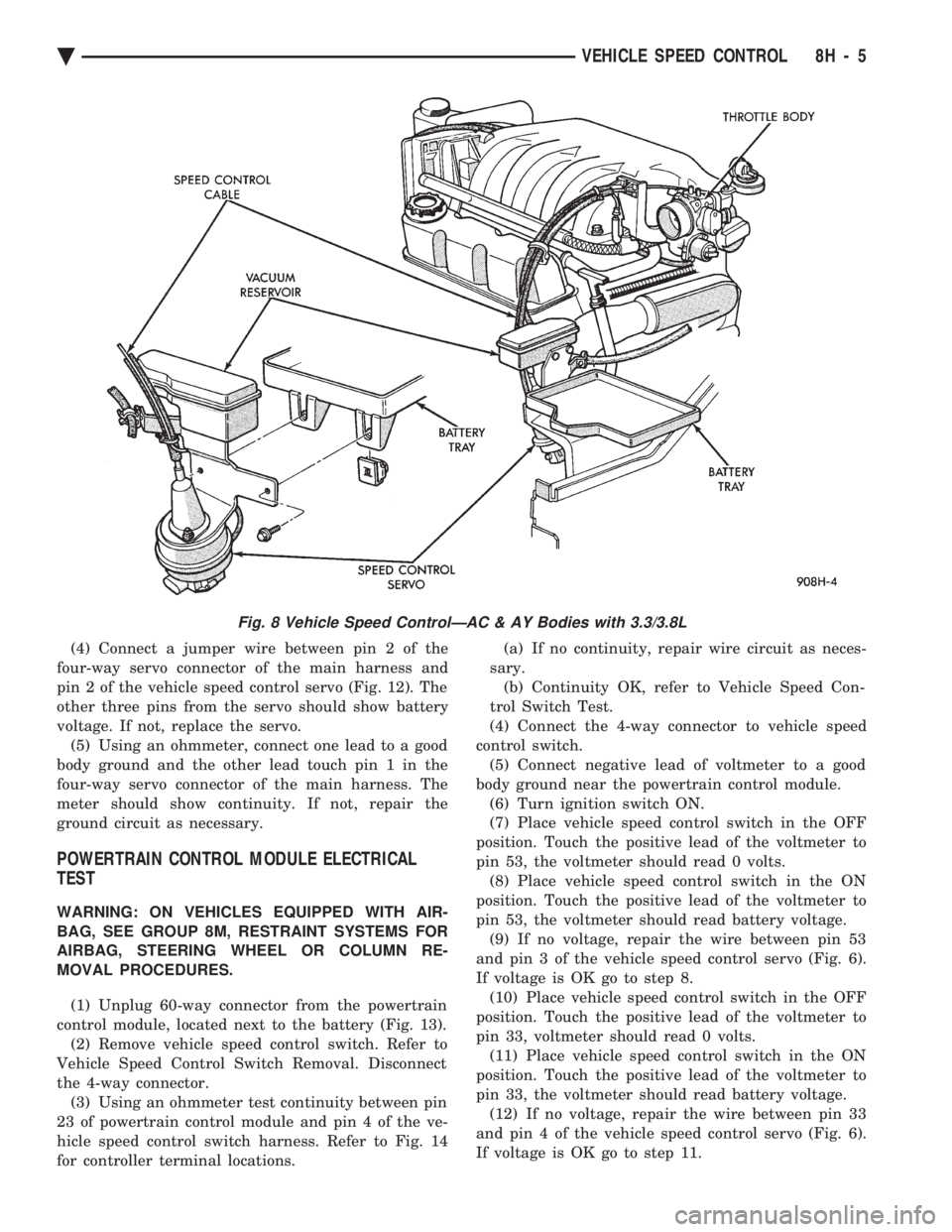

(4) Connect a jumper wire between pin 2 of the

four-way servo connector of the main harness and

pin 2 of the vehicle speed control servo (Fig. 12). The

other three pins from the servo should show battery

voltage. If not, replace the servo. (5) Using an ohmmeter, connect one lead to a good

body ground and the other lead touch pin 1 in the

four-way servo connector of the main harness. The

meter should show continuity. If not, repair the

ground circuit as necessary.

POWERTRAIN CONTROL MODULE ELECTRICAL

TEST

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG, STEERING WHEEL OR COLUMN RE-

MOVAL PROCEDURES.

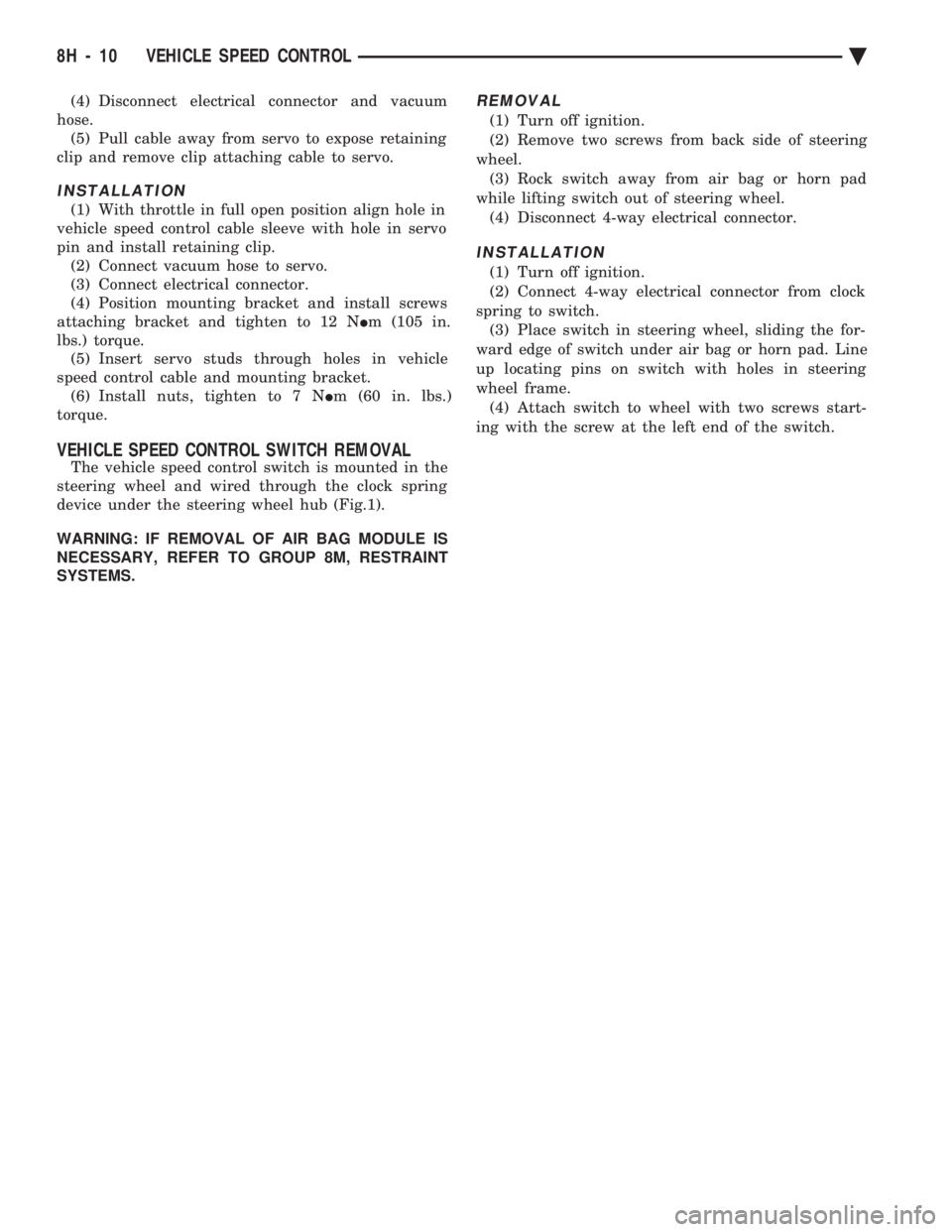

(1) Unplug 60-way connector from the powertrain

control module, located next to the battery (Fig. 13). (2) Remove vehicle speed control switch. Refer to

Vehicle Speed Control Switch Removal. Disconnect

the 4-way connector. (3) Using an ohmmeter test continuity between pin

23 of powertrain control module and pin 4 of the ve-

hicle speed control switch harness. Refer to Fig. 14

for controller terminal locations. (a) If no continuity, repair wire circuit as neces-

sary. (b) Continuity OK, refer to Vehicle Speed Con-

trol Switch Test.

(4) Connect the 4-way connector to vehicle speed

control switch. (5) Connect negative lead of voltmeter to a good

body ground near the powertrain control module. (6) Turn ignition switch ON.

(7) Place vehicle speed control switch in the OFF

position. Touch the positive lead of the voltmeter to

pin 53, the voltmeter should read 0 volts. (8) Place vehicle speed control switch in the ON

position. Touch the positive lead of the voltmeter to

pin 53, the voltmeter should read battery voltage. (9) If no voltage, repair the wire between pin 53

and pin 3 of the vehicle speed control servo (Fig. 6).

If voltage is OK go to step 8. (10) Place vehicle speed control switch in the OFF

position. Touch the positive lead of the voltmeter to

pin 33, voltmeter should read 0 volts. (11) Place vehicle speed control switch in the ON

position. Touch the positive lead of the voltmeter to

pin 33, the voltmeter should read battery voltage. (12) If no voltage, repair the wire between pin 33

and pin 4 of the vehicle speed control servo (Fig. 6).

If voltage is OK go to step 11.

Fig. 8 Vehicle Speed ControlÐAC & AY Bodies with 3.3/3.8L

Ä VEHICLE SPEED CONTROL 8H - 5

Page 610 of 2438

meter should show continuity. If no continuity per-

form the following test. Continuity OK, go to step 12.(a) Using an ohmmeter test continuity between

pin 29 of powertrain control module and pin 3 of

the stop lamp switch connector. (b) If no continuity, repair as necessary.

(c) If continuity, refer to Stop Lamp Switch Test.

(d) If stop lamp switch test OK, Test continuity

between pin 6 of stop lamp switch and ground.

(14) Using an ohmmeter, touch one lead to a good

body ground and touch the other lead to pin 30. The

meter should show no continuity when transmission

is in DRIVE and continuity when in PARK or NEU-

TRAL. If not test Neutral Start and Back-Up switch

using DRB II.

VEHICLE SPEED CONTROL SWITCH TEST

WARNING: IF REMOVAL OF AIR BAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

(1) Remove the switch and disconnect 4-way con-

nector. (2) Using an ohmmeter, test continuity at the four

pins of the vehicle speed control switch. Refer to Ve-

hicle Speed Control Switch Continuity (Fig. 15). (3) If there is no continuity or incorrect continuity

at any one of the switch positions, replace the switch.

STOP LAMP VEHICLE SPEED CONTROL SWITCH

TEST

(1) Disconnect the six way connector at the stop

lamp switch (Fig.16). Using an ohmmeter, continuity

may be checked at the switch side of the connector as

follows:

Fig. 11 Vehicle Speed Control Circuit

Fig. 12 Servo Harness Connector

Fig. 13 Powertrain Control Module and Connector Location

Fig. 14 Powertrain Control Module 60-WayConnector Shown from Terminal End

8H - 8 VEHICLE SPEED CONTROL Ä

Page 612 of 2438

(4) Disconnect electrical connector and vacuum

hose. (5) Pull cable away from servo to expose retaining

clip and remove clip attaching cable to servo.

INSTALLATION

(1) With throttle in full open position align hole in

vehicle speed control cable sleeve with hole in servo

pin and install retaining clip. (2) Connect vacuum hose to servo.

(3) Connect electrical connector.

(4) Position mounting bracket and install screws

attaching bracket and tighten to 12 N Im (105 in.

lbs.) torque. (5) Insert servo studs through holes in vehicle

speed control cable and mounting bracket. (6) Install nuts, tighten to 7 N Im (60 in. lbs.)

torque.

VEHICLE SPEED CONTROL SWITCH REMOVAL

The vehicle speed control switch is mounted in the

steering wheel and wired through the clock spring

device under the steering wheel hub (Fig.1).

WARNING: IF REMOVAL OF AIR BAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

REMOVAL

(1) Turn off ignition.

(2) Remove two screws from back side of steering

wheel. (3) Rock switch away from air bag or horn pad

while lifting switch out of steering wheel. (4) Disconnect 4-way electrical connector.

INSTALLATION

(1) Turn off ignition.

(2) Connect 4-way electrical connector from clock

spring to switch. (3) Place switch in steering wheel, sliding the for-

ward edge of switch under air bag or horn pad. Line

up locating pins on switch with holes in steering

wheel frame. (4) Attach switch to wheel with two screws start-

ing with the screw at the left end of the switch.

8H - 10 VEHICLE SPEED CONTROL Ä