oil CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 52 of 2438

DRIVETRAIN INDEX

page page

Automatic Transaxle ...................... 16

Automatic Transaxle Floor Shift .............. 16

Clutch and Gearshift Linkage ............... 16

Drive Shaft Cv and Tripod Joint Boots ........ 17 Front Wheel Bearings

..................... 17

Manual Transaxle ........................ 16

Tires .................................. 17

CLUTCH AND GEARSHIFT LINKAGE

If the clutch or gearshift begins to operate with dif-

ficulty, squeak or grunt, the cables and linkage

should be lubricated before service replacement is

performed. For proper lubrication and service proce-

dures refer to Group 6, Clutch, or Group 21, Manual

Transaxle.

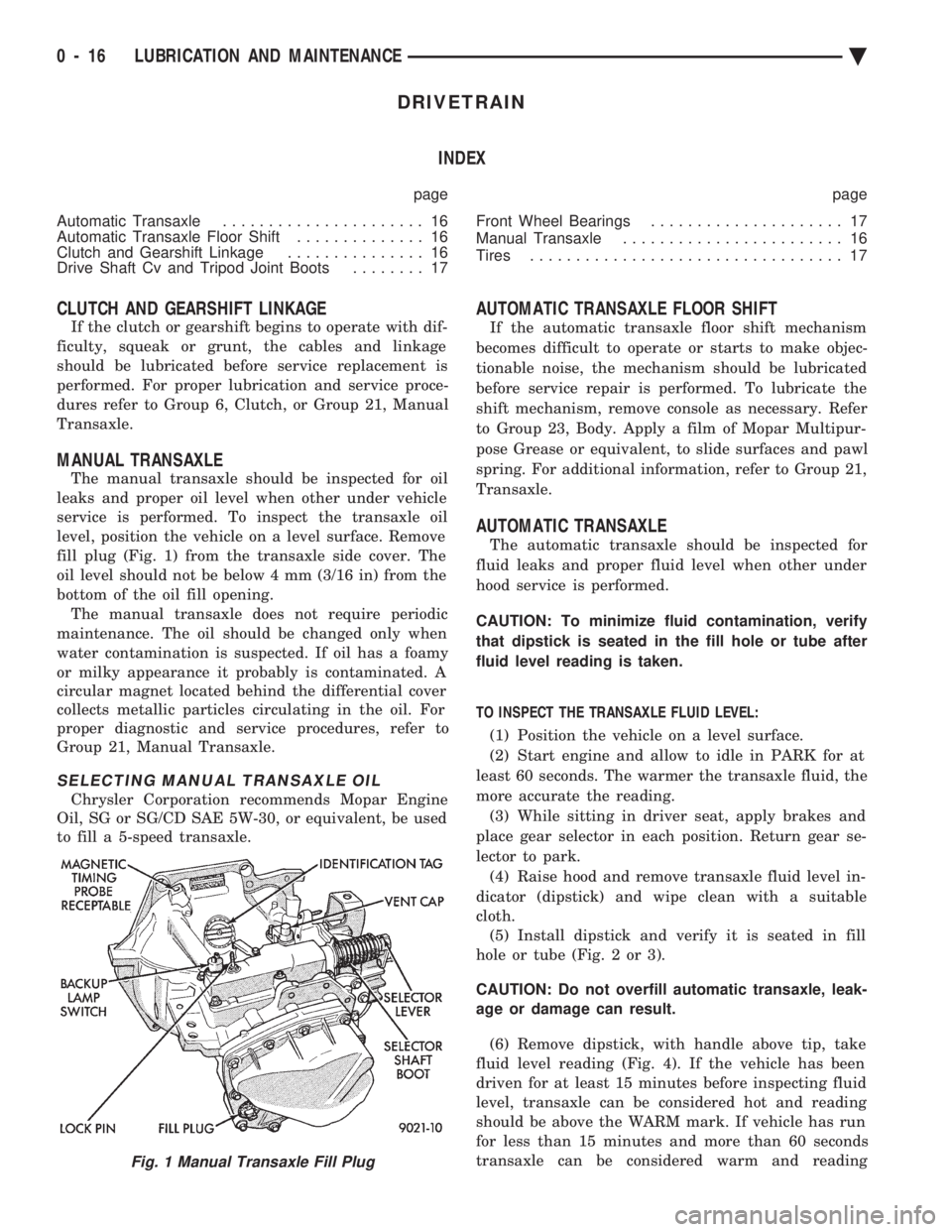

MANUAL TRANSAXLE

The manual transaxle should be inspected for oil

leaks and proper oil level when other under vehicle

service is performed. To inspect the transaxle oil

level, position the vehicle on a level surface. Remove

fill plug (Fig. 1) from the transaxle side cover. The

oil level should not be below 4 mm (3/16 in) from the

bottom of the oil fill opening. The manual transaxle does not require periodic

maintenance. The oil should be changed only when

water contamination is suspected. If oil has a foamy

or milky appearance it probably is contaminated. A

circular magnet located behind the differential cover

collects metallic particles circulating in the oil. For

proper diagnostic and service procedures, refer to

Group 21, Manual Transaxle.

SELECTING MANUAL TRANSAXLE OIL

Chrysler Corporation recommends Mopar Engine

Oil, SG or SG/CD SAE 5W-30, or equivalent, be used

to fill a 5-speed transaxle.

AUTOMATIC TRANSAXLE FLOOR SHIFT

If the automatic transaxle floor shift mechanism

becomes difficult to operate or starts to make objec-

tionable noise, the mechanism should be lubricated

before service repair is performed. To lubricate the

shift mechanism, remove console as necessary. Refer

to Group 23, Body. Apply a film of Mopar Multipur-

pose Grease or equivalent, to slide surfaces and pawl

spring. For additional information, refer to Group 21,

Transaxle.

AUTOMATIC TRANSAXLE

The automatic transaxle should be inspected for

fluid leaks and proper fluid level when other under

hood service is performed.

CAUTION: To minimize fluid contamination, verify

that dipstick is seated in the fill hole or tube after

fluid level reading is taken.

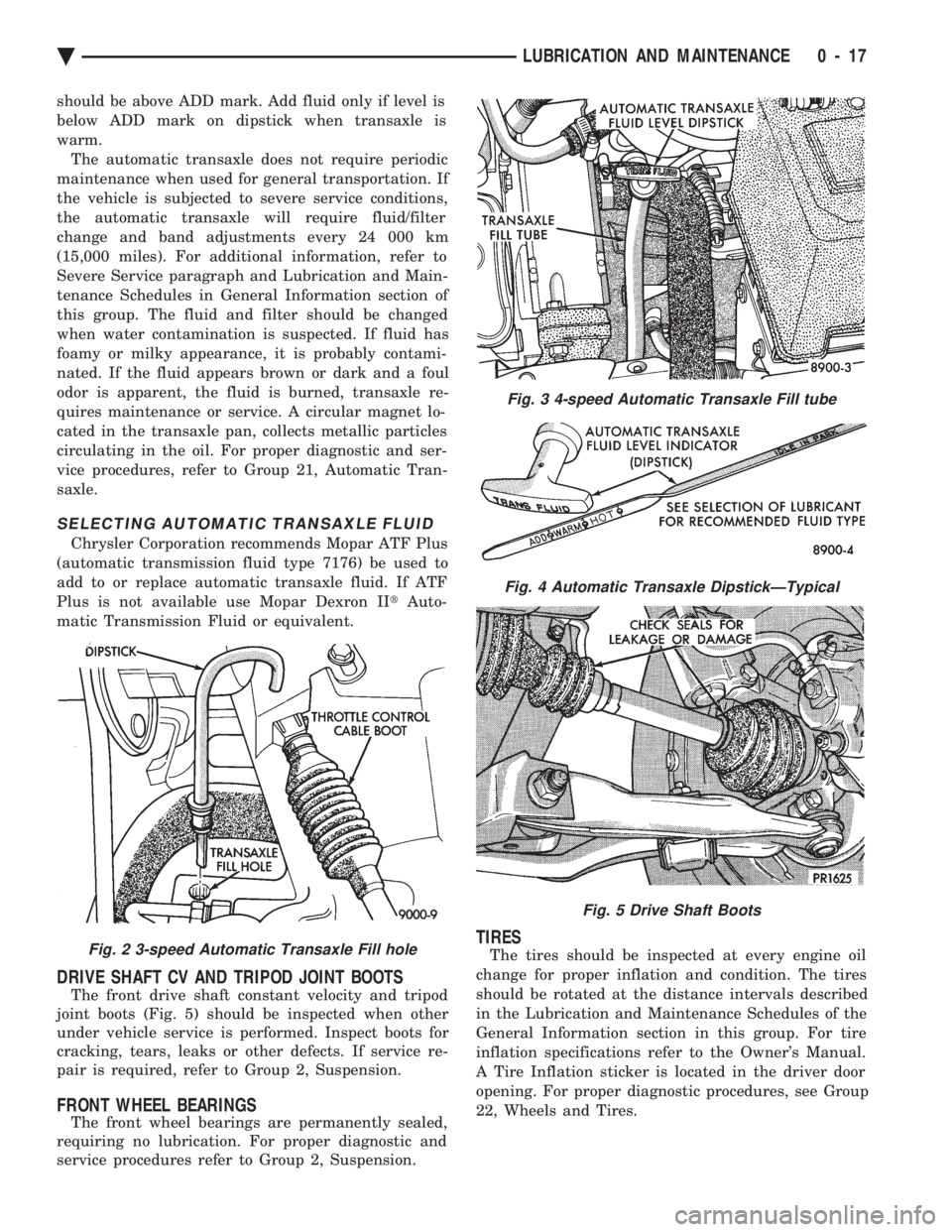

TO INSPECT THE TRANSAXLE FLUID LEVEL: (1) Position the vehicle on a level surface.

(2) Start engine and allow to idle in PARK for at

least 60 seconds. The warmer the transaxle fluid, the

more accurate the reading. (3) While sitting in driver seat, apply brakes and

place gear selector in each position. Return gear se-

lector to park. (4) Raise hood and remove transaxle fluid level in-

dicator (dipstick) and wipe clean with a suitable

cloth. (5) Install dipstick and verify it is seated in fill

hole or tube (Fig. 2 or 3).

CAUTION: Do not overfill automatic transaxle, leak-

age or damage can result.

(6) Remove dipstick, with handle above tip, take

fluid level reading (Fig. 4). If the vehicle has been

driven for at least 15 minutes before inspecting fluid

level, transaxle can be considered hot and reading

should be above the WARM mark. If vehicle has run

for less than 15 minutes and more than 60 seconds

transaxle can be considered warm and reading

Fig. 1 Manual Transaxle Fill Plug

0 - 16 LUBRICATION AND MAINTENANCE Ä

Page 53 of 2438

should be above ADD mark. Add fluid only if level is

below ADD mark on dipstick when transaxle is

warm.The automatic transaxle does not require periodic

maintenance when used for general transportation. If

the vehicle is subjected to severe service conditions,

the automatic transaxle will require fluid/filter

change and band adjustments every 24 000 km

(15,000 miles). For additional information, refer to

Severe Service paragraph and Lubrication and Main-

tenance Schedules in General Information section of

this group. The fluid and filter should be changed

when water contamination is suspected. If fluid has

foamy or milky appearance, it is probably contami-

nated. If the fluid appears brown or dark and a foul

odor is apparent, the fluid is burned, transaxle re-

quires maintenance or service. A circular magnet lo-

cated in the transaxle pan, collects metallic particles

circulating in the oil. For proper diagnostic and ser-

vice procedures, refer to Group 21, Automatic Tran-

saxle.

SELECTING AUTOMATIC TRANSAXLE FLUID

Chrysler Corporation recommends Mopar ATF Plus

(automatic transmission fluid type 7176) be used to

add to or replace automatic transaxle fluid. If ATF

Plus is not available use Mopar Dexron II tAuto-

matic Transmission Fluid or equivalent.

DRIVE SHAFT CV AND TRIPOD JOINT BOOTS

The front drive shaft constant velocity and tripod

joint boots (Fig. 5) should be inspected when other

under vehicle service is performed. Inspect boots for

cracking, tears, leaks or other defects. If service re-

pair is required, refer to Group 2, Suspension.

FRONT WHEEL BEARINGS

The front wheel bearings are permanently sealed,

requiring no lubrication. For proper diagnostic and

service procedures refer to Group 2, Suspension.

TIRES

The tires should be inspected at every engine oil

change for proper inflation and condition. The tires

should be rotated at the distance intervals described

in the Lubrication and Maintenance Schedules of the

General Information section in this group. For tire

inflation specifications refer to the Owner's Manual.

A Tire Inflation sticker is located in the driver door

opening. For proper diagnostic procedures, see Group

22, Wheels and Tires.Fig. 2 3-speed Automatic Transaxle Fill hole

Fig. 3 4-speed Automatic Transaxle Fill tube

Fig. 4 Automatic Transaxle DipstickÐTypical

Fig. 5 Drive Shaft Boots

Ä LUBRICATION AND MAINTENANCE 0 - 17

Page 55 of 2438

CHASSIS AND BODY INDEX

page page

Body Lubrication ......................... 22

Brakes ................................ 21

Headlamps ............................. 22

Lower Ball Joints ......................... 19 Power Steering

.......................... 19

Rear Wheel Bearings ..................... 20

Steering Linkage ......................... 19

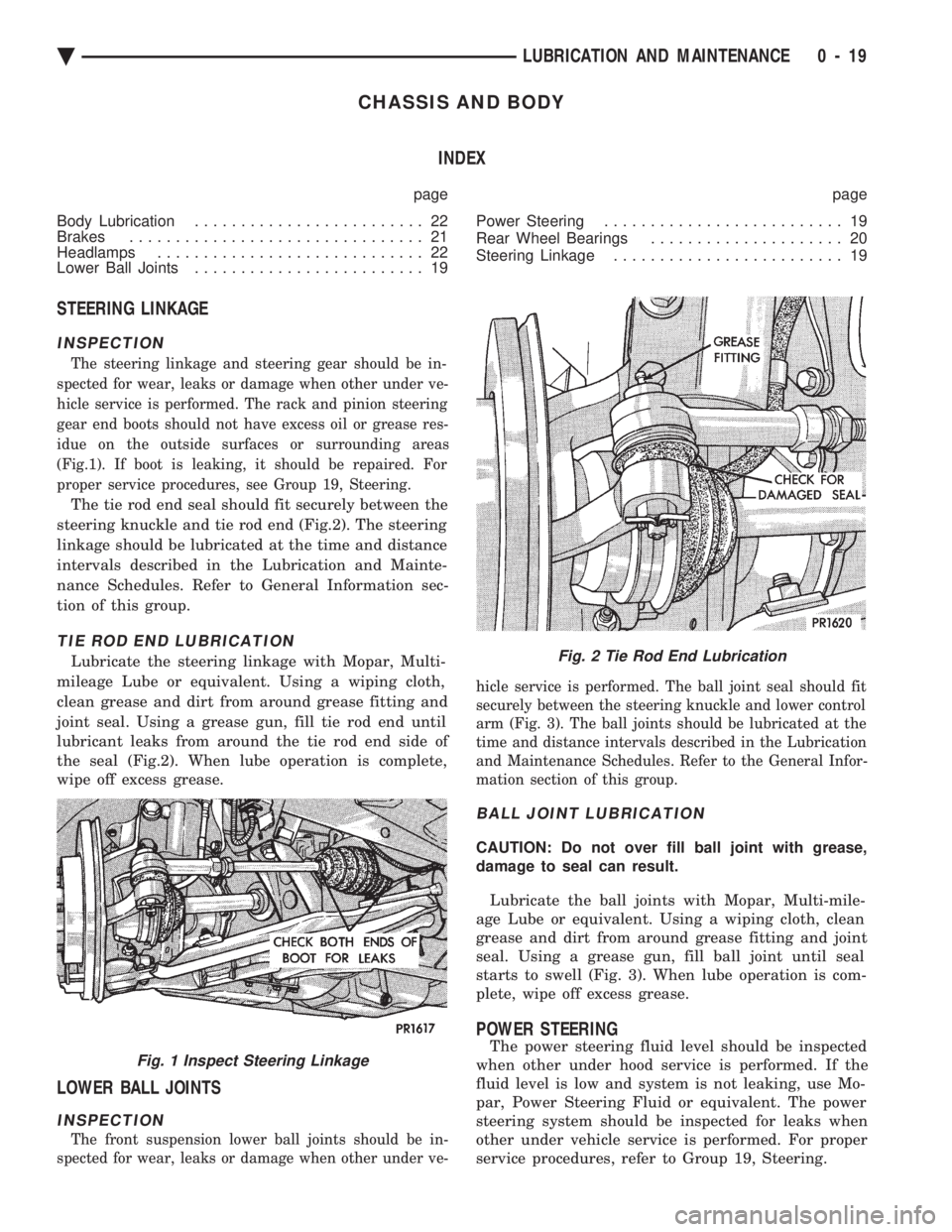

STEERING LINKAGE

INSPECTION

The steering linkage and steering gear should be in-

spected for wear, leaks or damage when other under ve-

hicle service is performed. The rack and pinion steering

gear end boots should not have excess oil or grease res-

idue on the outside surfaces or surrounding areas

(Fig.1). If boot is leaking, it should be repaired. For

proper service procedures, see Group 19, Steering.

The tie rod end seal should fit securely between the

steering knuckle and tie rod end (Fig.2). The steering

linkage should be lubricated at the time and distance

intervals described in the Lubrication and Mainte-

nance Schedules. Refer to General Information sec-

tion of this group.

TIE ROD END LUBRICATION

Lubricate the steering linkage with Mopar, Multi-

mileage Lube or equivalent. Using a wiping cloth,

clean grease and dirt from around grease fitting and

joint seal. Using a grease gun, fill tie rod end until

lubricant leaks from around the tie rod end side of

the seal (Fig.2). When lube operation is complete,

wipe off excess grease.

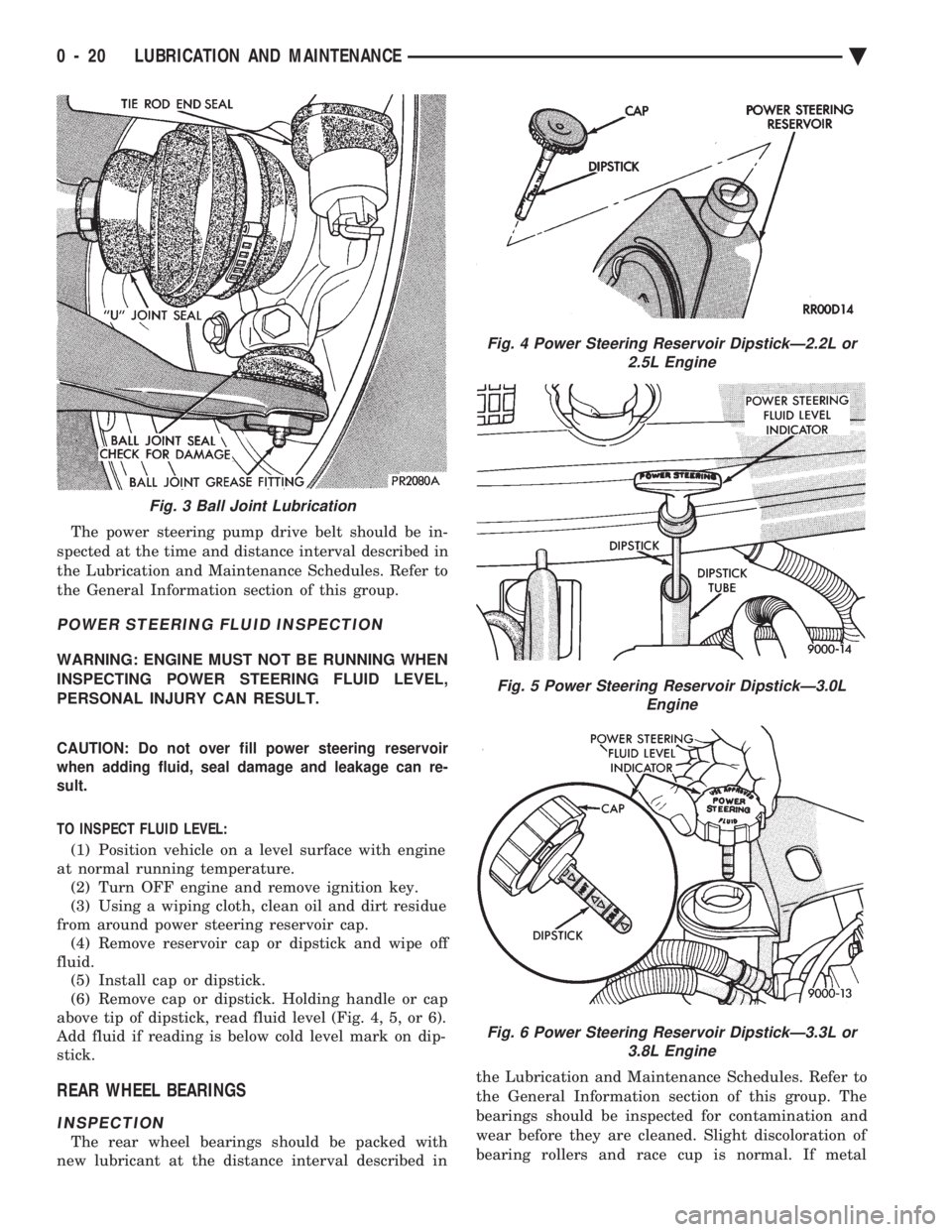

LOWER BALL JOINTS

INSPECTION

The front suspension lower ball joints should be in-

spected for wear, leaks or damage when other under ve- hicle service is performed. The ball joint seal should fit

securely between the steering knuckle and lower control

arm (Fig. 3). The ball joints should be lubricated at the

time and distance intervals described in the Lubrication

and Maintenance Schedules. Refer to the General Infor-

mation section of this group.

BALL JOINT LUBRICATION

CAUTION: Do not over fill ball joint with grease,

damage to seal can result.

Lubricate the ball joints with Mopar, Multi-mile-

age Lube or equivalent. Using a wiping cloth, clean

grease and dirt from around grease fitting and joint

seal. Using a grease gun, fill ball joint until seal

starts to swell (Fig. 3). When lube operation is com-

plete, wipe off excess grease.

POWER STEERING

The power steering fluid level should be inspected

when other under hood service is performed. If the

fluid level is low and system is not leaking, use Mo-

par, Power Steering Fluid or equivalent. The power

steering system should be inspected for leaks when

other under vehicle service is performed. For proper

service procedures, refer to Group 19, Steering.Fig. 1 Inspect Steering Linkage

Fig. 2 Tie Rod End Lubrication

Ä LUBRICATION AND MAINTENANCE 0 - 19

Page 56 of 2438

The power steering pump drive belt should be in-

spected at the time and distance interval described in

the Lubrication and Maintenance Schedules. Refer to

the General Information section of this group.

POWER STEERING FLUID INSPECTION

WARNING: ENGINE MUST NOT BE RUNNING WHEN

INSPECTING POWER STEERING FLUID LEVEL,

PERSONAL INJURY CAN RESULT.

CAUTION: Do not over fill power steering reservoir

when adding fluid, seal damage and leakage can re-

sult.

TO INSPECT FLUID LEVEL:

(1) Position vehicle on a level surface with engine

at normal running temperature. (2) Turn OFF engine and remove ignition key.

(3) Using a wiping cloth, clean oil and dirt residue

from around power steering reservoir cap. (4) Remove reservoir cap or dipstick and wipe off

fluid. (5) Install cap or dipstick.

(6) Remove cap or dipstick. Holding handle or cap

above tip of dipstick, read fluid level (Fig. 4, 5, or 6).

Add fluid if reading is below cold level mark on dip-

stick.

REAR WHEEL BEARINGS

INSPECTION

The rear wheel bearings should be packed with

new lubricant at the distance interval described in the Lubrication and Maintenance Schedules. Refer to

the General Information section of this group. The

bearings should be inspected for contamination and

wear before they are cleaned. Slight discoloration of

bearing rollers and race cup is normal. If metal

Fig. 3 Ball Joint Lubrication

Fig. 4 Power Steering Reservoir DipstickÐ2.2L or 2.5L Engine

Fig. 5 Power Steering Reservoir DipstickÐ3.0L Engine

Fig. 6 Power Steering Reservoir DipstickÐ3.3L or3.8L Engine

0 - 20 LUBRICATION AND MAINTENANCE Ä

Page 58 of 2438

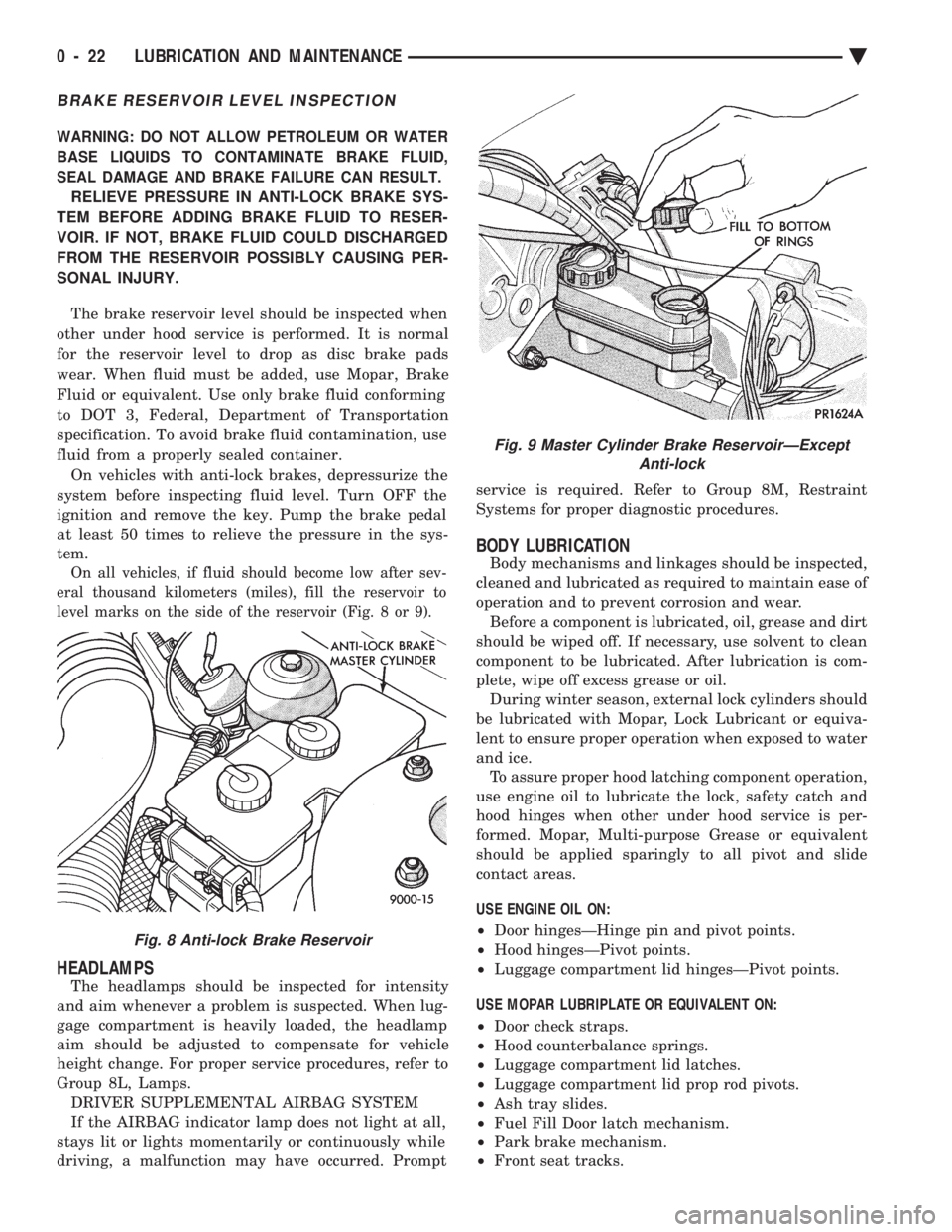

BRAKE RESERVOIR LEVEL INSPECTION

WARNING: DO NOT ALLOW PETROLEUM OR WATER

BASE LIQUIDS TO CONTAMINATE BRAKE FLUID,

SEAL DAMAGE AND BRAKE FAILURE CAN RESULT.

RELIEVE PRESSURE IN ANTI-LOCK BRAKE SYS-

TEM BEFORE ADDING BRAKE FLUID TO RESER-

VOIR. IF NOT, BRAKE FLUID COULD DISCHARGED

FROM THE RESERVOIR POSSIBLY CAUSING PER-

SONAL INJURY.

The brake reservoir level should be inspected when

other under hood service is performed. It is normal

for the reservoir level to drop as disc brake pads

wear. When fluid must be added, use Mopar, Brake

Fluid or equivalent. Use only brake fluid conforming

to DOT 3, Federal, Department of Transportation

specification. To avoid brake fluid contamination, use

fluid from a properly sealed container. On vehicles with anti-lock brakes, depressurize the

system before inspecting fluid level. Turn OFF the

ignition and remove the key. Pump the brake pedal

at least 50 times to relieve the pressure in the sys-

tem.

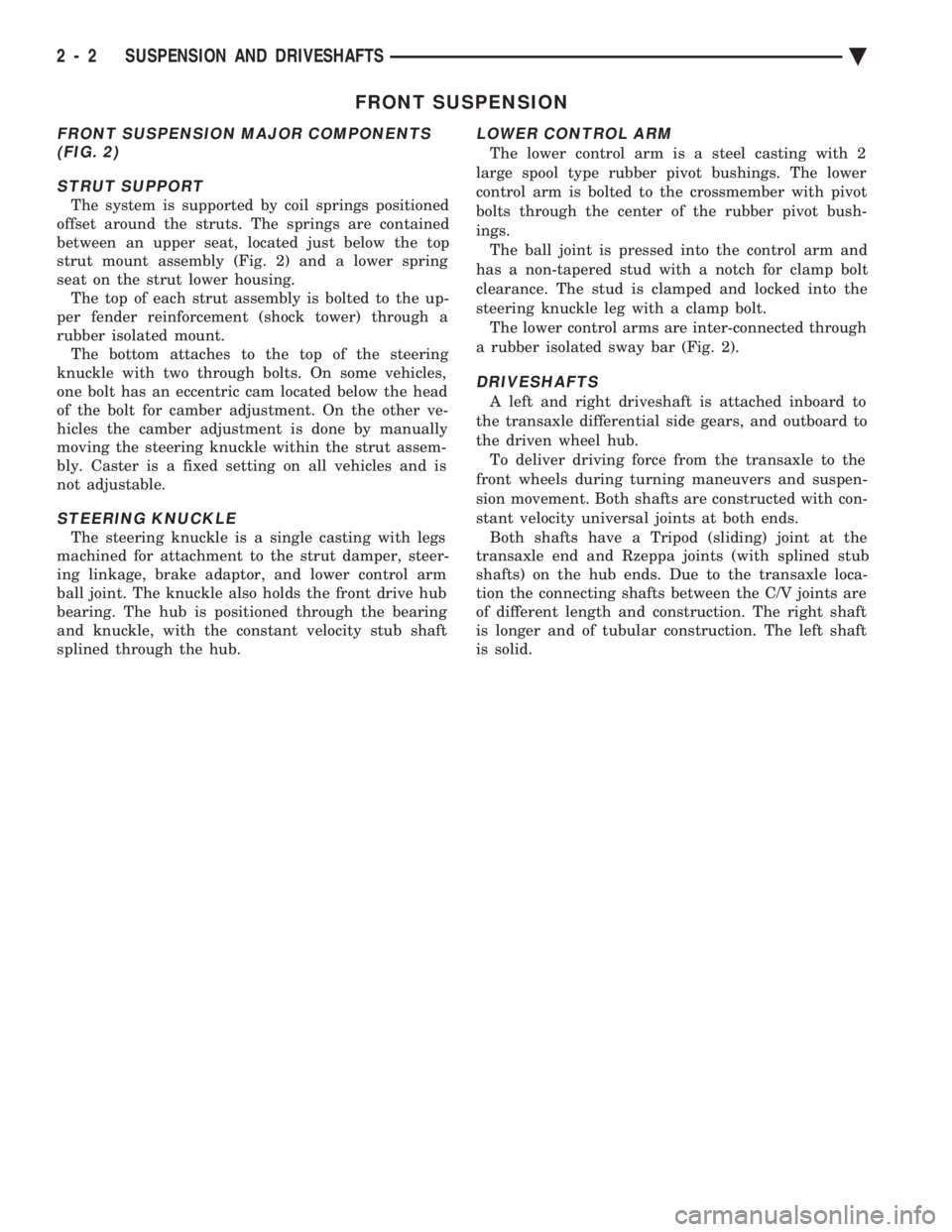

On all vehicles, if fluid should become low after sev-

eral thousand kilometers (miles), fill the reservoir to

level marks on the side of the reservoir (Fig. 8 or 9).

HEADLAMPS

The headlamps should be inspected for intensity

and aim whenever a problem is suspected. When lug-

gage compartment is heavily loaded, the headlamp

aim should be adjusted to compensate for vehicle

height change. For proper service procedures, refer to

Group 8L, Lamps. DRIVER SUPPLEMENTAL AIRBAG SYSTEM

If the AIRBAG indicator lamp does not light at all,

stays lit or lights momentarily or continuously while

driving, a malfunction may have occurred. Prompt service is required. Refer to Group 8M, Restraint

Systems for proper diagnostic procedures.

BODY LUBRICATION

Body mechanisms and linkages should be inspected,

cleaned and lubricated as required to maintain ease of

operation and to prevent corrosion and wear. Before a component is lubricated, oil, grease and dirt

should be wiped off. If necessary, use solvent to clean

component to be lubricated. After lubrication is com-

plete, wipe off excess grease or oil. During winter season, external lock cylinders should

be lubricated with Mopar, Lock Lubricant or equiva-

lent to ensure proper operation when exposed to water

and ice. To assure proper hood latching component operation,

use engine oil to lubricate the lock, safety catch and

hood hinges when other under hood service is per-

formed. Mopar, Multi-purpose Grease or equivalent

should be applied sparingly to all pivot and slide

contact areas.

USE ENGINE OIL ON:

² Door hingesÐHinge pin and pivot points.

² Hood hingesÐPivot points.

² Luggage compartment lid hingesÐPivot points.

USE MOPAR LUBRIPLATE OR EQUIVALENT ON:

² Door check straps.

² Hood counterbalance springs.

² Luggage compartment lid latches.

² Luggage compartment lid prop rod pivots.

² Ash tray slides.

² Fuel Fill Door latch mechanism.

² Park brake mechanism.

² Front seat tracks.

Fig. 8 Anti-lock Brake Reservoir

Fig. 9 Master Cylinder Brake ReservoirÐExcept

Anti-lock

0 - 22 LUBRICATION AND MAINTENANCE Ä

Page 60 of 2438

FRONT SUSPENSION

FRONT SUSPENSION MAJOR COMPONENTS (FIG. 2)

STRUT SUPPORT

The system is supported by coil springs positioned

offset around the struts. The springs are contained

between an upper seat, located just below the top

strut mount assembly (Fig. 2) and a lower spring

seat on the strut lower housing. The top of each strut assembly is bolted to the up-

per fender reinforcement (shock tower) through a

rubber isolated mount. The bottom attaches to the top of the steering

knuckle with two through bolts. On some vehicles,

one bolt has an eccentric cam located below the head

of the bolt for camber adjustment. On the other ve-

hicles the camber adjustment is done by manually

moving the steering knuckle within the strut assem-

bly. Caster is a fixed setting on all vehicles and is

not adjustable.

STEERING KNUCKLE

The steering knuckle is a single casting with legs

machined for attachment to the strut damper, steer-

ing linkage, brake adaptor, and lower control arm

ball joint. The knuckle also holds the front drive hub

bearing. The hub is positioned through the bearing

and knuckle, with the constant velocity stub shaft

splined through the hub.

LOWER CONTROL ARM

The lower control arm is a steel casting with 2

large spool type rubber pivot bushings. The lower

control arm is bolted to the crossmember with pivot

bolts through the center of the rubber pivot bush-

ings. The ball joint is pressed into the control arm and

has a non-tapered stud with a notch for clamp bolt

clearance. The stud is clamped and locked into the

steering knuckle leg with a clamp bolt. The lower control arms are inter-connected through

a rubber isolated sway bar (Fig. 2).

DRIVESHAFTS

A left and right driveshaft is attached inboard to

the transaxle differential side gears, and outboard to

the driven wheel hub. To deliver driving force from the transaxle to the

front wheels during turning maneuvers and suspen-

sion movement. Both shafts are constructed with con-

stant velocity universal joints at both ends. Both shafts have a Tripod (sliding) joint at the

transaxle end and Rzeppa joints (with splined stub

shafts) on the hub ends. Due to the transaxle loca-

tion the connecting shafts between the C/V joints are

of different length and construction. The right shaft

is longer and of tubular construction. The left shaft

is solid.

2 - 2 SUSPENSION AND DRIVESHAFTS Ä

Page 63 of 2438

FRONT SUSPENSION SERVICE PROCEDURES INDEX

page page

Ball Joints .............................. 13

Hub and Bearing Assembly ................. 20

Knuckle (Front Suspension) ................. 16

Lower Control Arm ....................... 10

Lower Control Arm Pivot Bushings ........... 11 Shock Absorbers (Strut Damper)

............. 10

Strut Damper Assembly ..................... 7

Suspension Coil Springs .................... 9

Sway Bar .............................. 14

Wheel Alignment .......................... 5

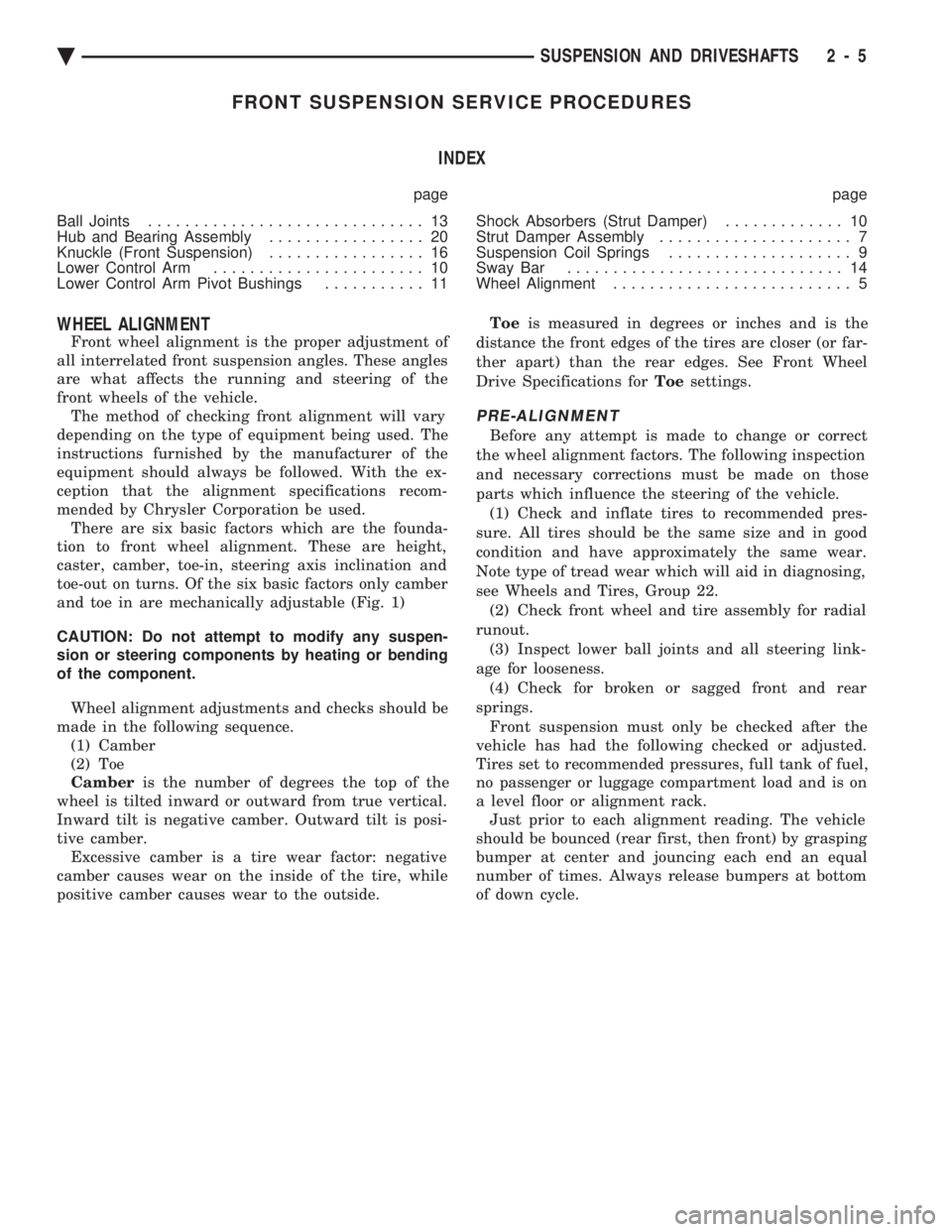

WHEEL ALIGNMENT

Front wheel alignment is the proper adjustment of

all interrelated front suspension angles. These angles

are what affects the running and steering of the

front wheels of the vehicle. The method of checking front alignment will vary

depending on the type of equipment being used. The

instructions furnished by the manufacturer of the

equipment should always be followed. With the ex-

ception that the alignment specifications recom-

mended by Chrysler Corporation be used. There are six basic factors which are the founda-

tion to front wheel alignment. These are height,

caster, camber, toe-in, steering axis inclination and

toe-out on turns. Of the six basic factors only camber

and toe in are mechanically adjustable (Fig. 1)

CAUTION: Do not attempt to modify any suspen-

sion or steering components by heating or bending

of the component.

Wheel alignment adjustments and checks should be

made in the following sequence. (1) Camber

(2) Toe

Camber is the number of degrees the top of the

wheel is tilted inward or outward from true vertical.

Inward tilt is negative camber. Outward tilt is posi-

tive camber. Excessive camber is a tire wear factor: negative

camber causes wear on the inside of the tire, while

positive camber causes wear to the outside. Toe

is measured in degrees or inches and is the

distance the front edges of the tires are closer (or far-

ther apart) than the rear edges. See Front Wheel

Drive Specifications for Toesettings.

PRE-ALIGNMENT

Before any attempt is made to change or correct

the wheel alignment factors. The following inspection

and necessary corrections must be made on those

parts which influence the steering of the vehicle. (1) Check and inflate tires to recommended pres-

sure. All tires should be the same size and in good

condition and have approximately the same wear.

Note type of tread wear which will aid in diagnosing,

see Wheels and Tires, Group 22. (2) Check front wheel and tire assembly for radial

runout. (3) Inspect lower ball joints and all steering link-

age for looseness. (4) Check for broken or sagged front and rear

springs. Front suspension must only be checked after the

vehicle has had the following checked or adjusted.

Tires set to recommended pressures, full tank of fuel,

no passenger or luggage compartment load and is on

a level floor or alignment rack. Just prior to each alignment reading. The vehicle

should be bounced (rear first, then front) by grasping

bumper at center and jouncing each end an equal

number of times. Always release bumpers at bottom

of down cycle.

Ä SUSPENSION AND DRIVESHAFTS 2 - 5

Page 66 of 2438

INSPECTION

Inspect for evidence of fluid running from the up-

per end of the reservoir. (Actual leakage will be a

stream of fluid running down the side and dripping

off lower end of unit). A slight amount of seepage be-

tween the strut rod and strut shaft seal is not un-

usual and does not affect performance of the strut

assembly.

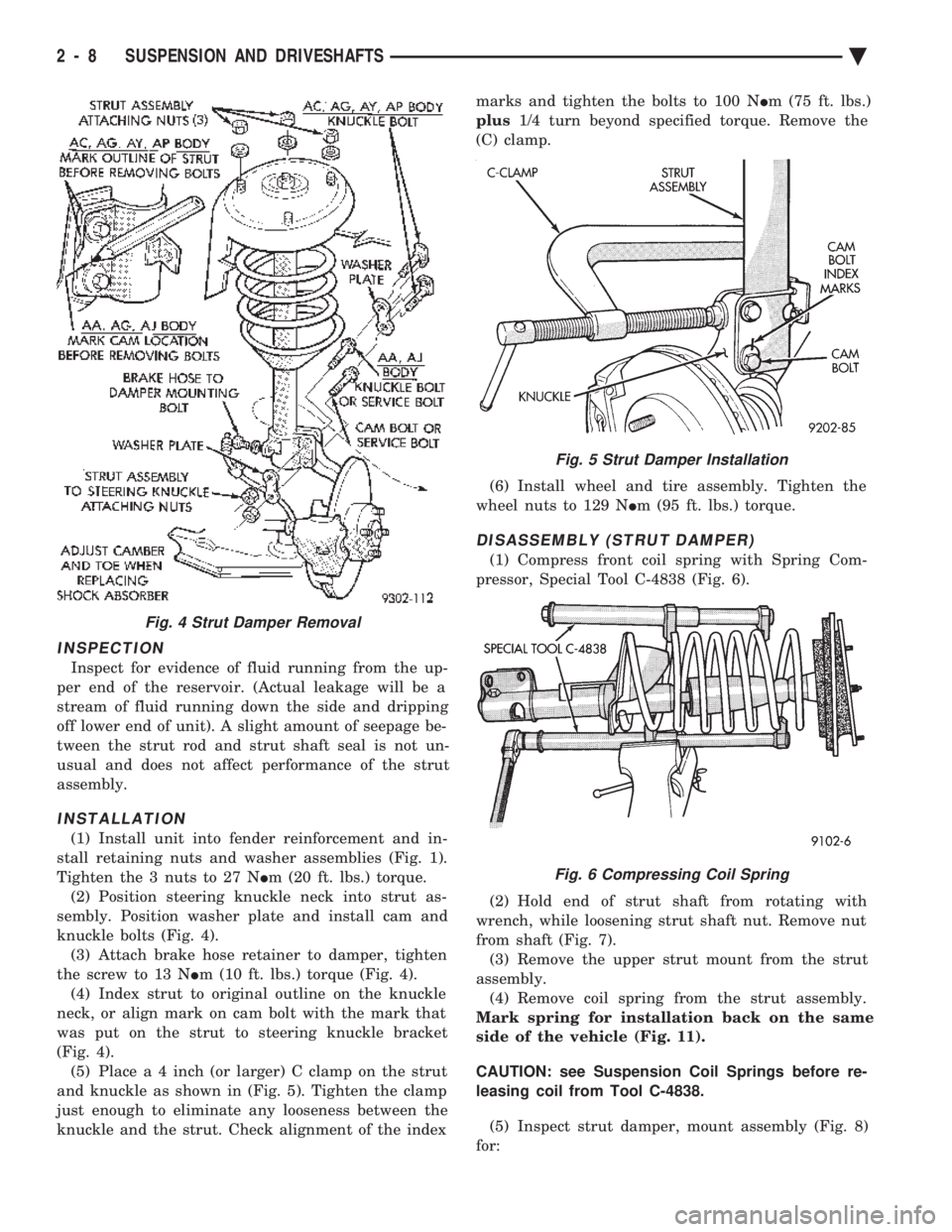

INSTALLATION

(1) Install unit into fender reinforcement and in-

stall retaining nuts and washer assemblies (Fig. 1).

Tighten the 3 nuts to 27 N Im (20 ft. lbs.) torque.

(2) Position steering knuckle neck into strut as-

sembly. Position washer plate and install cam and

knuckle bolts (Fig. 4). (3) Attach brake hose retainer to damper, tighten

the screw to 13 N Im (10 ft. lbs.) torque (Fig. 4).

(4) Index strut to original outline on the knuckle

neck, or align mark on cam bolt with the mark that

was put on the strut to steering knuckle bracket

(Fig. 4). (5) Plac e a 4 inch (or larger) C clamp on the strut

and knuckle as shown in (Fig. 5). Tighten the clamp

just enough to eliminate any looseness between the

knuckle and the strut. Check alignment of the index marks and tighten the bolts to 100 N

Im (75 ft. lbs.)

plus 1/4 turn beyond specified torque. Remove the

(C) clamp.

(6) Install wheel and tire assembly. Tighten the

wheel nuts to 129 N Im (95 ft. lbs.) torque.

DISASSEMBLY (STRUT DAMPER)

(1) Compress front coil spring with Spring Com-

pressor, Special Tool C-4838 (Fig. 6).

(2) Hold end of strut shaft from rotating with

wrench, while loosening strut shaft nut. Remove nut

from shaft (Fig. 7). (3) Remove the upper strut mount from the strut

assembly. (4) Remove coil spring from the strut assembly.

Mark spring for installation back on the same

side of the vehicle (Fig. 11).

CAUTION: see Suspension Coil Springs before re-

leasing coil from Tool C-4838.

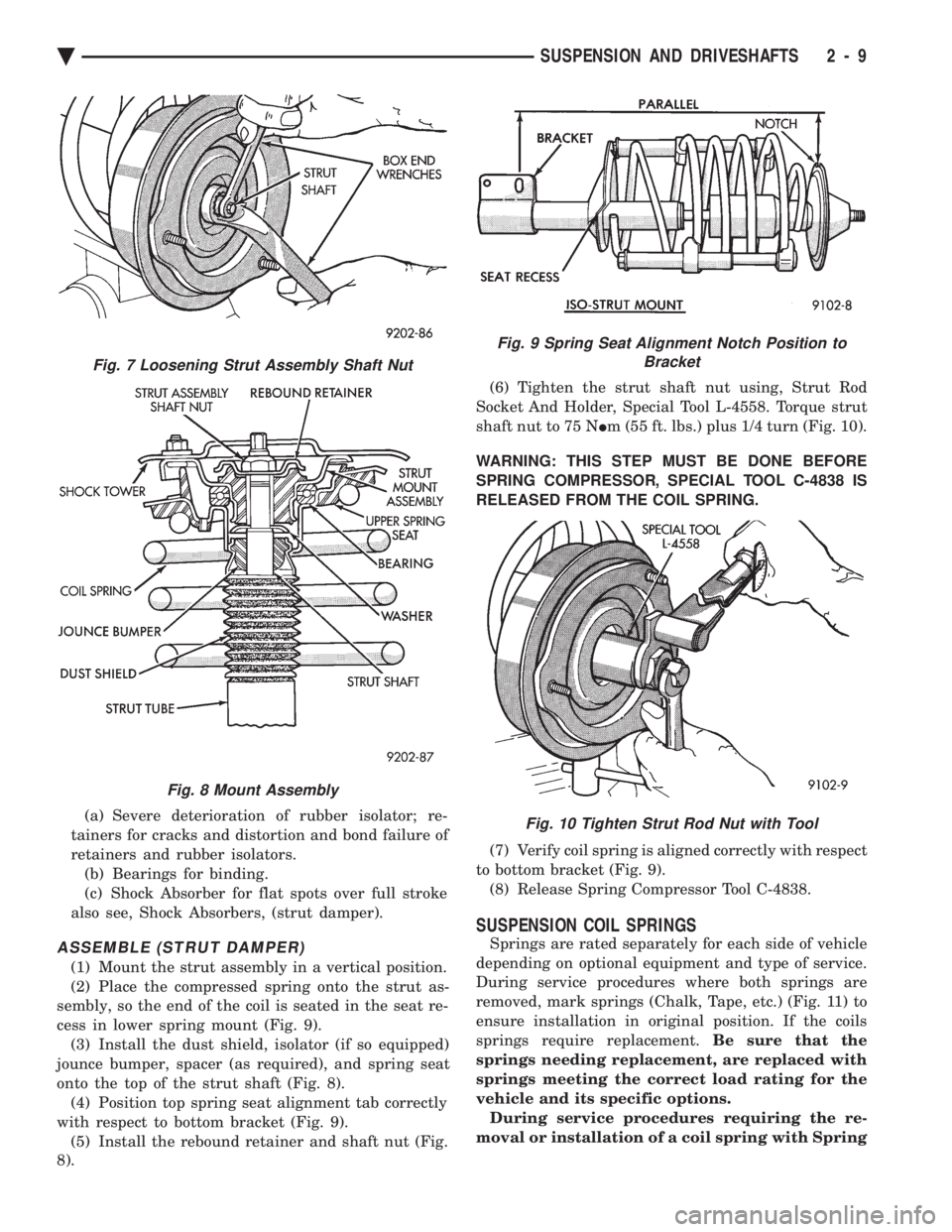

(5) Inspect strut damper, mount assembly (Fig. 8)

for:

Fig. 4 Strut Damper Removal

Fig. 5 Strut Damper Installation

Fig. 6 Compressing Coil Spring

2 - 8 SUSPENSION AND DRIVESHAFTS Ä

Page 67 of 2438

(a) Severe deterioration of rubber isolator; re-

tainers for cracks and distortion and bond failure of

retainers and rubber isolators. (b) Bearings for binding.

(c) Shock Absorber for flat spots over full stroke

also see, Shock Absorbers, (strut damper).

ASSEMBLE (STRUT DAMPER)

(1) Mount the strut assembly in a vertical position.

(2) Place the compressed spring onto the strut as-

sembly, so the end of the coil is seated in the seat re-

cess in lower spring mount (Fig. 9). (3) Install the dust shield, isolator (if so equipped)

jounce bumper, spacer (as required), and spring seat

onto the top of the strut shaft (Fig. 8). (4) Position top spring seat alignment tab correctly

with respect to bottom bracket (Fig. 9). (5) Install the rebound retainer and shaft nut (Fig.

8). (6) Tighten the strut shaft nut using, Strut Rod

Socket And Holder, Special Tool L-4558. Torque strut

shaft nut to 75 N Im (55 ft. lbs.) plus 1/4 turn (Fig. 10).

WARNING: THIS STEP MUST BE DONE BEFORE

SPRING COMPRESSOR, SPECIAL TOOL C-4838 IS

RELEASED FROM THE COIL SPRING.

(7) Verify coil spring is aligned correctly with respect

to bottom bracket (Fig. 9). (8) Release Spring Compressor Tool C-4838.

SUSPENSION COIL SPRINGS

Springs are rated separately for each side of vehicle

depending on optional equipment and type of service.

During service procedures where both springs are

removed, mark springs (Chalk, Tape, etc.) (Fig. 11) to

ensure installation in original position. If the coils

springs require replacement. Be sure that the

springs needing replacement, are replaced with

springs meeting the correct load rating for the

vehicle and its specific options. During service procedures requiring the re-

moval or installation of a coil spring with Spring

Fig. 7 Loosening Strut Assembly Shaft Nut

Fig. 8 Mount Assembly

Fig. 9 Spring Seat Alignment Notch Position to Bracket

Fig. 10 Tighten Strut Rod Nut with Tool

Ä SUSPENSION AND DRIVESHAFTS 2 - 9

Page 68 of 2438

Compressor, Special Tool C-4838. It is required

that five coils be captured within the jaws of the

tool (Fig. 11).

SPRING RETAINER UPPER

Ensure that upper spring retainer is positioned

properly, see; step (4), Assemble (Strut Damper).

SPRING SEAT LOWER

During assembly of the coil spring to strut damper.

Ensure that lower coil spring end is seated in strut

damper spring seat recess refer to (Fig. 9) in assem-

ble (Strut Damper) section.

SHOCK ABSORBERS (Strut Damper)

INSPECTION

Inspect for evidence of fluid leaking from around

the strut assembly shaft seal at the upper end of the

reservoir. (Actual leakage will be a stream of fluid

running down the side and dripping off lower end of

unit. A slight amount of seepage around the strut

rod is not unusual and does not affect performance.

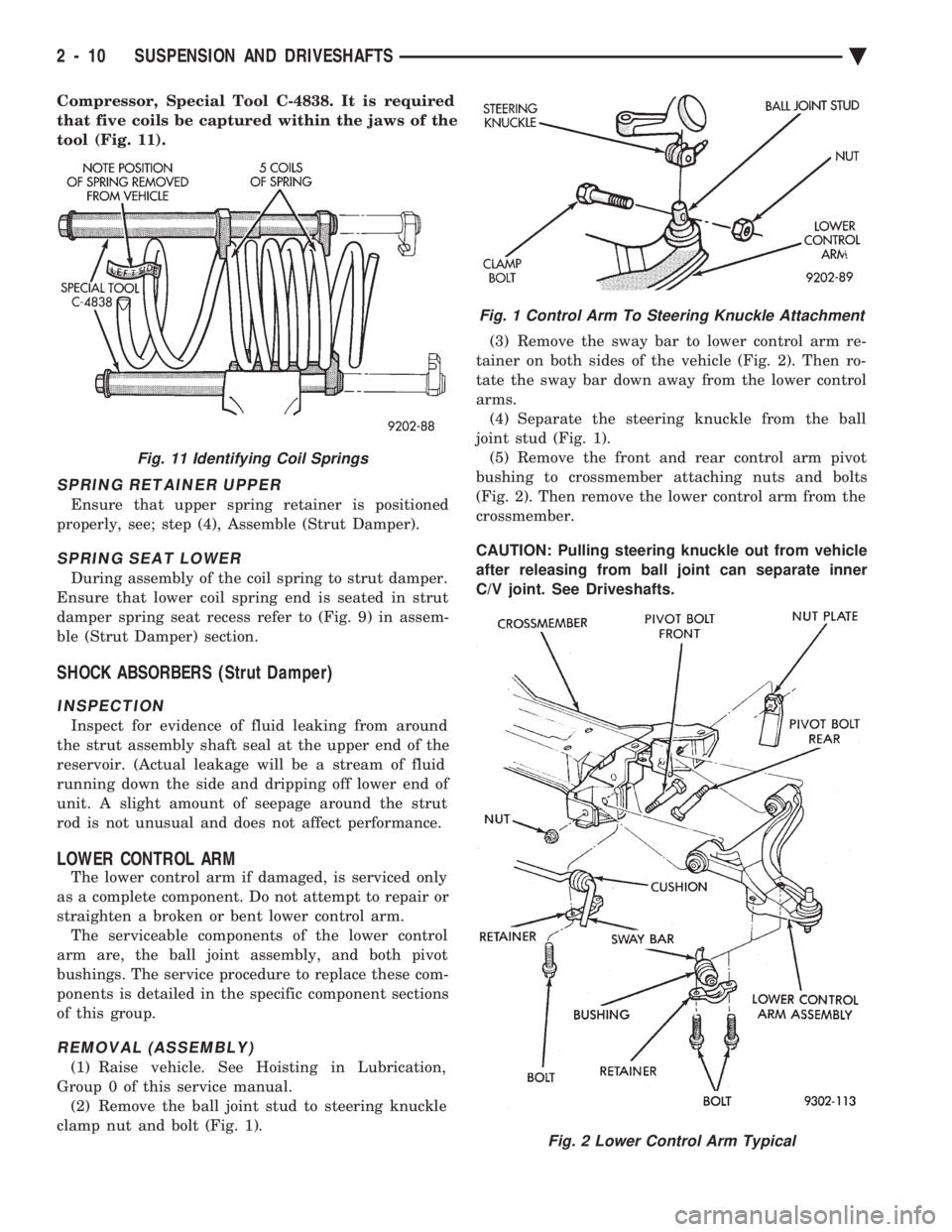

LOWER CONTROL ARM

The lower control arm if damaged, is serviced only

as a complete component. Do not attempt to repair or

straighten a broken or bent lower control arm. The serviceable components of the lower control

arm are, the ball joint assembly, and both pivot

bushings. The service procedure to replace these com-

ponents is detailed in the specific component sections

of this group.

REMOVAL (ASSEMBLY)

(1) Raise vehicle. See Hoisting in Lubrication,

Group 0 of this service manual. (2) Remove the ball joint stud to steering knuckle

clamp nut and bolt (Fig. 1). (3) Remove the sway bar to lower control arm re-

tainer on both sides of the vehicle (Fig. 2). Then ro-

tate the sway bar down away from the lower control

arms. (4) Separate the steering knuckle from the ball

joint stud (Fig. 1). (5) Remove the front and rear control arm pivot

bushing to crossmember attaching nuts and bolts

(Fig. 2). Then remove the lower control arm from the

crossmember.

CAUTION: Pulling steering knuckle out from vehicle

after releasing from ball joint can separate inner

C/V joint. See Driveshafts.

Fig. 11 Identifying Coil Springs

Fig. 1 Control Arm To Steering Knuckle Attachment

Fig. 2 Lower Control Arm Typical

2 - 10 SUSPENSION AND DRIVESHAFTS Ä