radio CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 502 of 2438

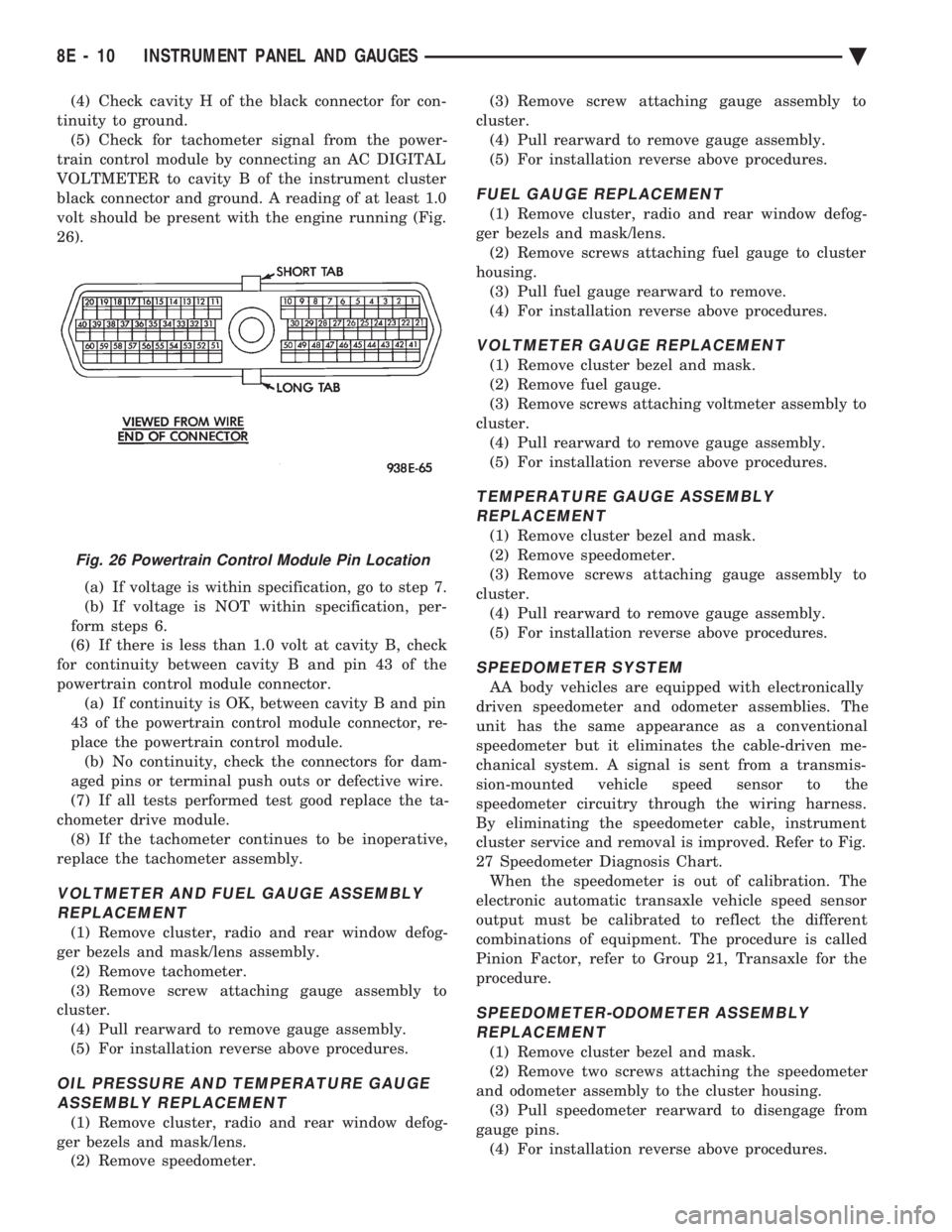

(4) Check cavity H of the black connector for con-

tinuity to ground. (5) Check for tachometer signal from the power-

train control module by connecting an AC DIGITAL

VOLTMETER to cavity B of the instrument cluster

black connector and ground. A reading of at least 1.0

volt should be present with the engine running (Fig.

26).

(a) If voltage is within specification, go to step 7.

(b) If voltage is NOT within specification, per-

form steps 6.

(6) If there is less than 1.0 volt at cavity B, check

for continuity between cavity B and pin 43 of the

powertrain control module connector. (a) If continuity is OK, between cavity B and pin

43 of the powertrain control module connector, re-

place the powertrain control module. (b) No continuity, check the connectors for dam-

aged pins or terminal push outs or defective wire.

(7) If all tests performed test good replace the ta-

chometer drive module. (8) If the tachometer continues to be inoperative,

replace the tachometer assembly.

VOLTMETER AND FUEL GAUGE ASSEMBLY REPLACEMENT

(1) Remove cluster, radio and rear window defog-

ger bezels and mask/lens assembly. (2) Remove tachometer.

(3) Remove screw attaching gauge assembly to

cluster. (4) Pull rearward to remove gauge assembly.

(5) For installation reverse above procedures.

OIL PRESSURE AND TEMPERATURE GAUGEASSEMBLY REPLACEMENT

(1) Remove cluster, radio and rear window defog-

ger bezels and mask/lens. (2) Remove speedometer. (3) Remove screw attaching gauge assembly to

cluster. (4) Pull rearward to remove gauge assembly.

(5) For installation reverse above procedures.

FUEL GAUGE REPLACEMENT

(1) Remove cluster, radio and rear window defog-

ger bezels and mask/lens. (2) Remove screws attaching fuel gauge to cluster

housing. (3) Pull fuel gauge rearward to remove.

(4) For installation reverse above procedures.

VOLTMETER GAUGE REPLACEMENT

(1) Remove cluster bezel and mask.

(2) Remove fuel gauge.

(3) Remove screws attaching voltmeter assembly to

cluster. (4) Pull rearward to remove gauge assembly.

(5) For installation reverse above procedures.

TEMPERATURE GAUGE ASSEMBLY REPLACEMENT

(1) Remove cluster bezel and mask.

(2) Remove speedometer.

(3) Remove screws attaching gauge assembly to

cluster. (4) Pull rearward to remove gauge assembly.

(5) For installation reverse above procedures.

SPEEDOMETER SYSTEM

AA body vehicles are equipped with electronically

driven speedometer and odometer assemblies. The

unit has the same appearance as a conventional

speedometer but it eliminates the cable-driven me-

chanical system. A signal is sent from a transmis-

sion-mounted vehicle speed sensor to the

speedometer circuitry through the wiring harness.

By eliminating the speedometer cable, instrument

cluster service and removal is improved. Refer to Fig.

27 Speedometer Diagnosis Chart. When the speedometer is out of calibration. The

electronic automatic transaxle vehicle speed sensor

output must be calibrated to reflect the different

combinations of equipment. The procedure is called

Pinion Factor, refer to Group 21, Transaxle for the

procedure.

SPEEDOMETER-ODOMETER ASSEMBLY REPLACEMENT

(1) Remove cluster bezel and mask.

(2) Remove two screws attaching the speedometer

and odometer assembly to the cluster housing. (3) Pull speedometer rearward to disengage from

gauge pins. (4) For installation reverse above procedures.

Fig. 26 Powertrain Control Module Pin Location

8E - 10 INSTRUMENT PANEL AND GAUGES Ä

Page 504 of 2438

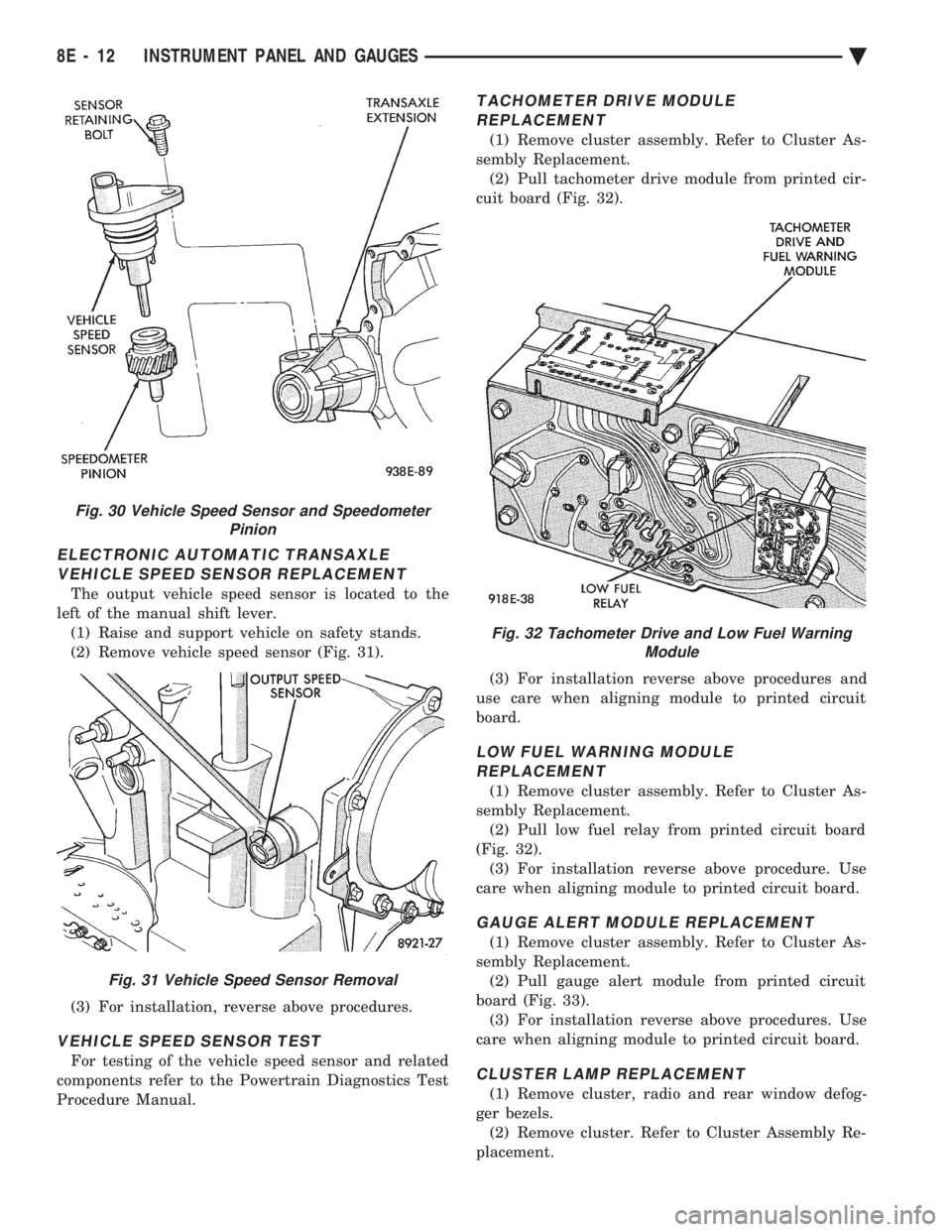

ELECTRONIC AUTOMATIC TRANSAXLE VEHICLE SPEED SENSOR REPLACEMENT

The output vehicle speed sensor is located to the

left of the manual shift lever. (1) Raise and support vehicle on safety stands.

(2) Remove vehicle speed sensor (Fig. 31).

(3) For installation, reverse above procedures.

VEHICLE SPEED SENSOR TEST

For testing of the vehicle speed sensor and related

components refer to the Powertrain Diagnostics Test

Procedure Manual.

TACHOMETER DRIVE MODULE REPLACEMENT

(1) Remove cluster assembly. Refer to Cluster As-

sembly Replacement. (2) Pull tachometer drive module from printed cir-

cuit board (Fig. 32).

(3) For installation reverse above procedures and

use care when aligning module to printed circuit

board.

LOW FUEL WARNING MODULE REPLACEMENT

(1) Remove cluster assembly. Refer to Cluster As-

sembly Replacement. (2) Pull low fuel relay from printed circuit board

(Fig. 32). (3) For installation reverse above procedure. Use

care when aligning module to printed circuit board.

GAUGE ALERT MODULE REPLACEMENT

(1) Remove cluster assembly. Refer to Cluster As-

sembly Replacement. (2) Pull gauge alert module from printed circuit

board (Fig. 33). (3) For installation reverse above procedures. Use

care when aligning module to printed circuit board.

CLUSTER LAMP REPLACEMENT

(1) Remove cluster, radio and rear window defog-

ger bezels. (2) Remove cluster. Refer to Cluster Assembly Re-

placement.

Fig. 30 Vehicle Speed Sensor and Speedometer Pinion

Fig. 31 Vehicle Speed Sensor Removal

Fig. 32 Tachometer Drive and Low Fuel WarningModule

8E - 12 INSTRUMENT PANEL AND GAUGES Ä

Page 513 of 2438

(3) Remove four screws from ash receiver/cup

holder housing. (4) For installation reverse above procedures.

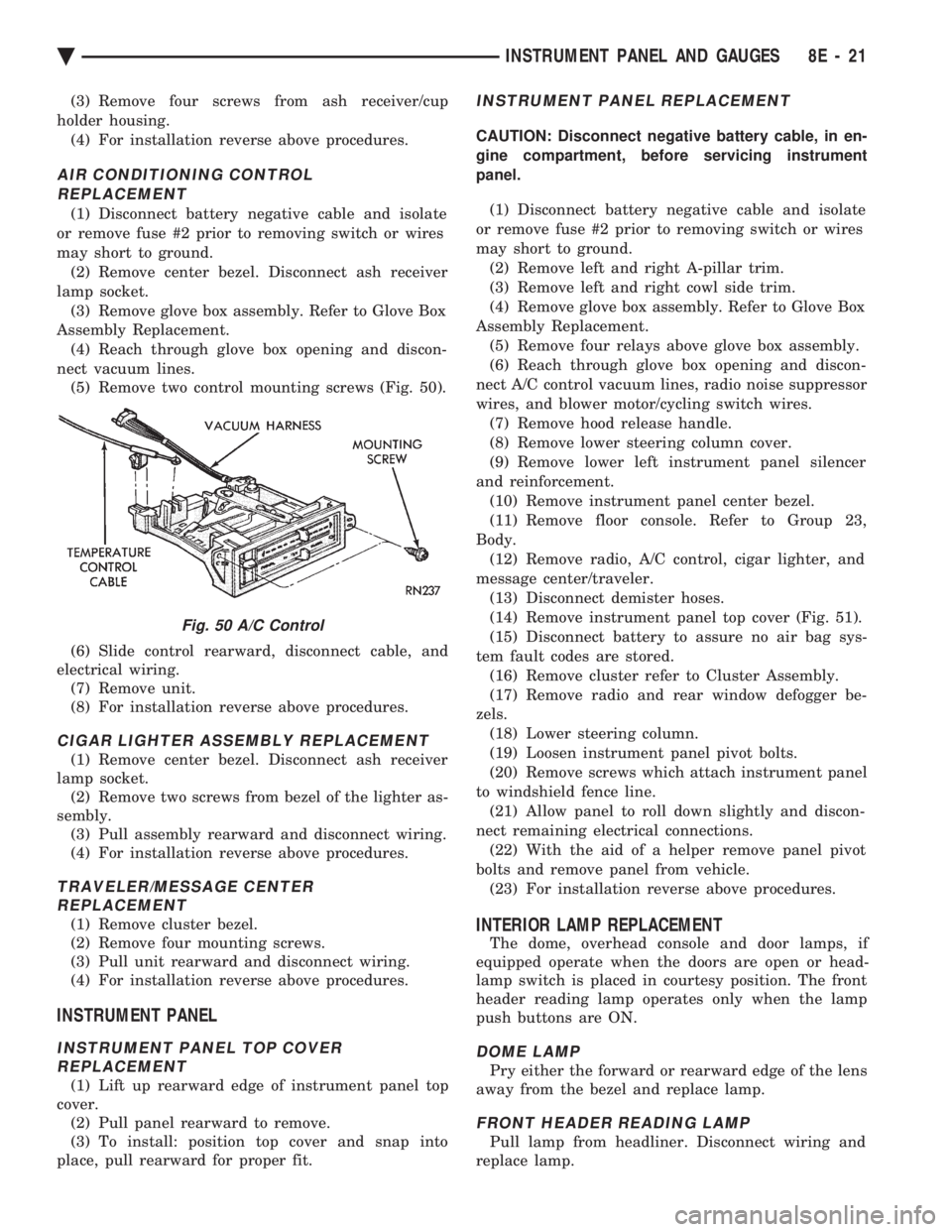

AIR CONDITIONING CONTROLREPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove center bezel. Disconnect ash receiver

lamp socket. (3) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (4) Reach through glove box opening and discon-

nect vacuum lines. (5) Remove two control mounting screws (Fig. 50).

(6) Slide control rearward, disconnect cable, and

electrical wiring. (7) Remove unit.

(8) For installation reverse above procedures.

CIGAR LIGHTER ASSEMBLY REPLACEMENT

(1) Remove center bezel. Disconnect ash receiver

lamp socket. (2) Remove two screws from bezel of the lighter as-

sembly. (3) Pull assembly rearward and disconnect wiring.

(4) For installation reverse above procedures.

TRAVELER/MESSAGE CENTER REPLACEMENT

(1) Remove cluster bezel.

(2) Remove four mounting screws.

(3) Pull unit rearward and disconnect wiring.

(4) For installation reverse above procedures.

INSTRUMENT PANEL

INSTRUMENT PANEL TOP COVER REPLACEMENT

(1) Lift up rearward edge of instrument panel top

cover. (2) Pull panel rearward to remove.

(3) To install: position top cover and snap into

place, pull rearward for proper fit.

INSTRUMENT PANEL REPLACEMENT

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel.

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove left and right A-pillar trim.

(3) Remove left and right cowl side trim.

(4) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (5) Remove four relays above glove box assembly.

(6) Reach through glove box opening and discon-

nect A/C control vacuum lines, radio noise suppressor

wires, and blower motor/cycling switch wires. (7) Remove hood release handle.

(8) Remove lower steering column cover.

(9) Remove lower left instrument panel silencer

and reinforcement. (10) Remove instrument panel center bezel.

(11) Remove floor console. Refer to Group 23,

Body. (12) Remove radio, A/C control, cigar lighter, and

message center/traveler. (13) Disconnect demister hoses.

(14) Remove instrument panel top cover (Fig. 51).

(15) Disconnect battery to assure no air bag sys-

tem fault codes are stored. (16) Remove cluster refer to Cluster Assembly.

(17) Remove radio and rear window defogger be-

zels. (18) Lower steering column.

(19) Loosen instrument panel pivot bolts.

(20) Remove screws which attach instrument panel

to windshield fence line. (21) Allow panel to roll down slightly and discon-

nect remaining electrical connections. (22) With the aid of a helper remove panel pivot

bolts and remove panel from vehicle. (23) For installation reverse above procedures.

INTERIOR LAMP REPLACEMENT

The dome, overhead console and door lamps, if

equipped operate when the doors are open or head-

lamp switch is placed in courtesy position. The front

header reading lamp operates only when the lamp

push buttons are ON.

DOME LAMP

Pry either the forward or rearward edge of the lens

away from the bezel and replace lamp.

FRONT HEADER READING LAMP

Pull lamp from headliner. Disconnect wiring and

replace lamp.

Fig. 50 A/C Control

Ä INSTRUMENT PANEL AND GAUGES 8E - 21

Page 516 of 2438

MESSAGE CENTER

The message center is a car graphic warning lamp

module. This conventional warning system and lo-

cated above the headlamp switch.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

ferred to in the Owner's Manual supplied with the

vehicle.

AIR BAG WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MECHANICAL CLUSTER AND GAUGE SERVICE

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel. When power is required for test purposes,

reconnect battery cable for the test only.

Disconnect negative battery cable after test and be-

fore continuing service procedures.

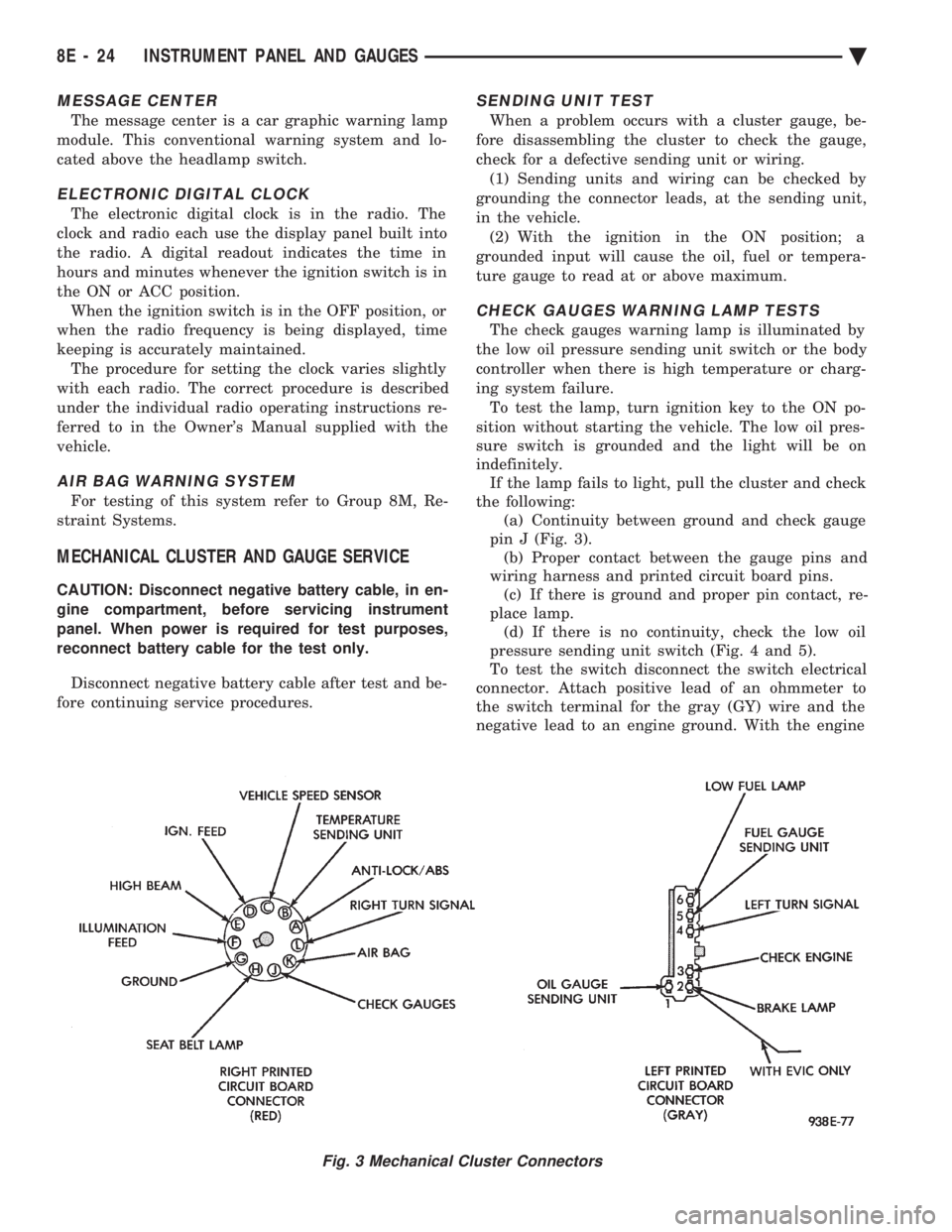

SENDING UNIT TEST

When a problem occurs with a cluster gauge, be-

fore disassembling the cluster to check the gauge,

check for a defective sending unit or wiring. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position; a

grounded input will cause the oil, fuel or tempera-

ture gauge to read at or above maximum.

CHECK GAUGES WARNING LAMP TESTS

The check gauges warning lamp is illuminated by

the low oil pressure sending unit switch or the body

controller when there is high temperature or charg-

ing system failure. To test the lamp, turn ignition key to the ON po-

sition without starting the vehicle. The low oil pres-

sure switch is grounded and the light will be on

indefinitely. If the lamp fails to light, pull the cluster and check

the following: (a) Continuity between ground and check gauge

pin J (Fig. 3). (b) Proper contact between the gauge pins and

wiring harness and printed circuit board pins. (c) If there is ground and proper pin contact, re-

place lamp. (d) If there is no continuity, check the low oil

pressure sending unit switch (Fig. 4 and 5).

To test the switch disconnect the switch electrical

connector. Attach positive lead of an ohmmeter to

the switch terminal for the gray (GY) wire and the

negative lead to an engine ground. With the engine

Fig. 3 Mechanical Cluster Connectors

8E - 24 INSTRUMENT PANEL AND GAUGES Ä

Page 535 of 2438

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the ON or OFF po-

sition, or when the radio frequency is being dis-

played, time keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

ferred to in the Owner's manual supplied with the

vehicle.

WARNING LAMPS

The AG & AJ Body instrument clusters have warn-

ing lamps or indicators with the electronic cluster for

six different systems. These include low oil pressure,

check gauges, brake system, air bag, seat belt, mal-

function indicator (check engine) lamp.

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel. When power is required for test purposes,

reconnect battery cable for test only. Disconnect negative battery cable after test and be-

fore continuing service procedures. It is not necessary to remove instrument cluster

from vehicle for gauge replacement. Gauges must be pulled straight out, when remov-

ing or pins may be damaged.

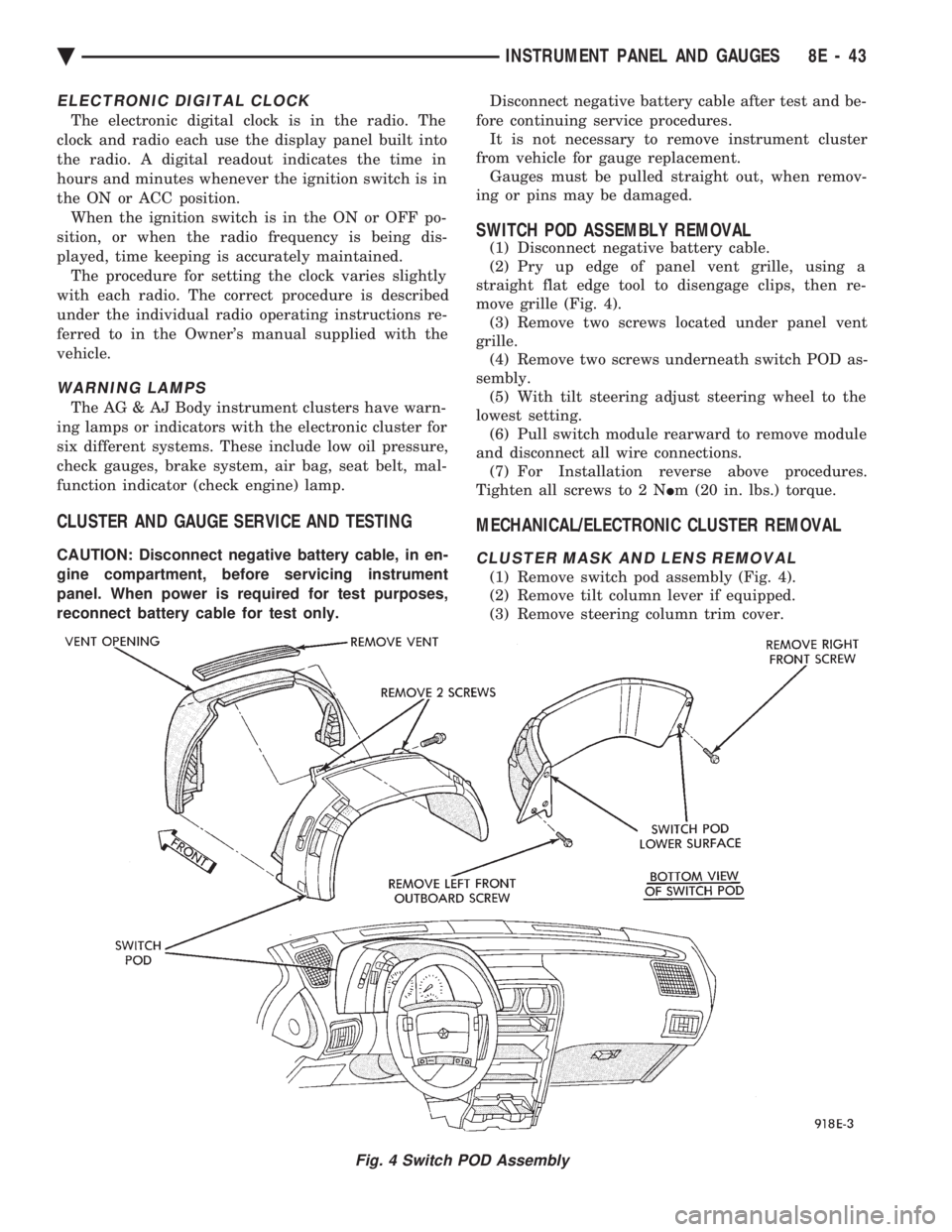

SWITCH POD ASSEMBLY REMOVAL

(1) Disconnect negative battery cable.

(2) Pry up edge of panel vent grille, using a

straight flat edge tool to disengage clips, then re-

move grille (Fig. 4). (3) Remove two screws located under panel vent

grille. (4) Remove two screws underneath switch POD as-

sembly. (5) With tilt steering adjust steering wheel to the

lowest setting. (6) Pull switch module rearward to remove module

and disconnect all wire connections. (7) For Installation reverse above procedures.

Tighten all screws to 2 N Im (20 in. lbs.) torque.

MECHANICAL/ELECTRONIC CLUSTER REMOVAL

CLUSTER MASK AND LENS REMOVAL

(1) Remove switch pod assembly (Fig. 4).

(2) Remove tilt column lever if equipped.

(3) Remove steering column trim cover.

Fig. 4 Switch POD Assembly

Ä INSTRUMENT PANEL AND GAUGES 8E - 43

Page 549 of 2438

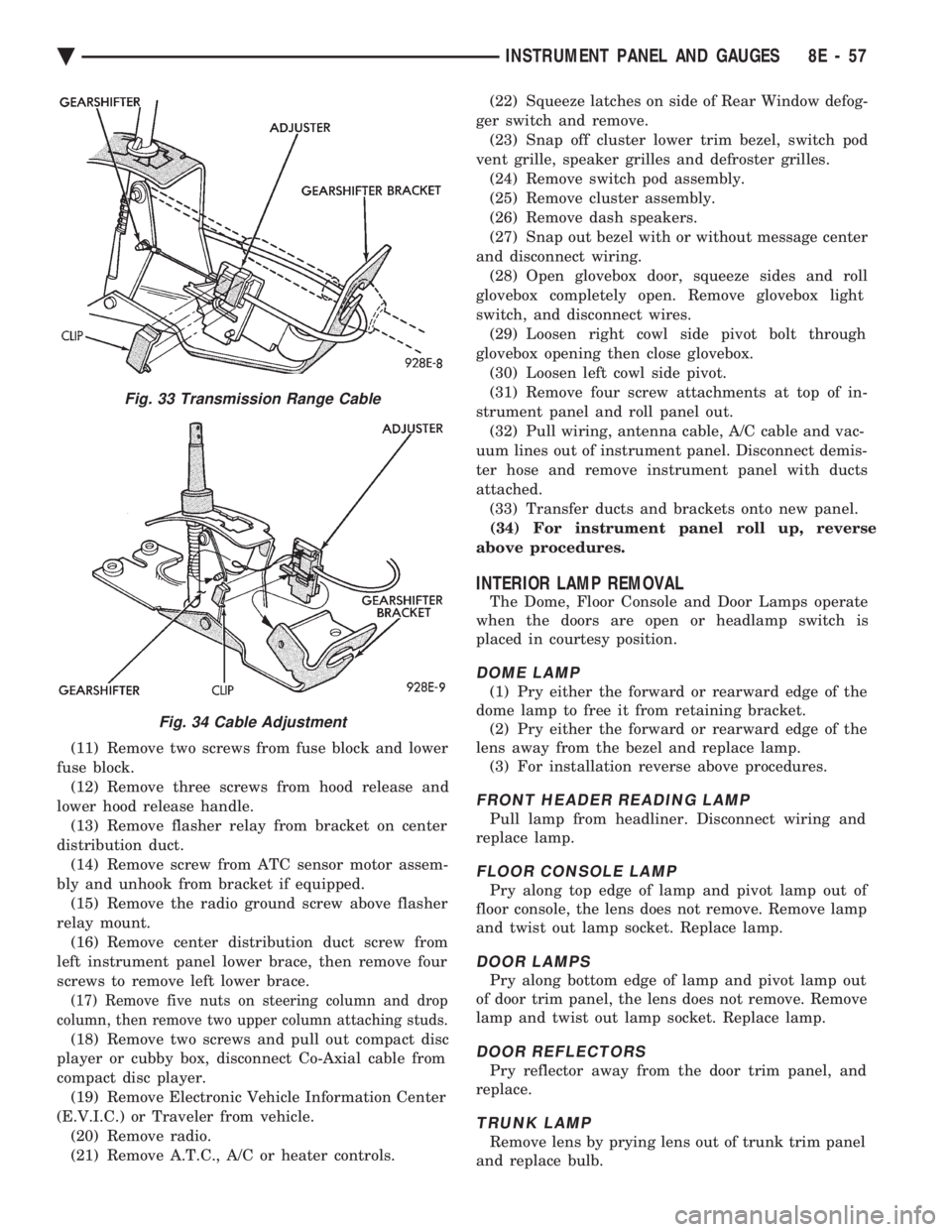

(11) Remove two screws from fuse block and lower

fuse block. (12) Remove three screws from hood release and

lower hood release handle. (13) Remove flasher relay from bracket on center

distribution duct. (14) Remove screw from ATC sensor motor assem-

bly and unhook from bracket if equipped. (15) Remove the radio ground screw above flasher

relay mount. (16) Remove center distribution duct screw from

left instrument panel lower brace, then remove four

screws to remove left lower brace.

(17) Remove five nuts on steering column and drop

column, then remove two upper column attaching studs.

(18) Remove two screws and pull out compact disc

player or cubby box, disconnect Co-Axial cable from

compact disc player. (19) Remove Electronic Vehicle Information Center

(E.V.I.C.) or Traveler from vehicle. (20) Remove radio.

(21) Remove A.T.C., A/C or heater controls. (22) Squeeze latches on side of Rear Window defog-

ger switch and remove. (23) Snap off cluster lower trim bezel, switch pod

vent grille, speaker grilles and defroster grilles. (24) Remove switch pod assembly.

(25) Remove cluster assembly.

(26) Remove dash speakers.

(27) Snap out bezel with or without message center

and disconnect wiring. (28) Open glovebox door, squeeze sides and roll

glovebox completely open. Remove glovebox light

switch, and disconnect wires. (29) Loosen right cowl side pivot bolt through

glovebox opening then close glovebox. (30) Loosen left cowl side pivot.

(31) Remove four screw attachments at top of in-

strument panel and roll panel out. (32) Pull wiring, antenna cable, A/C cable and vac-

uum lines out of instrument panel. Disconnect demis-

ter hose and remove instrument panel with ducts

attached. (33) Transfer ducts and brackets onto new panel.

(34) For instrument panel roll up, reverse

above procedures.

INTERIOR LAMP REMOVAL

The Dome, Floor Console and Door Lamps operate

when the doors are open or headlamp switch is

placed in courtesy position.

DOME LAMP

(1) Pry either the forward or rearward edge of the

dome lamp to free it from retaining bracket. (2) Pry either the forward or rearward edge of the

lens away from the bezel and replace lamp. (3) For installation reverse above procedures.

FRONT HEADER READING LAMP

Pull lamp from headliner. Disconnect wiring and

replace lamp.

FLOOR CONSOLE LAMP

Pry along top edge of lamp and pivot lamp out of

floor console, the lens does not remove. Remove lamp

and twist out lamp socket. Replace lamp.

DOOR LAMPS

Pry along bottom edge of lamp and pivot lamp out

of door trim panel, the lens does not remove. Remove

lamp and twist out lamp socket. Replace lamp.

DOOR REFLECTORS

Pry reflector away from the door trim panel, and

replace.

TRUNK LAMP

Remove lens by prying lens out of trunk trim panel

and replace bulb.

Fig. 33 Transmission Range Cable

Fig. 34 Cable Adjustment

Ä INSTRUMENT PANEL AND GAUGES 8E - 57

Page 550 of 2438

AP BODY INDEX

page page

Cluster and Gauge Service and Testing ....... 58

Gauges ................................ 61

General Information ....................... 58 Instrument Panel Replacement

.............. 72

Interior Lamp Replacement ................. 73

Switch and Panel Component Service ......... 67

GENERAL INFORMATION

INSTRUMENT CLUSTER

There are two conventional instrument cluster as-

semblies available. The clusters incorporates mag-

netic type gauges and an electronically driven

speedometer and odometer assembly (Fig. 1 and 2).

MAGNETIC GAUGES

All gauges on the AP Body clusters are the mag-

netic type gauges. When the ignition switch is in the

OFF position each gauge, except for the voltmeter

and tachometer will show a reading. However, the

readings are only accurate when the ignition switch

is in the ON position.

TACHOMETER DRIVE MODULE

The tachometer drive module is an electronic mod-

ule used to drive the magnetic tachometer in the

high line cluster. This module is located on top of the instrument

cluster.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

fer to the Sound Systems Manual supplied with the

vehicle.

WARNING LAMPS AND INDICATOR LIGHTS

The instrument cluster has warning and indicators

lamps for eight different systems:

² Low oil pressure

² Brake warning

² Seat belt warning

² Malfunction indicator (check engine) lamp

² Air Bag

² High beam indicator

² Right and left turn signals.

² Anti-lock (ABS)

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect the negative battery cable

before servicing the instrument panel. When power

is required for test purposes, reconnect battery ca-

ble for test only. Disconnect the negative battery

cable after test and before continuing service pro-

cedures.

SENDING UNIT TEST

Check for a defective sending unit or wiring, when

a problem occurs with a cluster gauge. Do this before

disassembling the cluster. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position, a

grounded input will cause the fuel or temperature

gauge to read at or above maximum.

Fig. 1 Instrument Cluster With Tachometer

Fig. 2 Instrument Cluster Without Tachometer

8E - 58 INSTRUMENT PANEL AND GAUGES Ä

Page 567 of 2438

AUDIO SYSTEM

CONTENTS

page page

ANTENNAS ............................ 20

COMPACT DISC PLAYER ................. 30 RADIOS

................................ 1

SPEAKERS ............................ 24

RADIOS INDEX

page page

Audio Diagnostic Test Procedures ............. 1

Description .............................. 1

Interference Elimination ..................... 1

Radio Removal AP Body Replacement ........ 19 Radio RemovalÐAA Body

.................. 18

Radio RemovalÐAC and AY Bodies .......... 18

Radio RemovalÐAG and AJ Bodies .......... 18

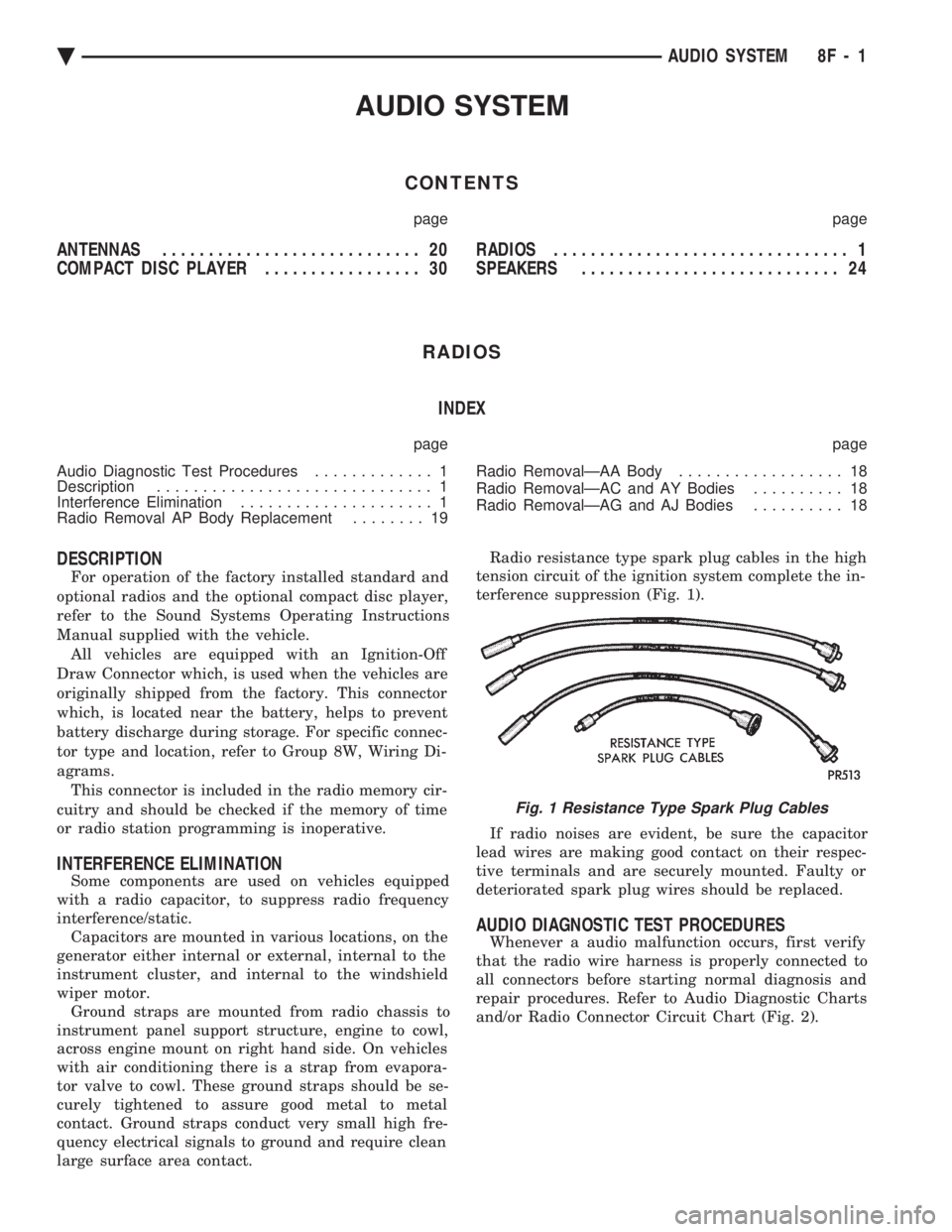

DESCRIPTION

For operation of the factory installed standard and

optional radios and the optional compact disc player,

refer to the Sound Systems Operating Instructions

Manual supplied with the vehicle. All vehicles are equipped with an Ignition-Off

Draw Connector which, is used when the vehicles are

originally shipped from the factory. This connector

which, is located near the battery, helps to prevent

battery discharge during storage. For specific connec-

tor type and location, refer to Group 8W, Wiring Di-

agrams. This connector is included in the radio memory cir-

cuitry and should be checked if the memory of time

or radio station programming is inoperative.

INTERFERENCE ELIMINATION

Some components are used on vehicles equipped

with a radio capacitor, to suppress radio frequency

interference/static. Capacitors are mounted in various locations, on the

generator either internal or external, internal to the

instrument cluster, and internal to the windshield

wiper motor. Ground straps are mounted from radio chassis to

instrument panel support structure, engine to cowl,

across engine mount on right hand side. On vehicles

with air conditioning there is a strap from evapora-

tor valve to cowl. These ground straps should be se-

curely tightened to assure good metal to metal

contact. Ground straps conduct very small high fre-

quency electrical signals to ground and require clean

large surface area contact. Radio resistance type spark plug cables in the high

tension circuit of the ignition system complete the in-

terference suppression (Fig. 1).

If radio noises are evident, be sure the capacitor

lead wires are making good contact on their respec-

tive terminals and are securely mounted. Faulty or

deteriorated spark plug wires should be replaced.

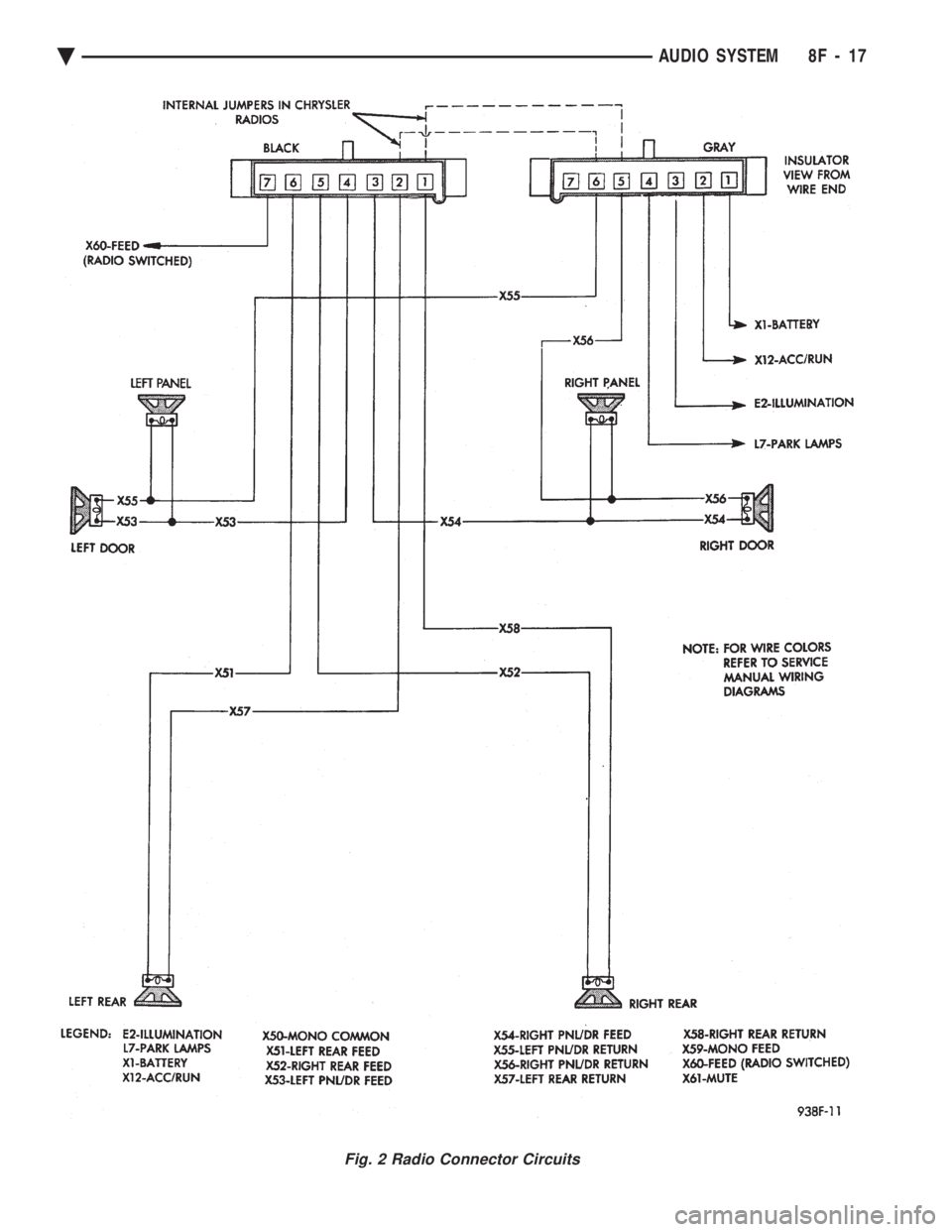

AUDIO DIAGNOSTIC TEST PROCEDURES

Whenever a audio malfunction occurs, first verify

that the radio wire harness is properly connected to

all connectors before starting normal diagnosis and

repair procedures. Refer to Audio Diagnostic Charts

and/or Radio Connector Circuit Chart (Fig. 2).

Fig. 1 Resistance Type Spark Plug Cables

Ä AUDIO SYSTEM 8F - 1

Page 583 of 2438

Fig. 2 Radio Connector Circuits

Ä AUDIO SYSTEM 8F - 17

Page 584 of 2438

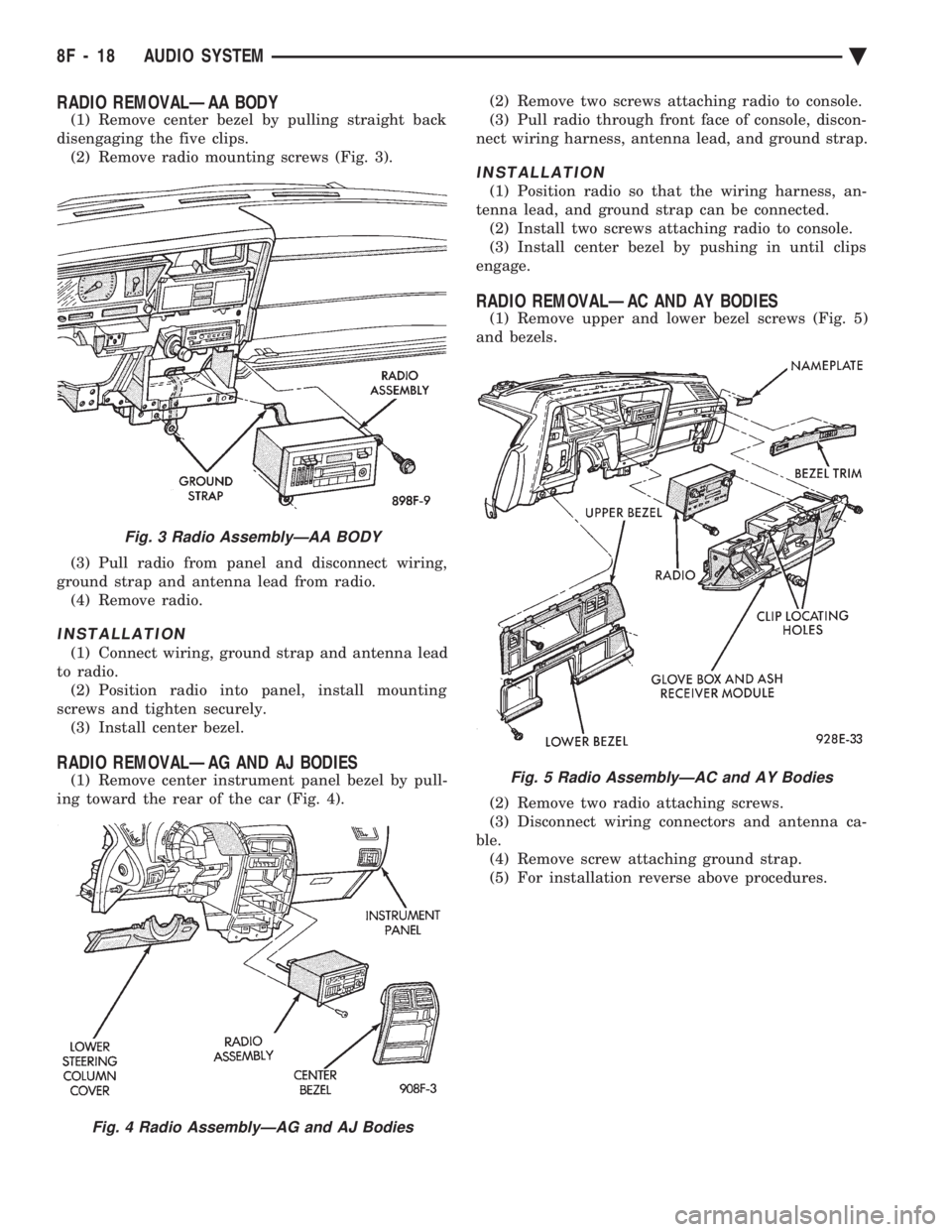

RADIO REMOVALÐAA BODY

(1) Remove center bezel by pulling straight back

disengaging the five clips. (2) Remove radio mounting screws (Fig. 3).

(3) Pull radio from panel and disconnect wiring,

ground strap and antenna lead from radio. (4) Remove radio.

INSTALLATION

(1) Connect wiring, ground strap and antenna lead

to radio. (2) Position radio into panel, install mounting

screws and tighten securely. (3) Install center bezel.

RADIO REMOVALÐAG AND AJ BODIES

(1) Remove center instrument panel bezel by pull-

ing toward the rear of the car (Fig. 4). (2) Remove two screws attaching radio to console.

(3) Pull radio through front face of console, discon-

nect wiring harness, antenna lead, and ground strap.

INSTALLATION

(1) Position radio so that the wiring harness, an-

tenna lead, and ground strap can be connected. (2) Install two screws attaching radio to console.

(3) Install center bezel by pushing in until clips

engage.

RADIO REMOVALÐAC AND AY BODIES

(1) Remove upper and lower bezel screws (Fig. 5)

and bezels.

(2) Remove two radio attaching screws.

(3) Disconnect wiring connectors and antenna ca-

ble. (4) Remove screw attaching ground strap.

(5) For installation reverse above procedures.

Fig. 3 Radio AssemblyÐAA BODY

Fig. 4 Radio AssemblyÐAG and AJ Bodies

Fig. 5 Radio AssemblyÐAC and AY Bodies

8F - 18 AUDIO SYSTEM Ä