radio CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 585 of 2438

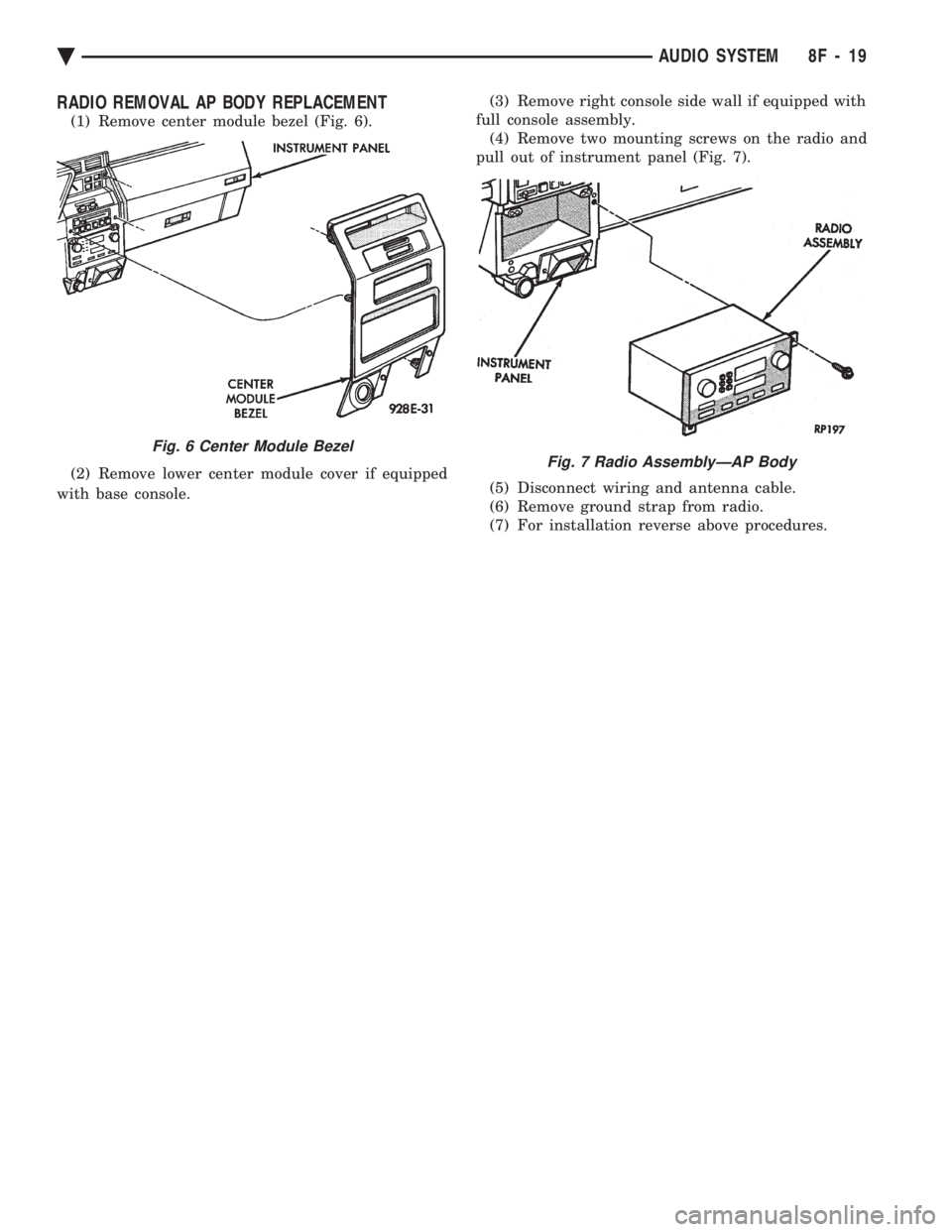

RADIO REMOVAL AP BODY REPLACEMENT

(1) Remove center module bezel (Fig. 6).

(2) Remove lower center module cover if equipped

with base console. (3) Remove right console side wall if equipped with

full console assembly. (4) Remove two mounting screws on the radio and

pull out of instrument panel (Fig. 7).

(5) Disconnect wiring and antenna cable.

(6) Remove ground strap from radio.

(7) For installation reverse above procedures.

Fig. 6 Center Module Bezel

Fig. 7 Radio AssemblyÐAP Body

Ä AUDIO SYSTEM 8F - 19

Page 586 of 2438

ANTENNAS INDEX

page page

Manual Antennas ........................ 20

Power Antenna .......................... 21 Power Antenna Mast

...................... 23

MANUAL ANTENNAS

TESTING

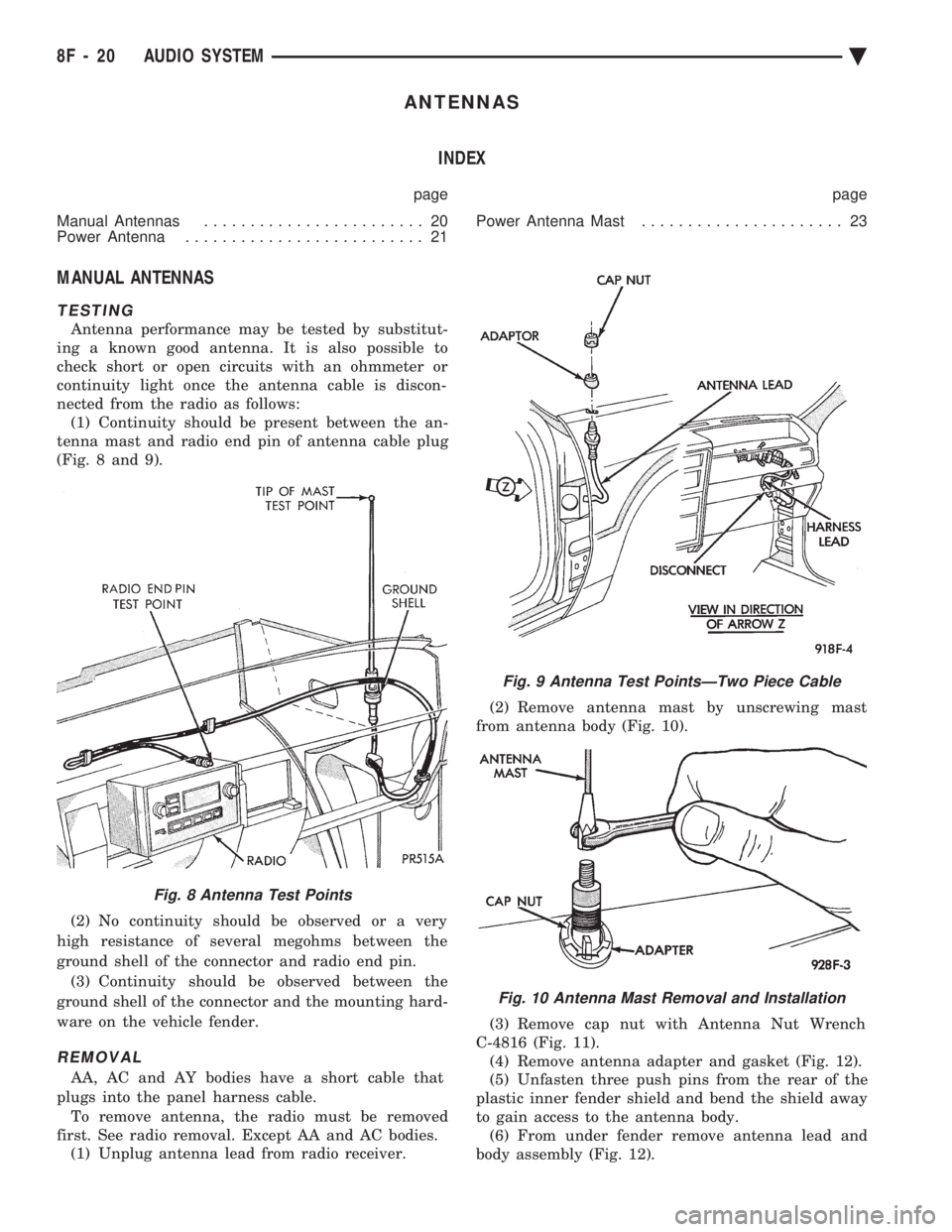

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows: (1) Continuity should be present between the an-

tenna mast and radio end pin of antenna cable plug

(Fig. 8 and 9).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin. (3) Continuity should be observed between the

ground shell of the connector and the mounting hard-

ware on the vehicle fender.

REMOVAL

AA, AC and AY bodies have a short cable that

plugs into the panel harness cable. To remove antenna, the radio must be removed

first. See radio removal. Except AA and AC bodies. (1) Unplug antenna lead from radio receiver. (2) Remove antenna mast by unscrewing mast

from antenna body (Fig. 10).

(3) Remove cap nut with Antenna Nut Wrench

C-4816 (Fig. 11). (4) Remove antenna adapter and gasket (Fig. 12).

(5) Unfasten three push pins from the rear of the

plastic inner fender shield and bend the shield away

to gain access to the antenna body. (6) From under fender remove antenna lead and

body assembly (Fig. 12).

Fig. 8 Antenna Test Points

Fig. 9 Antenna Test PointsÐTwo Piece Cable

Fig. 10 Antenna Mast Removal and Installation

8F - 20 AUDIO SYSTEM Ä

Page 587 of 2438

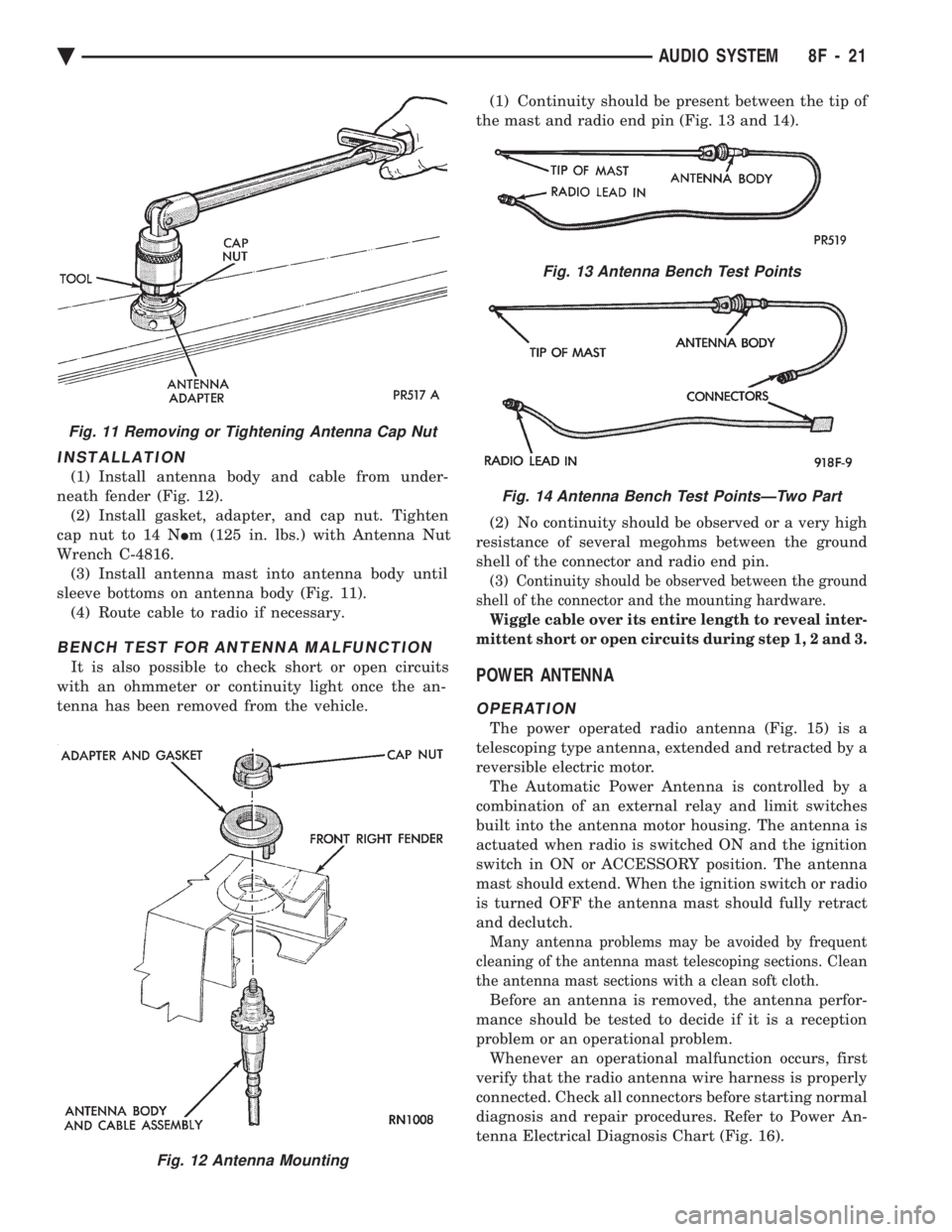

INSTALLATION

(1) Install antenna body and cable from under-

neath fender (Fig. 12). (2) Install gasket, adapter, and cap nut. Tighten

cap nut to 14 N Im (125 in. lbs.) with Antenna Nut

Wrench C-4816. (3) Install antenna mast into antenna body until

sleeve bottoms on antenna body (Fig. 11). (4) Route cable to radio if necessary.

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the an-

tenna has been removed from the vehicle. (1) Continuity should be present between the tip of

the mast and radio end pin (Fig. 13 and 14).

(2) No continuity should be observed or a very high

resistance of several megohms between the ground

shell of the connector and radio end pin.

(3) Continuity should be observed between the ground

shell of the connector and the mounting hardware.

Wiggle cable over its entire length to reveal inter-

mittent short or open circuits during step 1, 2 and 3.

POWER ANTENNA

OPERATION

The power operated radio antenna (Fig. 15) is a

telescoping type antenna, extended and retracted by a

reversible electric motor. The Automatic Power Antenna is controlled by a

combination of an external relay and limit switches

built into the antenna motor housing. The antenna is

actuated when radio is switched ON and the ignition

switch in ON or ACCESSORY position. The antenna

mast should extend. When the ignition switch or radio

is turned OFF the antenna mast should fully retract

and declutch.

Many antenna problems may be avoided by frequent

cleaning of the antenna mast telescoping sections. Clean

the antenna mast sections with a clean soft cloth.

Before an antenna is removed, the antenna perfor-

mance should be tested to decide if it is a reception

problem or an operational problem. Whenever an operational malfunction occurs, first

verify that the radio antenna wire harness is properly

connected. Check all connectors before starting normal

diagnosis and repair procedures. Refer to Power An-

tenna Electrical Diagnosis Chart (Fig. 16).

Fig. 12 Antenna Mounting

Fig. 11 Removing or Tightening Antenna Cap Nut

Fig. 13 Antenna Bench Test Points

Fig. 14 Antenna Bench Test PointsÐTwo Part

Ä AUDIO SYSTEM 8F - 21

Page 589 of 2438

(8) Upon establishing that the fault is in the an-

tenna assembly, it may be traced to one or more of

the following conditions: (a) Broken lead-in wire or shielding.

(b) Grounded lead-in wire or mast assembly.

(c) Moisture in support tube or lead-in assembly.

(d) Poor connection at antenna lead-in assembly

or shielding ground.

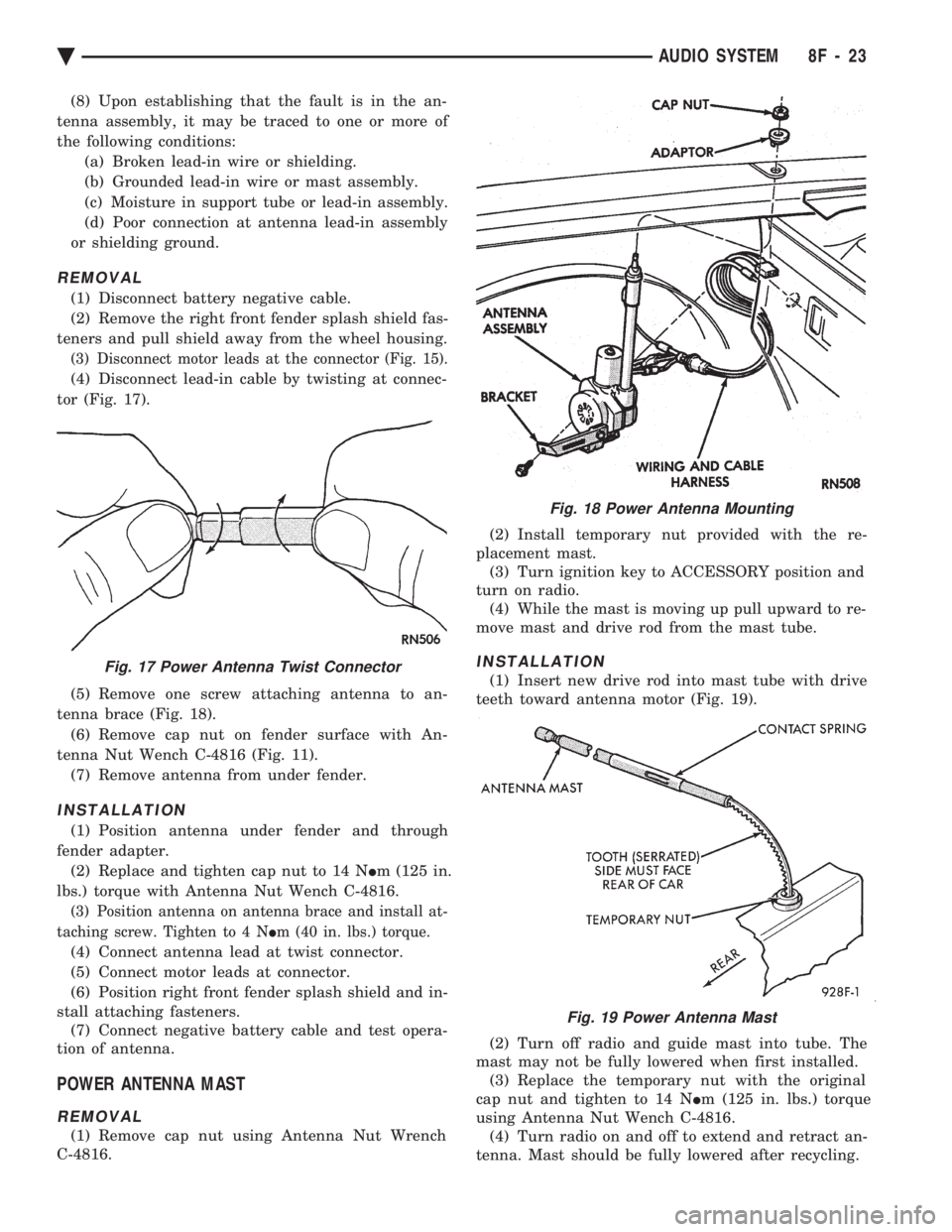

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the right front fender splash shield fas-

teners and pull shield away from the wheel housing.

(3) Disconnect motor leads at the connector (Fig. 15).

(4) Disconnect lead-in cable by twisting at connec-

tor (Fig. 17).

(5) Remove one screw attaching antenna to an-

tenna brace (Fig. 18). (6) Remove cap nut on fender surface with An-

tenna Nut Wench C-4816 (Fig. 11). (7) Remove antenna from under fender.

INSTALLATION

(1) Position antenna under fender and through

fender adapter. (2) Replace and tighten cap nut to 14 N Im (125 in.

lbs.) torque with Antenna Nut Wench C-4816.

(3) Position antenna on antenna brace and install at-

taching screw. Tighten to 4 N Im (40 in. lbs.) torque.

(4) Connect antenna lead at twist connector.

(5) Connect motor leads at connector.

(6) Position right front fender splash shield and in-

stall attaching fasteners. (7) Connect negative battery cable and test opera-

tion of antenna.

POWER ANTENNA MAST

REMOVAL

(1) Remove cap nut using Antenna Nut Wrench

C-4816. (2) Install temporary nut provided with the re-

placement mast. (3) Turn ignition key to ACCESSORY position and

turn on radio. (4) While the mast is moving up pull upward to re-

move mast and drive rod from the mast tube.

INSTALLATION

(1) Insert new drive rod into mast tube with drive

teeth toward antenna motor (Fig. 19).

(2) Turn off radio and guide mast into tube. The

mast may not be fully lowered when first installed. (3) Replace the temporary nut with the original

cap nut and tighten to 14 N Im (125 in. lbs.) torque

using Antenna Nut Wench C-4816. (4) Turn radio on and off to extend and retract an-

tenna. Mast should be fully lowered after recycling.

Fig. 18 Power Antenna Mounting

Fig. 17 Power Antenna Twist Connector

Fig. 19 Power Antenna Mast

Ä AUDIO SYSTEM 8F - 23

Page 594 of 2438

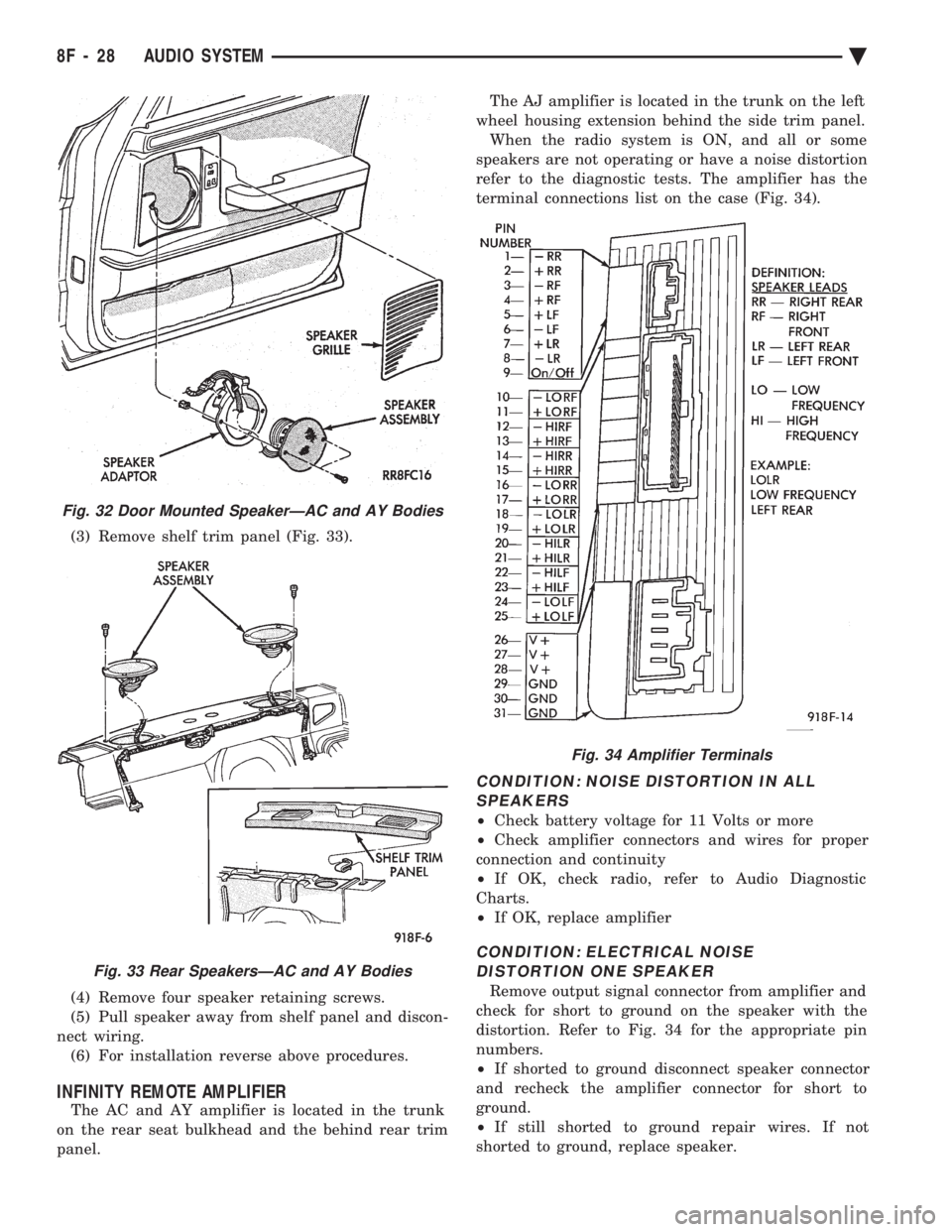

(3) Remove shelf trim panel (Fig. 33).

(4) Remove four speaker retaining screws.

(5) Pull speaker away from shelf panel and discon-

nect wiring. (6) For installation reverse above procedures.

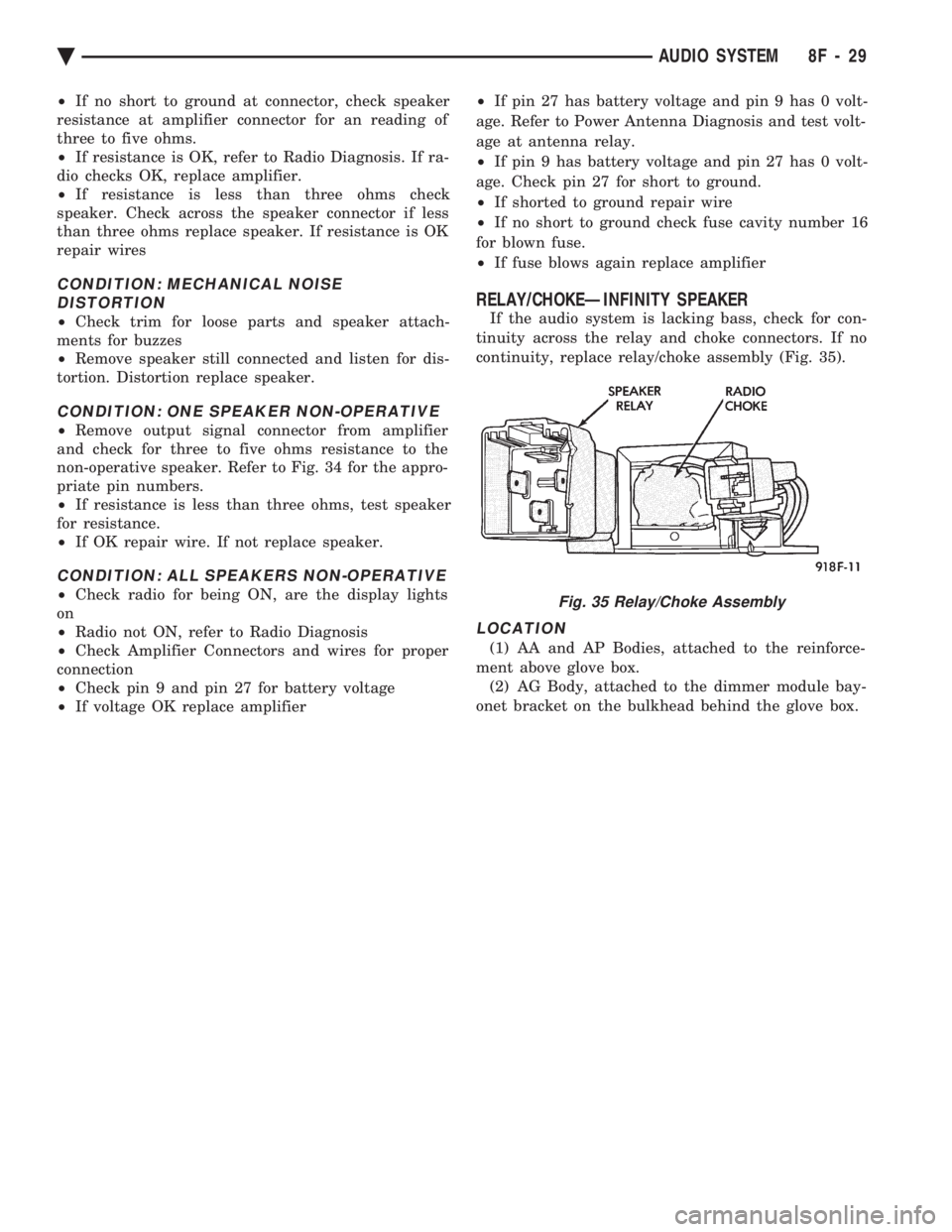

INFINITY REMOTE AMPLIFIER

The AC and AY amplifier is located in the trunk

on the rear seat bulkhead and the behind rear trim

panel. The AJ amplifier is located in the trunk on the left

wheel housing extension behind the side trim panel. When the radio system is ON, and all or some

speakers are not operating or have a noise distortion

refer to the diagnostic tests. The amplifier has the

terminal connections list on the case (Fig. 34).

CONDITION: NOISE DISTORTION IN ALL SPEAKERS

² Check battery voltage for 11 Volts or more

² Check amplifier connectors and wires for proper

connection and continuity

² If OK, check radio, refer to Audio Diagnostic

Charts.

² If OK, replace amplifier

CONDITION: ELECTRICAL NOISE

DISTORTION ONE SPEAKER

Remove output signal connector from amplifier and

check for short to ground on the speaker with the

distortion. Refer to Fig. 34 for the appropriate pin

numbers.

² If shorted to ground disconnect speaker connector

and recheck the amplifier connector for short to

ground.

² If still shorted to ground repair wires. If not

shorted to ground, replace speaker.

Fig. 32 Door Mounted SpeakerÐAC and AY Bodies

Fig. 33 Rear SpeakersÐAC and AY Bodies

Fig. 34 Amplifier Terminals

8F - 28 AUDIO SYSTEM Ä

Page 595 of 2438

² If no short to ground at connector, check speaker

resistance at amplifier connector for an reading of

three to five ohms.

² If resistance is OK, refer to Radio Diagnosis. If ra-

dio checks OK, replace amplifier.

² If resistance is less than three ohms check

speaker. Check across the speaker connector if less

than three ohms replace speaker. If resistance is OK

repair wires

CONDITION: MECHANICAL NOISE DISTORTION

² Check trim for loose parts and speaker attach-

ments for buzzes

² Remove speaker still connected and listen for dis-

tortion. Distortion replace speaker.

CONDITION: ONE SPEAKER NON-OPERATIVE

² Remove output signal connector from amplifier

and check for three to five ohms resistance to the

non-operative speaker. Refer to Fig. 34 for the appro-

priate pin numbers.

² If resistance is less than three ohms, test speaker

for resistance.

² If OK repair wire. If not replace speaker.

CONDITION: ALL SPEAKERS NON-OPERATIVE

²Check radio for being ON, are the display lights

on

² Radio not ON, refer to Radio Diagnosis

² Check Amplifier Connectors and wires for proper

connection

² Check pin 9 and pin 27 for battery voltage

² If voltage OK replace amplifier ²

If pin 27 has battery voltage and pin 9 has 0 volt-

age. Refer to Power Antenna Diagnosis and test volt-

age at antenna relay.

² If pin 9 has battery voltage and pin 27 has 0 volt-

age. Check pin 27 for short to ground.

² If shorted to ground repair wire

² If no short to ground check fuse cavity number 16

for blown fuse.

² If fuse blows again replace amplifier

RELAY/CHOKEÐINFINITY SPEAKER

If the audio system is lacking bass, check for con-

tinuity across the relay and choke connectors. If no

continuity, replace relay/choke assembly (Fig. 35).

LOCATION

(1) AA and AP Bodies, attached to the reinforce-

ment above glove box. (2) AG Body, attached to the dimmer module bay-

onet bracket on the bulkhead behind the glove box.

Fig. 35 Relay/Choke Assembly

Ä AUDIO SYSTEM 8F - 29

Page 596 of 2438

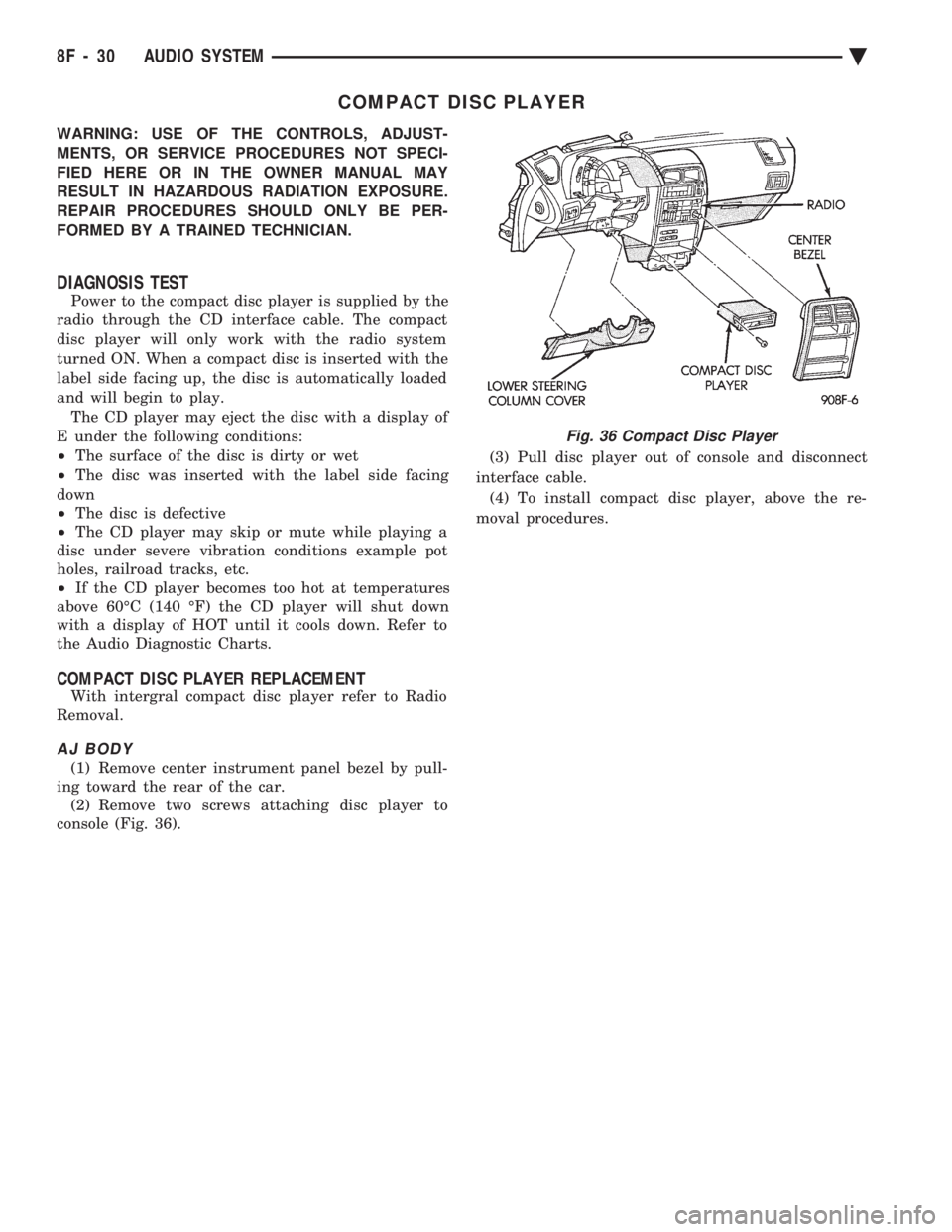

COMPACT DISC PLAYER

WARNING: USE OF THE CONTROLS, ADJUST-

MENTS, OR SERVICE PROCEDURES NOT SPECI-

FIED HERE OR IN THE OWNER MANUAL MAY

RESULT IN HAZARDOUS RADIATION EXPOSURE.

REPAIR PROCEDURES SHOULD ONLY BE PER-

FORMED BY A TRAINED TECHNICIAN.

DIAGNOSIS TEST

Power to the compact disc player is supplied by the

radio through the CD interface cable. The compact

disc player will only work with the radio system

turned ON. When a compact disc is inserted with the

label side facing up, the disc is automatically loaded

and will begin to play. The CD player may eject the disc with a display of

E under the following conditions:

² The surface of the disc is dirty or wet

² The disc was inserted with the label side facing

down

² The disc is defective

² The CD player may skip or mute while playing a

disc under severe vibration conditions example pot

holes, railroad tracks, etc.

² If the CD player becomes too hot at temperatures

above 60ÉC (140 ÉF) the CD player will shut down

with a display of HOT until it cools down. Refer to

the Audio Diagnostic Charts.

COMPACT DISC PLAYER REPLACEMENT

With intergral compact disc player refer to Radio

Removal.

AJ BODY

(1) Remove center instrument panel bezel by pull-

ing toward the rear of the car. (2) Remove two screws attaching disc player to

console (Fig. 36). (3) Pull disc player out of console and disconnect

interface cable. (4) To install compact disc player, above the re-

moval procedures.

Fig. 36 Compact Disc Player

8F - 30 AUDIO SYSTEM Ä

Page 681 of 2438

AA .............................................................................74

Low Fuel

AA ...........................................................................103

AP ............................................................................161

AC, AY...............................................................PC194

AG, AJ ............................................................5269245

Low Washer Fluid

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Oil Pressure

All .......................................................................PC194

Trunk Open

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Theft Alarm Set

AC, AY....................................................................168

AG, AJ ............................................................4437661

Turn Signal (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Turn Signal (EIC)

AA, AY ..............................................................PC194

Seat Belt (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Seat Belt (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

DIMMER CONTROLLED LAMPS

Service procedures for most of the lamps in the in-

strument panel, Instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges. A/C Heater Control

All ..............................................................................37

Automatic Temperature Control

All ....................................................................4437661

Column Gearshift Indicator

AA, AC, AY ...........................................................161

Console Gearshift Indicator

AP ............................................................................194

AA, AG, AJ ............................................................161

Fog Lamp Switch Symbol

AG ......................................................................PC194

Headlamp Dimmer Switch

AG, AJ ......................................................................37

Headlamp Switch Symbol

AC, AY....................................................................161

AG, AJ ......................................................................37

Heater Control

All ............................................................................158

EVIC

AJ...........................................................................ASC

Instrument Cluster (MIC)

All .......................................................................PC194

Instrument Cluster (EIC) AA, AY .....................................................................74

Message Center

AA, AC, AY .............................................................74

AP ............................................................................161

Navigator/Travel Companion

AA, AJ ......................................................................74

Radio

All ..........................................................................ASC

Rear Defogger Switch

Not Serviceable, Replace Switch

Rear Wiper Switch

AG .............................................................................37

Theft Alarm

AC, AY....................................................................161

Top Lift Switch

AJ ....................................................................5268053

Travel Computer

All ..........................................................................ASC

Turbo Gauge

AP ............................................................................161

Windshield Wiper Switch

AG, AJ ......................................................................37

NON-DIMMING LAMPS

Service procedures for most of the lamps in the fol-

lowing list can be found in Group 23, Body. Some

components have lamps that can only be serviced by

a Authorized Service Center (ASC) after the compo-

nent is removed from the vehicle. Contact local

dealer for location of nearest ASC. Ash Receiver

AA .............................................................................74

AC, AP, AY ............................................................161

AG, AJ ......................................................................37

Center Console Rear

AJ ............................................................................906

Cigar Lighter

AA, AP ....................................................................161

Courtesy

AA, AC, AY-S .....................................................214-2

AJ ............................................................................906

AY-P.....................................................................212-2

Dome

ALL ......................................................................211-2

Engine Compartment

All ............................................................................105

Glove Compartment

All ..........................................................................1891

Ignition Lock

All ..............................................................................37

Inside Rear View Mirror

AJ ............................................................................168

Overhead Console

AA ...........................................................................912

AC, AY....................................................................906

AG, AJ, AP .........................................................212-2

Reading Lamp Front

All ............................................................................906

Ä LAMPS 8L - 39

Page 695 of 2438

POWER LOCKS

CONTENTS

page page

CIRCUIT BREAKER TEST .................. 1

DECK LID OPERATION ................... 3

DECK LID PULL-DOWN SYSTEMÐAC and AY BODIES .............................. 3

DOOR LOCK INHIBIT ..................... 6

DOOR LOCK INHIBIT ..................... 1

DOOR LOCK MOTOR REPLACEMENT ........ 3

DOOR LOCK SYSTEM TEST ............... 3

ELECTRIC MOTOR TEST .................. 2 GENERAL INFORMATION

.................. 1

KEYLESS ENTRY SYSTEM ................ 1

LAMP OUTAGE MODULE REPLACEMENT .... 6

POWER DOOR LOCKS .................... 2

POWER PULL DOWN .................... 4

REMOTE KEYLESS ENTRY ................ 5

REMOTE KEYLESS MODULE REPLACEMENT . . 6

SWITCH TEST .......................... 1

WIRING VOLTAGE TEST .................. 1

GENERAL INFORMATION

All doors can be locked or unlocked electrically by

operating the switch on a front door panel or arm

rest. The rear doors can be locked or unlocked by actu-

ation of the front door switch, or can be locked or un-

locked mechanically and independently with their

respective locking knobs. The front doors can be locked or unlocked mechan-

ically with the locking knob regardless of electrical

locking and unlocking actuation with the front door

knobs. The right and left front door on all car lines can be

locked or unlocked mechanically from the outside

with the key or electrically as described above. The

left front can also be unlocked by actuation of the in-

side remote door handle. The right front door on AC,

AG, AJ and AY can be unlocked by actuation of the

inside remote door handle. The deck lid lock consists of a latch with internal

solenoid and push button switch. The solenoid is en-

ergized only when the push button is depressed.

DOOR LOCK INHIBIT

The power door lock inhibit system prevents the

doors from being locked using the power door locks

when either of two conditions occur: (1) The key is in the ignition switch and any of the

doors are open. The ignition switch does not have to

be ON. (2) The key is in the ignition switch and the head-

lamp are on.

KEYLESS ENTRY SYSTEM

The system allows locking and unlocking of vehicle

door(s) and Trunk lid by remote control using a hand

held radio transmitter. The ignition switch must be

OFF before the trunk lid can be unlocked with the

transmitter. The receiver may receive signals from two trans-

mitters. Each transmitter has its own code, and the

code has been stored in memory. If the transmitter is

replaced or a second transmitter is add, the code on

both units have to be placed in memory.

CIRCUIT BREAKER TEST

Find correct circuit breaker on fuse block. Pull out

slightly but be sure that circuit breaker terminals

still contact terminals in fuse block. Connect ground

wire of voltmeter to a good ground. With probe of

voltmeter positive wire, check both terminals of cir-

cuit breaker for 12 volts. If only one terminal checks

at 12 volts, circuit breaker is defective and must be

replaced. If neither terminal shows 12 volts, check

for open or shorted circuit to circuit breaker.

WIRING VOLTAGE TEST

The following wiring test sequence determines

whether or not voltage is continuous through the

body harness to switch. (1) Remove left side switch from trim panel.

(2) Carefully separate multiple terminal block on

wiring harness from switch body. (3) Connect one lead of test light to a ground ter-

minal:

² Black Wire AA and AC Bodies

² Gray wire AG and AJ Bodies

² Touch other test light lead to Red Wire terminal.

² If test light comes on, the wiring circuit between

the battery and switch is functional.

² If test light does not come on, check 30 amp circuit

breaker or for a open circuit.

SWITCH TEST

Remove the switch from its mounting location. Us-

ing an ohmmeter, refer to (Fig. 1) to determine if

continuity is correct in the Lock and Unlock switch

positions. If these results are not obtained, replace

the switch.

Ä POWER LOCKS 8P - 1

Page 931 of 2438

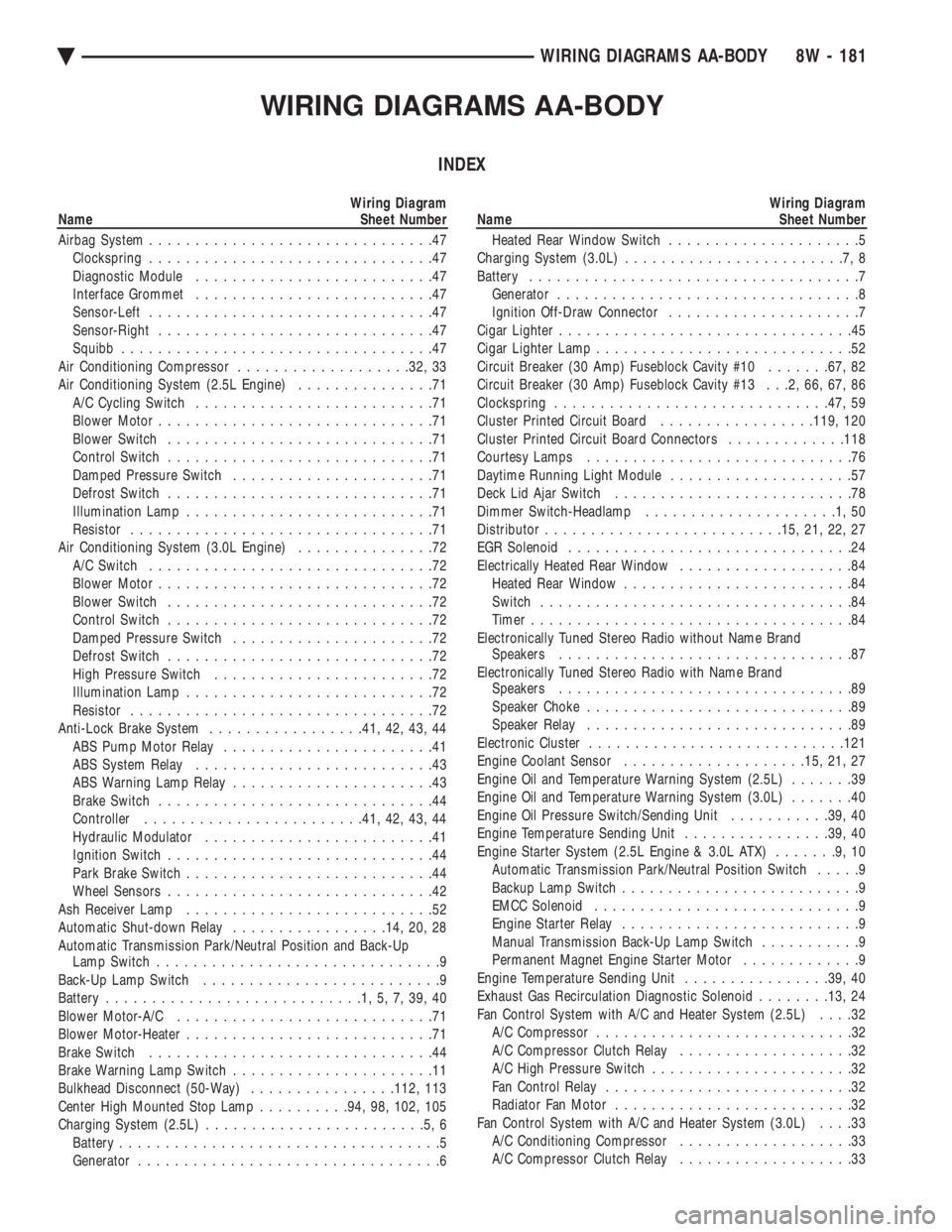

WIRING DIAGRAMS AA-BODY

INDEX

Wiring Diagram

Name Sheet Number

Airbag System ...............................47

Clockspring ...............................47

Diagnostic Module ..........................47

Interface Grommet ..........................47

Sensor-Left ...............................47

Sensor-Right ..............................47

Squibb ..................................47

Air Conditioning Compressor ...................32, 33

Air Conditioning System (2.5L Engine) ...............71

A/C Cycling Switch ..........................71

Blower Motor ..............................71

Blower Switch .............................71

Control Switch .............................71

Damped Pressure Switch ......................71

Defrost Switch .............................71

Illumination Lamp ...........................71

Resistor .................................71

Air Conditioning System (3.0L Engine) ...............72

A/C Switch ...............................72

Blower Motor ..............................72

Blower Switch .............................72

Control Switch .............................72

Damped Pressure Switch ......................72

Defrost Switch .............................72

High Pressure Switch ........................72

Illumination Lamp ...........................72

Resistor .................................72

Anti-Lock Brake System .................41, 42, 43, 44

ABS Pump Motor Relay .......................41

ABS System Relay ..........................43

ABS Warning Lamp Relay ......................43

Brake Switch ..............................44

Controller ....................... .41, 42, 43, 44

Hydraulic Modulator .........................41

Ignition Switch .............................44

Park Brake Switch ...........................44

Wheel Sensors .............................42

Ash Receiver Lamp ...........................52

Automatic Shut-down Relay .................14, 20, 28

Automatic Transmission Park/Neutral Position and Back-Up Lamp Switch ...............................9

Back-Up Lamp Switch ..........................9

Battery ............................1,5,7,39,40

Blower Motor-A/C ............................71

Blower Motor-Heater ...........................71

Brake Switch ...............................44

Brake Warning Lamp Switch ......................11

Bulkhead Disconnect (50-Way) ................112, 113

Center High Mounted Stop Lamp ..........94, 98, 102, 105

Charging System (2.5L) ........................5,6

Battery ...................................5

Generator .................................6Wiring Diagram

Name Sheet Number

Heated Rear Window Switch .....................5

Charging System (3.0L) ........................7,8

Battery ....................................7

Generator .................................8

Ignition Off-Draw Connector .....................7

Cigar Lighter ................................45

Cigar Lighter Lamp ............................52

Circuit Breaker (30 Amp) Fuseblock Cavity #10 .......67, 82

Circuit Breaker (30 Amp) Fuseblock Cavity #13 . . .2, 66, 67, 86

Clockspring ............................. .47, 59

Cluster Printed Circuit Board .................119, 120

Cluster Printed Circuit Board Connectors .............118

Courtesy Lamps .............................76

Daytime Running Light Module ....................57

Deck Lid Ajar Switch ..........................78

Dimmer Switch-Headlamp .....................1,50

Distributor ......................... .15, 21, 22, 27

EGR Solenoid ...............................24

Electrically Heated Rear Window ...................84

Heated Rear Window .........................84

Switch ..................................84

Timer ...................................84

Electronically Tuned Stereo Radio without Name Brand Speakers ................................87

Electronically Tuned Stereo Radio with Name Brand Speakers ................................89

Speaker Choke .............................89

Speaker Relay .............................89

Electronic Cluster ........................... .121

Engine Coolant Sensor ................... .15, 21, 27

Engine Oil and Temperature Warning System (2.5L) .......39

Engine Oil and Temperature Warning System (3.0L) .......40

Engine Oil Pressure Switch/Sending Unit ...........39, 40

Engine Temperature Sending Unit ................39, 40

Engine Starter System (2.5L Engine & 3.0L ATX) .......9,10

Automatic Transmission Park/Neutral Position Switch .....9

Backup Lamp Switch ..........................9

EMCC Solenoid .............................9

Engine Starter Relay ..........................9

Manual Transmission Back-Up Lamp Switch ...........9

Permanent Magnet Engine Starter Motor .............9

Engine Temperature Sending Unit ................39, 40

Exhaust Gas Recirculation Diagnostic Solenoid ........13, 24

Fan Control System with A/C and Heater System (2.5L) ....32

A/C Compressor ............................32

A/C Compressor Clutch Relay ...................32

A/C High Pressure Switch ......................32

Fan Control Relay ...........................32

Radiator Fan Motor ..........................32

Fan Control System with A/C and Heater System (3.0L) ....33

A/C Conditioning Compressor ...................33

A/C Compressor Clutch Relay ...................33

Ä WIRING DIAGRAMS AA-BODY 8W - 181