steering CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 65 of 2438

WHEEL ALIGNMENT SERVICE PROCEDURE

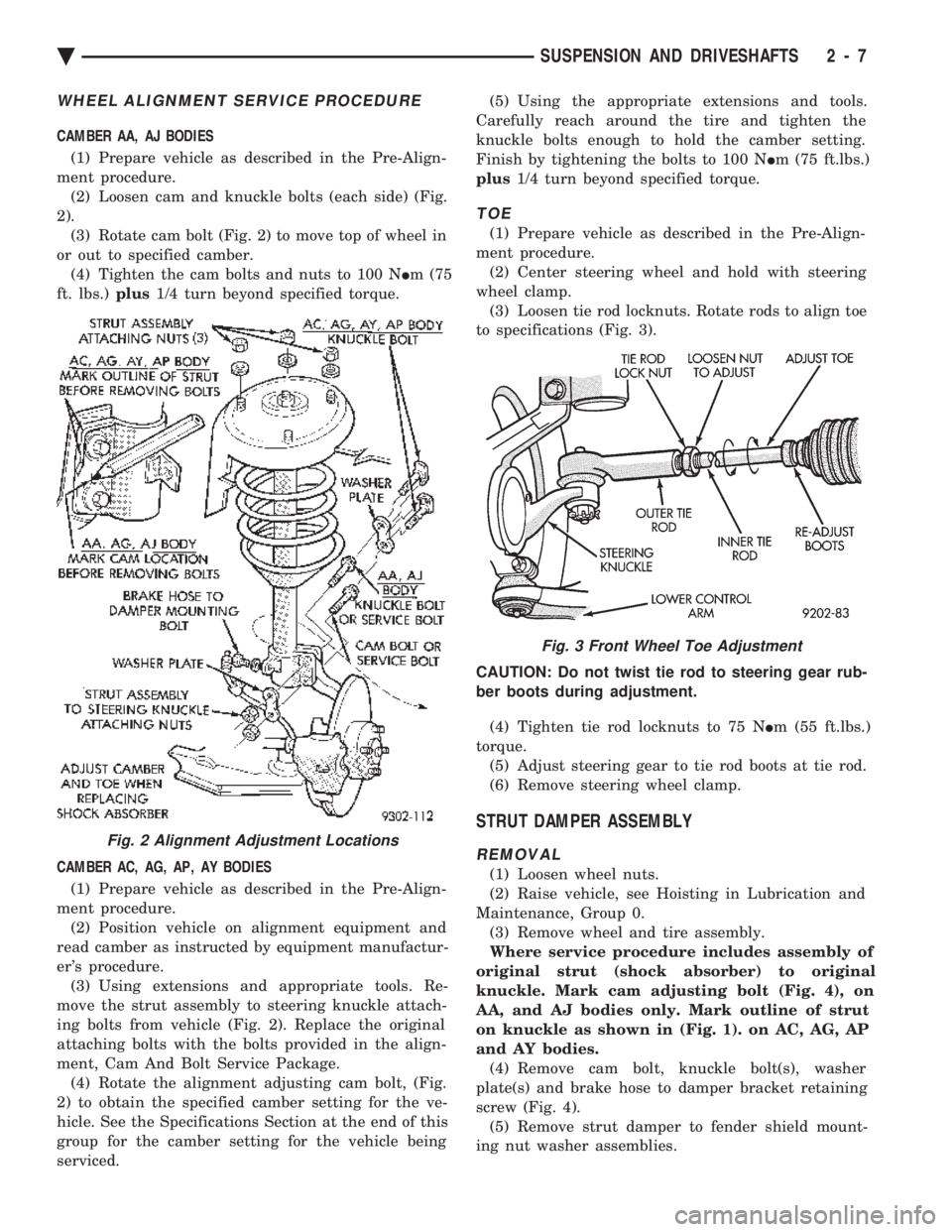

CAMBER AA, AJ BODIES (1) Prepare vehicle as described in the Pre-Align-

ment procedure. (2) Loosen cam and knuckle bolts (each side) (Fig.

2). (3) Rotate cam bolt (Fig. 2) to move top of wheel in

or out to specified camber. (4) Tighten the cam bolts and nuts to 100 N Im (75

ft. lbs.) plus1/4 turn beyond specified torque.

CAMBER AC, AG, AP, AY BODIES (1) Prepare vehicle as described in the Pre-Align-

ment procedure. (2) Position vehicle on alignment equipment and

read camber as instructed by equipment manufactur-

er's procedure. (3) Using extensions and appropriate tools. Re-

move the strut assembly to steering knuckle attach-

ing bolts from vehicle (Fig. 2). Replace the original

attaching bolts with the bolts provided in the align-

ment, Cam And Bolt Service Package. (4) Rotate the alignment adjusting cam bolt, (Fig.

2) to obtain the specified camber setting for the ve-

hicle. See the Specifications Section at the end of this

group for the camber setting for the vehicle being

serviced. (5) Using the appropriate extensions and tools.

Carefully reach around the tire and tighten the

knuckle bolts enough to hold the camber setting.

Finish by tightening the bolts to 100 N Im (75 ft.lbs.)

plus 1/4 turn beyond specified torque.

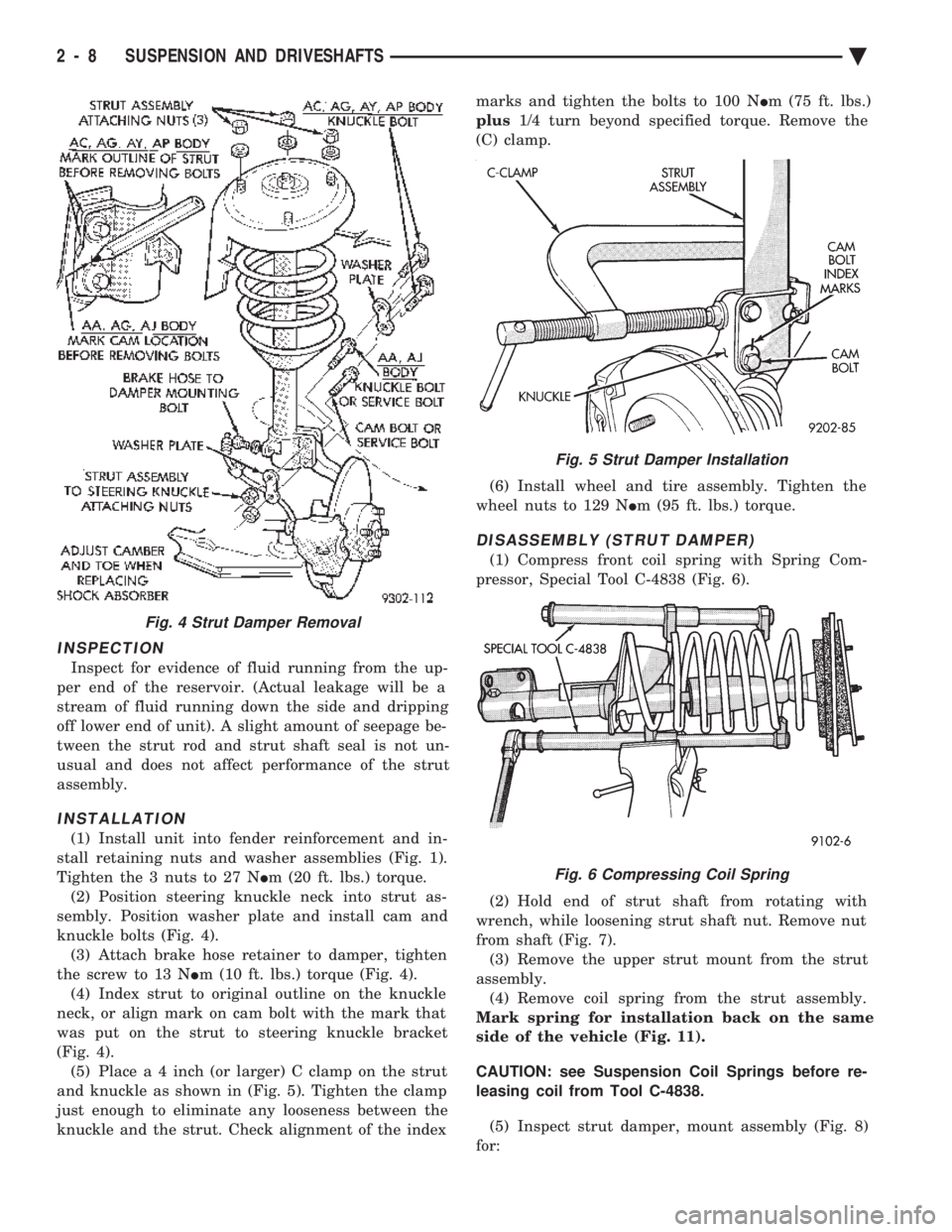

TOE

(1) Prepare vehicle as described in the Pre-Align-

ment procedure. (2) Center steering wheel and hold with steering

wheel clamp. (3) Loosen tie rod locknuts. Rotate rods to align toe

to specifications (Fig. 3).

CAUTION: Do not twist tie rod to steering gear rub-

ber boots during adjustment. (4) Tighten tie rod locknuts to 75 N Im (55 ft.lbs.)

torque. (5) Adjust steering gear to tie rod boots at tie rod.

(6) Remove steering wheel clamp.

STRUT DAMPER ASSEMBLY

REMOVAL

(1) Loosen wheel nuts.

(2) Raise vehicle, see Hoisting in Lubrication and

Maintenance, Group 0. (3) Remove wheel and tire assembly.

Where service procedure includes assembly of

original strut (shock absorber) to original

knuckle. Mark cam adjusting bolt (Fig. 4), on

AA, and AJ bodies only. Mark outline of strut

on knuckle as shown in (Fig. 1). on AC, AG, AP

and AY bodies. (4) Remove cam bolt, knuckle bolt(s), washer

plate(s) and brake hose to damper bracket retaining

screw (Fig. 4). (5) Remove strut damper to fender shield mount-

ing nut washer assemblies.

Fig. 2 Alignment Adjustment Locations

Fig. 3 Front Wheel Toe Adjustment

Ä SUSPENSION AND DRIVESHAFTS 2 - 7

Page 66 of 2438

INSPECTION

Inspect for evidence of fluid running from the up-

per end of the reservoir. (Actual leakage will be a

stream of fluid running down the side and dripping

off lower end of unit). A slight amount of seepage be-

tween the strut rod and strut shaft seal is not un-

usual and does not affect performance of the strut

assembly.

INSTALLATION

(1) Install unit into fender reinforcement and in-

stall retaining nuts and washer assemblies (Fig. 1).

Tighten the 3 nuts to 27 N Im (20 ft. lbs.) torque.

(2) Position steering knuckle neck into strut as-

sembly. Position washer plate and install cam and

knuckle bolts (Fig. 4). (3) Attach brake hose retainer to damper, tighten

the screw to 13 N Im (10 ft. lbs.) torque (Fig. 4).

(4) Index strut to original outline on the knuckle

neck, or align mark on cam bolt with the mark that

was put on the strut to steering knuckle bracket

(Fig. 4). (5) Plac e a 4 inch (or larger) C clamp on the strut

and knuckle as shown in (Fig. 5). Tighten the clamp

just enough to eliminate any looseness between the

knuckle and the strut. Check alignment of the index marks and tighten the bolts to 100 N

Im (75 ft. lbs.)

plus 1/4 turn beyond specified torque. Remove the

(C) clamp.

(6) Install wheel and tire assembly. Tighten the

wheel nuts to 129 N Im (95 ft. lbs.) torque.

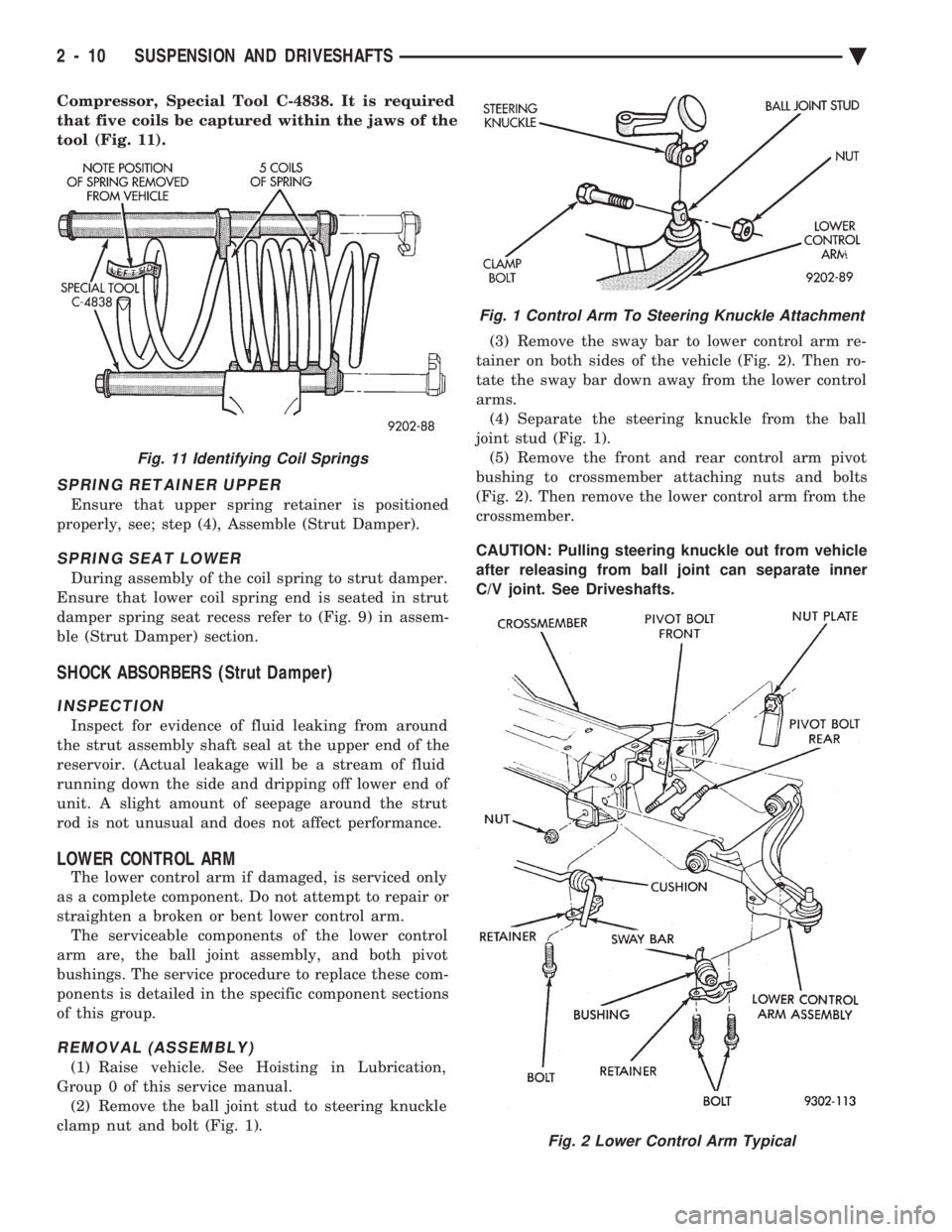

DISASSEMBLY (STRUT DAMPER)

(1) Compress front coil spring with Spring Com-

pressor, Special Tool C-4838 (Fig. 6).

(2) Hold end of strut shaft from rotating with

wrench, while loosening strut shaft nut. Remove nut

from shaft (Fig. 7). (3) Remove the upper strut mount from the strut

assembly. (4) Remove coil spring from the strut assembly.

Mark spring for installation back on the same

side of the vehicle (Fig. 11).

CAUTION: see Suspension Coil Springs before re-

leasing coil from Tool C-4838.

(5) Inspect strut damper, mount assembly (Fig. 8)

for:

Fig. 4 Strut Damper Removal

Fig. 5 Strut Damper Installation

Fig. 6 Compressing Coil Spring

2 - 8 SUSPENSION AND DRIVESHAFTS Ä

Page 68 of 2438

Compressor, Special Tool C-4838. It is required

that five coils be captured within the jaws of the

tool (Fig. 11).

SPRING RETAINER UPPER

Ensure that upper spring retainer is positioned

properly, see; step (4), Assemble (Strut Damper).

SPRING SEAT LOWER

During assembly of the coil spring to strut damper.

Ensure that lower coil spring end is seated in strut

damper spring seat recess refer to (Fig. 9) in assem-

ble (Strut Damper) section.

SHOCK ABSORBERS (Strut Damper)

INSPECTION

Inspect for evidence of fluid leaking from around

the strut assembly shaft seal at the upper end of the

reservoir. (Actual leakage will be a stream of fluid

running down the side and dripping off lower end of

unit. A slight amount of seepage around the strut

rod is not unusual and does not affect performance.

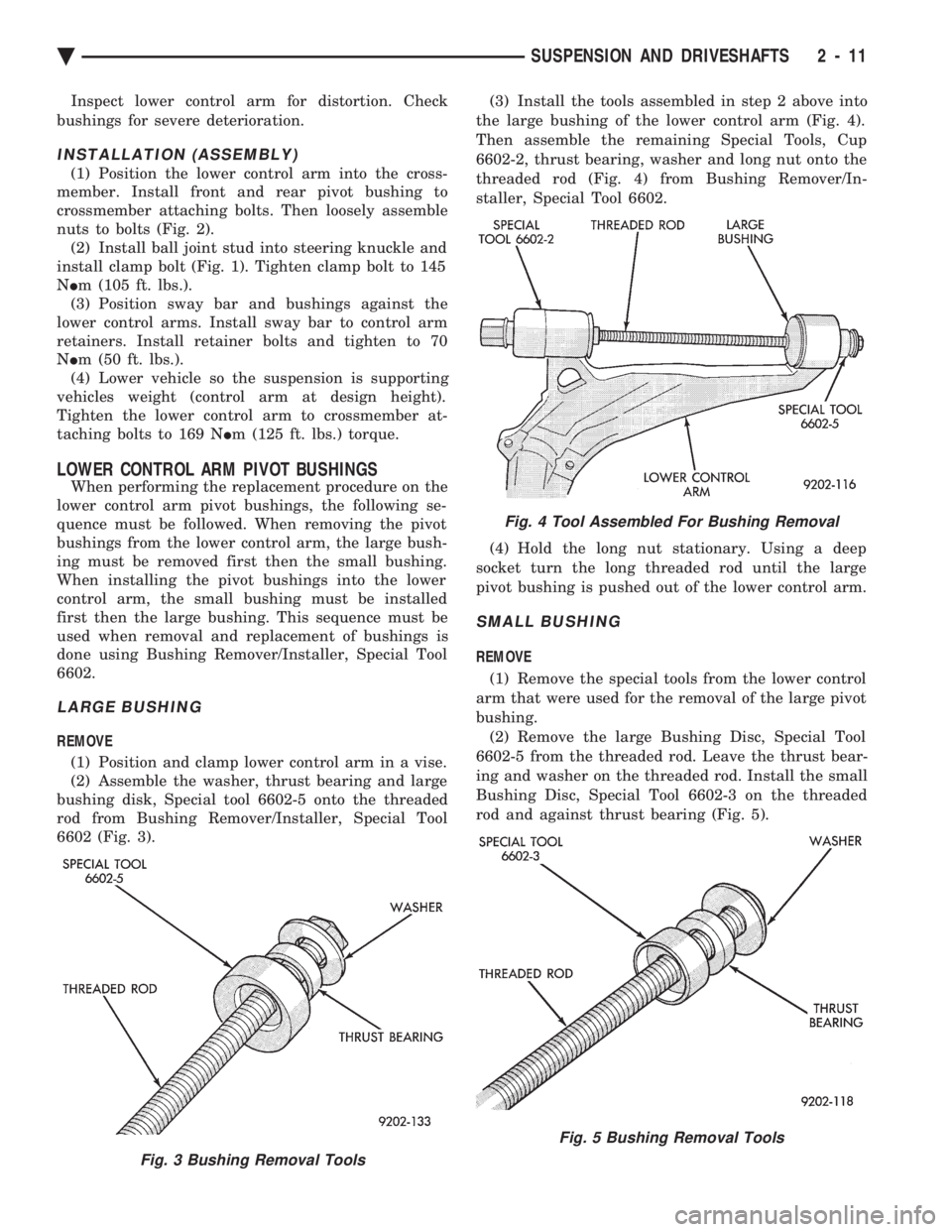

LOWER CONTROL ARM

The lower control arm if damaged, is serviced only

as a complete component. Do not attempt to repair or

straighten a broken or bent lower control arm. The serviceable components of the lower control

arm are, the ball joint assembly, and both pivot

bushings. The service procedure to replace these com-

ponents is detailed in the specific component sections

of this group.

REMOVAL (ASSEMBLY)

(1) Raise vehicle. See Hoisting in Lubrication,

Group 0 of this service manual. (2) Remove the ball joint stud to steering knuckle

clamp nut and bolt (Fig. 1). (3) Remove the sway bar to lower control arm re-

tainer on both sides of the vehicle (Fig. 2). Then ro-

tate the sway bar down away from the lower control

arms. (4) Separate the steering knuckle from the ball

joint stud (Fig. 1). (5) Remove the front and rear control arm pivot

bushing to crossmember attaching nuts and bolts

(Fig. 2). Then remove the lower control arm from the

crossmember.

CAUTION: Pulling steering knuckle out from vehicle

after releasing from ball joint can separate inner

C/V joint. See Driveshafts.

Fig. 11 Identifying Coil Springs

Fig. 1 Control Arm To Steering Knuckle Attachment

Fig. 2 Lower Control Arm Typical

2 - 10 SUSPENSION AND DRIVESHAFTS Ä

Page 69 of 2438

Inspect lower control arm for distortion. Check

bushings for severe deterioration.

INSTALLATION (ASSEMBLY)

(1) Position the lower control arm into the cross-

member. Install front and rear pivot bushing to

crossmember attaching bolts. Then loosely assemble

nuts to bolts (Fig. 2). (2) Install ball joint stud into steering knuckle and

install clamp bolt (Fig. 1). Tighten clamp bolt to 145

N Im (105 ft. lbs.).

(3) Position sway bar and bushings against the

lower control arms. Install sway bar to control arm

retainers. Install retainer bolts and tighten to 70

N Im (50 ft. lbs.).

(4) Lower vehicle so the suspension is supporting

vehicles weight (control arm at design height).

Tighten the lower control arm to crossmember at-

taching bolts to 169 N Im (125 ft. lbs.) torque.

LOWER CONTROL ARM PIVOT BUSHINGS

When performing the replacement procedure on the

lower control arm pivot bushings, the following se-

quence must be followed. When removing the pivot

bushings from the lower control arm, the large bush-

ing must be removed first then the small bushing.

When installing the pivot bushings into the lower

control arm, the small bushing must be installed

first then the large bushing. This sequence must be

used when removal and replacement of bushings is

done using Bushing Remover/Installer, Special Tool

6602.

LARGE BUSHING

REMOVE

(1) Position and clamp lower control arm in a vise.

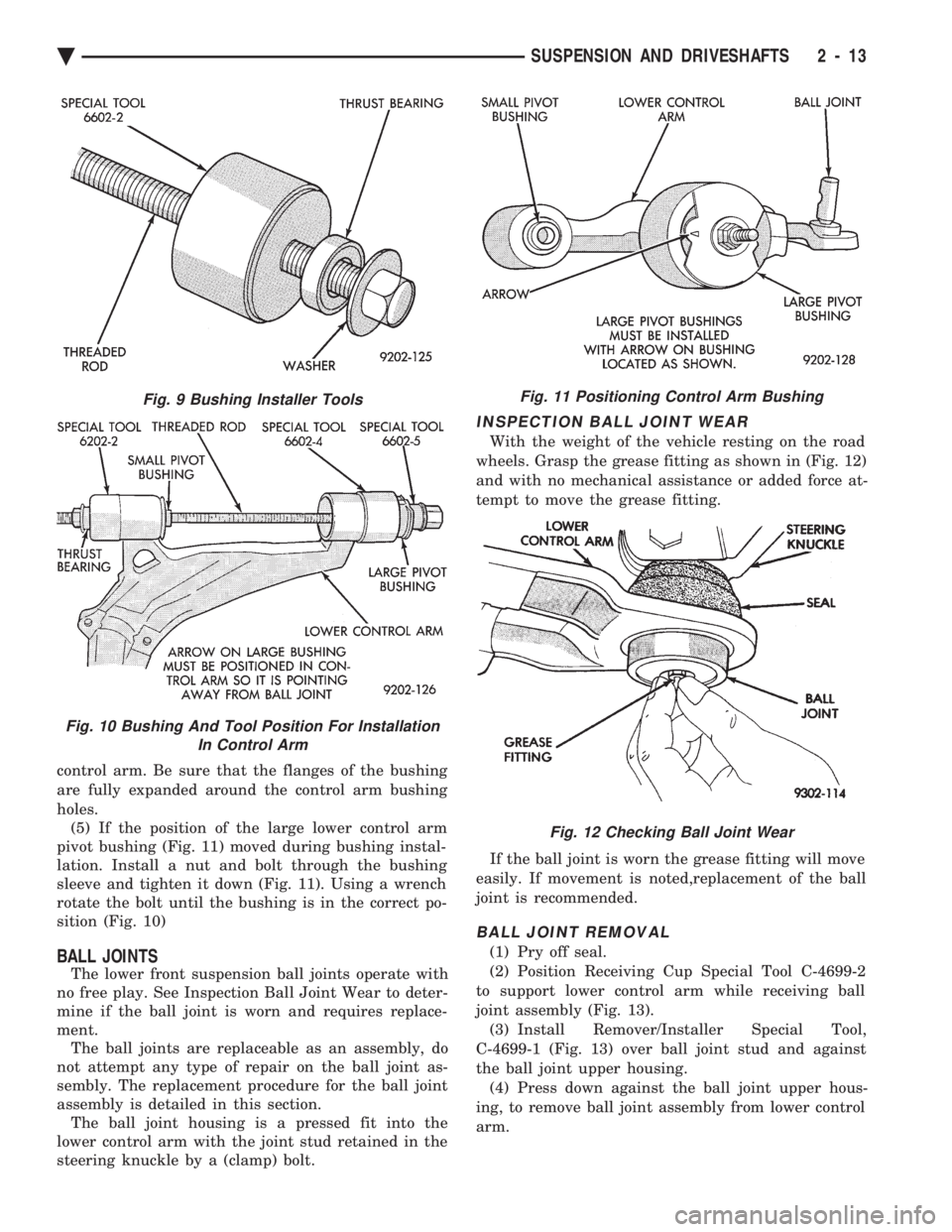

(2) Assemble the washer, thrust bearing and large

bushing disk, Special tool 6602-5 onto the threaded

rod from Bushing Remover/Installer, Special Tool

6602 (Fig. 3). (3) Install the tools assembled in step 2 above into

the large bushing of the lower control arm (Fig. 4).

Then assemble the remaining Special Tools, Cup

6602-2, thrust bearing, washer and long nut onto the

threaded rod (Fig. 4) from Bushing Remover/In-

staller, Special Tool 6602.

(4) Hold the long nut stationary. Using a deep

socket turn the long threaded rod until the large

pivot bushing is pushed out of the lower control arm.

SMALL BUSHING

REMOVE

(1) Remove the special tools from the lower control

arm that were used for the removal of the large pivot

bushing. (2) Remove the large Bushing Disc, Special Tool

6602-5 from the threaded rod. Leave the thrust bear-

ing and washer on the threaded rod. Install the small

Bushing Disc, Special Tool 6602-3 on the threaded

rod and against thrust bearing (Fig. 5).

Fig. 3 Bushing Removal Tools

Fig. 4 Tool Assembled For Bushing Removal

Fig. 5 Bushing Removal Tools

Ä SUSPENSION AND DRIVESHAFTS 2 - 11

Page 71 of 2438

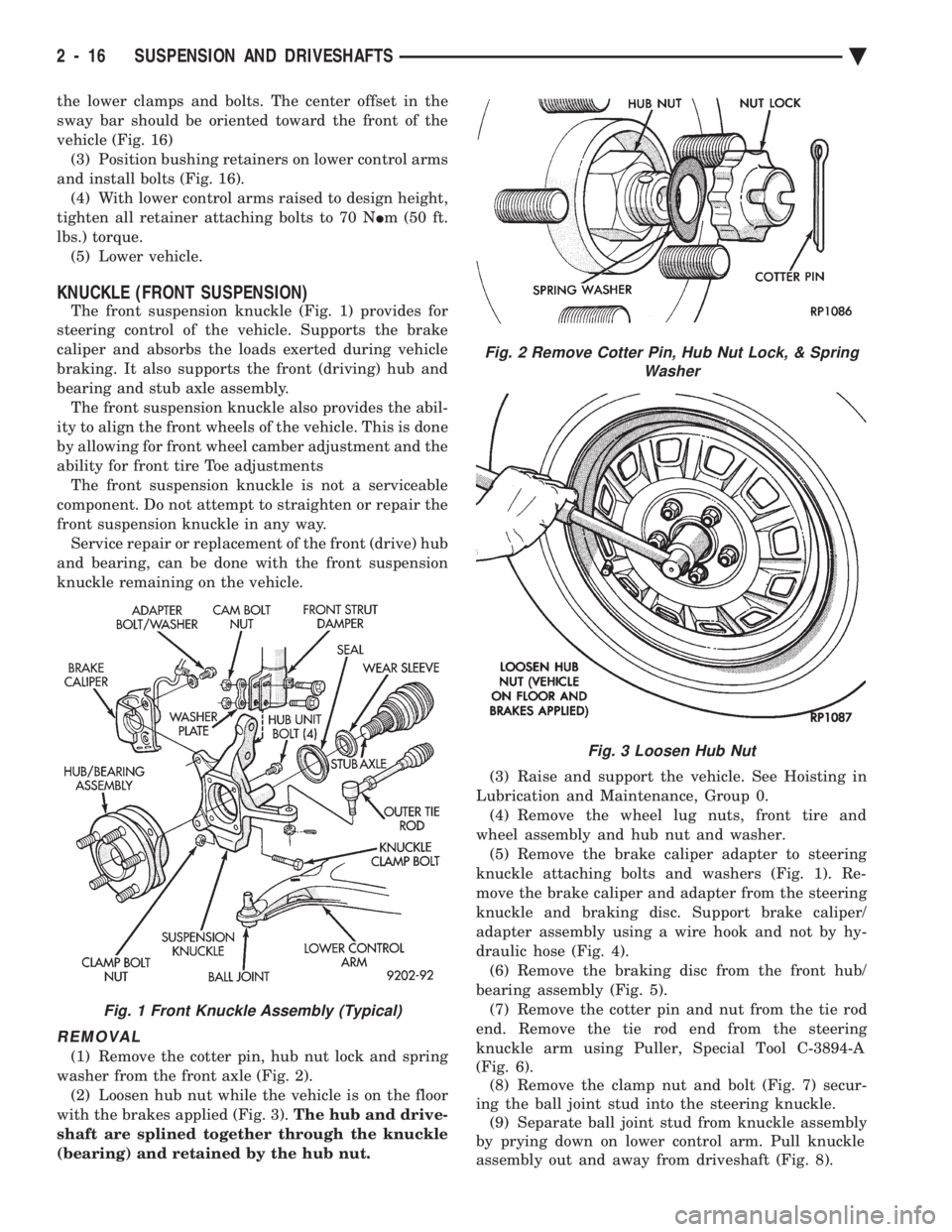

control arm. Be sure that the flanges of the bushing

are fully expanded around the control arm bushing

holes. (5) If the position of the large lower control arm

pivot bushing (Fig. 11) moved during bushing instal-

lation. Install a nut and bolt through the bushing

sleeve and tighten it down (Fig. 11). Using a wrench

rotate the bolt until the bushing is in the correct po-

sition (Fig. 10)

BALL JOINTS

The lower front suspension ball joints operate with

no free play. See Inspection Ball Joint Wear to deter-

mine if the ball joint is worn and requires replace-

ment. The ball joints are replaceable as an assembly, do

not attempt any type of repair on the ball joint as-

sembly. The replacement procedure for the ball joint

assembly is detailed in this section. The ball joint housing is a pressed fit into the

lower control arm with the joint stud retained in the

steering knuckle by a (clamp) bolt.

INSPECTION BALL JOINT WEAR

With the weight of the vehicle resting on the road

wheels. Grasp the grease fitting as shown in (Fig. 12)

and with no mechanical assistance or added force at-

tempt to move the grease fitting.

If the ball joint is worn the grease fitting will move

easily. If movement is noted,replacement of the ball

joint is recommended.

BALL JOINT REMOVAL

(1) Pry off seal.

(2) Position Receiving Cup Special Tool C-4699-2

to support lower control arm while receiving ball

joint assembly (Fig. 13). (3) Install Remover/Installer Special Tool,

C-4699-1 (Fig. 13) over ball joint stud and against

the ball joint upper housing. (4) Press down against the ball joint upper hous-

ing, to remove ball joint assembly from lower control

arm.

Fig. 9 Bushing Installer Tools

Fig. 10 Bushing And Tool Position For Installation In Control Arm

Fig. 11 Positioning Control Arm Bushing

Fig. 12 Checking Ball Joint Wear

Ä SUSPENSION AND DRIVESHAFTS 2 - 13

Page 74 of 2438

the lower clamps and bolts. The center offset in the

sway bar should be oriented toward the front of the

vehicle (Fig. 16)(3) Position bushing retainers on lower control arms

and install bolts (Fig. 16). (4) With lower control arms raised to design height,

tighten all retainer attaching bolts to 70 N Im (50 ft.

lbs.) torque. (5) Lower vehicle.

KNUCKLE (FRONT SUSPENSION)

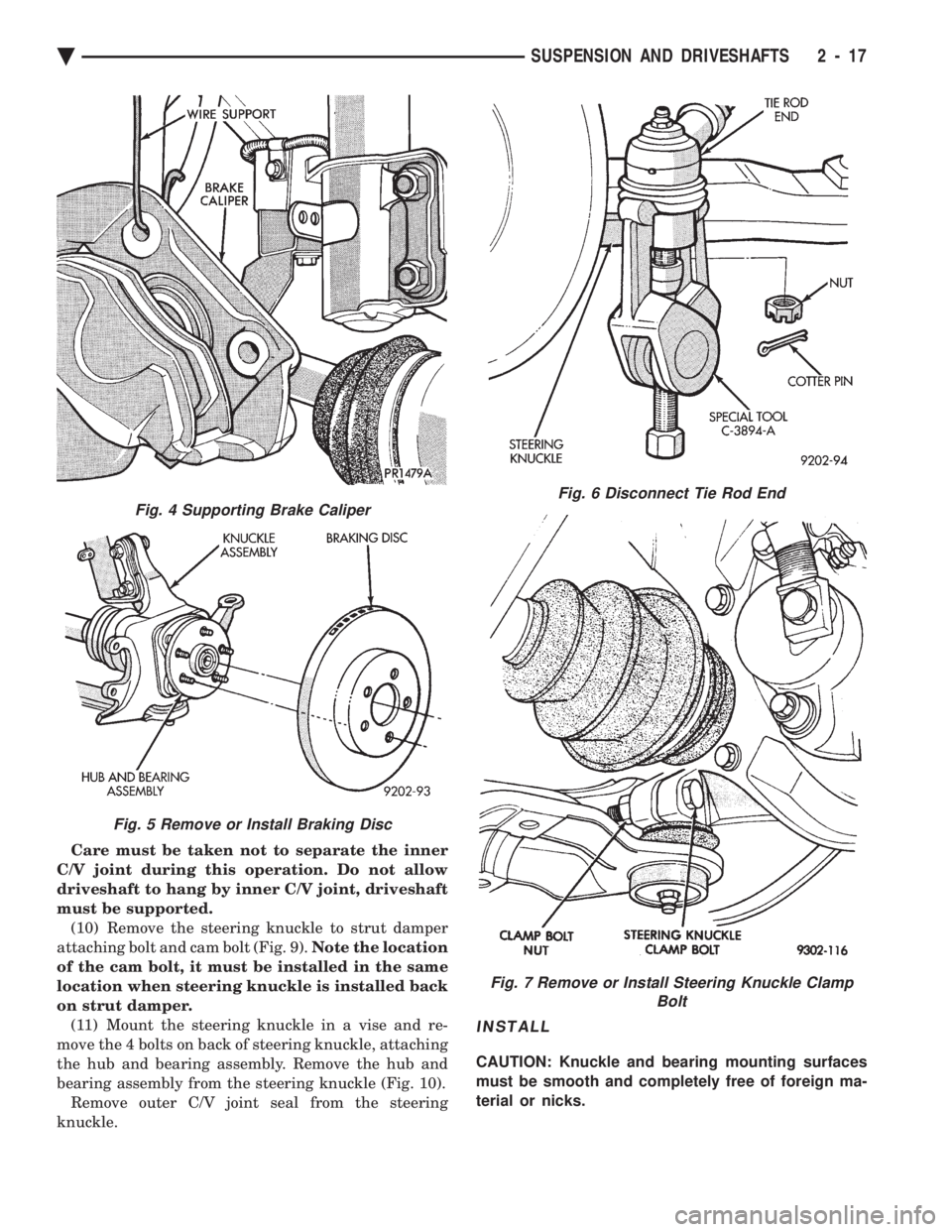

The front suspension knuckle (Fig. 1) provides for

steering control of the vehicle. Supports the brake

caliper and absorbs the loads exerted during vehicle

braking. It also supports the front (driving) hub and

bearing and stub axle assembly. The front suspension knuckle also provides the abil-

ity to align the front wheels of the vehicle. This is done

by allowing for front wheel camber adjustment and the

ability for front tire Toe adjustments The front suspension knuckle is not a serviceable

component. Do not attempt to straighten or repair the

front suspension knuckle in any way. Service repair or replacement of the front (drive) hub

and bearing, can be done with the front suspension

knuckle remaining on the vehicle.

REMOVAL

(1) Remove the cotter pin, hub nut lock and spring

washer from the front axle (Fig. 2). (2) Loosen hub nut while the vehicle is on the floor

with the brakes applied (Fig. 3). The hub and drive-

shaft are splined together through the knuckle

(bearing) and retained by the hub nut. (3) Raise and support the vehicle. See Hoisting in

Lubrication and Maintenance, Group 0. (4) Remove the wheel lug nuts, front tire and

wheel assembly and hub nut and washer. (5) Remove the brake caliper adapter to steering

knuckle attaching bolts and washers (Fig. 1). Re-

move the brake caliper and adapter from the steering

knuckle and braking disc. Support brake caliper/

adapter assembly using a wire hook and not by hy-

draulic hose (Fig. 4). (6) Remove the braking disc from the front hub/

bearing assembly (Fig. 5). (7) Remove the cotter pin and nut from the tie rod

end. Remove the tie rod end from the steering

knuckle arm using Puller, Special Tool C-3894-A

(Fig. 6). (8) Remove the clamp nut and bolt (Fig. 7) secur-

ing the ball joint stud into the steering knuckle. (9) Separate ball joint stud from knuckle assembly

by prying down on lower control arm. Pull knuckle

assembly out and away from driveshaft (Fig. 8).

Fig. 2 Remove Cotter Pin, Hub Nut Lock, & Spring Washer

Fig. 3 Loosen Hub Nut

Fig. 1 Front Knuckle Assembly (Typical)

2 - 16 SUSPENSION AND DRIVESHAFTS Ä

Page 75 of 2438

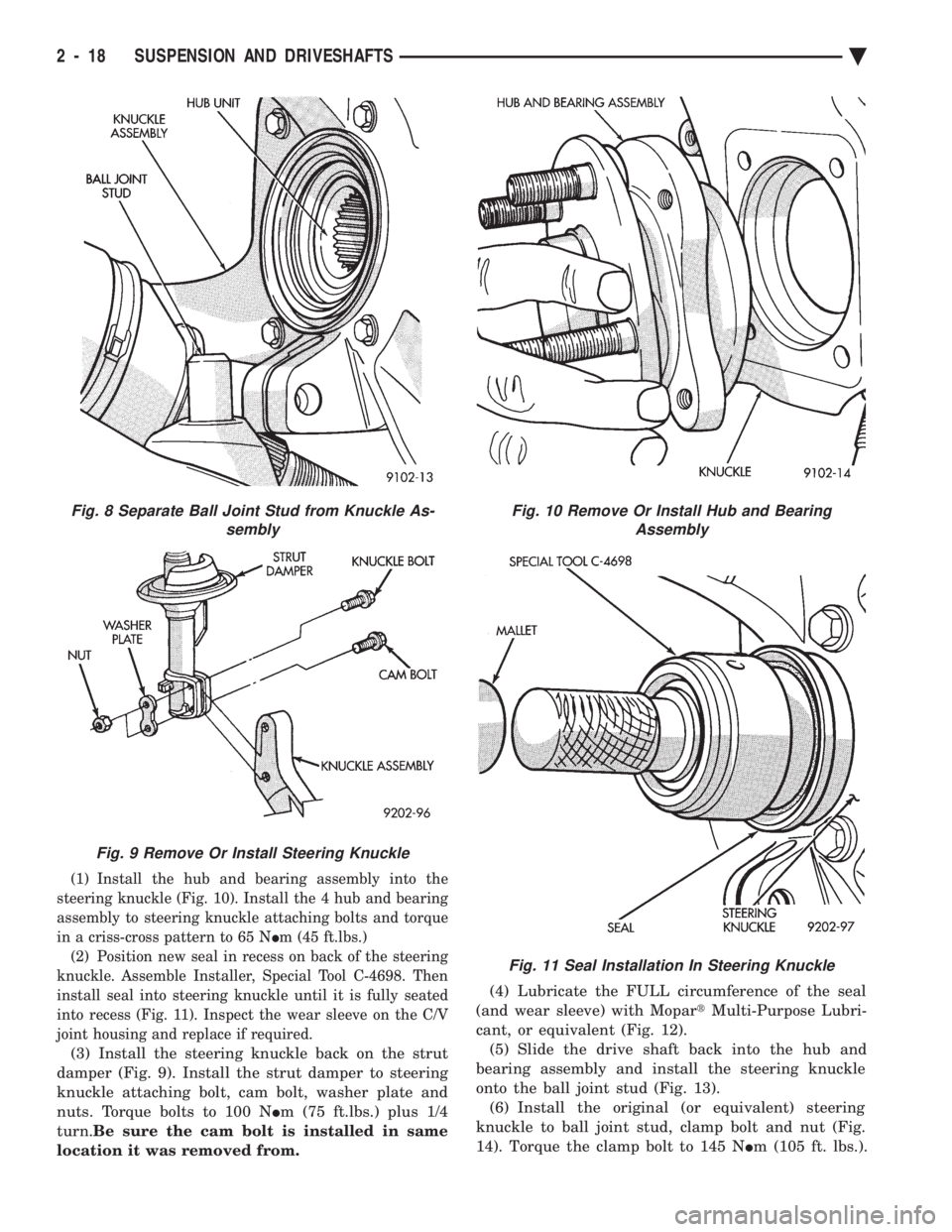

Care must be taken not to separate the inner

C/V joint during this operation. Do not allow

driveshaft to hang by inner C/V joint, driveshaft

must be supported. (10) Remove the steering knuckle to strut damper

attaching bolt and cam bolt (Fig. 9). Note the location

of the cam bolt, it must be installed in the same

location when steering knuckle is installed back

on strut damper. (11) Mount the steering knuckle in a vise and re-

move the 4 bolts on back of steering knuckle, attaching

the hub and bearing assembly. Remove the hub and

bearing assembly from the steering knuckle (Fig. 10). Remove outer C/V joint seal from the steering

knuckle.

INSTALL

CAUTION: Knuckle and bearing mounting surfaces

must be smooth and completely free of foreign ma-

terial or nicks.

Fig. 6 Disconnect Tie Rod End

Fig. 7 Remove or Install Steering Knuckle Clamp Bolt

Fig. 4 Supporting Brake Caliper

Fig. 5 Remove or Install Braking Disc

Ä SUSPENSION AND DRIVESHAFTS 2 - 17

Page 76 of 2438

(1) Install the hub and bearing assembly into the

steering knuckle (Fig. 10). Install the 4 hub and bearing

assembly to steering knuckle attaching bolts and torque

in a criss-cross pattern to 65 N Im (45 ft.lbs.)

(2) Position new seal in recess on back of the steering

knuckle. Assemble Installer, Special Tool C-4698. Then

install seal into steering knuckle until it is fully seated

into recess (Fig. 11). Inspect the wear sleeve on the C/V

joint housing and replace if required.

(3) Install the steering knuckle back on the strut

damper (Fig. 9). Install the strut damper to steering

knuckle attaching bolt, cam bolt, washer plate and

nuts. Torque bolts to 100 N Im (75 ft.lbs.) plus 1/4

turn. Be sure the cam bolt is installed in same

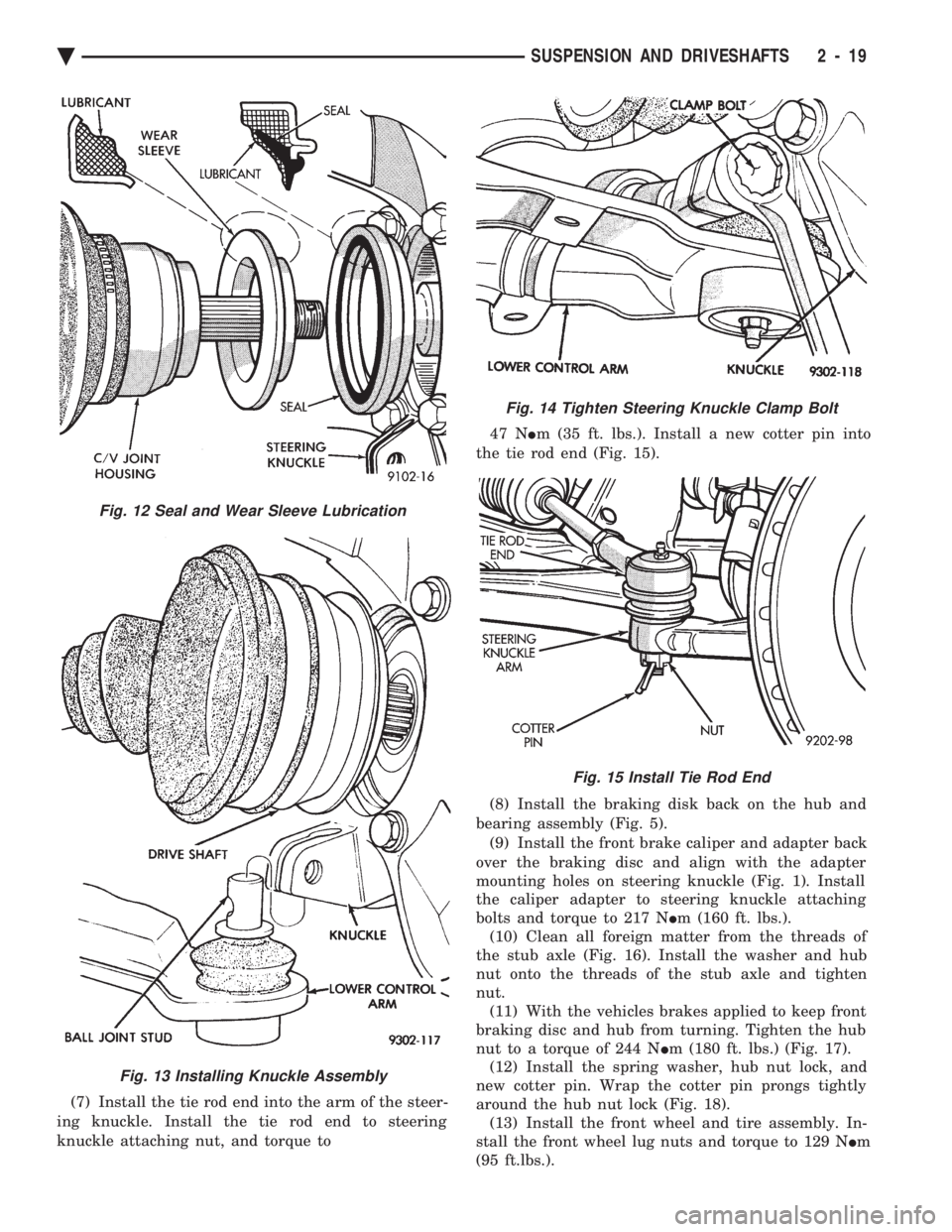

location it was removed from. (4) Lubricate the FULL circumference of the seal

(and wear sleeve) with Mopar tMulti-Purpose Lubri-

cant, or equivalent (Fig. 12). (5) Slide the drive shaft back into the hub and

bearing assembly and install the steering knuckle

onto the ball joint stud (Fig. 13). (6) Install the original (or equivalent) steering

knuckle to ball joint stud, clamp bolt and nut (Fig.

14). Torque the clamp bolt to 145 N Im (105 ft. lbs.).

Fig. 10 Remove Or Install Hub and Bearing

Assembly

Fig. 11 Seal Installation In Steering Knuckle

Fig. 8 Separate Ball Joint Stud from Knuckle As- sembly

Fig. 9 Remove Or Install Steering Knuckle

2 - 18 SUSPENSION AND DRIVESHAFTS Ä

Page 77 of 2438

(7) Install the tie rod end into the arm of the steer-

ing knuckle. Install the tie rod end to steering

knuckle attaching nut, and torque to 47 N

Im (35 ft. lbs.). Install a new cotter pin into

the tie rod end (Fig. 15).

(8) Install the braking disk back on the hub and

bearing assembly (Fig. 5). (9) Install the front brake caliper and adapter back

over the braking disc and align with the adapter

mounting holes on steering knuckle (Fig. 1). Install

the caliper adapter to steering knuckle attaching

bolts and torque to 217 N Im (160 ft. lbs.).

(10) Clean all foreign matter from the threads of

the stub axle (Fig. 16). Install the washer and hub

nut onto the threads of the stub axle and tighten

nut. (11) With the vehicles brakes applied to keep front

braking disc and hub from turning. Tighten the hub

nut to a torque of 244 N Im (180 ft. lbs.) (Fig. 17).

(12) Install the spring washer, hub nut lock, and

new cotter pin. Wrap the cotter pin prongs tightly

around the hub nut lock (Fig. 18). (13) Install the front wheel and tire assembly. In-

stall the front wheel lug nuts and torque to 129 N Im

(95 ft.lbs.).

Fig. 13 Installing Knuckle Assembly

Fig. 12 Seal and Wear Sleeve Lubrication

Fig. 14 Tighten Steering Knuckle Clamp Bolt

Fig. 15 Install Tie Rod End

Ä SUSPENSION AND DRIVESHAFTS 2 - 19

Page 78 of 2438

(14) Lower vehicle.

(15) Align the front wheels of the vehicle. Use the

procedure listed under Wheel Alignment, in the

Front Suspension Service Procedures section of this

service manual.

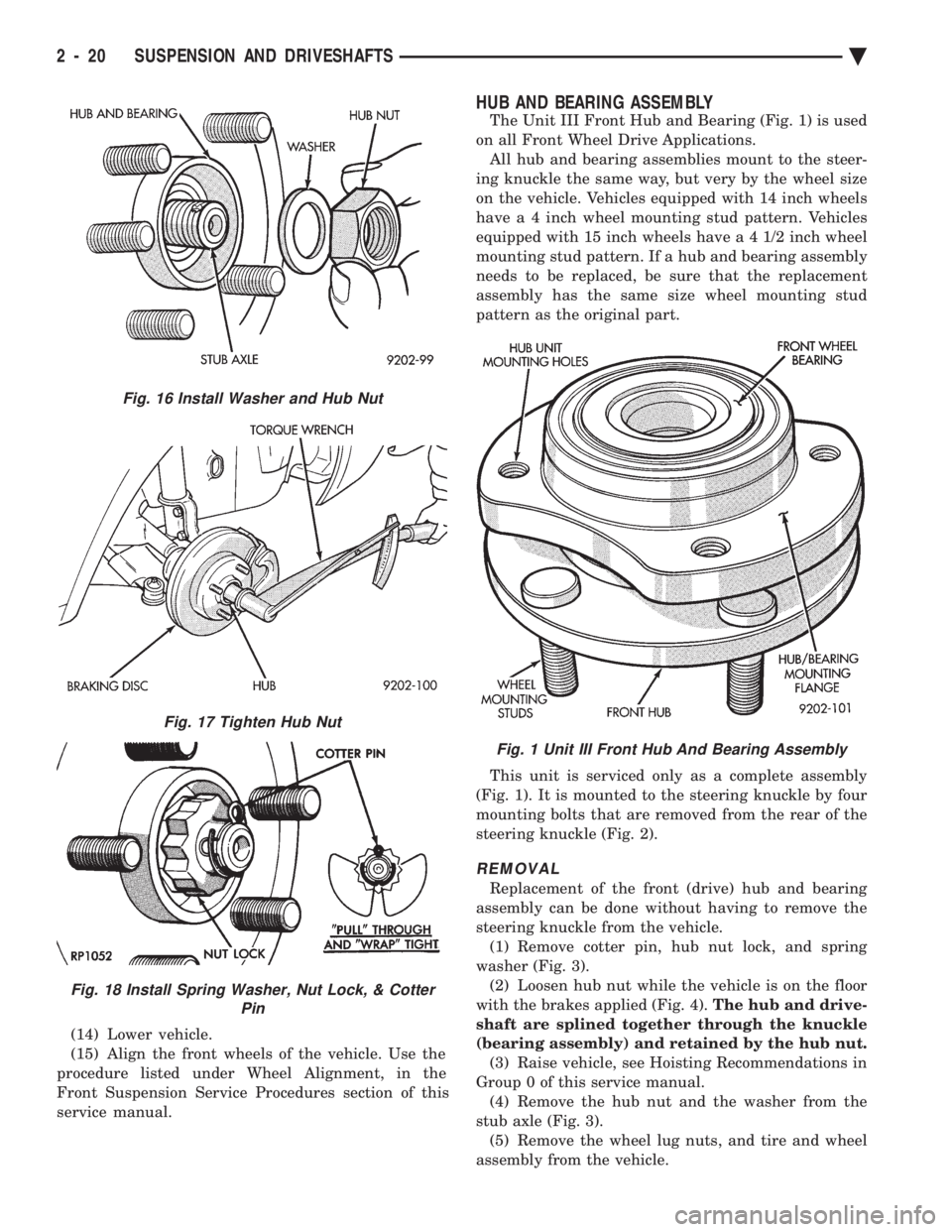

HUB AND BEARING ASSEMBLY

The Unit III Front Hub and Bearing (Fig. 1) is used

on all Front Wheel Drive Applications. All hub and bearing assemblies mount to the steer-

ing knuckle the same way, but very by the wheel size

on the vehicle. Vehicles equipped with 14 inch wheels

have a 4 inch wheel mounting stud pattern. Vehicles

equipped with 15 inch wheels hav e a 4 1/2 inch wheel

mounting stud pattern. If a hub and bearing assembly

needs to be replaced, be sure that the replacement

assembly has the same size wheel mounting stud

pattern as the original part.

This unit is serviced only as a complete assembly

(Fig. 1). It is mounted to the steering knuckle by four

mounting bolts that are removed from the rear of the

steering knuckle (Fig. 2).

REMOVAL

Replacement of the front (drive) hub and bearing

assembly can be done without having to remove the

steering knuckle from the vehicle. (1) Remove cotter pin, hub nut lock, and spring

washer (Fig. 3). (2) Loosen hub nut while the vehicle is on the floor

with the brakes applied (Fig. 4). The hub and drive-

shaft are splined together through the knuckle

(bearing assembly) and retained by the hub nut. (3) Raise vehicle, see Hoisting Recommendations in

Group 0 of this service manual. (4) Remove the hub nut and the washer from the

stub axle (Fig. 3). (5) Remove the wheel lug nuts, and tire and wheel

assembly from the vehicle.

Fig. 16 Install Washer and Hub Nut

Fig. 17 Tighten Hub Nut

Fig. 18 Install Spring Washer, Nut Lock, & Cotter Pin

Fig. 1 Unit III Front Hub And Bearing Assembly

2 - 20 SUSPENSION AND DRIVESHAFTS Ä