steering CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 305 of 2438

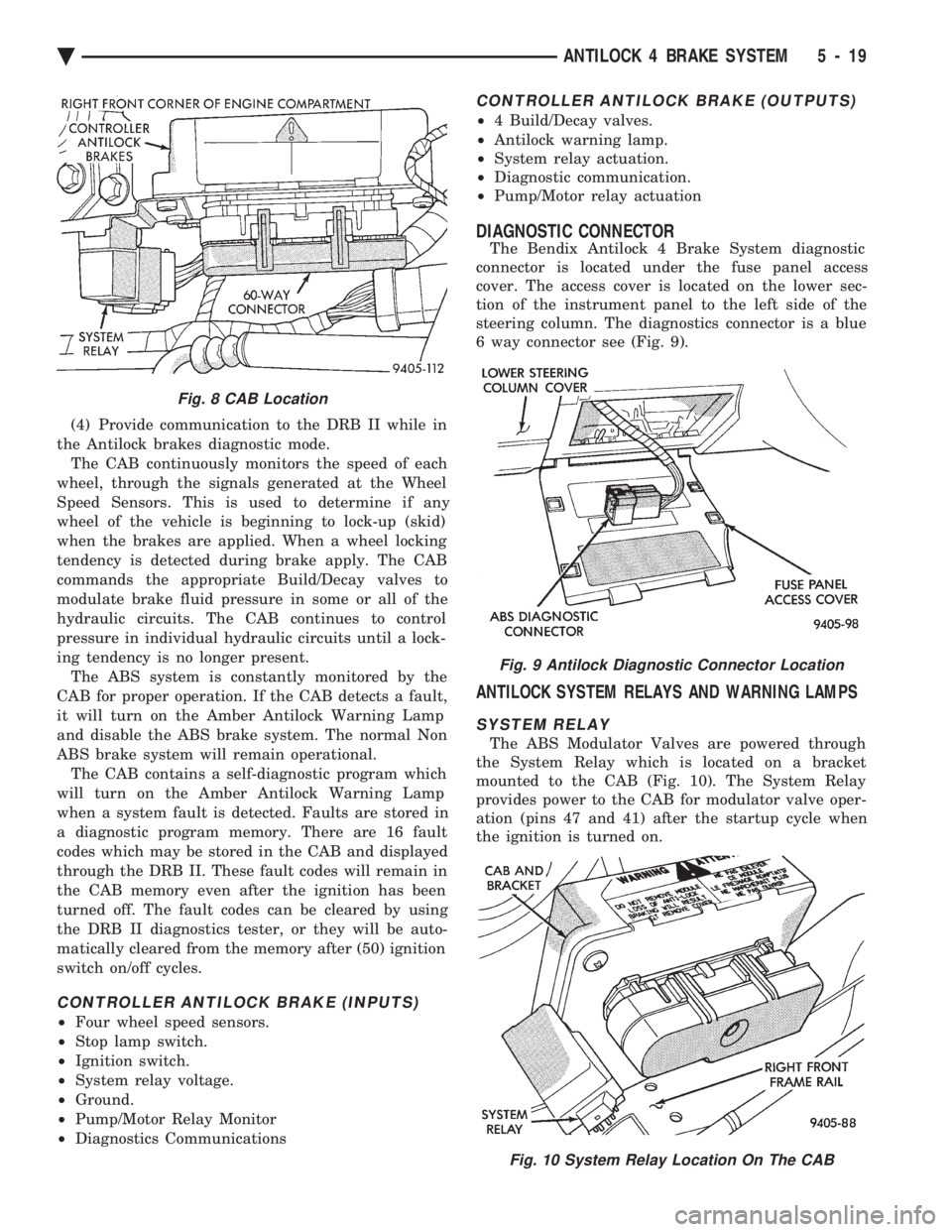

(4) Provide communication to the DRB II while in

the Antilock brakes diagnostic mode. The CAB continuously monitors the speed of each

wheel, through the signals generated at the Wheel

Speed Sensors. This is used to determine if any

wheel of the vehicle is beginning to lock-up (skid)

when the brakes are applied. When a wheel locking

tendency is detected during brake apply. The CAB

commands the appropriate Build/Decay valves to

modulate brake fluid pressure in some or all of the

hydraulic circuits. The CAB continues to control

pressure in individual hydraulic circuits until a lock-

ing tendency is no longer present. The ABS system is constantly monitored by the

CAB for proper operation. If the CAB detects a fault,

it will turn on the Amber Antilock Warning Lamp

and disable the ABS brake system. The normal Non

ABS brake system will remain operational. The CAB contains a self-diagnostic program which

will turn on the Amber Antilock Warning Lamp

when a system fault is detected. Faults are stored in

a diagnostic program memory. There are 16 fault

codes which may be stored in the CAB and displayed

through the DRB II. These fault codes will remain in

the CAB memory even after the ignition has been

turned off. The fault codes can be cleared by using

the DRB II diagnostics tester, or they will be auto-

matically cleared from the memory after (50) ignition

switch on/off cycles.

CONTROLLER ANTILOCK BRAKE (INPUTS)

² Four wheel speed sensors.

² Stop lamp switch.

² Ignition switch.

² System relay voltage.

² Ground.

² Pump/Motor Relay Monitor

² Diagnostics Communications

CONTROLLER ANTILOCK BRAKE (OUTPUTS)

²4 Build/Decay valves.

² Antilock warning lamp.

² System relay actuation.

² Diagnostic communication.

² Pump/Motor relay actuation

DIAGNOSTIC CONNECTOR

The Bendix Antilock 4 Brake System diagnostic

connector is located under the fuse panel access

cover. The access cover is located on the lower sec-

tion of the instrument panel to the left side of the

steering column. The diagnostics connector is a blue

6 way connector see (Fig. 9).

ANTILOCK SYSTEM RELAYS AND WARNING LAMPS

SYSTEM RELAY

The ABS Modulator Valves are powered through

the System Relay which is located on a bracket

mounted to the CAB (Fig. 10). The System Relay

provides power to the CAB for modulator valve oper-

ation (pins 47 and 41) after the startup cycle when

the ignition is turned on.

Fig. 8 CAB Location

Fig. 9 Antilock Diagnostic Connector Location

Fig. 10 System Relay Location On The CAB

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 19

Page 312 of 2438

BENDIX ANTILOCK 4 MODULATOR ASSEMBLY BLEEDING PROCEDURE

(1) Assemble and install all brake system compo-

nents on the vehicle, making sure all hydraulic fluid

lines are installed and properly torqued. (2) Bleed the base brake system, using ONLYthe

bleeding procedure outlined in the Service Adjust-

ments section of this service manual supplement. To perform the bleeding procedure on the ABS modu-

lator assembly, the battery, battery tray and acid shield

must be removed from vehicle. Then reconnect the

vehicle's battery to vehicle's battery cables, using

ONLY approved battery jumper cables. (3) Connect the DRB Diagnostics Tester to the vehi-

cle's diagnostics connector. The vehicle diagnostic con-

nector is located behind the fuse panel access cover on

the lower section of the dash panel left of the steering

column. The diagnostic connector is a blue 6 way

connector. (4) Using the DRB check to make sure the CAB does

not have any stored fault codes. If it does, remove them

using the DRB.

WARNING: WHEN BLEEDING THE MODULATOR AS-

SEMBLY WEAR SAFETY GLASSES. A CLEAR BLEED

TUBE MUST BE ATTACHED TO THE MODULATOR

BLEED SCREWS AND SUBMERGED IN A CLEAR

CONTAINER FILLED PART WAY WITH FRESH CLEAN

BRAKE FLUID. DIRECT THE FLOW OF BRAKE FLUID

AWAY FROM THE PAINTED SURFACES OF THE VE-

HICLE. BRAKE FLUID AT HIGH PRESSURE MAY

COME OUT OF THE BLEEDER SCREWS, WHEN

OPENED.

When bleeding Antilock modulator assembly, the

following bleeding sequence MUSTbe followed to

insure a complete bleeding of all air from the Antilock

brake, and base brake hydraulic systems. The modu-

lator assembly can ONLY be bled using a manual

bleeding procedure to pressurize the hydraulic

system.

MODULATOR ASSEMBLY CIRCUIT BLEEDING PROCEDURE AND SEQUENCE

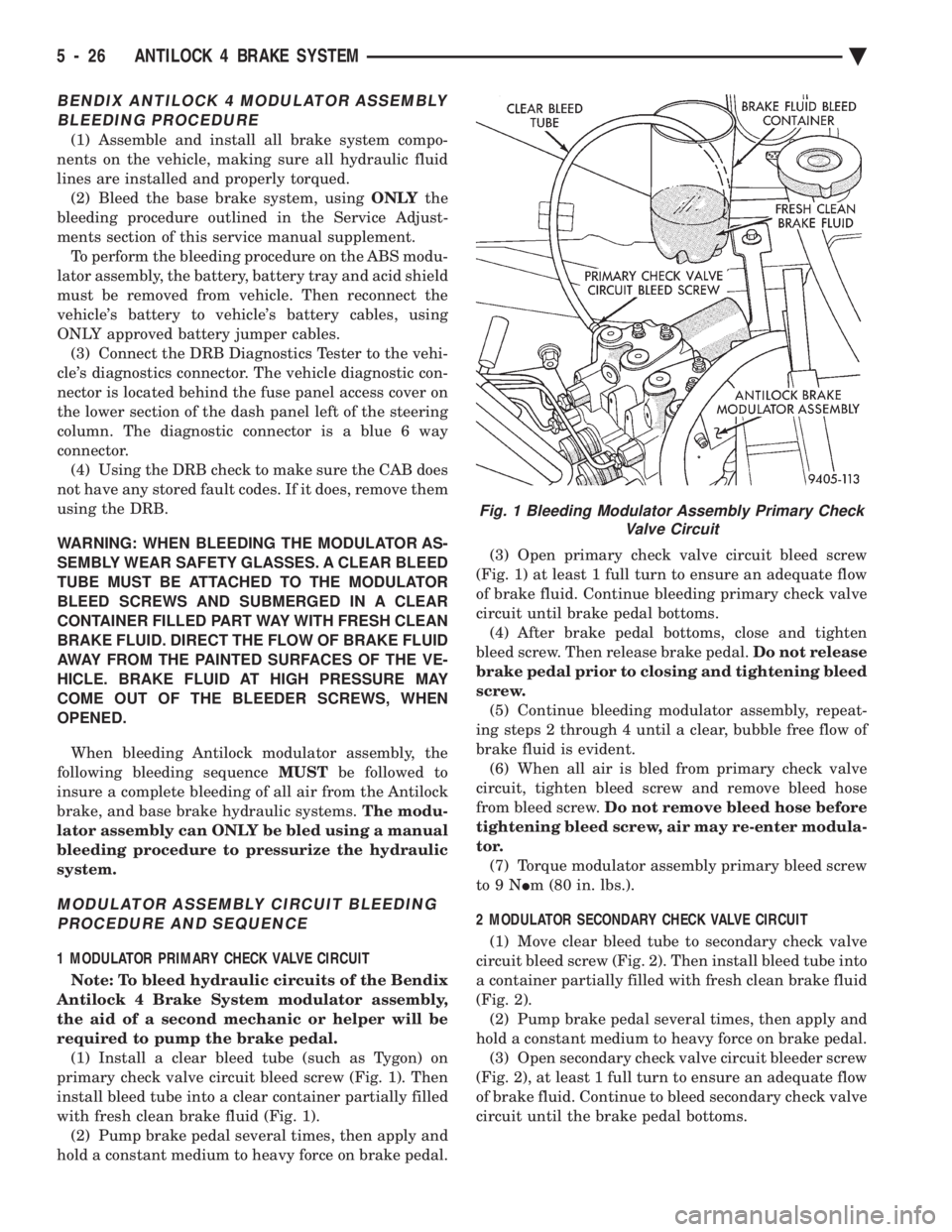

1 MODULATOR PRIMARY CHECK VALVE CIRCUIT

Note: To bleed hydraulic circuits of the Bendix

Antilock 4 Brake System modulator assembly,

the aid of a second mechanic or helper will be

required to pump the brake pedal. (1) Install a clear bleed tube (such as Tygon) on

primary check valve circuit bleed screw (Fig. 1). Then

install bleed tube into a clear container partially filled

with fresh clean brake fluid (Fig. 1). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open primary check valve circuit bleed screw

(Fig. 1) at least 1 full turn to ensure an adequate flow

of brake fluid. Continue bleeding primary check valve

circuit until brake pedal bottoms. (4) After brake pedal bottoms, close and tighten

bleed screw. Then release brake pedal. Do not release

brake pedal prior to closing and tightening bleed

screw. (5) Continue bleeding modulator assembly, repeat-

ing steps 2 through 4 until a clear, bubble free flow of

brake fluid is evident. (6) When all air is bled from primary check valve

circuit, tighten bleed screw and remove bleed hose

from bleed screw. Do not remove bleed hose before

tightening bleed screw, air may re-enter modula-

tor. (7) Torque modulator assembly primary bleed screw

to9N Im (80 in. lbs.).

2 MODULATOR SECONDARY CHECK VALVE CIRCUIT (1) Move clear bleed tube to secondary check valve

circuit bleed screw (Fig. 2). Then install bleed tube into

a container partially filled with fresh clean brake fluid

(Fig. 2). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open secondary check valve circuit bleeder screw

(Fig. 2), at least 1 full turn to ensure an adequate flow

of brake fluid. Continue to bleed secondary check valve

circuit until the brake pedal bottoms.

Fig. 1 Bleeding Modulator Assembly Primary Check Valve Circuit

5 - 26 ANTILOCK 4 BRAKE SYSTEM Ä

Page 330 of 2438

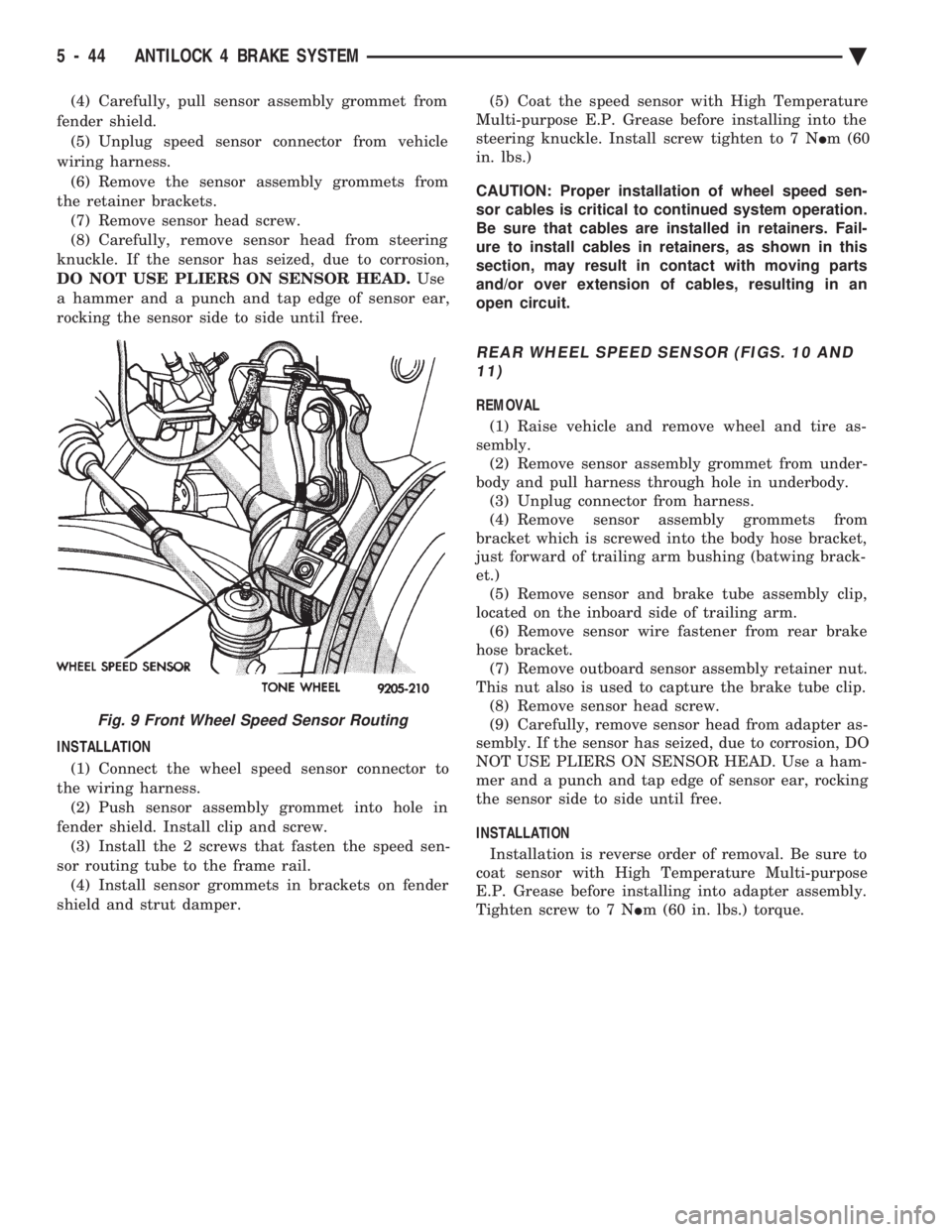

(4) Carefully, pull sensor assembly grommet from

fender shield. (5) Unplug speed sensor connector from vehicle

wiring harness. (6) Remove the sensor assembly grommets from

the retainer brackets. (7) Remove sensor head screw.

(8) Carefully, remove sensor head from steering

knuckle. If the sensor has seized, due to corrosion,

DO NOT USE PLIERS ON SENSOR HEAD. Use

a hammer and a punch and tap edge of sensor ear,

rocking the sensor side to side until free.

INSTALLATION

(1) Connect the wheel speed sensor connector to

the wiring harness. (2) Push sensor assembly grommet into hole in

fender shield. Install clip and screw. (3) Install the 2 screws that fasten the speed sen-

sor routing tube to the frame rail. (4) Install sensor grommets in brackets on fender

shield and strut damper. (5) Coat the speed sensor with High Temperature

Multi-purpose E.P. Grease before installing into the

steering knuckle. Install screw tighten to 7 N Im (60

in. lbs.)

CAUTION: Proper installation of wheel speed sen-

sor cables is critical to continued system operation.

Be sure that cables are installed in retainers. Fail-

ure to install cables in retainers, as shown in this

section, may result in contact with moving parts

and/or over extension of cables, resulting in an

open circuit.

REAR WHEEL SPEED SENSOR (FIGS. 10 AND 11)

REMOVAL

(1) Raise vehicle and remove wheel and tire as-

sembly. (2) Remove sensor assembly grommet from under-

body and pull harness through hole in underbody. (3) Unplug connector from harness.

(4) Remove sensor assembly grommets from

bracket which is screwed into the body hose bracket,

just forward of trailing arm bushing (batwing brack-

et.) (5) Remove sensor and brake tube assembly clip,

located on the inboard side of trailing arm. (6) Remove sensor wire fastener from rear brake

hose bracket. (7) Remove outboard sensor assembly retainer nut.

This nut also is used to capture the brake tube clip. (8) Remove sensor head screw.

(9) Carefully, remove sensor head from adapter as-

sembly. If the sensor has seized, due to corrosion, DO

NOT USE PLIERS ON SENSOR HEAD. Use a ham-

mer and a punch and tap edge of sensor ear, rocking

the sensor side to side until free.

INSTALLATION Installation is reverse order of removal. Be sure to

coat sensor with High Temperature Multi-purpose

E.P. Grease before installing into adapter assembly.

Tighten screw to 7 N Im (60 in. lbs.) torque.

Fig. 9 Front Wheel Speed Sensor Routing

5 - 44 ANTILOCK 4 BRAKE SYSTEM Ä

Page 367 of 2438

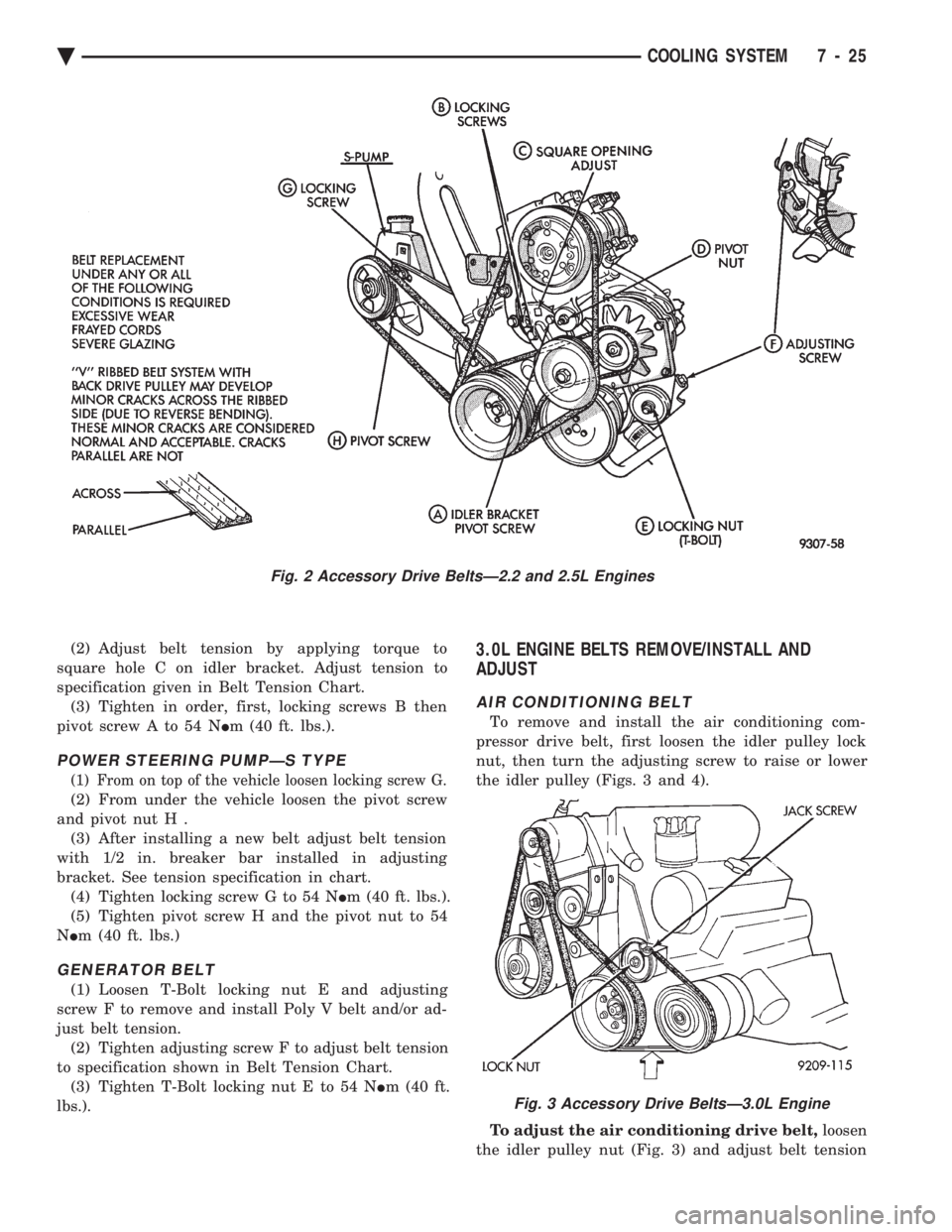

(2) Adjust belt tension by applying torque to

square hole C on idler bracket. Adjust tension to

specification given in Belt Tension Chart. (3) Tighten in order, first, locking screws B then

pivot screw A to 54 N Im (40 ft. lbs.).

POWER STEERING PUMPÐS TYPE

(1) From on top of the vehicle loosen locking screw G.

(2) From under the vehicle loosen the pivot screw

and pivot nut H . (3) After installing a new belt adjust belt tension

with 1/2 in. breaker bar installed in adjusting

bracket. See tension specification in chart. (4) Tighten locking screw G to 54 N Im (40 ft. lbs.).

(5) Tighten pivot screw H and the pivot nut to 54

N Im (40 ft. lbs.)

GENERATOR BELT

(1) Loosen T-Bolt locking nut E and adjusting

screw F to remove and install Poly V belt and/or ad-

just belt tension. (2) Tighten adjusting screw F to adjust belt tension

to specification shown in Belt Tension Chart. (3) Tighten T-Bolt locking nut E to 54 N Im (40 ft.

lbs.).

3.0L ENGINE BELTS REMOVE/INSTALL AND

ADJUST

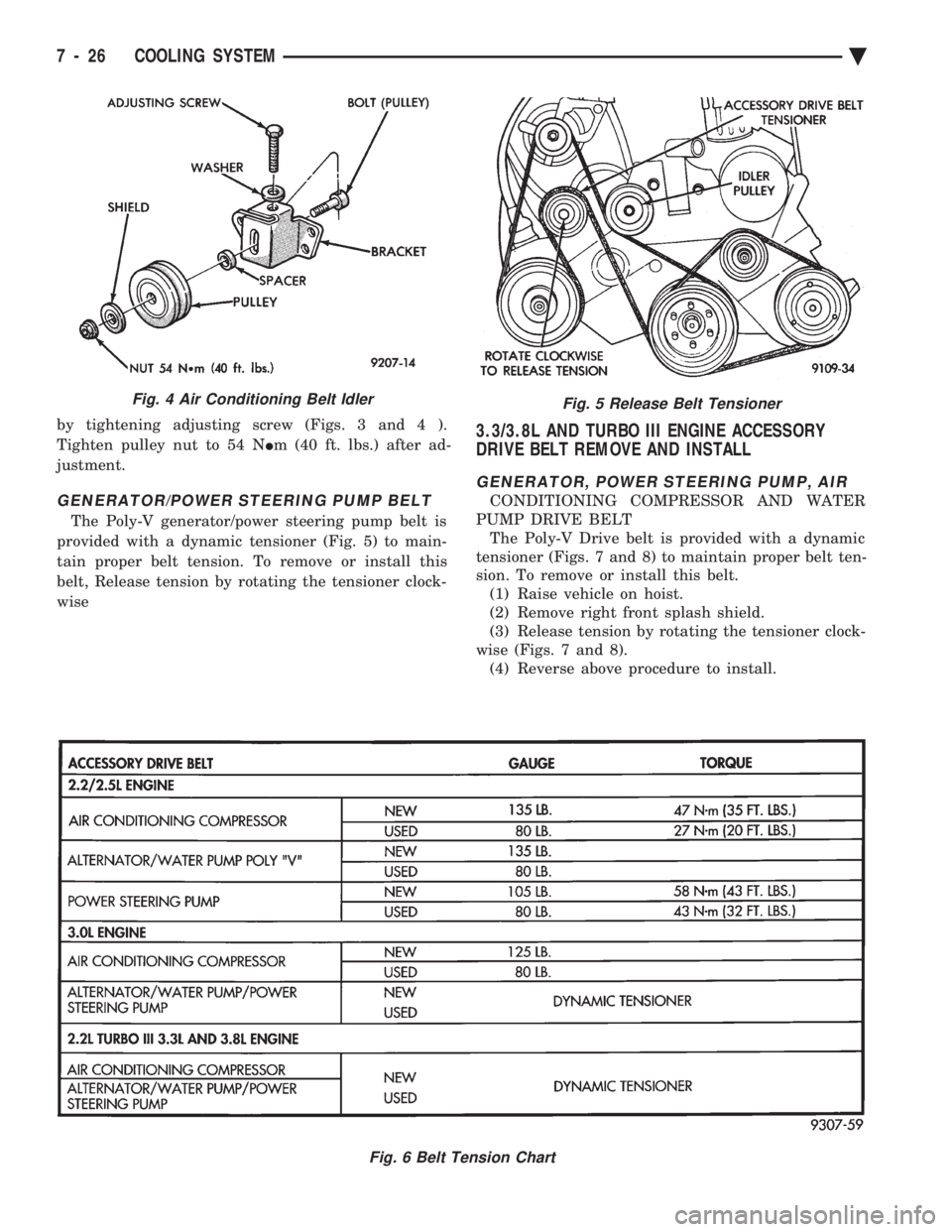

AIR CONDITIONING BELT

To remove and install the air conditioning com-

pressor drive belt, first loosen the idler pulley lock

nut, then turn the adjusting screw to raise or lower

the idler pulley (Figs. 3 and 4).

To adjust the air conditioning drive belt, loosen

the idler pulley nut (Fig. 3) and adjust belt tension

Fig. 2 Accessory Drive BeltsÐ2.2 and 2.5L Engines

Fig. 3 Accessory Drive BeltsÐ3.0L Engine

Ä COOLING SYSTEM 7 - 25

Page 368 of 2438

by tightening adjusting screw (Figs. 3 and 4 ).

Tighten pulley nut to 54 N Im (40 ft. lbs.) after ad-

justment.

GENERATOR/POWER STEERING PUMP BELT

The Poly-V generator/power steering pump belt is

provided with a dynamic tensioner (Fig. 5) to main-

tain proper belt tension. To remove or install this

belt, Release tension by rotating the tensioner clock-

wise

3.3/3.8L AND TURBO III ENGINE ACCESSORY

DRIVE BELT REMOVE AND INSTALL

GENERATOR, POWER STEERING PUMP, AIR

CONDITIONING COMPRESSOR AND WATER

PUMP DRIVE BELT The Poly-V Drive belt is provided with a dynamic

tensioner (Figs. 7 and 8) to maintain proper belt ten-

sion. To remove or install this belt. (1) Raise vehicle on hoist.

(2) Remove right front splash shield.

(3) Release tension by rotating the tensioner clock-

wise (Figs. 7 and 8). (4) Reverse above procedure to install.

Fig. 5 Release Belt Tensioner

Fig. 6 Belt Tension Chart

Fig. 4 Air Conditioning Belt Idler

7 - 26 COOLING SYSTEM Ä

Page 413 of 2438

(6) For installation, reverse above procedure.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

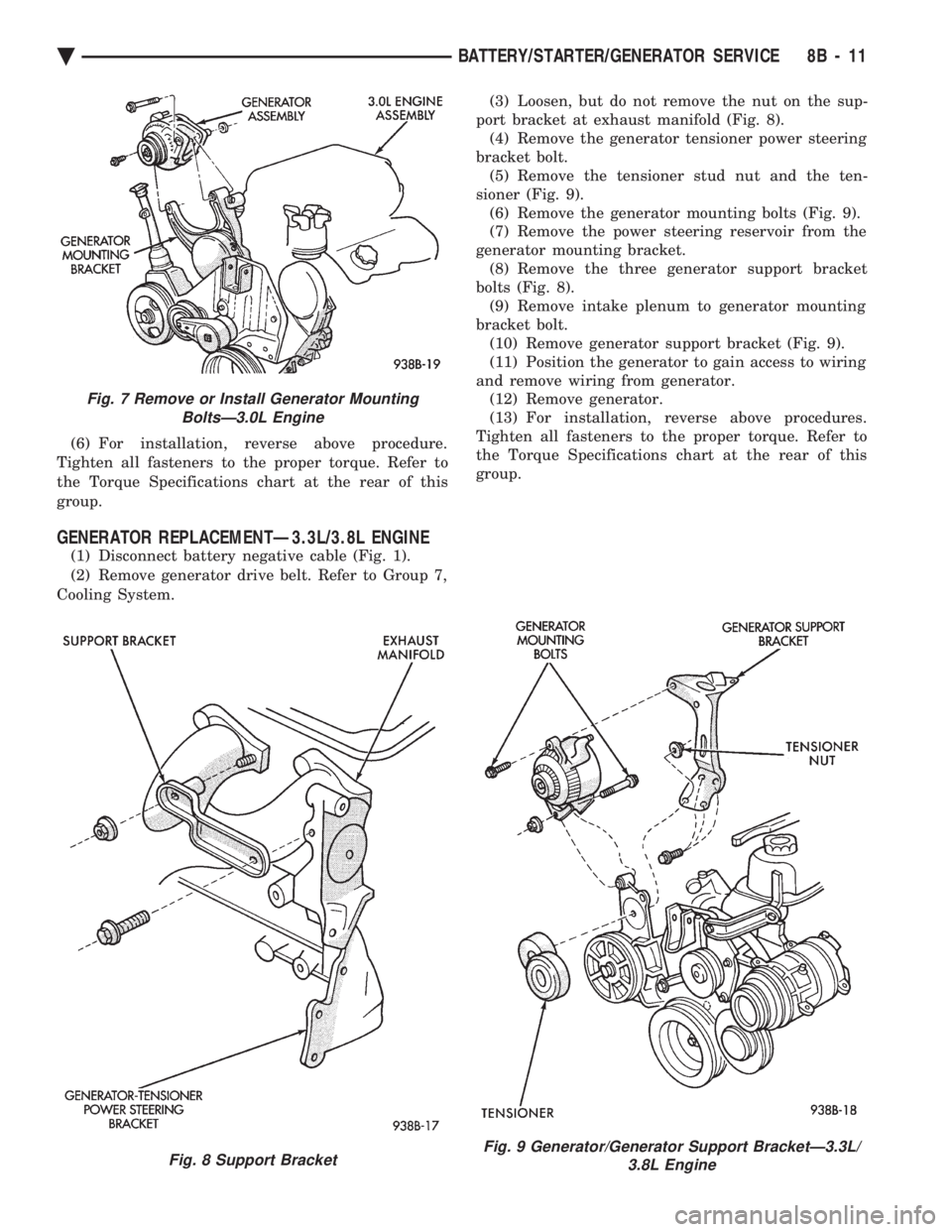

GENERATOR REPLACEMENTÐ3.3L/3.8L ENGINE

(1) Disconnect battery negative cable (Fig. 1).

(2) Remove generator drive belt. Refer to Group 7,

Cooling System. (3) Loosen, but do not remove the nut on the sup-

port bracket at exhaust manifold (Fig. 8). (4) Remove the generator tensioner power steering

bracket bolt. (5) Remove the tensioner stud nut and the ten-

sioner (Fig. 9). (6) Remove the generator mounting bolts (Fig. 9).

(7) Remove the power steering reservoir from the

generator mounting bracket. (8) Remove the three generator support bracket

bolts (Fig. 8). (9) Remove intake plenum to generator mounting

bracket bolt. (10) Remove generator support bracket (Fig. 9).

(11) Position the generator to gain access to wiring

and remove wiring from generator. (12) Remove generator.

(13) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

Fig. 7 Remove or Install Generator Mounting BoltsÐ3.0L Engine

Fig. 8 Support BracketFig. 9 Generator/Generator Support BracketÐ3.3L/ 3.8L Engine

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 11

Page 487 of 2438

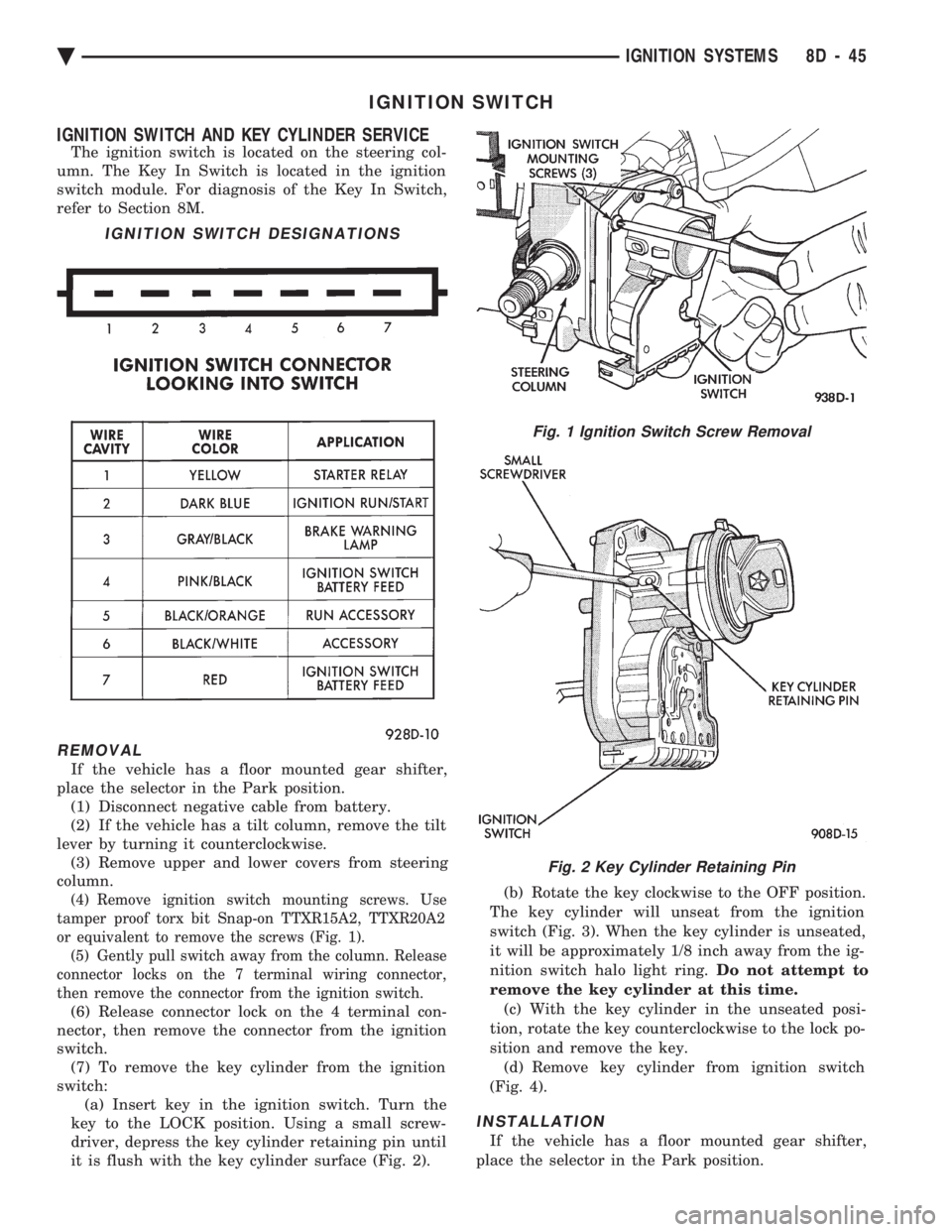

IGNITION SWITCH

IGNITION SWITCH AND KEY CYLINDER SERVICE

The ignition switch is located on the steering col-

umn. The Key In Switch is located in the ignition

switch module. For diagnosis of the Key In Switch,

refer to Section 8M.

REMOVAL

If the vehicle has a floor mounted gear shifter,

place the selector in the Park position. (1) Disconnect negative cable from battery.

(2) If the vehicle has a tilt column, remove the tilt

lever by turning it counterclockwise. (3) Remove upper and lower covers from steering

column.

(4) Remove ignition switch mounting screws. Use

tamper proof torx bit Snap-on TTXR15A2, TTXR20A2

or equivalent to remove the screws (Fig. 1). (5) Gently pull switch away from the column. Release

connector locks on the 7 terminal wiring connector,

then remove the connector from the ignition switch.

(6) Release connector lock on the 4 terminal con-

nector, then remove the connector from the ignition

switch. (7) To remove the key cylinder from the ignition

switch: (a) Insert key in the ignition switch. Turn the

key to the LOCK position. Using a small screw-

driver, depress the key cylinder retaining pin until

it is flush with the key cylinder surface (Fig. 2). (b) Rotate the key clockwise to the OFF position.

The key cylinder will unseat from the ignition

switch (Fig. 3). When the key cylinder is unseated,

it will be approximately 1/8 inch away from the ig-

nition switch halo light ring. Do not attempt to

remove the key cylinder at this time. (c) With the key cylinder in the unseated posi-

tion, rotate the key counterclockwise to the lock po-

sition and remove the key. (d) Remove key cylinder from ignition switch

(Fig. 4).

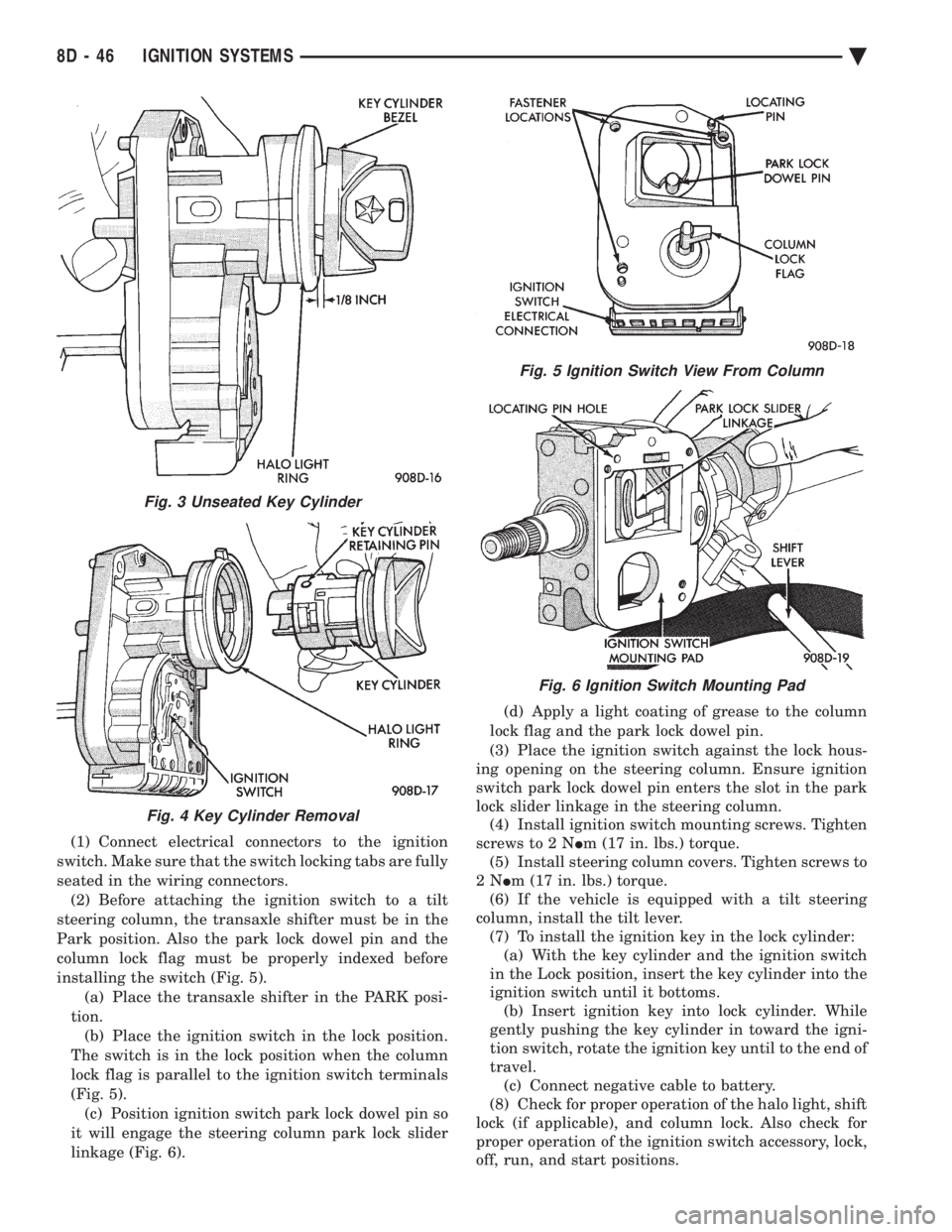

INSTALLATION

If the vehicle has a floor mounted gear shifter,

place the selector in the Park position.

IGNITION SWITCH DESIGNATIONS

Fig. 1 Ignition Switch Screw Removal

Fig. 2 Key Cylinder Retaining Pin

Ä IGNITION SYSTEMS 8D - 45

Page 488 of 2438

(1) Connect electrical connectors to the ignition

switch. Make sure that the switch locking tabs are fully

seated in the wiring connectors. (2) Before attaching the ignition switch to a tilt

steering column, the transaxle shifter must be in the

Park position. Also the park lock dowel pin and the

column lock flag must be properly indexed before

installing the switch (Fig. 5). (a) Place the transaxle shifter in the PARK posi-

tion. (b) Place the ignition switch in the lock position.

The switch is in the lock position when the column

lock flag is parallel to the ignition switch terminals

(Fig. 5). (c) Position ignition switch park lock dowel pin so

it will engage the steering column park lock slider

linkage (Fig. 6). (d) Apply a light coating of grease to the column

lock flag and the park lock dowel pin.

(3) Place the ignition switch against the lock hous-

ing opening on the steering column. Ensure ignition

switch park lock dowel pin enters the slot in the park

lock slider linkage in the steering column. (4) Install ignition switch mounting screws. Tighten

screws to 2 N Im (17 in. lbs.) torque.

(5) Install steering column covers. Tighten screws to

2N Im (17 in. lbs.) torque.

(6) If the vehicle is equipped with a tilt steering

column, install the tilt lever. (7) To install the ignition key in the lock cylinder:(a) With the key cylinder and the ignition switch

in the Lock position, insert the key cylinder into the

ignition switch until it bottoms. (b) Insert ignition key into lock cylinder. While

gently pushing the key cylinder in toward the igni-

tion switch, rotate the ignition key until to the end of

travel. (c) Connect negative cable to battery.

(8) Check for proper operation of the halo light, shift

lock (if applicable), and column lock. Also check for

proper operation of the ignition switch accessory, lock,

off, run, and start positions.

Fig. 3 Unseated Key Cylinder

Fig. 4 Key Cylinder Removal

Fig. 5 Ignition Switch View From Column

Fig. 6 Ignition Switch Mounting Pad

8D - 46 IGNITION SYSTEMS Ä

Page 497 of 2438

MECHANICAL/ELECTRONIC CLUSTER REMOVAL

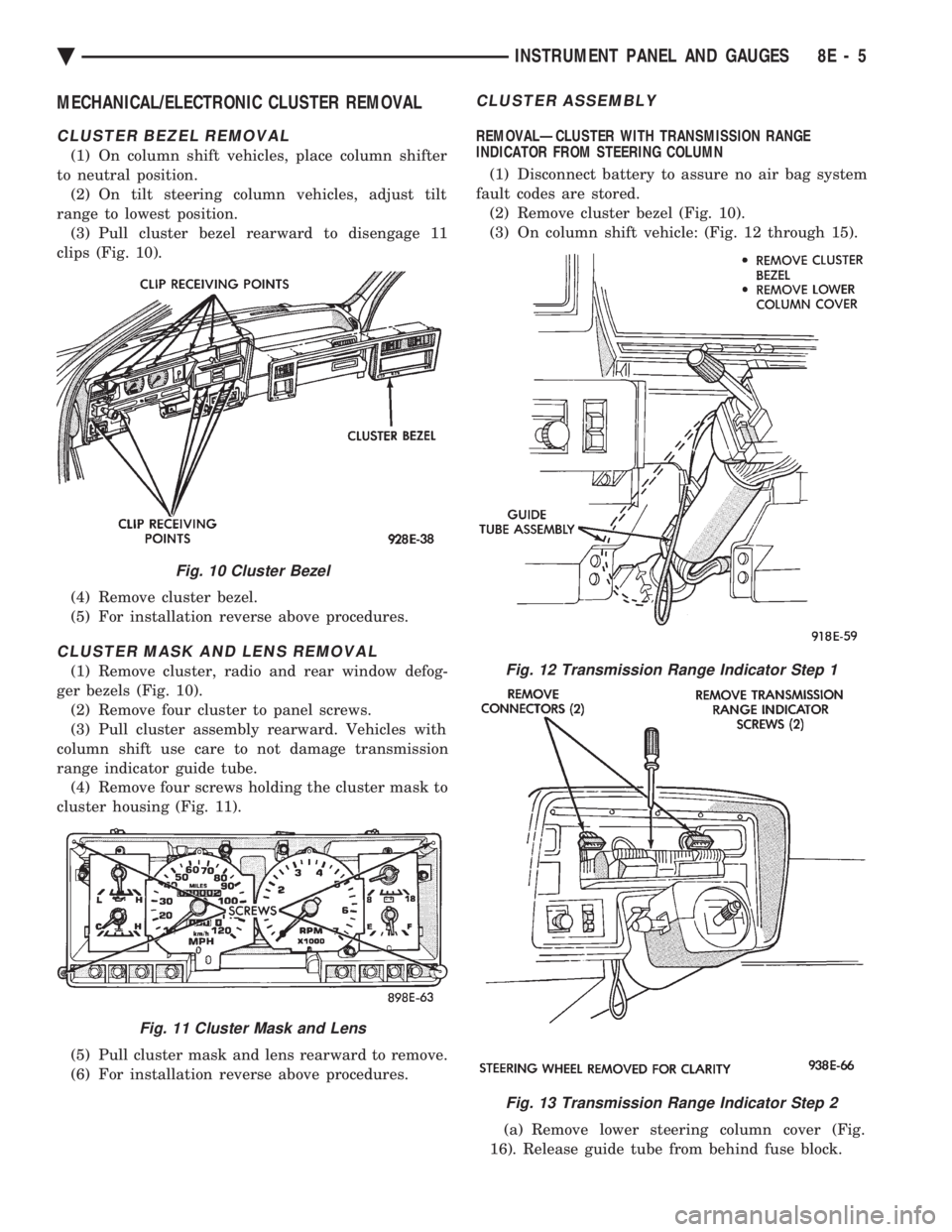

CLUSTER BEZEL REMOVAL

(1) On column shift vehicles, place column shifter

to neutral position. (2) On tilt steering column vehicles, adjust tilt

range to lowest position. (3) Pull cluster bezel rearward to disengage 11

clips (Fig. 10).

(4) Remove cluster bezel.

(5) For installation reverse above procedures.

CLUSTER MASK AND LENS REMOVAL

(1) Remove cluster, radio and rear window defog-

ger bezels (Fig. 10). (2) Remove four cluster to panel screws.

(3) Pull cluster assembly rearward. Vehicles with

column shift use care to not damage transmission

range indicator guide tube. (4) Remove four screws holding the cluster mask to

cluster housing (Fig. 11).

(5) Pull cluster mask and lens rearward to remove.

(6) For installation reverse above procedures.

CLUSTER ASSEMBLY

REMOVALÐCLUSTER WITH TRANSMISSION RANGE

INDICATOR FROM STEERING COLUMN

(1) Disconnect battery to assure no air bag system

fault codes are stored. (2) Remove cluster bezel (Fig. 10).

(3) On column shift vehicle: (Fig. 12 through 15).

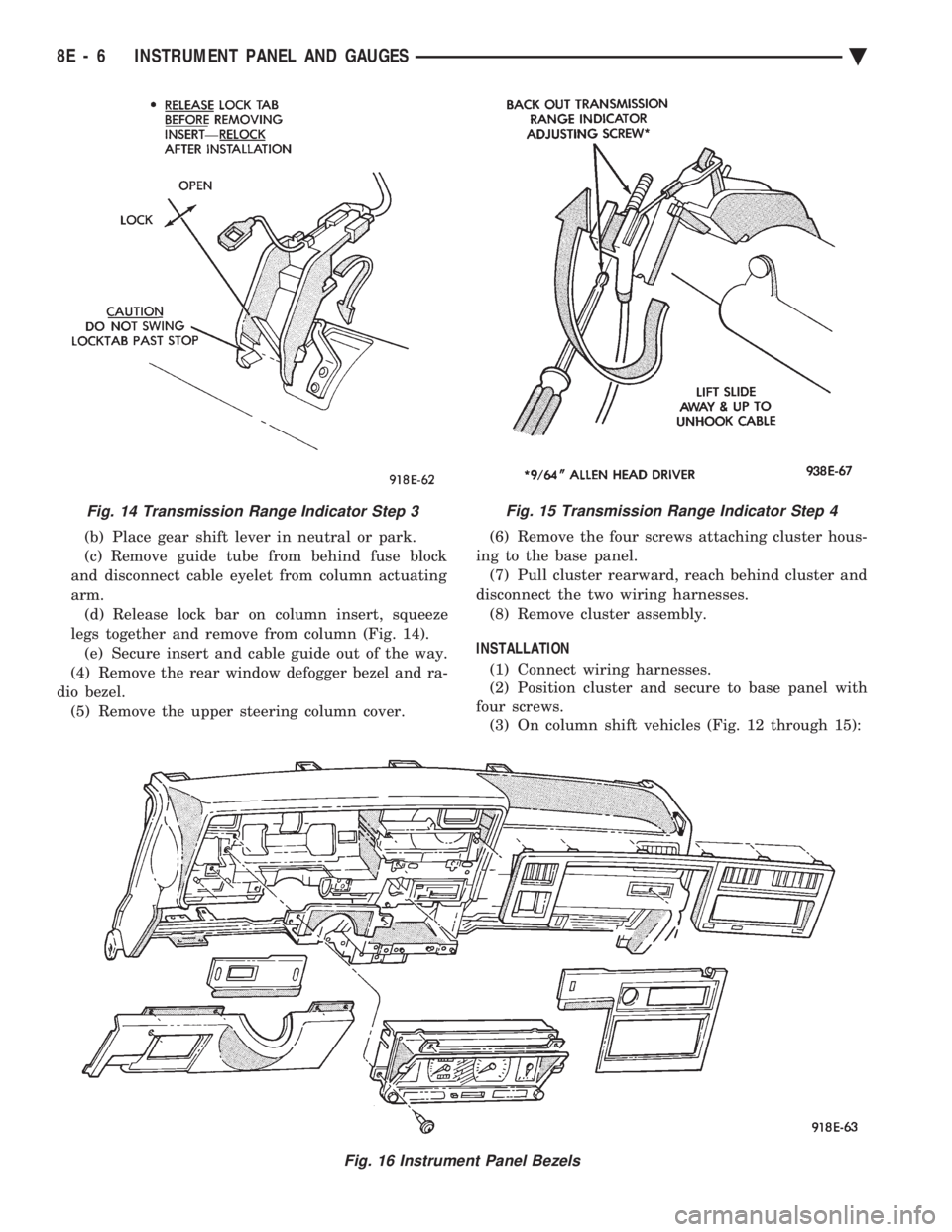

(a) Remove lower steering column cover (Fig.

16). Release guide tube from behind fuse block.

Fig. 10 Cluster Bezel

Fig. 11 Cluster Mask and Lens

Fig. 12 Transmission Range Indicator Step 1

Fig. 13 Transmission Range Indicator Step 2

Ä INSTRUMENT PANEL AND GAUGES 8E - 5

Page 498 of 2438

(b) Place gear shift lever in neutral or park.

(c) Remove guide tube from behind fuse block

and disconnect cable eyelet from column actuating

arm. (d) Release lock bar on column insert, squeeze

legs together and remove from column (Fig. 14). (e) Secure insert and cable guide out of the way.

(4) Remove the rear window defogger bezel and ra-

dio bezel. (5) Remove the upper steering column cover. (6) Remove the four screws attaching cluster hous-

ing to the base panel. (7) Pull cluster rearward, reach behind cluster and

disconnect the two wiring harnesses. (8) Remove cluster assembly.

INSTALLATION (1) Connect wiring harnesses.

(2) Position cluster and secure to base panel with

four screws. (3) On column shift vehicles (Fig. 12 through 15):

Fig. 15 Transmission Range Indicator Step 4

Fig. 16 Instrument Panel Bezels

Fig. 14 Transmission Range Indicator Step 3

8E - 6 INSTRUMENT PANEL AND GAUGES Ä