steering CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 263 of 2438

ANTI-LOCK BRAKE SYSTEMÐBENDIX ANTI-LOCK 6 AA,AG,AJ,AP BODY INDEX

page page

ABS Brake System Diagnosis .............. 123

ABS Brake System Diagnostic Features ...... 125

ABS Computer System Service Precautions . . . 124

ABS General Service Precautions ........... 124

Anti-Lock Brake System Components ........ 116

Anti-Lock Brake System Definitions .......... 113

Anti-Lock Brakes Operation and Performance . . 115

Anti-Lock System Relays and Warning Lamps . . 120

Controller Anti-Lock Brake (CAB) ............ 119

Diagnostic Connector ..................... 120

Electronic Components ................... 130 General Information

...................... 113

Hydraulic Circuits and Valve Operation ....... 121

Major Components ...................... 114

Mechanical Diagnostics and Service Procedures . 125

Normal Braking System Function ............ 114

On-Car ABS Brake System Service .......... 126

Specifications .......................... 135

System Self-Diagnostics .................. 115

Vehicle Performance ..................... 115

Warning Systems Operation ............... 116

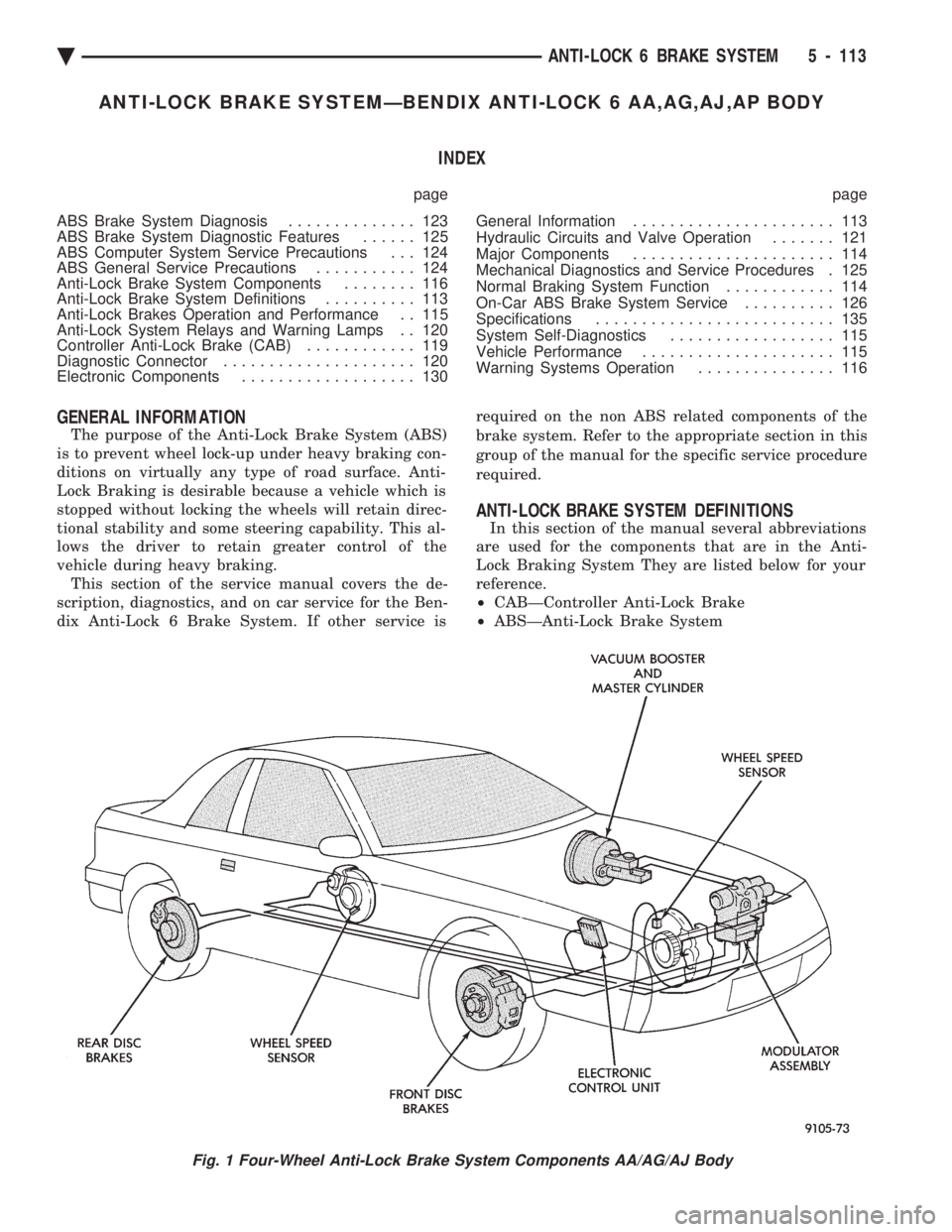

GENERAL INFORMATION

The purpose of the Anti-Lock Brake System (ABS)

is to prevent wheel lock-up under heavy braking con-

ditions on virtually any type of road surface. Anti-

Lock Braking is desirable because a vehicle which is

stopped without locking the wheels will retain direc-

tional stability and some steering capability. This al-

lows the driver to retain greater control of the

vehicle during heavy braking. This section of the service manual covers the de-

scription, diagnostics, and on car service for the Ben-

dix Anti-Lock 6 Brake System. If other service is required on the non ABS related components of the

brake system. Refer to the appropriate section in this

group of the manual for the specific service procedure

required.

ANTI-LOCK BRAKE SYSTEM DEFINITIONS

In this section of the manual several abbreviations

are used for the components that are in the Anti-

Lock Braking System They are listed below for your

reference.

² CABÐController Anti-Lock Brake

² ABSÐAnti-Lock Brake System

Fig. 1 Four-Wheel Anti-Lock Brake System Components AA/AG/AJ Body

Ä ANTI-LOCK 6 BRAKE SYSTEM 5 - 113

Page 265 of 2438

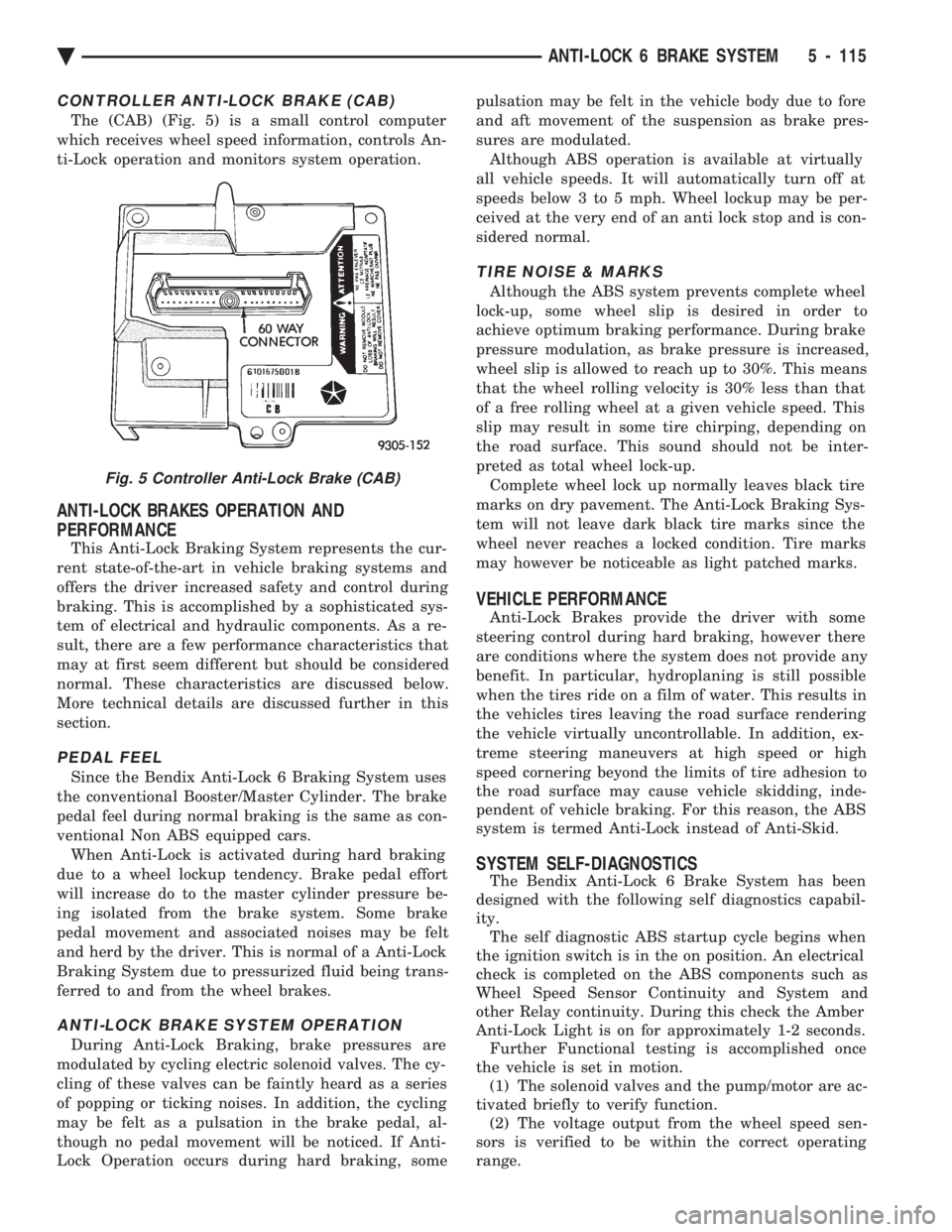

CONTROLLER ANTI-LOCK BRAKE (CAB)

The (CAB) (Fig. 5) is a small control computer

which receives wheel speed information, controls An-

ti-Lock operation and monitors system operation.

ANTI-LOCK BRAKES OPERATION AND

PERFORMANCE

This Anti-Lock Braking System represents the cur-

rent state-of-the-art in vehicle braking systems and

offers the driver increased safety and control during

braking. This is accomplished by a sophisticated sys-

tem of electrical and hydraulic components. As a re-

sult, there are a few performance characteristics that

may at first seem different but should be considered

normal. These characteristics are discussed below.

More technical details are discussed further in this

section.

PEDAL FEEL

Since the Bendix Anti-Lock 6 Braking System uses

the conventional Booster/Master Cylinder. The brake

pedal feel during normal braking is the same as con-

ventional Non ABS equipped cars. When Anti-Lock is activated during hard braking

due to a wheel lockup tendency. Brake pedal effort

will increase do to the master cylinder pressure be-

ing isolated from the brake system. Some brake

pedal movement and associated noises may be felt

and herd by the driver. This is normal of a Anti-Lock

Braking System due to pressurized fluid being trans-

ferred to and from the wheel brakes.

ANTI-LOCK BRAKE SYSTEM OPERATION

During Anti-Lock Braking, brake pressures are

modulated by cycling electric solenoid valves. The cy-

cling of these valves can be faintly heard as a series

of popping or ticking noises. In addition, the cycling

may be felt as a pulsation in the brake pedal, al-

though no pedal movement will be noticed. If Anti-

Lock Operation occurs during hard braking, some pulsation may be felt in the vehicle body due to fore

and aft movement of the suspension as brake pres-

sures are modulated.

Although ABS operation is available at virtually

all vehicle speeds. It will automatically turn off at

speeds below 3 to 5 mph. Wheel lockup may be per-

ceived at the very end of an anti lock stop and is con-

sidered normal.

TIRE NOISE & MARKS

Although the ABS system prevents complete wheel

lock-up, some wheel slip is desired in order to

achieve optimum braking performance. During brake

pressure modulation, as brake pressure is increased,

wheel slip is allowed to reach up to 30%. This means

that the wheel rolling velocity is 30% less than that

of a free rolling wheel at a given vehicle speed. This

slip may result in some tire chirping, depending on

the road surface. This sound should not be inter-

preted as total wheel lock-up. Complete wheel lock up normally leaves black tire

marks on dry pavement. The Anti-Lock Braking Sys-

tem will not leave dark black tire marks since the

wheel never reaches a locked condition. Tire marks

may however be noticeable as light patched marks.

VEHICLE PERFORMANCE

Anti-Lock Brakes provide the driver with some

steering control during hard braking, however there

are conditions where the system does not provide any

benefit. In particular, hydroplaning is still possible

when the tires ride on a film of water. This results in

the vehicles tires leaving the road surface rendering

the vehicle virtually uncontrollable. In addition, ex-

treme steering maneuvers at high speed or high

speed cornering beyond the limits of tire adhesion to

the road surface may cause vehicle skidding, inde-

pendent of vehicle braking. For this reason, the ABS

system is termed Anti-Lock instead of Anti-Skid.

SYSTEM SELF-DIAGNOSTICS

The Bendix Anti-Lock 6 Brake System has been

designed with the following self diagnostics capabil-

ity. The self diagnostic ABS startup cycle begins when

the ignition switch is in the on position. An electrical

check is completed on the ABS components such as

Wheel Speed Sensor Continuity and System and

other Relay continuity. During this check the Amber

Anti-Lock Light is on for approximately 1-2 seconds. Further Functional testing is accomplished once

the vehicle is set in motion. (1) The solenoid valves and the pump/motor are ac-

tivated briefly to verify function. (2) The voltage output from the wheel speed sen-

sors is verified to be within the correct operating

range.

Fig. 5 Controller Anti-Lock Brake (CAB)

Ä ANTI-LOCK 6 BRAKE SYSTEM 5 - 115

Page 268 of 2438

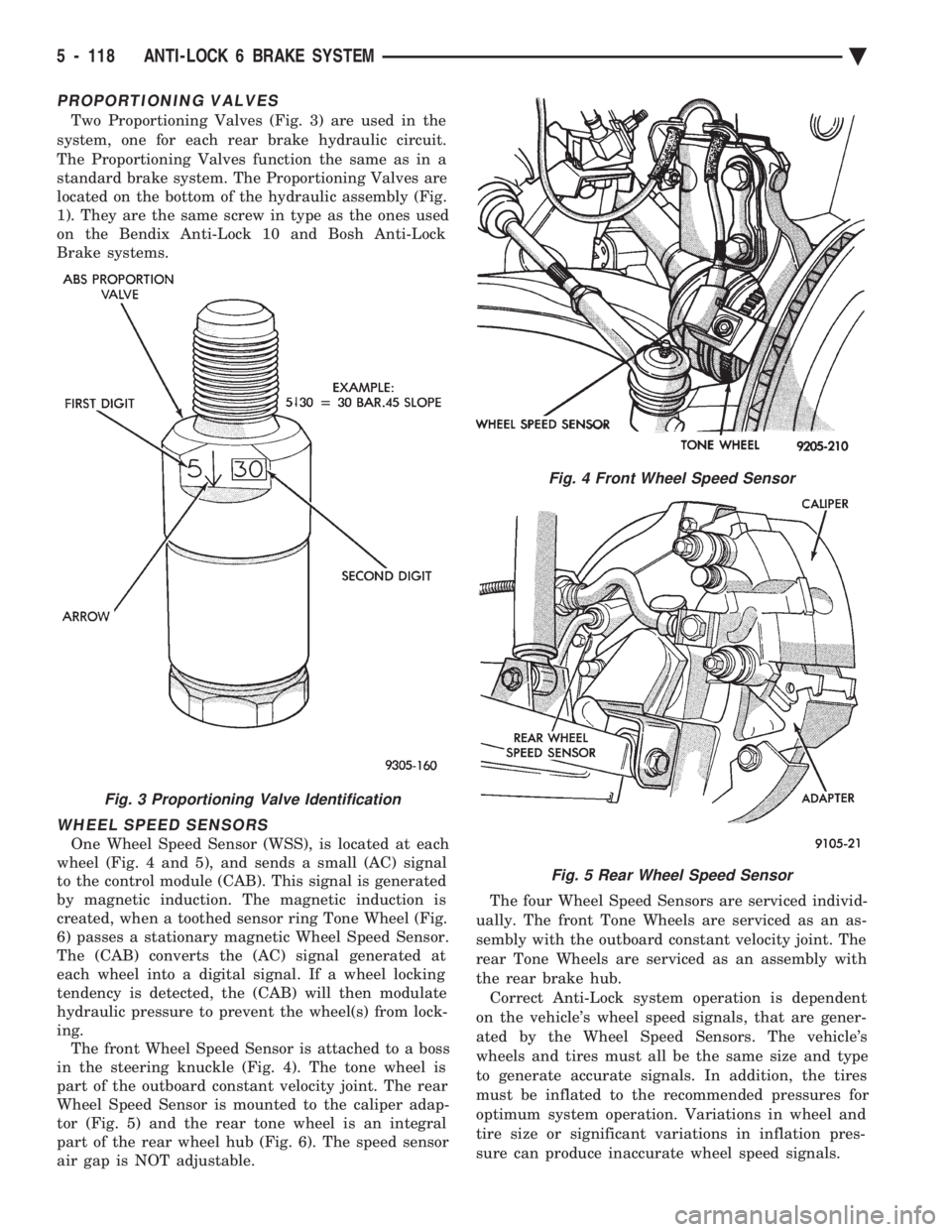

PROPORTIONING VALVES

Two Proportioning Valves (Fig. 3) are used in the

system, one for each rear brake hydraulic circuit.

The Proportioning Valves function the same as in a

standard brake system. The Proportioning Valves are

located on the bottom of the hydraulic assembly (Fig.

1). They are the same screw in type as the ones used

on the Bendix Anti-Lock 10 and Bosh Anti-Lock

Brake systems.

WHEEL SPEED SENSORS

One Wheel Speed Sensor (WSS), is located at each

wheel (Fig. 4 and 5), and sends a small (AC) signal

to the control module (CAB). This signal is generated

by magnetic induction. The magnetic induction is

created, when a toothed sensor ring Tone Wheel (Fig.

6) passes a stationary magnetic Wheel Speed Sensor.

The (CAB) converts the (AC) signal generated at

each wheel into a digital signal. If a wheel locking

tendency is detected, the (CAB) will then modulate

hydraulic pressure to prevent the wheel(s) from lock-

ing. The front Wheel Speed Sensor is attached to a boss

in the steering knuckle (Fig. 4). The tone wheel is

part of the outboard constant velocity joint. The rear

Wheel Speed Sensor is mounted to the caliper adap-

tor (Fig. 5) and the rear tone wheel is an integral

part of the rear wheel hub (Fig. 6). The speed sensor

air gap is NOT adjustable. The four Wheel Speed Sensors are serviced individ-

ually. The front Tone Wheels are serviced as an as-

sembly with the outboard constant velocity joint. The

rear Tone Wheels are serviced as an assembly with

the rear brake hub. Correct Anti-Lock system operation is dependent

on the vehicle's wheel speed signals, that are gener-

ated by the Wheel Speed Sensors. The vehicle's

wheels and tires must all be the same size and type

to generate accurate signals. In addition, the tires

must be inflated to the recommended pressures for

optimum system operation. Variations in wheel and

tire size or significant variations in inflation pres-

sure can produce inaccurate wheel speed signals.

Fig. 3 Proportioning Valve Identification

Fig. 4 Front Wheel Speed Sensor

Fig. 5 Rear Wheel Speed Sensor

5 - 118 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 270 of 2438

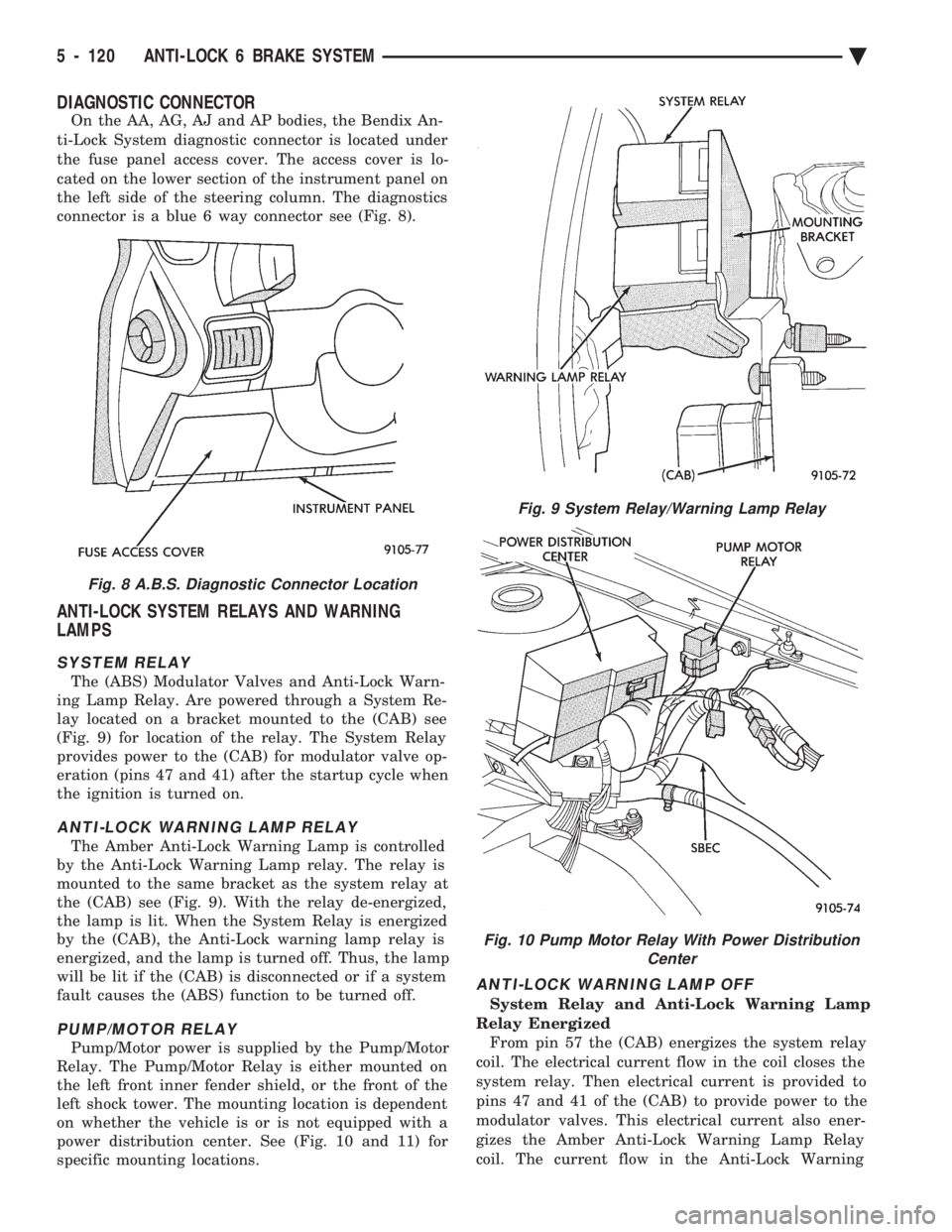

DIAGNOSTIC CONNECTOR

On the AA, AG, AJ and AP bodies, the Bendix An-

ti-Lock System diagnostic connector is located under

the fuse panel access cover. The access cover is lo-

cated on the lower section of the instrument panel on

the left side of the steering column. The diagnostics

connector is a blue 6 way connector see (Fig. 8).

ANTI-LOCK SYSTEM RELAYS AND WARNING

LAMPS

SYSTEM RELAY

The (ABS) Modulator Valves and Anti-Lock Warn-

ing Lamp Relay. Are powered through a System Re-

lay located on a bracket mounted to the (CAB) see

(Fig. 9) for location of the relay. The System Relay

provides power to the (CAB) for modulator valve op-

eration (pins 47 and 41) after the startup cycle when

the ignition is turned on.

ANTI-LOCK WARNING LAMP RELAY

The Amber Anti-Lock Warning Lamp is controlled

by the Anti-Lock Warning Lamp relay. The relay is

mounted to the same bracket as the system relay at

the (CAB) see (Fig. 9). With the relay de-energized,

the lamp is lit. When the System Relay is energized

by the (CAB), the Anti-Lock warning lamp relay is

energized, and the lamp is turned off. Thus, the lamp

will be lit if the (CAB) is disconnected or if a system

fault causes the (ABS) function to be turned off.

PUMP/MOTOR RELAY

Pump/Motor power is supplied by the Pump/Motor

Relay. The Pump/Motor Relay is either mounted on

the left front inner fender shield, or the front of the

left shock tower. The mounting location is dependent

on whether the vehicle is or is not equipped with a

power distribution center. See (Fig. 10 and 11) for

specific mounting locations.

ANTI-LOCK WARNING LAMP OFF

System Relay and Anti-Lock Warning Lamp

Relay Energized From pin 57 the (CAB) energizes the system relay

coil. The electrical current flow in the coil closes the

system relay. Then electrical current is provided to

pins 47 and 41 of the (CAB) to provide power to the

modulator valves. This electrical current also ener-

gizes the Amber Anti-Lock Warning Lamp Relay

coil. The current flow in the Anti-Lock Warning

Fig. 8 A.B.S. Diagnostic Connector Location

Fig. 9 System Relay/Warning Lamp Relay

Fig. 10 Pump Motor Relay With Power Distribution Center

5 - 120 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 276 of 2438

As soon as the condition goes away, the Anti-Lock

Warning Light is turned off. Although a fault code

will be set in most cases.

BENDIX ABS SYSTEMS DIAGNOSTICS

Bendix Anti-Lock 6 Brake System Diagnostics, be-

yond basic mechanical diagnostics, covered earlier in

this section. Are accomplished by using the DRB II

scan tool. See testing procedures outlined in the Ben-

dix Anti-Lock 6 Diagnostics Manual for the 1992

M.Y. vehicles. Please refer to the above mentioned manual for

any further electronic diagnostics and service proce-

dures that are required on the Bendix Anti-Lock 6

Brake System.

ON-CAR ABS BRAKE SYSTEM SERVICE

GENERAL SERVICE PRECAUTIONS

The following are general cautions which should be

observed when servicing the Anti-Lock brake system

and/or other vehicle systems. Failure to observe

these precautions may result in Anti-Lock Brake

System component damage. If welding work is to be performed on the vehicle,

using an electric arc welder, the (CAB) connector

should be disconnected during the welding operation. The (CAB) connector should never be connected or

disconnected with the ignition switch in the ON po-

sition. Many components of the Anti-Lock Brake System

are not serviceable and must be replaced as an as-

sembly. Do not disassemble any component which is

not designed to be serviced.

CHECKING BRAKE FLUID LEVEL

CAUTION: Only use brake fluid conforming to DOT

3 specifications, such as Mopar or Equivalent. Do

not use any fluid which contains a petroleum base.

Do not use a container which has been used for pe-

troleum based fluids or a container which is wet

with water. Petroleum based fluids will cause swell-

ing and distortion of rubber parts in the hydraulic

brake system. Water will mix with brake fluid, low-

ering the fluid boiling point. Keep all brake fluid

containers capped to prevent contamination. Re-

move the front cap of the master cylinder reservoir

and fill to the bottom of the split ring.

For the specific procedure for the inspection of

brake fluid level and adding of brake to the reser-

voir. Refer to the Service Adjustments Section in this

group of the service manual.

BLEEDING BENDIX ANTI-LOCK 6 BRAKE SYSTEM

The Anti-Lock Brake System must be bled anytime

air is permitted to enter the hydraulic system, due to

disconnection of brake lines, hoses of components. If the Modulator Assembly is removed from the ve-

hicle, both the Base Brake System and the Anti-Lock

Brake System must be bled using the appropriate

procedures. It is important to note that excessive air

in the brake system will cause a soft or spongy feel-

ing brake pedal. During bleeding operations, be sure that the brake

fluid level remains close to the FULL level in the

reservoir. Check the fluid level periodically during

the bleeding procedure and add DOT 3 brake fluid as

required. The Bendix Anti-Lock 6 Brake System must be

bled as two independent braking systems. The non

ABS portion of the brake system is to be bled the

same as any non ABS system. Refer to the Service

Adjustments section in this manual for the proper

bleeding procedure to be used. This brake system can

be either pressure bled or manually bled. The Anti-Lock portion of brake system MUST be

bled separately. This bleeding procedure requires the

use of the DRB II Diagnostic tester and the bleeding

sequence procedure outlined below.

ABS BLEEDING PROCEDURE (FIG. 1)

(1) Assemble and install all brake system compo-

nents on vehicle making sure all hydraulic fluid

lines are installed and properly torqued. (2) Bleed the base brake system. Using the stan-

dard pressure or manual bleeding procedure as out-

lined in the Service Adjustments section of this

service manual. To perform the bleeding procedure on the ABS

unit. The battery and acid shield must be removed

from the vehicle. Reconnect the vehicles battery, to

the vehicles positive and negative battery cables us-

ing jumper cables. This is necessary to allow access

to the 4 bleeder screws located on the top of the Mod-

ulator assembly. (3) Connect the DRB II Diagnostics Tester to the

diagnostics connector. Located behind the Fuse Panel

access cover on the lower section of the dash panel to

the left of the steering column. (It is a blue 6 way

connector). (4) Using the DRB II check to make sure the

(CAB) does not have any fault codes stored. If it does

remove them using the DRB II.

5 - 126 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 282 of 2438

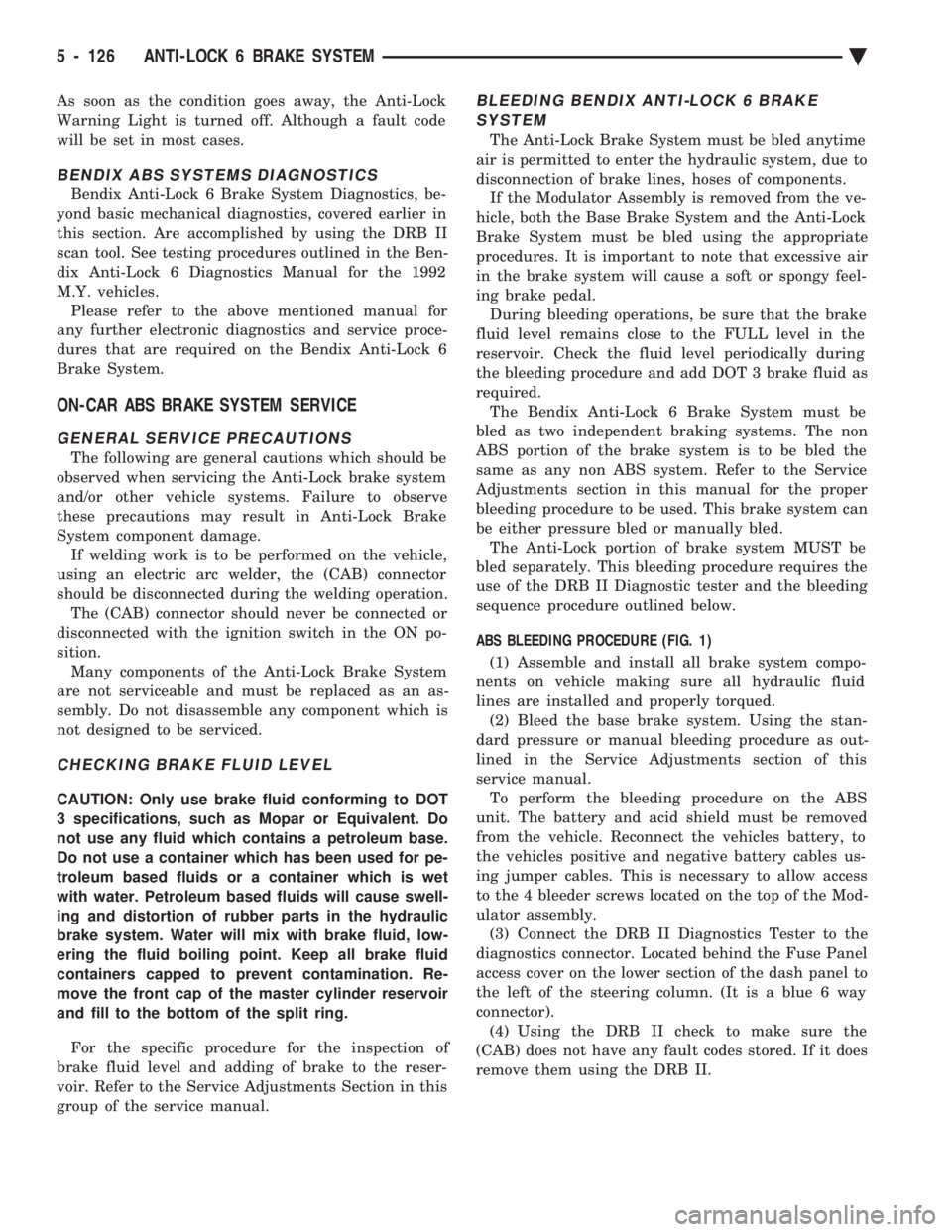

REMOVE/INSTALL PUMP MOTOR RELAY

Find the location of the Pump Motor Relay (Fig. 10

& 11), depending on whether the vehicle has or does

not have a Power Distribution Center.

(1) Hold the relay with one hand. While pulling

the relay connector strait off the relay terminals. (2) Remove the relay from the vehicle.

(3) Installation is done in the reverse order off re-

moval. Be sure that the wiring harness connector is

fully seated onto the terminals of the Pump Motor

Relay.

WHEEL SPEED SENSORS

INSPECTION

Inspect tonewheel for missing or broken teeth, this

can cause erratic sensor signals. Tonewheel should show no evidence of contact with

the wheel speed sensor. If contact was made, deter-

mine cause and correct. Excessive runout of the tonewheel can cause er-

ratic wheel speed sensor. Replace assembly if runout

exceeds approximately 0.25 mm (0.010 inch).

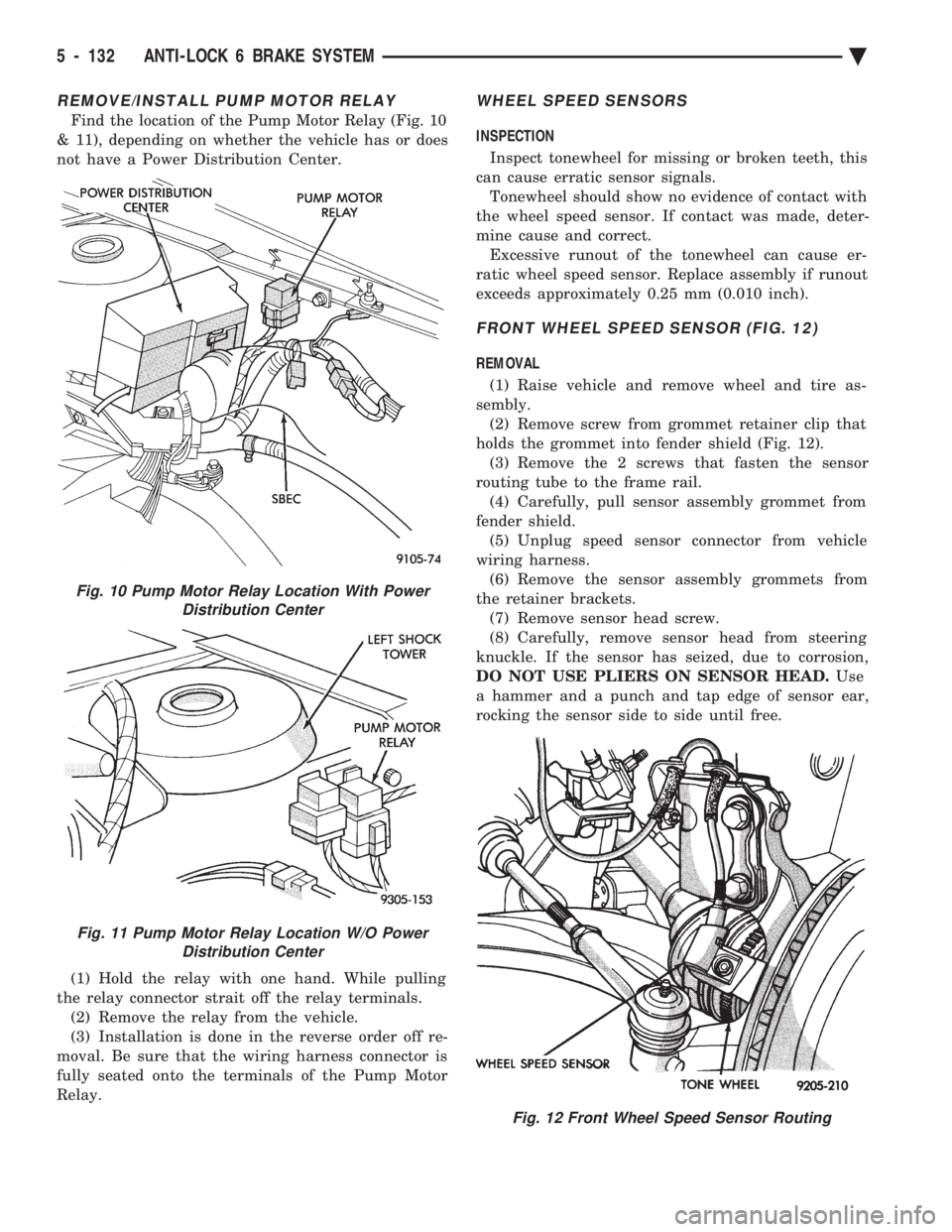

FRONT WHEEL SPEED SENSOR (FIG. 12)

REMOVAL

(1) Raise vehicle and remove wheel and tire as-

sembly. (2) Remove screw from grommet retainer clip that

holds the grommet into fender shield (Fig. 12). (3) Remove the 2 screws that fasten the sensor

routing tube to the frame rail. (4) Carefully, pull sensor assembly grommet from

fender shield. (5) Unplug speed sensor connector from vehicle

wiring harness. (6) Remove the sensor assembly grommets from

the retainer brackets. (7) Remove sensor head screw.

(8) Carefully, remove sensor head from steering

knuckle. If the sensor has seized, due to corrosion,

DO NOT USE PLIERS ON SENSOR HEAD. Use

a hammer and a punch and tap edge of sensor ear,

rocking the sensor side to side until free.

Fig. 10 Pump Motor Relay Location With Power Distribution Center

Fig. 11 Pump Motor Relay Location W/O PowerDistribution Center

Fig. 12 Front Wheel Speed Sensor Routing

5 - 132 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 283 of 2438

INSTALLATION (1) Connect the wheel speed sensor connector to

the wiring harness. (2) Push sensor assembly grommet into hole in

fender shield. Install clip and screw. (3) Install the 2 screws that fasten the speed sen-

sor routing tube to the frame rail. (4) Install sensor grommets in brackets on fender

shield and strut damper. (5) Coat the speed sensor with High Temperature

Multi-purpose E.P. Grease before installing into the

steering knuckle. Install screw tighten to 7 N Im (60

in. lbs.)

CAUTION: Proper installation of wheel speed sen-

sor cables is critical to continued system operation.

Be sure that cables are installed in retainers. Fail-

ure to install cables in retainers, as shown in this

section, may result in contact with moving parts

and/or over extension of cables, resulting in an

open circuit.

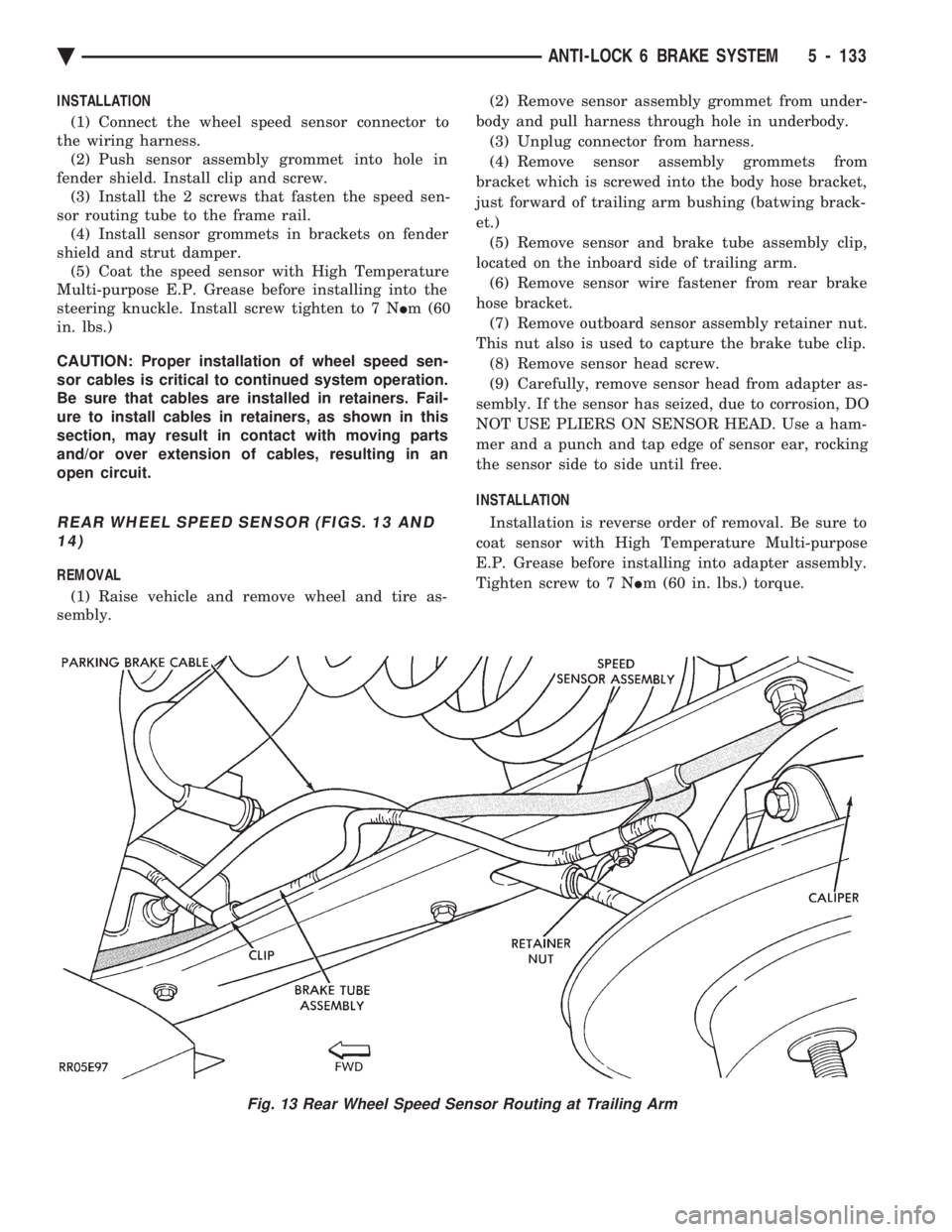

REAR WHEEL SPEED SENSOR (FIGS. 13 AND 14)

REMOVAL

(1) Raise vehicle and remove wheel and tire as-

sembly. (2) Remove sensor assembly grommet from under-

body and pull harness through hole in underbody. (3) Unplug connector from harness.

(4) Remove sensor assembly grommets from

bracket which is screwed into the body hose bracket,

just forward of trailing arm bushing (batwing brack-

et.) (5) Remove sensor and brake tube assembly clip,

located on the inboard side of trailing arm. (6) Remove sensor wire fastener from rear brake

hose bracket. (7) Remove outboard sensor assembly retainer nut.

This nut also is used to capture the brake tube clip. (8) Remove sensor head screw.

(9) Carefully, remove sensor head from adapter as-

sembly. If the sensor has seized, due to corrosion, DO

NOT USE PLIERS ON SENSOR HEAD. Use a ham-

mer and a punch and tap edge of sensor ear, rocking

the sensor side to side until free.

INSTALLATION Installation is reverse order of removal. Be sure to

coat sensor with High Temperature Multi-purpose

E.P. Grease before installing into adapter assembly.

Tighten screw to 7 N Im (60 in. lbs.) torque.

Fig. 13 Rear Wheel Speed Sensor Routing at Trailing Arm

Ä ANTI-LOCK 6 BRAKE SYSTEM 5 - 133

Page 298 of 2438

BENDIX ANTILOCK 4 BRAKE SYSTEM INDEX

page page

ABS Brake System Diagnostic Features ....... 24

ABS Computer System Service Precautions .... 23

ABS General Service Precautions ............ 23

Antilock Brake System Components .......... 16

Antilock Brake System Definitions ............ 14

Antilock Brakes Operation and Performance .... 15

Antilock System Relays and Warning Lamps .... 19

Bendix Antilock 4 Brake System Diagnostics .... 22

Bleeding Bendix Antilock 4 Brake System ...... 25

Controller Antilock Brake Cab ............... 18

Diagnostic Connector ..................... 19 Electronic Components

.................... 41

General Information ....................... 12

Hydraulic Circuits and Valve Operation ........ 20

Major Components ....................... 14

Mechanical Diagnostics and Service Procedures . 24

Normal Brake System Function .............. 14

On-Car ABS Brake System Service ........... 25

Specifications ........................... 46

System Self-Diagnostics ................... 15

Vehicle Performance ...................... 15

Warning Systems Operation ................ 16

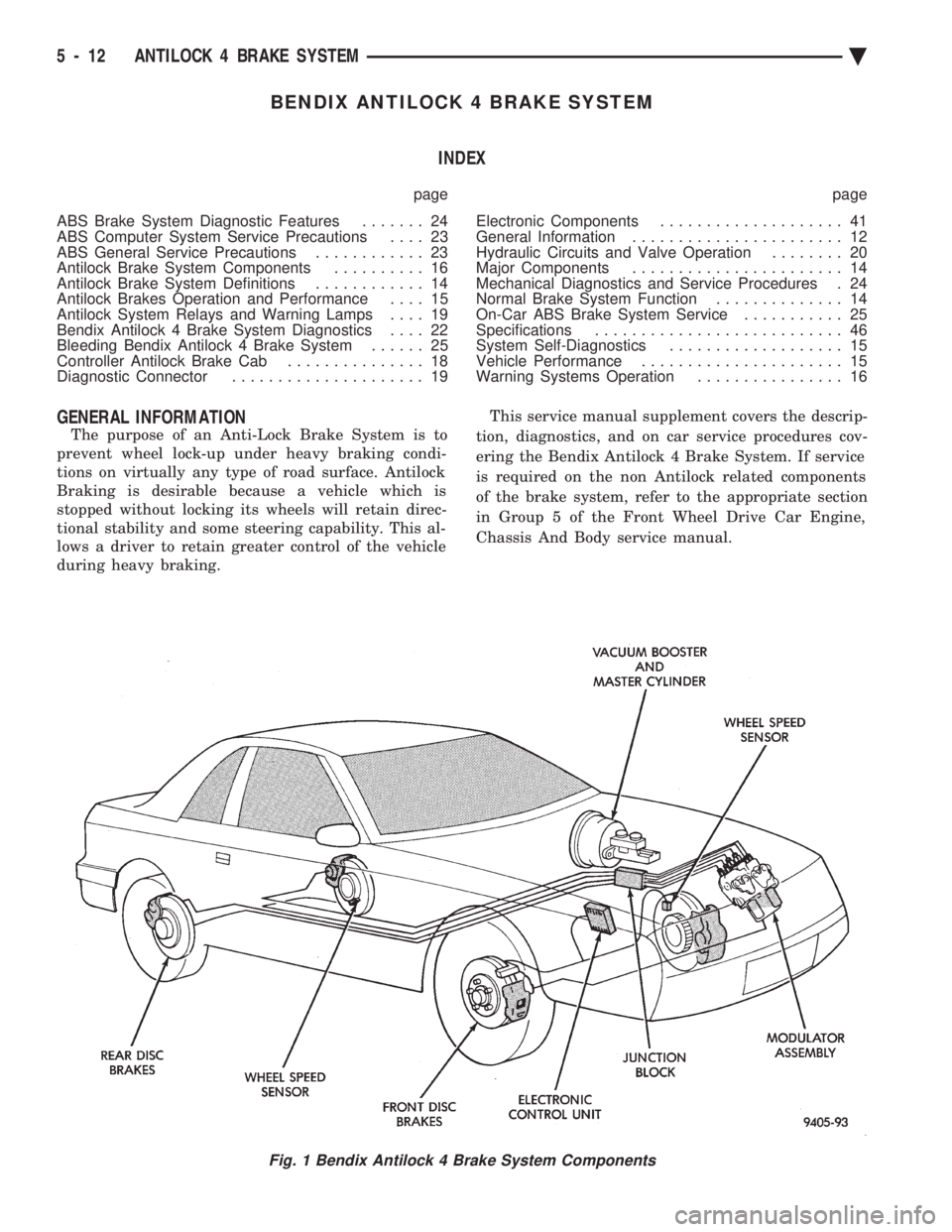

GENERAL INFORMATION

The purpose of an Anti-Lock Brake System is to

prevent wheel lock-up under heavy braking condi-

tions on virtually any type of road surface. Antilock

Braking is desirable because a vehicle which is

stopped without locking its wheels will retain direc-

tional stability and some steering capability. This al-

lows a driver to retain greater control of the vehicle

during heavy braking. This service manual supplement covers the descrip-

tion, diagnostics, and on car service procedures cov-

ering the Bendix Antilock 4 Brake System. If service

is required on the non Antilock related components

of the brake system, refer to the appropriate section

in Group 5 of the Front Wheel Drive Car Engine,

Chassis And Body service manual.

Fig. 1 Bendix Antilock 4 Brake System Components

5 - 12 ANTILOCK 4 BRAKE SYSTEM Ä

Page 301 of 2438

ANTILOCK BRAKES OPERATION AND

PERFORMANCE

The Bendix Antilock 4 Brake System represents

the current state-of-the-art in vehicle brake systems

and offers the driver increased safety and control

during braking. This is accomplished by a sophisti-

cated system of electrical and hydraulic components.

As a result, there are a few performance characteris-

tics that may at first seem different but should be

considered normal. These characteristics are dis-

cussed below. More technical details are discussed

further in this section.

PEDAL FEEL

Since the Bendix Antilock 4 Brake System uses the

vehicle's conventional brake system power booster

and master cylinder. The brake pedal feel during

normal braking is the same as on a conventional

Non ABS equipped vehicle. When the Antilock system becomes activated dur-

ing hard braking due to a wheel lockup tendency.

The brake pedal effort will increase do to the master

cylinder pressure being isolated from the brake sys-

tem. Some brake pedal movement and associated

noises may be felt and heard by the driver. This is

normal operation of the Bendix Antilock 4 Brake

System due to pressurized brake fluid being trans-

ferred to and from the wheel brakes.

ANTILOCK BRAKE SYSTEM OPERATION

During Antilock Brake system operation, brake

pressures are modulated by cycling electric solenoid

valves. The cycling of these valves can be heard as a

series of popping or ticking noises. In addition, the

cycling may be felt as a pulsation in the brake pedal.

If Antilock operation occurs during a hard applica-

tion of the brakes, some pulsation may be felt in the

vehicle body due to fore and aft movement of vehicle

suspension components. Although ABS operation is available at virtually

all vehicle speeds, it will automatically turn off at

speeds below 3 to 5 mph. Wheel lockup may be per-

ceived at the very end of an anti lock stop and is con-

sidered normal.

TIRE NOISE & MARKS

Although the ABS system prevents complete wheel

lock-up, some wheel slip is desired in order to

achieve optimum vehicle braking performance. During brake fluid pressure modulation, as the

brake fluid pressure is increased, wheel slip is al-

lowed to reach up to 30%. This means that wheel

rolling speed is 30% less than that of a free rolling

wheel at a given vehicle speed. This slip may result

in some tire chirping, depending on the road surface.

This sound should not be interpreted as total wheel

lock-up. Complete wheel lock up normally leaves black tire

marks on dry pavement. The Antilock Brake System

will not leave dark black tire marks since the wheel

never reaches a locked condition. Tire marks may

however be noticeable as light patched marks.

VEHICLE PERFORMANCE

Antilock Brakes provide the driver with some

steering control during hard braking, however there

are conditions where the system does not provide any

benefit. In particular, hydroplaning is still possible

when the tires ride on a film of water. This results in

the vehicles tires leaving the road surface rendering

the vehicle virtually uncontrollable. In addition, ex-

treme steering maneuvers at high speed or high

speed cornering beyond the limits of tire adhesion to

the road surface may cause vehicle skidding, inde-

pendent of vehicle braking. For this reason, the ABS

system is termed Antilock instead of Anti-Skid.

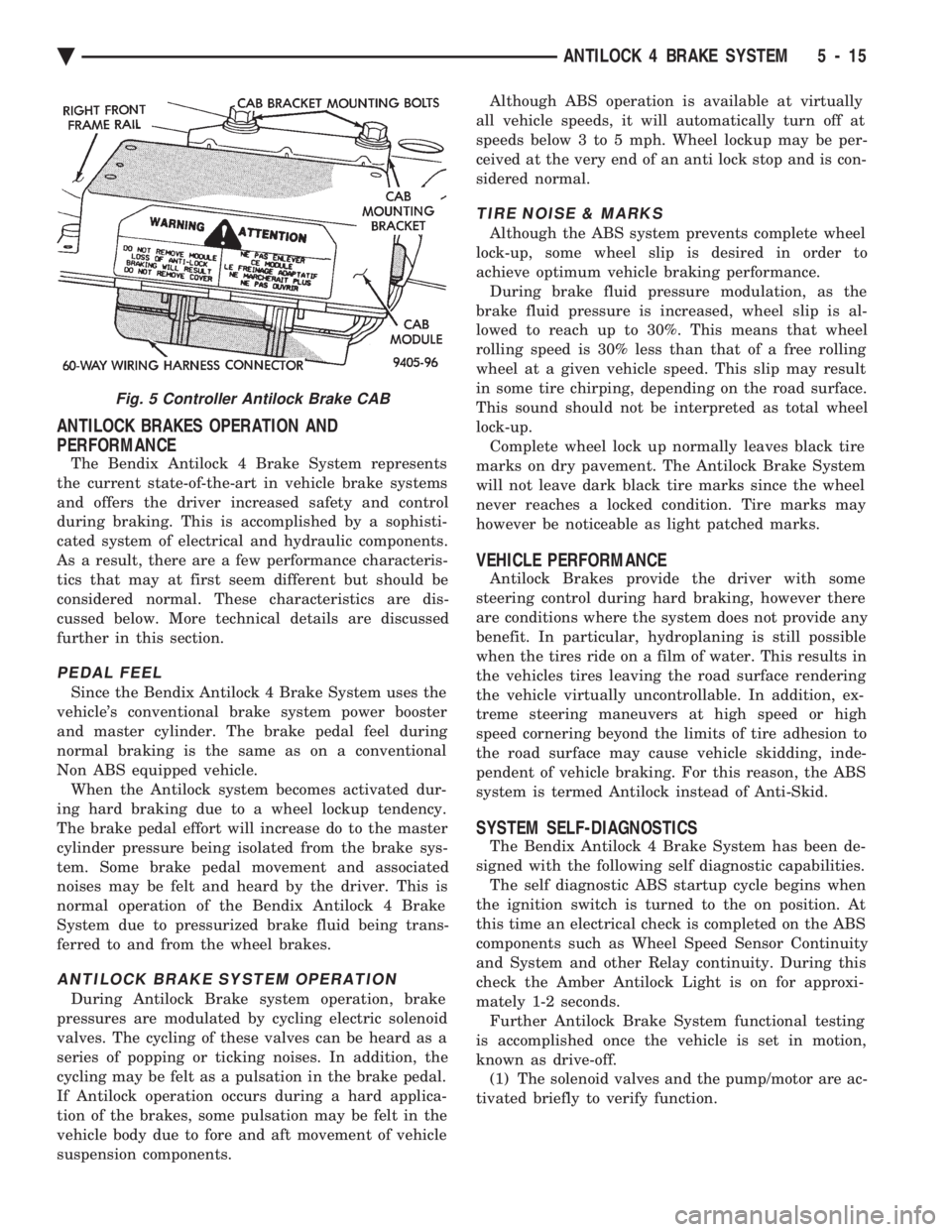

SYSTEM SELF-DIAGNOSTICS

The Bendix Antilock 4 Brake System has been de-

signed with the following self diagnostic capabilities. The self diagnostic ABS startup cycle begins when

the ignition switch is turned to the on position. At

this time an electrical check is completed on the ABS

components such as Wheel Speed Sensor Continuity

and System and other Relay continuity. During this

check the Amber Antilock Light is on for approxi-

mately 1-2 seconds. Further Antilock Brake System functional testing

is accomplished once the vehicle is set in motion,

known as drive-off. (1) The solenoid valves and the pump/motor are ac-

tivated briefly to verify function.

Fig. 5 Controller Antilock Brake CAB

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 15

Page 304 of 2438

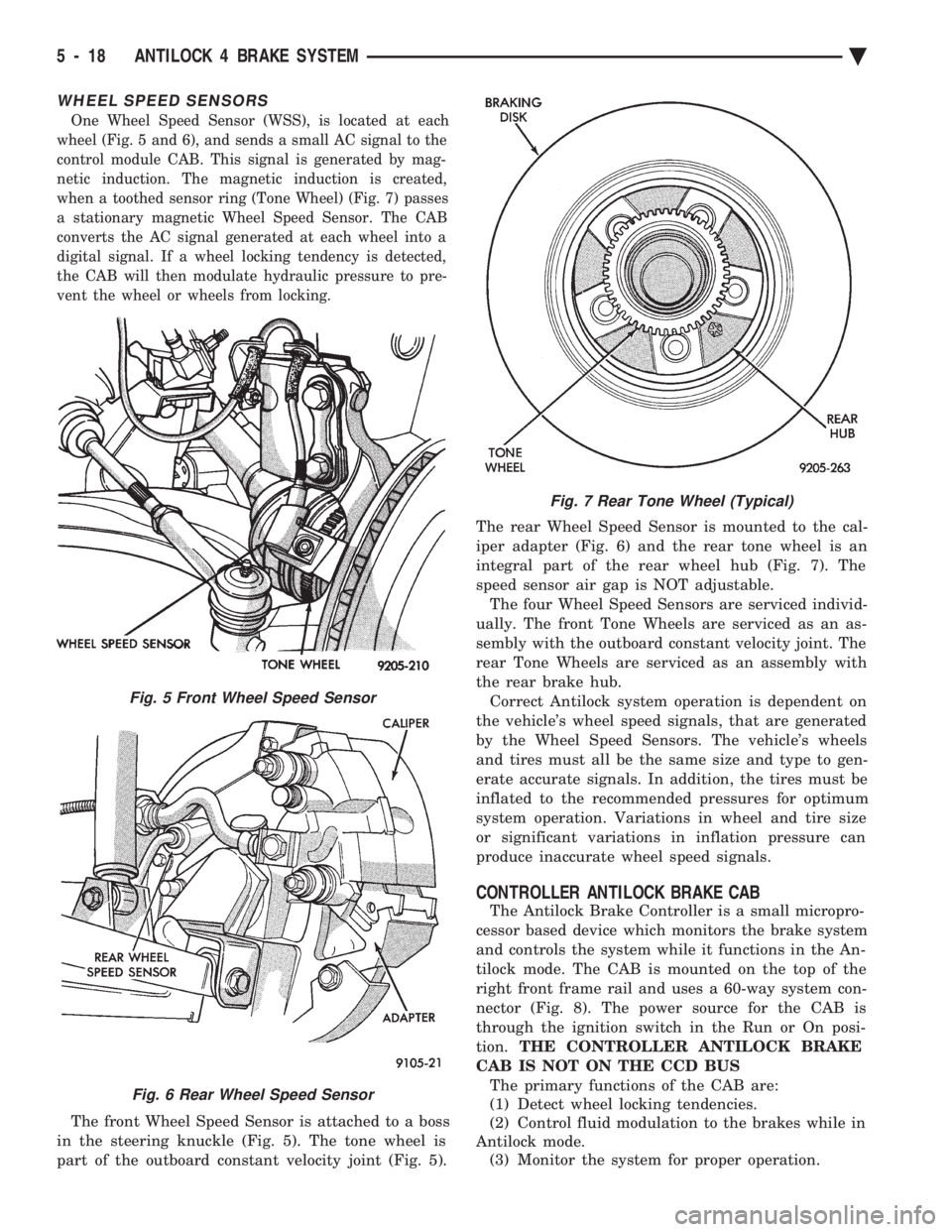

WHEEL SPEED SENSORS

One Wheel Speed Sensor (WSS), is located at each

wheel (Fig. 5 and 6), and sends a small AC signal to the

control module CAB. This signal is generated by mag-

netic induction. The magnetic induction is created,

when a toothed sensor ring (Tone Wheel) (Fig. 7) passes

a stationary magnetic Wheel Speed Sensor. The CAB

converts the AC signal generated at each wheel into a

digital signal. If a wheel locking tendency is detected,

the CAB will then modulate hydraulic pressure to pre-

vent the wheel or wheels from locking.

The front Wheel Speed Sensor is attached to a boss

in the steering knuckle (Fig. 5). The tone wheel is

part of the outboard constant velocity joint (Fig. 5). The rear Wheel Speed Sensor is mounted to the cal-

iper adapter (Fig. 6) and the rear tone wheel is an

integral part of the rear wheel hub (Fig. 7). The

speed sensor air gap is NOT adjustable.

The four Wheel Speed Sensors are serviced individ-

ually. The front Tone Wheels are serviced as an as-

sembly with the outboard constant velocity joint. The

rear Tone Wheels are serviced as an assembly with

the rear brake hub. Correct Antilock system operation is dependent on

the vehicle's wheel speed signals, that are generated

by the Wheel Speed Sensors. The vehicle's wheels

and tires must all be the same size and type to gen-

erate accurate signals. In addition, the tires must be

inflated to the recommended pressures for optimum

system operation. Variations in wheel and tire size

or significant variations in inflation pressure can

produce inaccurate wheel speed signals.

CONTROLLER ANTILOCK BRAKE CAB

The Antilock Brake Controller is a small micropro-

cessor based device which monitors the brake system

and controls the system while it functions in the An-

tilock mode. The CAB is mounted on the top of the

right front frame rail and uses a 60-way system con-

nector (Fig. 8). The power source for the CAB is

through the ignition switch in the Run or On posi-

tion. THE CONTROLLER ANTILOCK BRAKE

CAB IS NOT ON THE CCD BUS The primary functions of the CAB are:

(1) Detect wheel locking tendencies.

(2) Control fluid modulation to the brakes while in

Antilock mode. (3) Monitor the system for proper operation.

Fig. 5 Front Wheel Speed Sensor

Fig. 6 Rear Wheel Speed Sensor

Fig. 7 Rear Tone Wheel (Typical)

5 - 18 ANTILOCK 4 BRAKE SYSTEM Ä