wiring CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 30 of 2438

GROUP TAB LOCATOR

GENERAL INFORMATION

FUSE CHARTS AND RELAY BANKS

WIRING AND COMPONENT

IDENTIFICATION

SPLICE LOCATIONS

AA-C, D, P WIRING DIAGRAMS

AC-C, D/AY-C WIRING DIAGRAMS

AG-D, AJ-C WIRING DIAGRAMS

AP-P, D WIRING DIAGRAMS

Service Manual Comment Forms (Rear of Manual)

Page 36 of 2438

BLEEDING BENDIX ANTILOCK 4 BRAKE SYSTEM......5-3

BASE BRAKE SYSTEM BLEEDING PROCEDURE.........5-3

MASTER CYLINDER FLUID LEVEL................5-3

TESTING FOR FLUID CONTAMINATION.............5-4 WIRING DIAGRAMS AA-BODY

..................8W-1

INDEX...............................8W-1

WIRING DIAGRAMS AJ BODY ..................8W-8

ALPHABETICAL INDEX.....................8W-8

Page 117 of 2438

AUTOMATIC AIR LOAD LEVELING SYSTEM INDEX

page page

Compressor Performance Test .............. 61

Compressor Relay ........................ 72

Control Module .......................... 72

General Information ....................... 59

Major Components ....................... 59 Rear Leveling Diagnostic Procedures

......... 65

Right Shock Absorber (With Height Sensor) .... 72

Service Procedures ....................... 62

System Operation ........................ 61

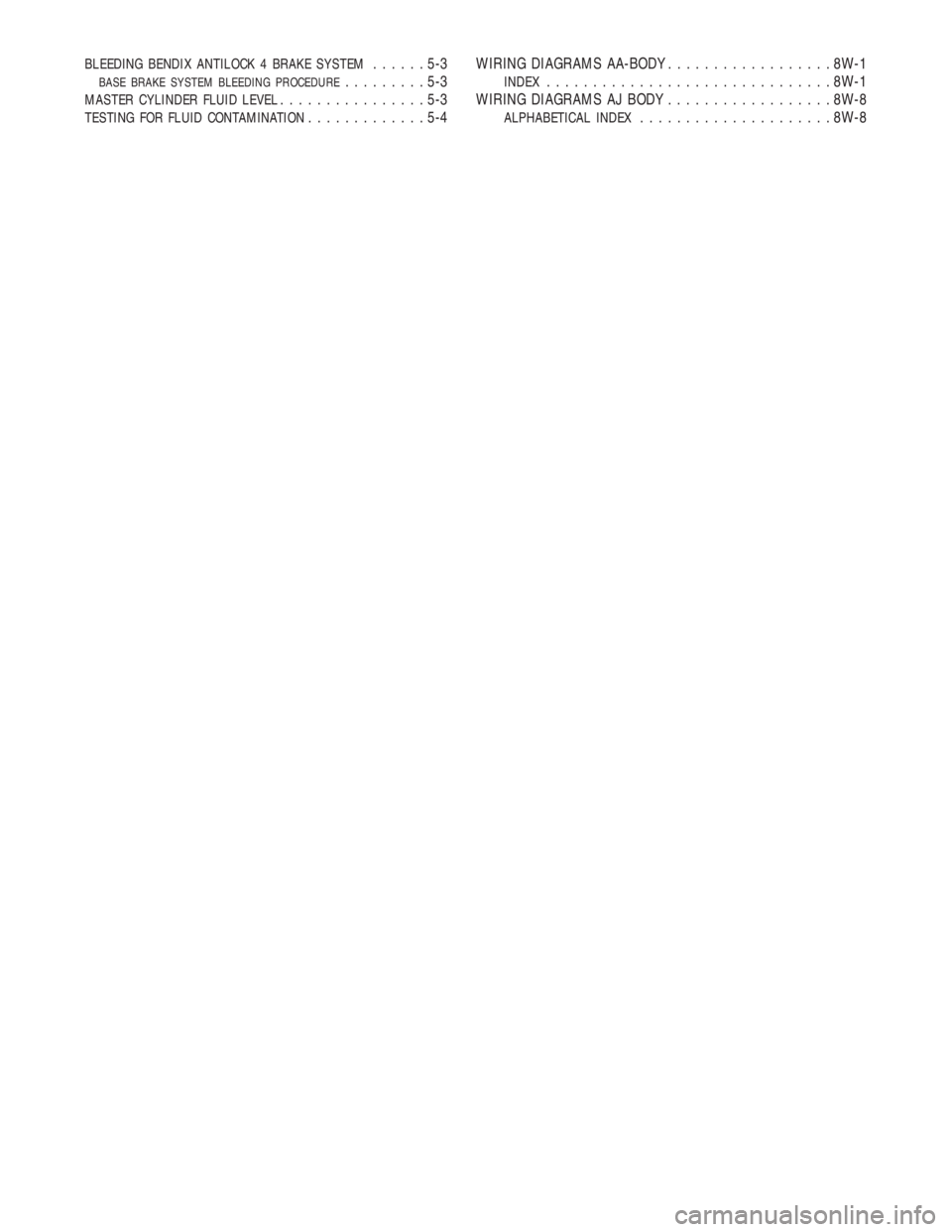

GENERAL INFORMATION

The automatic air load leveling system includes

the following (Fig. 1).:

² Compressor Assembly

² Control Module Wiring Harness

² Air Lines

² Compressor Relay

² Air Shock Absorbers

² Air Dryer

This system is used to supplement standard sus-

pension systems on vehicles so equipped.

MAJOR COMPONENTS

COMPRESSOR ASSEMBLY

The compressor assembly is driven by an electric

motor and supplies air pressure between 1172 to

1516 kPa (170 to 220 psi) (Fig. 2). A solenoid oper-

ated exhaust valve, located in the compressor head

assembly, releases air when energized.

CONTROL MODULE

The Control Module (CM) is a device that controls

the ground circuits for the compressor relay and the

exhaust valve solenoid. A microprocessor within the

module limits the compressor pump operation time to

140 to 160 seconds. To prevent damage to the com-

pressor motor.

Fig. 1 Automatic Air Load Leveling System

Ä SUSPENSION AND DRIVESHAFTS 2 - 59

Page 119 of 2438

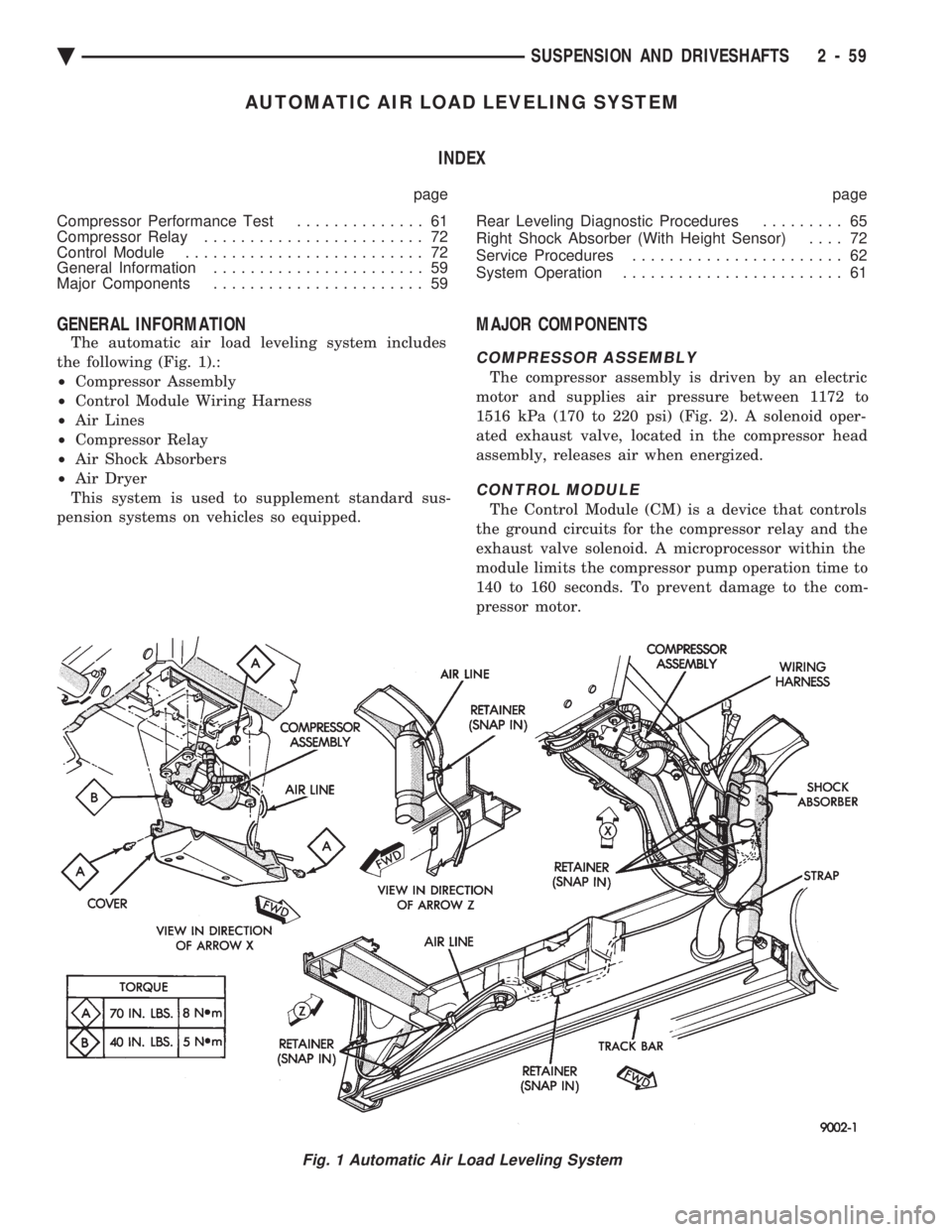

A compression ball sleeve nut and sleeve for 3/16

inch tubing with ball sleeve connector and an inter-

nal pipe T-fitting. Can be used to attach the tubing

to the pressure gauge. (3) Cycle ignition from OFF to ON.

(4) Apply a load to the rear of the vehicle (two as-

sistants or approximately 300-325 lbs.) to run com-

pressor and raise the vehicle. (5) Remove the load applied in Step 4. Allow the

system to exhaust and lower the vehicle. (6) When no more air can be exhausted, the gauge

should indicate 69 to 152 kPa (10 to 22 psi). (7) Remove the pressure gauge and nylon tubing.

Attach the air line between the dryer and shock ab-

sorber. Repeat Steps 3, 4, and 5 to ensure system air

pressure is in the shocks.

LEAK CHECKS

(1) Repeat Residual Air Check Steps 1, 2, 3, and 4.

Allow the system to fill until gauge reads 483 to 621

kPa (70 to 90 psi). If compressor is permitted to run until it reaches

its maximum output pressure, the vent solenoid

valve will function as a relief valve. The resulting

leak down, when compressor shuts off, will indicate a

false air leak. (2) With load still applied, disconnect wire harness

connector from the control module, then remove ap-

plied load. Vehicle should rise. Cycle ignition switch

to OFF. (3) Observe if pressure leaks down or holds steady

(wait approximately 15 minutes). (A) If system will not inflate beyond 345 kPa (50

psi). A severe leak may be indicated. Check for a

pinched pressure line between compressor and

shocks. (B) The standard soap solution check procedure is

acceptable. (C) If pressure holds steady, perform the diagnosis

procedures.

SYSTEM OPERATION

RAISING VEHICLE HEIGHT

When weight is added to the rear suspension. The

body of the vehicle is lowered, moving the height

sensor down. This action will activate the internal time delay

circuit. After a time delay of 12 to 18 seconds. The

control module (CM) activates the ground circuit to

the compressor relay. With the relay energized, the compressor motor

runs and air is sent through the system. As the

shock absorbers inflate, the body moves upward to a

corrected position. When the body reaches the correct

height, the control module (CM) stops the compressor

operation.

LOWERING VEHICLE HEIGHT

When the weight is removed from the vehicle. The

body moves upward, which allows the height sensor

to move upward and activate the internal time delay

circuit. After a time delay of 12 to 18 seconds. The (CM)

activates the exhaust solenoid circuit. Air is ex-

hausted from the shock absorbers through the air

dryer and exhaust solenoid to the atmosphere. As the body lowers, the height sensor is lowered to-

ward its original position. When the body reaches the

original vehicle height, the (CM) opens the exhaust

solenoid valve circuit.

COMPRESSOR PERFORMANCE TEST

This test can be performed on the vehicle. It is

used to evaluate compressor current draw, pressure

output, and leak down. (1) Disconnect the compressor motor wiring har-

ness connector. (2) Disconnect air line between dryer and right

shock absorber. (3) Connect an air pressure gauge into the system

(Fig. 5). (4) Connect an ammeter in series between the red

wire terminal on compressor connector and a 12 volt

power source. Also, connect a ground wire from the

black wire terminal on the compressor connector to a

good ground on the frame (Fig. 6). (5) If the current draw to the compressor motor ex-

ceeds 21 amperes, replace the compressor assembly. (6) When the air pressure stabilizes at 827 kPa

(120 psi), disconnect the (+) wire lead from the con-

nector. Replace the compressor assembly if any of the

following conditions exists:

Fig. 5 Pressure Gauge Installed in System

Ä SUSPENSION AND DRIVESHAFTS 2 - 61

Page 121 of 2438

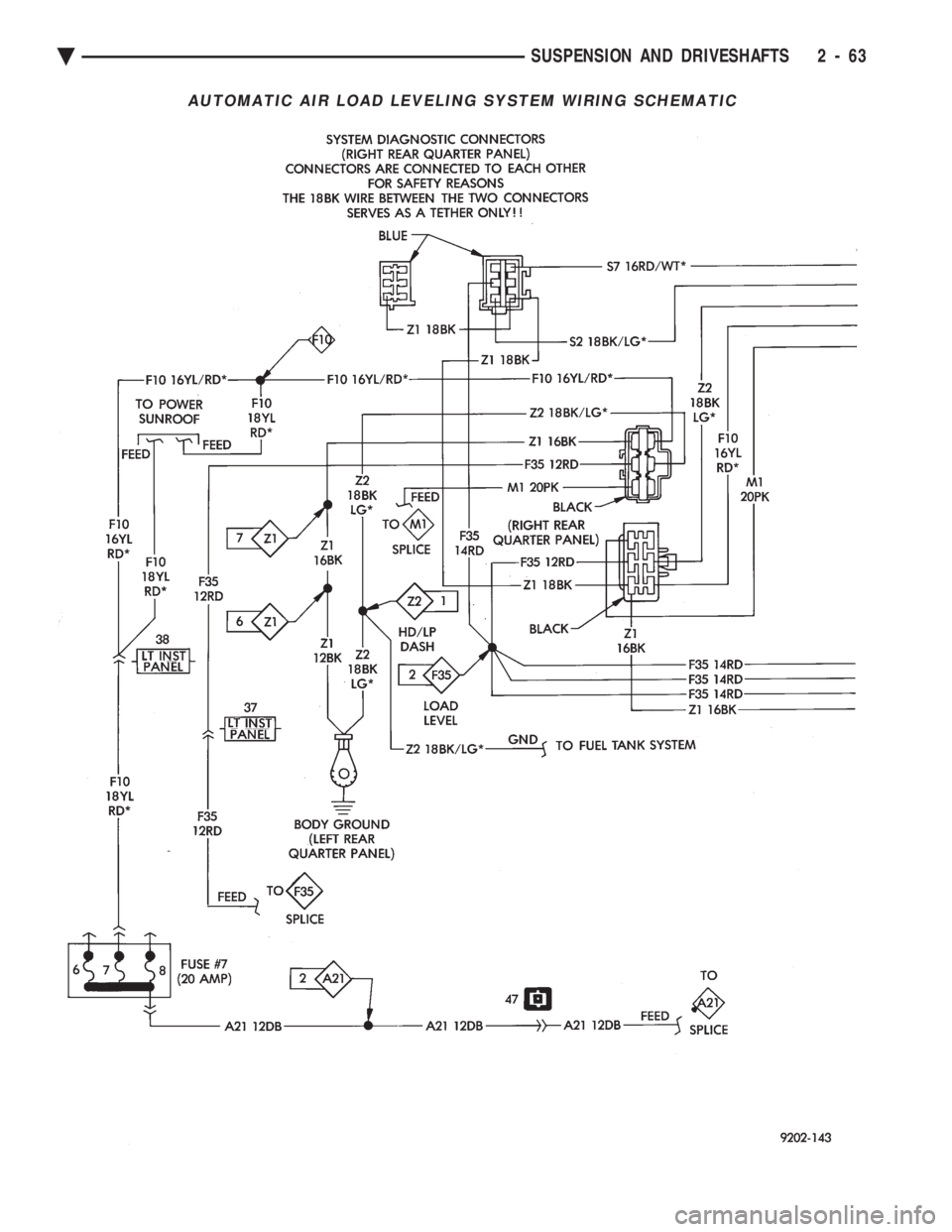

AUTOMATIC AIR LOAD LEVELING SYSTEM WIRING SCHEMATIC

Ä SUSPENSION AND DRIVESHAFTS 2 - 63

Page 122 of 2438

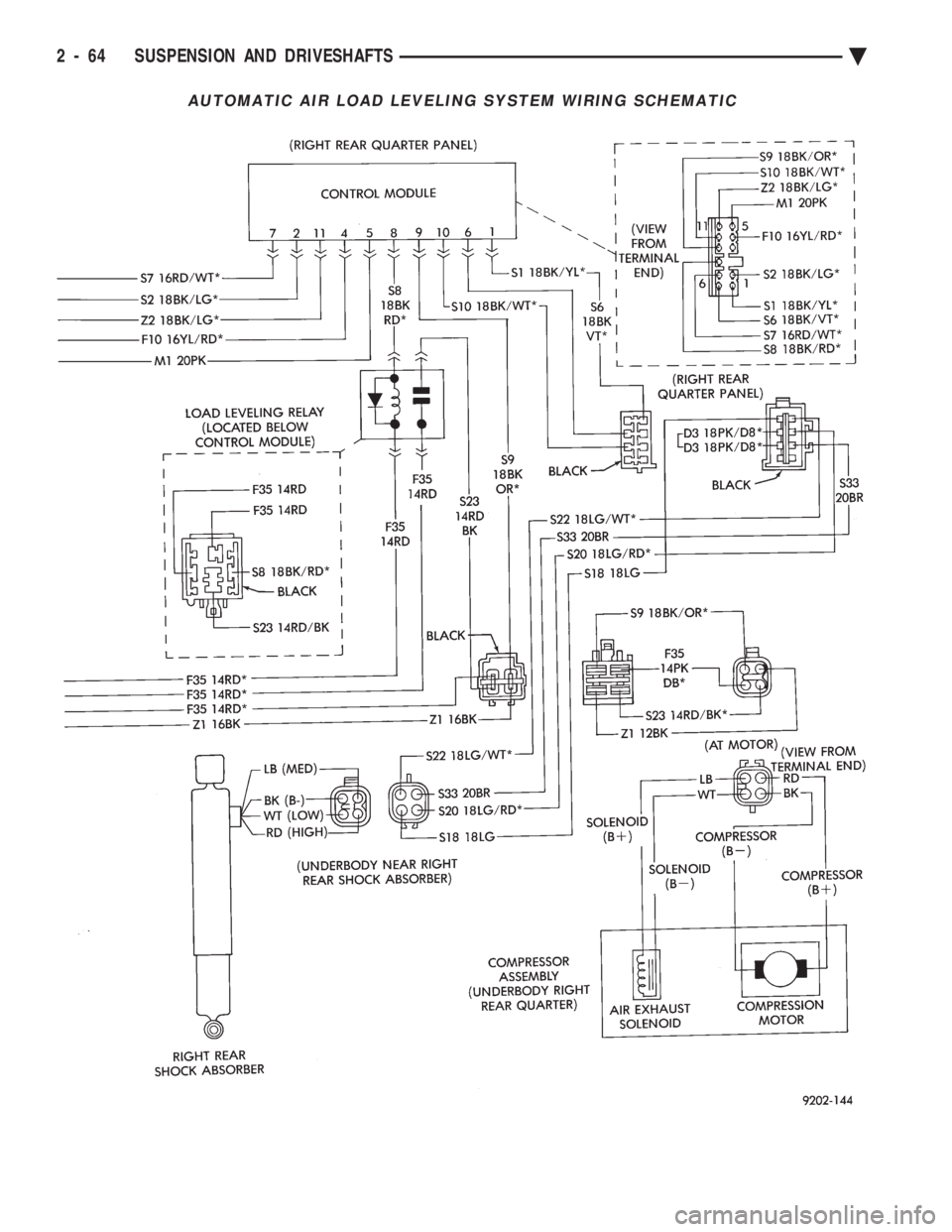

AUTOMATIC AIR LOAD LEVELING SYSTEM WIRING SCHEMATIC

2 - 64 SUSPENSION AND DRIVESHAFTS Ä

Page 123 of 2438

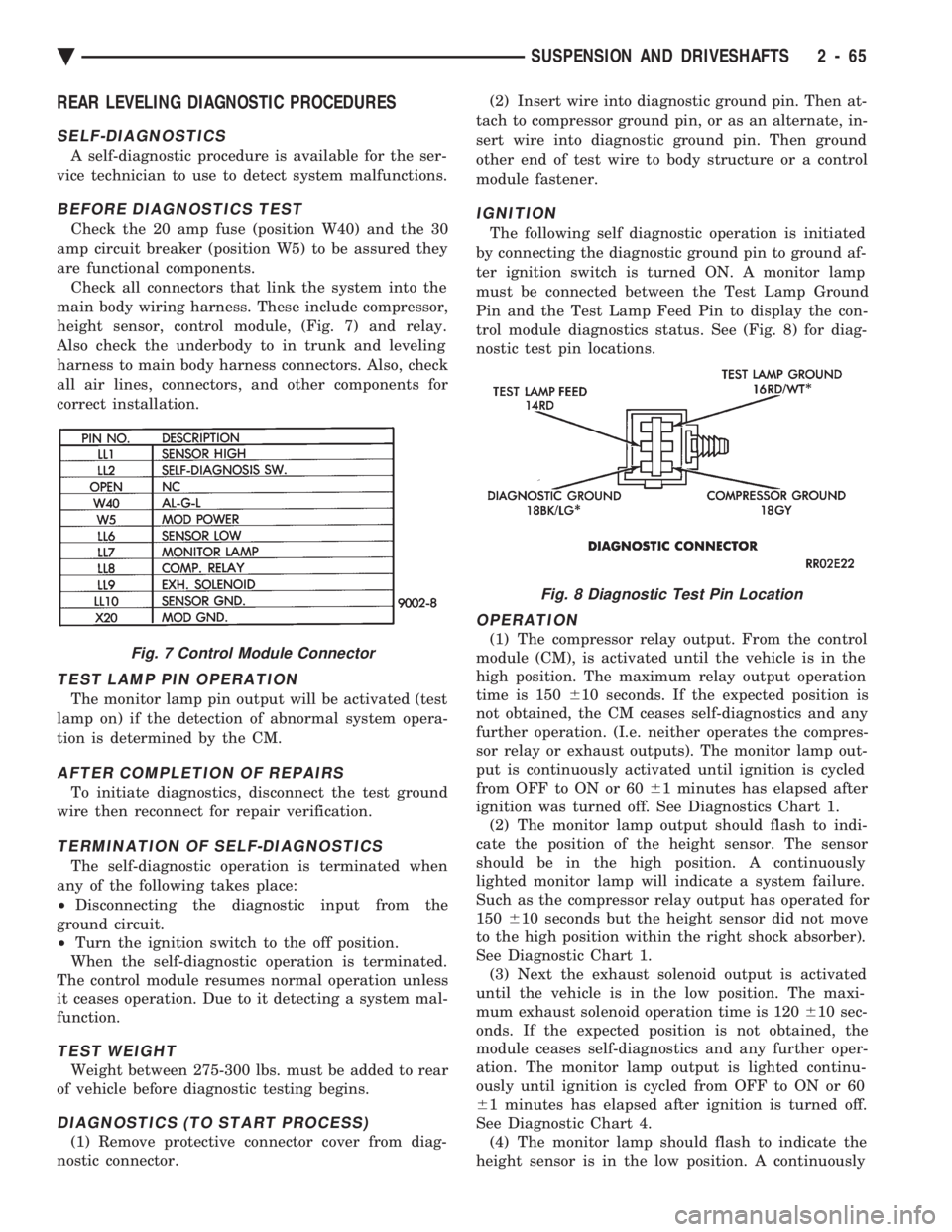

REAR LEVELING DIAGNOSTIC PROCEDURES

SELF-DIAGNOSTICS

A self-diagnostic procedure is available for the ser-

vice technician to use to detect system malfunctions.

BEFORE DIAGNOSTICS TEST

Check the 20 amp fuse (position W40) and the 30

amp circuit breaker (position W5) to be assured they

are functional components. Check all connectors that link the system into the

main body wiring harness. These include compressor,

height sensor, control module, (Fig. 7) and relay.

Also check the underbody to in trunk and leveling

harness to main body harness connectors. Also, check

all air lines, connectors, and other components for

correct installation.

TEST LAMP PIN OPERATION

The monitor lamp pin output will be activated (test

lamp on) if the detection of abnormal system opera-

tion is determined by the CM.

AFTER COMPLETION OF REPAIRS

To initiate diagnostics, disconnect the test ground

wire then reconnect for repair verification.

TERMINATION OF SELF-DIAGNOSTICS

The self-diagnostic operation is terminated when

any of the following takes place:

² Disconnecting the diagnostic input from the

ground circuit.

² Turn the ignition switch to the off position.

When the self-diagnostic operation is terminated.

The control module resumes normal operation unless

it ceases operation. Due to it detecting a system mal-

function.

TEST WEIGHT

Weight between 275-300 lbs. must be added to rear

of vehicle before diagnostic testing begins.

DIAGNOSTICS (TO START PROCESS)

(1) Remove protective connector cover from diag-

nostic connector. (2) Insert wire into diagnostic ground pin. Then at-

tach to compressor ground pin, or as an alternate, in-

sert wire into diagnostic ground pin. Then ground

other end of test wire to body structure or a control

module fastener.

IGNITION

The following self diagnostic operation is initiated

by connecting the diagnostic ground pin to ground af-

ter ignition switch is turned ON. A monitor lamp

must be connected between the Test Lamp Ground

Pin and the Test Lamp Feed Pin to display the con-

trol module diagnostics status. See (Fig. 8) for diag-

nostic test pin locations.

OPERATION

(1) The compressor relay output. From the control

module (CM), is activated until the vehicle is in the

high position. The maximum relay output operation

time is 150 610 seconds. If the expected position is

not obtained, the CM ceases self-diagnostics and any

further operation. (I.e. neither operates the compres-

sor relay or exhaust outputs). The monitor lamp out-

put is continuously activated until ignition is cycled

from OFF to ON or 60 61 minutes has elapsed after

ignition was turned off. See Diagnostics Chart 1. (2) The monitor lamp output should flash to indi-

cate the position of the height sensor. The sensor

should be in the high position. A continuously

lighted monitor lamp will indicate a system failure.

Such as the compressor relay output has operated for

150 610 seconds but the height sensor did not move

to the high position within the right shock absorber).

See Diagnostic Chart 1. (3) Next the exhaust solenoid output is activated

until the vehicle is in the low position. The maxi-

mum exhaust solenoid operation time is 120 610 sec-

onds. If the expected position is not obtained, the

module ceases self-diagnostics and any further oper-

ation. The monitor lamp output is lighted continu-

ously until ignition is cycled from OFF to ON or 60

6 1 minutes has elapsed after ignition is turned off.

See Diagnostic Chart 4. (4) The monitor lamp should flash to indicate the

height sensor is in the low position. A continuouslyFig. 7 Control Module Connector

Fig. 8 Diagnostic Test Pin Location

Ä SUSPENSION AND DRIVESHAFTS 2 - 65

Page 130 of 2438

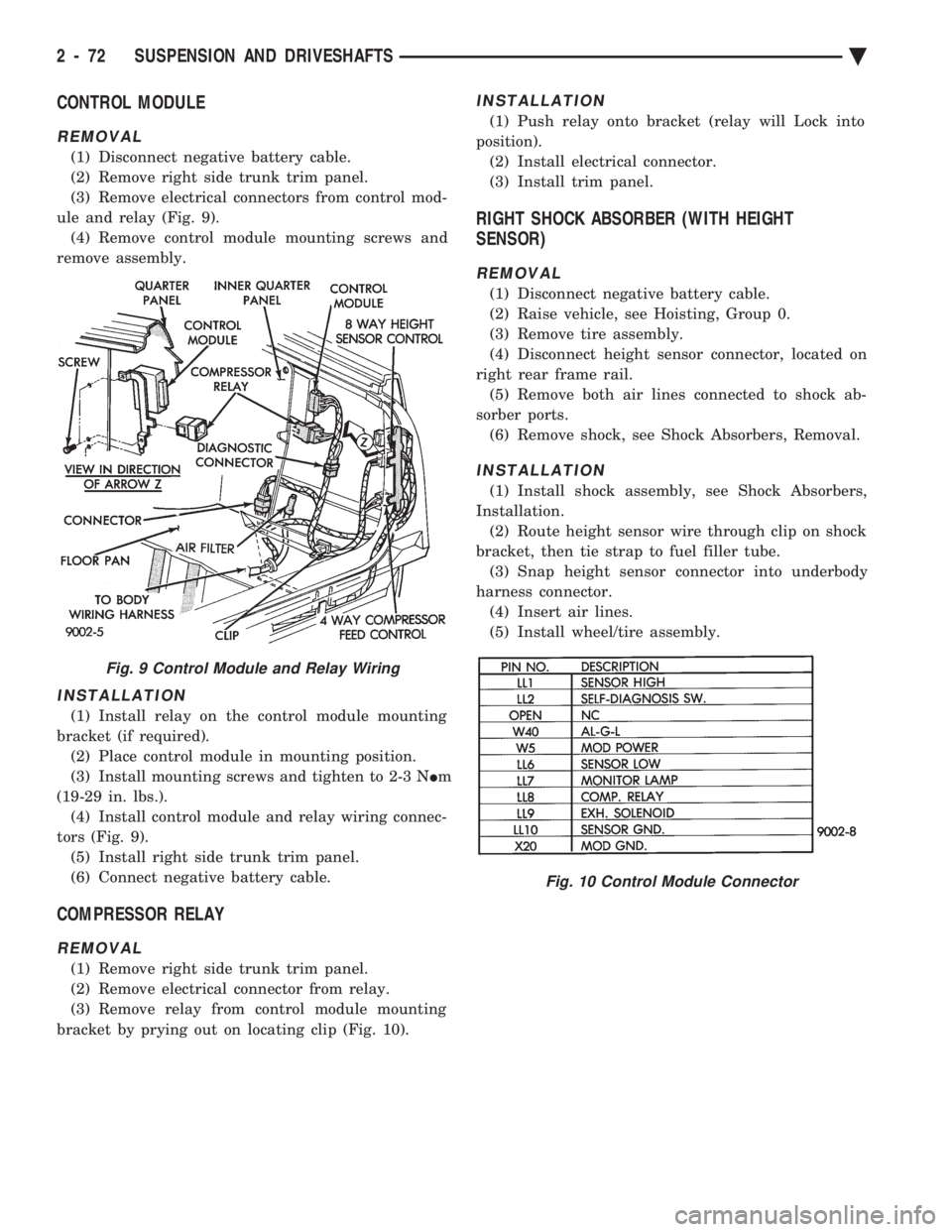

CONTROL MODULE

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove right side trunk trim panel.

(3) Remove electrical connectors from control mod-

ule and relay (Fig. 9). (4) Remove control module mounting screws and

remove assembly.

INSTALLATION

(1) Install relay on the control module mounting

bracket (if required). (2) Place control module in mounting position.

(3) Install mounting screws and tighten to 2-3 N Im

(19-29 in. lbs.). (4) Install control module and relay wiring connec-

tors (Fig. 9). (5) Install right side trunk trim panel.

(6) Connect negative battery cable.

COMPRESSOR RELAY

REMOVAL

(1) Remove right side trunk trim panel.

(2) Remove electrical connector from relay.

(3) Remove relay from control module mounting

bracket by prying out on locating clip (Fig. 10).

INSTALLATION

(1) Push relay onto bracket (relay will Lock into

position). (2) Install electrical connector.

(3) Install trim panel.

RIGHT SHOCK ABSORBER (WITH HEIGHT

SENSOR)

REMOVAL

(1) Disconnect negative battery cable.

(2) Raise vehicle, see Hoisting, Group 0.

(3) Remove tire assembly.

(4) Disconnect height sensor connector, located on

right rear frame rail. (5) Remove both air lines connected to shock ab-

sorber ports. (6) Remove shock, see Shock Absorbers, Removal.

INSTALLATION

(1) Install shock assembly, see Shock Absorbers,

Installation. (2) Route height sensor wire through clip on shock

bracket, then tie strap to fuel filler tube. (3) Snap height sensor connector into underbody

harness connector. (4) Insert air lines.

(5) Install wheel/tire assembly.

Fig. 9 Control Module and Relay Wiring

Fig. 10 Control Module Connector

2 - 72 SUSPENSION AND DRIVESHAFTS Ä

Page 131 of 2438

AUTOMATIC AIR SUSPENSION INDEX

page page

Air Lines ............................... 75

Air Springs Rear ......................... 87

Compressor Performance Test .............. 77

Diagnosis .............................. 78

General Information ....................... 73

Recharge Air Spring ...................... 87 Right Shock Absorber (With Height Sensor)

.... 88

Safety Concerns ......................... 78

Service Procedures ....................... 85

Shipping Mode .......................... 78

Solenoids (Struts and Air Springs) ............ 86

System Operation ........................ 78

GENERAL INFORMATION

This system provides automatic height control and

low spring rates to improve suspension characteristics

of the vehicle. And it will automatically level the front

and rear of the vehicle. It will also maintain the opti-

mum vehicle attitude from one passenger through full

vehicle load.

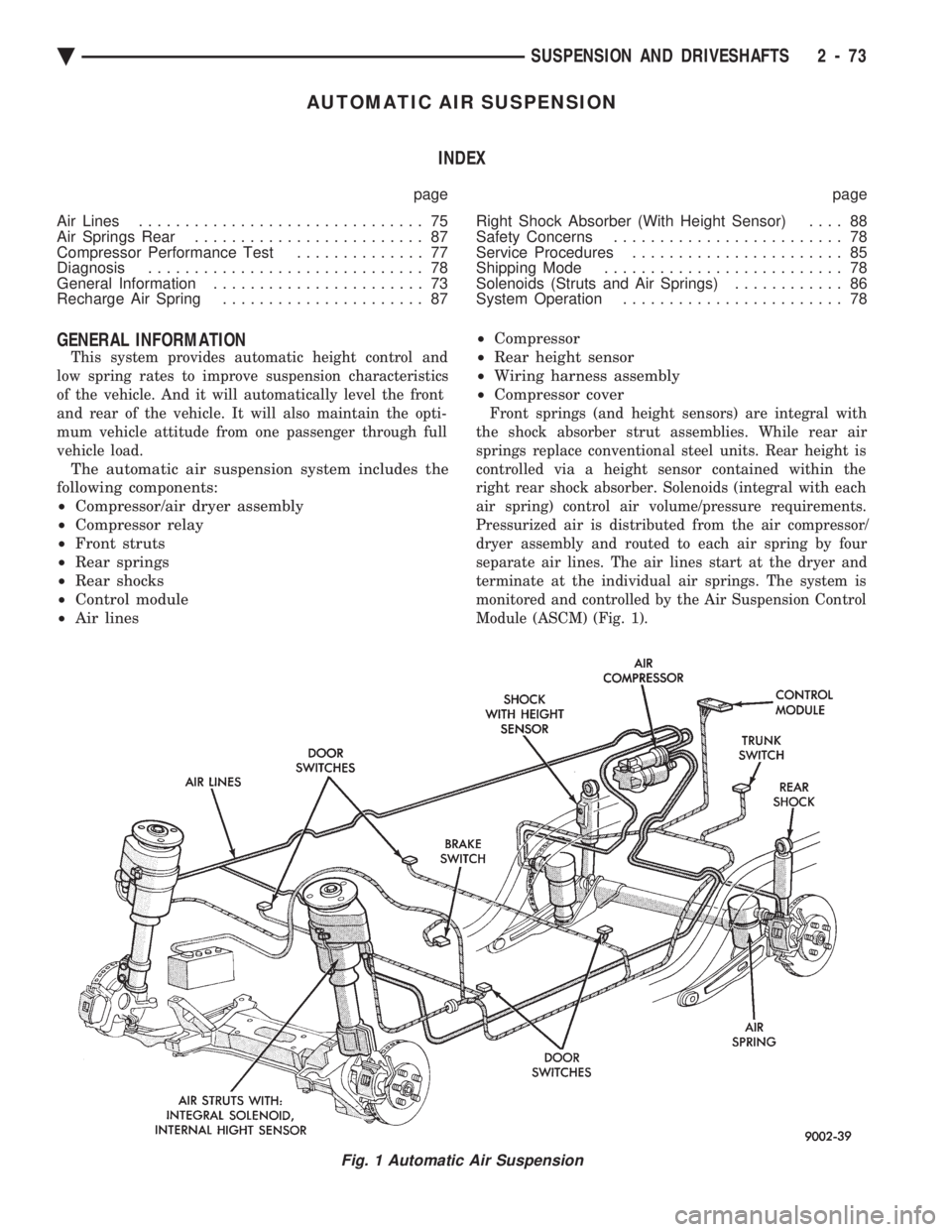

The automatic air suspension system includes the

following components:

² Compressor/air dryer assembly

² Compressor relay

² Front struts

² Rear springs

² Rear shocks

² Control module

² Air lines ²

Compressor

² Rear height sensor

² Wiring harness assembly

² Compressor cover

Front springs (and height sensors) are integral with

the shock absorber strut assemblies. While rear air

springs replace conventional steel units. Rear height is

controlled via a height sensor contained within the

right rear shock absorber. Solenoids (integral with each

air spring) control air volume/pressure requirements.

Pressurized air is distributed from the air compressor/

dryer assembly and routed to each air spring by four

separate air lines. The air lines start at the dryer and

terminate at the individual air springs. The system is

monitored and controlled by the Air Suspension Control

Module (ASCM) (Fig. 1).

Fig. 1 Automatic Air Suspension

Ä SUSPENSION AND DRIVESHAFTS 2 - 73

Page 135 of 2438

AIR LINE FITTINGS

To remove an air supply line from an air compres-

sor assembly air line fitting. Push in (toward re-

ceiver dryer) on the plastic ring of the receiver dryer

air supply air line fitting. While holding in the air

line fitting on the receiver dryer pull the air supply

line strait out of the fitting (Fig. 6).

The fitting has a unique push-in feature. A brass

type collet locks the air line in place. One rubber

O-Ring seals the air line to prevent air leakage. To

attach air line, just push into fitting (Fig. 7).

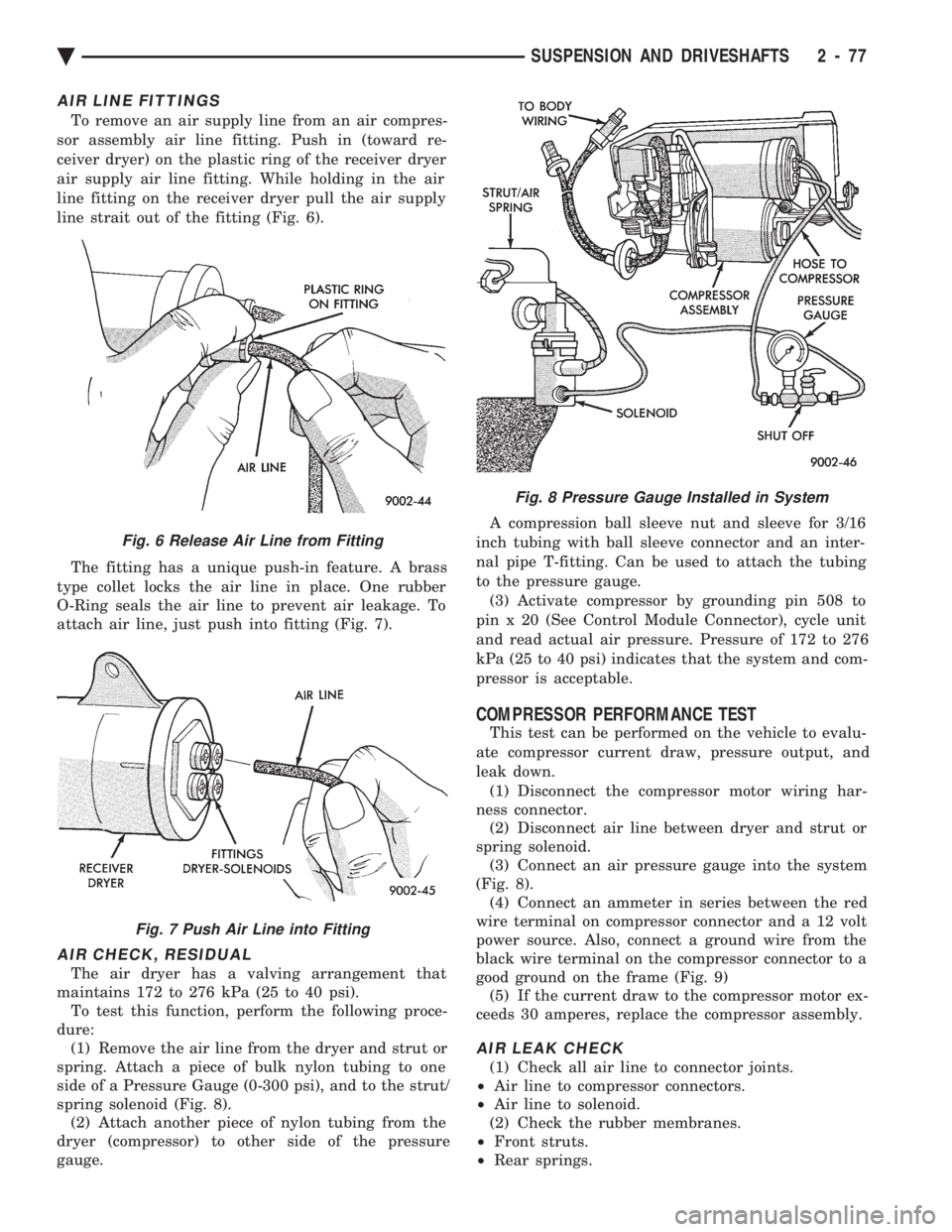

AIR CHECK, RESIDUAL

The air dryer has a valving arrangement that

maintains 172 to 276 kPa (25 to 40 psi). To test this function, perform the following proce-

dure: (1) Remove the air line from the dryer and strut or

spring. Attach a piece of bulk nylon tubing to one

side of a Pressure Gauge (0-300 psi), and to the strut/

spring solenoid (Fig. 8). (2) Attach another piece of nylon tubing from the

dryer (compressor) to other side of the pressure

gauge. A compression ball sleeve nut and sleeve for 3/16

inch tubing with ball sleeve connector and an inter-

nal pipe T-fitting. Can be used to attach the tubing

to the pressure gauge. (3) Activate compressor by grounding pin 508 to

pin x 20 (See Control Module Connector), cycle unit

and read actual air pressure. Pressure of 172 to 276

kPa (25 to 40 psi) indicates that the system and com-

pressor is acceptable.

COMPRESSOR PERFORMANCE TEST

This test can be performed on the vehicle to evalu-

ate compressor current draw, pressure output, and

leak down. (1) Disconnect the compressor motor wiring har-

ness connector. (2) Disconnect air line between dryer and strut or

spring solenoid. (3) Connect an air pressure gauge into the system

(Fig. 8). (4) Connect an ammeter in series between the red

wire terminal on compressor connector and a 12 volt

power source. Also, connect a ground wire from the

black wire terminal on the compressor connector to a

good ground on the frame (Fig. 9) (5) If the current draw to the compressor motor ex-

ceeds 30 amperes, replace the compressor assembly.

AIR LEAK CHECK

(1) Check all air line to connector joints.

² Air line to compressor connectors.

² Air line to solenoid.

(2) Check the rubber membranes.

² Front struts.

² Rear springs.

Fig. 6 Release Air Line from Fitting

Fig. 7 Push Air Line into Fitting

Fig. 8 Pressure Gauge Installed in System

Ä SUSPENSION AND DRIVESHAFTS 2 - 77