wiring CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 242 of 2438

(11) Remove all special tools previously installed,

from the ABS hydraulic assembly. (12) Install accumulator port plug into hydraulic

assembly. Torque accumulator port plug to 12 N Im(9

ft. lbs.). (13) Install high pressure brake hose from the

pump motor assembly into hydraulic fitting on ABS

hydraulic assembly. Torque high pressure brake hose

tube nut to 16 N Im (145 in. lbs.).

(14) Turn ignition switch to the run position to en-

ergize the pump/motor assembly and pressurize hy-

draulic system. Check for leakage at the hydraulic

assembly to hydraulic bladder accumulator fitting. (15) Again de-pressurize accumulator by pumping

brake pedal a minimum of 40 times. Use procedure

described in De-Pressurizing Hydraulic Accumulator

in this section of the service manual. (16) Then check the brake fluid level in the hy-

draulic assembly reservoir. If brake fluid level is low,

fill reservoir to proper level with Mopar tbrake fluid

or equivalent conforming to DOT 3 requirements.

INTERMITTENT FAULTS

As with almost any electronic system, intermittent

faults in the ABS system may be difficult to accu-

rately diagnose. Most intermittent faults are caused by faulty elec-

trical connections or wiring. When an intermittent

fault is encountered, check suspect circuits for: (1) Poor mating of electrical connector halves, or

electrical terminals not fully seated in the connector

body. (2) Improperly formed or damaged electrical termi-

nals. All connector terminals in a suspect circuit

should be carefully reformed to increase contact ten-

sion. (3) Poor terminal to wire connection. This requires

removing the terminal from the connector body and

inspecting for proper terminal to wire connection. If a visual check does not find the cause of the

problem, operate the vehicle in an attempt to dupli-

cate the condition and record the Fault Code. Most failures of the ABS system will disable the

Anti-Lock function for the entire ignition cycle even

if the fault clears before ignition key-off. There are

some failure conditions however, which will allow

ABS operation to resume during the ignition cycle in

which a failure occurred. If the failure conditions are

no longer present. The following conditions may result in intermittent

illumination of the Red Brake Warning Lamp and/or

Amber Anti-Lock Warning Lamp. All other failures

will cause the lamp(s) to remain on until the ignition

switch is turned off. Circuits and or components in-

volving these inputs to the (CAB) should be investi-

gated if a complaint of intermittent warning system

operation is encountered. ²

Low system voltage. If low system voltage is de-

tected by the (CAB), the (CAB) will turn on the Am-

ber Anti-Lock Warning Lamp until normal system

voltage is achieved. Once normal voltage is seen at

the (CAB), normal operation resumes.

² Low Brake Fluid. A low brake fluid condition will

cause the Red Brake Warning Lamp to illuminate.

When the fluid sensor again indicates an acceptable

fluid level, the Red Brake Warning Lamp will go out.

This condition may exist during hard cornering or

while the vehicle is on a grade. If the vehicle is in

motion above 3 M.P.H. the Amber Anti-Lock Warn-

ing Lamp will also be turned on.

² Low Accumulator Pressure. Low Accumulator

Pressure will cause both the Red Brake Warning and

Amber Anti-Lock Warning Lamps to illuminate.

Once normal operating pressure is achieved, the

lamps will extinguish and the system will return to

normal operation. Additionally, any condition that results in an inter-

ruption of power to the (CAB) or hydraulic assembly.

May cause the Red Brake Warning and Amber Anti-

Lock Warning Lamps to illuminate intermittently. All the conditions (or faults) mentioned above, can

store a fault code in the (CAB) module.

ABS BRAKE SYSTEM DIAGNOSTIC FEATURES

SYSTEM SELF DIAGNOSIS

The ABS system is equipped with a diagnostic ca-

pability that may be used to assist in isolation of

ABS faults. The features of the diagnostics system

are described below.

CONTROLLER ANTI-LOCK BRAKE (CAB)

Fault codes are kept in a Non-Volatile memory un-

til either erased by the technician using the DRB II

or erased automatically after 50 ignition cycles (key

ON-OFF cycles). The only fault that will not be

erased after 50 (KEY CYCLES) is the (CAB) fault.

The (CAB) fault can only be erased by using the

DRB II diagnostic tester. More than one fault can be

stored at a time. The number of key cycles since the

most recent fault was stored is also displayed. Most

functions of the (CAB) and (ABS) system can be ac-

cessed by the technician for testing and diagnostic

purposes by using the DRB II Diagnostic Tester.

START-UP CYCLE

The START-UP CYCLE takes place immediately

after the ignition switch is turned on. It is an elec-

trical check of basic electrical functions such as the

System Relay and Anti-Lock Warning Lamp Relay.

During this check, the Amber Anti-Lock Warning

Lamp is turned on, then turned off at the end of the

test. The test takes approximatel y1-2seconds to

complete.

5 - 92 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 246 of 2438

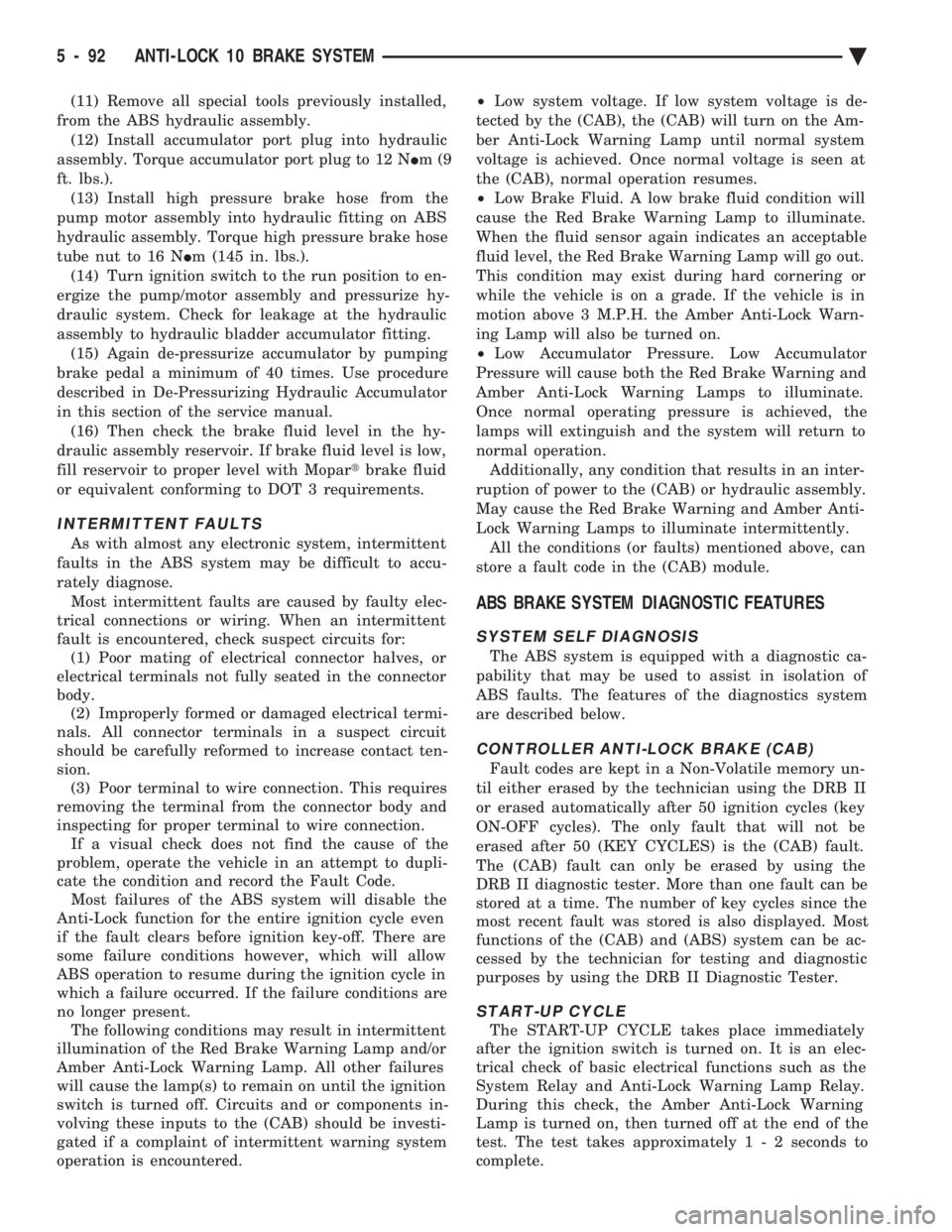

PUMP/MOTOR SERVICE (FIG. 4)

REMOVE (1) Fully de-pressurize the hydraulic accumulator

by pumping the pedal a minimum of 40 times. Use

the procedure described in De-Pressurizing Hydraulic

Accumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(2) Remove the fresh air intake ducts from the en-

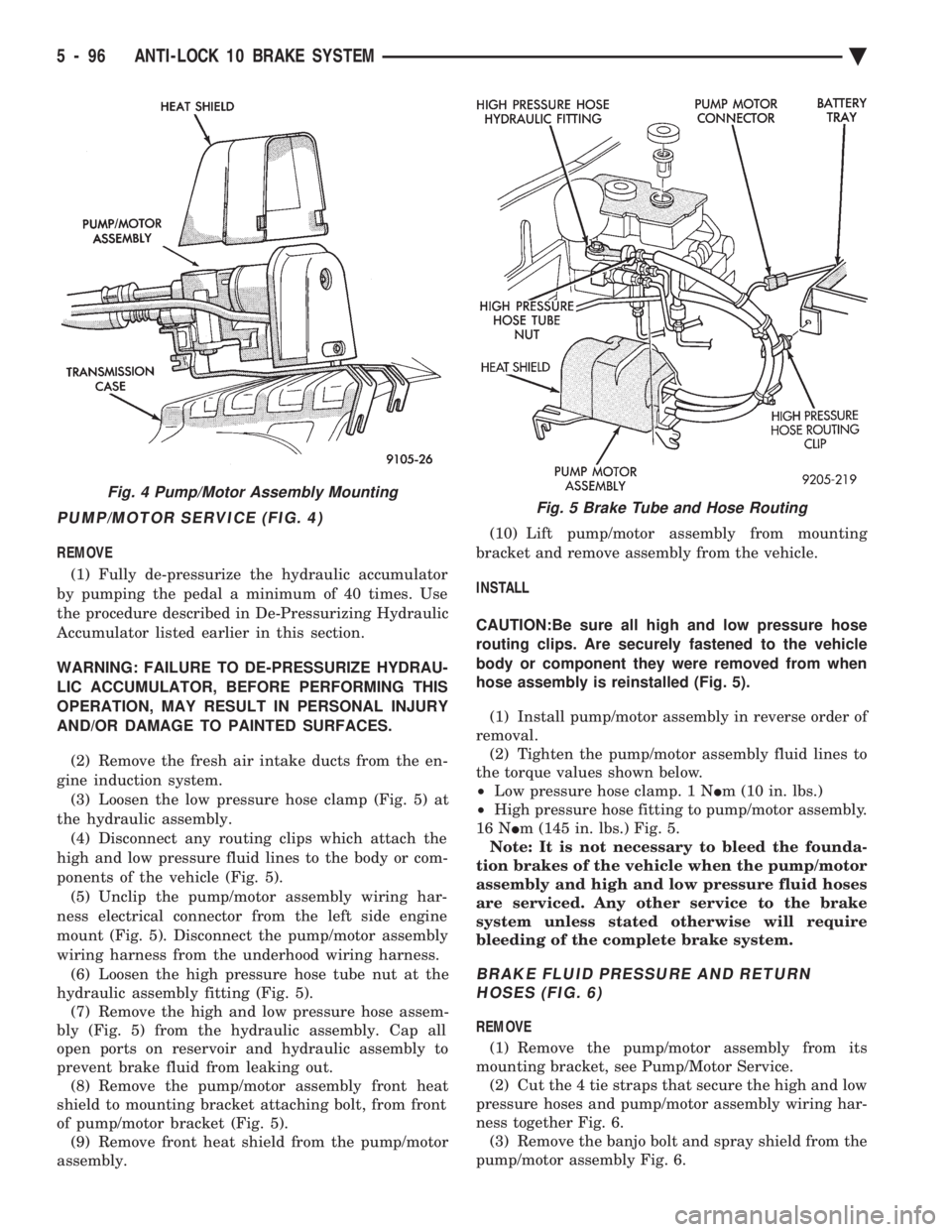

gine induction system. (3) Loosen the low pressure hose clamp (Fig. 5) at

the hydraulic assembly. (4) Disconnect any routing clips which attach the

high and low pressure fluid lines to the body or com-

ponents of the vehicle (Fig. 5). (5) Unclip the pump/motor assembly wiring har-

ness electrical connector from the left side engine

mount (Fig. 5). Disconnect the pump/motor assembly

wiring harness from the underhood wiring harness. (6) Loosen the high pressure hose tube nut at the

hydraulic assembly fitting (Fig. 5). (7) Remove the high and low pressure hose assem-

bly (Fig. 5) from the hydraulic assembly. Cap all

open ports on reservoir and hydraulic assembly to

prevent brake fluid from leaking out. (8) Remove the pump/motor assembly front heat

shield to mounting bracket attaching bolt, from front

of pump/motor bracket (Fig. 5). (9) Remove front heat shield from the pump/motor

assembly. (10) Lift pump/motor assembly from mounting

bracket and remove assembly from the vehicle.

INSTALL

CAUTION:Be sure all high and low pressure hose

routing clips. Are securely fastened to the vehicle

body or component they were removed from when

hose assembly is reinstalled (Fig. 5).

(1) Install pump/motor assembly in reverse order of

removal. (2) Tighten the pump/motor assembly fluid lines to

the torque values shown below.

² Low pressure hose clamp. 1 N Im (10 in. lbs.)

² High pressure hose fitting to pump/motor assembly.

16 N Im (145 in. lbs.) Fig. 5.

Note: It is not necessary to bleed the founda-

tion brakes of the vehicle when the pump/motor

assembly and high and low pressure fluid hoses

are serviced. Any other service to the brake

system unless stated otherwise will require

bleeding of the complete brake system.

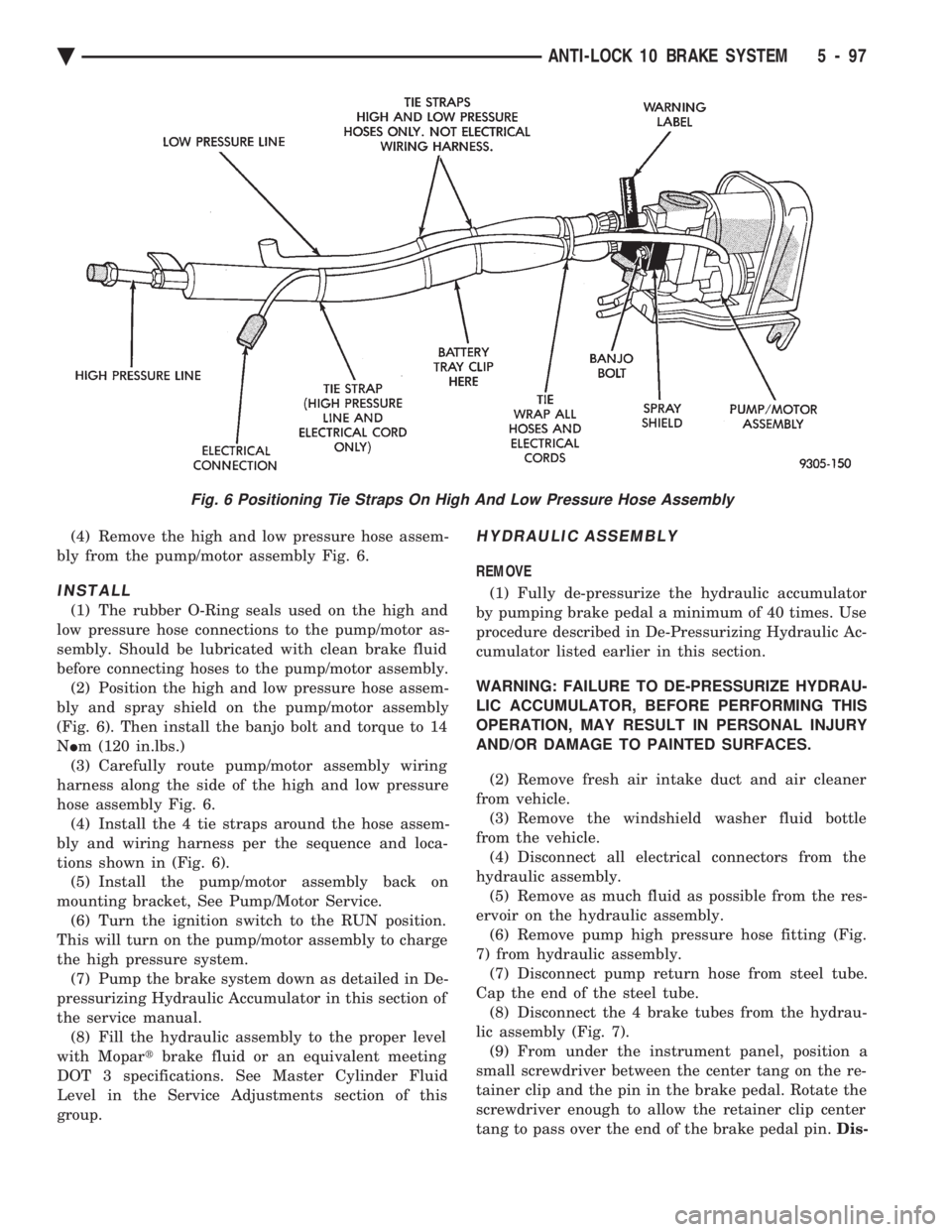

BRAKE FLUID PRESSURE AND RETURN HOSES (FIG. 6)

REMOVE

(1) Remove the pump/motor assembly from its

mounting bracket, see Pump/Motor Service. (2) Cut the 4 tie straps that secure the high and low

pressure hoses and pump/motor assembly wiring har-

ness together Fig. 6. (3) Remove the banjo bolt and spray shield from the

pump/motor assembly Fig. 6.

Fig. 4 Pump/Motor Assembly MountingFig. 5 Brake Tube and Hose Routing

5 - 96 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 247 of 2438

(4) Remove the high and low pressure hose assem-

bly from the pump/motor assembly Fig. 6.

INSTALL

(1) The rubber O-Ring seals used on the high and

low pressure hose connections to the pump/motor as-

sembly. Should be lubricated with clean brake fluid

before connecting hoses to the pump/motor assembly. (2) Position the high and low pressure hose assem-

bly and spray shield on the pump/motor assembly

(Fig. 6). Then install the banjo bolt and torque to 14

N Im (120 in.lbs.)

(3) Carefully route pump/motor assembly wiring

harness along the side of the high and low pressure

hose assembly Fig. 6. (4) Install the 4 tie straps around the hose assem-

bly and wiring harness per the sequence and loca-

tions shown in (Fig. 6). (5) Install the pump/motor assembly back on

mounting bracket, See Pump/Motor Service. (6) Turn the ignition switch to the RUN position.

This will turn on the pump/motor assembly to charge

the high pressure system. (7) Pump the brake system down as detailed in De-

pressurizing Hydraulic Accumulator in this section of

the service manual. (8) Fill the hydraulic assembly to the proper level

with Mopar tbrake fluid or an equivalent meeting

DOT 3 specifications. See Master Cylinder Fluid

Level in the Service Adjustments section of this

group.

HYDRAULIC ASSEMBLY

REMOVE

(1) Fully de-pressurize the hydraulic accumulator

by pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(2) Remove fresh air intake duct and air cleaner

from vehicle. (3) Remove the windshield washer fluid bottle

from the vehicle. (4) Disconnect all electrical connectors from the

hydraulic assembly. (5) Remove as much fluid as possible from the res-

ervoir on the hydraulic assembly. (6) Remove pump high pressure hose fitting (Fig.

7) from hydraulic assembly. (7) Disconnect pump return hose from steel tube.

Cap the end of the steel tube. (8) Disconnect the 4 brake tubes from the hydrau-

lic assembly (Fig. 7). (9) From under the instrument panel, position a

small screwdriver between the center tang on the re-

tainer clip and the pin in the brake pedal. Rotate the

screwdriver enough to allow the retainer clip center

tang to pass over the end of the brake pedal pin. Dis-

Fig. 6 Positioning Tie Straps On High And Low Pressure Hose Assembly

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 97

Page 253 of 2438

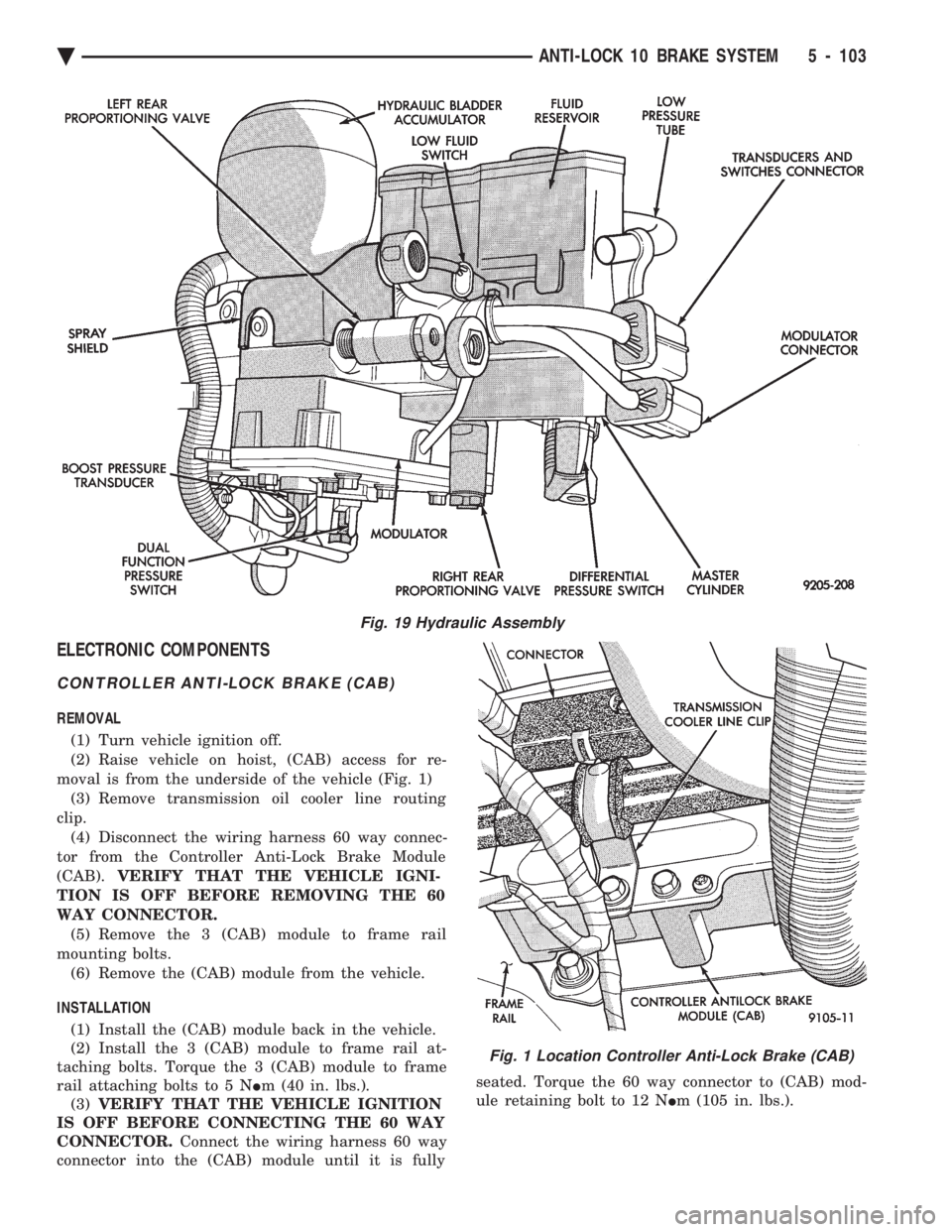

ELECTRONIC COMPONENTS

CONTROLLER ANTI-LOCK BRAKE (CAB)

REMOVAL (1) Turn vehicle ignition off.

(2) Raise vehicle on hoist, (CAB) access for re-

moval is from the underside of the vehicle (Fig. 1) (3) Remove transmission oil cooler line routing

clip. (4) Disconnect the wiring harness 60 way connec-

tor from the Controller Anti-Lock Brake Module

(CAB). VERIFY THAT THE VEHICLE IGNI-

TION IS OFF BEFORE REMOVING THE 60

WAY CONNECTOR. (5) Remove the 3 (CAB) module to frame rail

mounting bolts. (6) Remove the (CAB) module from the vehicle.

INSTALLATION (1) Install the (CAB) module back in the vehicle.

(2) Install the 3 (CAB) module to frame rail at-

taching bolts. Torque the 3 (CAB) module to frame

rail attaching bolts to 5 N Im (40 in. lbs.).

(3) VERIFY THAT THE VEHICLE IGNITION

IS OFF BEFORE CONNECTING THE 60 WAY

CONNECTOR. Connect the wiring harness 60 way

connector into the (CAB) module until it is fully seated. Torque the 60 way connector to (CAB) mod-

ule retaining bolt to 12 N Im (105 in. lbs.).

Fig. 19 Hydraulic Assembly

Fig. 1 Location Controller Anti-Lock Brake (CAB)

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 103

Page 254 of 2438

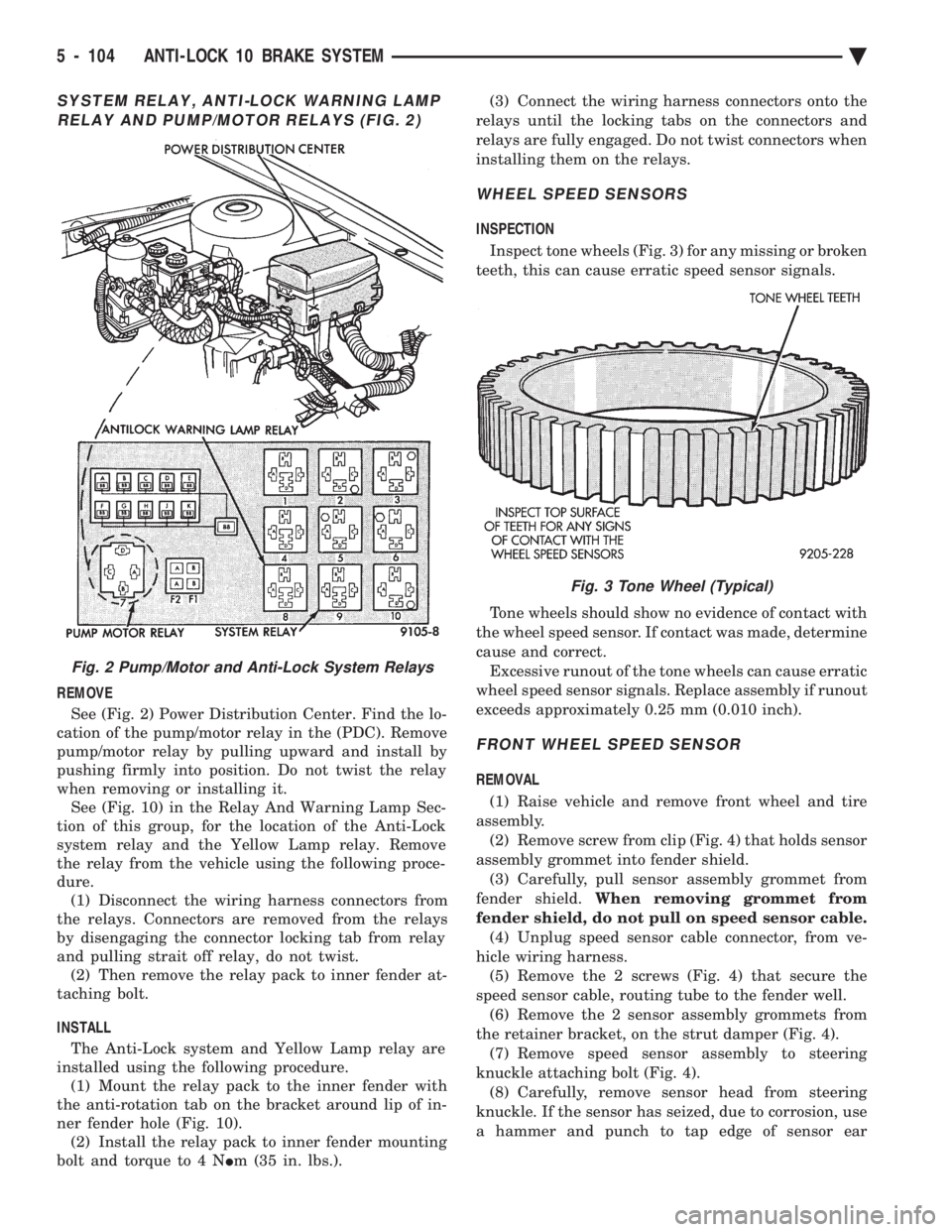

SYSTEM RELAY, ANTI-LOCK WARNING LAMP RELAY AND PUMP/MOTOR RELAYS (FIG. 2)

REMOVE

See (Fig. 2) Power Distribution Center. Find the lo-

cation of the pump/motor relay in the (PDC). Remove

pump/motor relay by pulling upward and install by

pushing firmly into position. Do not twist the relay

when removing or installing it. See (Fig. 10) in the Relay And Warning Lamp Sec-

tion of this group, for the location of the Anti-Lock

system relay and the Yellow Lamp relay. Remove

the relay from the vehicle using the following proce-

dure. (1) Disconnect the wiring harness connectors from

the relays. Connectors are removed from the relays

by disengaging the connector locking tab from relay

and pulling strait off relay, do not twist. (2) Then remove the relay pack to inner fender at-

taching bolt.

INSTALL The Anti-Lock system and Yellow Lamp relay are

installed using the following procedure. (1) Mount the relay pack to the inner fender with

the anti-rotation tab on the bracket around lip of in-

ner fender hole (Fig. 10). (2) Install the relay pack to inner fender mounting

bolt and torque to 4 N Im (35 in. lbs.). (3) Connect the wiring harness connectors onto the

relays until the locking tabs on the connectors and

relays are fully engaged. Do not twist connectors when

installing them on the relays.

WHEEL SPEED SENSORS

INSPECTION

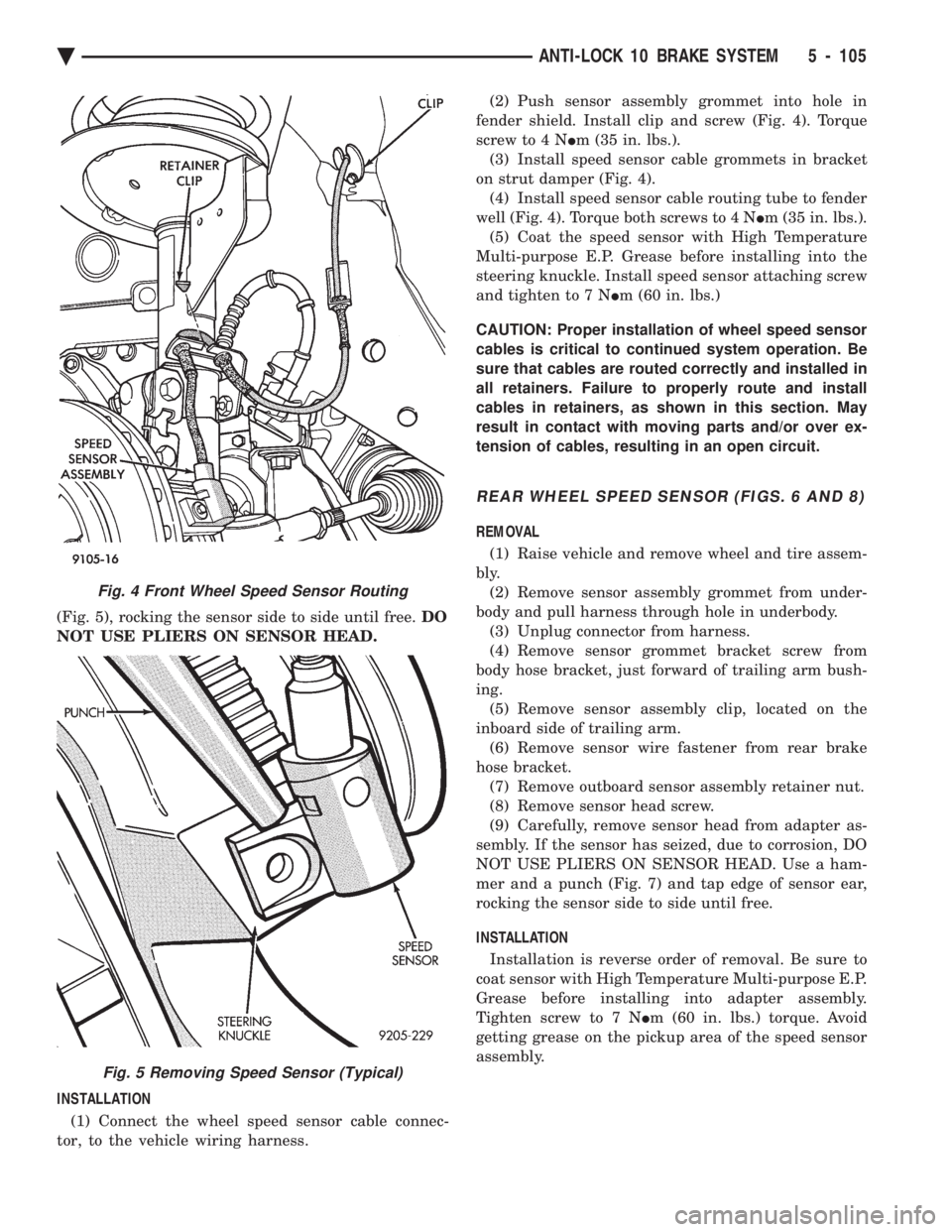

Inspect tone wheels (Fig. 3) for any missing or broken

teeth, this can cause erratic speed sensor signals.

Tone wheels should show no evidence of contact with

the wheel speed sensor. If contact was made, determine

cause and correct. Excessive runout of the tone wheels can cause erratic

wheel speed sensor signals. Replace assembly if runout

exceeds approximately 0.25 mm (0.010 inch).

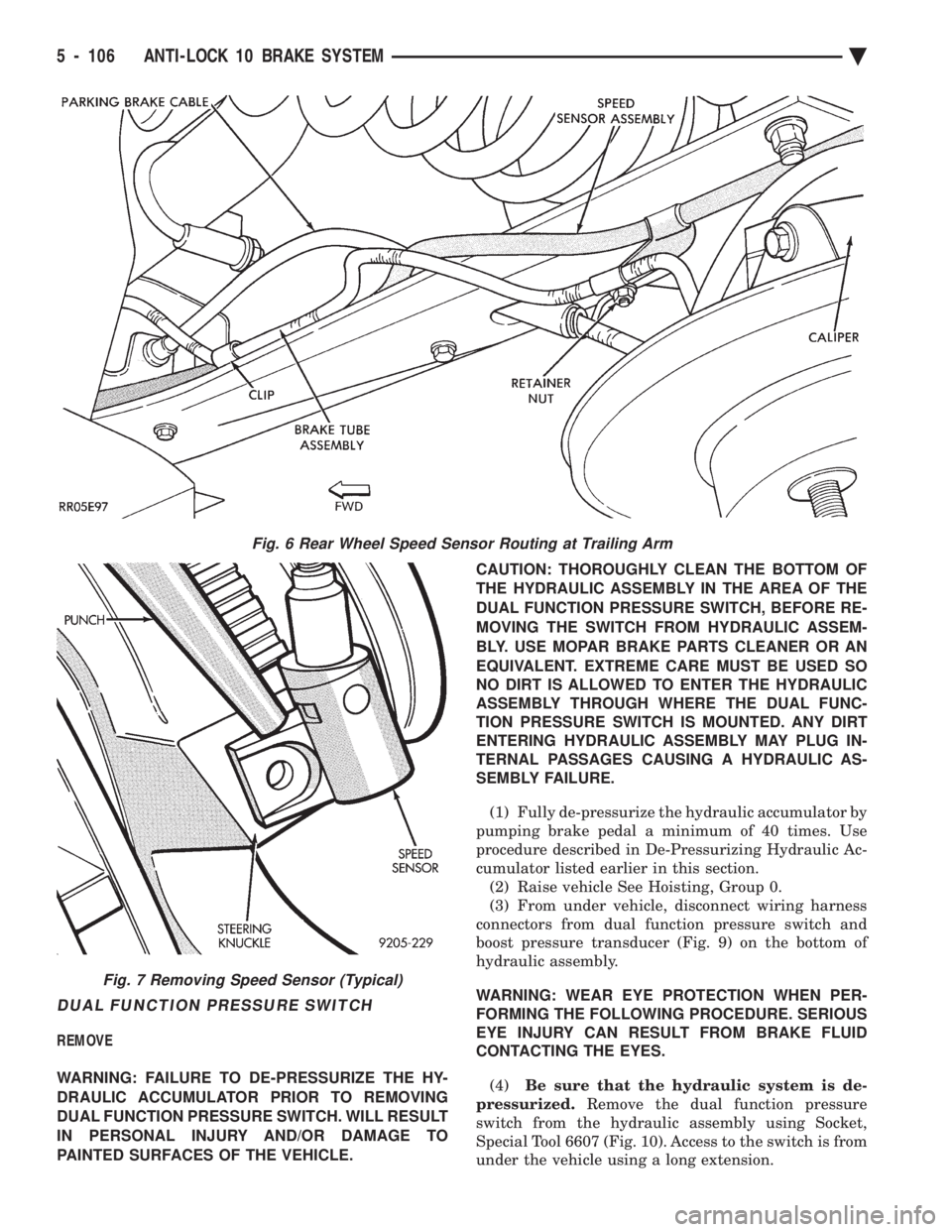

FRONT WHEEL SPEED SENSOR

REMOVAL

(1) Raise vehicle and remove front wheel and tire

assembly. (2) Remove screw from clip (Fig. 4) that holds sensor

assembly grommet into fender shield. (3) Carefully, pull sensor assembly grommet from

fender shield. When removing grommet from

fender shield, do not pull on speed sensor cable. (4) Unplug speed sensor cable connector, from ve-

hicle wiring harness. (5) Remove the 2 screws (Fig. 4) that secure the

speed sensor cable, routing tube to the fender well. (6) Remove the 2 sensor assembly grommets from

the retainer bracket, on the strut damper (Fig. 4). (7) Remove speed sensor assembly to steering

knuckle attaching bolt (Fig. 4). (8) Carefully, remove sensor head from steering

knuckle. If the sensor has seized, due to corrosion, use

a hammer and punch to tap edge of sensor ear

Fig. 2 Pump/Motor and Anti-Lock System Relays

Fig. 3 Tone Wheel (Typical)

5 - 104 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 255 of 2438

(Fig. 5), rocking the sensor side to side until free. DO

NOT USE PLIERS ON SENSOR HEAD.

INSTALLATION (1) Connect the wheel speed sensor cable connec-

tor, to the vehicle wiring harness. (2) Push sensor assembly grommet into hole in

fender shield. Install clip and screw (Fig. 4). Torque

screw to 4 N Im (35 in. lbs.).

(3) Install speed sensor cable grommets in bracket

on strut damper (Fig. 4). (4) Install speed sensor cable routing tube to fender

well (Fig. 4). Torque both screws to 4 N Im (35 in. lbs.).

(5) Coat the speed sensor with High Temperature

Multi-purpose E.P. Grease before installing into the

steering knuckle. Install speed sensor attaching screw

and tighten to 7 N Im (60 in. lbs.)

CAUTION: Proper installation of wheel speed sensor

cables is critical to continued system operation. Be

sure that cables are routed correctly and installed in

all retainers. Failure to properly route and install

cables in retainers, as shown in this section. May

result in contact with moving parts and/or over ex-

tension of cables, resulting in an open circuit.

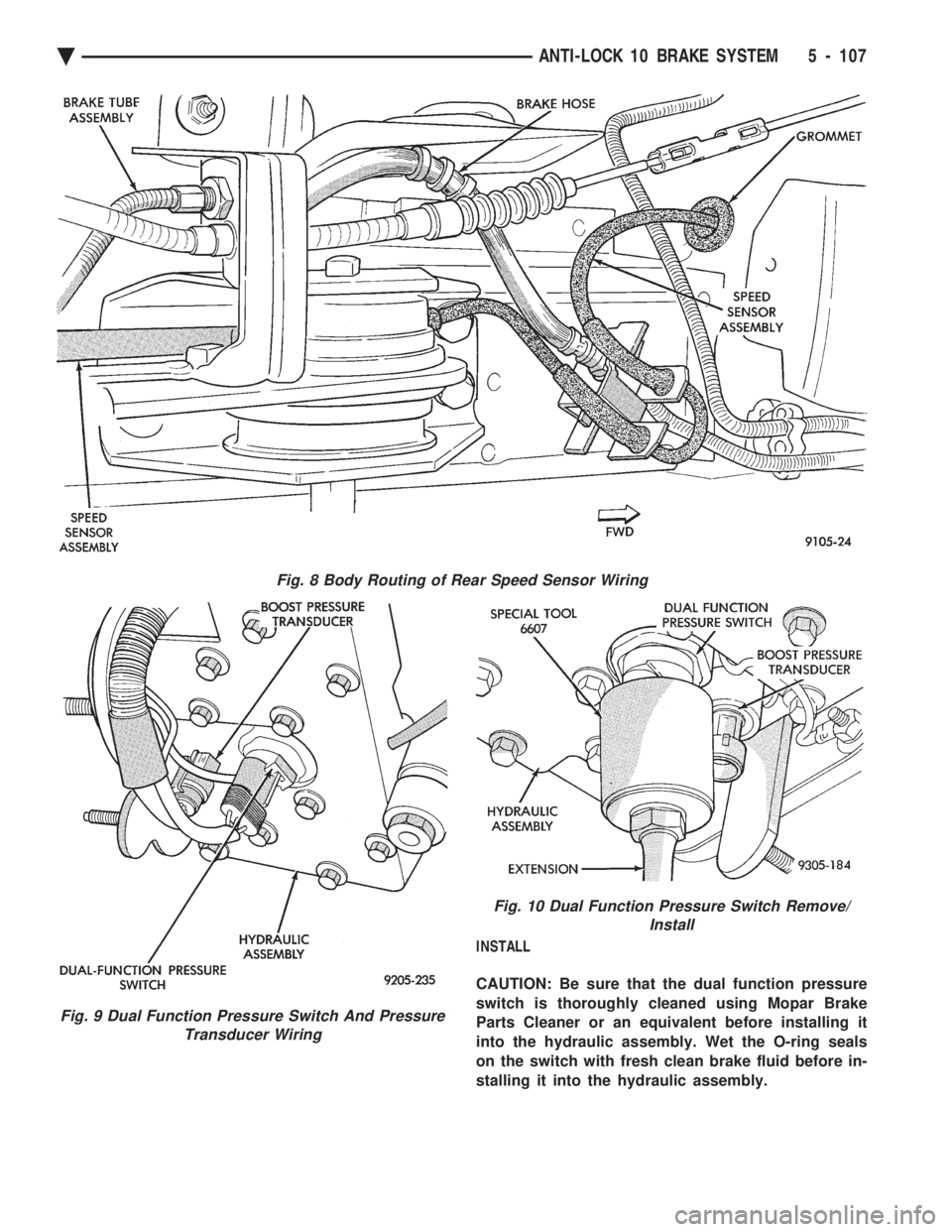

REAR WHEEL SPEED SENSOR (FIGS. 6 AND 8)

REMOVAL

(1) Raise vehicle and remove wheel and tire assem-

bly. (2) Remove sensor assembly grommet from under-

body and pull harness through hole in underbody. (3) Unplug connector from harness.

(4) Remove sensor grommet bracket screw from

body hose bracket, just forward of trailing arm bush-

ing. (5) Remove sensor assembly clip, located on the

inboard side of trailing arm. (6) Remove sensor wire fastener from rear brake

hose bracket. (7) Remove outboard sensor assembly retainer nut.

(8) Remove sensor head screw.

(9) Carefully, remove sensor head from adapter as-

sembly. If the sensor has seized, due to corrosion, DO

NOT USE PLIERS ON SENSOR HEAD. Use a ham-

mer and a punch (Fig. 7) and tap edge of sensor ear,

rocking the sensor side to side until free.

INSTALLATION

Installation is reverse order of removal. Be sure to

coat sensor with High Temperature Multi-purpose E.P.

Grease before installing into adapter assembly.

Tighten screw to 7 N Im (60 in. lbs.) torque. Avoid

getting grease on the pickup area of the speed sensor

assembly.

Fig. 4 Front Wheel Speed Sensor Routing

Fig. 5 Removing Speed Sensor (Typical)

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 105

Page 256 of 2438

DUAL FUNCTION PRESSURE SWITCH

REMOVE

WARNING: FAILURE TO DE-PRESSURIZE THE HY-

DRAULIC ACCUMULATOR PRIOR TO REMOVING

DUAL FUNCTION PRESSURE SWITCH. WILL RESULT

IN PERSONAL INJURY AND/OR DAMAGE TO

PAINTED SURFACES OF THE VEHICLE. CAUTION: THOROUGHLY CLEAN THE BOTTOM OF

THE HYDRAULIC ASSEMBLY IN THE AREA OF THE

DUAL FUNCTION PRESSURE SWITCH, BEFORE RE-

MOVING THE SWITCH FROM HYDRAULIC ASSEM-

BLY. USE MOPAR BRAKE PARTS CLEANER OR AN

EQUIVALENT. EXTREME CARE MUST BE USED SO

NO DIRT IS ALLOWED TO ENTER THE HYDRAULIC

ASSEMBLY THROUGH WHERE THE DUAL FUNC-

TION PRESSURE SWITCH IS MOUNTED. ANY DIRT

ENTERING HYDRAULIC ASSEMBLY MAY PLUG IN-

TERNAL PASSAGES CAUSING A HYDRAULIC AS-

SEMBLY FAILURE.

(1) Fully de-pressurize the hydraulic accumulator by

pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section. (2) Raise vehicle See Hoisting, Group 0.

(3) From under vehicle, disconnect wiring harness

connectors from dual function pressure switch and

boost pressure transducer (Fig. 9) on the bottom of

hydraulic assembly.

WARNING: WEAR EYE PROTECTION WHEN PER-

FORMING THE FOLLOWING PROCEDURE. SERIOUS

EYE INJURY CAN RESULT FROM BRAKE FLUID

CONTACTING THE EYES.

(4) Be sure that the hydraulic system is de-

pressurized. Remove the dual function pressure

switch from the hydraulic assembly using Socket,

Special Tool 6607 (Fig. 10). Access to the switch is from

under the vehicle using a long extension.

Fig. 6 Rear Wheel Speed Sensor Routing at Trailing Arm

Fig. 7 Removing Speed Sensor (Typical)

5 - 106 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 257 of 2438

INSTALL

CAUTION: Be sure that the dual function pressure

switch is thoroughly cleaned using Mopar Brake

Parts Cleaner or an equivalent before installing it

into the hydraulic assembly. Wet the O-ring seals

on the switch with fresh clean brake fluid before in-

stalling it into the hydraulic assembly.

Fig. 8 Body Routing of Rear Speed Sensor Wiring

Fig. 9 Dual Function Pressure Switch And Pressure Transducer Wiring

Fig. 10 Dual Function Pressure Switch Remove/ Install

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 107

Page 258 of 2438

CAUTION: Do not insert dual function pressure

switch into hydraulic assembly using the socket

and ratchet. Cross threading of the switch may oc-

cur. (1) Install the dual function pressure switch into

the hydraulic assembly by hand until the O-ring

seals are seated. (2) Using Socket, Special Tool 6607, (Fig. 10)

torque the dual function pressure switch into the hy-

draulic assembly to 12 N Im (9 ft. lbs.).

(3) Connect the wiring harness connectors (Fig. 9)

onto the dual function pressure switch and the boost

pressure transducer. Be sure the locking tabs on the

connectors are fully engaged on the switches. (4) Lower the vehicle.

(5) Turn the ignition switch to the on position and

let the system pressurize. Check for any leaks at the

dual function pressure switch. (6) Fully de-pressurize the hydraulic assembly a

second time. This will purge any air out that may

have entered hydraulic assembly when the switch

was removed. Turn the ignition switch to the on po-

sition and let the system pressurize again. (7) Road test vehicle to insure that the brake sys-

tem is performing correctly.

PRIMARY PRESSURE TRANSDUCER

REMOVE

WARNING: FAILURE TO FULLY DE-PRESSURIZE

THE HYDRAULIC BLADDER ACCUMULATOR PRIOR

TO REMOVING PRIMARY PRESSURE TRANS-

DUCER. WILL RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES OF THE

VEHICLE.

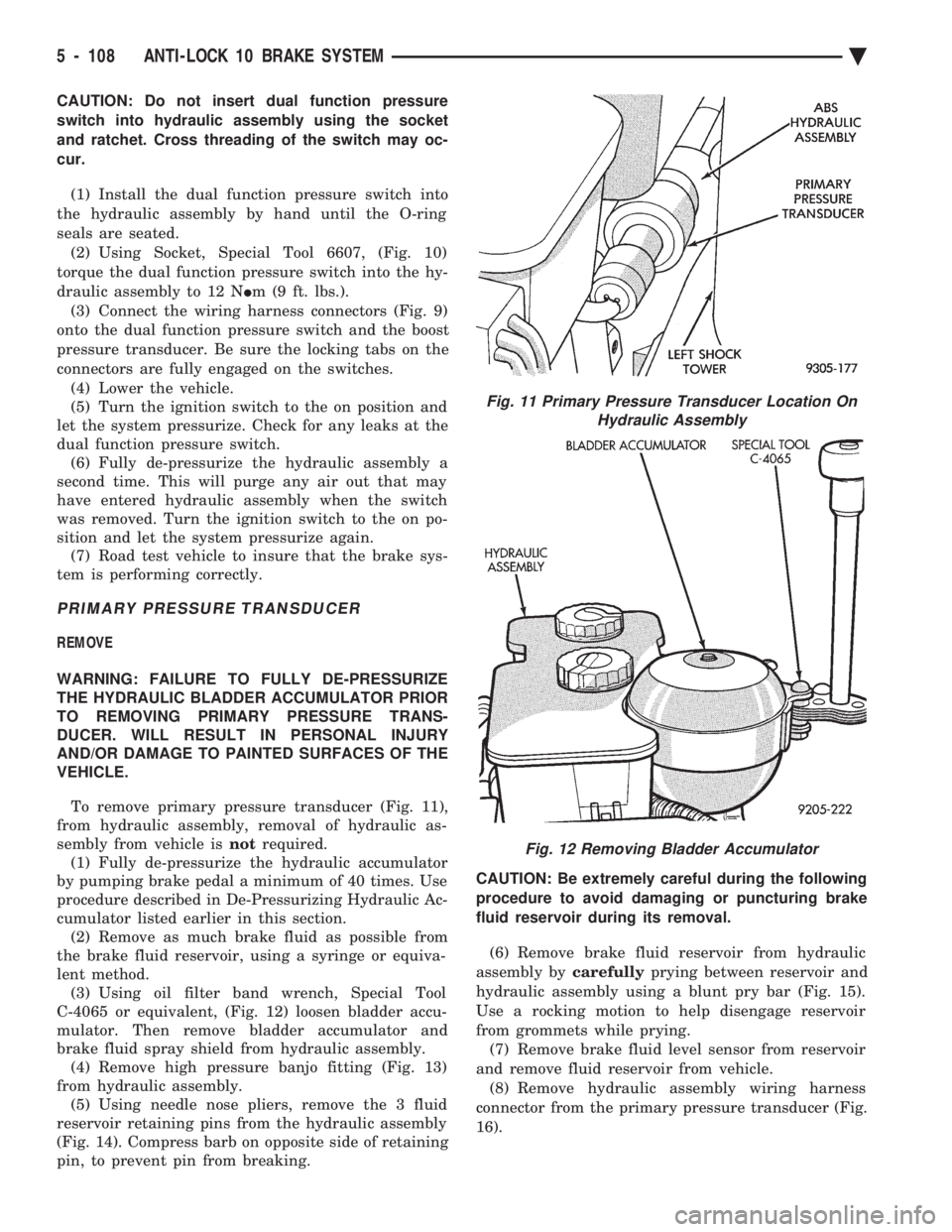

To remove primary pressure transducer (Fig. 11),

from hydraulic assembly, removal of hydraulic as-

sembly from vehicle is notrequired.

(1) Fully de-pressurize the hydraulic accumulator

by pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section. (2) Remove as much brake fluid as possible from

the brake fluid reservoir, using a syringe or equiva-

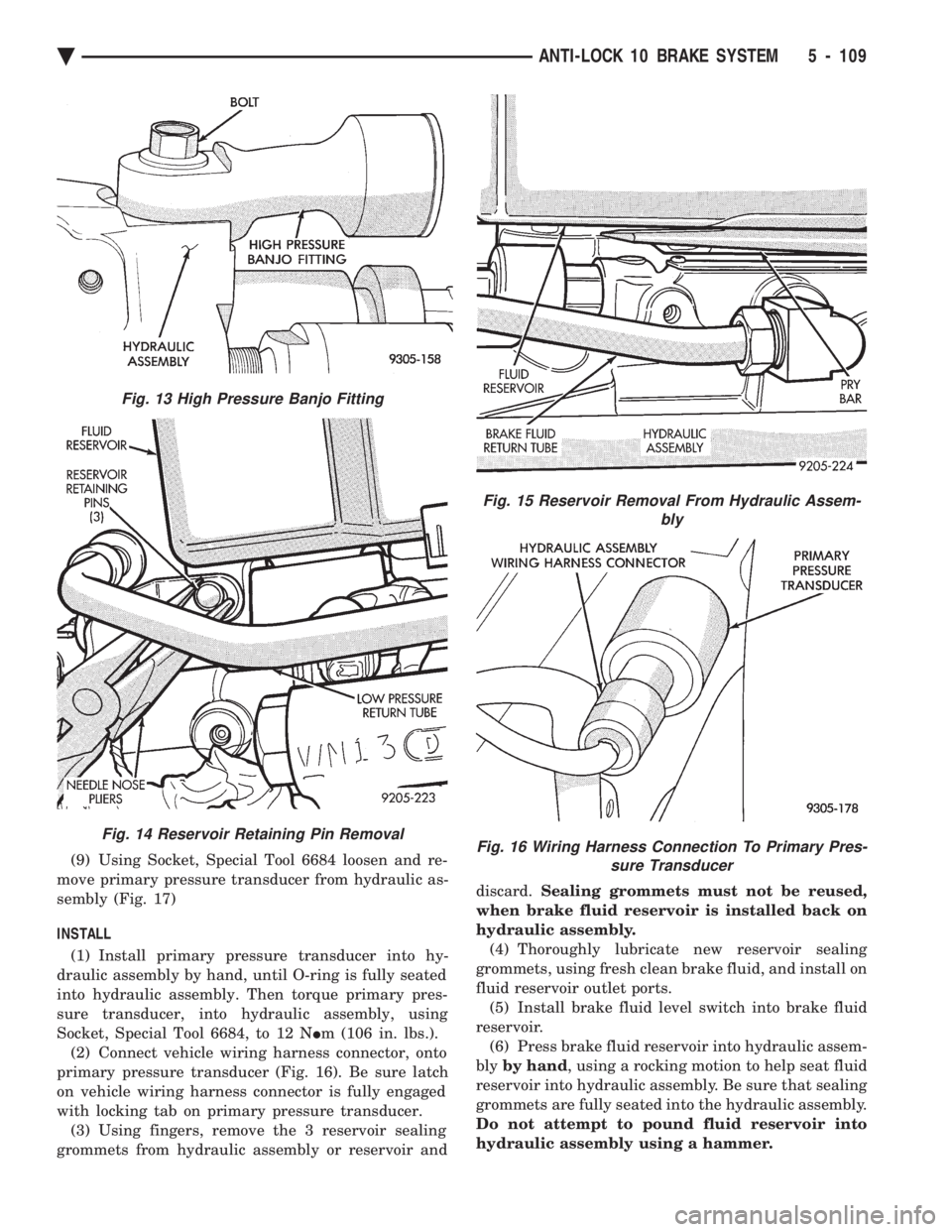

lent method. (3) Using oil filter band wrench, Special Tool

C-4065 or equivalent, (Fig. 12) loosen bladder accu-

mulator. Then remove bladder accumulator and

brake fluid spray shield from hydraulic assembly. (4) Remove high pressure banjo fitting (Fig. 13)

from hydraulic assembly. (5) Using needle nose pliers, remove the 3 fluid

reservoir retaining pins from the hydraulic assembly

(Fig. 14). Compress barb on opposite side of retaining

pin, to prevent pin from breaking. CAUTION: Be extremely careful during the following

procedure to avoid damaging or puncturing brake

fluid reservoir during its removal.

(6) Remove brake fluid reservoir from hydraulic

assembly by carefullyprying between reservoir and

hydraulic assembly using a blunt pry bar (Fig. 15).

Use a rocking motion to help disengage reservoir

from grommets while prying. (7) Remove brake fluid level sensor from reservoir

and remove fluid reservoir from vehicle. (8) Remove hydraulic assembly wiring harness

connector from the primary pressure transducer (Fig.

16).

Fig. 11 Primary Pressure Transducer Location On Hydraulic Assembly

Fig. 12 Removing Bladder Accumulator

5 - 108 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 259 of 2438

(9) Using Socket, Special Tool 6684 loosen and re-

move primary pressure transducer from hydraulic as-

sembly (Fig. 17)

INSTALL

(1) Install primary pressure transducer into hy-

draulic assembly by hand, until O-ring is fully seated

into hydraulic assembly. Then torque primary pres-

sure transducer, into hydraulic assembly, using

Socket, Special Tool 6684, to 12 N Im (106 in. lbs.).

(2) Connect vehicle wiring harness connector, onto

primary pressure transducer (Fig. 16). Be sure latch

on vehicle wiring harness connector is fully engaged

with locking tab on primary pressure transducer. (3) Using fingers, remove the 3 reservoir sealing

grommets from hydraulic assembly or reservoir and discard.

Sealing grommets must not be reused,

when brake fluid reservoir is installed back on

hydraulic assembly. (4) Thoroughly lubricate new reservoir sealing

grommets, using fresh clean brake fluid, and install on

fluid reservoir outlet ports. (5) Install brake fluid level switch into brake fluid

reservoir. (6) Press brake fluid reservoir into hydraulic assem-

bly by hand , using a rocking motion to help seat fluid

reservoir into hydraulic assembly. Be sure that sealing

grommets are fully seated into the hydraulic assembly.

Do not attempt to pound fluid reservoir into

hydraulic assembly using a hammer.

Fig. 13 High Pressure Banjo Fitting

Fig. 14 Reservoir Retaining Pin Removal

Fig. 15 Reservoir Removal From Hydraulic Assem- bly

Fig. 16 Wiring Harness Connection To Primary Pres-sure Transducer

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 109