battery CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1705 of 2438

EXHAUST MANIFOLD

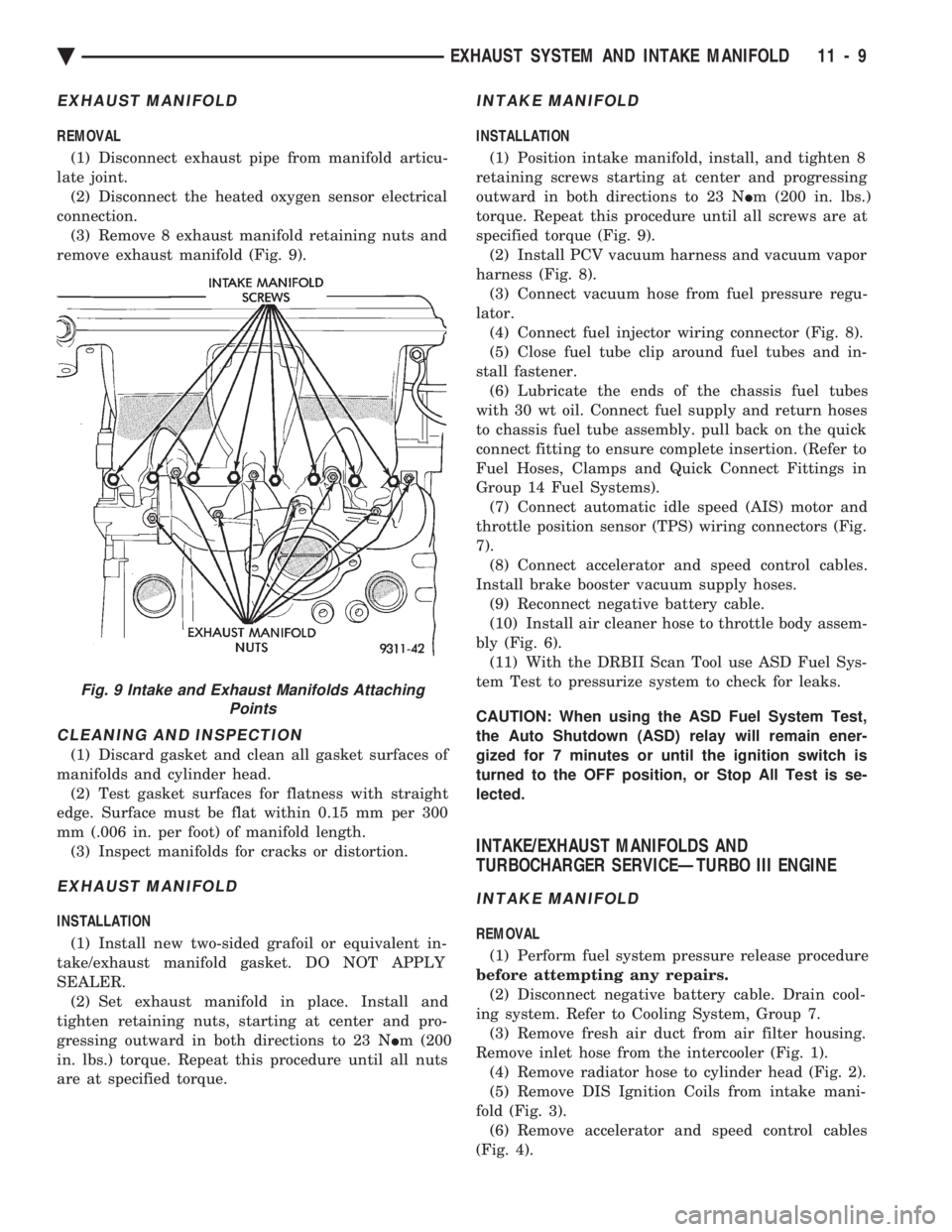

REMOVAL (1) Disconnect exhaust pipe from manifold articu-

late joint. (2) Disconnect the heated oxygen sensor electrical

connection. (3) Remove 8 exhaust manifold retaining nuts and

remove exhaust manifold (Fig. 9).

CLEANING AND INSPECTION

(1) Discard gasket and clean all gasket surfaces of

manifolds and cylinder head. (2) Test gasket surfaces for flatness with straight

edge. Surface must be flat within 0.15 mm per 300

mm (.006 in. per foot) of manifold length. (3) Inspect manifolds for cracks or distortion.

EXHAUST MANIFOLD

INSTALLATION

(1) Install new two-sided grafoil or equivalent in-

take/exhaust manifold gasket. DO NOT APPLY

SEALER. (2) Set exhaust manifold in place. Install and

tighten retaining nuts, starting at center and pro-

gressing outward in both directions to 23 N Im (200

in. lbs.) torque. Repeat this procedure until all nuts

are at specified torque.

INTAKE MANIFOLD

INSTALLATION

(1) Position intake manifold, install, and tighten 8

retaining screws starting at center and progressing

outward in both directions to 23 N Im (200 in. lbs.)

torque. Repeat this procedure until all screws are at

specified torque (Fig. 9). (2) Install PCV vacuum harness and vacuum vapor

harness (Fig. 8). (3) Connect vacuum hose from fuel pressure regu-

lator. (4) Connect fuel injector wiring connector (Fig. 8).

(5) Close fuel tube clip around fuel tubes and in-

stall fastener. (6) Lubricate the ends of the chassis fuel tubes

with 30 wt oil. Connect fuel supply and return hoses

to chassis fuel tube assembly. pull back on the quick

connect fitting to ensure complete insertion. (Refer to

Fuel Hoses, Clamps and Quick Connect Fittings in

Group 14 Fuel Systems). (7) Connect automatic idle speed (AIS) motor and

throttle position sensor (TPS) wiring connectors (Fig.

7). (8) Connect accelerator and speed control cables.

Install brake booster vacuum supply hoses. (9) Reconnect negative battery cable.

(10) Install air cleaner hose to throttle body assem-

bly (Fig. 6). (11) With the DRBII Scan Tool use ASD Fuel Sys-

tem Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is se-

lected.

INTAKE/EXHAUST MANIFOLDS AND

TURBOCHARGER SERVICEÐTURBO III ENGINE

INTAKE MANIFOLD

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs. (2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Cooling System, Group 7. (3) Remove fresh air duct from air filter housing.

Remove inlet hose from the intercooler (Fig. 1). (4) Remove radiator hose to cylinder head (Fig. 2).

(5) Remove DIS Ignition Coils from intake mani-

fold (Fig. 3). (6) Remove accelerator and speed control cables

(Fig. 4).

Fig. 9 Intake and Exhaust Manifolds Attaching Points

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 9

Page 1707 of 2438

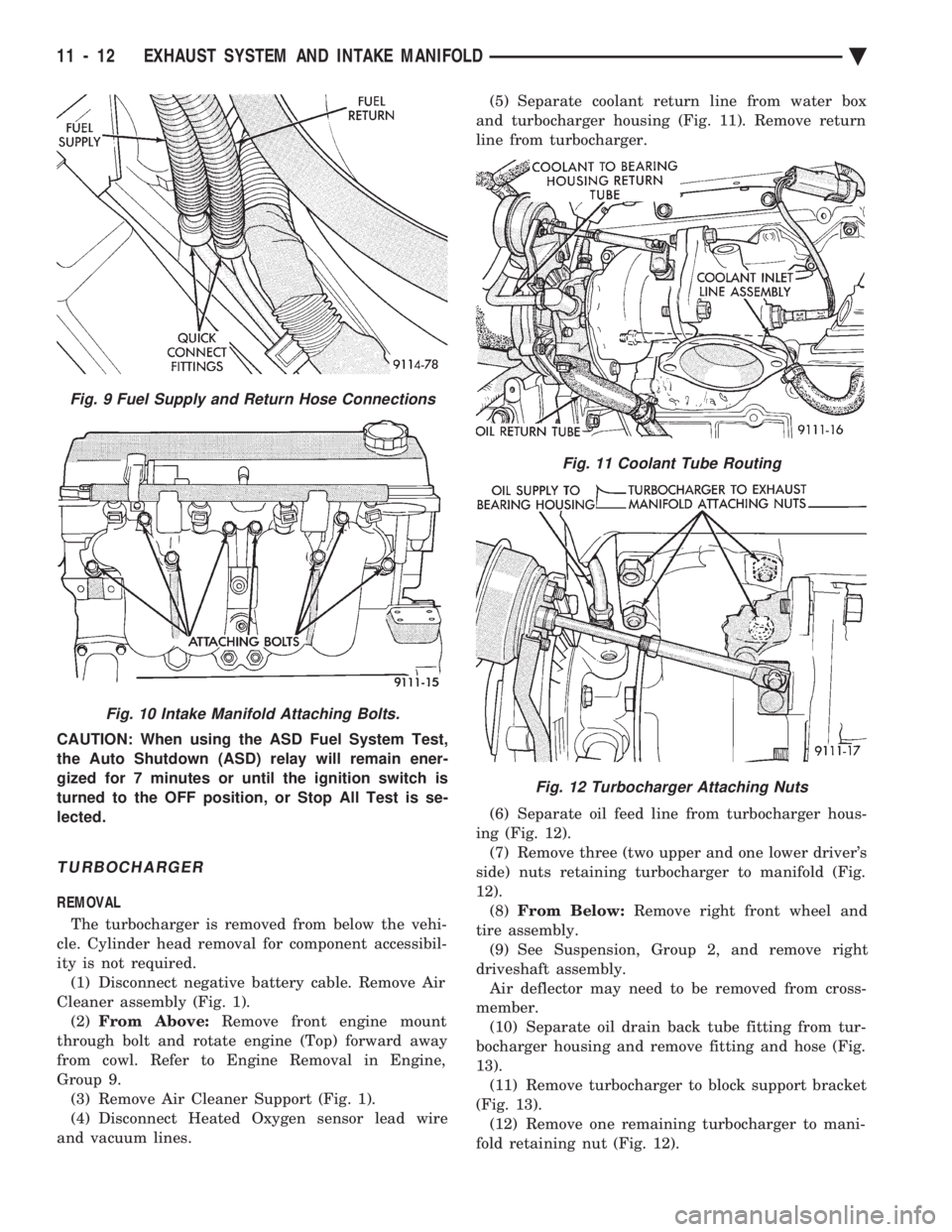

(3) Inspect quick connect fittings for damage, re-

place if necessary Refer to Fuel System, Group 14 for

procedure. Lube tube with clean 30w engine oil, Con-

nect fuel supply and return hoses to chassis tube as-

sembly. Check connection by pulling on connector to

insure it locked into position (Fig. 9). (4) Connect Fuel Injector (Fig. 8), and Charge

Temperature Sensor wiring connectors (Fig. 7).

INTAKE MANIFOLD

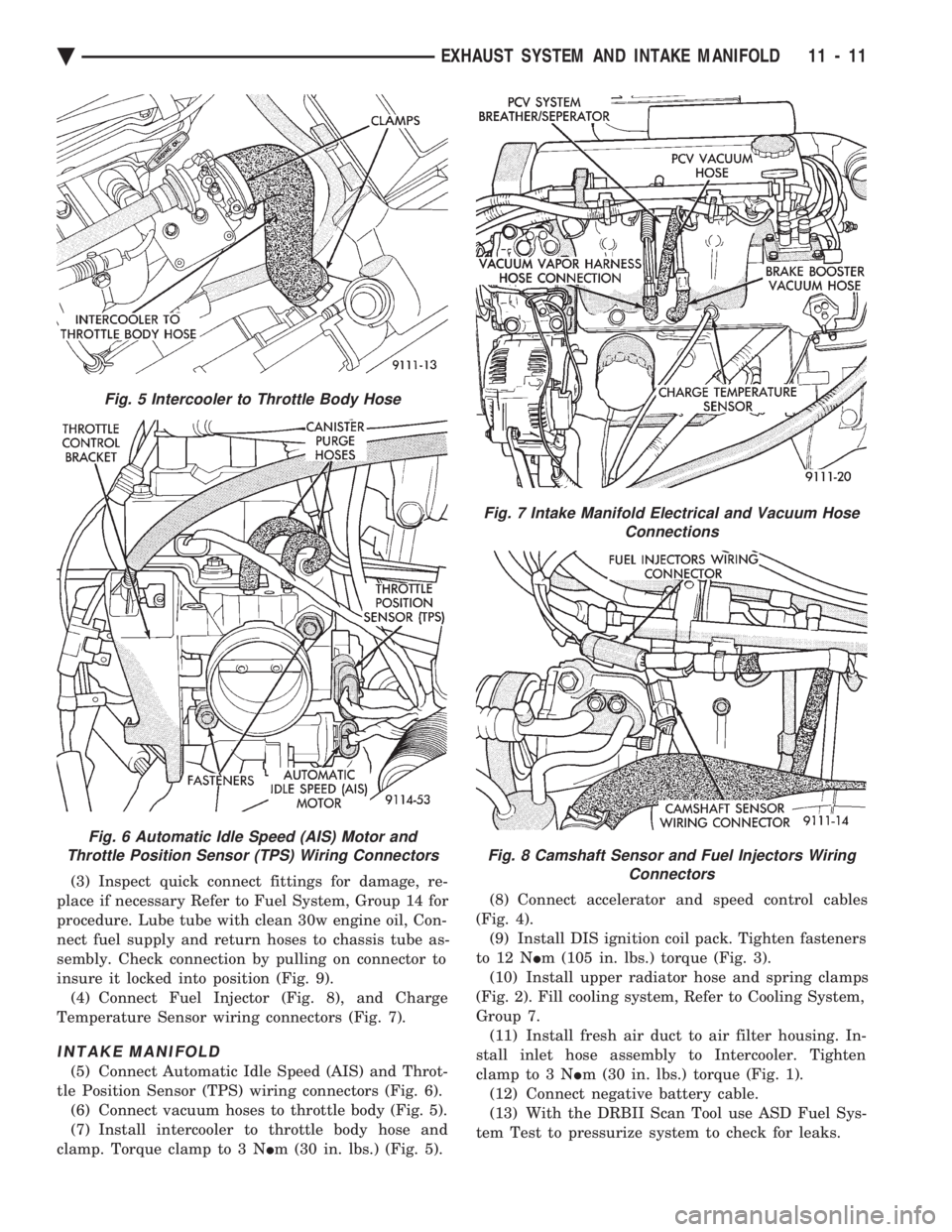

(5) Connect Automatic Idle Speed (AIS) and Throt-

tle Position Sensor (TPS) wiring connectors (Fig. 6). (6) Connect vacuum hoses to throttle body (Fig. 5).

(7) Install intercooler to throttle body hose and

clamp. Torque clamp to 3 N Im (30 in. lbs.) (Fig. 5). (8) Connect accelerator and speed control cables

(Fig. 4). (9) Install DIS ignition coil pack. Tighten fasteners

to 12 N Im (105 in. lbs.) torque (Fig. 3).

(10) Install upper radiator hose and spring clamps

(Fig. 2). Fill cooling system, Refer to Cooling System,

Group 7. (11) Install fresh air duct to air filter housing. In-

stall inlet hose assembly to Intercooler. Tighten

clamp to 3 N Im (30 in. lbs.) torque (Fig. 1).

(12) Connect negative battery cable.

(13) With the DRBII Scan Tool use ASD Fuel Sys-

tem Test to pressurize system to check for leaks.

Fig. 5 Intercooler to Throttle Body Hose

Fig. 6 Automatic Idle Speed (AIS) Motor and

Throttle Position Sensor (TPS) Wiring Connectors

Fig. 7 Intake Manifold Electrical and Vacuum Hose Connections

Fig. 8 Camshaft Sensor and Fuel Injectors WiringConnectors

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 11

Page 1708 of 2438

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is se-

lected.

TURBOCHARGER

REMOVAL

The turbocharger is removed from below the vehi-

cle. Cylinder head removal for component accessibil-

ity is not required. (1) Disconnect negative battery cable. Remove Air

Cleaner assembly (Fig. 1). (2) From Above: Remove front engine mount

through bolt and rotate engine (Top) forward away

from cowl. Refer to Engine Removal in Engine,

Group 9. (3) Remove Air Cleaner Support (Fig. 1).

(4) Disconnect Heated Oxygen sensor lead wire

and vacuum lines. (5) Separate coolant return line from water box

and turbocharger housing (Fig. 11). Remove return

line from turbocharger.

(6) Separate oil feed line from turbocharger hous-

ing (Fig. 12). (7) Remove three (two upper and one lower driver's

side) nuts retaining turbocharger to manifold (Fig.

12). (8) From Below: Remove right front wheel and

tire assembly. (9) See Suspension, Group 2, and remove right

driveshaft assembly. Air deflector may need to be removed from cross-

member. (10) Separate oil drain back tube fitting from tur-

bocharger housing and remove fitting and hose (Fig.

13). (11) Remove turbocharger to block support bracket

(Fig. 13). (12) Remove one remaining turbocharger to mani-

fold retaining nut (Fig. 12).

Fig. 11 Coolant Tube Routing

Fig. 12 Turbocharger Attaching Nuts

Fig. 9 Fuel Supply and Return Hose Connections

Fig. 10 Intake Manifold Attaching Bolts.

11 - 12 EXHAUST SYSTEM AND INTAKE MANIFOLD Ä

Page 1710 of 2438

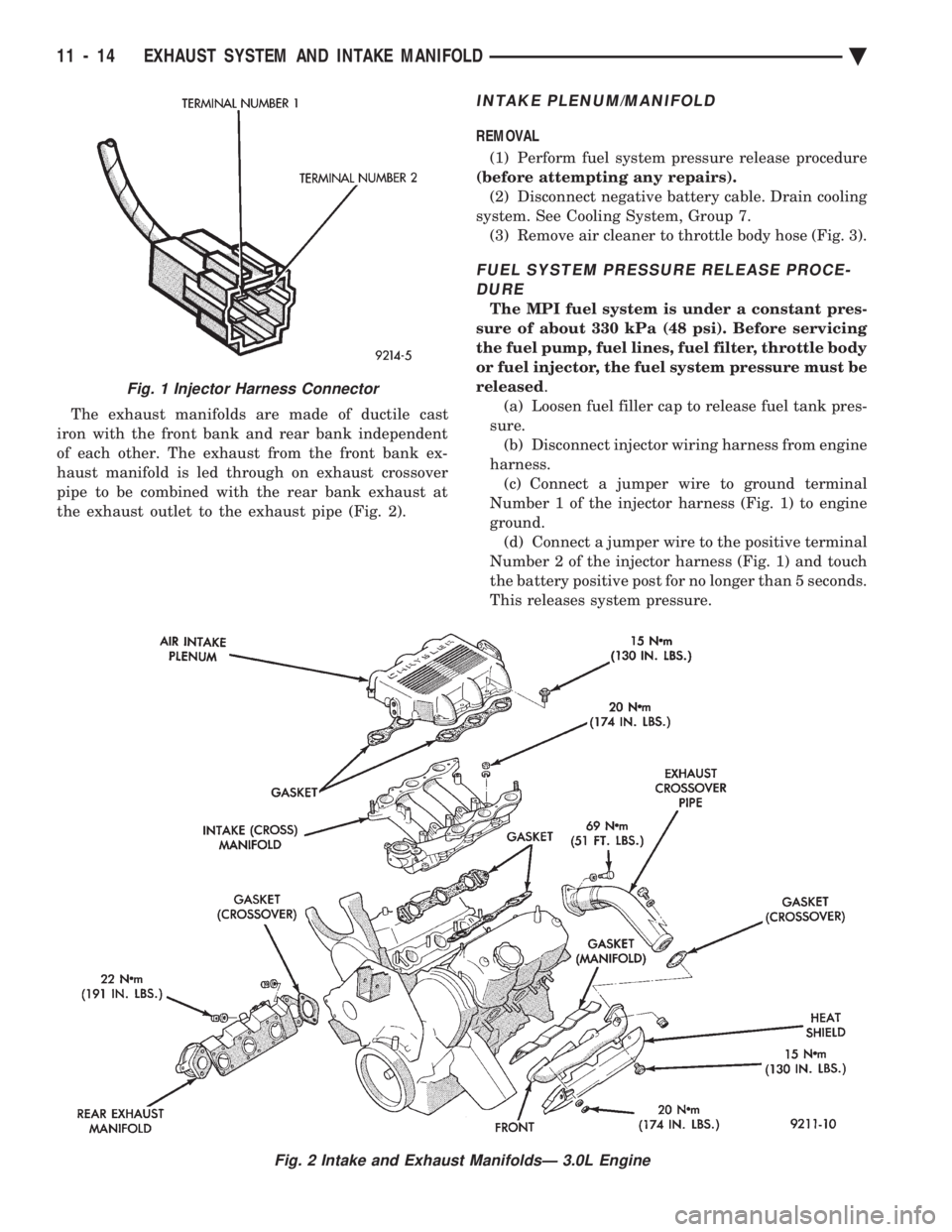

The exhaust manifolds are made of ductile cast

iron with the front bank and rear bank independent

of each other. The exhaust from the front bank ex-

haust manifold is led through on exhaust crossover

pipe to be combined with the rear bank exhaust at

the exhaust outlet to the exhaust pipe (Fig. 2).

INTAKE PLENUM/MANIFOLD

REMOVAL

(1) Perform fuel system pressure release procedure

(before attempting any repairs). (2) Disconnect negative battery cable. Drain cooling

system. See Cooling System, Group 7. (3) Remove air cleaner to throttle body hose (Fig. 3).

FUEL SYSTEM PRESSURE RELEASE PROCE-DURE

The MPI fuel system is under a constant pres-

sure of about 330 kPa (48 psi). Before servicing

the fuel pump, fuel lines, fuel filter, throttle body

or fuel injector, the fuel system pressure must be

released .

(a) Loosen fuel filler cap to release fuel tank pres-

sure. (b) Disconnect injector wiring harness from engine

harness. (c) Connect a jumper wire to ground terminal

Number 1 of the injector harness (Fig. 1) to engine

ground. (d) Connect a jumper wire to the positive terminal

Number 2 of the injector harness (Fig. 1) and touch

the battery positive post for no longer than 5 seconds.

This releases system pressure.

Fig. 1 Injector Harness Connector

Fig. 2 Intake and Exhaust ManifoldsÐ 3.0L Engine

11 - 14 EXHAUST SYSTEM AND INTAKE MANIFOLD Ä

Page 1712 of 2438

place. Install attaching fasteners (8) and tighten in

several steps in sequence shown (Fig. 17) to 13 N Im

(115 in. lbs.). (13) Connect fuel line to fuel rail (Fig. 7). Torque

hose clamps to 1 N Im (10 in. lbs.).

(14) Connect vacuum harness to air intake ple-

num. (15) Connect coolant temperature sensor electrical

connector to sensor (Fig. 7). (16) Connect PCV and brake booster supply hose

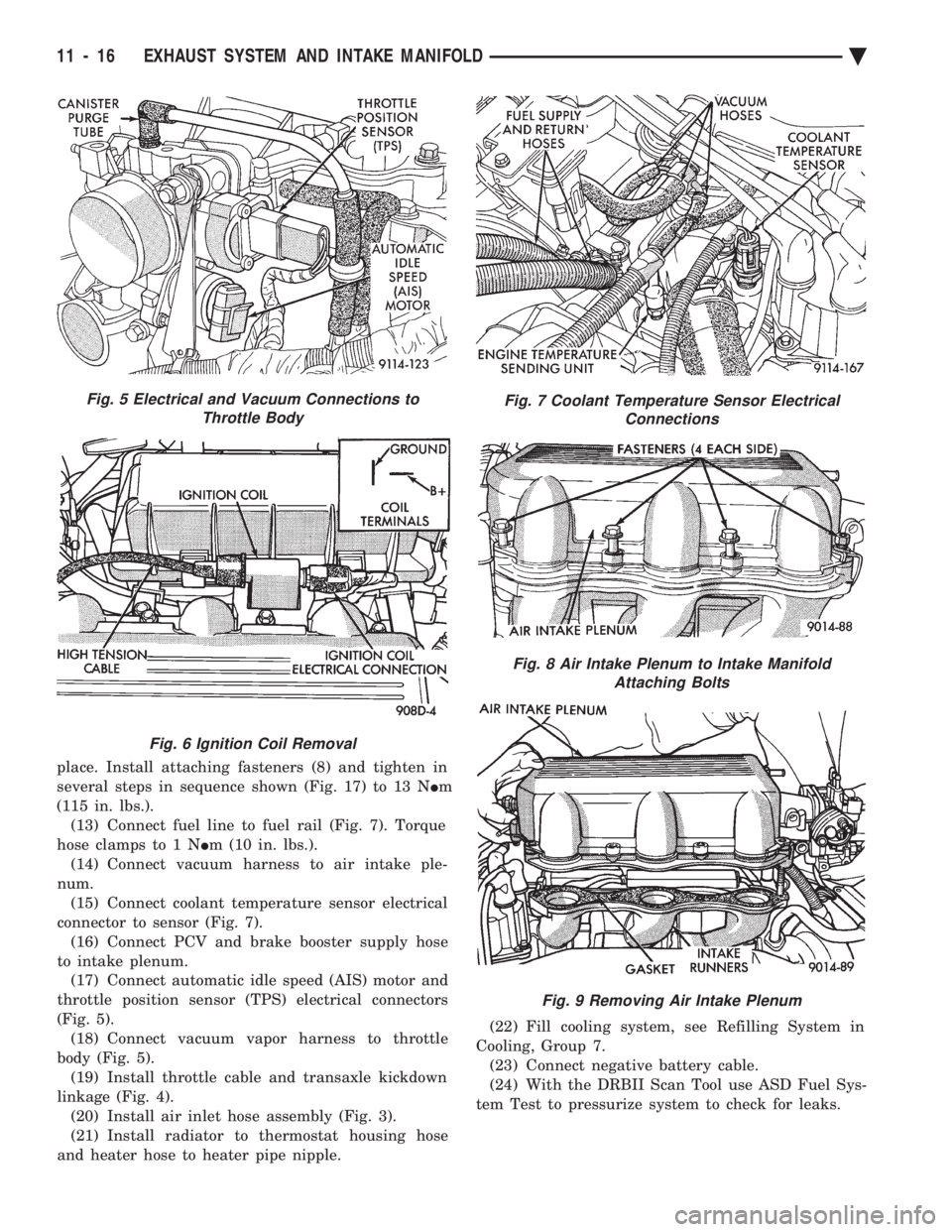

to intake plenum. (17) Connect automatic idle speed (AIS) motor and

throttle position sensor (TPS) electrical connectors

(Fig. 5). (18) Connect vacuum vapor harness to throttle

body (Fig. 5). (19) Install throttle cable and transaxle kickdown

linkage (Fig. 4). (20) Install air inlet hose assembly (Fig. 3).

(21) Install radiator to thermostat housing hose

and heater hose to heater pipe nipple. (22) Fill cooling system, see Refilling System in

Cooling, Group 7. (23) Connect negative battery cable.

(24) With the DRBII Scan Tool use ASD Fuel Sys-

tem Test to pressurize system to check for leaks.

Fig. 5 Electrical and Vacuum Connections to Throttle Body

Fig. 6 Ignition Coil Removal

Fig. 7 Coolant Temperature Sensor Electrical Connections

Fig. 8 Air Intake Plenum to Intake ManifoldAttaching Bolts

Fig. 9 Removing Air Intake Plenum

11 - 16 EXHAUST SYSTEM AND INTAKE MANIFOLD Ä

Page 1715 of 2438

(2) Attach exhaust pipe to exhaust manifold and

tighten shoulder bolt to 28 N Im (250 in. lbs.)

(3) Attach crossover pipe to exhaust manifold and

tighten bolt to 69 N Im (51 ft. lbs.)

(4) Connect heated oxygen sensor lead (Fig. 18).

(5) Install front exhaust manifold and attach ex-

haust crossover. (6) Install front manifold heat shield and tighten

attaching screws to 15 N Im (130 in. lbs.) (Fig. 2).

INTAKE/EXHAUST MANIFOLD SERVICEÐ3.3/3.8L

ENGINES

INTAKE MANIFOLD

REMOVAL

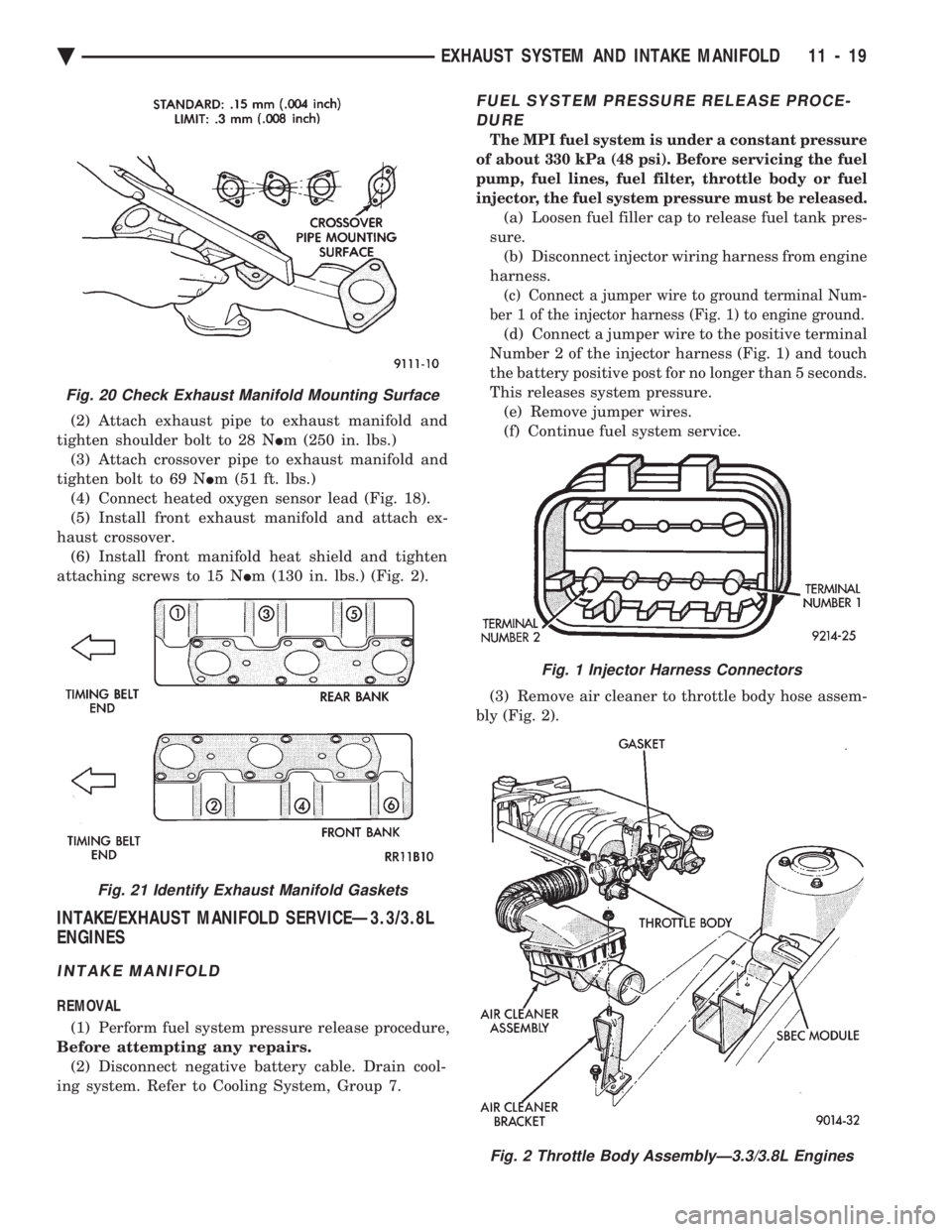

(1) Perform fuel system pressure release procedure,

Before attempting any repairs. (2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Cooling System, Group 7.

FUEL SYSTEM PRESSURE RELEASE PROCE- DURE

The MPI fuel system is under a constant pressure

of about 330 kPa (48 psi). Before servicing the fuel

pump, fuel lines, fuel filter, throttle body or fuel

injector, the fuel system pressure must be released.

(a) Loosen fuel filler cap to release fuel tank pres-

sure. (b) Disconnect injector wiring harness from engine

harness.

(c) Connect a jumper wire to ground terminal Num-

ber 1 of the injector harness (Fig. 1) to engine ground.

(d) Connect a jumper wire to the positive terminal

Number 2 of the injector harness (Fig. 1) and touch

the battery positive post for no longer than 5 seconds.

This releases system pressure. (e) Remove jumper wires.

(f) Continue fuel system service.

(3) Remove air cleaner to throttle body hose assem-

bly (Fig. 2).

Fig. 20 Check Exhaust Manifold Mounting Surface

Fig. 21 Identify Exhaust Manifold Gaskets

Fig. 1 Injector Harness Connectors

Fig. 2 Throttle Body AssemblyÐ3.3/3.8L Engines

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 19

Page 1719 of 2438

(7) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports (Fig. 12). (8) Install the (4) fuel rail attaching bolts and

tighten to 22 N Im (200 in. lbs.) torque (Fig. 10).

(9) Install fuel tube retaining bracket screw and

tighten to 4 N Im (35 in. lbs.) torque (Fig. 10).

(10) Reconnect cam sensor, coolant temperature

sensor and engine temperature sensors (Fig. 11). (11) Install fuel injector harness wiring clips on

the generator bracket and intake manifold water

tube (Fig. 11). (12) Connect fuel pressure regulator vacuum line.

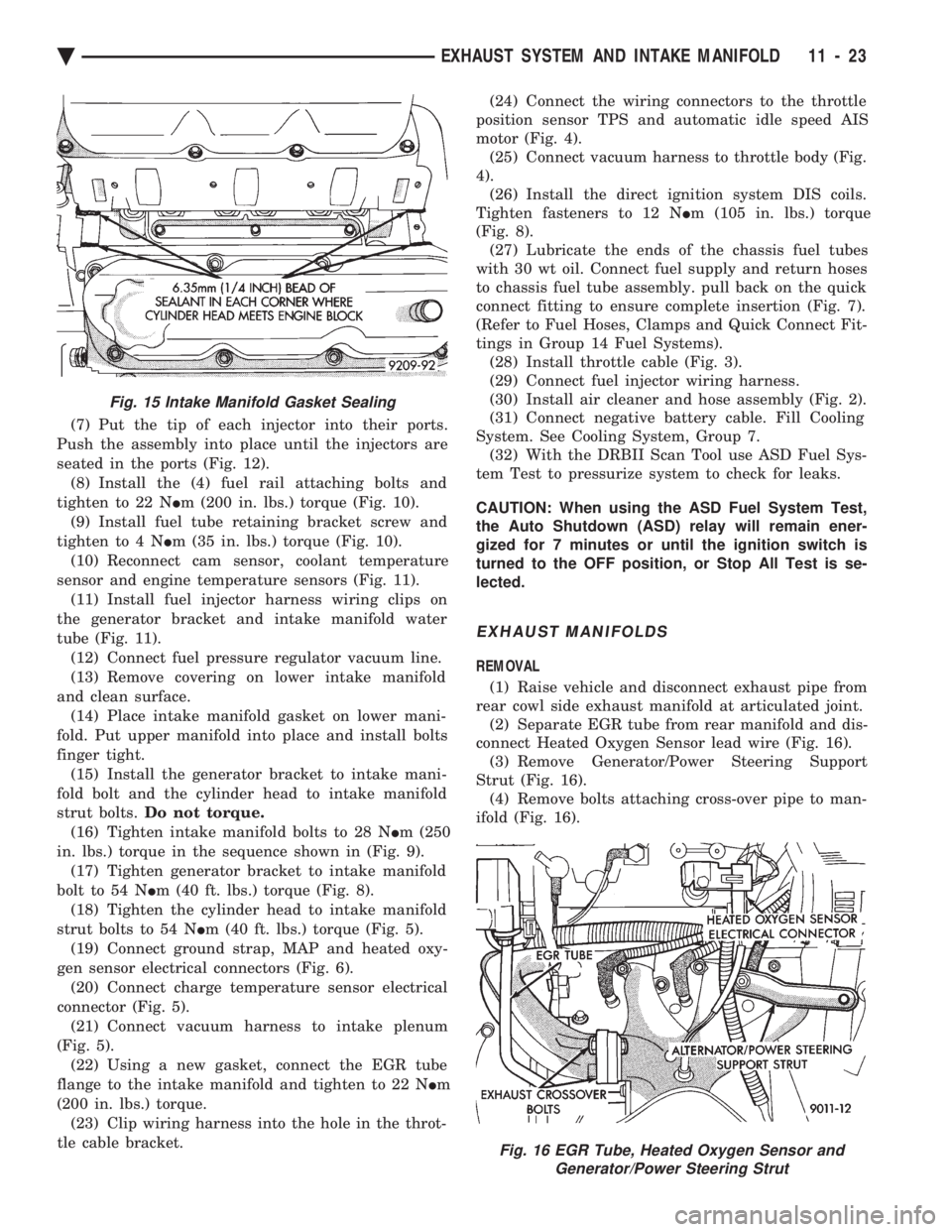

(13) Remove covering on lower intake manifold

and clean surface. (14) Place intake manifold gasket on lower mani-

fold. Put upper manifold into place and install bolts

finger tight. (15) Install the generator bracket to intake mani-

fold bolt and the cylinder head to intake manifold

strut bolts. Do not torque.

(16) Tighten intake manifold bolts to 28 N Im (250

in. lbs.) torque in the sequence shown in (Fig. 9). (17) Tighten generator bracket to intake manifold

bolt to 54 N Im (40 ft. lbs.) torque (Fig. 8).

(18) Tighten the cylinder head to intake manifold

strut bolts to 54 N Im (40 ft. lbs.) torque (Fig. 5).

(19) Connect ground strap, MAP and heated oxy-

gen sensor electrical connectors (Fig. 6). (20) Connect charge temperature sensor electrical

connector (Fig. 5). (21) Connect vacuum harness to intake plenum

(Fig. 5). (22) Using a new gasket, connect the EGR tube

flange to the intake manifold and tighten to 22 N Im

(200 in. lbs.) torque. (23) Clip wiring harness into the hole in the throt-

tle cable bracket. (24) Connect the wiring connectors to the throttle

position sensor TPS and automatic idle speed AIS

motor (Fig. 4). (25) Connect vacuum harness to throttle body (Fig.

4). (26) Install the direct ignition system DIS coils.

Tighten fasteners to 12 N Im (105 in. lbs.) torque

(Fig. 8). (27) Lubricate the ends of the chassis fuel tubes

with 30 wt oil. Connect fuel supply and return hoses

to chassis fuel tube assembly. pull back on the quick

connect fitting to ensure complete insertion (Fig. 7).

(Refer to Fuel Hoses, Clamps and Quick Connect Fit-

tings in Group 14 Fuel Systems). (28) Install throttle cable (Fig. 3).

(29) Connect fuel injector wiring harness.

(30) Install air cleaner and hose assembly (Fig. 2).

(31) Connect negative battery cable. Fill Cooling

System. See Cooling System, Group 7. (32) With the DRBII Scan Tool use ASD Fuel Sys-

tem Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is se-

lected.

EXHAUST MANIFOLDS

REMOVAL

(1) Raise vehicle and disconnect exhaust pipe from

rear cowl side exhaust manifold at articulated joint. (2) Separate EGR tube from rear manifold and dis-

connect Heated Oxygen Sensor lead wire (Fig. 16). (3) Remove Generator/Power Steering Support

Strut (Fig. 16). (4) Remove bolts attaching cross-over pipe to man-

ifold (Fig. 16).

Fig. 15 Intake Manifold Gasket Sealing

Fig. 16 EGR Tube, Heated Oxygen Sensor and Generator/Power Steering Strut

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 23

Page 1744 of 2438

INSTRUMENT PANEL CLUSTER IDENTIFICATIONÐFLEXIBLE FUEL AA-BODY

Flexible fuel A-Body vehicles use a unique gauge

cluster. To identify the cluster, remove it from the

instrument panel and check the number on the tag

on the top. If the part number matches the number

in the parts book for flexible fuel A-bodies, the vehi-

cle was built with the correct cluster. Refer to Group

8E, Instrument Panel and Gauges, for cluster re-

moval and installation.

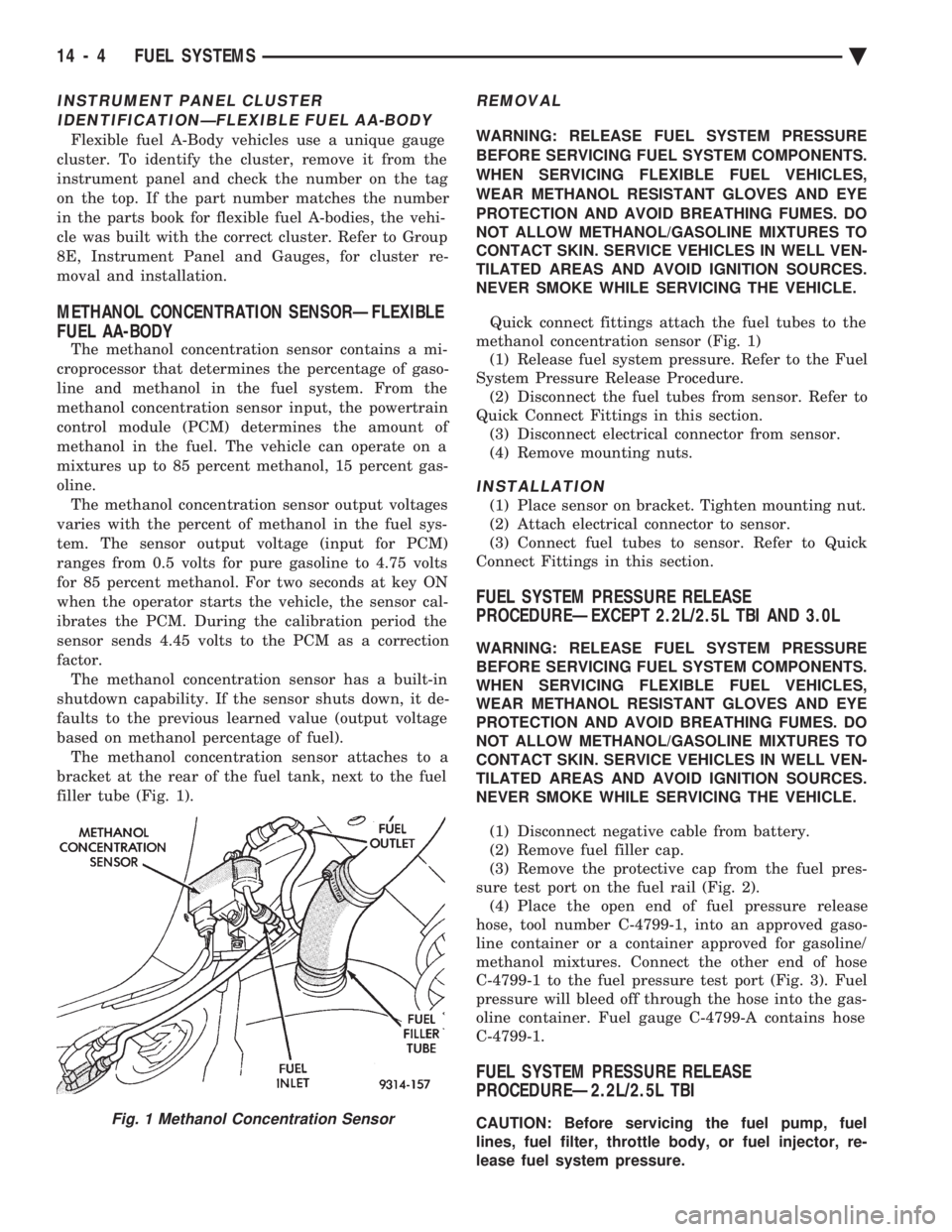

METHANOL CONCENTRATION SENSORÐFLEXIBLE

FUEL AA-BODY

The methanol concentration sensor contains a mi-

croprocessor that determines the percentage of gaso-

line and methanol in the fuel system. From the

methanol concentration sensor input, the powertrain

control module (PCM) determines the amount of

methanol in the fuel. The vehicle can operate on a

mixtures up to 85 percent methanol, 15 percent gas-

oline. The methanol concentration sensor output voltages

varies with the percent of methanol in the fuel sys-

tem. The sensor output voltage (input for PCM)

ranges from 0.5 volts for pure gasoline to 4.75 volts

for 85 percent methanol. For two seconds at key ON

when the operator starts the vehicle, the sensor cal-

ibrates the PCM. During the calibration period the

sensor sends 4.45 volts to the PCM as a correction

factor. The methanol concentration sensor has a built-in

shutdown capability. If the sensor shuts down, it de-

faults to the previous learned value (output voltage

based on methanol percentage of fuel). The methanol concentration sensor attaches to a

bracket at the rear of the fuel tank, next to the fuel

filler tube (Fig. 1).

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

Quick connect fittings attach the fuel tubes to the

methanol concentration sensor (Fig. 1) (1) Release fuel system pressure. Refer to the Fuel

System Pressure Release Procedure. (2) Disconnect the fuel tubes from sensor. Refer to

Quick Connect Fittings in this section. (3) Disconnect electrical connector from sensor.

(4) Remove mounting nuts.

INSTALLATION

(1) Place sensor on bracket. Tighten mounting nut.

(2) Attach electrical connector to sensor.

(3) Connect fuel tubes to sensor. Refer to Quick

Connect Fittings in this section.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐEXCEPT 2.2L/2.5L TBI AND 3.0L

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 2). (4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso-

line container or a container approved for gasoline/

methanol mixtures. Connect the other end of hose

C-4799-1 to the fuel pressure test port (Fig. 3). Fuel

pressure will bleed off through the hose into the gas-

oline container. Fuel gauge C-4799-A contains hose

C-4799-1.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.2L/2.5L TBI

CAUTION: Before servicing the fuel pump, fuel

lines, fuel filter, throttle body, or fuel injector, re-

lease fuel system pressure.Fig. 1 Methanol Concentration Sensor

14 - 4 FUEL SYSTEMS Ä

Page 1751 of 2438

fuel tube enters the fitting, the retainer locks the shoul-

der of the nipple in place and the O-rings seal the tube.

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

When installing fuel tubes, route them in the holders

along the frame rail, fuel tank and the rear of the en-

gine.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from the battery.

(2) Perform the Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section. (3) Remove any loose dirt from quick connect fit-

tings.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY FUEL SPILLAGE.

(4) Push the quick connect fitting toward the fuel

tube while depressing the built-in release tool. Then

slightly twist the fitting and pull it off the fuel tube

(Fig. 14). (5) Cover the fitting to prevent contamination.

TUBE/FITTING SERVICE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

If a quick connect fitting needs service, the follow-

ing procedure must be followed: (1) Disconnect the battery negative battery cable.

(2) Perform the Fuel System Pressure Release Pro-

cedure.

WARNING: WRAP SHOP TOWELS AROUND HOSES

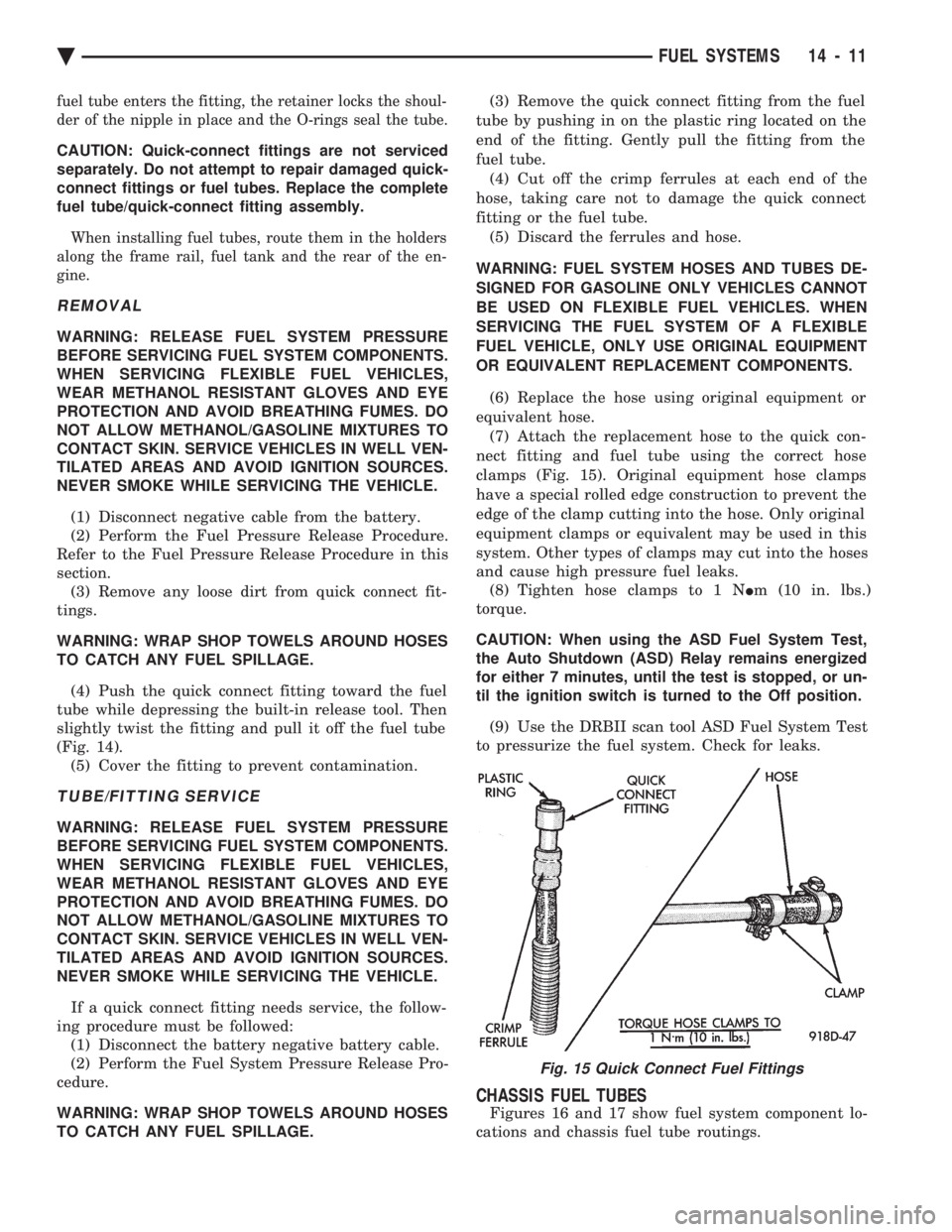

TO CATCH ANY FUEL SPILLAGE. (3) Remove the quick connect fitting from the fuel

tube by pushing in on the plastic ring located on the

end of the fitting. Gently pull the fitting from the

fuel tube. (4) Cut off the crimp ferrules at each end of the

hose, taking care not to damage the quick connect

fitting or the fuel tube. (5) Discard the ferrules and hose.

WARNING: FUEL SYSTEM HOSES AND TUBES DE-

SIGNED FOR GASOLINE ONLY VEHICLES CANNOT

BE USED ON FLEXIBLE FUEL VEHICLES. WHEN

SERVICING THE FUEL SYSTEM OF A FLEXIBLE

FUEL VEHICLE, ONLY USE ORIGINAL EQUIPMENT

OR EQUIVALENT REPLACEMENT COMPONENTS.

(6) Replace the hose using original equipment or

equivalent hose. (7) Attach the replacement hose to the quick con-

nect fitting and fuel tube using the correct hose

clamps (Fig. 15). Original equipment hose clamps

have a special rolled edge construction to prevent the

edge of the clamp cutting into the hose. Only original

equipment clamps or equivalent may be used in this

system. Other types of clamps may cut into the hoses

and cause high pressure fuel leaks. (8) Tighten hose clamps to 1 N Im (10 in. lbs.)

torque.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(9) Use the DRBII scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

CHASSIS FUEL TUBES

Figures 16 and 17 show fuel system component lo-

cations and chassis fuel tube routings.

Fig. 15 Quick Connect Fuel Fittings

Ä FUEL SYSTEMS 14 - 11

Page 1755 of 2438

WARNING: FUEL FILLER TUBE CAPS DESIGNED

FOR GASOLINE ONLY VEHICLES CANNOT BE

USED ON FLEXIBLE FUEL AA-BODY VEHICLES.

WHEN SERVICING THE FUEL SYSTEM OF A FLEX-

IBLE FUEL VEHICLE, ONLY USE ORIGINAL EQUIP-

MENT OR EQUIVALENT REPLACEMENT

COMPONENTS.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐEXCEPT 2.2L/2.5L TBI AND 3.0L

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

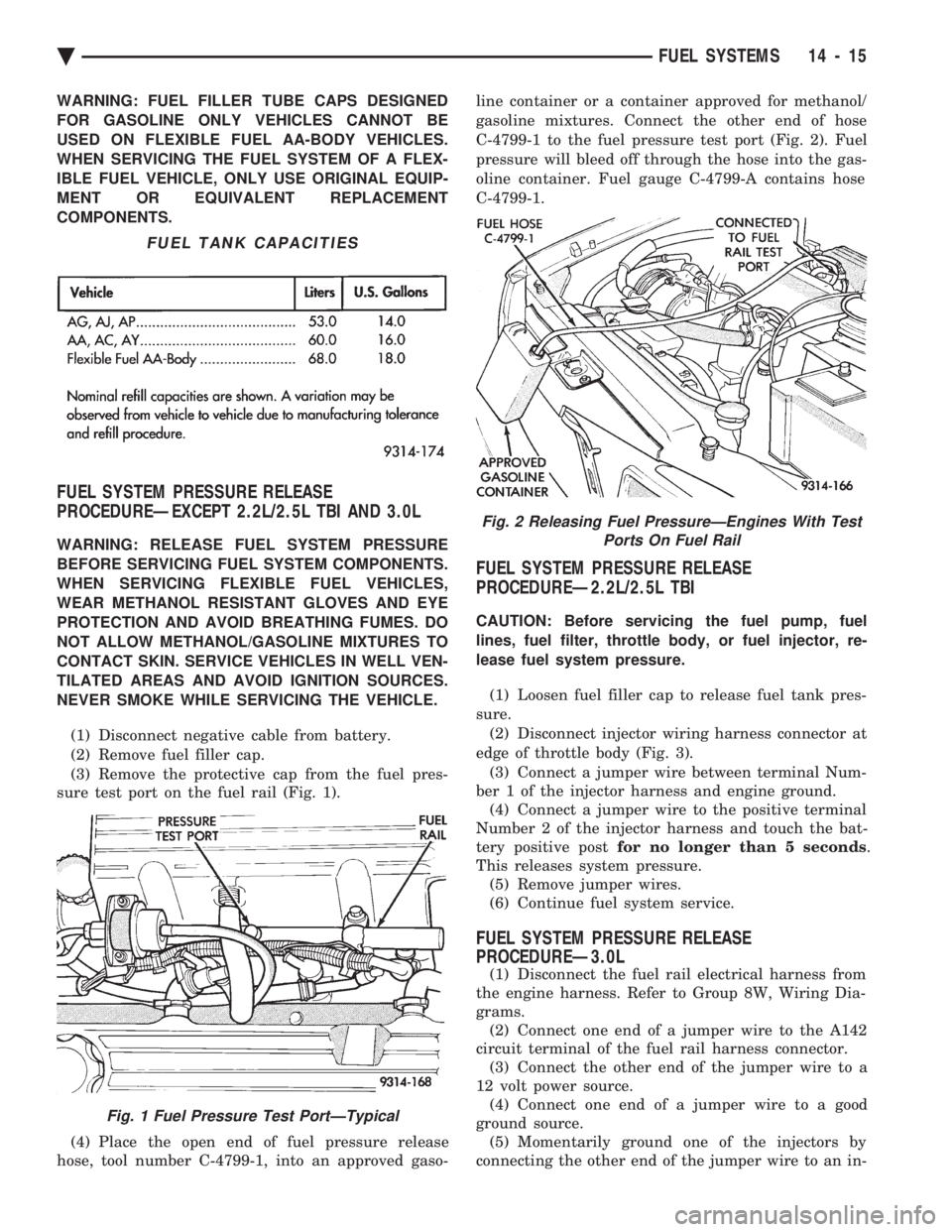

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 1).

(4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso- line container or a container approved for methanol/

gasoline mixtures. Connect the other end of hose

C-4799-1 to the fuel pressure test port (Fig. 2). Fuel

pressure will bleed off through the hose into the gas-

oline container. Fuel gauge C-4799-A contains hose

C-4799-1.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.2L/2.5L TBI

CAUTION: Before servicing the fuel pump, fuel

lines, fuel filter, throttle body, or fuel injector, re-

lease fuel system pressure.

(1) Loosen fuel filler cap to release fuel tank pres-

sure. (2) Disconnect injector wiring harness connector at

edge of throttle body (Fig. 3). (3) Connect a jumper wire between terminal Num-

ber 1 of the injector harness and engine ground. (4) Connect a jumper wire to the positive terminal

Number 2 of the injector harness and touch the bat-

tery positive post for no longer than 5 seconds .

This releases system pressure. (5) Remove jumper wires.

(6) Continue fuel system service.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ3.0L

(1) Disconnect the fuel rail electrical harness from

the engine harness. Refer to Group 8W, Wiring Dia-

grams. (2) Connect one end of a jumper wire to the A142

circuit terminal of the fuel rail harness connector. (3) Connect the other end of the jumper wire to a

12 volt power source. (4) Connect one end of a jumper wire to a good

ground source. (5) Momentarily ground one of the injectors by

connecting the other end of the jumper wire to an in-

FUEL TANK CAPACITIES

Fig. 1 Fuel Pressure Test PortÐTypical

Fig. 2 Releasing Fuel PressureÐEngines With Test Ports On Fuel Rail

Ä FUEL SYSTEMS 14 - 15