battery CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1283 of 2438

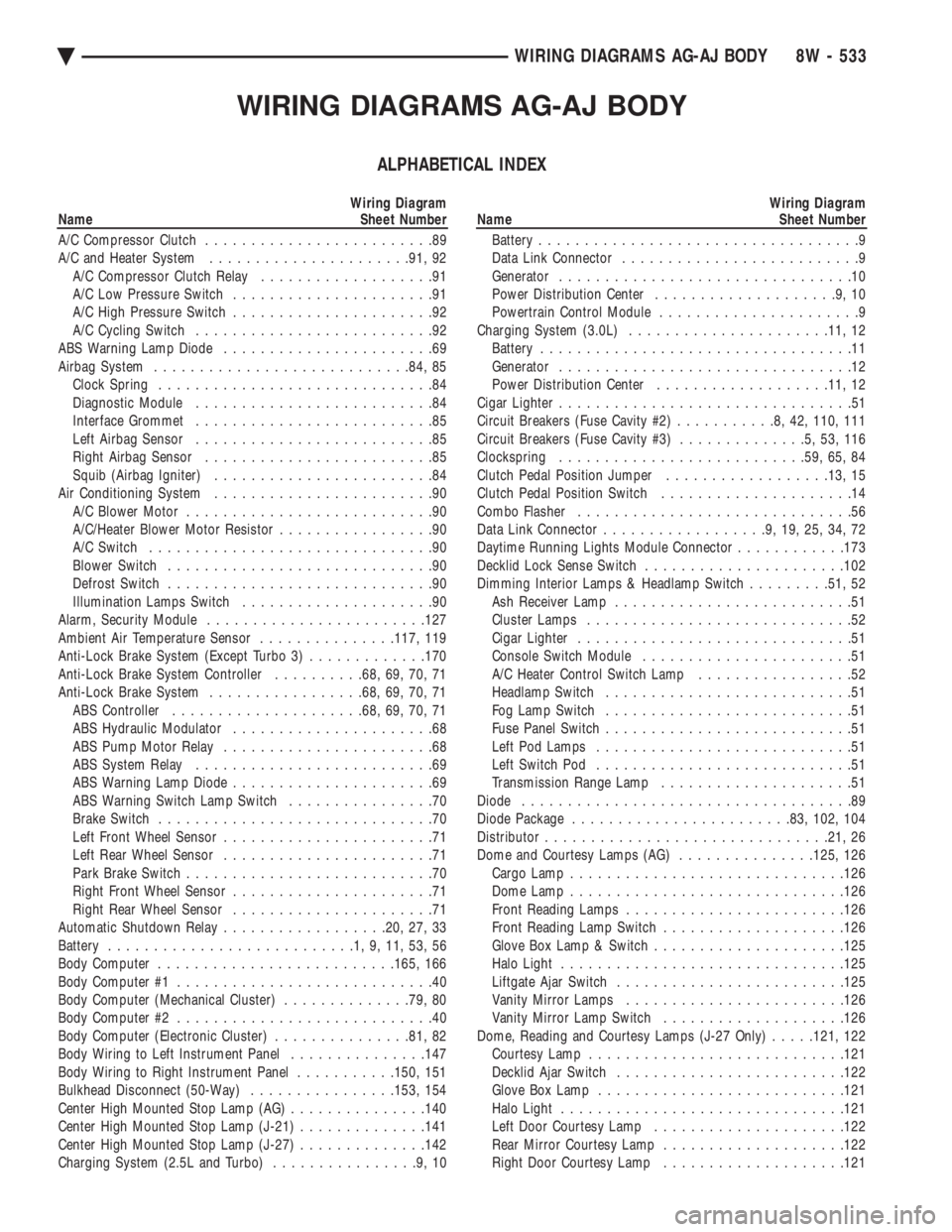

WIRING DIAGRAMS AG-AJ BODY

ALPHABETICAL INDEX

Wiring Diagram

Name Sheet Number

A/C Compressor Clutch .........................89

A/C and Heater System ..................... .91, 92

A/C Compressor Clutch Relay ...................91

A/C Low Pressure Switch ......................91

A/C High Pressure Switch ......................92

A/C Cycling Switch ..........................92

ABS Warning Lamp Diode .......................69

Airbag System ........................... .84, 85

Clock Spring ..............................84

Diagnostic Module ..........................84

Interface Grommet ..........................85

Left Airbag Sensor ..........................85

Right Airbag Sensor .........................85

Squib (Airbag Igniter) ........................84

Air Conditioning System ........................90

A/C Blower Motor ...........................90

A/C/Heater Blower Motor Resistor .................90

A/C Switch ...............................90

Blower Switch .............................90

Defrost Switch .............................90

Illumination Lamps Switch .....................90

Alarm, Security Module ....................... .127

Ambient Air Temperature Sensor ...............117, 119

Anti-Lock Brake System (Except Turbo 3) .............170

Anti-Lock Brake System Controller ..........68, 69, 70, 71

Anti-Lock Brake System .................68, 69, 70, 71

ABS Controller .................... .68, 69, 70, 71

ABS Hydraulic Modulator ......................68

ABS Pump Motor Relay .......................68

ABS System Relay ..........................69

ABS Warning Lamp Diode ......................69

ABS Warning Switch Lamp Switch ................70

Brake Switch ..............................70

Left Front Wheel Sensor .......................71

Left Rear Wheel Sensor .......................71

Park Brake Switch ...........................70

Right Front Wheel Sensor ......................71

Right Rear Wheel Sensor ......................71

Automatic Shutdown Relay ..................20, 27, 33

Battery ...........................1,9,11,53,56

Body Computer ......................... .165, 166

Body Computer #1 ............................40

Body Computer (Mechanical Cluster) ..............79, 80

Body Computer #2 ............................40

Body Computer (Electronic Cluster) ...............81, 82

Body Wiring to Left Instrument Panel ...............147

Body Wiring to Right Instrument Panel ...........150, 151

Bulkhead Disconnect (50-Way) ................153, 154

Center High Mounted Stop Lamp (AG) ...............140

Center High Mounted Stop Lamp (J-21) ..............141

Center High Mounted Stop Lamp (J-27) ..............142

Charging System (2.5L and Turbo) ................9,10Wiring Diagram

Name Sheet Number

Battery ...................................9

Data Link Connector ..........................9

Generator ................................10

Power Distribution Center ....................9,10

Powertrain Control Module ......................9

Charging System (3.0L) ..................... .11, 12

Battery ..................................11

Generator ................................12

Power Distribution Center .................. .11, 12

Cigar Lighter ................................51

Circuit Breakers (Fuse Cavity #2) ...........8,42,110, 111

Circuit Breakers (Fuse Cavity #3) ..............5,53,116

Clockspring .......................... .59, 65, 84

Clutch Pedal Position Jumper ..................13, 15

Clutch Pedal Position Switch .....................14

Combo Flasher ..............................56

Data Link Connector ..................9,19,25,34,72

Daytime Running Lights Module Connector ............173

Decklid Lock Sense Switch ..................... .102

Dimming Interior Lamps & Headlamp Switch .........51, 52

Ash Receiver Lamp ..........................51

Cluster Lamps .............................52

Cigar Lighter ..............................51

Console Switch Module .......................51

A/C Heater Control Switch Lamp .................52

Headlamp Switch ...........................51

Fog Lamp Switch ...........................51

Fuse Panel Switch ...........................51

Left Pod Lamps ............................51

Left Switch Pod ............................51

Transmission Range Lamp .....................51

Diode ....................................89

Diode Package ....................... .83, 102, 104

Distributor .............................. .21, 26

Dome and Courtesy Lamps (AG) ...............125, 126

Cargo Lamp ............................. .126

Dome Lamp ............................. .126

Front Reading Lamps ....................... .126

Front Reading Lamp Switch ................... .126

Glove Box Lamp & Switch .................... .125

Halo Light .............................. .125

Liftgate Ajar Switch ........................ .125

Vanity Mirror Lamps ....................... .126

Vanity Mirror Lamp Switch ................... .126

Dome, Reading and Courtesy Lamps (J-27 Only) .....121, 122

Courtesy Lamp ........................... .121

Decklid Ajar Switch ........................ .122

Glove Box Lamp .......................... .121

Halo Light .............................. .121

Left Door Courtesy Lamp .................... .122

Rear Mirror Courtesy Lamp ................... .122

Right Door Courtesy Lamp ................... .121

Ä WIRING DIAGRAMS AG-AJ BODY 8W - 533

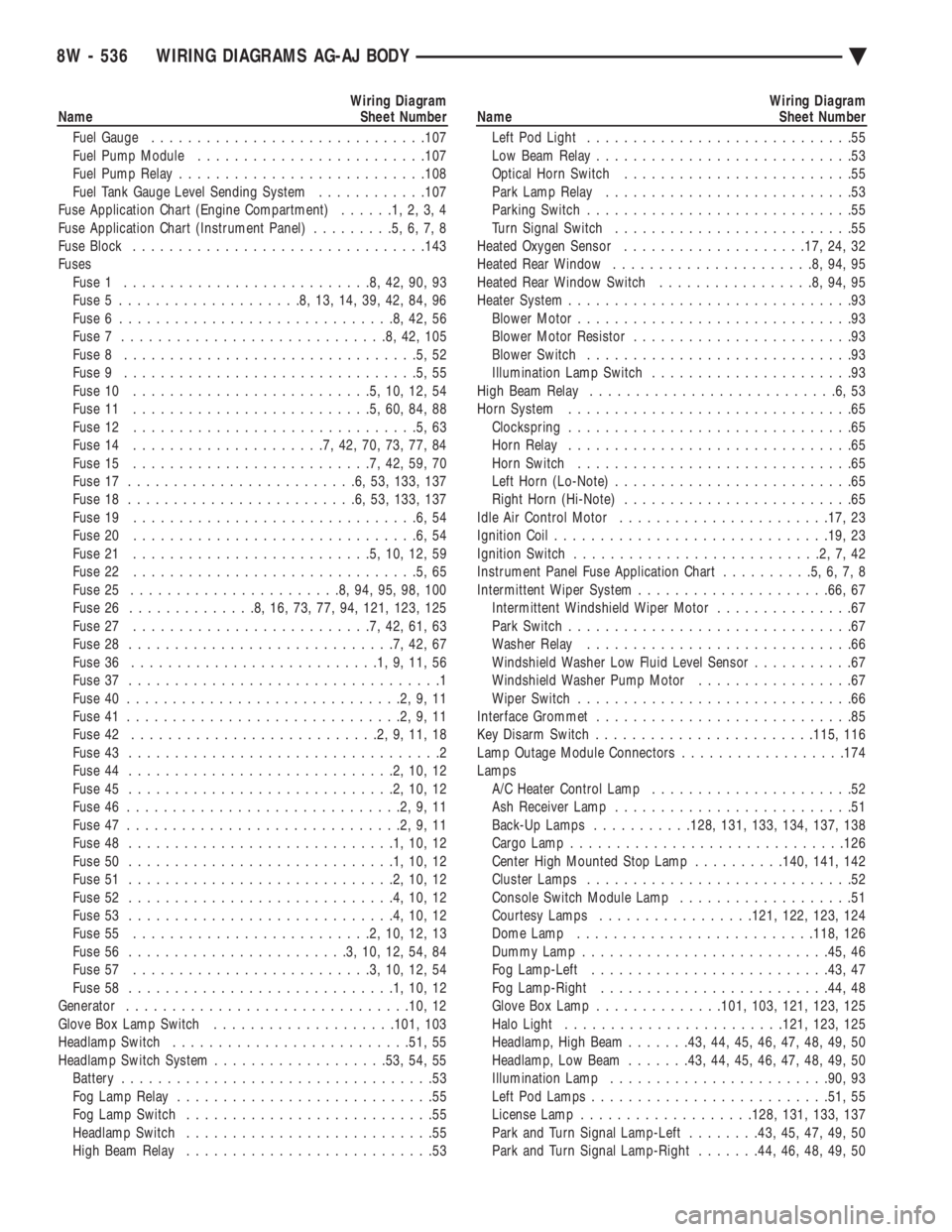

Page 1286 of 2438

Wiring Diagram

Name Sheet Number

Fuel Gauge ............................. .107

Fuel Pump Module ........................ .107

Fuel Pump Relay .......................... .108

Fuel Tank Gauge Level Sending System ............107

Fuse Application Chart (Engine Compartment) ......1,2,3,4

Fuse Application Chart (Instrument Panel) .........5,6,7,8

Fuse Block ............................... .143

Fuses Fuse 1 ...........................8,42,90,93

Fuse 5 ....................8,13,14,39,42,84,96

Fuse 6 ..............................8,42,56

Fuse 7 .............................8,42,105

Fuse 8 ................................5,52

Fuse 9 ................................5,55

Fuse 10 ..........................5,10,12,54

Fuse 11 ..........................5,60,84,88

Fuse 12 ...............................5,63

Fuse 14 .....................7,42,70,73,77,84

Fuse 15 ..........................7,42,59,70

Fuse 17 .........................6,53, 133, 137

Fuse 18 .........................6,53, 133, 137

Fuse 19 ...............................6,54

Fuse 20 ...............................6,54

Fuse 21 ..........................5,10,12,59

Fuse 22 ...............................5,65

Fuse 25 .......................8,94,95,98,100

Fuse 26 ..............8,16,73,77,94, 121, 123, 125

Fuse 27 ..........................7,42,61,63

Fuse 28 .............................7,42,67

Fuse 36 ...........................1,9,11,56

Fuse 37 ..................................1

Fuse 40 ..............................2,9,11

Fuse 41 ..............................2,9,11

Fuse 42 ...........................2,9,11,18

Fuse 43 ..................................2

Fuse 44 .............................2,10,12

Fuse 45 .............................2,10,12

Fuse 46 ..............................2,9,11

Fuse 47 ..............................2,9,11

Fuse 48 .............................1,10,12

Fuse 50 .............................1,10,12

Fuse 51 .............................2,10,12

Fuse 52 .............................4,10,12

Fuse 53 .............................4,10,12

Fuse 55 ..........................2,10,12,13

Fuse 56 ........................3,10,12,54,84

Fuse 57 ..........................3,10,12,54

Fuse 58 .............................1,10,12

Generator .............................. .10, 12

Glove Box Lamp Switch ................... .101, 103

Headlamp Switch ......................... .51, 55

Headlamp Switch System .................. .53, 54, 55

Battery ..................................53

Fog Lamp Relay ............................55

Fog Lamp Switch ...........................55

Headlamp Switch ...........................55

High Beam Relay ...........................53Wiring Diagram

Name Sheet Number

Left Pod Light .............................55

Low Beam Relay ............................53

Optical Horn Switch .........................55

Park Lamp Relay ...........................53

Parking Switch .............................55

Turn Signal Switch ..........................55

Heated Oxygen Sensor ................... .17, 24, 32

Heated Rear Window ......................8,94,95

Heated Rear Window Switch .................8,94,95

Heater System ...............................93

Blower Motor ..............................93

Blower Motor Resistor ........................93

Blower Switch .............................93

Illumination Lamp Switch ......................93

High Beam Relay ...........................6,53

Horn System ...............................65

Clockspring ...............................65

Horn Relay ...............................65

Horn Switch ..............................65

Left Horn (Lo-Note) ..........................65

Right Horn (Hi-Note) .........................65

Idle Air Control Motor ...................... .17, 23

Ignition Coil ............................. .19, 23

Ignition Switch ...........................2,7,42

Instrument Panel Fuse Application Chart ..........5,6,7,8

Intermittent Wiper System .................... .66, 67

Intermittent Windshield Wiper Motor ...............67

Park Switch ...............................67

Washer Relay .............................66

Windshield Washer Low Fluid Level Sensor ...........67

Windshield Washer Pump Motor .................67

Wiper Switch ..............................66

Interface Grommet ............................85

Key Disarm Switch ....................... .115, 116

Lamp Outage Module Connectors ..................174

Lamps A/C Heater Control Lamp ......................52

Ash Receiver Lamp ..........................51

Back-Up Lamps ...........128, 131, 133, 134, 137, 138

Cargo Lamp ............................. .126

Center High Mounted Stop Lamp ..........140, 141, 142

Cluster Lamps .............................52

Console Switch Module Lamp ...................51

Courtesy Lamps ................ .121, 122, 123, 124

Dome Lamp ......................... .118, 126

Dummy Lamp .......................... .45, 46

Fog Lamp-Left ......................... .43, 47

Fog Lamp-Right ........................ .44, 48

Glove Box Lamp ............. .101, 103, 121, 123, 125

Halo Light ....................... .121, 123, 125

Headlamp, High Beam .......43, 44, 45, 46, 47, 48, 49, 50

Headlamp, Low Beam .......43, 44, 45, 46, 47, 48, 49, 50

Illumination Lamp ....................... .90, 93

Left Pod Lamps ......................... .51, 55

License Lamp .................. .128, 131, 133, 137

Park and Turn Signal Lamp-Left ........43, 45, 47, 49, 50

Park and Turn Signal Lamp-Right .......44, 46, 48, 49, 50

8W - 536 WIRING DIAGRAMS AG-AJ BODY Ä

Page 1467 of 2438

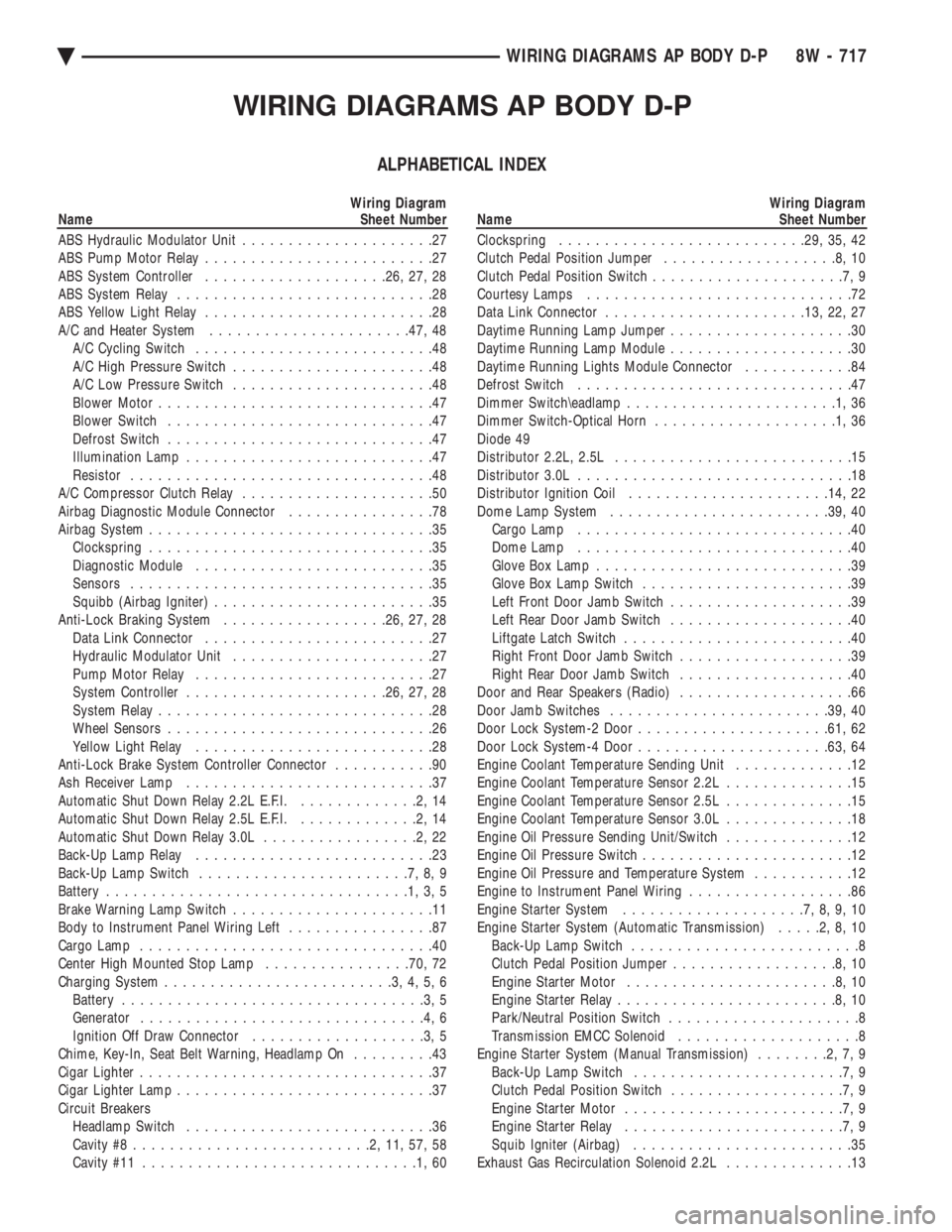

WIRING DIAGRAMS AP BODY D-P

ALPHABETICAL INDEX

Wiring Diagram

Name Sheet Number

ABS Hydraulic Modulator Unit .....................27

ABS Pump Motor Relay .........................27

ABS System Controller ................... .26, 27, 28

ABS System Relay ............................28

ABS Yellow Light Relay .........................28

A/C and Heater System ..................... .47, 48

A/C Cycling Switch ..........................48

A/C High Pressure Switch ......................48

A/C Low Pressure Switch ......................48

Blower Motor ..............................47

Blower Switch .............................47

Defrost Switch .............................47

Illumination Lamp ...........................47

Resistor .................................48

A/C Compressor Clutch Relay .....................50

Airbag Diagnostic Module Connector ................78

Airbag System ...............................35

Clockspring ...............................35

Diagnostic Module ..........................35

Sensors .................................35

Squibb (Airbag Igniter) ........................35

Anti-Lock Braking System ..................26, 27, 28

Data Link Connector .........................27

Hydraulic Modulator Unit ......................27

Pump Motor Relay ..........................27

System Controller ..................... .26, 27, 28

System Relay ..............................28

Wheel Sensors .............................26

Yellow Light Relay ..........................28

Anti-Lock Brake System Controller Connector ...........90

Ash Receiver Lamp ...........................37

Automatic Shut Down Relay 2.2L E.F.I. .............2,14

Automatic Shut Down Relay 2.5L E.F.I. .............2,14

Automatic Shut Down Relay 3.0L .................2,22

Back-Up Lamp Relay ..........................23

Back-Up Lamp Switch .......................7,8,9

Battery .................................1,3,5

Brake Warning Lamp Switch ......................11

Body to Instrument Panel Wiring Left ................87

Cargo Lamp ................................40

Center High Mounted Stop Lamp ................70, 72

Charging System .........................3,4,5,6

Battery .................................3,5

Generator ...............................4,6

Ignition Off Draw Connector ...................3,5

Chime, Key-In, Seat Belt Warning, Headlamp On .........43

Cigar Lighter ................................37

Cigar Lighter Lamp ............................37

Circuit Breakers Headlamp Switch ...........................36

Cavity #8 ..........................2,11,57,58

Cavity #11 ..............................1,60Wiring Diagram

Name Sheet Number

Clockspring .......................... .29, 35, 42

Clutch Pedal Position Jumper ...................8,10

Clutch Pedal Position Switch .....................7,9

Courtesy Lamps .............................72

Data Link Connector ..................... .13, 22, 27

Daytime Running Lamp Jumper ....................30

Daytime Running Lamp Module ....................30

Daytime Running Lights Module Connector ............84

Defrost Switch ..............................47

Dimmer Switch\eadlamp .......................1,36

Dimmer Switch-Optical Horn ....................1,36

Diode 49

Distributor 2.2L, 2.5L ..........................15

Distributor 3.0L ..............................18

Distributor Ignition Coil ..................... .14, 22

Dome Lamp System ....................... .39, 40

Cargo Lamp ..............................40

Dome Lamp ..............................40

Glove Box Lamp ............................39

Glove Box Lamp Switch .......................39

Left Front Door Jamb Switch ....................39

Left Rear Door Jamb Switch ....................40

Liftgate Latch Switch .........................40

Right Front Door Jamb Switch ...................39

Right Rear Door Jamb Switch ...................40

Door and Rear Speakers (Radio) ...................66

Door Jamb Switches ....................... .39, 40

Door Lock System-2 Door .................... .61, 62

Door Lock System-4 Door .................... .63, 64

Engine Coolant Temperature Sending Unit .............12

Engine Coolant Temperature Sensor 2.2L ..............15

Engine Coolant Temperature Sensor 2.5L ..............15

Engine Coolant Temperature Sensor 3.0L ..............18

Engine Oil Pressure Sending Unit/Switch ..............12

Engine Oil Pressure Switch .......................12

Engine Oil Pressure and Temperature System ...........12

Engine to Instrument Panel Wiring ..................86

Engine Starter System ....................7,8,9,10

Engine Starter System (Automatic Transmission) .....2,8,10

Back-Up Lamp Switch .........................8

Clutch Pedal Position Jumper ..................8,10

Engine Starter Motor .......................8,10

Engine Starter Relay ........................8,10

Park/Neutral Position Switch .....................8

Transmission EMCC Solenoid ....................8

Engine Starter System (Manual Transmission) ........2,7,9

Back-Up Lamp Switch .......................7,9

Clutch Pedal Position Switch ...................7,9

Engine Starter Motor ........................7,9

Engine Starter Relay ........................7,9

Squib Igniter (Airbag) ........................35

Exhaust Gas Recirculation Solenoid 2.2L ..............13

Ä WIRING DIAGRAMS AP BODY D-P 8W - 717

Page 1571 of 2438

CAUTION: Be sure that the tapped holes maintain

the original centerline.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HYDROSTATIC LOCKED ENGINE

When an engine is suspected to be hydrostaticly

locked, regardless of what caused the problem, these

steps should be used.

CAUTION: Do Not Use Starter Motor To Rotate En-

gine, severe damage may occur.

(1) Inspect air cleaner, induction system and in-

take manifold to insure system is dry and clear of

foreign material. (2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will

catch any fluid that may possibly be in the cylinder

under pressure. (4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket. (5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other). (6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., Connecting

Rods, Pistons, Valves etc.) (7) Repair engine or components as necessary to

prevent this problem from occurring again.

CAUTION: Squirt approximately 1 teaspoon of oil

into cylinders, rotate engine to lubricate the cylin-

der walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Fill engine with specified amount of approved

oil and install new oil filter. (11) Connect negative battery cable.

(12) Start engine and check for any leaks.

Ä ENGINE 9 - 5

Page 1579 of 2438

² Drive shaft distress: See Driveshafts in Suspension,

Group 2.

² Any front end structural damage (after repair).

² Insulator replacement.

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts by

carefully supporting the engine and transmission as-

sembly with a floor jack. (2) Loosen the right engine mount insulator vertical

fasteners, and the front engine mount bracket to front

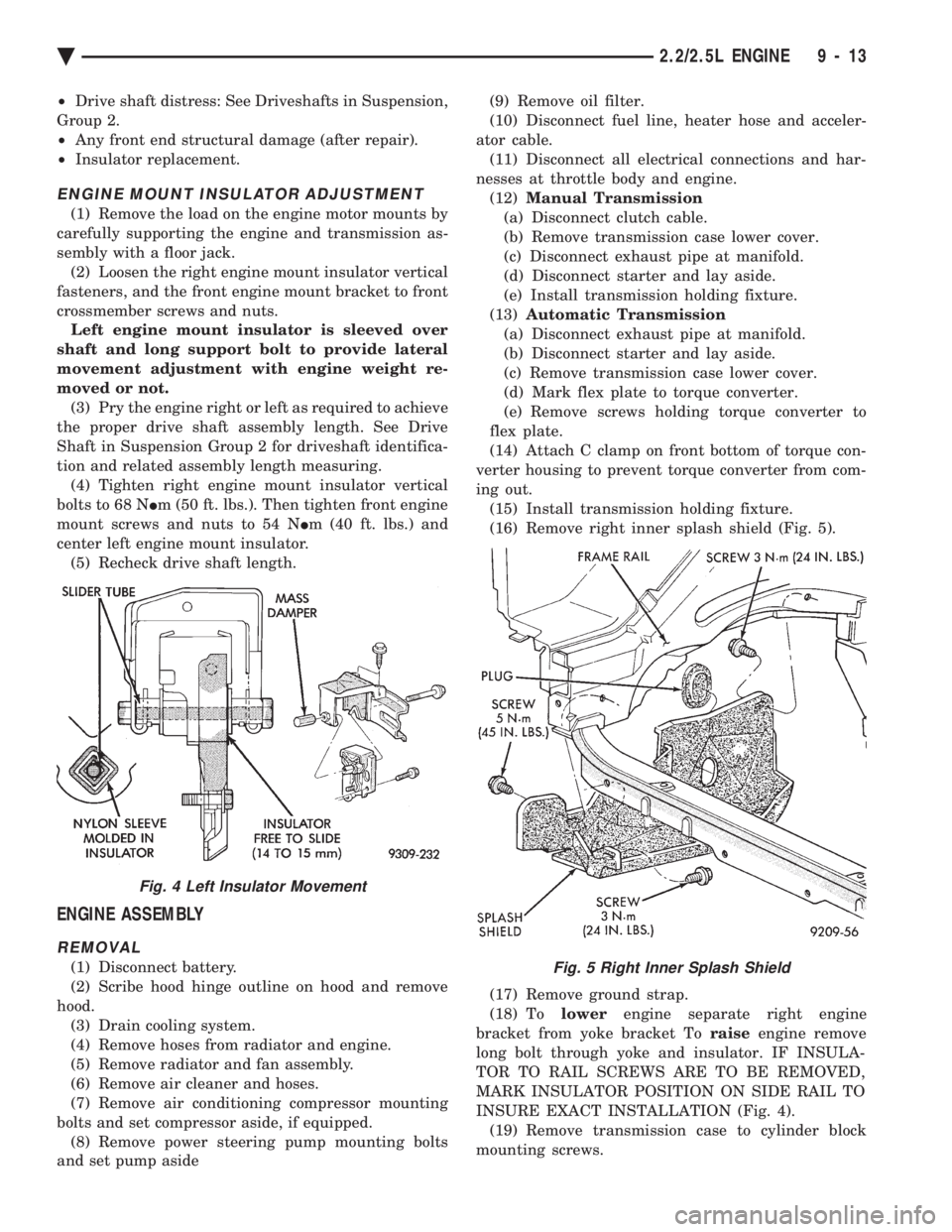

crossmember screws and nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to achieve

the proper drive shaft assembly length. See Drive

Shaft in Suspension Group 2 for driveshaft identifica-

tion and related assembly length measuring. (4) Tighten right engine mount insulator vertical

bolts to 68 N Im (50 ft. lbs.). Then tighten front engine

mount screws and nuts to 54 N Im (40 ft. lbs.) and

center left engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Scribe hood hinge outline on hood and remove

hood. (3) Drain cooling system.

(4) Remove hoses from radiator and engine.

(5) Remove radiator and fan assembly.

(6) Remove air cleaner and hoses.

(7) Remove air conditioning compressor mounting

bolts and set compressor aside, if equipped. (8) Remove power steering pump mounting bolts

and set pump aside (9) Remove oil filter.

(10) Disconnect fuel line, heater hose and acceler-

ator cable. (11) Disconnect all electrical connections and har-

nesses at throttle body and engine. (12) Manual Transmission

(a) Disconnect clutch cable.

(b) Remove transmission case lower cover.

(c) Disconnect exhaust pipe at manifold.

(d) Disconnect starter and lay aside.

(e) Install transmission holding fixture.

(13) Automatic Transmission

(a) Disconnect exhaust pipe at manifold.

(b) Disconnect starter and lay aside.

(c) Remove transmission case lower cover.

(d) Mark flex plate to torque converter.

(e) Remove screws holding torque converter to

flex plate.

(14) Attach C clamp on front bottom of torque con-

verter housing to prevent torque converter from com-

ing out. (15) Install transmission holding fixture.

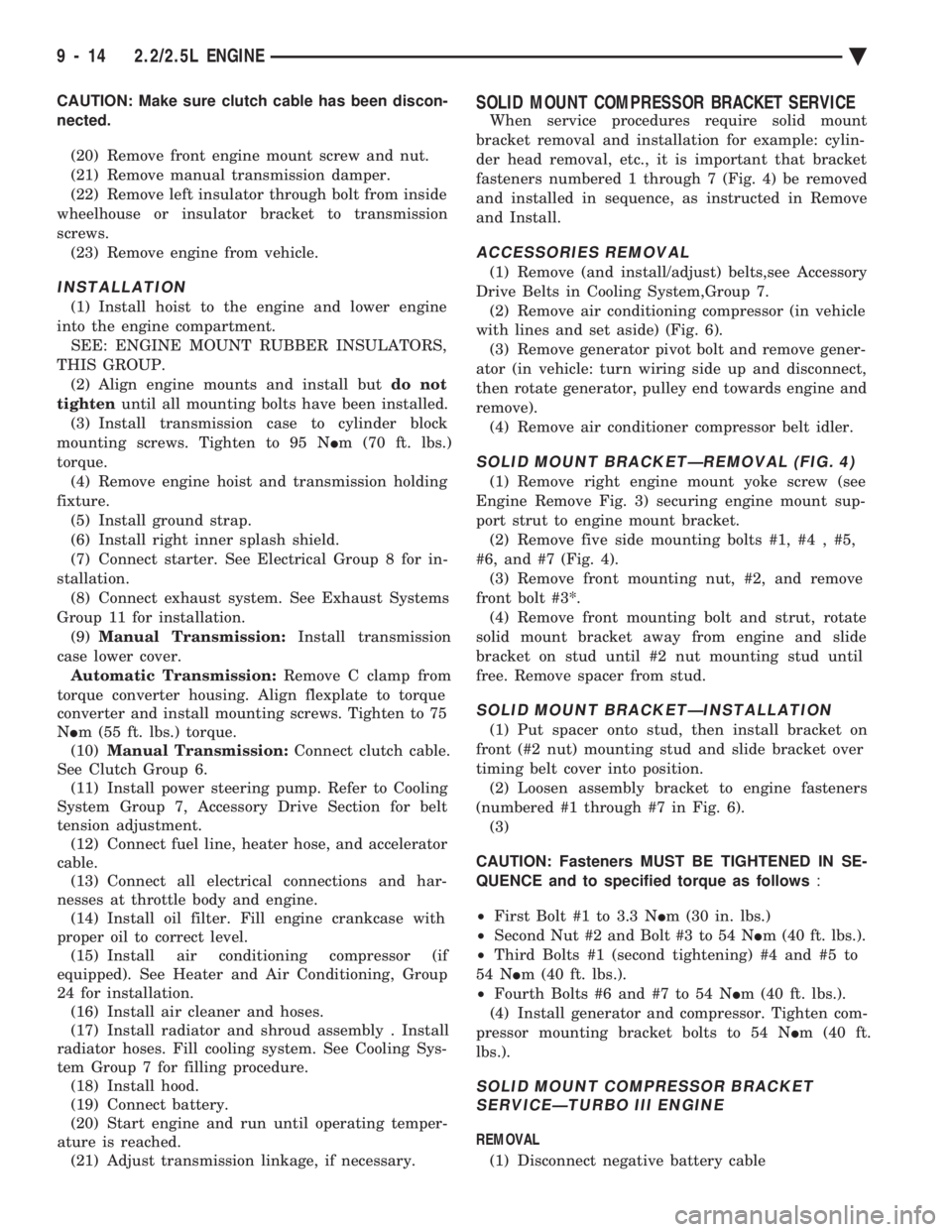

(16) Remove right inner splash shield (Fig. 5).

(17) Remove ground strap.

(18) To lowerengine separate right engine

bracket from yoke bracket To raiseengine remove

long bolt through yoke and insulator. IF INSULA-

TOR TO RAIL SCREWS ARE TO BE REMOVED,

MARK INSULATOR POSITION ON SIDE RAIL TO

INSURE EXACT INSTALLATION (Fig. 4). (19) Remove transmission case to cylinder block

mounting screws.Fig. 5 Right Inner Splash Shield

Fig. 4 Left Insulator Movement

Ä 2.2/2.5L ENGINE 9 - 13

Page 1580 of 2438

CAUTION: Make sure clutch cable has been discon-

nected. (20) Remove front engine mount screw and nut.

(21) Remove manual transmission damper.

(22) Remove left insulator through bolt from inside

wheelhouse or insulator bracket to transmission

screws. (23) Remove engine from vehicle.

INSTALLATION

(1) Install hoist to the engine and lower engine

into the engine compartment. SEE: ENGINE MOUNT RUBBER INSULATORS,

THIS GROUP. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

(3) Install transmission case to cylinder block

mounting screws. Tighten to 95 N Im (70 ft. lbs.)

torque. (4) Remove engine hoist and transmission holding

fixture. (5) Install ground strap.

(6) Install right inner splash shield.

(7) Connect starter. See Electrical Group 8 for in-

stallation. (8) Connect exhaust system. See Exhaust Systems

Group 11 for installation. (9) Manual Transmission: Install transmission

case lower cover. Automatic Transmission: Remove C clamp from

torque converter housing. Align flexplate to torque

converter and install mounting screws. Tighten to 75

N Im (55 ft. lbs.) torque.

(10) Manual Transmission: Connect clutch cable.

See Clutch Group 6. (11) Install power steering pump. Refer to Cooling

System Group 7, Accessory Drive Section for belt

tension adjustment. (12) Connect fuel line, heater hose, and accelerator

cable. (13) Connect all electrical connections and har-

nesses at throttle body and engine. (14) Install oil filter. Fill engine crankcase with

proper oil to correct level. (15) Install air conditioning compressor (if

equipped). See Heater and Air Conditioning, Group

24 for installation. (16) Install air cleaner and hoses.

(17) Install radiator and shroud assembly . Install

radiator hoses. Fill cooling system. See Cooling Sys-

tem Group 7 for filling procedure. (18) Install hood.

(19) Connect battery.

(20) Start engine and run until operating temper-

ature is reached. (21) Adjust transmission linkage, if necessary.

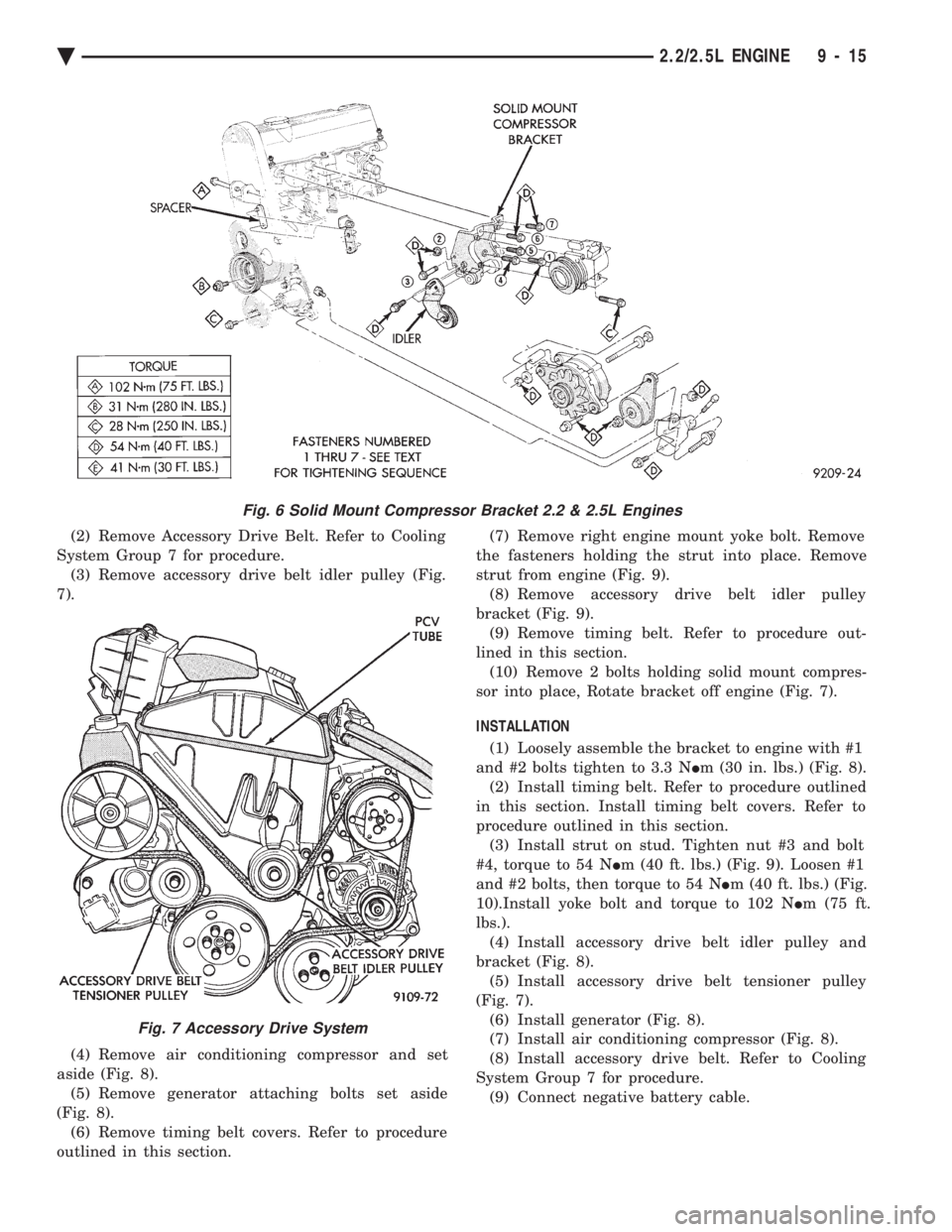

SOLID MOUNT COMPRESSOR BRACKET SERVICE

When service procedures require solid mount

bracket removal and installation for example: cylin-

der head removal, etc., it is important that bracket

fasteners numbered 1 through 7 (Fig. 4) be removed

and installed in sequence, as instructed in Remove

and Install.

ACCESSORIES REMOVAL

(1) Remove (and install/adjust) belts,see Accessory

Drive Belts in Cooling System,Group 7. (2) Remove air conditioning compressor (in vehicle

with lines and set aside) (Fig. 6). (3) Remove generator pivot bolt and remove gener-

ator (in vehicle: turn wiring side up and disconnect,

then rotate generator, pulley end towards engine and

remove). (4) Remove air conditioner compressor belt idler.

SOLID MOUNT BRACKETÐREMOVAL (FIG. 4)

(1) Remove right engine mount yoke screw (see

Engine Remove Fig. 3) securing engine mount sup-

port strut to engine mount bracket. (2) Remove five side mounting bolts #1, #4 , #5,

#6, and #7 (Fig. 4). (3) Remove front mounting nut, #2, and remove

front bolt #3*. (4) Remove front mounting bolt and strut, rotate

solid mount bracket away from engine and slide

bracket on stud until #2 nut mounting stud until

free. Remove spacer from stud.

SOLID MOUNT BRACKETÐINSTALLATION

(1) Put spacer onto stud, then install bracket on

front (#2 nut) mounting stud and slide bracket over

timing belt cover into position. (2) Loosen assembly bracket to engine fasteners

(numbered #1 through #7 in Fig. 6). (3)

CAUTION: Fasteners MUST BE TIGHTENED IN SE-

QUENCE and to specified torque as follows :

² First Bolt #1 to 3.3 N Im (30 in. lbs.)

² Second Nut #2 and Bolt #3 to 54 N Im (40 ft. lbs.).

² Third Bolts #1 (second tightening) #4 and #5 to

54 N Im (40 ft. lbs.).

² Fourth Bolts #6 and #7 to 54 N Im (40 ft. lbs.).

(4) Install generator and compressor. Tighten com-

pressor mounting bracket bolts to 54 N Im (40 ft.

lbs.).

SOLID MOUNT COMPRESSOR BRACKET SERVICEÐTURBO III ENGINE

REMOVAL

(1) Disconnect negative battery cable

9 - 14 2.2/2.5L ENGINE Ä

Page 1581 of 2438

(2) Remove Accessory Drive Belt. Refer to Cooling

System Group 7 for procedure. (3) Remove accessory drive belt idler pulley (Fig.

7).

(4) Remove air conditioning compressor and set

aside (Fig. 8). (5) Remove generator attaching bolts set aside

(Fig. 8). (6) Remove timing belt covers. Refer to procedure

outlined in this section. (7) Remove right engine mount yoke bolt. Remove

the fasteners holding the strut into place. Remove

strut from engine (Fig. 9). (8) Remove accessory drive belt idler pulley

bracket (Fig. 9). (9) Remove timing belt. Refer to procedure out-

lined in this section. (10) Remove 2 bolts holding solid mount compres-

sor into place, Rotate bracket off engine (Fig. 7).

INSTALLATION

(1) Loosely assemble the bracket to engine with #1

and #2 bolts tighten to 3.3 N Im (30 in. lbs.) (Fig. 8).

(2) Install timing belt. Refer to procedure outlined

in this section. Install timing belt covers. Refer to

procedure outlined in this section. (3) Install strut on stud. Tighten nut #3 and bolt

#4, torque to 54 N Im (40 ft. lbs.) (Fig. 9). Loosen #1

and #2 bolts, then torque to 54 N Im (40 ft. lbs.) (Fig.

10).Install yoke bolt and torque to 102 N Im (75 ft.

lbs.). (4) Install accessory drive belt idler pulley and

bracket (Fig. 8). (5) Install accessory drive belt tensioner pulley

(Fig. 7). (6) Install generator (Fig. 8).

(7) Install air conditioning compressor (Fig. 8).

(8) Install accessory drive belt. Refer to Cooling

System Group 7 for procedure. (9) Connect negative battery cable.

Fig. 6 Solid Mount Compressor Bracket 2.2 & 2.5L Engines

Fig. 7 Accessory Drive System

Ä 2.2/2.5L ENGINE 9 - 15

Page 1592 of 2438

valve spring retainer locks to become dislocated

when depressing the valve spring. Check and make

sure the locks are in their proper location. (3) Install valve cover as previously outlined in

this section.

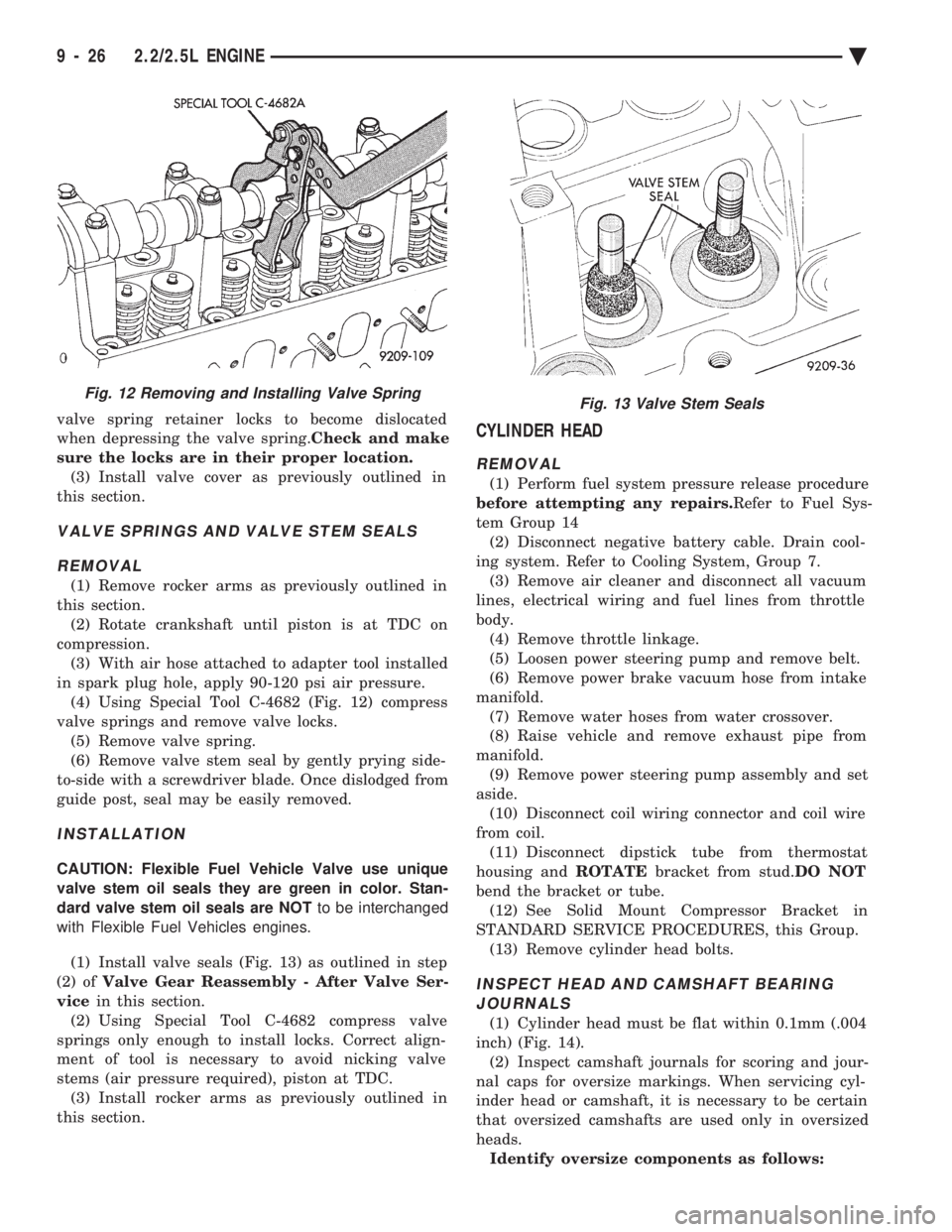

VALVE SPRINGS AND VALVE STEM SEALS

REMOVAL

(1) Remove rocker arms as previously outlined in

this section. (2) Rotate crankshaft until piston is at TDC on

compression. (3) With air hose attached to adapter tool installed

in spark plug hole, apply 90-120 psi air pressure. (4) Using Special Tool C-4682 (Fig. 12) compress

valve springs and remove valve locks. (5) Remove valve spring.

(6) Remove valve stem seal by gently prying side-

to-side with a screwdriver blade. Once dislodged from

guide post, seal may be easily removed.

INSTALLATION

CAUTION: Flexible Fuel Vehicle Valve use unique

valve stem oil seals they are green in color. Stan-

dard valve stem oil seals are NOT to be interchanged

with Flexible Fuel Vehicles engines.

(1) Install valve seals (Fig. 13) as outlined in step

(2) of Valve Gear Reassembly - After Valve Ser-

vice in this section.

(2) Using Special Tool C-4682 compress valve

springs only enough to install locks. Correct align-

ment of tool is necessary to avoid nicking valve

stems (air pressure required), piston at TDC. (3) Install rocker arms as previously outlined in

this section.

CYLINDER HEAD

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs. Refer to Fuel Sys-

tem Group 14 (2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Cooling System, Group 7. (3) Remove air cleaner and disconnect all vacuum

lines, electrical wiring and fuel lines from throttle

body. (4) Remove throttle linkage.

(5) Loosen power steering pump and remove belt.

(6) Remove power brake vacuum hose from intake

manifold. (7) Remove water hoses from water crossover.

(8) Raise vehicle and remove exhaust pipe from

manifold. (9) Remove power steering pump assembly and set

aside. (10) Disconnect coil wiring connector and coil wire

from coil. (11) Disconnect dipstick tube from thermostat

housing and ROTATEbracket from stud. DO NOT

bend the bracket or tube. (12) See Solid Mount Compressor Bracket in

STANDARD SERVICE PROCEDURES, this Group. (13) Remove cylinder head bolts.

INSPECT HEAD AND CAMSHAFT BEARINGJOURNALS

(1) Cylinder head must be flat within 0.1mm (.004

inch) (Fig. 14). (2) Inspect camshaft journals for scoring and jour-

nal caps for oversize markings. When servicing cyl-

inder head or camshaft, it is necessary to be certain

that oversized camshafts are used only in oversized

heads. Identify oversize components as follows:

Fig. 12 Removing and Installing Valve SpringFig. 13 Valve Stem Seals

9 - 26 2.2/2.5L ENGINE Ä

Page 1635 of 2438

LEFT SIDE MOUNT

(1) Raise vehicle on hoist and remove left front

wheel. (2) Remove inter splash shield.

(3) Support the transmission with a transmission

jack. (4) Remove the insulator thru bolt from the mount.

(5) Remove the transmission mount fasteners and

remove mount. (6) Reverse removal procedure for installation. En-

sure that the slide tube is seated into the rail

bracket guides. Refer to (Fig. 3) for bolt tightening

specifications. (7) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

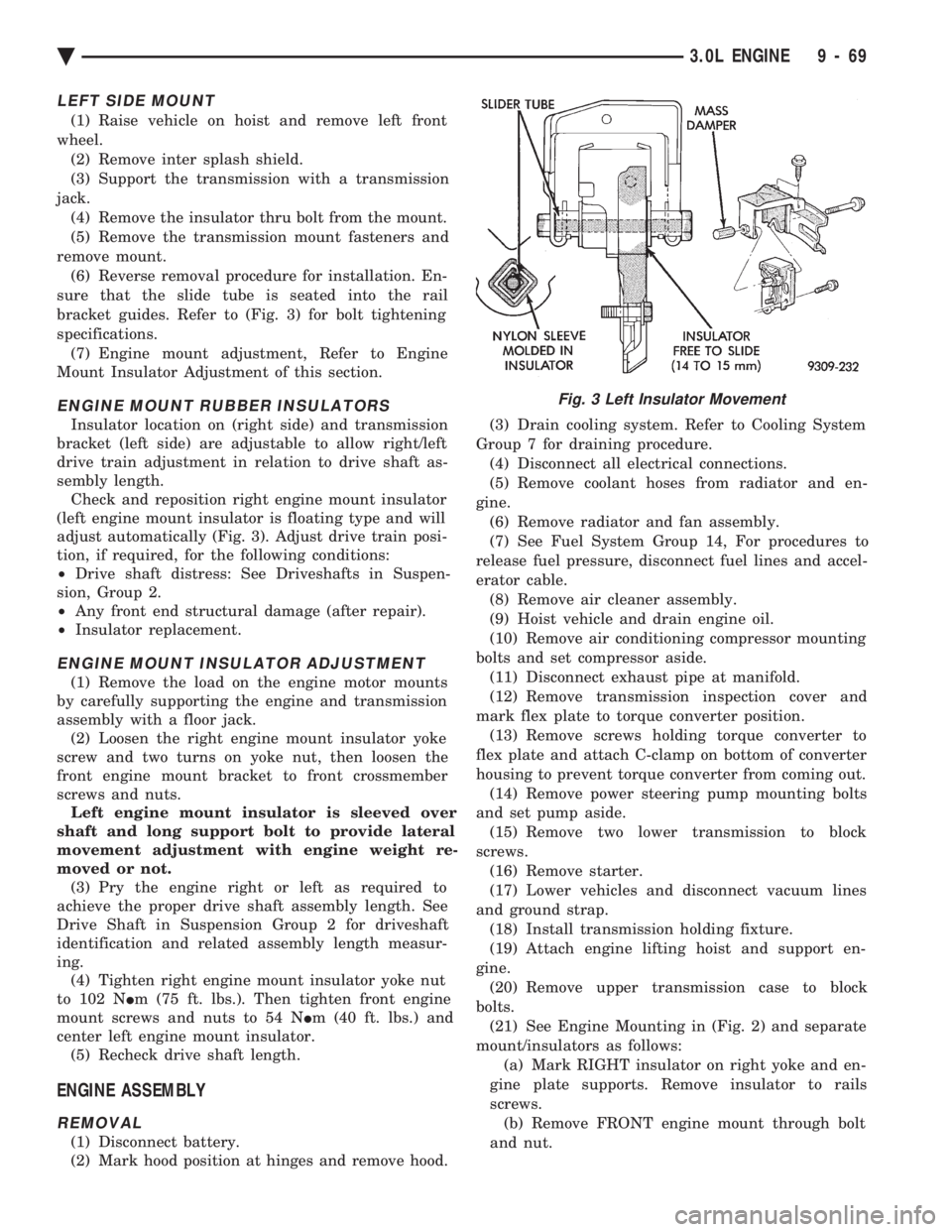

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) and transmission

bracket (left side) are adjustable to allow right/left

drive train adjustment in relation to drive shaft as-

sembly length. Check and reposition right engine mount insulator

(left engine mount insulator is floating type and will

adjust automatically (Fig. 3). Adjust drive train posi-

tion, if required, for the following conditions:

² Drive shaft distress: See Driveshafts in Suspen-

sion, Group 2.

² Any front end structural damage (after repair).

² Insulator replacement.

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack. (2) Loosen the right engine mount insulator yoke

screw and two turns on yoke nut, then loosen the

front engine mount bracket to front crossmember

screws and nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to

achieve the proper drive shaft assembly length. See

Drive Shaft in Suspension Group 2 for driveshaft

identification and related assembly length measur-

ing. (4) Tighten right engine mount insulator yoke nut

to 102 N Im (75 ft. lbs.). Then tighten front engine

mount screws and nuts to 54 N Im (40 ft. lbs.) and

center left engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Mark hood position at hinges and remove hood. (3) Drain cooling system. Refer to Cooling System

Group 7 for draining procedure. (4) Disconnect all electrical connections.

(5) Remove coolant hoses from radiator and en-

gine. (6) Remove radiator and fan assembly.

(7) See Fuel System Group 14, For procedures to

release fuel pressure, disconnect fuel lines and accel-

erator cable. (8) Remove air cleaner assembly.

(9) Hoist vehicle and drain engine oil.

(10) Remove air conditioning compressor mounting

bolts and set compressor aside. (11) Disconnect exhaust pipe at manifold.

(12) Remove transmission inspection cover and

mark flex plate to torque converter position. (13) Remove screws holding torque converter to

flex plate and attach C-clamp on bottom of converter

housing to prevent torque converter from coming out. (14) Remove power steering pump mounting bolts

and set pump aside. (15) Remove two lower transmission to block

screws. (16) Remove starter.

(17) Lower vehicles and disconnect vacuum lines

and ground strap. (18) Install transmission holding fixture.

(19) Attach engine lifting hoist and support en-

gine. (20) Remove upper transmission case to block

bolts. (21) See Engine Mounting in (Fig. 2) and separate

mount/insulators as follows: (a) Mark RIGHT insulator on right yoke and en-

gine plate supports. Remove insulator to rails

screws. (b) Remove FRONT engine mount through bolt

and nut.

Fig. 3 Left Insulator Movement

Ä 3.0L ENGINE 9 - 69

Page 1636 of 2438

(c) Remove LEFT insulator through bolt from in-

side wheelhouse or insulator bracket to transmis-

sion screws.

(22) Remove engine.

INSTALLATION

(1) Attach hoist and lower engine into engine com-

partment. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

Tighten bolts to torque specified in (Fig. 2). (3) Install transmission case to cylinder block,

tighten bolts to 102 N Im (75 ft. lbs.) torque.

(4) Remove engine hoist and transmission holding

fixture. (5) Remove C clamp from torque converter hous-

ing. Align flex plate to torque converter and install

mounting screws. Tighten to 75 N Im (55 ft. lbs.)

(6) Install transmission inspection cover.

(7) Connect exhaust system at manifold.

(8) Install starter.

(9) Install power steering pump and air condition-

ing compressor. For belt installation Refer to Acces-

sory Belt Drive in Cooling System Group 7. (10) Lower vehicle and connect all vacuum lines.

(11) Connect all electrical connections including

ground strap. (12) Connect fuel lines and accelerator cable. (13) Install radiator and fan assembly. Connect fan

motor electrical lead. Install radiator hoses. Fill cool-

ing system. Refer to Cooling System Group 7 for fill-

ing procedure. (14) Fill engine crankcase with proper oil to cor-

rect level. (15) Install hood.

(16) Connect battery.

(17) Start engine and run until operating temper-

ature is reached. (18) Adjust transmission or linkage if necessary.

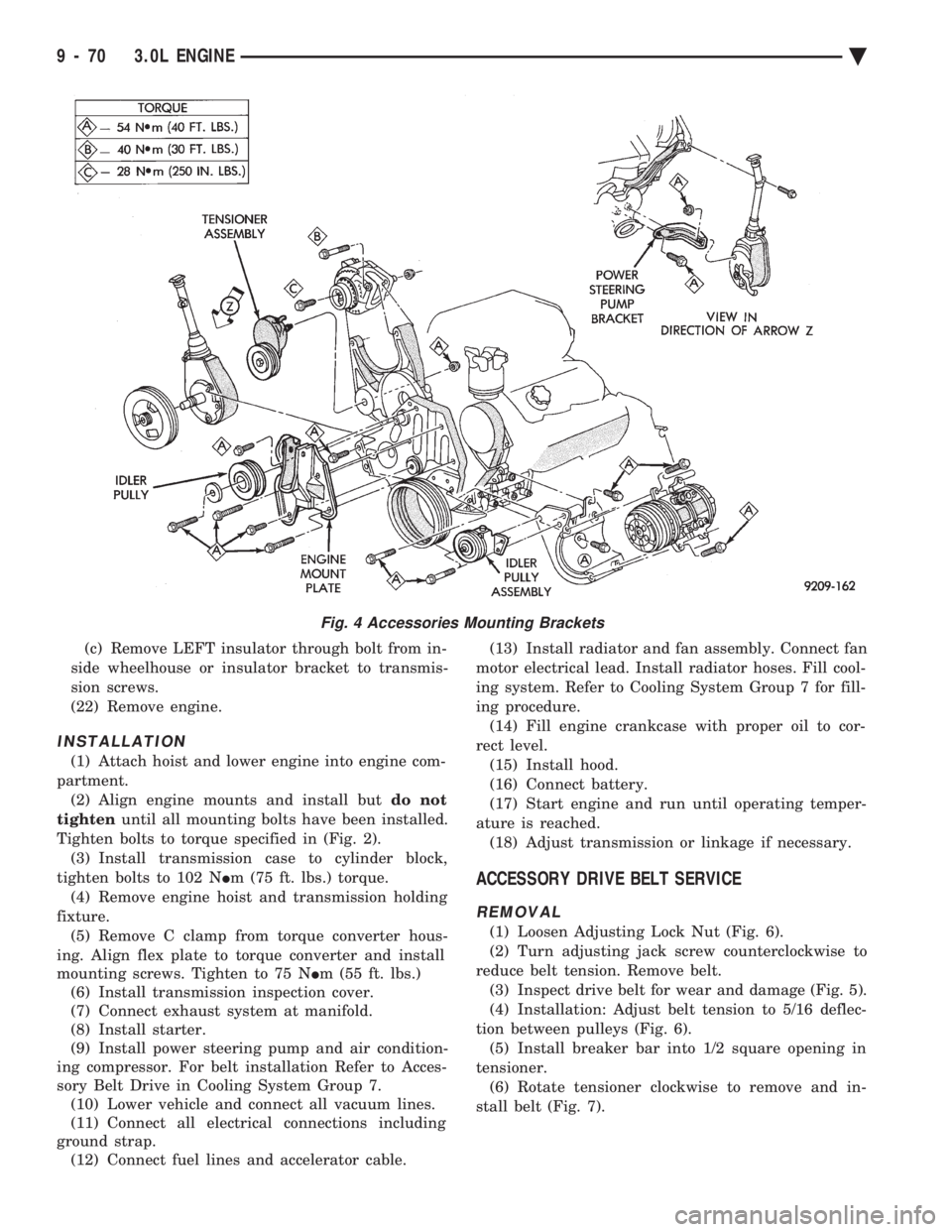

ACCESSORY DRIVE BELT SERVICE

REMOVAL

(1) Loosen Adjusting Lock Nut (Fig. 6).

(2) Turn adjusting jack screw counterclockwise to

reduce belt tension. Remove belt. (3) Inspect drive belt for wear and damage (Fig. 5).

(4) Installation: Adjust belt tension to 5/16 deflec-

tion between pulleys (Fig. 6). (5) Install breaker bar into 1/2 square opening in

tensioner. (6) Rotate tensioner clockwise to remove and in-

stall belt (Fig. 7).

Fig. 4 Accessories Mounting Brackets

9 - 70 3.0L ENGINE Ä