battery CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2353 of 2438

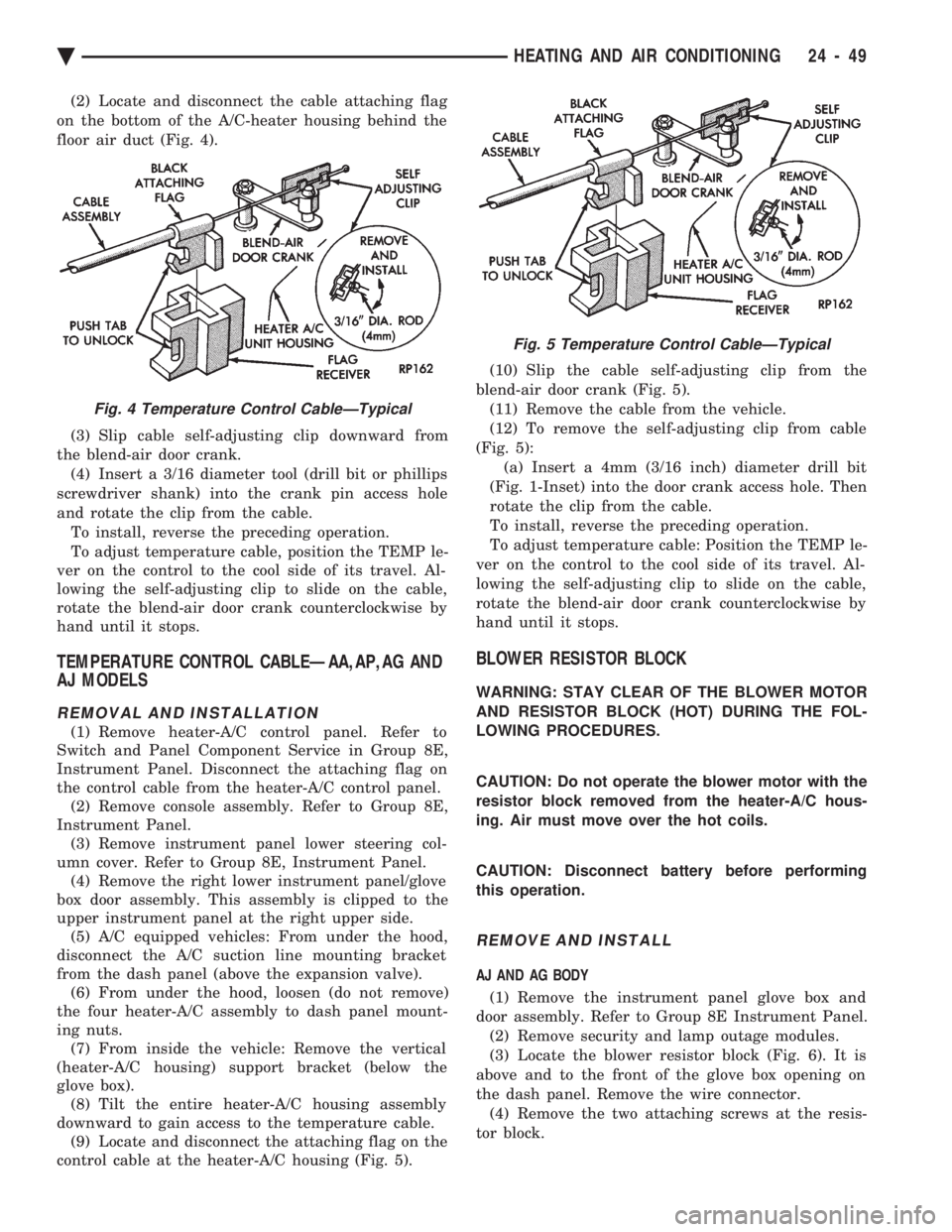

(2) Locate and disconnect the cable attaching flag

on the bottom of the A/C-heater housing behind the

floor air duct (Fig. 4).

(3) Slip cable self-adjusting clip downward from

the blend-air door crank. (4) Insert a 3/16 diameter tool (drill bit or phillips

screwdriver shank) into the crank pin access hole

and rotate the clip from the cable. To install, reverse the preceding operation.

To adjust temperature cable, position the TEMP le-

ver on the control to the cool side of its travel. Al-

lowing the self-adjusting clip to slide on the cable,

rotate the blend-air door crank counterclockwise by

hand until it stops.

TEMPERATURE CONTROL CABLEÐAA,AP,AG AND

AJ MODELS

REMOVAL AND INSTALLATION

(1) Remove heater-A/C control panel. Refer to

Switch and Panel Component Service in Group 8E,

Instrument Panel. Disconnect the attaching flag on

the control cable from the heater-A/C control panel. (2) Remove console assembly. Refer to Group 8E,

Instrument Panel. (3) Remove instrument panel lower steering col-

umn cover. Refer to Group 8E, Instrument Panel. (4) Remove the right lower instrument panel/glove

box door assembly. This assembly is clipped to the

upper instrument panel at the right upper side. (5) A/C equipped vehicles: From under the hood,

disconnect the A/C suction line mounting bracket

from the dash panel (above the expansion valve). (6) From under the hood, loosen (do not remove)

the four heater-A/C assembly to dash panel mount-

ing nuts. (7) From inside the vehicle: Remove the vertical

(heater-A/C housing) support bracket (below the

glove box). (8) Tilt the entire heater-A/C housing assembly

downward to gain access to the temperature cable. (9) Locate and disconnect the attaching flag on the

control cable at the heater-A/C housing (Fig. 5). (10) Slip the cable self-adjusting clip from the

blend-air door crank (Fig. 5). (11) Remove the cable from the vehicle.

(12) To remove the self-adjusting clip from cable

(Fig. 5): (a) Insert a 4mm (3/16 inch) diameter drill bit

(Fig. 1-Inset) into the door crank access hole. Then

rotate the clip from the cable.

To install, reverse the preceding operation.

To adjust temperature cable: Position the TEMP le-

ver on the control to the cool side of its travel. Al-

lowing the self-adjusting clip to slide on the cable,

rotate the blend-air door crank counterclockwise by

hand until it stops.

BLOWER RESISTOR BLOCK

WARNING: STAY CLEAR OF THE BLOWER MOTOR

AND RESISTOR BLOCK (HOT) DURING THE FOL-

LOWING PROCEDURES.

CAUTION: Do not operate the blower motor with the

resistor block removed from the heater-A/C hous-

ing. Air must move over the hot coils.

CAUTION: Disconnect battery before performing

this operation.

REMOVE AND INSTALL

AJ AND AG BODY

(1) Remove the instrument panel glove box and

door assembly. Refer to Group 8E Instrument Panel. (2) Remove security and lamp outage modules.

(3) Locate the blower resistor block (Fig. 6). It is

above and to the front of the glove box opening on

the dash panel. Remove the wire connector. (4) Remove the two attaching screws at the resis-

tor block.

Fig. 4 Temperature Control CableÐTypical

Fig. 5 Temperature Control CableÐTypical

Ä HEATING AND AIR CONDITIONING 24 - 49

Page 2362 of 2438

new condenser, refer to Oil Level in the Refrigerant

section. Tighten the refrigerant line mounting nut to

23 N Im (200 inch pounds).

Evacuate and recharge system.

BLOWER MOTOR

BLOWER MOTOR VIBRATION AND/OR NOISE DIAGNOSIS

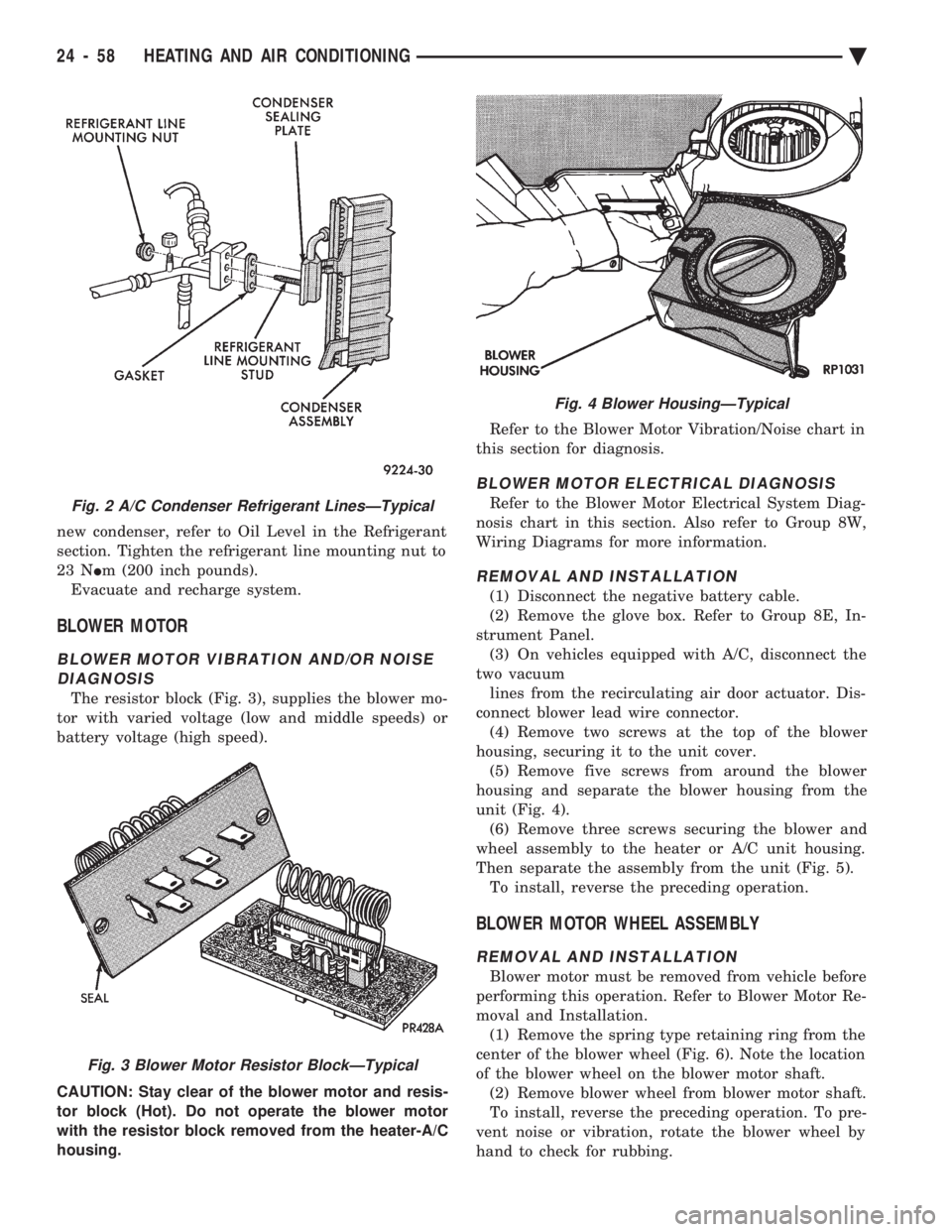

The resistor block (Fig. 3), supplies the blower mo-

tor with varied voltage (low and middle speeds) or

battery voltage (high speed).

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater-A/C

housing. Refer to the Blower Motor Vibration/Noise chart in

this section for diagnosis.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

Refer to the Blower Motor Electrical System Diag-

nosis chart in this section. Also refer to Group 8W,

Wiring Diagrams for more information.

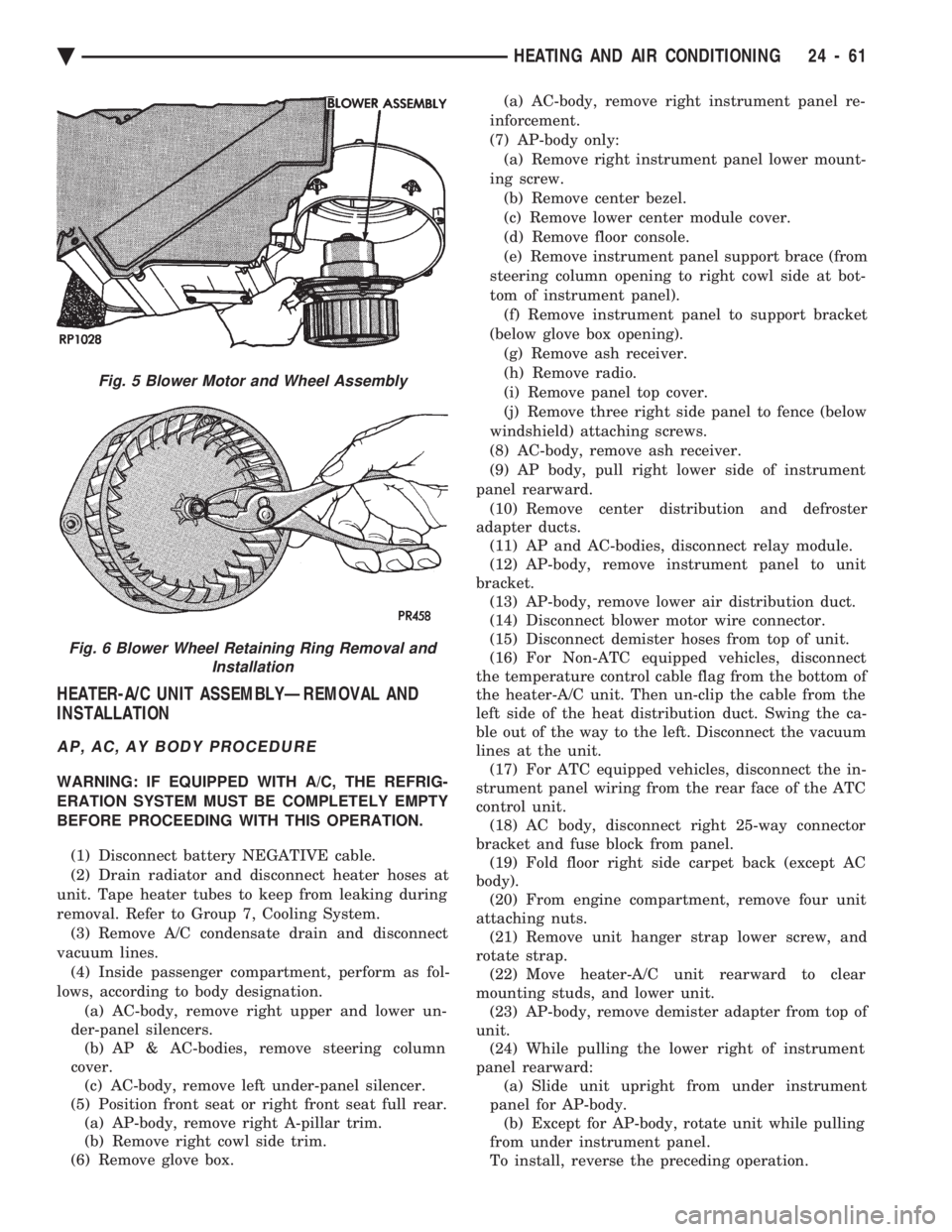

REMOVAL AND INSTALLATION

(1) Disconnect the negative battery cable.

(2) Remove the glove box. Refer to Group 8E, In-

strument Panel. (3) On vehicles equipped with A/C, disconnect the

two vacuum lines from the recirculating air door actuator. Dis-

connect blower lead wire connector. (4) Remove two screws at the top of the blower

housing, securing it to the unit cover. (5) Remove five screws from around the blower

housing and separate the blower housing from the

unit (Fig. 4). (6) Remove three screws securing the blower and

wheel assembly to the heater or A/C unit housing.

Then separate the assembly from the unit (Fig. 5). To install, reverse the preceding operation.

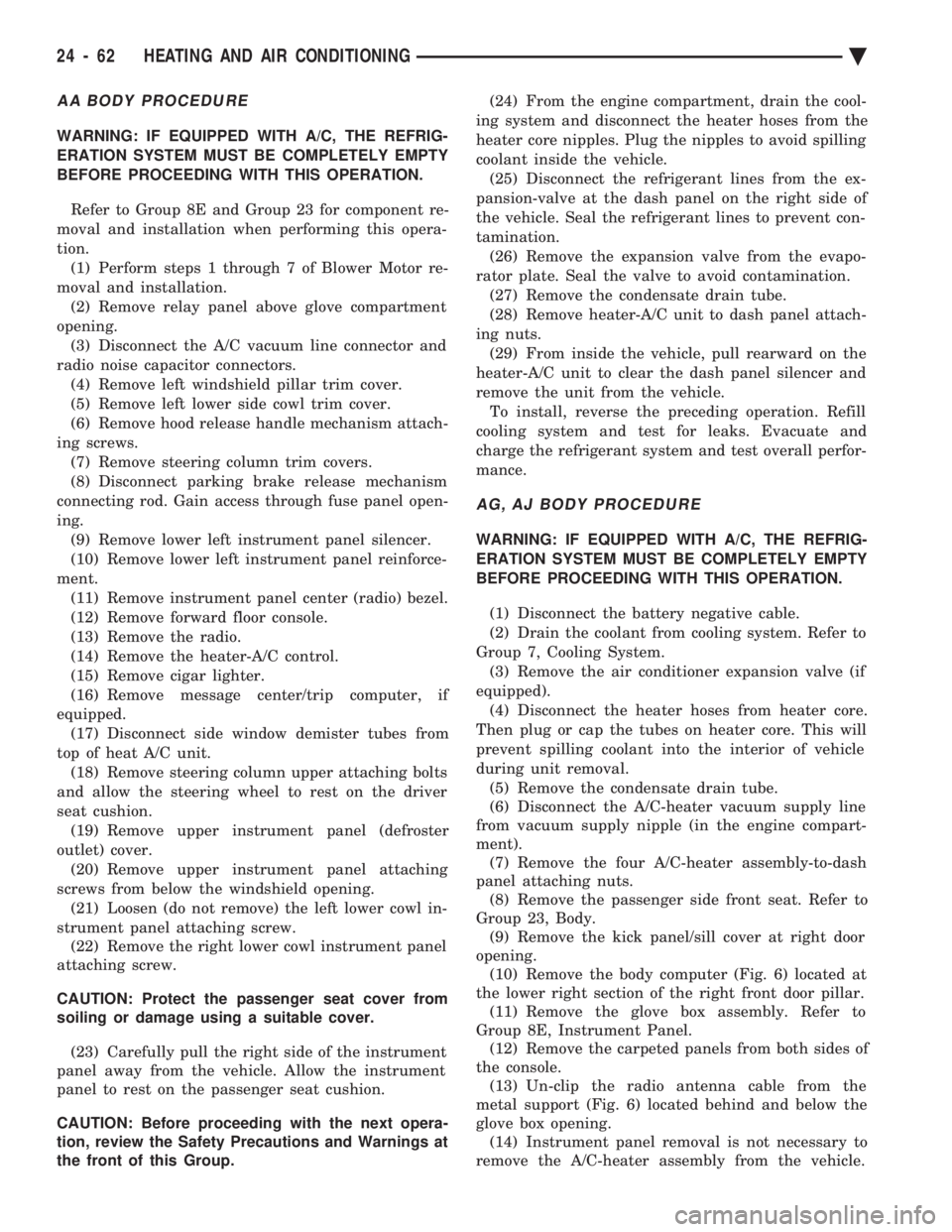

BLOWER MOTOR WHEEL ASSEMBLY

REMOVAL AND INSTALLATION

Blower motor must be removed from vehicle before

performing this operation. Refer to Blower Motor Re-

moval and Installation. (1) Remove the spring type retaining ring from the

center of the blower wheel (Fig. 6). Note the location

of the blower wheel on the blower motor shaft. (2) Remove blower wheel from blower motor shaft.

To install, reverse the preceding operation. To pre-

vent noise or vibration, rotate the blower wheel by

hand to check for rubbing.

Fig. 2 A/C Condenser Refrigerant LinesÐTypical

Fig. 3 Blower Motor Resistor BlockÐTypical

Fig. 4 Blower HousingÐTypical

24 - 58 HEATING AND AIR CONDITIONING Ä

Page 2365 of 2438

HEATER-A/C UNIT ASSEMBLYÐREMOVAL AND

INSTALLATION

AP, AC, AY BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect battery NEGATIVE cable.

(2) Drain radiator and disconnect heater hoses at

unit. Tape heater tubes to keep from leaking during

removal. Refer to Group 7, Cooling System. (3) Remove A/C condensate drain and disconnect

vacuum lines. (4) Inside passenger compartment, perform as fol-

lows, according to body designation. (a) AC-body, remove right upper and lower un-

der-panel silencers. (b) AP & AC-bodies, remove steering column

cover. (c) AC-body, remove left under-panel silencer.

(5) Position front seat or right front seat full rear. (a) AP-body, remove right A-pillar trim.

(b) Remove right cowl side trim.

(6) Remove glove box. (a) AC-body, remove right instrument panel re-

inforcement.

(7) AP-body only: (a) Remove right instrument panel lower mount-

ing screw. (b) Remove center bezel.

(c) Remove lower center module cover.

(d) Remove floor console.

(e) Remove instrument panel support brace (from

steering column opening to right cowl side at bot-

tom of instrument panel). (f) Remove instrument panel to support bracket

(below glove box opening). (g) Remove ash receiver.

(h) Remove radio.

(i) Remove panel top cover.

(j) Remove three right side panel to fence (below

windshield) attaching screws.

(8) AC-body, remove ash receiver.

(9) AP body, pull right lower side of instrument

panel rearward. (10) Remove center distribution and defroster

adapter ducts. (11) AP and AC-bodies, disconnect relay module.

(12) AP-body, remove instrument panel to unit

bracket. (13) AP-body, remove lower air distribution duct.

(14) Disconnect blower motor wire connector.

(15) Disconnect demister hoses from top of unit.

(16) For Non-ATC equipped vehicles, disconnect

the temperature control cable flag from the bottom of

the heater-A/C unit. Then un-clip the cable from the

left side of the heat distribution duct. Swing the ca-

ble out of the way to the left. Disconnect the vacuum

lines at the unit. (17) For ATC equipped vehicles, disconnect the in-

strument panel wiring from the rear face of the ATC

control unit. (18) AC body, disconnect right 25-way connector

bracket and fuse block from panel. (19) Fold floor right side carpet back (except AC

body). (20) From engine compartment, remove four unit

attaching nuts. (21) Remove unit hanger strap lower screw, and

rotate strap. (22) Move heater-A/C unit rearward to clear

mounting studs, and lower unit. (23) AP-body, remove demister adapter from top of

unit. (24) While pulling the lower right of instrument

panel rearward: (a) Slide unit upright from under instrument

panel for AP-body. (b) Except for AP-body, rotate unit while pulling

from under instrument panel.

To install, reverse the preceding operation.

Fig. 5 Blower Motor and Wheel Assembly

Fig. 6 Blower Wheel Retaining Ring Removal and Installation

Ä HEATING AND AIR CONDITIONING 24 - 61

Page 2366 of 2438

AA BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION. Refer to Group 8E and Group 23 for component re-

moval and installation when performing this opera-

tion. (1) Perform steps 1 through 7 of Blower Motor re-

moval and installation. (2) Remove relay panel above glove compartment

opening. (3) Disconnect the A/C vacuum line connector and

radio noise capacitor connectors. (4) Remove left windshield pillar trim cover.

(5) Remove left lower side cowl trim cover.

(6) Remove hood release handle mechanism attach-

ing screws. (7) Remove steering column trim covers.

(8) Disconnect parking brake release mechanism

connecting rod. Gain access through fuse panel open-

ing. (9) Remove lower left instrument panel silencer.

(10) Remove lower left instrument panel reinforce-

ment. (11) Remove instrument panel center (radio) bezel.

(12) Remove forward floor console.

(13) Remove the radio.

(14) Remove the heater-A/C control.

(15) Remove cigar lighter.

(16) Remove message center/trip computer, if

equipped. (17) Disconnect side window demister tubes from

top of heat A/C unit. (18) Remove steering column upper attaching bolts

and allow the steering wheel to rest on the driver

seat cushion. (19) Remove upper instrument panel (defroster

outlet) cover. (20) Remove upper instrument panel attaching

screws from below the windshield opening. (21) Loosen (do not remove) the left lower cowl in-

strument panel attaching screw. (22) Remove the right lower cowl instrument panel

attaching screw.

CAUTION: Protect the passenger seat cover from

soiling or damage using a suitable cover.

(23) Carefully pull the right side of the instrument

panel away from the vehicle. Allow the instrument

panel to rest on the passenger seat cushion.

CAUTION: Before proceeding with the next opera-

tion, review the Safety Precautions and Warnings at

the front of this Group. (24) From the engine compartment, drain the cool-

ing system and disconnect the heater hoses from the

heater core nipples. Plug the nipples to avoid spilling

coolant inside the vehicle. (25) Disconnect the refrigerant lines from the ex-

pansion-valve at the dash panel on the right side of

the vehicle. Seal the refrigerant lines to prevent con-

tamination. (26) Remove the expansion valve from the evapo-

rator plate. Seal the valve to avoid contamination. (27) Remove the condensate drain tube.

(28) Remove heater-A/C unit to dash panel attach-

ing nuts. (29) From inside the vehicle, pull rearward on the

heater-A/C unit to clear the dash panel silencer and

remove the unit from the vehicle. To install, reverse the preceding operation. Refill

cooling system and test for leaks. Evacuate and

charge the refrigerant system and test overall perfor-

mance.

AG, AJ BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect the battery negative cable.

(2) Drain the coolant from cooling system. Refer to

Group 7, Cooling System. (3) Remove the air conditioner expansion valve (if

equipped). (4) Disconnect the heater hoses from heater core.

Then plug or cap the tubes on heater core. This will

prevent spilling coolant into the interior of vehicle

during unit removal. (5) Remove the condensate drain tube.

(6) Disconnect the A/C-heater vacuum supply line

from vacuum supply nipple (in the engine compart-

ment). (7) Remove the four A/C-heater assembly-to-dash

panel attaching nuts. (8) Remove the passenger side front seat. Refer to

Group 23, Body. (9) Remove the kick panel/sill cover at right door

opening. (10) Remove the body computer (Fig. 6) located at

the lower right section of the right front door pillar. (11) Remove the glove box assembly. Refer to

Group 8E, Instrument Panel. (12) Remove the carpeted panels from both sides of

the console. (13) Un-clip the radio antenna cable from the

metal support (Fig. 6) located behind and below the

glove box opening. (14) Instrument panel removal is not necessary to

remove the A/C-heater assembly from the vehicle.

24 - 62 HEATING AND AIR CONDITIONING Ä

Page 2371 of 2438

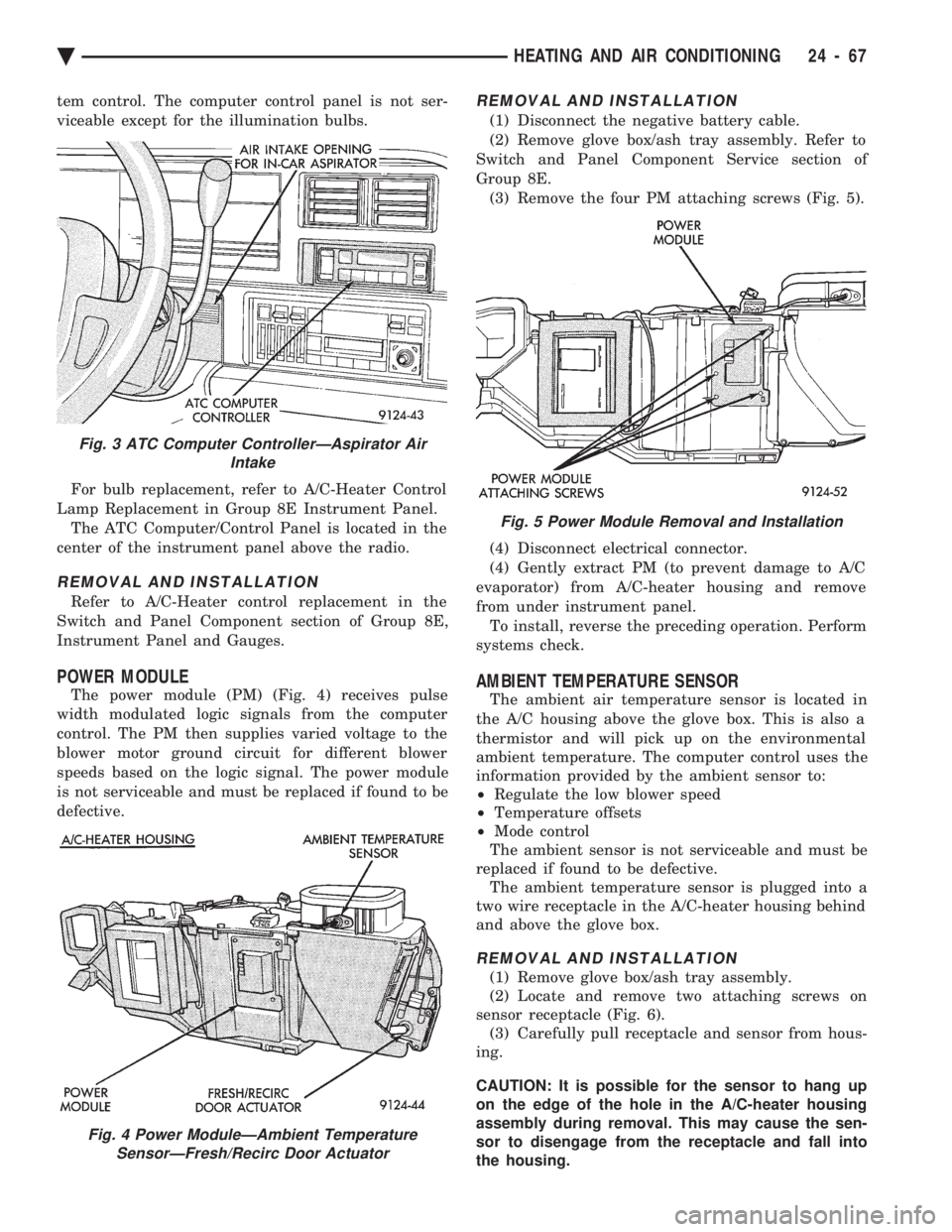

tem control. The computer control panel is not ser-

viceable except for the illumination bulbs. For bulb replacement, refer to A/C-Heater Control

Lamp Replacement in Group 8E Instrument Panel. The ATC Computer/Control Panel is located in the

center of the instrument panel above the radio.

REMOVAL AND INSTALLATION

Refer to A/C-Heater control replacement in the

Switch and Panel Component section of Group 8E,

Instrument Panel and Gauges.

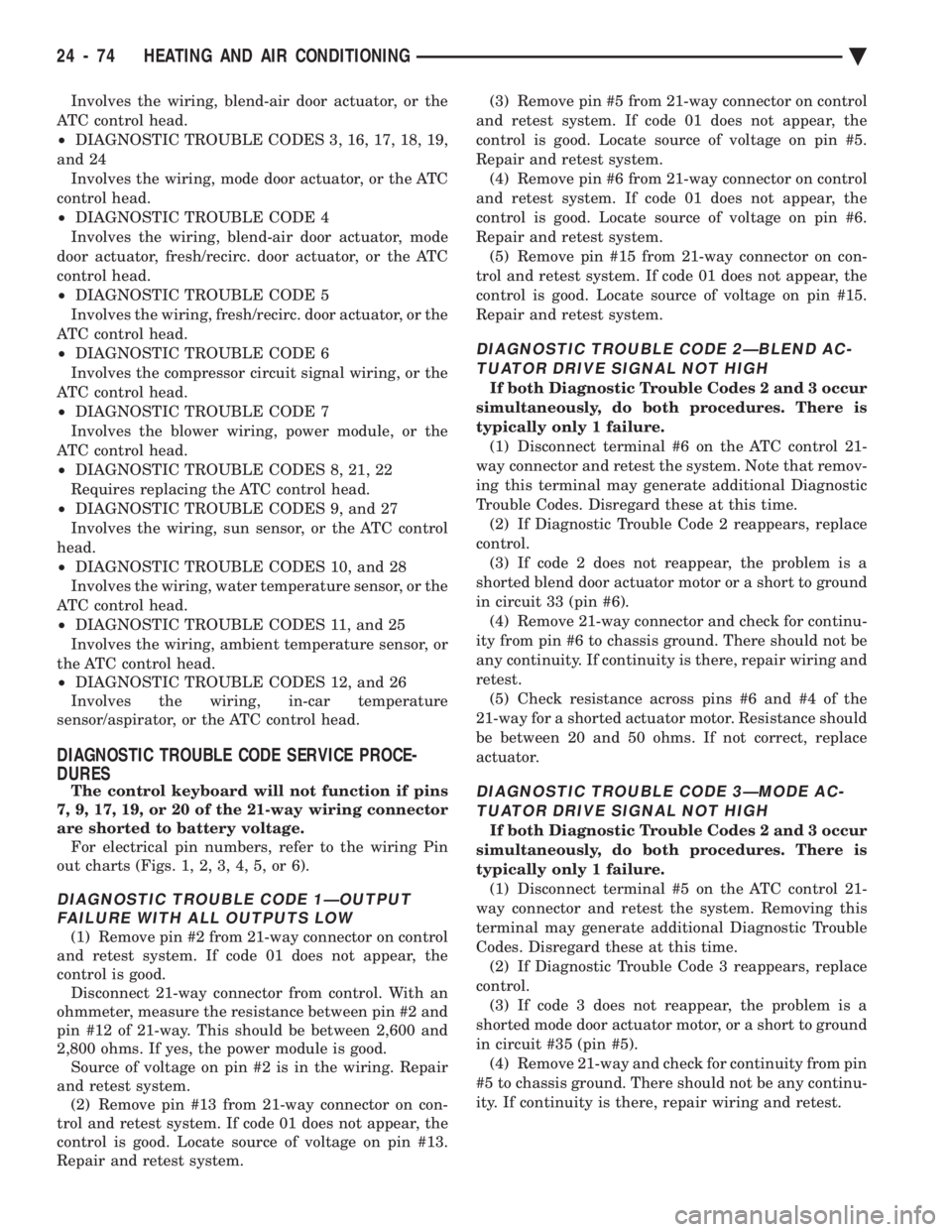

POWER MODULE

The power module (PM) (Fig. 4) receives pulse

width modulated logic signals from the computer

control. The PM then supplies varied voltage to the

blower motor ground circuit for different blower

speeds based on the logic signal. The power module

is not serviceable and must be replaced if found to be

defective.

REMOVAL AND INSTALLATION

(1) Disconnect the negative battery cable.

(2) Remove glove box/ash tray assembly. Refer to

Switch and Panel Component Service section of

Group 8E. (3) Remove the four PM attaching screws (Fig. 5).

(4) Disconnect electrical connector.

(4) Gently extract PM (to prevent damage to A/C

evaporator) from A/C-heater housing and remove

from under instrument panel. To install, reverse the preceding operation. Perform

systems check.

AMBIENT TEMPERATURE SENSOR

The ambient air temperature sensor is located in

the A/C housing above the glove box. This is also a

thermistor and will pick up on the environmental

ambient temperature. The computer control uses the

information provided by the ambient sensor to:

² Regulate the low blower speed

² Temperature offsets

² Mode control

The ambient sensor is not serviceable and must be

replaced if found to be defective. The ambient temperature sensor is plugged into a

two wire receptacle in the A/C-heater housing behind

and above the glove box.

REMOVAL AND INSTALLATION

(1) Remove glove box/ash tray assembly.

(2) Locate and remove two attaching screws on

sensor receptacle (Fig. 6). (3) Carefully pull receptacle and sensor from hous-

ing.

CAUTION: It is possible for the sensor to hang up

on the edge of the hole in the A/C-heater housing

assembly during removal. This may cause the sen-

sor to disengage from the receptacle and fall into

the housing.

Fig. 3 ATC Computer ControllerÐAspirator Air Intake

Fig. 4 Power ModuleÐAmbient TemperatureSensorÐFresh/Recirc Door Actuator

Fig. 5 Power Module Removal and Installation

Ä HEATING AND AIR CONDITIONING 24 - 67

Page 2378 of 2438

Involves the wiring, blend-air door actuator, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODES 3, 16, 17, 18, 19,

and 24 Involves the wiring, mode door actuator, or the ATC

control head.

² DIAGNOSTIC TROUBLE CODE 4

Involves the wiring, blend-air door actuator, mode

door actuator, fresh/recirc. door actuator, or the ATC

control head.

² DIAGNOSTIC TROUBLE CODE 5

Involves the wiring, fresh/recirc. door actuator, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODE 6

Involves the compressor circuit signal wiring, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODE 7

Involves the blower wiring, power module, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODES 8, 21, 22

Requires replacing the ATC control head.

² DIAGNOSTIC TROUBLE CODES 9, and 27

Involves the wiring, sun sensor, or the ATC control

head.

² DIAGNOSTIC TROUBLE CODES 10, and 28

Involves the wiring, water temperature sensor, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODES 11, and 25

Involves the wiring, ambient temperature sensor, or

the ATC control head.

² DIAGNOSTIC TROUBLE CODES 12, and 26

Involves the wiring, in-car temperature

sensor/aspirator, or the ATC control head.

DIAGNOSTIC TROUBLE CODE SERVICE PROCE-

DURES

The control keyboard will not function if pins

7, 9, 17, 19, or 20 of the 21-way wiring connector

are shorted to battery voltage. For electrical pin numbers, refer to the wiring Pin

out charts (Figs. 1, 2, 3, 4, 5, or 6).

DIAGNOSTIC TROUBLE CODE 1ÐOUTPUT FAILURE WITH ALL OUTPUTS LOW

(1) Remove pin #2 from 21-way connector on control

and retest system. If code 01 does not appear, the

control is good. Disconnect 21-way connector from control. With an

ohmmeter, measure the resistance between pin #2 and

pin #12 of 21-way. This should be between 2,600 and

2,800 ohms. If yes, the power module is good. Source of voltage on pin #2 is in the wiring. Repair

and retest system. (2) Remove pin #13 from 21-way connector on con-

trol and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #13.

Repair and retest system. (3) Remove pin #5 from 21-way connector on control

and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #5.

Repair and retest system. (4) Remove pin #6 from 21-way connector on control

and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #6.

Repair and retest system. (5) Remove pin #15 from 21-way connector on con-

trol and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #15.

Repair and retest system.

DIAGNOSTIC TROUBLE CODE 2ÐBLEND AC- TUATOR DRIVE SIGNAL NOT HIGH

If both Diagnostic Trouble Codes 2 and 3 occur

simultaneously, do both procedures. There is

typically only 1 failure. (1) Disconnect terminal #6 on the ATC control 21-

way connector and retest the system. Note that remov-

ing this terminal may generate additional Diagnostic

Trouble Codes. Disregard these at this time. (2) If Diagnostic Trouble Code 2 reappears, replace

control. (3) If code 2 does not reappear, the problem is a

shorted blend door actuator motor or a short to ground

in circuit 33 (pin #6). (4) Remove 21-way connector and check for continu-

ity from pin #6 to chassis ground. There should not be

any continuity. If continuity is there, repair wiring and

retest. (5) Check resistance across pins #6 and #4 of the

21-way for a shorted actuator motor. Resistance should

be between 20 and 50 ohms. If not correct, replace

actuator.

DIAGNOSTIC TROUBLE CODE 3ÐMODE AC- TUATOR DRIVE SIGNAL NOT HIGH

If both Diagnostic Trouble Codes 2 and 3 occur

simultaneously, do both procedures. There is

typically only 1 failure. (1) Disconnect terminal #5 on the ATC control 21-

way connector and retest the system. Removing this

terminal may generate additional Diagnostic Trouble

Codes. Disregard these at this time. (2) If Diagnostic Trouble Code 3 reappears, replace

control. (3) If code 3 does not reappear, the problem is a

shorted mode door actuator motor, or a short to ground

in circuit #35 (pin #5). (4) Remove 21-way and check for continuity from pin

#5 to chassis ground. There should not be any continu-

ity. If continuity is there, repair wiring and retest.

24 - 74 HEATING AND AIR CONDITIONING Ä