light CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2332 of 2438

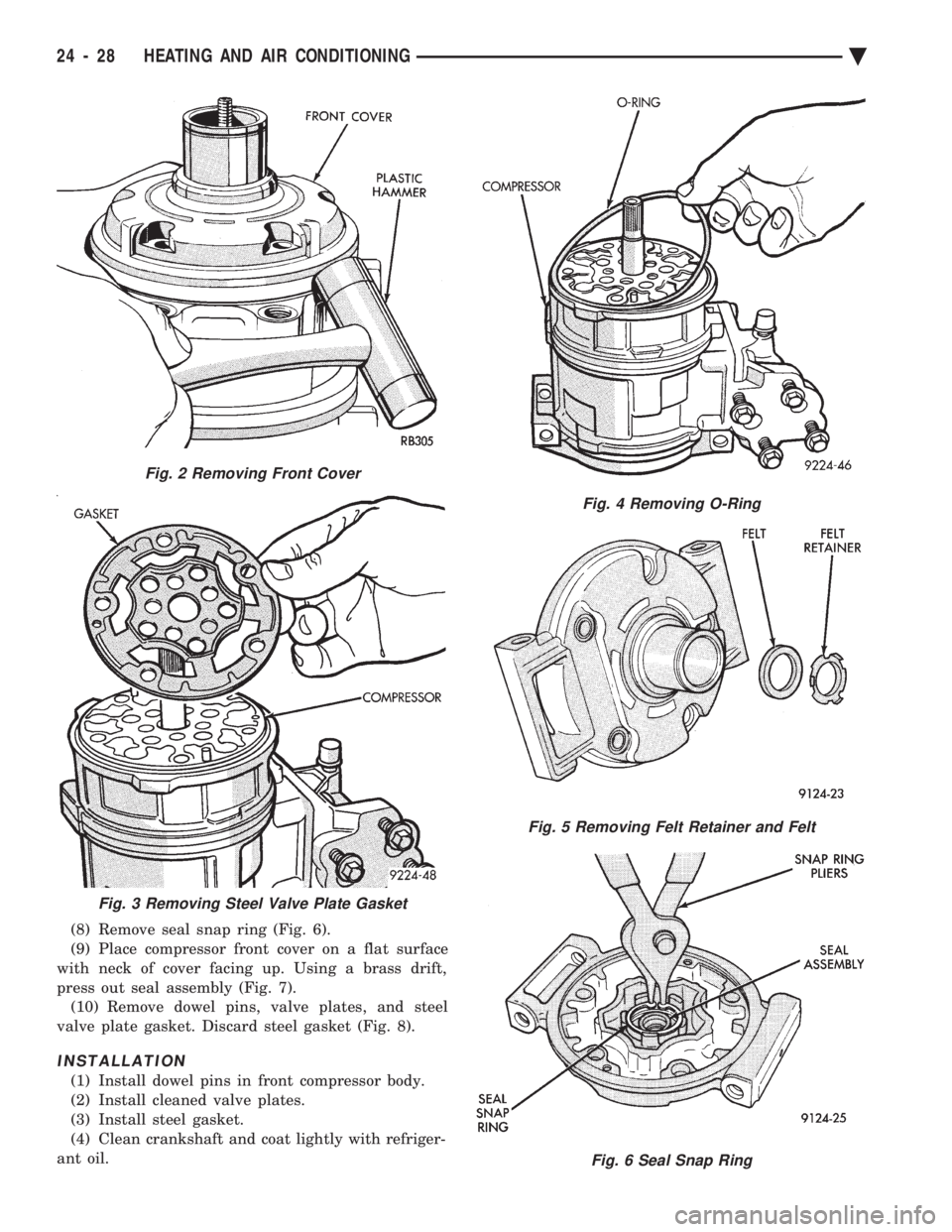

(8) Remove seal snap ring (Fig. 6).

(9) Place compressor front cover on a flat surface

with neck of cover facing up. Using a brass drift,

press out seal assembly (Fig. 7). (10) Remove dowel pins, valve plates, and steel

valve plate gasket. Discard steel gasket (Fig. 8).

INSTALLATION

(1) Install dowel pins in front compressor body.

(2) Install cleaned valve plates.

(3) Install steel gasket.

(4) Clean crankshaft and coat lightly with refriger-

ant oil.

Fig. 2 Removing Front Cover

Fig. 4 Removing O-Ring

Fig. 5 Removing Felt Retainer and Felt

Fig. 6 Seal Snap Ring

Fig. 3 Removing Steel Valve Plate Gasket

24 - 28 HEATING AND AIR CONDITIONING Ä

Page 2342 of 2438

FIXED DISPLACEMENT COMPRESSORÐMODEL SD709P INDEX

page page

Compressor ............................. 38

Compressor Clutch/Coil Assembly ............ 38

Compressor Shaft Seal .................... 41 Cylinder Head/Valve Plate

.................. 44

Description ............................. 38

Refrigerant System Diagnosis ............... 45

DESCRIPTION

The Sanden compressor is a 7 piston design. Sys-

tem lubrication is provided by 135 ml 615 ml (4.6 oz.

6 0.5 oz.) of 500 viscosity refrigerant oil.

The clutch used on the compressor consists of 3 ba-

sic components:

² The pulley

² Front plate

² Field coil

The pulley and field coil are attached to the front

head of the compressor with tapered snap rings. The

hub is keyed to the compressor shaft and is retained

on the shaft with a self-locking nut. Special service

tools are required to remove and install the clutch

plate on the compressor shaft.

COMPRESSOR

The A/C compressor may be removed and posi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the A/C

compressor clutch/coil assembly, engine, cylinder

head, or generator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. BEFORE REMOVING A FULLY

CHARGED COMPRESSOR, REVIEW THE SAFETY

PRECAUTIONS AND WARNINGS SECTION IN THIS

GROUP. DO NOT TWIST OR KINK THE REFRIGER-

ANT LINES WHEN REMOVING A FULLY CHARGED

COMPRESSOR. SAFETY GLASSES MUST BE

WORN.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Loosen and remove drive belts (refer to group

7, Cooling System) and disconnect compressor clutch

wire lead. (3) Remove refrigerant lines from compressor (if

necessary). (4) Remove compressor attaching nuts and bolts.

(5) Remove compressor. If refrigerant lines were

not removed, lift compressor/clutch assembly and tie

it to a suitable component. To install, reverse the removal procedure.

COMPRESSOR CLUTCH/COIL ASSEMBLY

The magnetic clutch consists of a stationary elec-

tro-magnetic coil and a rotating pulley and plate as-

sembly. The electromagnetic coil is retained on the com-

pressor with a snap ring and is dimpled to maintain

its position. The pulley and plate assembly are mounted on the

compressor shaft. When the compressor is not in operation, the pul-

ley free wheels on the clutch hub bearing. When the

coil is energized the plate is magnetically engaged

with the pulley and turns the compressor shaft.

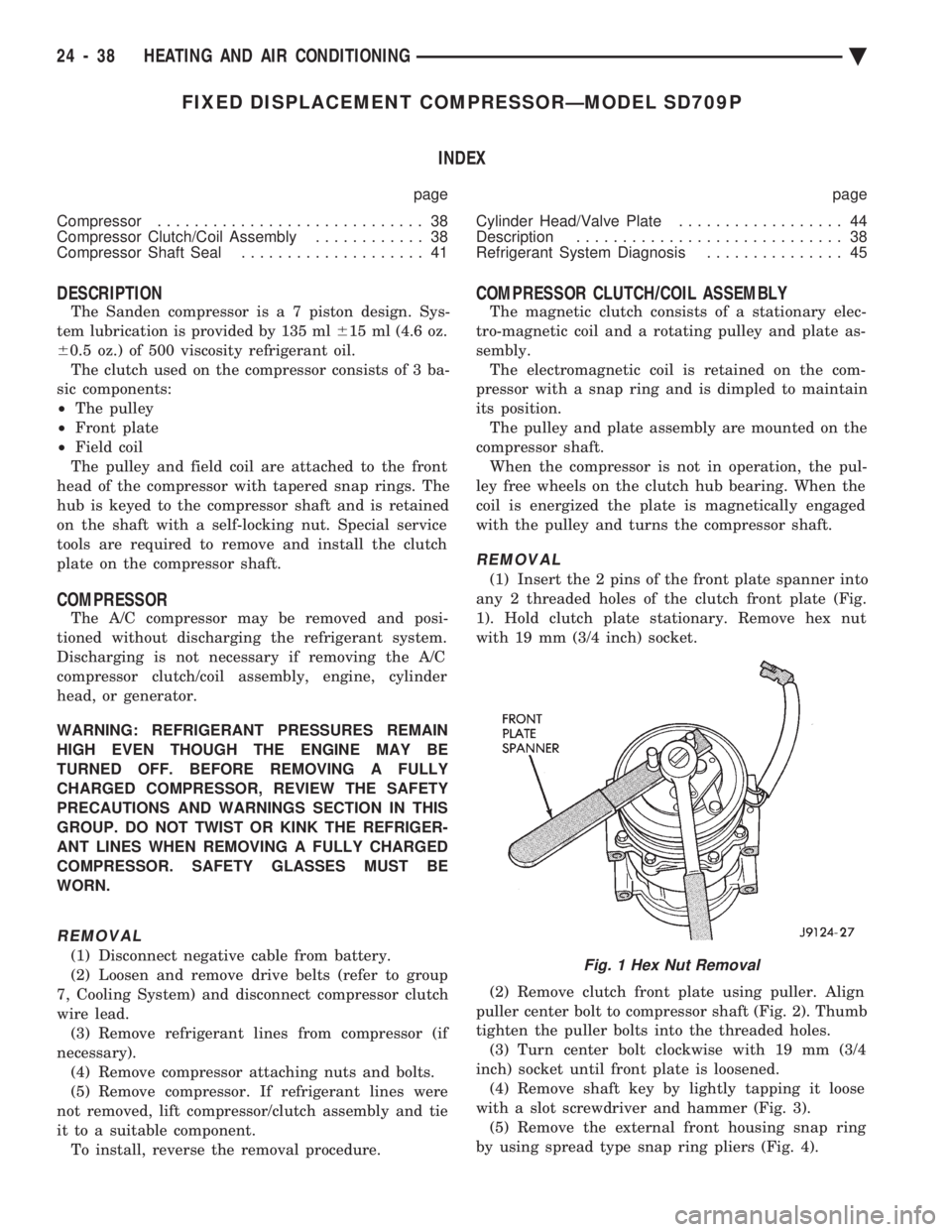

REMOVAL

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

1). Hold clutch plate stationary. Remove hex nut

with 19 mm (3/4 inch) socket.

(2) Remove clutch front plate using puller. Align

puller center bolt to compressor shaft (Fig. 2). Thumb

tighten the puller bolts into the threaded holes. (3) Turn center bolt clockwise with 19 mm (3/4

inch) socket until front plate is loosened. (4) Remove shaft key by lightly tapping it loose

with a slot screwdriver and hammer (Fig. 3). (5) Remove the external front housing snap ring

by using spread type snap ring pliers (Fig. 4).

Fig. 1 Hex Nut Removal

24 - 38 HEATING AND AIR CONDITIONING Ä

Page 2345 of 2438

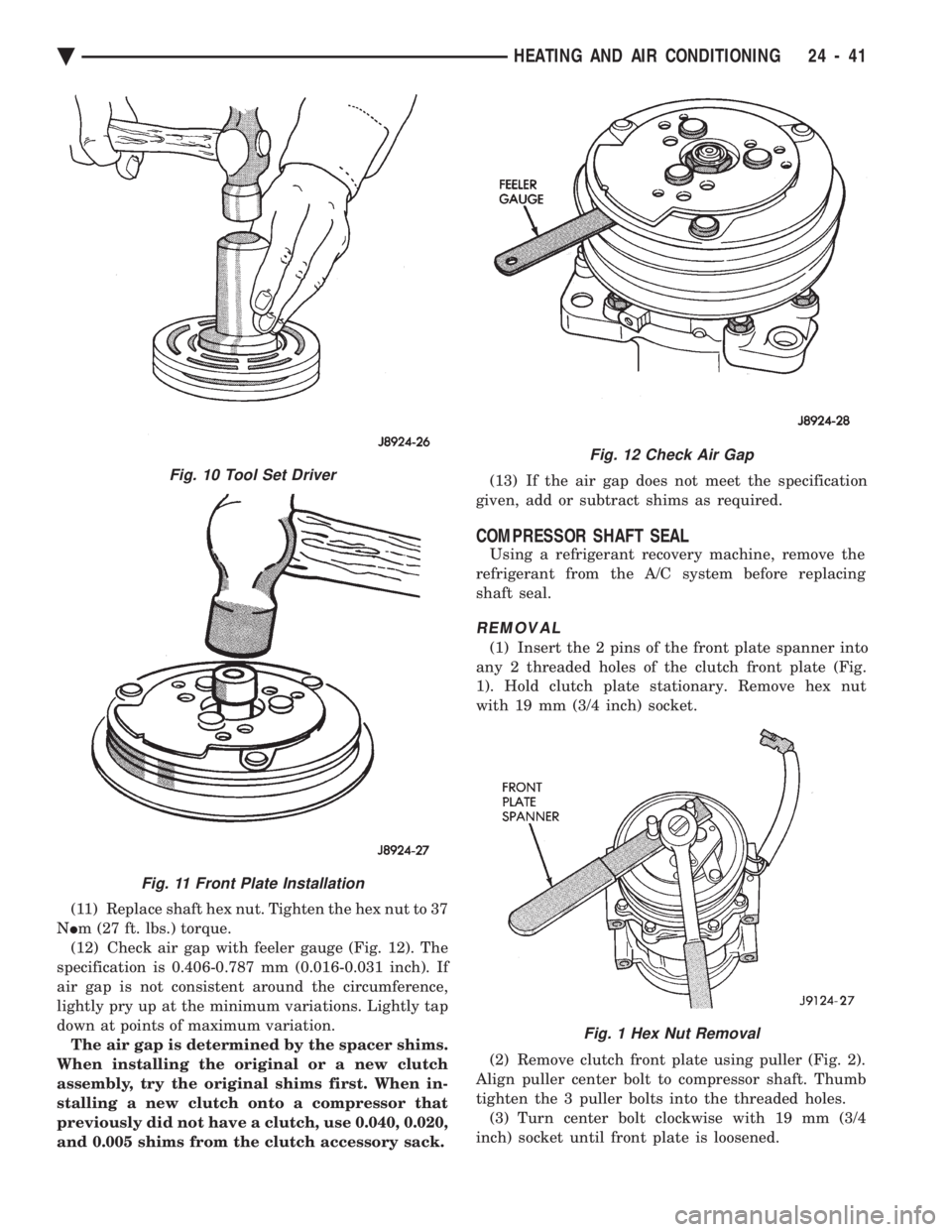

(11) Replace shaft hex nut. Tighten the hex nut to 37

N Im (27 ft. lbs.) torque.

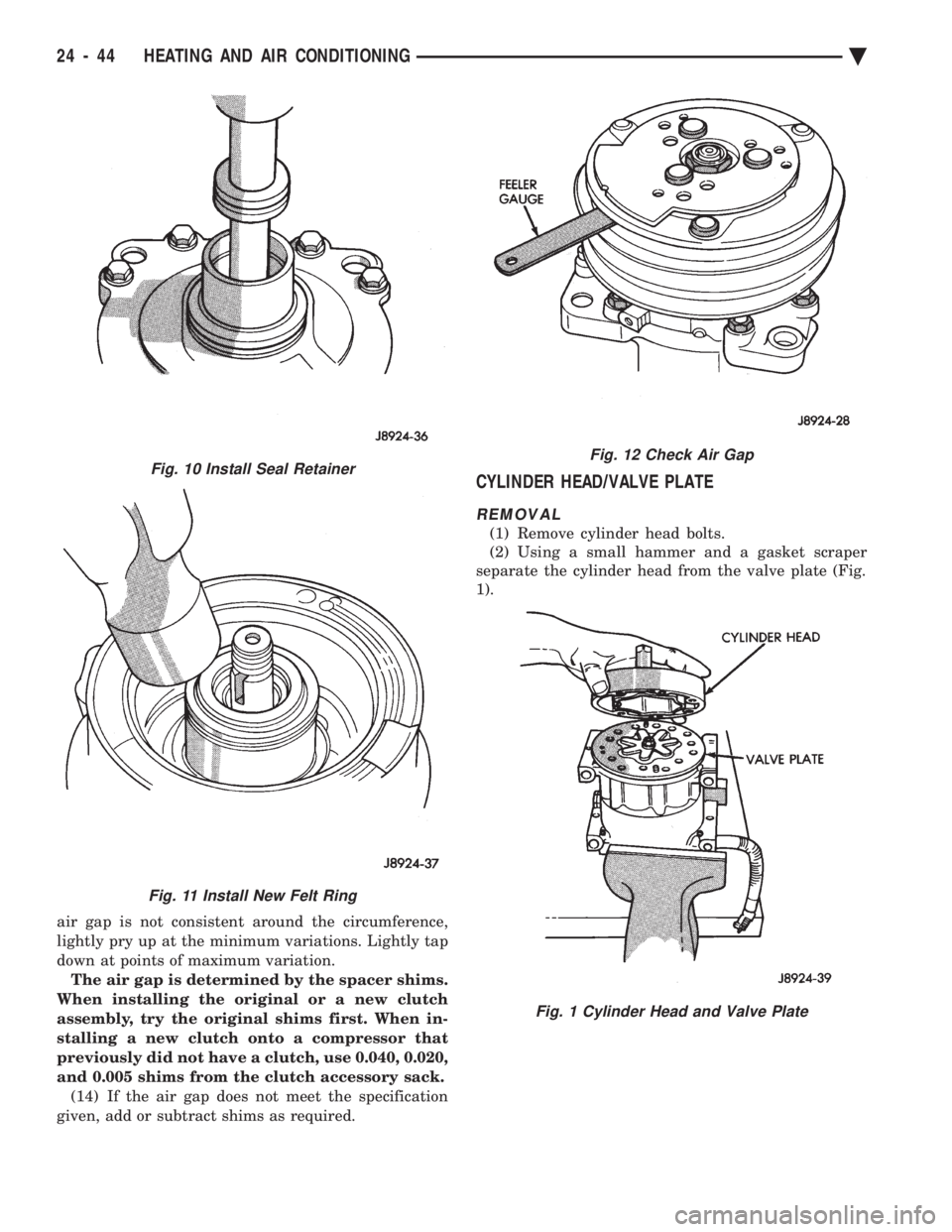

(12) Check air gap with feeler gauge (Fig. 12). The

specification is 0.406-0.787 mm (0.016-0.031 inch). If

air gap is not consistent around the circumference,

lightly pry up at the minimum variations. Lightly tap

down at points of maximum variation. The air gap is determined by the spacer shims.

When installing the original or a new clutch

assembly, try the original shims first. When in-

stalling a new clutch onto a compressor that

previously did not have a clutch, use 0.040, 0.020,

and 0.005 shims from the clutch accessory sack. (13) If the air gap does not meet the specification

given, add or subtract shims as required.

COMPRESSOR SHAFT SEAL

Using a refrigerant recovery machine, remove the

refrigerant from the A/C system before replacing

shaft seal.

REMOVAL

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

1). Hold clutch plate stationary. Remove hex nut

with 19 mm (3/4 inch) socket.

(2) Remove clutch front plate using puller (Fig. 2).

Align puller center bolt to compressor shaft. Thumb

tighten the 3 puller bolts into the threaded holes. (3) Turn center bolt clockwise with 19 mm (3/4

inch) socket until front plate is loosened.

Fig. 12 Check Air Gap

Fig. 1 Hex Nut Removal

Fig. 10 Tool Set Driver

Fig. 11 Front Plate Installation

Ä HEATING AND AIR CONDITIONING 24 - 41

Page 2347 of 2438

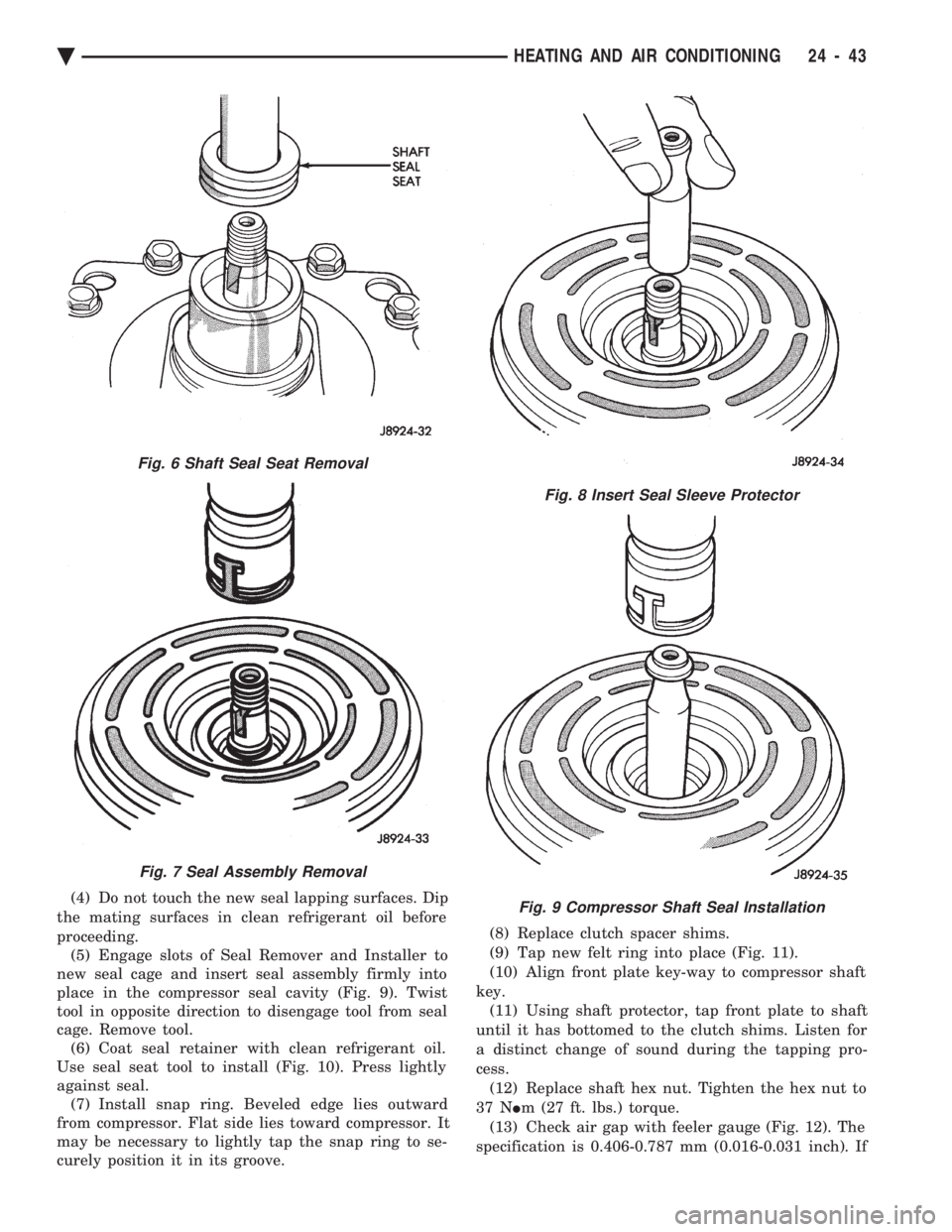

(4) Do not touch the new seal lapping surfaces. Dip

the mating surfaces in clean refrigerant oil before

proceeding. (5) Engage slots of Seal Remover and Installer to

new seal cage and insert seal assembly firmly into

place in the compressor seal cavity (Fig. 9). Twist

tool in opposite direction to disengage tool from seal

cage. Remove tool. (6) Coat seal retainer with clean refrigerant oil.

Use seal seat tool to install (Fig. 10). Press lightly

against seal. (7) Install snap ring. Beveled edge lies outward

from compressor. Flat side lies toward compressor. It

may be necessary to lightly tap the snap ring to se-

curely position it in its groove. (8) Replace clutch spacer shims.

(9) Tap new felt ring into place (Fig. 11).

(10) Align front plate key-way to compressor shaft

key. (11) Using shaft protector, tap front plate to shaft

until it has bottomed to the clutch shims. Listen for

a distinct change of sound during the tapping pro-

cess. (12) Replace shaft hex nut. Tighten the hex nut to

37 N Im (27 ft. lbs.) torque.

(13) Check air gap with feeler gauge (Fig. 12). The

specification is 0.406-0.787 mm (0.016-0.031 inch). If

Fig. 6 Shaft Seal Seat Removal

Fig. 7 Seal Assembly Removal

Fig. 8 Insert Seal Sleeve Protector

Fig. 9 Compressor Shaft Seal Installation

Ä HEATING AND AIR CONDITIONING 24 - 43

Page 2348 of 2438

air gap is not consistent around the circumference,

lightly pry up at the minimum variations. Lightly tap

down at points of maximum variation.The air gap is determined by the spacer shims.

When installing the original or a new clutch

assembly, try the original shims first. When in-

stalling a new clutch onto a compressor that

previously did not have a clutch, use 0.040, 0.020,

and 0.005 shims from the clutch accessory sack. (14) If the air gap does not meet the specification

given, add or subtract shims as required.

CYLINDER HEAD/VALVE PLATE

REMOVAL

(1) Remove cylinder head bolts.

(2) Using a small hammer and a gasket scraper

separate the cylinder head from the valve plate (Fig.

1).

Fig. 12 Check Air Gap

Fig. 1 Cylinder Head and Valve Plate

Fig. 10 Install Seal Retainer

Fig. 11 Install New Felt Ring

24 - 44 HEATING AND AIR CONDITIONING Ä

Page 2355 of 2438

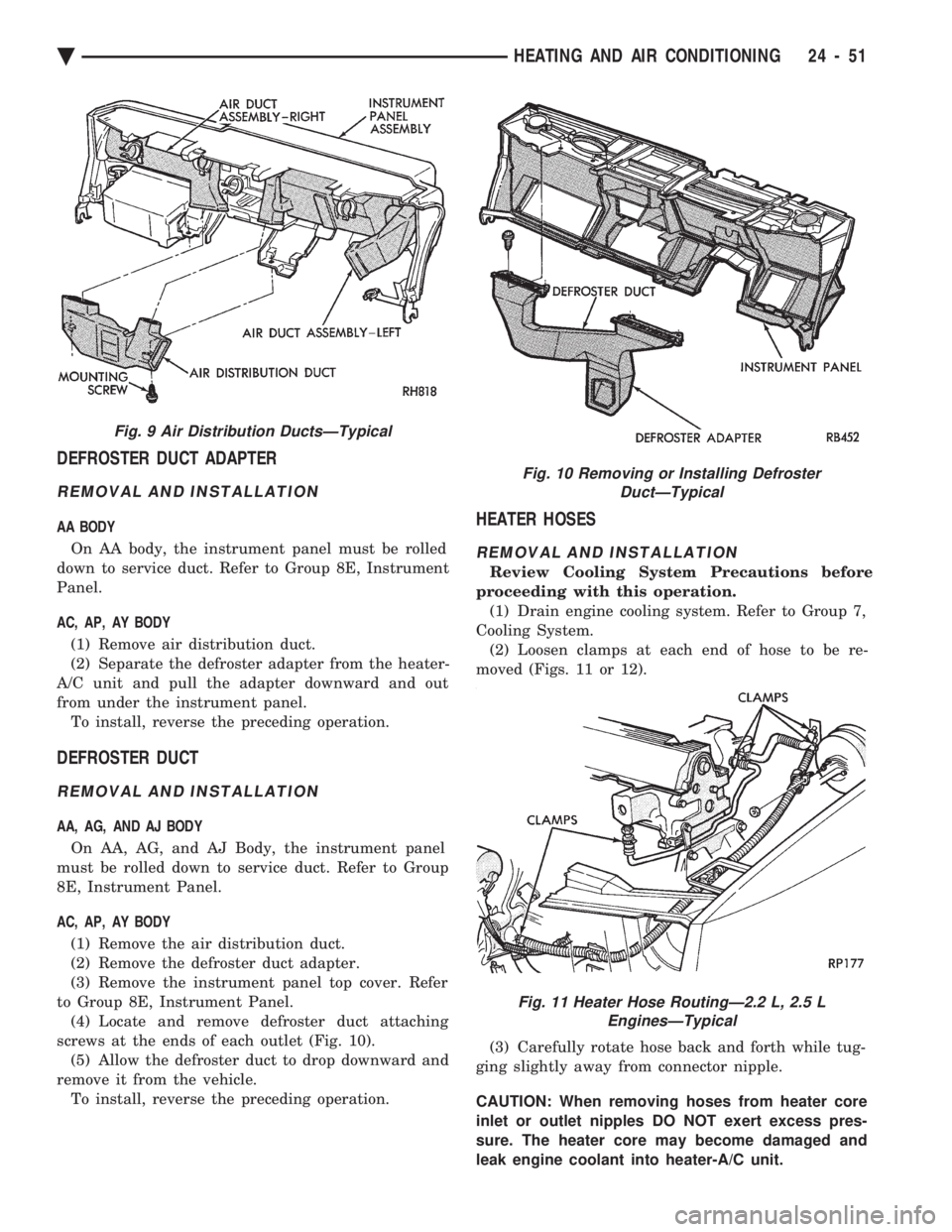

DEFROSTER DUCT ADAPTER

REMOVAL AND INSTALLATION

AA BODY On AA body, the instrument panel must be rolled

down to service duct. Refer to Group 8E, Instrument

Panel.

AC, AP, AY BODY

(1) Remove air distribution duct.

(2) Separate the defroster adapter from the heater-

A/C unit and pull the adapter downward and out

from under the instrument panel. To install, reverse the preceding operation.

DEFROSTER DUCT

REMOVAL AND INSTALLATION

AA, AG, AND AJ BODY

On AA, AG, and AJ Body, the instrument panel

must be rolled down to service duct. Refer to Group

8E, Instrument Panel.

AC, AP, AY BODY

(1) Remove the air distribution duct.

(2) Remove the defroster duct adapter.

(3) Remove the instrument panel top cover. Refer

to Group 8E, Instrument Panel. (4) Locate and remove defroster duct attaching

screws at the ends of each outlet (Fig. 10). (5) Allow the defroster duct to drop downward and

remove it from the vehicle. To install, reverse the preceding operation.

HEATER HOSES

REMOVAL AND INSTALLATION

Review Cooling System Precautions before

proceeding with this operation. (1) Drain engine cooling system. Refer to Group 7,

Cooling System. (2) Loosen clamps at each end of hose to be re-

moved (Figs. 11 or 12).

(3) Carefully rotate hose back and forth while tug-

ging slightly away from connector nipple.

CAUTION: When removing hoses from heater core

inlet or outlet nipples DO NOT exert excess pres-

sure. The heater core may become damaged and

leak engine coolant into heater-A/C unit.

Fig. 9 Air Distribution DuctsÐTypical

Fig. 10 Removing or Installing Defroster DuctÐTypical

Fig. 11 Heater Hose RoutingÐ2.2 L, 2.5 LEnginesÐTypical

Ä HEATING AND AIR CONDITIONING 24 - 51

Page 2361 of 2438

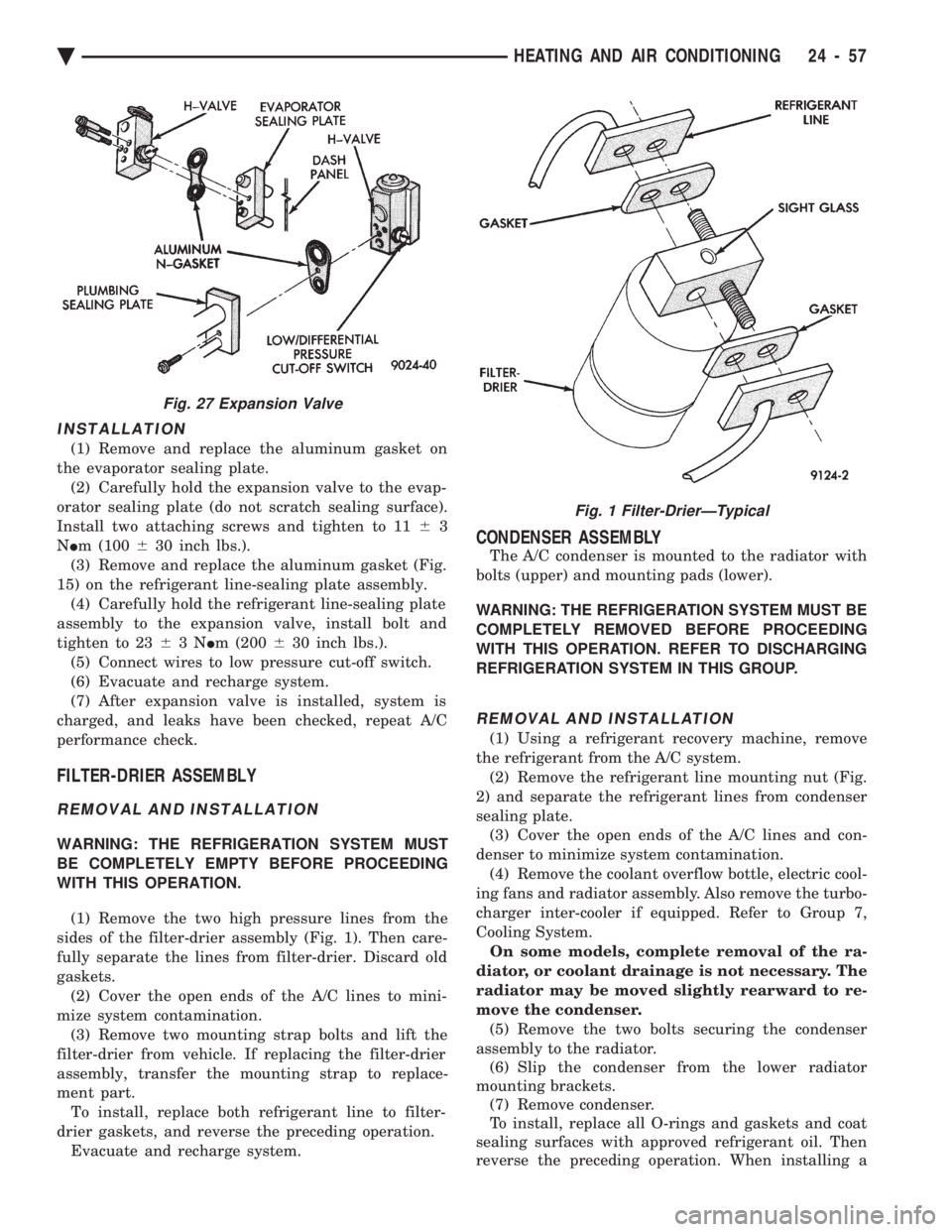

INSTALLATION

(1) Remove and replace the aluminum gasket on

the evaporator sealing plate. (2) Carefully hold the expansion valve to the evap-

orator sealing plate (do not scratch sealing surface).

Install two attaching screws and tighten to 11 63

N Im (100 630 inch lbs.).

(3) Remove and replace the aluminum gasket (Fig.

15) on the refrigerant line-sealing plate assembly. (4) Carefully hold the refrigerant line-sealing plate

assembly to the expansion valve, install bolt and

tighten to 23 63N Im (200 630 inch lbs.).

(5) Connect wires to low pressure cut-off switch.

(6) Evacuate and recharge system.

(7) After expansion valve is installed, system is

charged, and leaks have been checked, repeat A/C

performance check.

FILTER-DRIER ASSEMBLY

REMOVAL AND INSTALLATION

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

(1) Remove the two high pressure lines from the

sides of the filter-drier assembly (Fig. 1). Then care-

fully separate the lines from filter-drier. Discard old

gaskets. (2) Cover the open ends of the A/C lines to mini-

mize system contamination. (3) Remove two mounting strap bolts and lift the

filter-drier from vehicle. If replacing the filter-drier

assembly, transfer the mounting strap to replace-

ment part. To install, replace both refrigerant line to filter-

drier gaskets, and reverse the preceding operation. Evacuate and recharge system.

CONDENSER ASSEMBLY

The A/C condenser is mounted to the radiator with

bolts (upper) and mounting pads (lower).

WARNING: THE REFRIGERATION SYSTEM MUST BE

COMPLETELY REMOVED BEFORE PROCEEDING

WITH THIS OPERATION. REFER TO DISCHARGING

REFRIGERATION SYSTEM IN THIS GROUP.

REMOVAL AND INSTALLATION

(1) Using a refrigerant recovery machine, remove

the refrigerant from the A/C system. (2) Remove the refrigerant line mounting nut (Fig.

2) and separate the refrigerant lines from condenser

sealing plate. (3) Cover the open ends of the A/C lines and con-

denser to minimize system contamination. (4) Remove the coolant overflow bottle, electric cool-

ing fans and radiator assembly. Also remove the turbo-

charger inter-cooler if equipped. Refer to Group 7,

Cooling System. On some models, complete removal of the ra-

diator, or coolant drainage is not necessary. The

radiator may be moved slightly rearward to re-

move the condenser. (5) Remove the two bolts securing the condenser

assembly to the radiator. (6) Slip the condenser from the lower radiator

mounting brackets. (7) Remove condenser.

To install, replace all O-rings and gaskets and coat

sealing surfaces with approved refrigerant oil. Then

reverse the preceding operation. When installing a

Fig. 27 Expansion Valve

Fig. 1 Filter-DrierÐTypical

Ä HEATING AND AIR CONDITIONING 24 - 57

Page 2366 of 2438

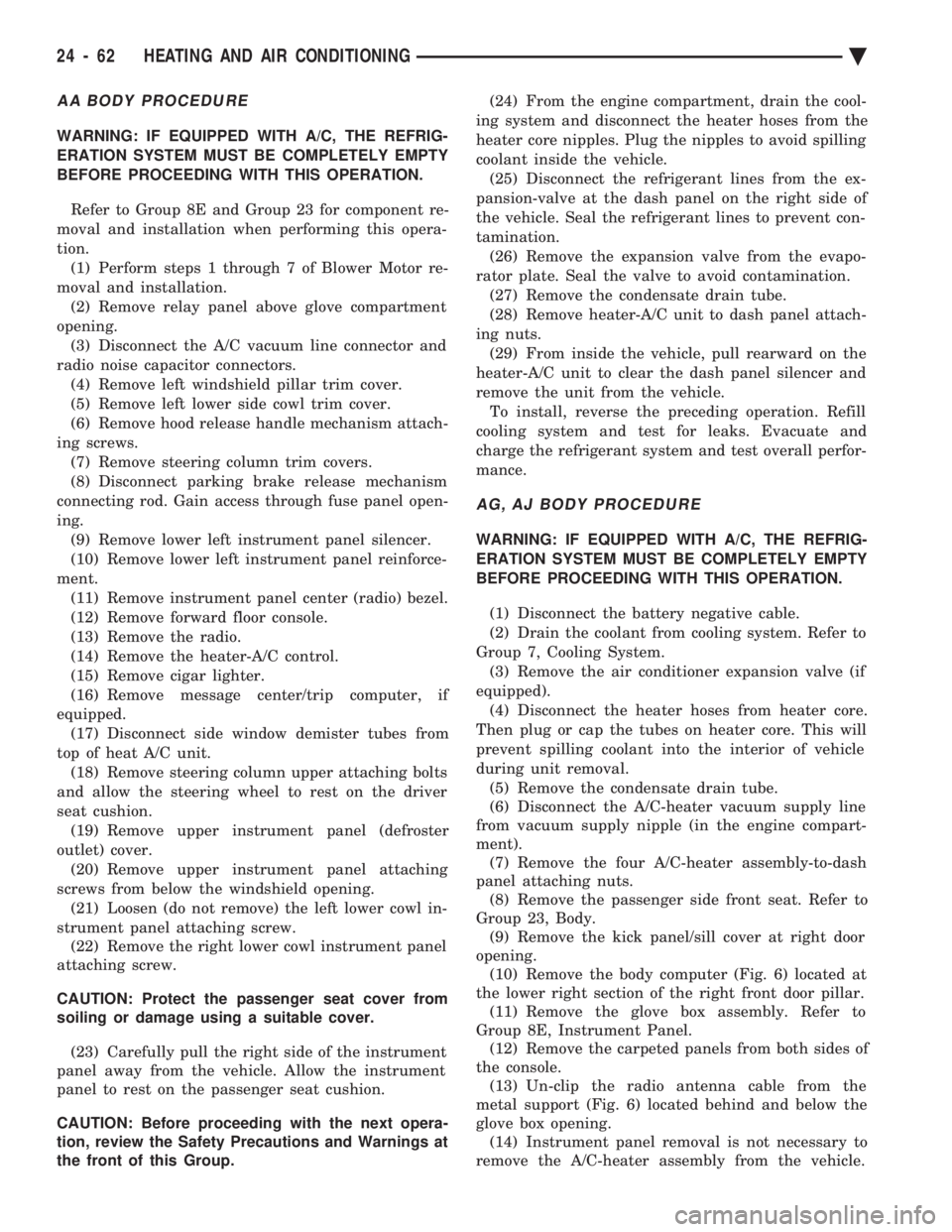

AA BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION. Refer to Group 8E and Group 23 for component re-

moval and installation when performing this opera-

tion. (1) Perform steps 1 through 7 of Blower Motor re-

moval and installation. (2) Remove relay panel above glove compartment

opening. (3) Disconnect the A/C vacuum line connector and

radio noise capacitor connectors. (4) Remove left windshield pillar trim cover.

(5) Remove left lower side cowl trim cover.

(6) Remove hood release handle mechanism attach-

ing screws. (7) Remove steering column trim covers.

(8) Disconnect parking brake release mechanism

connecting rod. Gain access through fuse panel open-

ing. (9) Remove lower left instrument panel silencer.

(10) Remove lower left instrument panel reinforce-

ment. (11) Remove instrument panel center (radio) bezel.

(12) Remove forward floor console.

(13) Remove the radio.

(14) Remove the heater-A/C control.

(15) Remove cigar lighter.

(16) Remove message center/trip computer, if

equipped. (17) Disconnect side window demister tubes from

top of heat A/C unit. (18) Remove steering column upper attaching bolts

and allow the steering wheel to rest on the driver

seat cushion. (19) Remove upper instrument panel (defroster

outlet) cover. (20) Remove upper instrument panel attaching

screws from below the windshield opening. (21) Loosen (do not remove) the left lower cowl in-

strument panel attaching screw. (22) Remove the right lower cowl instrument panel

attaching screw.

CAUTION: Protect the passenger seat cover from

soiling or damage using a suitable cover.

(23) Carefully pull the right side of the instrument

panel away from the vehicle. Allow the instrument

panel to rest on the passenger seat cushion.

CAUTION: Before proceeding with the next opera-

tion, review the Safety Precautions and Warnings at

the front of this Group. (24) From the engine compartment, drain the cool-

ing system and disconnect the heater hoses from the

heater core nipples. Plug the nipples to avoid spilling

coolant inside the vehicle. (25) Disconnect the refrigerant lines from the ex-

pansion-valve at the dash panel on the right side of

the vehicle. Seal the refrigerant lines to prevent con-

tamination. (26) Remove the expansion valve from the evapo-

rator plate. Seal the valve to avoid contamination. (27) Remove the condensate drain tube.

(28) Remove heater-A/C unit to dash panel attach-

ing nuts. (29) From inside the vehicle, pull rearward on the

heater-A/C unit to clear the dash panel silencer and

remove the unit from the vehicle. To install, reverse the preceding operation. Refill

cooling system and test for leaks. Evacuate and

charge the refrigerant system and test overall perfor-

mance.

AG, AJ BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect the battery negative cable.

(2) Drain the coolant from cooling system. Refer to

Group 7, Cooling System. (3) Remove the air conditioner expansion valve (if

equipped). (4) Disconnect the heater hoses from heater core.

Then plug or cap the tubes on heater core. This will

prevent spilling coolant into the interior of vehicle

during unit removal. (5) Remove the condensate drain tube.

(6) Disconnect the A/C-heater vacuum supply line

from vacuum supply nipple (in the engine compart-

ment). (7) Remove the four A/C-heater assembly-to-dash

panel attaching nuts. (8) Remove the passenger side front seat. Refer to

Group 23, Body. (9) Remove the kick panel/sill cover at right door

opening. (10) Remove the body computer (Fig. 6) located at

the lower right section of the right front door pillar. (11) Remove the glove box assembly. Refer to

Group 8E, Instrument Panel. (12) Remove the carpeted panels from both sides of

the console. (13) Un-clip the radio antenna cable from the

metal support (Fig. 6) located behind and below the

glove box opening. (14) Instrument panel removal is not necessary to

remove the A/C-heater assembly from the vehicle.

24 - 62 HEATING AND AIR CONDITIONING Ä

Page 2367 of 2438

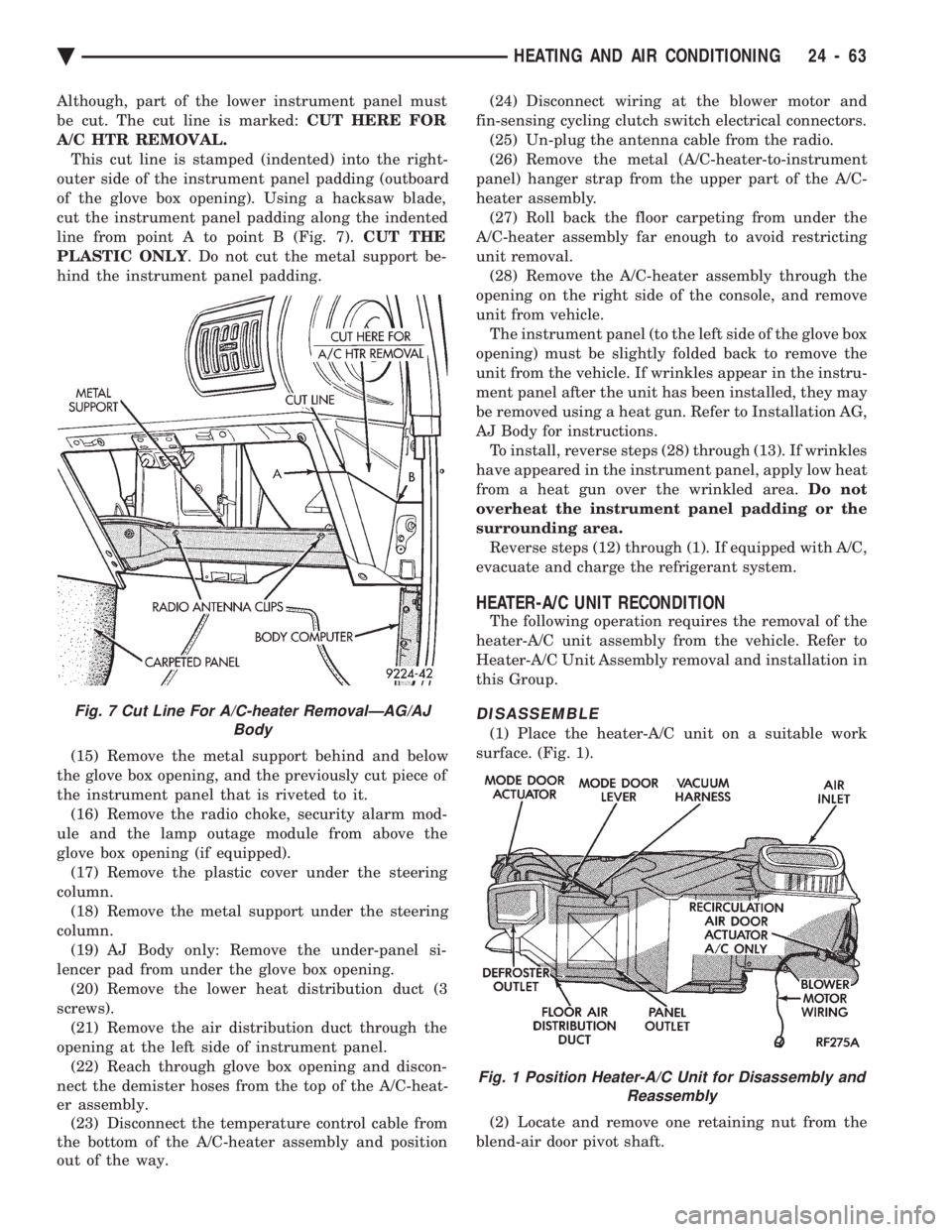

Although, part of the lower instrument panel must

be cut. The cut line is marked: CUT HERE FOR

A/C HTR REMOVAL. This cut line is stamped (indented) into the right-

outer side of the instrument panel padding (outboard

of the glove box opening). Using a hacksaw blade,

cut the instrument panel padding along the indented

line from point A to point B (Fig. 7). CUT THE

PLASTIC ONLY . Do not cut the metal support be-

hind the instrument panel padding.

(15) Remove the metal support behind and below

the glove box opening, and the previously cut piece of

the instrument panel that is riveted to it. (16) Remove the radio choke, security alarm mod-

ule and the lamp outage module from above the

glove box opening (if equipped). (17) Remove the plastic cover under the steering

column. (18) Remove the metal support under the steering

column. (19) AJ Body only: Remove the under-panel si-

lencer pad from under the glove box opening. (20) Remove the lower heat distribution duct (3

screws). (21) Remove the air distribution duct through the

opening at the left side of instrument panel. (22) Reach through glove box opening and discon-

nect the demister hoses from the top of the A/C-heat-

er assembly. (23) Disconnect the temperature control cable from

the bottom of the A/C-heater assembly and position

out of the way. (24) Disconnect wiring at the blower motor and

fin-sensing cycling clutch switch electrical connectors. (25) Un-plug the antenna cable from the radio.

(26) Remove the metal (A/C-heater-to-instrument

panel) hanger strap from the upper part of the A/C-

heater assembly. (27) Roll back the floor carpeting from under the

A/C-heater assembly far enough to avoid restricting

unit removal. (28) Remove the A/C-heater assembly through the

opening on the right side of the console, and remove

unit from vehicle. The instrument panel (to the left side of the glove box

opening) must be slightly folded back to remove the

unit from the vehicle. If wrinkles appear in the instru-

ment panel after the unit has been installed, they may

be removed using a heat gun. Refer to Installation AG,

AJ Body for instructions. To install, reverse steps (28) through (13). If wrinkles

have appeared in the instrument panel, apply low heat

from a heat gun over the wrinkled area. Do not

overheat the instrument panel padding or the

surrounding area. Reverse steps (12) through (1). If equipped with A/C,

evacuate and charge the refrigerant system.

HEATER-A/C UNIT RECONDITION

The following operation requires the removal of the

heater-A/C unit assembly from the vehicle. Refer to

Heater-A/C Unit Assembly removal and installation in

this Group.

DISASSEMBLE

(1) Place the heater-A/C unit on a suitable work

surface. (Fig. 1).

(2) Locate and remove one retaining nut from the

blend-air door pivot shaft.

Fig. 7 Cut Line For A/C-heater RemovalÐAG/AJ Body

Fig. 1 Position Heater-A/C Unit for Disassembly andReassembly

Ä HEATING AND AIR CONDITIONING 24 - 63

Page 2375 of 2438

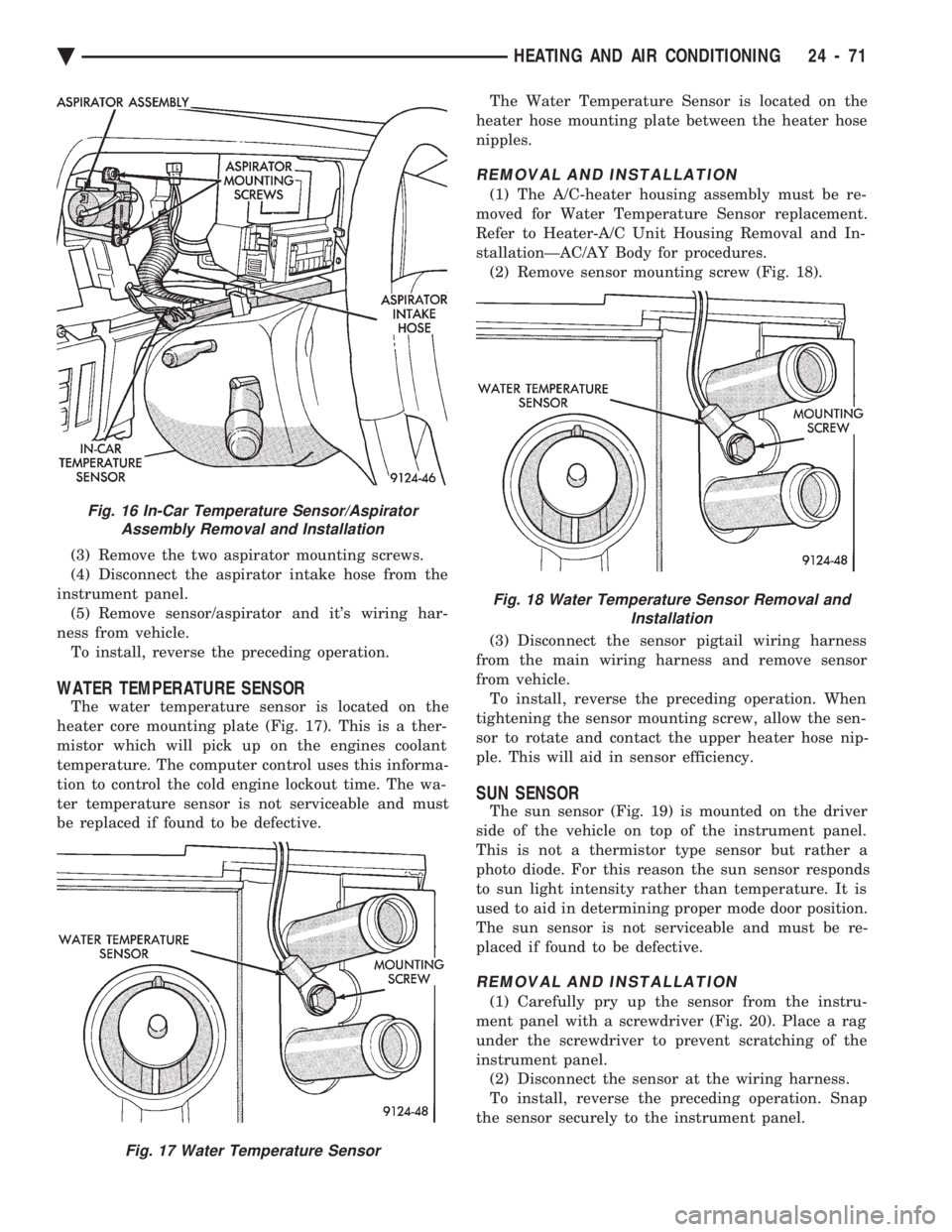

(3) Remove the two aspirator mounting screws.

(4) Disconnect the aspirator intake hose from the

instrument panel. (5) Remove sensor/aspirator and it's wiring har-

ness from vehicle. To install, reverse the preceding operation.

WATER TEMPERATURE SENSOR

The water temperature sensor is located on the

heater core mounting plate (Fig. 17). This is a ther-

mistor which will pick up on the engines coolant

temperature. The computer control uses this informa-

tion to control the cold engine lockout time. The wa-

ter temperature sensor is not serviceable and must

be replaced if found to be defective. The Water Temperature Sensor is located on the

heater hose mounting plate between the heater hose

nipples.

REMOVAL AND INSTALLATION

(1) The A/C-heater housing assembly must be re-

moved for Water Temperature Sensor replacement.

Refer to Heater-A/C Unit Housing Removal and In-

stallationÐAC/AY Body for procedures. (2) Remove sensor mounting screw (Fig. 18).

(3) Disconnect the sensor pigtail wiring harness

from the main wiring harness and remove sensor

from vehicle. To install, reverse the preceding operation. When

tightening the sensor mounting screw, allow the sen-

sor to rotate and contact the upper heater hose nip-

ple. This will aid in sensor efficiency.

SUN SENSOR

The sun sensor (Fig. 19) is mounted on the driver

side of the vehicle on top of the instrument panel.

This is not a thermistor type sensor but rather a

photo diode. For this reason the sun sensor responds

to sun light intensity rather than temperature. It is

used to aid in determining proper mode door position.

The sun sensor is not serviceable and must be re-

placed if found to be defective.

REMOVAL AND INSTALLATION

(1) Carefully pry up the sensor from the instru-

ment panel with a screwdriver (Fig. 20). Place a rag

under the screwdriver to prevent scratching of the

instrument panel. (2) Disconnect the sensor at the wiring harness.

To install, reverse the preceding operation. Snap

the sensor securely to the instrument panel.

Fig. 16 In-Car Temperature Sensor/Aspirator Assembly Removal and Installation

Fig. 17 Water Temperature Sensor

Fig. 18 Water Temperature Sensor Removal and Installation

Ä HEATING AND AIR CONDITIONING 24 - 71