light CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2159 of 2438

gage compartment. If light is visible through a nor-

mally sealed location, water could enter through the

opening.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compartment

can not be detected by water testing, pressurize the

passenger compartment and soap test exterior of the

vehicle. To pressurize the passenger compartment,

close all doors and windows, start engine, and set

heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to assure adequate voltage to the blower. With

interior pressurized, apply dish detergent solution to

suspected leak area on the exterior of the vehicle.

Apply detergent solution with spray device or soft

bristle brush. If soap bubbles occur at a body seam,

joint, seal or gasket the leak entry point could be at

that location.

WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be air tight in normal

driving conditions. Moving sealing surfaces will not

always seal air tight under all conditions. At times,

side glass, door, or convertible top seals will allow wind

noise to be noticed in the passenger compartment

during high cross-winds. Over compensating on door,

glass, or top adjustments to stop wind noise that occurs

under severe conditions, can cause premature seal

wear and excessive closing or latching effort. After a repair procedure has been performed, test vehicle to

verify leak has stopped before returning vehicle to use. Wind noise can also be caused by improperly fitted

exterior mouldings or body ornamentation. Loose

mouldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place, body

drains are clear and body components are aligned and

sealed. If component alignment or sealing is necessary,

refer to the appropriate section of this group for proper

procedures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location of

the wind noise. (2) Apply 50 mm (2 in.) masking tape in 150 mm (6

in.) lengths along weatherstrips, weld seams or moul-

dings. After each length is applied drive vehicle. If

noise goes away after a piece of tape is applied, remove

tape, locate and repair defect.

POSSIBLE CAUSE OF WIND NOISE

² Mouldings standing away from body surface can

catch wind and whistle.

² Gaps in sealed areas behind overhanging body

flanges can cause wind rushing sounds.

² Misaligned movable components.

² Missing or improperly installed plugs in pillars.

² Weld burn through holes.

Ä BODY 23 - 3

Page 2160 of 2438

PAINT

INTRODUCTION

A paint code is provided on the body code plate

located in the engine compartment. Refer to the Intro-

duction section at the front of this manual for body code

plate description. The color names provided in the

Paint and Trim Code Description chart are the color

names used on most repair product containers. The

color names in the new vehicle ordering guides vary

depending on car line but use the same color code.

BASE COAT/CLEAR COAT FINISH

On most vehicles a two part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultra violet light and provides a durable

high gloss finish.

WET SANDING,BUFFING AND POLISHING

Minor acid etching, orange peel or smudging in clear

coat can be reduced with light wet sanding, hand

buffing and polishing. If the finish has been wet sanded

in the past, it can not be repeated. Wet sanding

operation should be performed by a trained automotive

painter.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat to

shine.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched or

chipped, it should be touched-up as soon as possible to avoid corrosion. For best results, use Mopar

tScratch

Filler/Primer, Touch-Up Paints and Clear Top Coat.

Refer to Introduction group of this manual for Body

Code Plate information.

TOUCH-UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip. (2) Clean affected area with Mopar tTar/Road Oil

Remover and allow to dry. (3) Fill the inside of the scratch or chip with a coat of

filler/primer. Do not overlap primer onto good surface

finish. The applicator brush should be wet enough to

puddle fill the defect without running. Do not stroke

brush applicator on body surface. Allow the filler/

primer to dry hard. (4) Cover the filler/primer with color touch-up paint.

Do not overlap touch-up color onto the original color

coat around the scratch or chip. Butt the new color to

the original color if possible. Do not stroke applicator

brush on body surface. Allow touch-up paint to dry

hard. (5) On vehicles without clear coat, the touch-up color

can be lightly (600 grit) wet sanded and polished with

rubbing compound. (6) On vehicles with clear coat, Apply clear top coat

to touch-up paint with the same technique as described

in step 4. Allow clear top coat to dry hard. If desired,

step 5 can be performed on clear top coat.

23 - 4 BODY Ä

Page 2190 of 2438

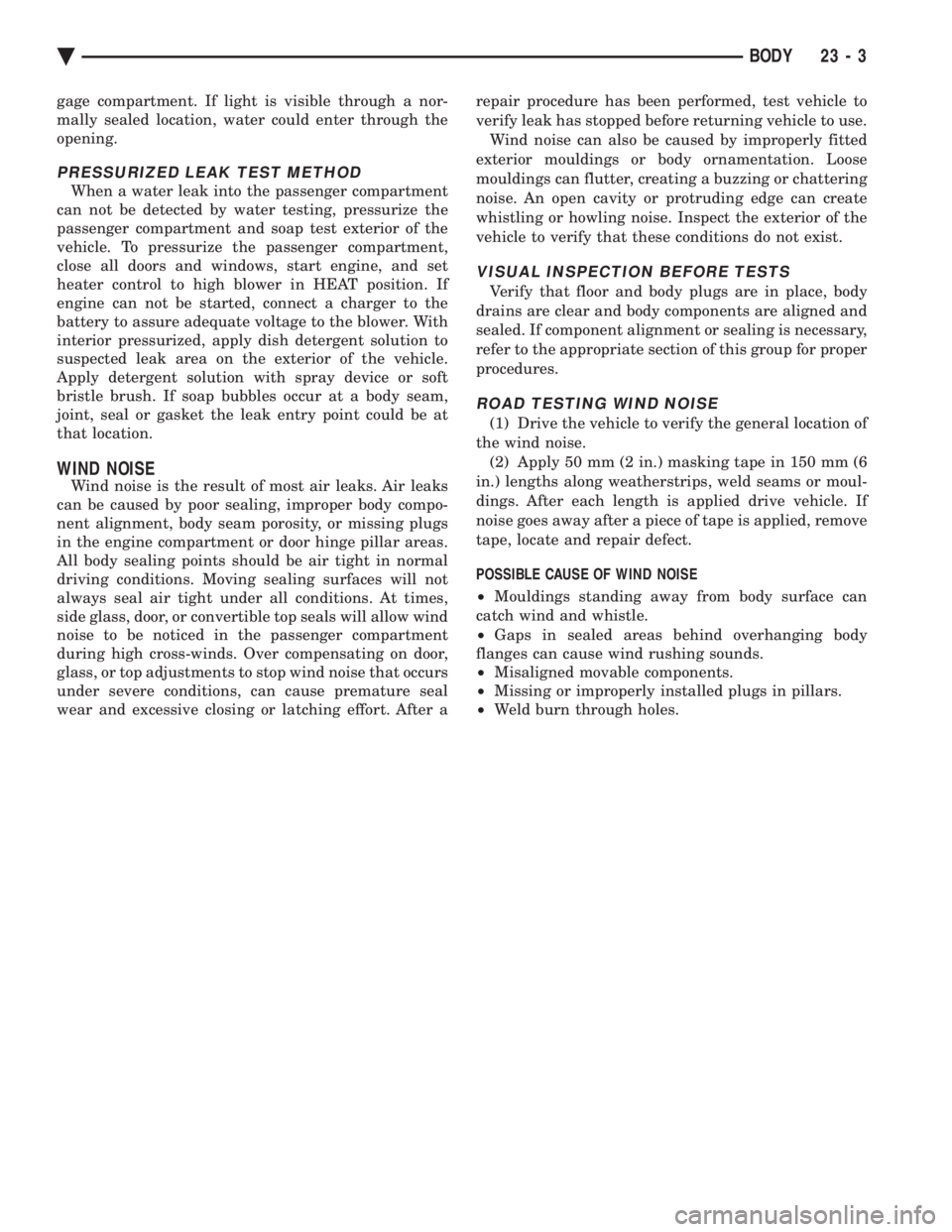

bottom trunk lid to hinge attaching bolts. Separate

the trunk lid from the vehicle.

INSTALLATION

Reverse the preceding operation.

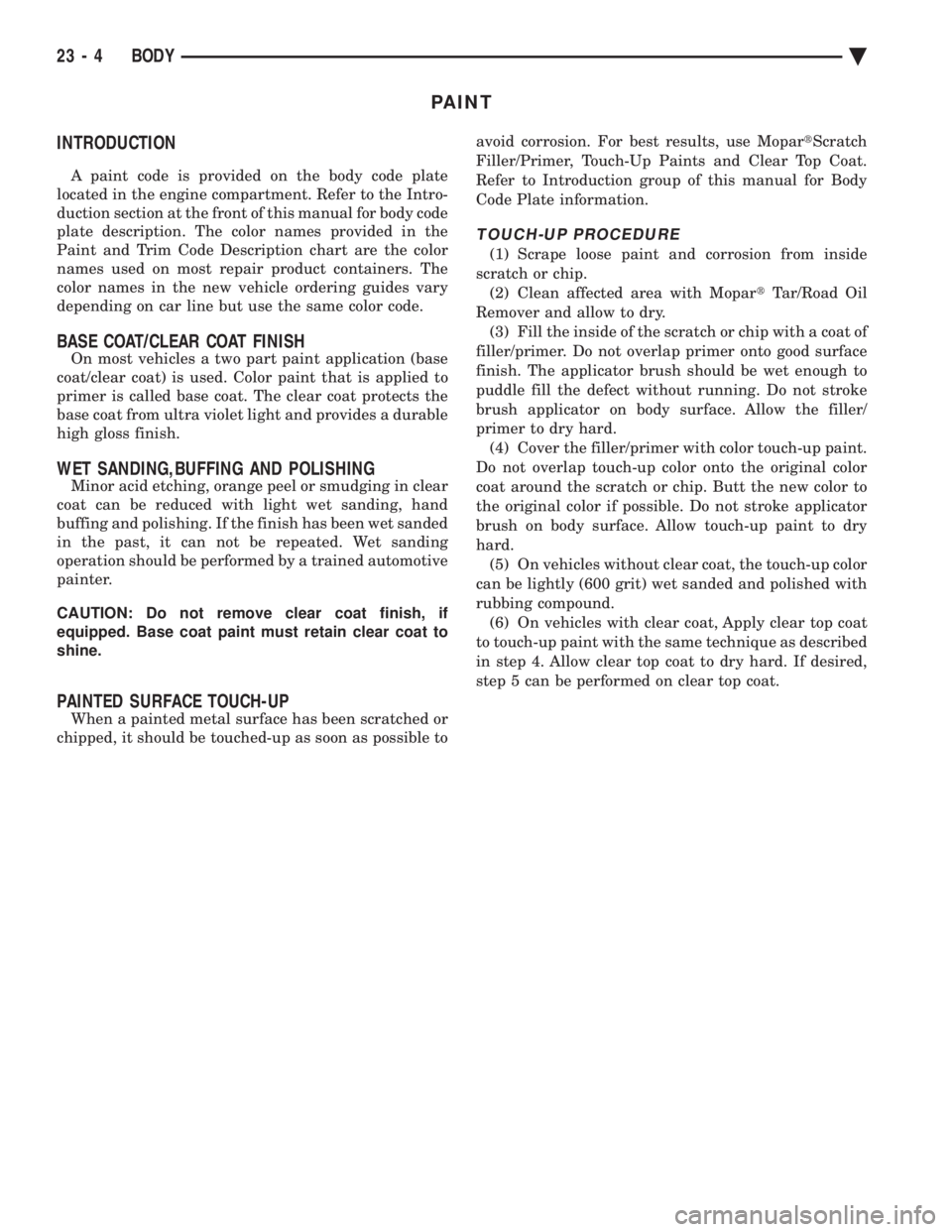

TRUNK LID HINGE

REMOVAL (FIG. 54)

(1) Remove rear deck filler panel.

(2) Disconnect trunk lid lift torsion bars from

hinges. (3) Mark all attaching bolt, nut, and component lo-

cations with a suitable marking device. Use marks

as a reference when installing hinge. (4) Remove bolts holding trunk lid to hinge.

(5) Remove nuts and bolts holding hinge to closure

panel below rear window glass. (6) Separate hinge from vehicle.

INSTALLATION

Reverse the preceding operation.

TRUNK LID TORSION BAR

REMOVAL (FIG. 54)

(1) Raise and support trunk lid in the full up posi-

tion. (2) Remove trunk lining as necessary to gain ac-

cess to torsion bars. (3) Disengage adjusting end of torsion bar from the

slot in the tension adjustment bracket. (4) Pivot torsion bar out of lift arm swivel.

(5) Disconnect torsion bar from hinge.

INSTALLATION

Reverse the preceding operation.

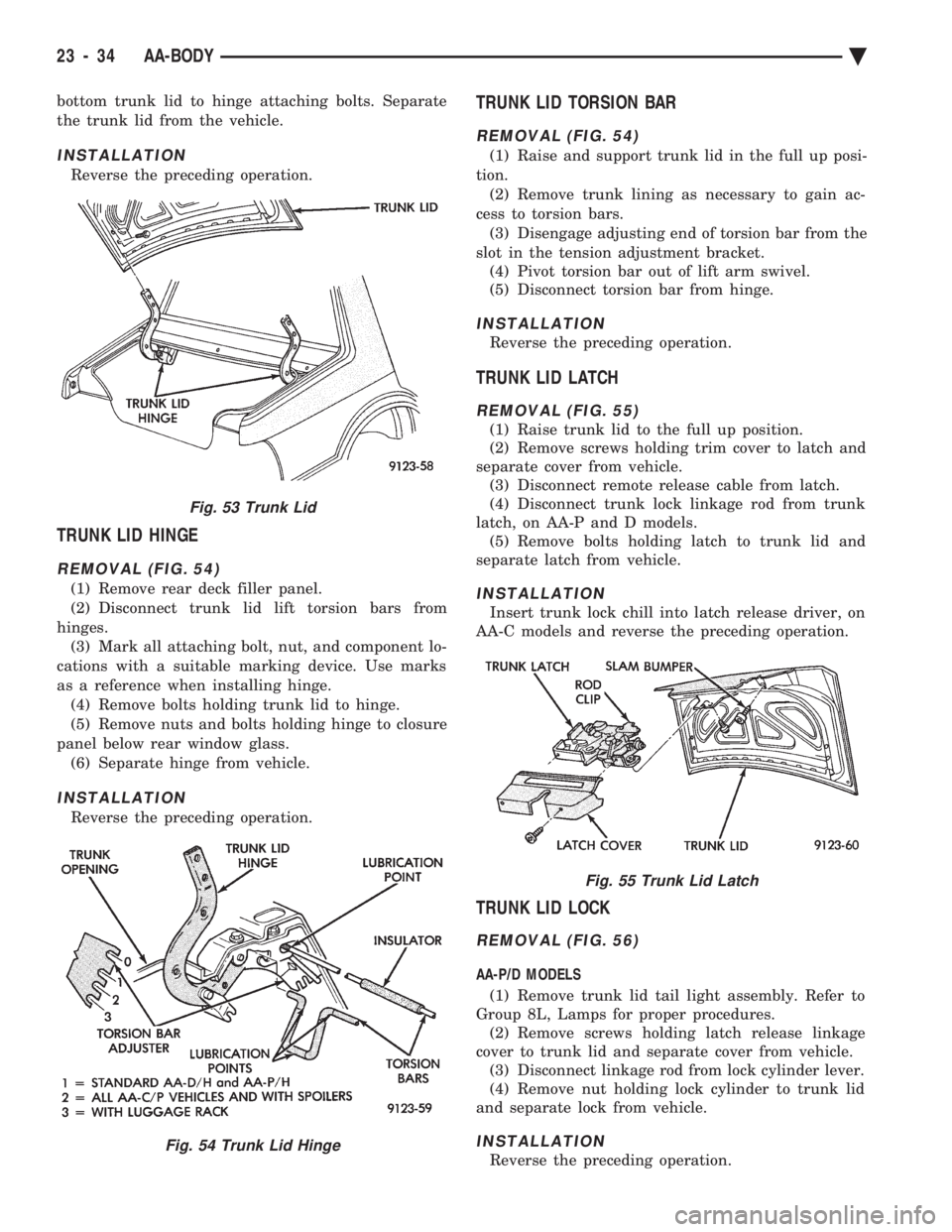

TRUNK LID LATCH

REMOVAL (FIG. 55)

(1) Raise trunk lid to the full up position.

(2) Remove screws holding trim cover to latch and

separate cover from vehicle. (3) Disconnect remote release cable from latch.

(4) Disconnect trunk lock linkage rod from trunk

latch, on AA-P and D models. (5) Remove bolts holding latch to trunk lid and

separate latch from vehicle.

INSTALLATION

Insert trunk lock chill into latch release driver, on

AA-C models and reverse the preceding operation.

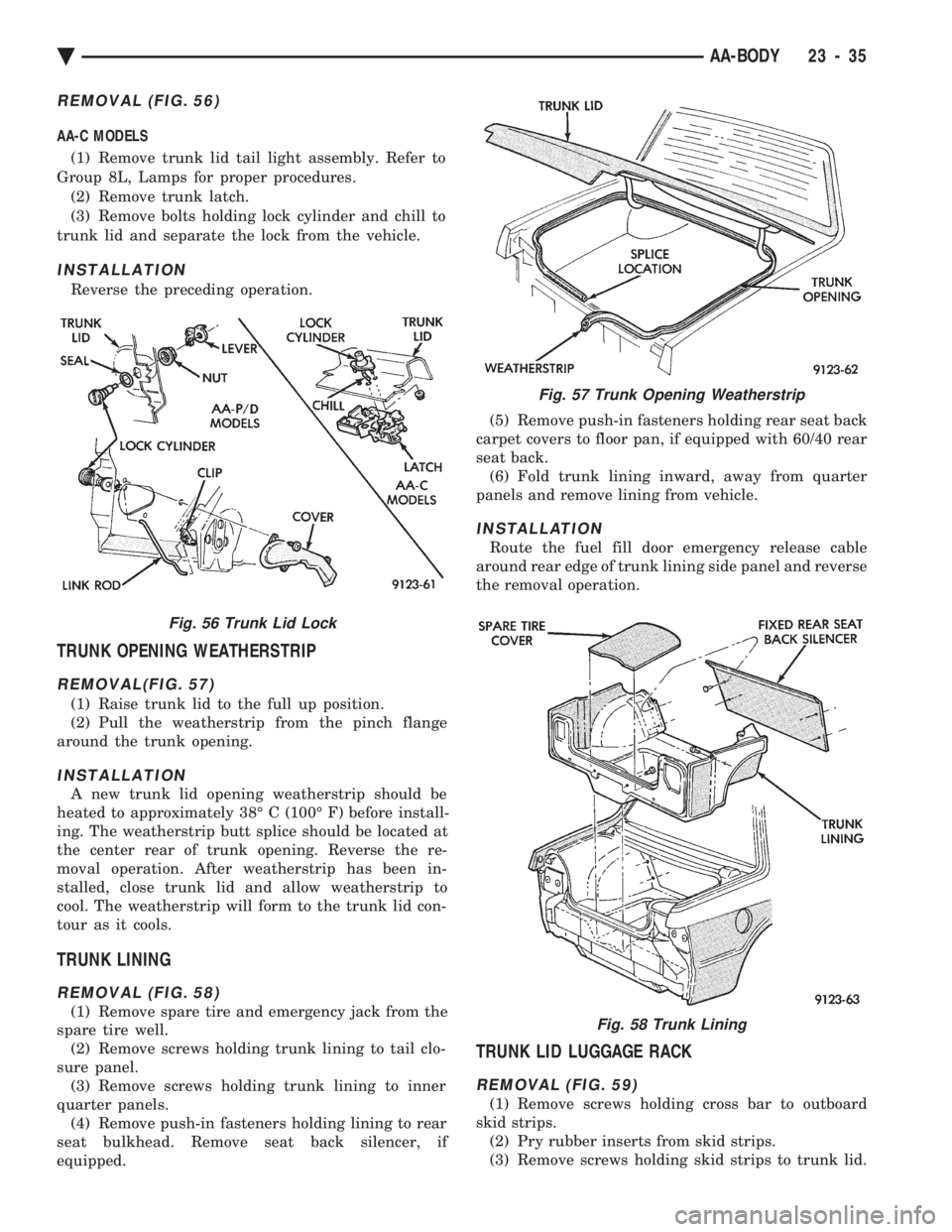

TRUNK LID LOCK

REMOVAL (FIG. 56)

AA-P/D MODELS

(1) Remove trunk lid tail light assembly. Refer to

Group 8L, Lamps for proper procedures. (2) Remove screws holding latch release linkage

cover to trunk lid and separate cover from vehicle. (3) Disconnect linkage rod from lock cylinder lever.

(4) Remove nut holding lock cylinder to trunk lid

and separate lock from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 53 Trunk Lid

Fig. 54 Trunk Lid Hinge

Fig. 55 Trunk Lid Latch

23 - 34 AA-BODY Ä

Page 2191 of 2438

REMOVAL (FIG. 56)

AA-C MODELS (1) Remove trunk lid tail light assembly. Refer to

Group 8L, Lamps for proper procedures. (2) Remove trunk latch.

(3) Remove bolts holding lock cylinder and chill to

trunk lid and separate the lock from the vehicle.

INSTALLATION

Reverse the preceding operation.

TRUNK OPENING WEATHERSTRIP

REMOVAL(FIG. 57)

(1) Raise trunk lid to the full up position.

(2) Pull the weatherstrip from the pinch flange

around the trunk opening.

INSTALLATION

A new trunk lid opening weatherstrip should be

heated to approximately 38É C (100É F) before install-

ing. The weatherstrip butt splice should be located at

the center rear of trunk opening. Reverse the re-

moval operation. After weatherstrip has been in-

stalled, close trunk lid and allow weatherstrip to

cool. The weatherstrip will form to the trunk lid con-

tour as it cools.

TRUNK LINING

REMOVAL (FIG. 58)

(1) Remove spare tire and emergency jack from the

spare tire well. (2) Remove screws holding trunk lining to tail clo-

sure panel. (3) Remove screws holding trunk lining to inner

quarter panels. (4) Remove push-in fasteners holding lining to rear

seat bulkhead. Remove seat back silencer, if

equipped. (5) Remove push-in fasteners holding rear seat back

carpet covers to floor pan, if equipped with 60/40 rear

seat back. (6) Fold trunk lining inward, away from quarter

panels and remove lining from vehicle.

INSTALLATION

Route the fuel fill door emergency release cable

around rear edge of trunk lining side panel and reverse

the removal operation.

TRUNK LID LUGGAGE RACK

REMOVAL (FIG. 59)

(1) Remove screws holding cross bar to outboard

skid strips. (2) Pry rubber inserts from skid strips.

(3) Remove screws holding skid strips to trunk lid.

Fig. 56 Trunk Lid Lock

Fig. 57 Trunk Opening Weatherstrip

Fig. 58 Trunk Lining

Ä AA-BODY 23 - 35

Page 2193 of 2438

AC-VEHICLE BODY COMPONENT SERVICE INDEX

page page

A-Pillar and Roof Rail Mouldings ............. 46

B-Pillar Trim Panel ....................... 46

Body Mouldings .......................... 49

Cowl Panel Trim and Scuff Plates ............ 46

Door Frame Trim Moulding ................. 41

Front Door and Hinge ..................... 41

Front Door Glass ........................ 43

Front Door Latch ......................... 42

Front Door Trim Panel .................... 40

Front Door Water Shield ................... 41

Front Door Window Regulator ............... 42

Front End Splash Shields .................. 40

Front Seat Belts ......................... 47

Front Seats ............................. 48

Grille AC/C Body ......................... 38

Grille AC/D or AC/C-H Body ................ 37

Grille Extension Moulding .................. 37

Grille Opening Panel AC/C-Body ............. 38

Grille Opening Panel AC/D and AC/C-H Body . . . 37

Head Lining ............................. 45

Hood and Hinges ........................ 38

Hood Latch and Release Cable .............. 39

Hood Latch Release Cable ................. 39 Hood Ornament AC/C

..................... 38

Outside Door Handle ...................... 42

Overhead Console ........................ 45

Quarter Trim Panel ....................... 46

Rear Deck Filler Panel .................... 49

Rear Door and Hinge ..................... 44

Rear Door Frame Trim Moulding ............. 43

Rear Door Glass ......................... 45

Rear Door Glass Lift Plate and Guide Bar ..... 45

Rear Door Latch ......................... 44

Rear Door Outside Handle ................. 44

Rear Door Silencer and Water Shield ......... 43

Rear Door Trim Panel ..................... 43

Rear Door Window Regulator ............... 45

Rear Seat Belts .......................... 47

Rear Seats ............................. 49

Rear Shelf Trim Panel ..................... 47

Rear Window Glass ...................... 50

Side View Mirror Trim Cover ................ 41

Trunk Lid .............................. 50

Trunk Lid Hinge ......................... 51

Trunk Lid Torsion Bar ..................... 51

Vinyl Roof Bonnet ........................ 49

GRILLE AC/D or AC/C-H BODY

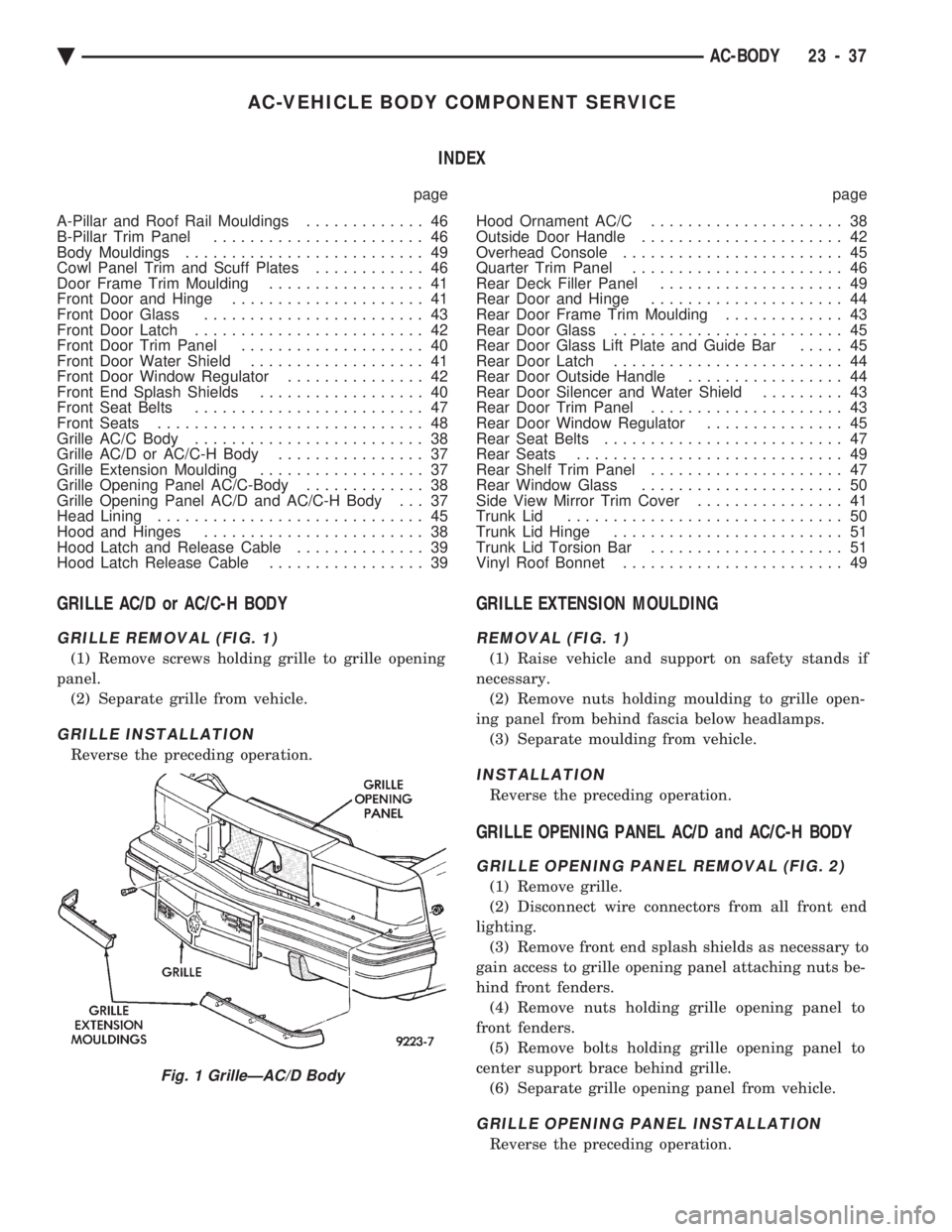

GRILLE REMOVAL (FIG. 1)

(1) Remove screws holding grille to grille opening

panel. (2) Separate grille from vehicle.

GRILLE INSTALLATION

Reverse the preceding operation.

GRILLE EXTENSION MOULDING

REMOVAL (FIG. 1)

(1) Raise vehicle and support on safety stands if

necessary. (2) Remove nuts holding moulding to grille open-

ing panel from behind fascia below headlamps. (3) Separate moulding from vehicle.

INSTALLATION

Reverse the preceding operation.

GRILLE OPENING PANEL AC/D and AC/C-H BODY

GRILLE OPENING PANEL REMOVAL (FIG. 2)

(1) Remove grille.

(2) Disconnect wire connectors from all front end

lighting. (3) Remove front end splash shields as necessary to

gain access to grille opening panel attaching nuts be-

hind front fenders. (4) Remove nuts holding grille opening panel to

front fenders. (5) Remove bolts holding grille opening panel to

center support brace behind grille. (6) Separate grille opening panel from vehicle.

GRILLE OPENING PANEL INSTALLATION

Reverse the preceding operation.

Fig. 1 GrilleÐAC/D Body

Ä AC-BODY 23 - 37

Page 2239 of 2438

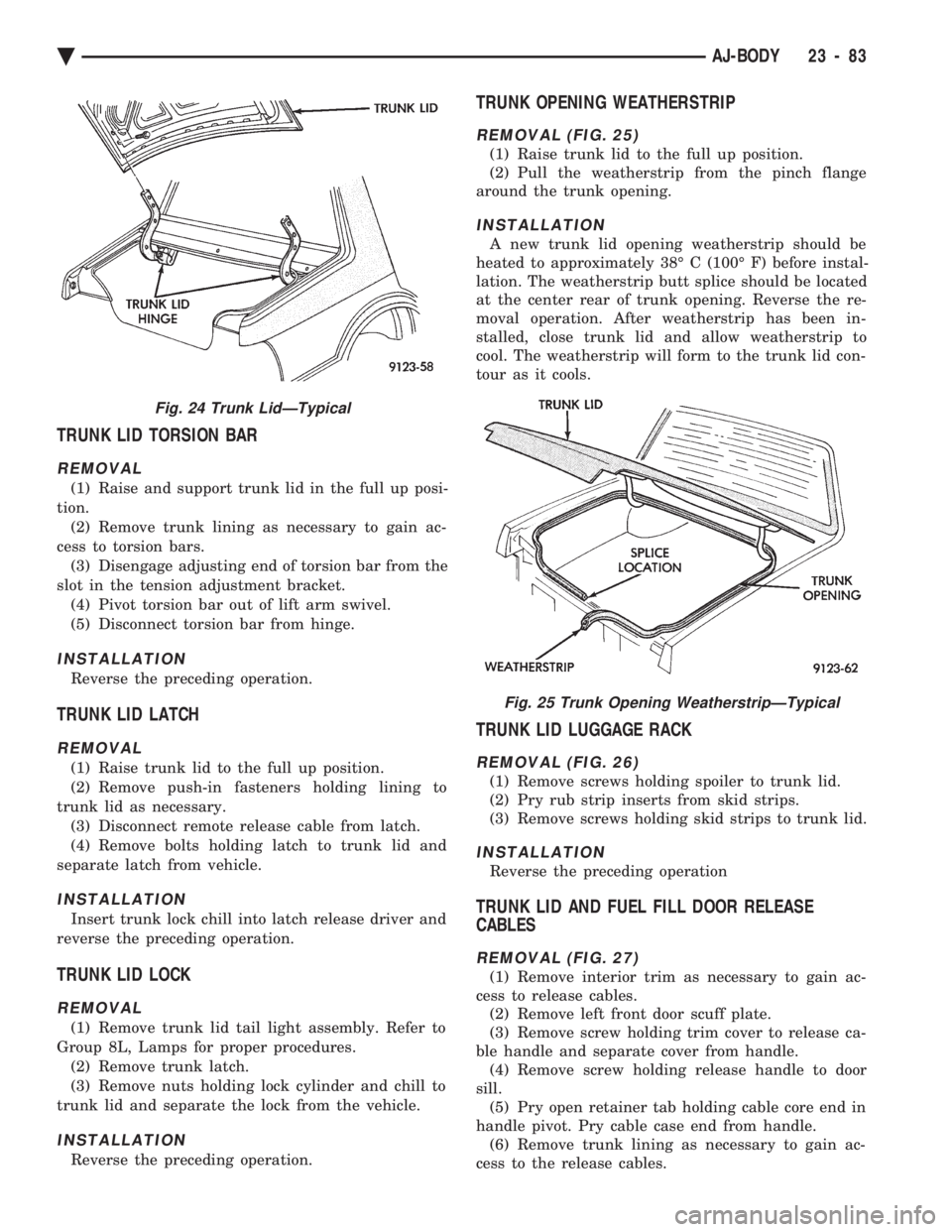

TRUNK LID TORSION BAR

REMOVAL

(1) Raise and support trunk lid in the full up posi-

tion. (2) Remove trunk lining as necessary to gain ac-

cess to torsion bars. (3) Disengage adjusting end of torsion bar from the

slot in the tension adjustment bracket. (4) Pivot torsion bar out of lift arm swivel.

(5) Disconnect torsion bar from hinge.

INSTALLATION

Reverse the preceding operation.

TRUNK LID LATCH

REMOVAL

(1) Raise trunk lid to the full up position.

(2) Remove push-in fasteners holding lining to

trunk lid as necessary. (3) Disconnect remote release cable from latch.

(4) Remove bolts holding latch to trunk lid and

separate latch from vehicle.

INSTALLATION

Insert trunk lock chill into latch release driver and

reverse the preceding operation.

TRUNK LID LOCK

REMOVAL

(1) Remove trunk lid tail light assembly. Refer to

Group 8L, Lamps for proper procedures. (2) Remove trunk latch.

(3) Remove nuts holding lock cylinder and chill to

trunk lid and separate the lock from the vehicle.

INSTALLATION

Reverse the preceding operation.

TRUNK OPENING WEATHERSTRIP

REMOVAL (FIG. 25)

(1) Raise trunk lid to the full up position.

(2) Pull the weatherstrip from the pinch flange

around the trunk opening.

INSTALLATION

A new trunk lid opening weatherstrip should be

heated to approximately 38É C (100É F) before instal-

lation. The weatherstrip butt splice should be located

at the center rear of trunk opening. Reverse the re-

moval operation. After weatherstrip has been in-

stalled, close trunk lid and allow weatherstrip to

cool. The weatherstrip will form to the trunk lid con-

tour as it cools.

TRUNK LID LUGGAGE RACK

REMOVAL (FIG. 26)

(1) Remove screws holding spoiler to trunk lid.

(2) Pry rub strip inserts from skid strips.

(3) Remove screws holding skid strips to trunk lid.

INSTALLATION

Reverse the preceding operation

TRUNK LID AND FUEL FILL DOOR RELEASE

CABLES

REMOVAL (FIG. 27)

(1) Remove interior trim as necessary to gain ac-

cess to release cables. (2) Remove left front door scuff plate.

(3) Remove screw holding trim cover to release ca-

ble handle and separate cover from handle. (4) Remove screw holding release handle to door

sill. (5) Pry open retainer tab holding cable core end in

handle pivot. Pry cable case end from handle. (6) Remove trunk lining as necessary to gain ac-

cess to the release cables.

Fig. 24 Trunk LidÐTypical

Fig. 25 Trunk Opening WeatherstripÐTypical

Ä AJ-BODY 23 - 83

Page 2275 of 2438

(5) Raise convertible top, do not latch top to wind-

shield header. (6) Remove pop-rivets holding stay pads and reten-

tion cables to top header. (7) Lower convertible top.

(8) Remove E-clips and clevis pins holding second

bow pivot link to top header (Fig. 7). (9) Remove bolts holding roof rail pivot bracket to

top header (Fig. 7). (10) Separate top header from convertible top

frame. If top header replacement is required, transfer

latching components to replacement header.

INSTALLATION

(1) Place replacement top header in position in

front of roof rail ends on top of cover material. (2) Install bolts to hold top header to roof rail pivot

brackets. (3) Install clevis pins and E-clips holding top

header to second bow pivot link. (4) Raise convertible top. Do not latch.

(5) Rivet retention cables to top header.

CAUTION: Do not stretch top material, top latching

effort increases if top cover or stay pads are to

tight.

(6) Rivet forward ends of stay pads to top header.

A foam tape over rivet heads. (7) Apply contact adhesive to forward rolled flange

of top header and inside forward two inches of top

cover material. Allow adhesive to cure until slight

tackiness is evident. (8) Pull top cover material forward until wrinkles

are gone. (9) Press adhesive coated surfaces together over

front edge of top header. (10) Verify opening and closing effort of the con-

vertible top and latches. (11) Verify that wrinkles in top cover, with head- ers latched, are minimal. Slight wrinkles in top cover

will decrease when top is heated by the sun or arti-

ficial heat source. If necessary, adjust top latch

hooks.

(12) Lower convertible top.

(13) Place retaining strip at front edge of top

header over edge turned material. Using a scratch

awl, align screws holes in retaining strip to holes in

top header. (14) Install screws to hold retaining strip to top

header. (15) Install top header trim panel.

SECOND ROOF BOW AND LINKAGE

REMOVAL

(1) Lower convertible top.

(2) Remove E-clip and clevis pin holding second

roof bow pivot link to top header (Fig. 8). (3) Remove screws holding second roof bow actuat-

ing link to pivot link (Fig. 8). (4) Remove screws holding second roof bow to top

cover listing retainer (Fig. 9).

Fig. 5 Top Latch

Fig. 6 Stay Pads and Retention Cables

Fig. 7 Pivot Link and Roof Rail Pivot Bracket.

Ä AP/27 CONVERTIBLE 23 - 119

Page 2295 of 2438

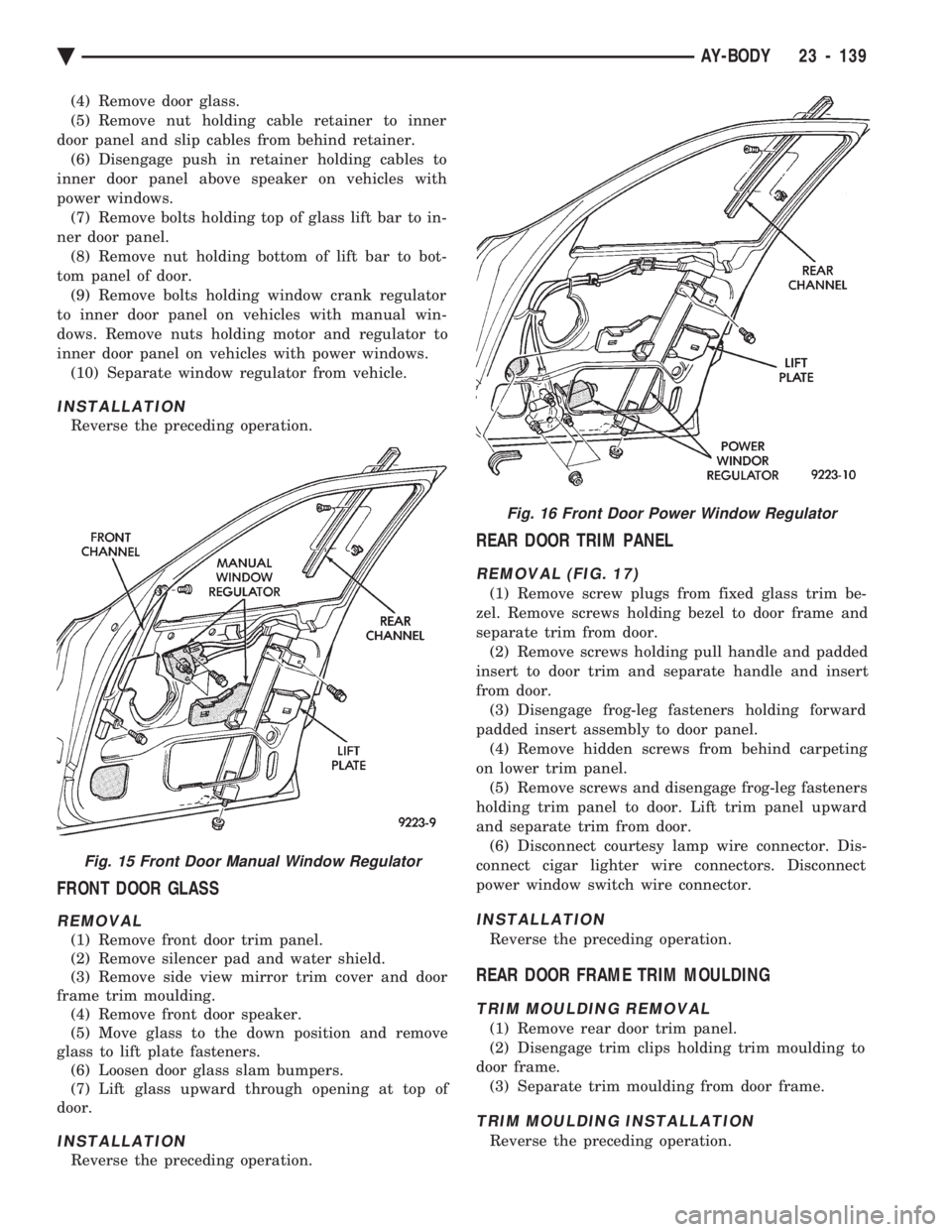

(4) Remove door glass.

(5) Remove nut holding cable retainer to inner

door panel and slip cables from behind retainer. (6) Disengage push in retainer holding cables to

inner door panel above speaker on vehicles with

power windows. (7) Remove bolts holding top of glass lift bar to in-

ner door panel. (8) Remove nut holding bottom of lift bar to bot-

tom panel of door. (9) Remove bolts holding window crank regulator

to inner door panel on vehicles with manual win-

dows. Remove nuts holding motor and regulator to

inner door panel on vehicles with power windows. (10) Separate window regulator from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR GLASS

REMOVAL

(1) Remove front door trim panel.

(2) Remove silencer pad and water shield.

(3) Remove side view mirror trim cover and door

frame trim moulding. (4) Remove front door speaker.

(5) Move glass to the down position and remove

glass to lift plate fasteners. (6) Loosen door glass slam bumpers.

(7) Lift glass upward through opening at top of

door.

INSTALLATION

Reverse the preceding operation.

REAR DOOR TRIM PANEL

REMOVAL (FIG. 17)

(1) Remove screw plugs from fixed glass trim be-

zel. Remove screws holding bezel to door frame and

separate trim from door. (2) Remove screws holding pull handle and padded

insert to door trim and separate handle and insert

from door. (3) Disengage frog-leg fasteners holding forward

padded insert assembly to door panel. (4) Remove hidden screws from behind carpeting

on lower trim panel. (5) Remove screws and disengage frog-leg fasteners

holding trim panel to door. Lift trim panel upward

and separate trim from door. (6) Disconnect courtesy lamp wire connector. Dis-

connect cigar lighter wire connectors. Disconnect

power window switch wire connector.

INSTALLATION

Reverse the preceding operation.

REAR DOOR FRAME TRIM MOULDING

TRIM MOULDING REMOVAL

(1) Remove rear door trim panel.

(2) Disengage trim clips holding trim moulding to

door frame. (3) Separate trim moulding from door frame.

TRIM MOULDING INSTALLATION

Reverse the preceding operation.

Fig. 15 Front Door Manual Window Regulator

Fig. 16 Front Door Power Window Regulator

Ä AY-BODY 23 - 139

Page 2310 of 2438

HEATER AND A/C PERFORMANCE TESTS

HEATER OUTPUT TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings before

performing the following procedures. Check the radiator coolant level, drive belt tension,

and engine vacuum line connections. Also check ra-

diator air flow and radiator fan operation. Start en-

gine and allow to warm up to normal operating

temperature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to es-

cape through the overflow tube. When the system

stabilizes, remove the cap completely.

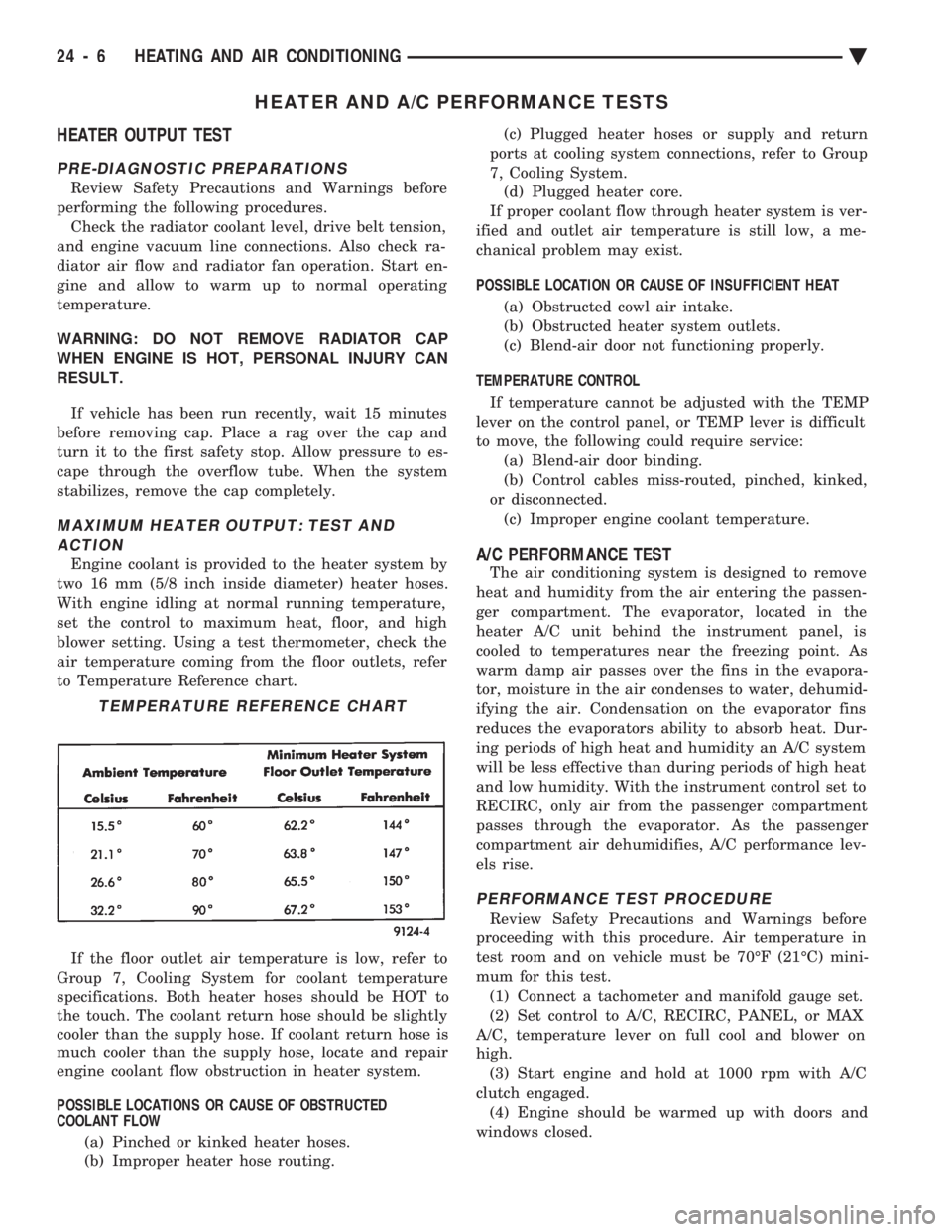

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference chart.

If the floor outlet air temperature is low, refer to

Group 7, Cooling System for coolant temperature

specifications. Both heater hoses should be HOT to

the touch. The coolant return hose should be slightly

cooler than the supply hose. If coolant return hose is

much cooler than the supply hose, locate and repair

engine coolant flow obstruction in heater system.

POSSIBLE LOCATIONS OR CAUSE OF OBSTRUCTED

COOLANT FLOW

(a) Pinched or kinked heater hoses.

(b) Improper heater hose routing. (c) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group

7, Cooling System. (d) Plugged heater core.

If proper coolant flow through heater system is ver-

ified and outlet air temperature is still low, a me-

chanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT HEAT

(a) Obstructed cowl air intake.

(b) Obstructed heater system outlets.

(c) Blend-air door not functioning properly.

TEMPERATURE CONTROL If temperature cannot be adjusted with the TEMP

lever on the control panel, or TEMP lever is difficult

to move, the following could require service: (a) Blend-air door binding.

(b) Control cables miss-routed, pinched, kinked,

or disconnected. (c) Improper engine coolant temperature.A/C PERFORMANCE TEST

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

heater A/C unit behind the instrument panel, is

cooled to temperatures near the freezing point. As

warm damp air passes over the fins in the evapora-

tor, moisture in the air condenses to water, dehumid-

ifying the air. Condensation on the evaporator fins

reduces the evaporators ability to absorb heat. Dur-

ing periods of high heat and humidity an A/C system

will be less effective than during periods of high heat

and low humidity. With the instrument control set to

RECIRC, only air from the passenger compartment

passes through the evaporator. As the passenger

compartment air dehumidifies, A/C performance lev-

els rise.

PERFORMANCE TEST PROCEDURE

Review Safety Precautions and Warnings before

proceeding with this procedure. Air temperature in

test room and on vehicle must be 70ÉF (21ÉC) mini-

mum for this test. (1) Connect a tachometer and manifold gauge set.

(2) Set control to A/C, RECIRC, PANEL, or MAX

A/C, temperature lever on full cool and blower on

high. (3) Start engine and hold at 1000 rpm with A/C

clutch engaged. (4) Engine should be warmed up with doors and

windows closed.

TEMPERATURE REFERENCE CHART

24 - 6 HEATING AND AIR CONDITIONING Ä

Page 2312 of 2438

REFRIGERANT SERVICE PROCEDURES INDEX

page page

Adding Partial Refrigerant Charge ............ 10

Charging Refrigerant SystemÐEmpty System . . . 11

Discharging Refrigerant System .............. 11

Evacuating Refrigerant System .............. 11

Manifold Gauge Set Connections ............. 9 Oil Level

............................... 12

R-12 Refrigerant Equipment ................. 8

Refrigerant Recycling ...................... 9

Sight Glass Refrigerant Level Inspection ........ 8

Testing for Refrigerant Leaks ............... 10

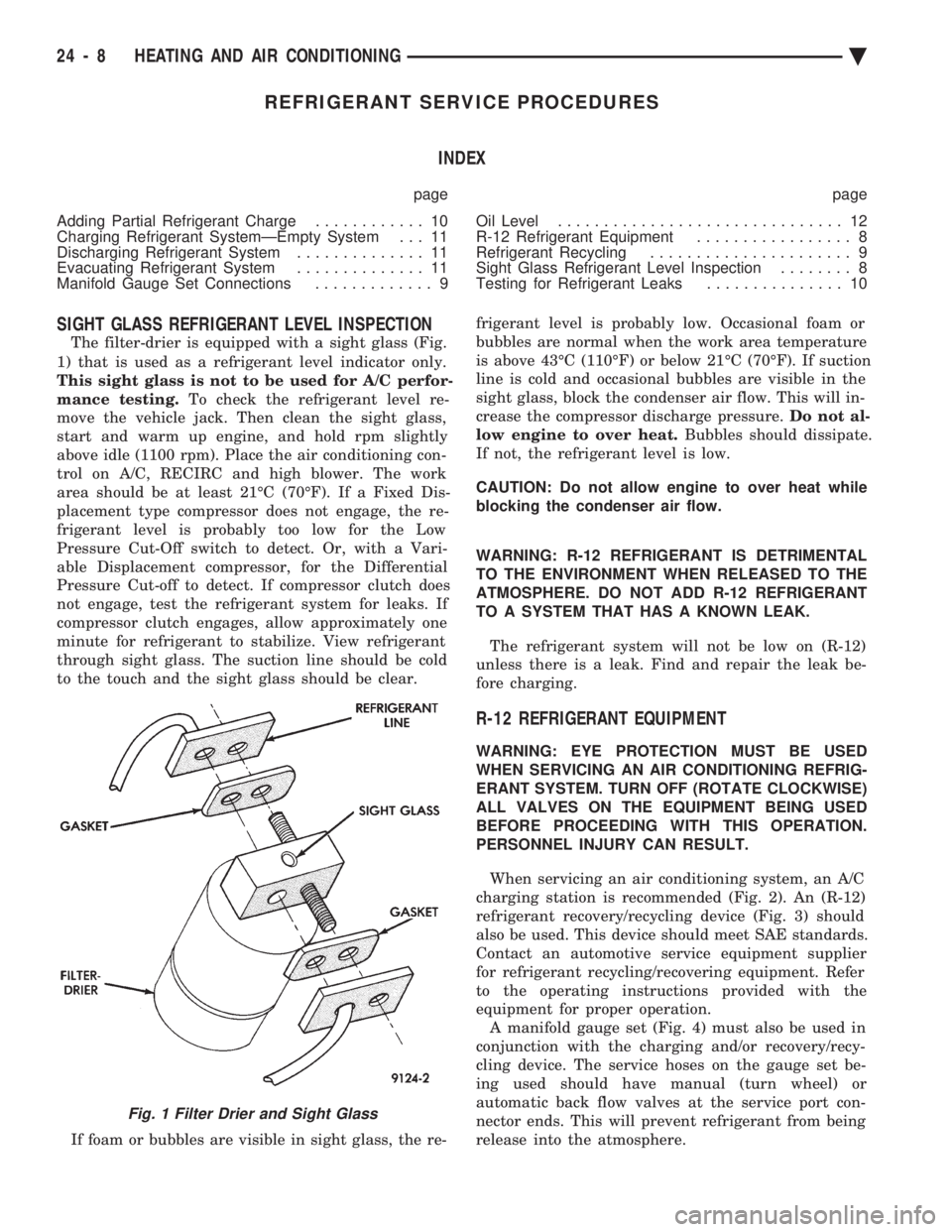

SIGHT GLASS REFRIGERANT LEVEL INSPECTION

The filter-drier is equipped with a sight glass (Fig.

1) that is used as a refrigerant level indicator only.

This sight glass is not to be used for A/C perfor-

mance testing. To check the refrigerant level re-

move the vehicle jack. Then clean the sight glass,

start and warm up engine, and hold rpm slightly

above idle (1100 rpm). Place the air conditioning con-

trol on A/C, RECIRC and high blower. The work

area should be at least 21ÉC (70ÉF). If a Fixed Dis-

placement type compressor does not engage, the re-

frigerant level is probably too low for the Low

Pressure Cut-Off switch to detect. Or, with a Vari-

able Displacement compressor, for the Differential

Pressure Cut-off to detect. If compressor clutch does

not engage, test the refrigerant system for leaks. If

compressor clutch engages, allow approximately one

minute for refrigerant to stabilize. View refrigerant

through sight glass. The suction line should be cold

to the touch and the sight glass should be clear.

If foam or bubbles are visible in sight glass, the re- frigerant level is probably low. Occasional foam or

bubbles are normal when the work area temperature

is above 43ÉC (110ÉF) or below 21ÉC (70ÉF). If suction

line is cold and occasional bubbles are visible in the

sight glass, block the condenser air flow. This will in-

crease the compressor discharge pressure. Do not al-

low engine to over heat. Bubbles should dissipate.

If not, the refrigerant level is low.

CAUTION: Do not allow engine to over heat while

blocking the condenser air flow.

WARNING: R-12 REFRIGERANT IS DETRIMENTAL

TO THE ENVIRONMENT WHEN RELEASED TO THE

ATMOSPHERE. DO NOT ADD R-12 REFRIGERANT

TO A SYSTEM THAT HAS A KNOWN LEAK.

The refrigerant system will not be low on (R-12)

unless there is a leak. Find and repair the leak be-

fore charging.

R-12 REFRIGERANT EQUIPMENT

WARNING: EYE PROTECTION MUST BE USED

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED

BEFORE PROCEEDING WITH THIS OPERATION.

PERSONNEL INJURY CAN RESULT.

When servicing an air conditioning system, an A/C

charging station is recommended (Fig. 2). An (R-12)

refrigerant recovery/recycling device (Fig. 3) should

also be used. This device should meet SAE standards.

Contact an automotive service equipment supplier

for refrigerant recycling/recovering equipment. Refer

to the operating instructions provided with the

equipment for proper operation. A manifold gauge set (Fig. 4) must also be used in

conjunction with the charging and/or recovery/recy-

cling device. The service hoses on the gauge set be-

ing used should have manual (turn wheel) or

automatic back flow valves at the service port con-

nector ends. This will prevent refrigerant from being

release into the atmosphere.

Fig. 1 Filter Drier and Sight Glass

24 - 8 HEATING AND AIR CONDITIONING Ä