display CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 431 of 2438

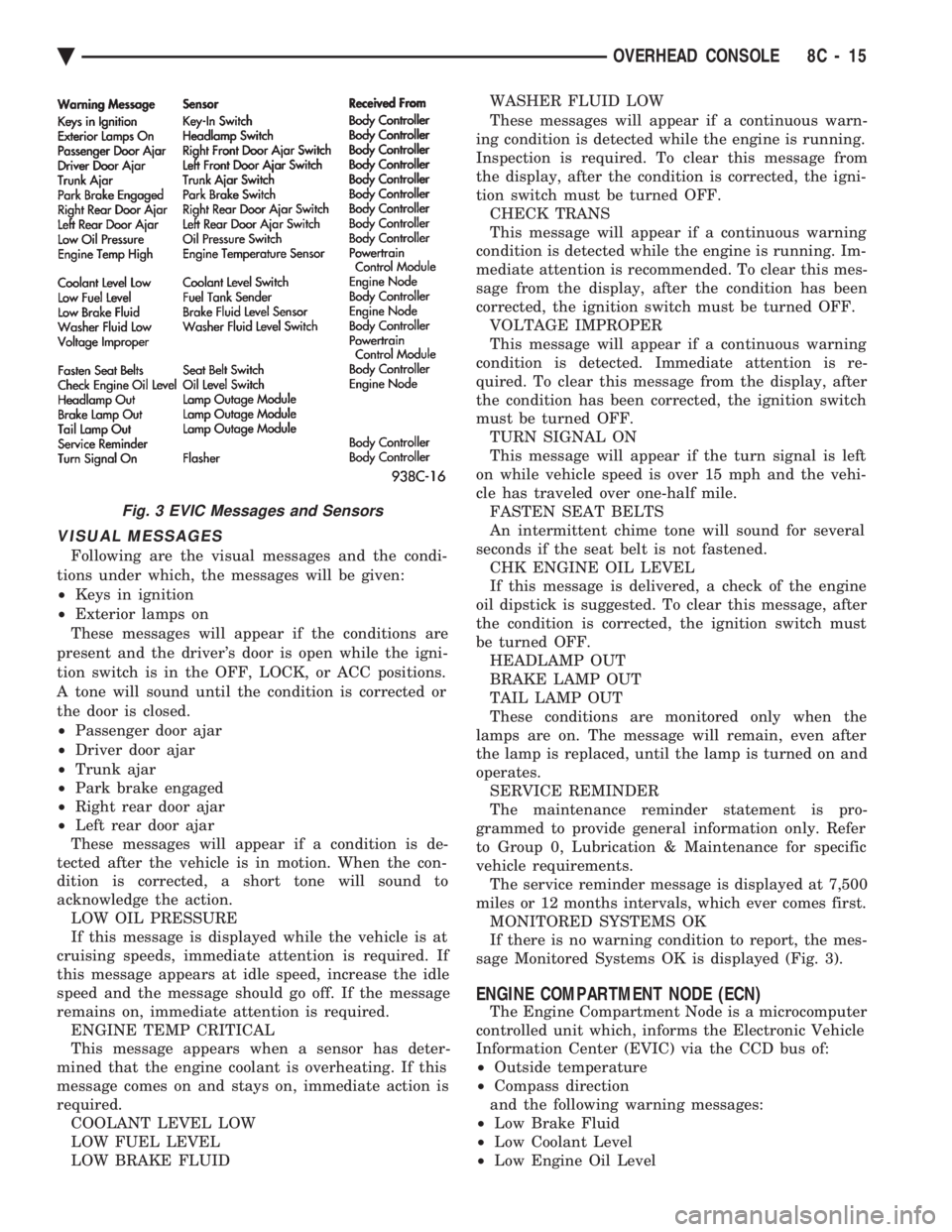

VISUAL MESSAGES

Following are the visual messages and the condi-

tions under which, the messages will be given:

² Keys in ignition

² Exterior lamps on

These messages will appear if the conditions are

present and the driver's door is open while the igni-

tion switch is in the OFF, LOCK, or ACC positions.

A tone will sound until the condition is corrected or

the door is closed.

² Passenger door ajar

² Driver door ajar

² Trunk ajar

² Park brake engaged

² Right rear door ajar

² Left rear door ajar

These messages will appear if a condition is de-

tected after the vehicle is in motion. When the con-

dition is corrected, a short tone will sound to

acknowledge the action. LOW OIL PRESSURE

If this message is displayed while the vehicle is at

cruising speeds, immediate attention is required. If

this message appears at idle speed, increase the idle

speed and the message should go off. If the message

remains on, immediate attention is required. ENGINE TEMP CRITICAL

This message appears when a sensor has deter-

mined that the engine coolant is overheating. If this

message comes on and stays on, immediate action is

required. COOLANT LEVEL LOW

LOW FUEL LEVEL

LOW BRAKE FLUID WASHER FLUID LOW

These messages will appear if a continuous warn-

ing condition is detected while the engine is running.

Inspection is required. To clear this message from

the display, after the condition is corrected, the igni-

tion switch must be turned OFF. CHECK TRANS

This message will appear if a continuous warning

condition is detected while the engine is running. Im-

mediate attention is recommended. To clear this mes-

sage from the display, after the condition has been

corrected, the ignition switch must be turned OFF. VOLTAGE IMPROPER

This message will appear if a continuous warning

condition is detected. Immediate attention is re-

quired. To clear this message from the display, after

the condition has been corrected, the ignition switch

must be turned OFF. TURN SIGNAL ON

This message will appear if the turn signal is left

on while vehicle speed is over 15 mph and the vehi-

cle has traveled over one-half mile. FASTEN SEAT BELTS

An intermittent chime tone will sound for several

seconds if the seat belt is not fastened. CHK ENGINE OIL LEVEL

If this message is delivered, a check of the engine

oil dipstick is suggested. To clear this message, after

the condition is corrected, the ignition switch must

be turned OFF. HEADLAMP OUT

BRAKE LAMP OUT

TAIL LAMP OUT

These conditions are monitored only when the

lamps are on. The message will remain, even after

the lamp is replaced, until the lamp is turned on and

operates. SERVICE REMINDER

The maintenance reminder statement is pro-

grammed to provide general information only. Refer

to Group 0, Lubrication & Maintenance for specific

vehicle requirements. The service reminder message is displayed at 7,500

miles or 12 months intervals, which ever comes first. MONITORED SYSTEMS OK

If there is no warning condition to report, the mes-

sage Monitored Systems OK is displayed (Fig. 3).

ENGINE COMPARTMENT NODE (ECN)

The Engine Compartment Node is a microcomputer

controlled unit which, informs the Electronic Vehicle

Information Center (EVIC) via the CCD bus of:

² Outside temperature

² Compass direction

and the following warning messages:

² Low Brake Fluid

² Low Coolant Level

² Low Engine Oil Level

Fig. 3 EVIC Messages and Sensors

Ä OVERHEAD CONSOLE 8C - 15

Page 432 of 2438

The Engine Compartment Node is located behind

the grille. For complete diagnostic procedures for the Engine

Compartment Node, refer to the Body Diagnostic

Test Procedure Manual.

ENGINE COMPARTMENT NODE COMPASS

CALIBRATION

Automatic or Manual Calibration, refer to AY

Body Compass Calibration.

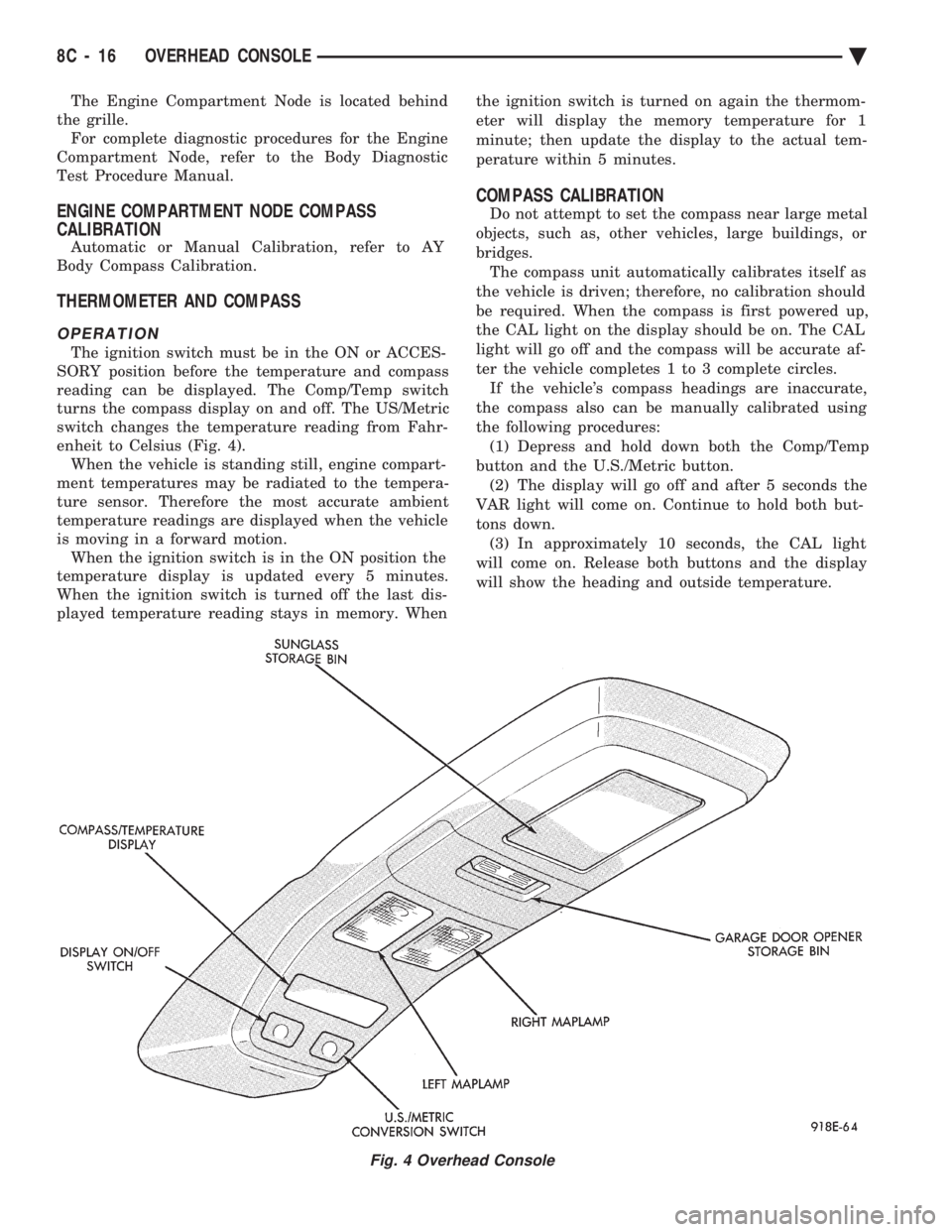

THERMOMETER AND COMPASS

OPERATION

The ignition switch must be in the ON or ACCES-

SORY position before the temperature and compass

reading can be displayed. The Comp/Temp switch

turns the compass display on and off. The US/Metric

switch changes the temperature reading from Fahr-

enheit to Celsius (Fig. 4). When the vehicle is standing still, engine compart-

ment temperatures may be radiated to the tempera-

ture sensor. Therefore the most accurate ambient

temperature readings are displayed when the vehicle

is moving in a forward motion. When the ignition switch is in the ON position the

temperature display is updated every 5 minutes.

When the ignition switch is turned off the last dis-

played temperature reading stays in memory. When the ignition switch is turned on again the thermom-

eter will display the memory temperature for 1

minute; then update the display to the actual tem-

perature within 5 minutes.

COMPASS CALIBRATION

Do not attempt to set the compass near large metal

objects, such as, other vehicles, large buildings, or

bridges. The compass unit automatically calibrates itself as

the vehicle is driven; therefore, no calibration should

be required. When the compass is first powered up,

the CAL light on the display should be on. The CAL

light will go off and the compass will be accurate af-

ter the vehicle completes 1 to 3 complete circles. If the vehicle's compass headings are inaccurate,

the compass also can be manually calibrated using

the following procedures: (1) Depress and hold down both the Comp/Temp

button and the U.S./Metric button. (2) The display will go off and after 5 seconds the

VAR light will come on. Continue to hold both but-

tons down. (3) In approximately 10 seconds, the CAL light

will come on. Release both buttons and the display

will show the heading and outside temperature.

Fig. 4 Overhead Console

8C - 16 OVERHEAD CONSOLE Ä

Page 433 of 2438

(4) Drive the vehicle 1 to 3 complete circles. The

CAL light will then go off, showing the compass is

calibrated. If the compass portion of the display:

² It does not display.

² Readings are not accurate after calibration.

² The vehicle may have too much magnetism for the

compass to be accurate.

² The compass circuitry is not working properly.

² Refer to Variance Procedure, Demagnetizing Pro-

cedure and/or Compass Diagnostics.

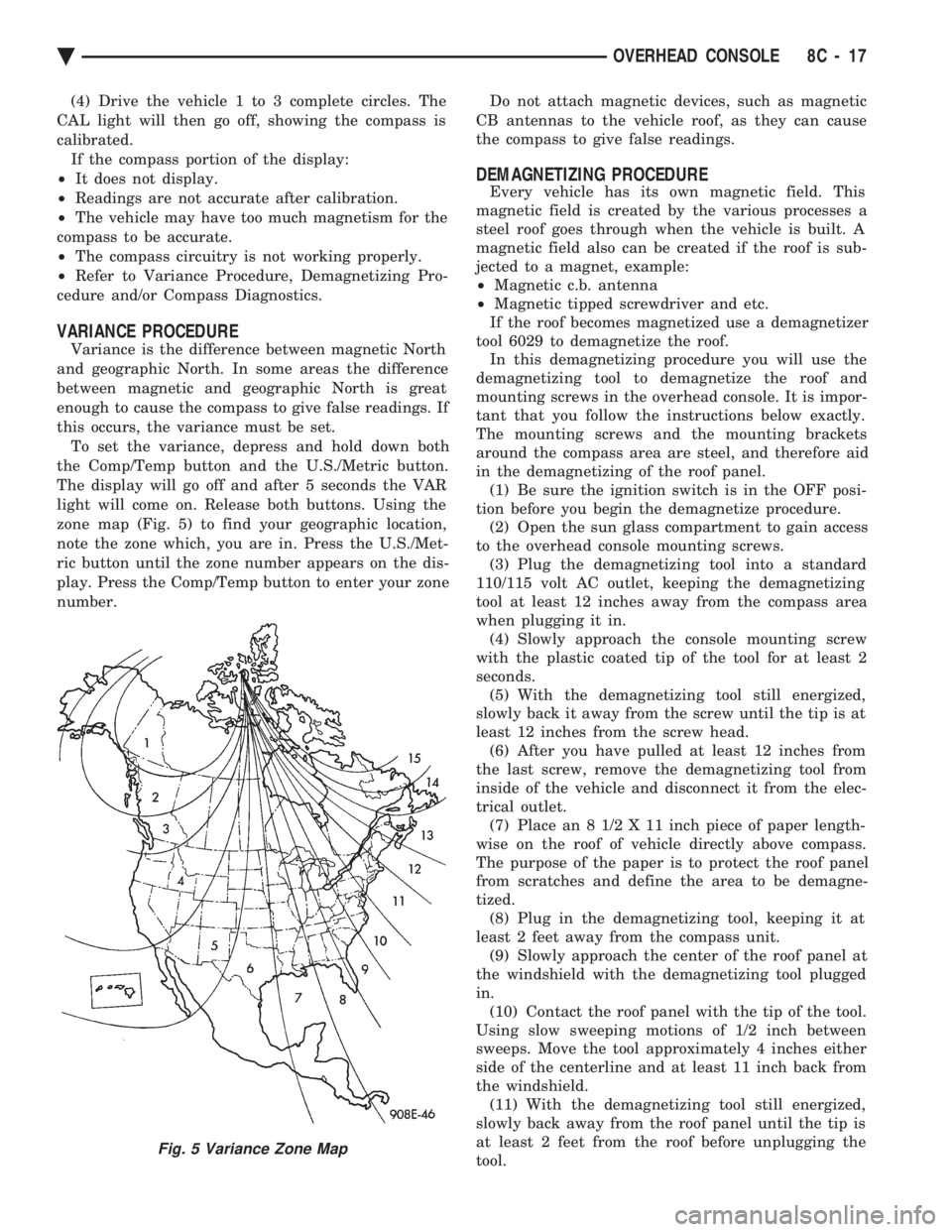

VARIANCE PROCEDURE

Variance is the difference between magnetic North

and geographic North. In some areas the difference

between magnetic and geographic North is great

enough to cause the compass to give false readings. If

this occurs, the variance must be set. To set the variance, depress and hold down both

the Comp/Temp button and the U.S./Metric button.

The display will go off and after 5 seconds the VAR

light will come on. Release both buttons. Using the

zone map (Fig. 5) to find your geographic location,

note the zone which, you are in. Press the U.S./Met-

ric button until the zone number appears on the dis-

play. Press the Comp/Temp button to enter your zone

number. Do not attach magnetic devices, such as magnetic

CB antennas to the vehicle roof, as they can cause

the compass to give false readings.

DEMAGNETIZING PROCEDURE

Every vehicle has its own magnetic field. This

magnetic field is created by the various processes a

steel roof goes through when the vehicle is built. A

magnetic field also can be created if the roof is sub-

jected to a magnet, example:

² Magnetic c.b. antenna

² Magnetic tipped screwdriver and etc.

If the roof becomes magnetized use a demagnetizer

tool 6029 to demagnetize the roof. In this demagnetizing procedure you will use the

demagnetizing tool to demagnetize the roof and

mounting screws in the overhead console. It is impor-

tant that you follow the instructions below exactly.

The mounting screws and the mounting brackets

around the compass area are steel, and therefore aid

in the demagnetizing of the roof panel. (1) Be sure the ignition switch is in the OFF posi-

tion before you begin the demagnetize procedure. (2) Open the sun glass compartment to gain access

to the overhead console mounting screws. (3) Plug the demagnetizing tool into a standard

110/115 volt AC outlet, keeping the demagnetizing

tool at least 12 inches away from the compass area

when plugging it in. (4) Slowly approach the console mounting screw

with the plastic coated tip of the tool for at least 2

seconds. (5) With the demagnetizing tool still energized,

slowly back it away from the screw until the tip is at

least 12 inches from the screw head. (6) After you have pulled at least 12 inches from

the last screw, remove the demagnetizing tool from

inside of the vehicle and disconnect it from the elec-

trical outlet. (7) Place an 8 1/2 X 11 inch piece of paper length-

wise on the roof of vehicle directly above compass.

The purpose of the paper is to protect the roof panel

from scratches and define the area to be demagne-

tized. (8) Plug in the demagnetizing tool, keeping it at

least 2 feet away from the compass unit. (9) Slowly approach the center of the roof panel at

the windshield with the demagnetizing tool plugged

in. (10) Contact the roof panel with the tip of the tool.

Using slow sweeping motions of 1/2 inch between

sweeps. Move the tool approximately 4 inches either

side of the centerline and at least 11 inch back from

the windshield. (11) With the demagnetizing tool still energized,

slowly back away from the roof panel until the tip is

at least 2 feet from the roof before unplugging the

tool.

Fig. 5 Variance Zone Map

Ä OVERHEAD CONSOLE 8C - 17

Page 434 of 2438

(12) Recalibrate compass.

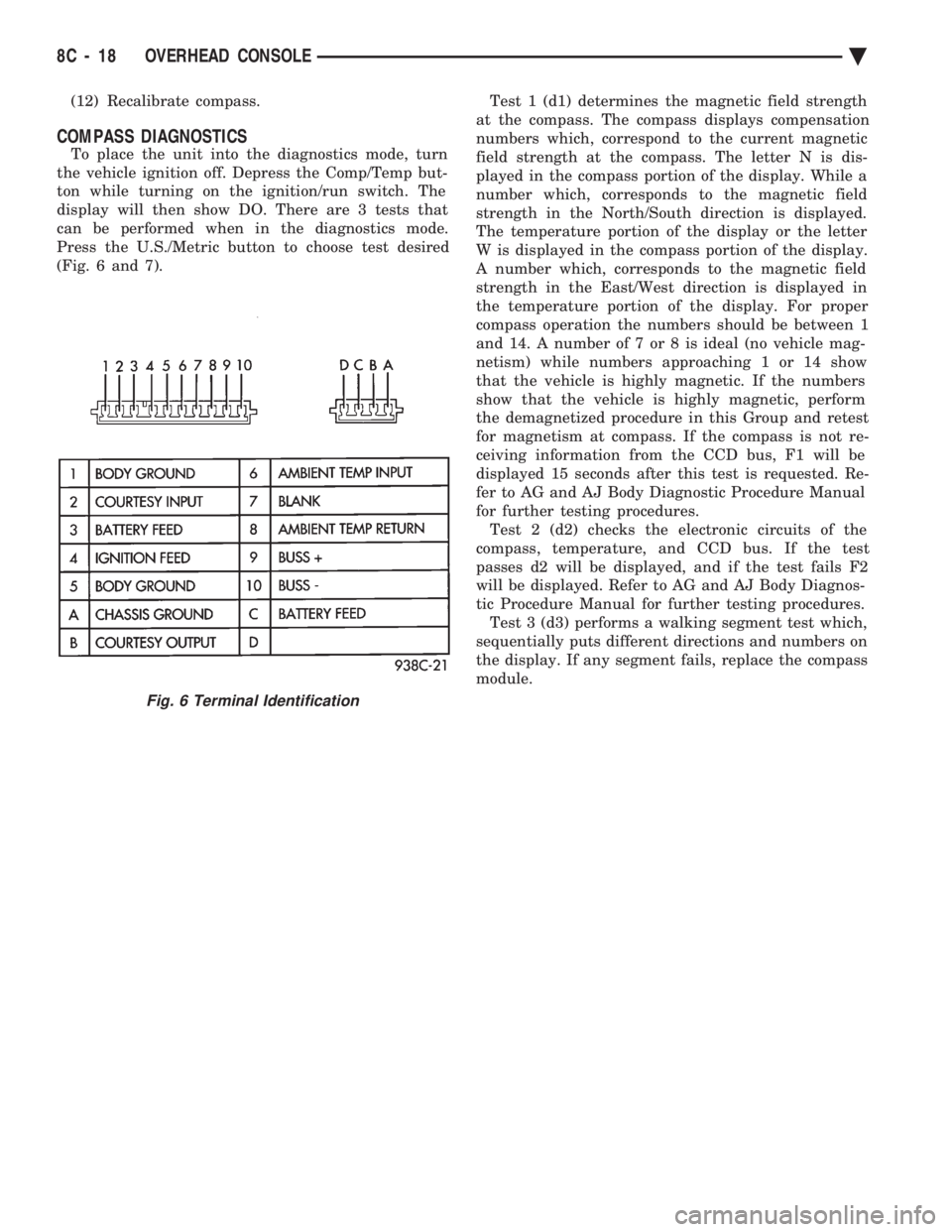

COMPASS DIAGNOSTICS

To place the unit into the diagnostics mode, turn

the vehicle ignition off. Depress the Comp/Temp but-

ton while turning on the ignition/run switch. The

display will then show DO. There are 3 tests that

can be performed when in the diagnostics mode.

Press the U.S./Metric button to choose test desired

(Fig. 6 and 7). Test 1 (d1) determines the magnetic field strength

at the compass. The compass displays compensation

numbers which, correspond to the current magnetic

field strength at the compass. The letter N is dis-

played in the compass portion of the display. While a

number which, corresponds to the magnetic field

strength in the North/South direction is displayed.

The temperature portion of the display or the letter

W is displayed in the compass portion of the display.

A number which, corresponds to the magnetic field

strength in the East/West direction is displayed in

the temperature portion of the display. For proper

compass operation the numbers should be between 1

and 14. A number of 7 or 8 is ideal (no vehicle mag-

netism) while numbers approaching 1 or 14 show

that the vehicle is highly magnetic. If the numbers

show that the vehicle is highly magnetic, perform

the demagnetized procedure in this Group and retest

for magnetism at compass. If the compass is not re-

ceiving information from the CCD bus, F1 will be

displayed 15 seconds after this test is requested. Re-

fer to AG and AJ Body Diagnostic Procedure Manual

for further testing procedures. Test 2 (d2) checks the electronic circuits of the

compass, temperature, and CCD bus. If the test

passes d2 will be displayed, and if the test fails F2

will be displayed. Refer to AG and AJ Body Diagnos-

tic Procedure Manual for further testing procedures. Test 3 (d3) performs a walking segment test which,

sequentially puts different directions and numbers on

the display. If any segment fails, replace the compass

module.

Fig. 6 Terminal Identification

8C - 18 OVERHEAD CONSOLE Ä

Page 437 of 2438

AP BODY INDEX

page page

Ambient Temperature Sensor Removal ........ 25

Compass Calibration ...................... 21

Compass Diagnostics ..................... 23

Compass Module Replacement .............. 25

Demagnetizing Procedure .................. 22 Map Reading Lamps Operation

.............. 21

Overhead Console Replacement ............. 25

Thermometer and Compass ................ 21

Variance Procedure ....................... 22

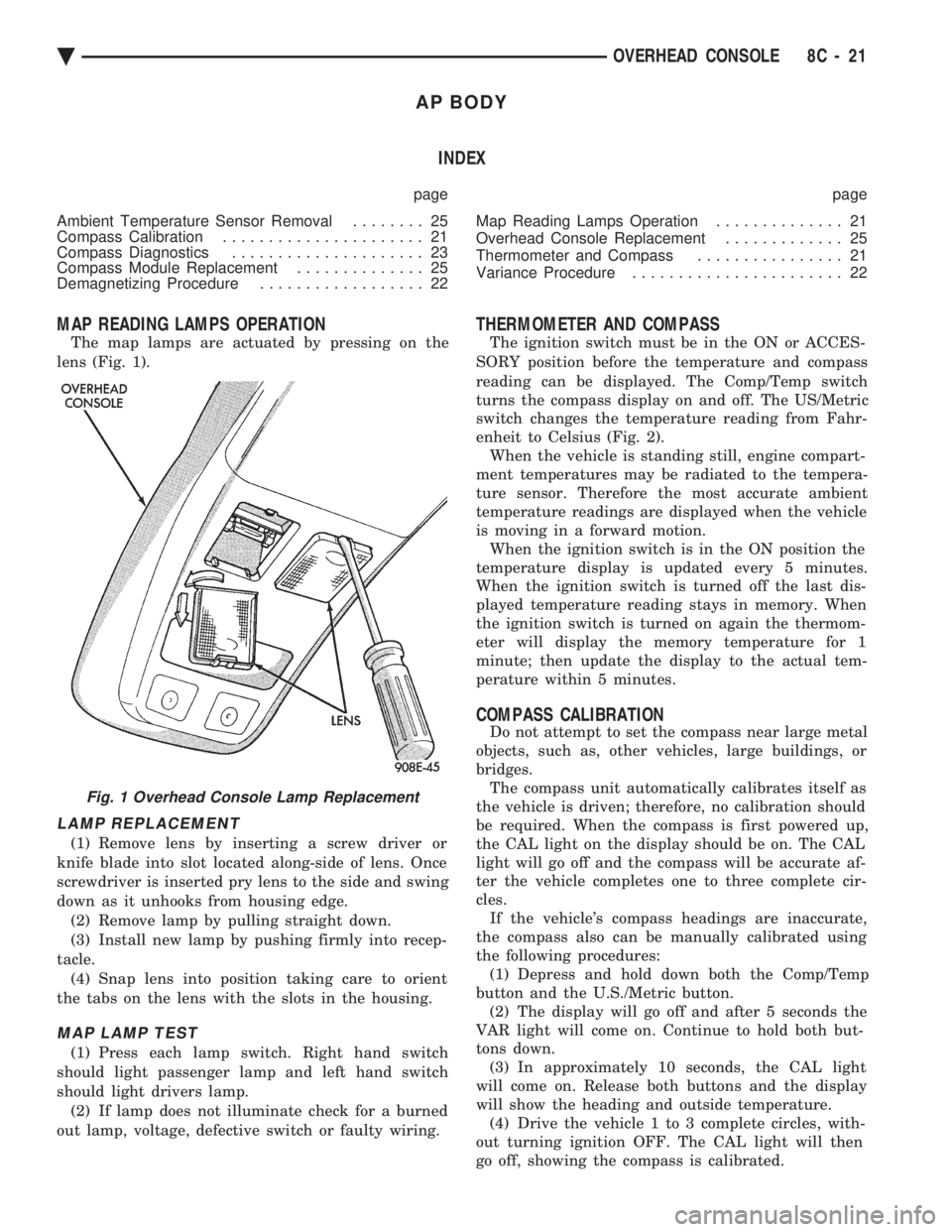

MAP READING LAMPS OPERATION

The map lamps are actuated by pressing on the

lens (Fig. 1).

LAMP REPLACEMENT

(1) Remove lens by inserting a screw driver or

knife blade into slot located along-side of lens. Once

screwdriver is inserted pry lens to the side and swing

down as it unhooks from housing edge. (2) Remove lamp by pulling straight down.

(3) Install new lamp by pushing firmly into recep-

tacle. (4) Snap lens into position taking care to orient

the tabs on the lens with the slots in the housing.

MAP LAMP TEST

(1) Press each lamp switch. Right hand switch

should light passenger lamp and left hand switch

should light drivers lamp. (2) If lamp does not illuminate check for a burned

out lamp, voltage, defective switch or faulty wiring.

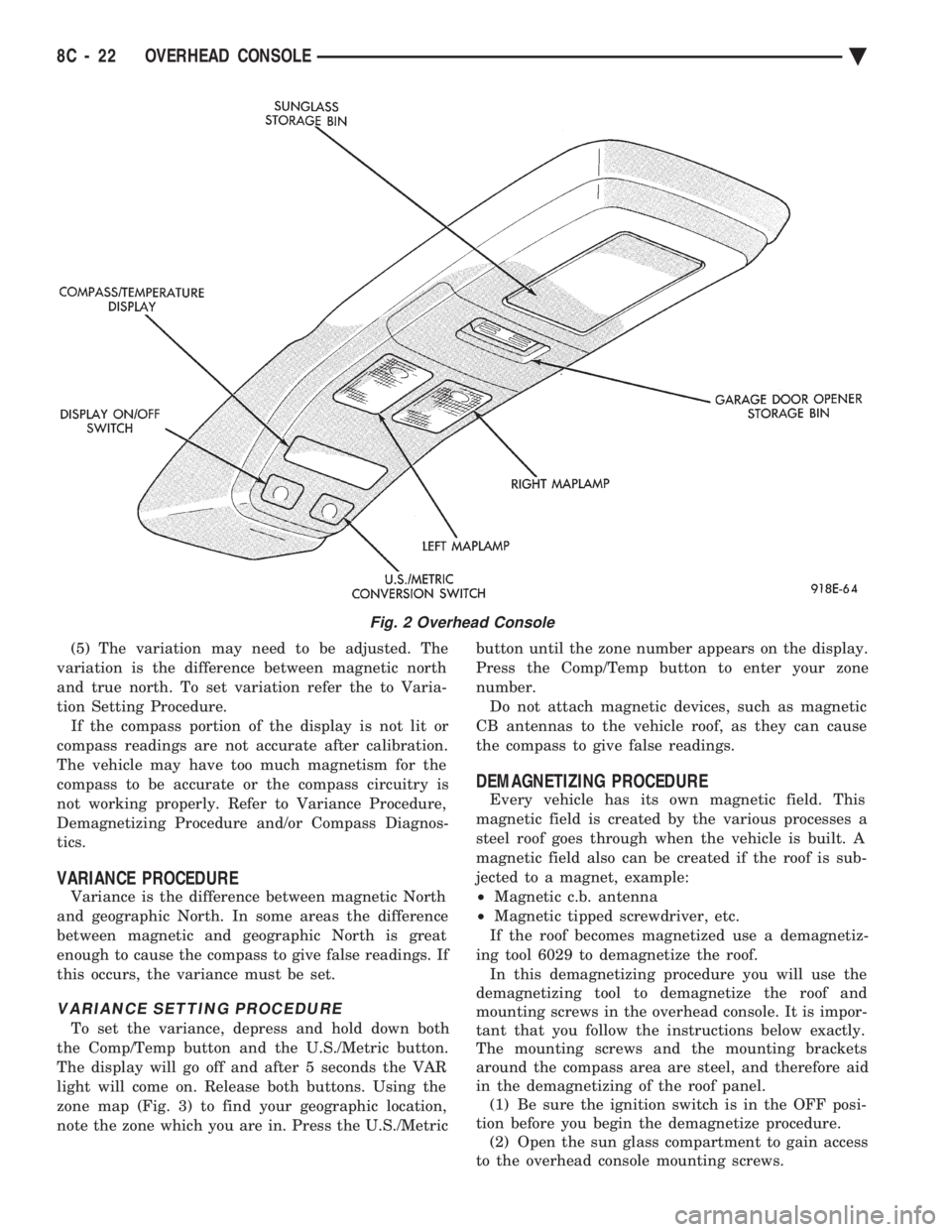

THERMOMETER AND COMPASS

The ignition switch must be in the ON or ACCES-

SORY position before the temperature and compass

reading can be displayed. The Comp/Temp switch

turns the compass display on and off. The US/Metric

switch changes the temperature reading from Fahr-

enheit to Celsius (Fig. 2). When the vehicle is standing still, engine compart-

ment temperatures may be radiated to the tempera-

ture sensor. Therefore the most accurate ambient

temperature readings are displayed when the vehicle

is moving in a forward motion. When the ignition switch is in the ON position the

temperature display is updated every 5 minutes.

When the ignition switch is turned off the last dis-

played temperature reading stays in memory. When

the ignition switch is turned on again the thermom-

eter will display the memory temperature for 1

minute; then update the display to the actual tem-

perature within 5 minutes.

COMPASS CALIBRATION

Do not attempt to set the compass near large metal

objects, such as, other vehicles, large buildings, or

bridges. The compass unit automatically calibrates itself as

the vehicle is driven; therefore, no calibration should

be required. When the compass is first powered up,

the CAL light on the display should be on. The CAL

light will go off and the compass will be accurate af-

ter the vehicle completes one to three complete cir-

cles. If the vehicle's compass headings are inaccurate,

the compass also can be manually calibrated using

the following procedures: (1) Depress and hold down both the Comp/Temp

button and the U.S./Metric button. (2) The display will go off and after 5 seconds the

VAR light will come on. Continue to hold both but-

tons down. (3) In approximately 10 seconds, the CAL light

will come on. Release both buttons and the display

will show the heading and outside temperature. (4) Drive the vehicle 1 to 3 complete circles, with-

out turning ignition OFF. The CAL light will then

go off, showing the compass is calibrated.

Fig. 1 Overhead Console Lamp Replacement

Ä OVERHEAD CONSOLE 8C - 21

Page 438 of 2438

(5) The variation may need to be adjusted. The

variation is the difference between magnetic north

and true north. To set variation refer the to Varia-

tion Setting Procedure. If the compass portion of the display is not lit or

compass readings are not accurate after calibration.

The vehicle may have too much magnetism for the

compass to be accurate or the compass circuitry is

not working properly. Refer to Variance Procedure,

Demagnetizing Procedure and/or Compass Diagnos-

tics.

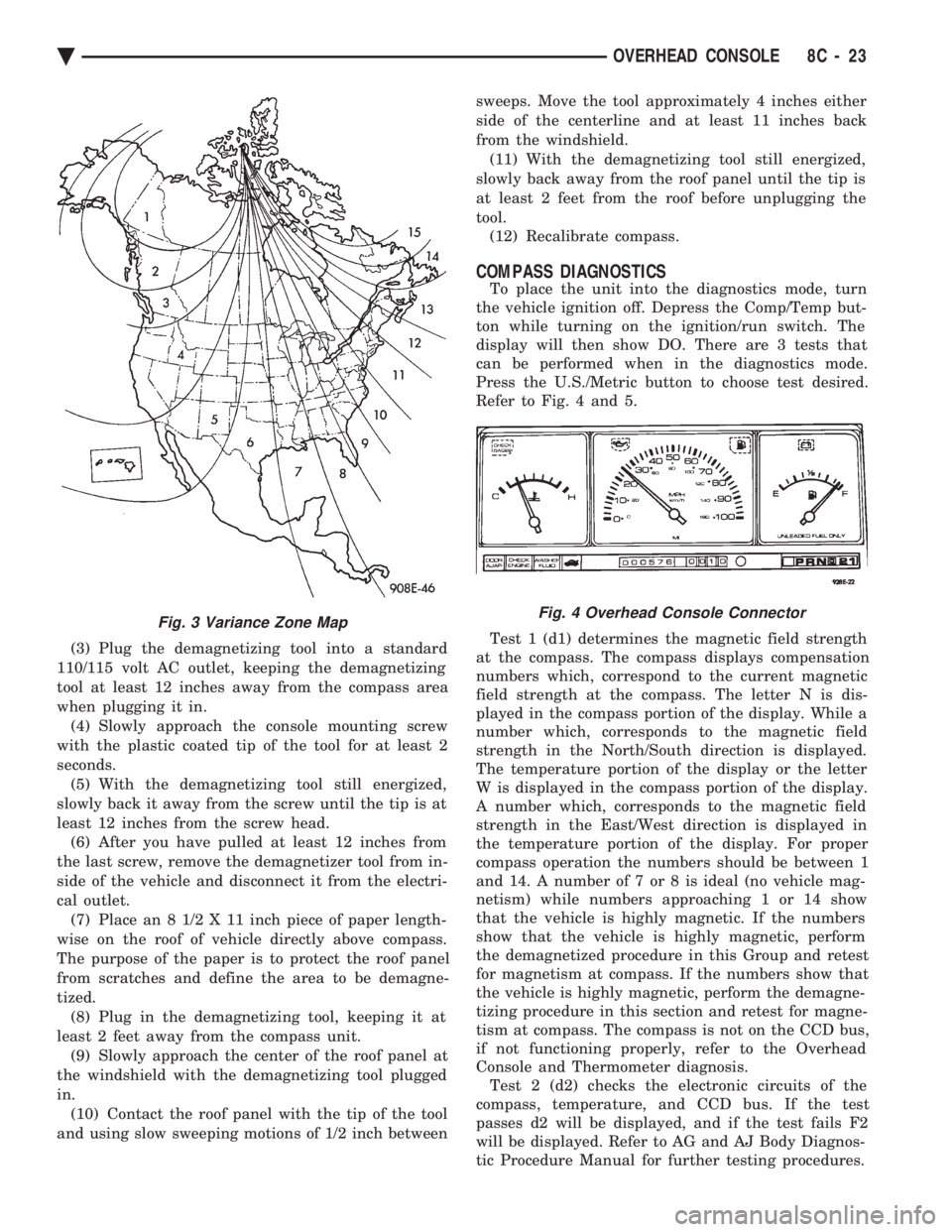

VARIANCE PROCEDURE

Variance is the difference between magnetic North

and geographic North. In some areas the difference

between magnetic and geographic North is great

enough to cause the compass to give false readings. If

this occurs, the variance must be set.

VARIANCE SETTING PROCEDURE

To set the variance, depress and hold down both

the Comp/Temp button and the U.S./Metric button.

The display will go off and after 5 seconds the VAR

light will come on. Release both buttons. Using the

zone map (Fig. 3) to find your geographic location,

note the zone which you are in. Press the U.S./Metric button until the zone number appears on the display.

Press the Comp/Temp button to enter your zone

number. Do not attach magnetic devices, such as magnetic

CB antennas to the vehicle roof, as they can cause

the compass to give false readings.

DEMAGNETIZING PROCEDURE

Every vehicle has its own magnetic field. This

magnetic field is created by the various processes a

steel roof goes through when the vehicle is built. A

magnetic field also can be created if the roof is sub-

jected to a magnet, example:

² Magnetic c.b. antenna

² Magnetic tipped screwdriver, etc.

If the roof becomes magnetized use a demagnetiz-

ing tool 6029 to demagnetize the roof. In this demagnetizing procedure you will use the

demagnetizing tool to demagnetize the roof and

mounting screws in the overhead console. It is impor-

tant that you follow the instructions below exactly.

The mounting screws and the mounting brackets

around the compass area are steel, and therefore aid

in the demagnetizing of the roof panel. (1) Be sure the ignition switch is in the OFF posi-

tion before you begin the demagnetize procedure. (2) Open the sun glass compartment to gain access

to the overhead console mounting screws.

Fig. 2 Overhead Console

8C - 22 OVERHEAD CONSOLE Ä

Page 439 of 2438

(3) Plug the demagnetizing tool into a standard

110/115 volt AC outlet, keeping the demagnetizing

tool at least 12 inches away from the compass area

when plugging it in. (4) Slowly approach the console mounting screw

with the plastic coated tip of the tool for at least 2

seconds. (5) With the demagnetizing tool still energized,

slowly back it away from the screw until the tip is at

least 12 inches from the screw head. (6) After you have pulled at least 12 inches from

the last screw, remove the demagnetizer tool from in-

side of the vehicle and disconnect it from the electri-

cal outlet. (7) Place an 8 1/2 X 11 inch piece of paper length-

wise on the roof of vehicle directly above compass.

The purpose of the paper is to protect the roof panel

from scratches and define the area to be demagne-

tized. (8) Plug in the demagnetizing tool, keeping it at

least 2 feet away from the compass unit. (9) Slowly approach the center of the roof panel at

the windshield with the demagnetizing tool plugged

in. (10) Contact the roof panel with the tip of the tool

and using slow sweeping motions of 1/2 inch between sweeps. Move the tool approximately 4 inches either

side of the centerline and at least 11 inches back

from the windshield. (11) With the demagnetizing tool still energized,

slowly back away from the roof panel until the tip is

at least 2 feet from the roof before unplugging the

tool. (12) Recalibrate compass.

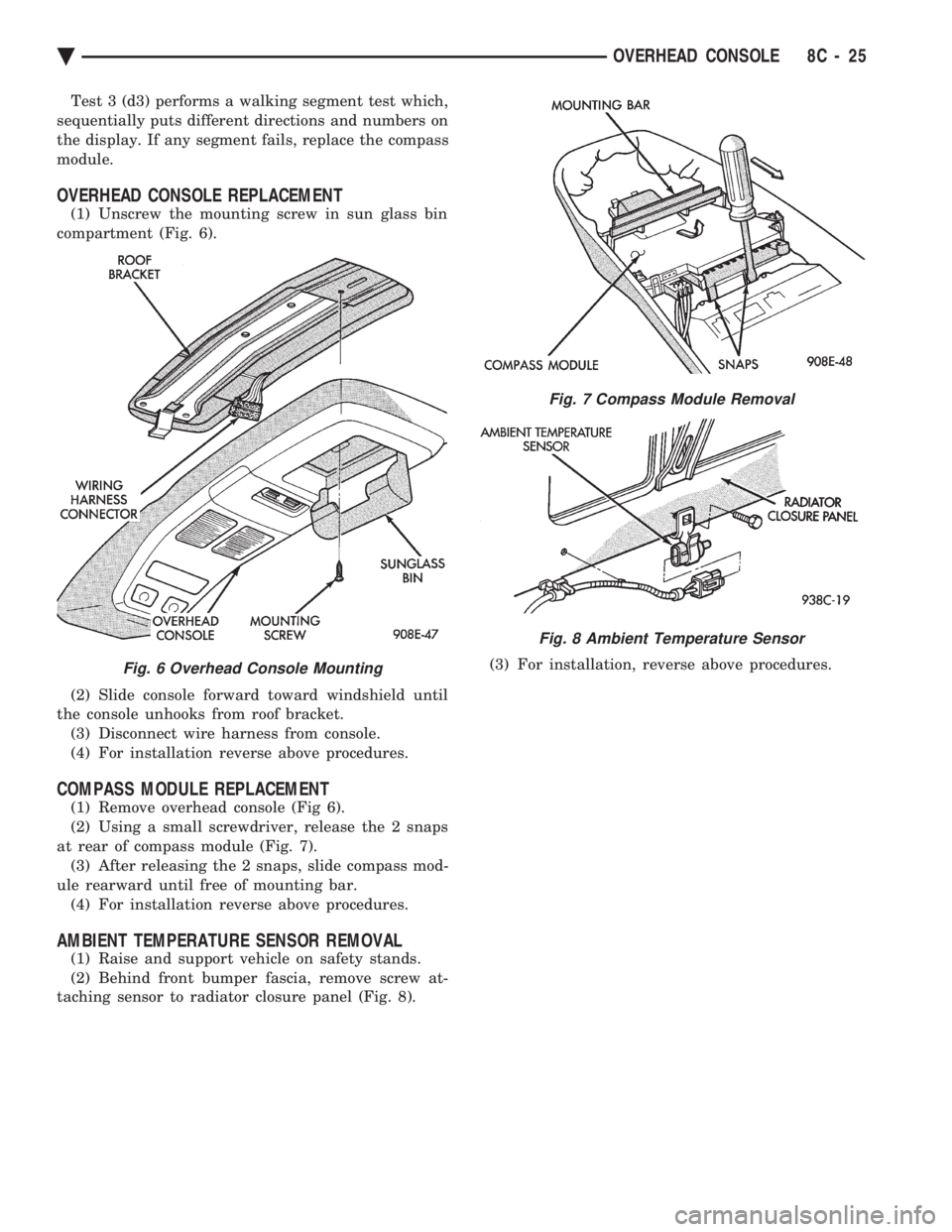

COMPASS DIAGNOSTICS

To place the unit into the diagnostics mode, turn

the vehicle ignition off. Depress the Comp/Temp but-

ton while turning on the ignition/run switch. The

display will then show DO. There are 3 tests that

can be performed when in the diagnostics mode.

Press the U.S./Metric button to choose test desired.

Refer to Fig. 4 and 5.

Test 1 (d1) determines the magnetic field strength

at the compass. The compass displays compensation

numbers which, correspond to the current magnetic

field strength at the compass. The letter N is dis-

played in the compass portion of the display. While a

number which, corresponds to the magnetic field

strength in the North/South direction is displayed.

The temperature portion of the display or the letter

W is displayed in the compass portion of the display.

A number which, corresponds to the magnetic field

strength in the East/West direction is displayed in

the temperature portion of the display. For proper

compass operation the numbers should be between 1

and 14. A number of 7 or 8 is ideal (no vehicle mag-

netism) while numbers approaching 1 or 14 show

that the vehicle is highly magnetic. If the numbers

show that the vehicle is highly magnetic, perform

the demagnetized procedure in this Group and retest

for magnetism at compass. If the numbers show that

the vehicle is highly magnetic, perform the demagne-

tizing procedure in this section and retest for magne-

tism at compass. The compass is not on the CCD bus,

if not functioning properly, refer to the Overhead

Console and Thermometer diagnosis. Test 2 (d2) checks the electronic circuits of the

compass, temperature, and CCD bus. If the test

passes d2 will be displayed, and if the test fails F2

will be displayed. Refer to AG and AJ Body Diagnos-

tic Procedure Manual for further testing procedures.

Fig. 3 Variance Zone MapFig. 4 Overhead Console Connector

Ä OVERHEAD CONSOLE 8C - 23

Page 441 of 2438

Test 3 (d3) performs a walking segment test which,

sequentially puts different directions and numbers on

the display. If any segment fails, replace the compass

module.

OVERHEAD CONSOLE REPLACEMENT

(1) Unscrew the mounting screw in sun glass bin

compartment (Fig. 6).

(2) Slide console forward toward windshield until

the console unhooks from roof bracket. (3) Disconnect wire harness from console.

(4) For installation reverse above procedures.

COMPASS MODULE REPLACEMENT

(1) Remove overhead console (Fig 6).

(2) Using a small screwdriver, release the 2 snaps

at rear of compass module (Fig. 7). (3) After releasing the 2 snaps, slide compass mod-

ule rearward until free of mounting bar. (4) For installation reverse above procedures.

AMBIENT TEMPERATURE SENSOR REMOVAL

(1) Raise and support vehicle on safety stands.

(2) Behind front bumper fascia, remove screw at-

taching sensor to radiator closure panel (Fig. 8). (3) For installation, reverse above procedures.

Fig. 6 Overhead Console Mounting

Fig. 7 Compass Module Removal

Fig. 8 Ambient Temperature Sensor

Ä

OVERHEAD CONSOLE 8C - 25

Page 445 of 2438

When testing secondary cables for punctures and

cracks with an oscilloscope follow the equipment

manufacturers instructions. If an oscilloscope is not available, secondary cables

can be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected any longer than necessary during test-

ing. Excessive heat could damage the catalytic con-

verter. Total test time must not exceed ten minutes.

(a) With the engine not running, connect one end

of a test probe to a good ground. Use a probe made of

insulated wire with insulated alligator clips on each

end. (b) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Check the coil cable the same way.

Replace cracked, leaking or faulty cables.

When replacing cables, install the new high

tension cable and nipple assembly over cap or

coil tower. When entering the terminal into the

tower, push lightly, then pinch the large diam-

eter of nipple to release air trapped between the

nipple and tower. Continue pushing on the cable

and nipple until cables are properly seated in the

cap towers. A snap should be heard as terminal

goes into place. Use the same procedure to install cable in coil tower.

Wipe the spark plug insulator clean before reinstalling

cable and cover. Use the following procedure when removing the high

tension cable from the spark plug. First, remove the

cable from the retaining bracket. Then grasp the ter-

minal as close as possible to the spark plug. Rotate the

cover and pull the cable straight back. Pulling on the

cable itself will damage the conductor and termi-

nal connection. Do not use pliers and do not pull

the cable at an angle. Doing so will damage the

insulation, cable terminal or the spark plug in-

sulator. Wipe spark plug insulator clean before

reinstalling cable and cover. Resistance type cable is identified by the words

Electronic Suppression printed on the cable jacket.

Use an ohmmeter to check resistance type cable for

open circuits, loose terminals or high resistance as

follows: (a) Remove cable from spark plug.

(b) Lift distributor cap from distributor with

cables intact. Do not remove cables from cap. The

cables must be removed from the spark plugs. (c) Connect the ohmmeter between spark plug end

terminal and the corresponding electrode inside the

cap, make sure ohmmeter probes are in good contact.

Resistance should be within tolerance shown in the cable resistance chart. If resistance is

not within tolerance, remove cable at cap tower

and check the cable. If resistance is still not within

tolerance, replace cable assembly. Test all spark

plug cables in same manner.

To test coil to distributor cap high tension cable,

remove distributor cap with the cable intact. Do not

remove cable from the cap. Connect the ohmmeter

between center contact in the cap and remove the ca-

ble at coil tower and check cable resistance. If resis-

tance is not within tolerance, replace the cable.

SPARK PLUGS

Resistor spark plugs are used in all engines and

have resistance values of 6,000 to 20,000 ohms when

checked with at least a 1000 volt tester. Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in Group O. Undamaged low milage spark plugs can be cleaned

and reused. Refer to the Spark Plug Condition sec-

tion of this group. After cleaning, file the center elec-

trode flat with a small point file or jewelers file.

Adjust the gap between the electrodes (Fig. 6) to the

dimensions specified in the chart at the end of this

section. Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and change

spark plug gap. Tighten spark plugs to 28 N Im (20 ft.

lbs.) torque.

SPARK PLUG CONDITION

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 7). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation. Spark plugs that have nor-

mal wear can usually be cleaned, have the electrodes

filed and regapped, and then reinstalled. Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

CABLE RESISTANCE CHART

Ä IGNITION SYSTEMS 8D - 3

Page 468 of 2438

tance. The cables provide suppression of radio fre-

quency emissions from the ignition system.Check the spark plug cable connections for good

contact at the coil and distributor cap towers and at

the spark plugs. Terminals should be fully seated.

The nipples and spark plug covers should be in good

condition. Nipples should fit tightly on the coil and

distributor cap towers and spark plug cover should

fit tight around spark plug insulators. Loose cable

connections can cause ignition malfunctions by per-

mitting water to enter the towers, corroding, and in-

creasing resistance.

SPARK PLUGS

The 2.2L Turbo III, 3.3L and 3.8L engines use re-

sistor spark plugs. They have resistance values of

6,000 to 20,000 ohms when checked with at least a

1000 volt tester. Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

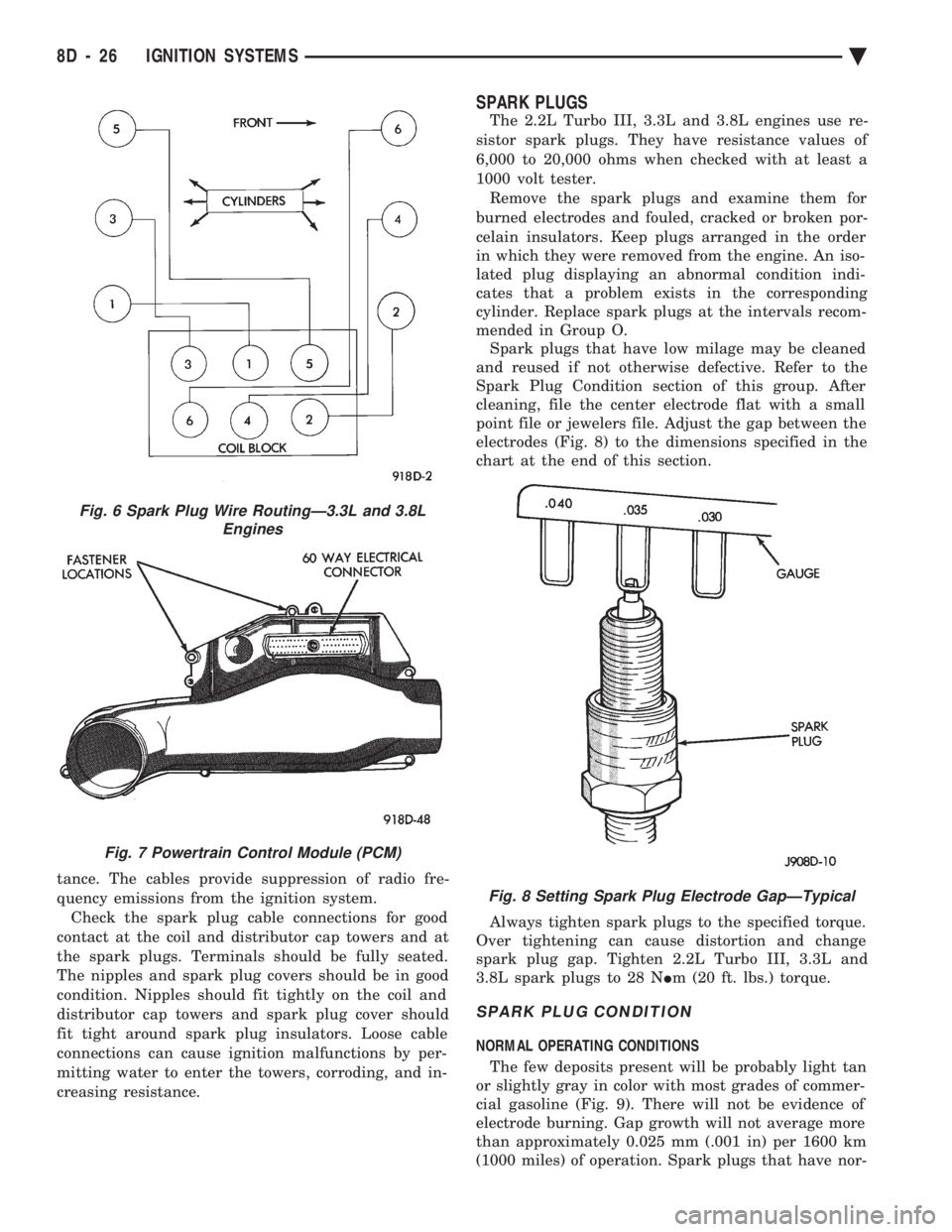

mended in Group O. Spark plugs that have low milage may be cleaned

and reused if not otherwise defective. Refer to the

Spark Plug Condition section of this group. After

cleaning, file the center electrode flat with a small

point file or jewelers file. Adjust the gap between the

electrodes (Fig. 8) to the dimensions specified in the

chart at the end of this section.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and change

spark plug gap. Tighten 2.2L Turbo III, 3.3L and

3.8L spark plugs to 28 N Im (20 ft. lbs.) torque.

SPARK PLUG CONDITION

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 9). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation. Spark plugs that have nor-

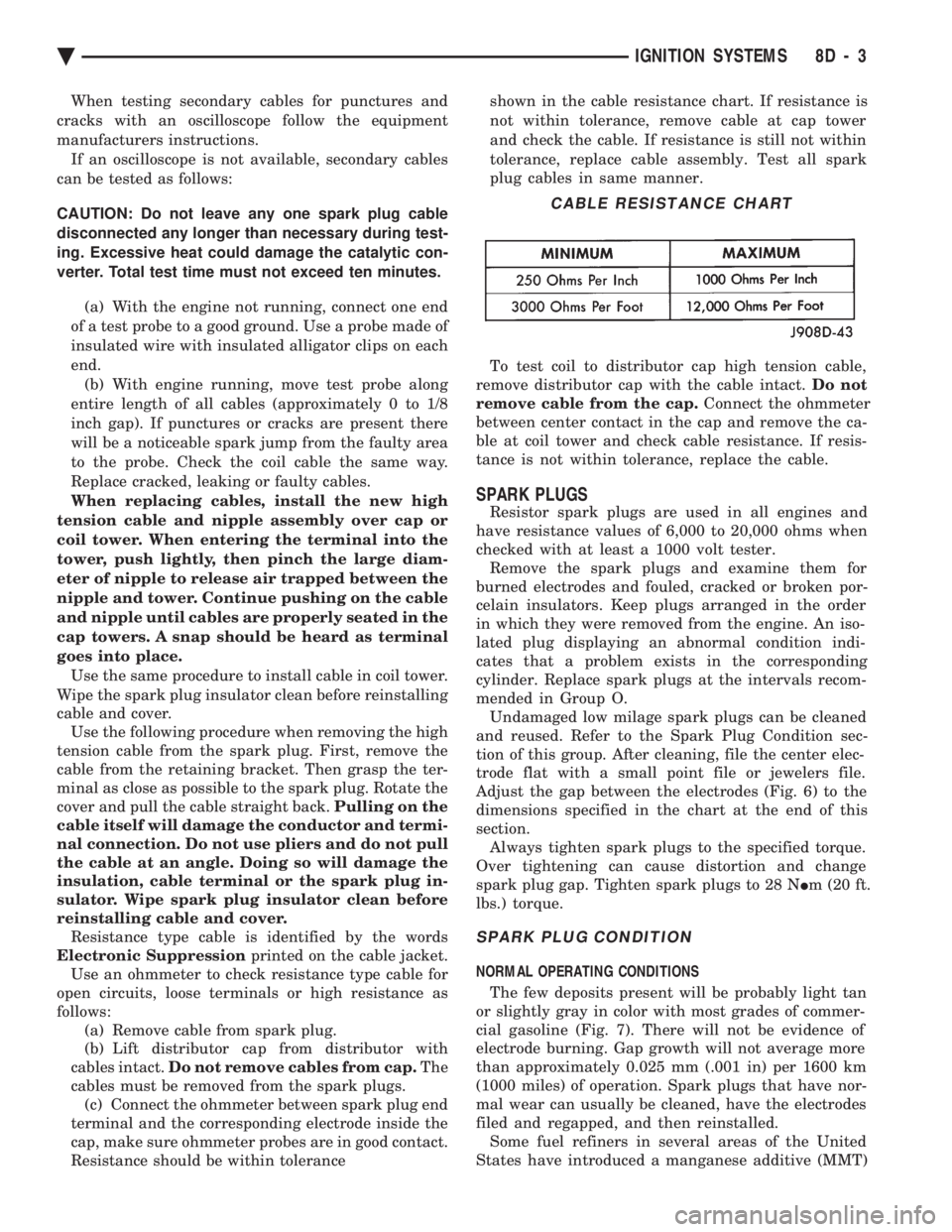

Fig. 6 Spark Plug Wire RoutingÐ3.3L and 3.8L Engines

Fig. 7 Powertrain Control Module (PCM)

Fig. 8 Setting Spark Plug Electrode GapÐTypical

8D - 26 IGNITION SYSTEMS Ä