service indicator CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1568 of 2438

The MOPAR Silicone Rubber Adhesive Sealant

gasket material or equivalent should be applied in a

continuous bead approximately 3mm (0.120 inch) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 inch.)

drop is placed in the center of the gasket contact

area. Uncured sealant may be removed with a shop

towels. Components should be torqued in place while

the sealant is still wet to the touch (within 10 min-

utes). The usage of a locating dowel is recommended

during assembly to prevent smearing of material off

location.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert proper size

socket, extension and rachet, when crankshaft rota-

tion is necessary.

ENGINE PERFORMANCE

If a loss of performance is noticed, ignition timing

should be checked. If ignition timing is retarded by

9, 18 or 27É indicating 1, 2 or 3 (timing belt or chain)

teeth may have skipped, then, camshaft and acces-

sory shaft timing with the crankshaft should be

checked. Refer to Engine Timing Sprockets and Oil

Seals of the Engine Section. To provide best vehicle performance and lowest ve-

hicle emissions, it is most important that the tune-up

be done accurately. Use the specifications listed on

the Vehicle Emission Control Information label

found in the engine compartment. (1) Test cranking amperage draw. See Starting

Motor Cranking Amperage Draw Electrical Section

of this manual. (2) Tighten the intake manifold bolts to specifica-

tions. (3) Perform cylinder compression test.(a) Check engine oil level and add oil if neces-

sary. (b) Drive the vehicle until engine reaches normal

operating temperature. (c) Select a route free from traffic and other

forms of congestion, observe all traffic laws, and ac-

celerate through the gears several times briskly.

CAUTION: Do not overspeed the engine. The higher

engine speed may help clean out valve seat deposits

which can prevent accurate compression readings.

(d) Remove all spark plugs from engine. As

spark plugs are being removed, check electrodes for

abnormal firing indicators fouled, hot, oily, etc.

Record cylinder number of spark plug for future

reference. (e) Disconnect coil wire from distributor and se-

cure to good ground to prevent a spark from start- ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector. (f) Be sure throttle blade is fully open during the

compression check. (g) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure. (h) Repeat Step G for all remaining cylinders.

(i) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from

cylinder to cylinder. (j) If one or more cylinders have abnormally low

compression pressures, repeat steps 3b through 3h. (k) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.

The recommended compression pressures are

to be used only as a guide to diagnosing engine

problems. An engine should not be disassembled

to determine the cause of low compression un-

less some malfunction is present. (4) Clean or replace spark plugs as necessary and

adjust gap as specified in Electrical Group 8. Tighten to

specifications. (5) Test resistance of spark plug cables. Refer to

Ignition System Secondary Circuit Inspection Electri-

cal Section Group 8. (6) Inspect the primary wire. Test coil output volt-

age, primary and secondary resistance. Replace parts

as necessary. Refer to Ignition System and make nec-

essary adjustment. (7) Ignition timing should be set to specifications.

(See Specification Label in engine compartment). (8) Test fuel pump for pressure and vacuum. Refer to

Fuel System Group 14, Specifications. (9) The air filter elements should be replaced as

specified in Lubrication and Maintenance, Group 0. (10) Inspect crankcase ventilation system as out

lined in Lubrication and Maintenance, Group 0. For

emission controls see Emission Controls Group 25 for

service procedures. (11) Inspect and adjust accessory belt drives refer-

ring to Accessory Belt Drive in Cooling System, Group

7 for proper adjustments. (12) Road test vehicle as a final test.

HONING CYLINDER BORES

Before honing, stuff plenty of clean shop towels

under the bores, over the crankshaft to keep abrasive

materials from entering crankcase area. (1) Used carefully, the cylinder bore resizing hone

C-823 equipped with 220 grit stones, is the best tool for

this job. In addition to deglazing, it will reduce taper

and out-of-round as well as removing light

9 - 2 ENGINE Ä

Page 1591 of 2438

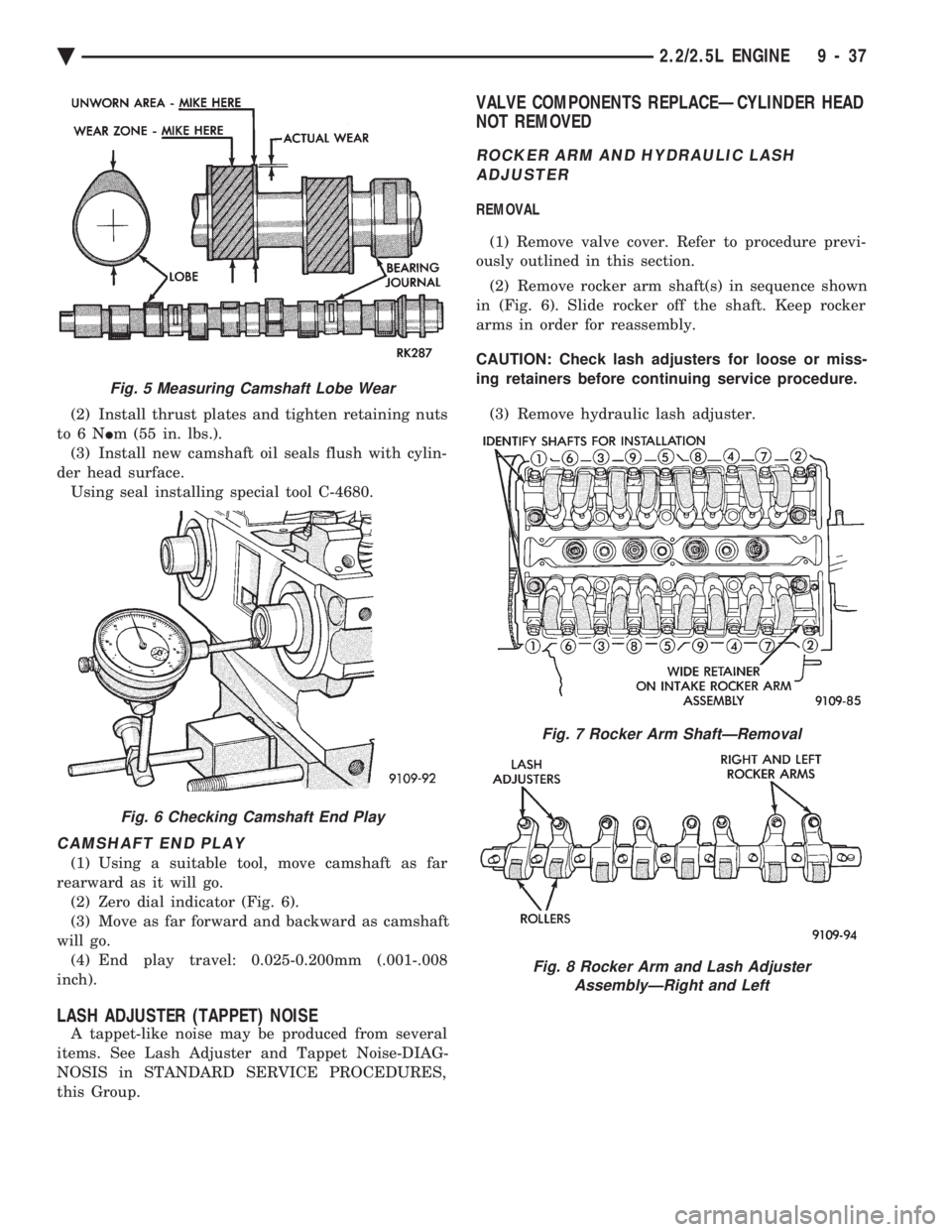

Camshaft bearing journals and lobe wear. Lobe

wear should not exceed .25mm (.010 inch). To mea-

sure cam lobe wear (Fig. 8), measure lobe diameter

in two places at the largest diameter (over the nose).

Take first reading with micrometer in unworn area

at the edge of the lobe. Take second reading in the

worn area where rocker arm contacts the lobe. Sub-

tract second reading from the first. The difference is

the cam lobe wear.

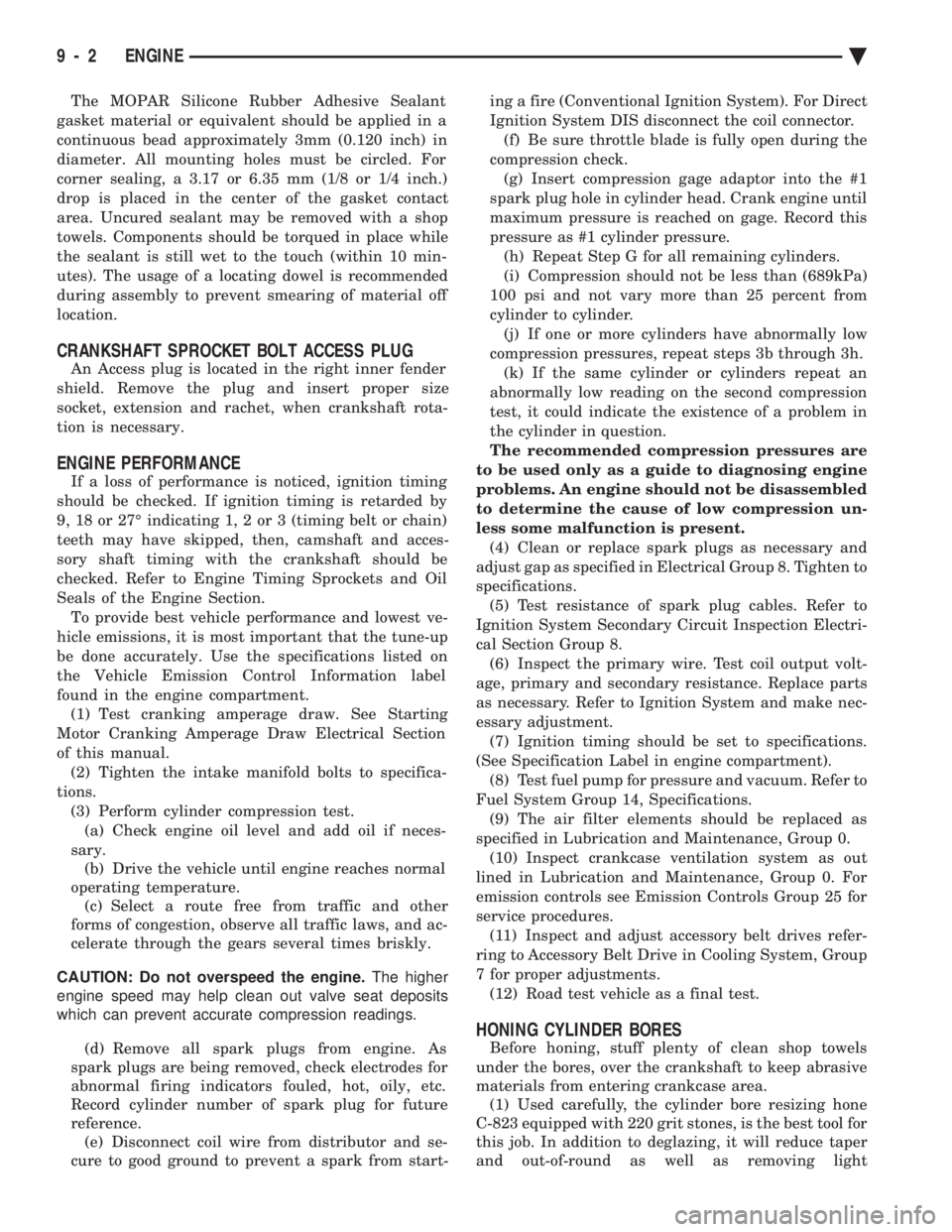

CAMSHAFT END PLAY

(1) Oil camshaft journals and install camshaft

without cam followers. Tighten screws to specified

torque. (2) Using a suitable tool, move camshaft as far

rearward as it will go. (3) Zero dial indicator (Fig. 9).

(4) Move camshaft as far forward as it will go.

(5) End play travel: 0.13 - 0.33mm (0.005 - 0.013

inch.). (6) Remove bearing caps and camshaft.

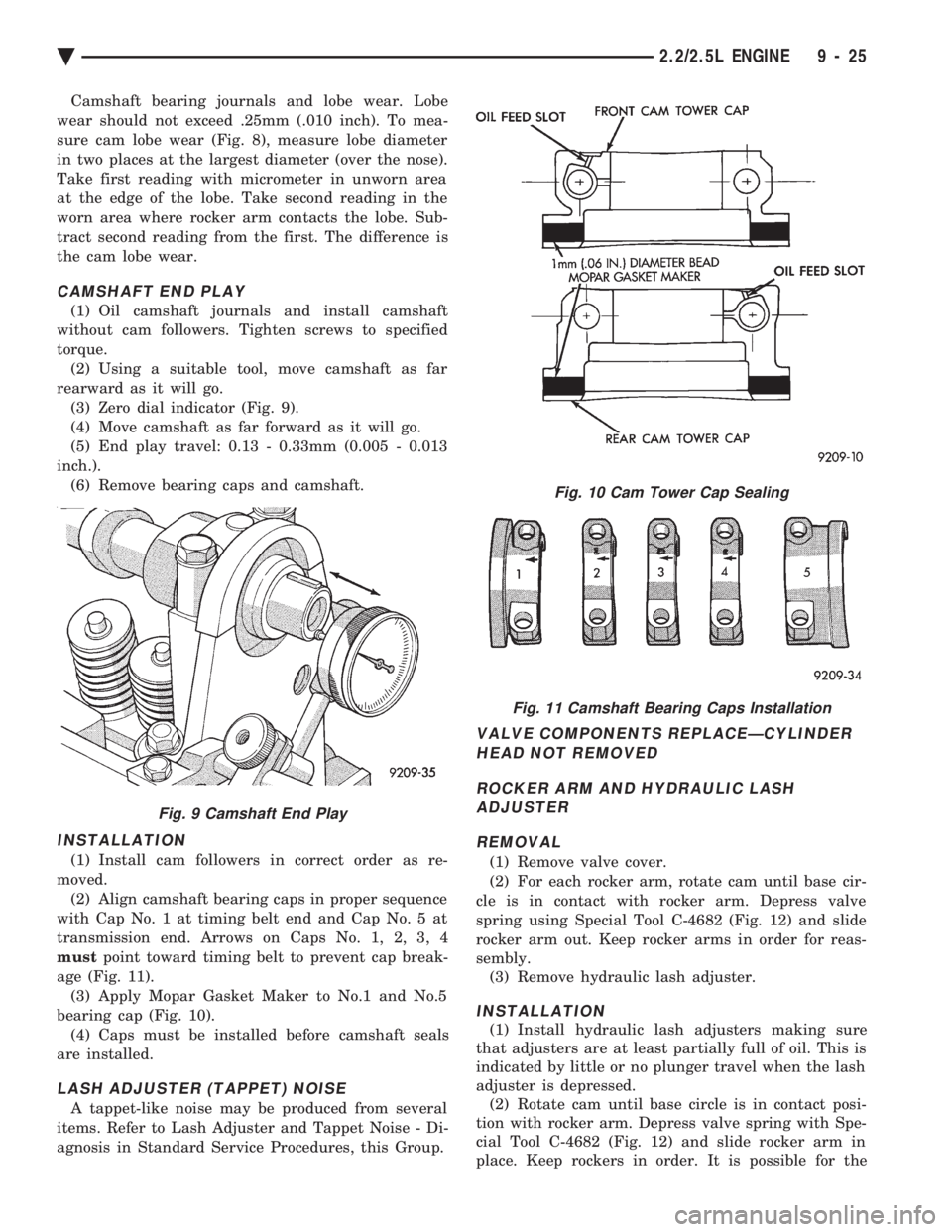

INSTALLATION

(1) Install cam followers in correct order as re-

moved. (2) Align camshaft bearing caps in proper sequence

with Cap No. 1 at timing belt end and Cap No. 5 at

transmission end. Arrows on Caps No. 1, 2, 3, 4

must point toward timing belt to prevent cap break-

age (Fig. 11). (3) Apply Mopar Gasket Maker to No.1 and No.5

bearing cap (Fig. 10). (4) Caps must be installed before camshaft seals

are installed.

LASH ADJUSTER (TAPPET) NOISE

A tappet-like noise may be produced from several

items. Refer to Lash Adjuster and Tappet Noise - Di-

agnosis in Standard Service Procedures, this Group.

VALVE COMPONENTS REPLACEÐCYLINDER HEAD NOT REMOVED

ROCKER ARM AND HYDRAULIC LASH ADJUSTER

REMOVAL

(1) Remove valve cover.

(2) For each rocker arm, rotate cam until base cir-

cle is in contact with rocker arm. Depress valve

spring using Special Tool C-4682 (Fig. 12) and slide

rocker arm out. Keep rocker arms in order for reas-

sembly. (3) Remove hydraulic lash adjuster.

INSTALLATION

(1) Install hydraulic lash adjusters making sure

that adjusters are at least partially full of oil. This is

indicated by little or no plunger travel when the lash

adjuster is depressed. (2) Rotate cam until base circle is in contact posi-

tion with rocker arm. Depress valve spring with Spe-

cial Tool C-4682 (Fig. 12) and slide rocker arm in

place. Keep rockers in order. It is possible for the

Fig. 9 Camshaft End Play

Fig. 10 Cam Tower Cap Sealing

Fig. 11 Camshaft Bearing Caps Installation

Ä 2.2/2.5L ENGINE 9 - 25

Page 1594 of 2438

springs using Tool C-3422-B. (2) Remove valve retaining locks, valve spring re-

tainers, valve stem seals and valve springs. (3) Before removing valves, remove any burrs

from valve stem lock grooves to prevent damage

to the valve guides. Identify valves to insure instal-

lation in original location.

VALVE INSPECTION (1) Clean valves thoroughly and discard burned,

warped and cracked valves. (2) Measure valve stems for wear.

(3) If valve stems are worn more than 0.05 mm (.002

inch.) replace valve.

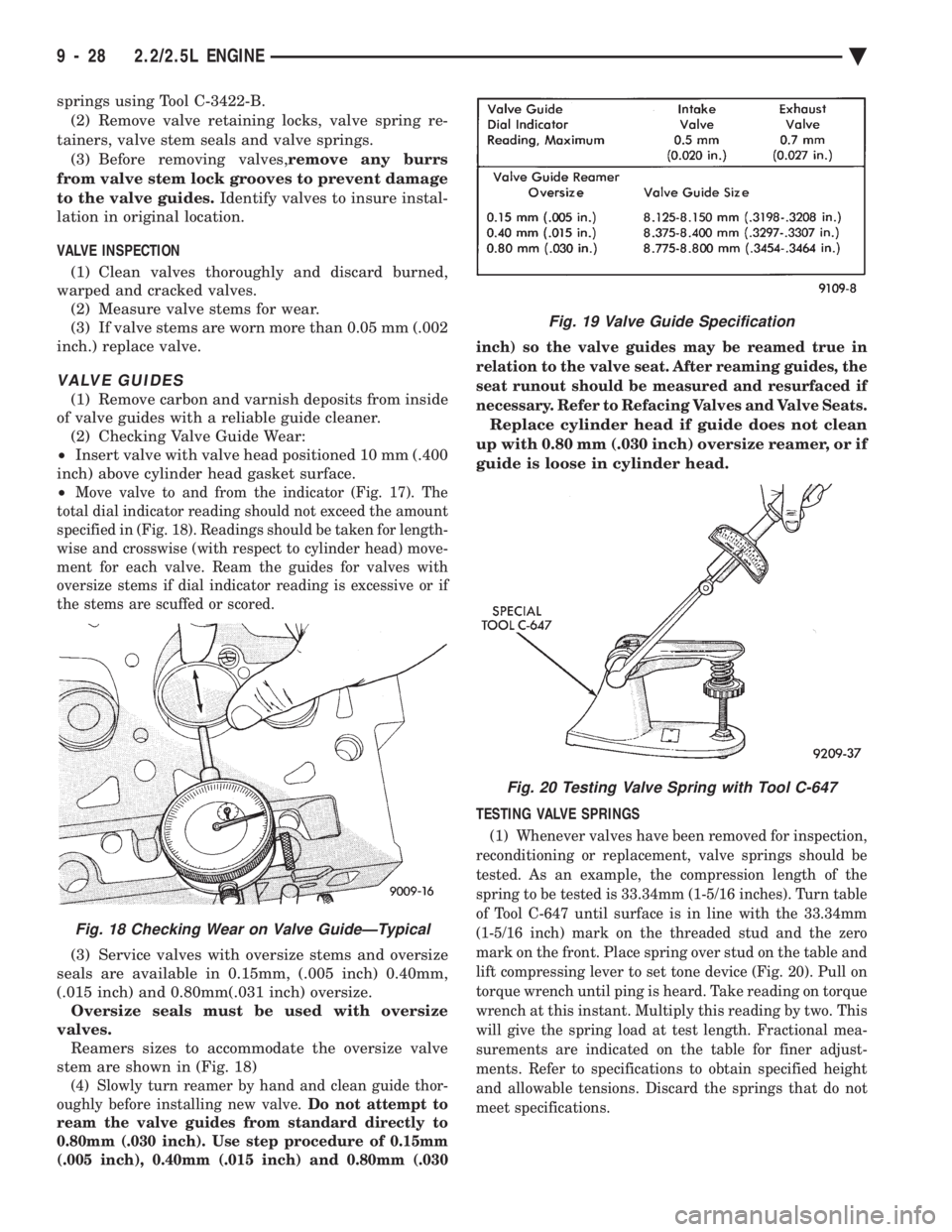

VALVE GUIDES

(1) Remove carbon and varnish deposits from inside

of valve guides with a reliable guide cleaner. (2) Checking Valve Guide Wear:

² Insert valve with valve head positioned 10 mm (.400

inch) above cylinder head gasket surface.

²

Move valve to and from the indicator (Fig. 17). The

total dial indicator reading should not exceed the amount

specified in (Fig. 18). Readings should be taken for length-

wise and crosswise (with respect to cylinder head) move-

ment for each valve. Ream the guides for valves with

oversize stems if dial indicator reading is excessive or if

the stems are scuffed or scored.

(3) Service valves with oversize stems and oversize

seals are available in 0.15mm, (.005 inch) 0.40mm,

(.015 inch) and 0.80mm(.031 inch) oversize. Oversize seals must be used with oversize

valves. Reamers sizes to accommodate the oversize valve

stem are shown in (Fig. 18)

(4) Slowly turn reamer by hand and clean guide thor-

oughly before installing new valve. Do not attempt to

ream the valve guides from standard directly to

0.80mm (.030 inch). Use step procedure of 0.15mm

(.005 inch), 0.40mm (.015 inch) and 0.80mm (.030 inch) so the valve guides may be reamed true in

relation to the valve seat. After reaming guides, the

seat runout should be measured and resurfaced if

necessary. Refer to Refacing Valves and Valve Seats.

Replace cylinder head if guide does not clean

up with 0.80 mm (.030 inch) oversize reamer, or if

guide is loose in cylinder head.

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should be

tested. As an example, the compression length of the

spring to be tested is 33.34mm (1-5/16 inches). Turn table

of Tool C-647 until surface is in line with the 33.34mm

(1-5/16 inch) mark on the threaded stud and the zero

mark on the front. Place spring over stud on the table and

lift compressing lever to set tone device (Fig. 20). Pull on

torque wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional mea-

surements are indicated on the table for finer adjust-

ments. Refer to specifications to obtain specified height

and allowable tensions. Discard the springs that do not

meet specifications.

Fig. 18 Checking Wear on Valve GuideÐTypical

Fig. 19 Valve Guide Specification

Fig. 20 Testing Valve Spring with Tool C-647

9 - 28 2.2/2.5L ENGINE Ä

Page 1600 of 2438

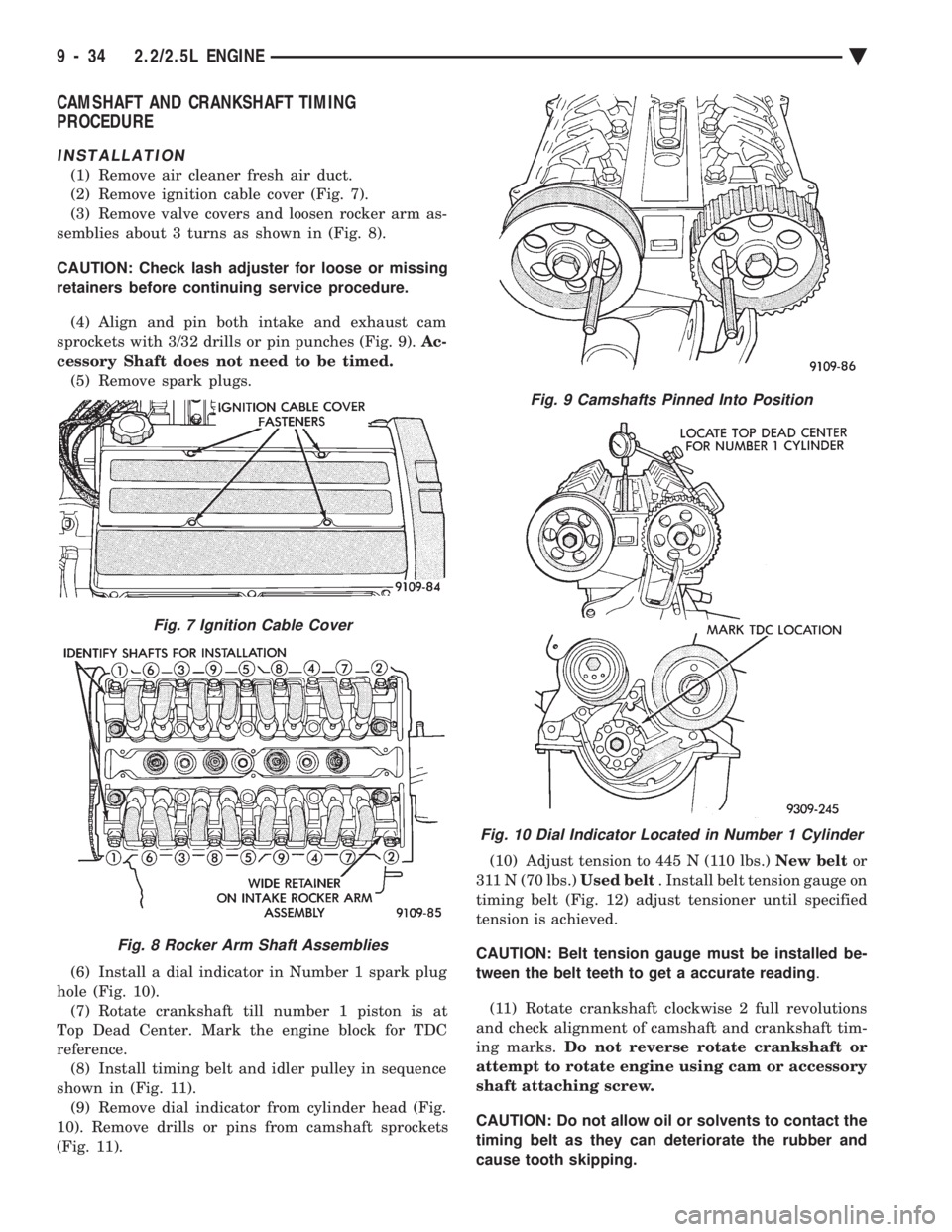

CAMSHAFT AND CRANKSHAFT TIMING

PROCEDURE

INSTALLATION

(1) Remove air cleaner fresh air duct.

(2) Remove ignition cable cover (Fig. 7).

(3) Remove valve covers and loosen rocker arm as-

semblies about 3 turns as shown in (Fig. 8).

CAUTION: Check lash adjuster for loose or missing

retainers before continuing service procedure.

(4) Align and pin both intake and exhaust cam

sprockets with 3/32 drills or pin punches (Fig. 9). Ac-

cessory Shaft does not need to be timed. (5) Remove spark plugs.

(6) Install a dial indicator in Number 1 spark plug

hole (Fig. 10). (7) Rotate crankshaft till number 1 piston is at

Top Dead Center. Mark the engine block for TDC

reference. (8) Install timing belt and idler pulley in sequence

shown in (Fig. 11). (9) Remove dial indicator from cylinder head (Fig.

10). Remove drills or pins from camshaft sprockets

(Fig. 11). (10) Adjust tension to 445 N (110 lbs.)

New beltor

311 N (70 lbs.) Used belt. Install belt tension gauge on

timing belt (Fig. 12) adjust tensioner until specified

tension is achieved.

CAUTION: Belt tension gauge must be installed be-

tween the belt teeth to get a accurate reading .

(11) Rotate crankshaft clockwise 2 full revolutions

and check alignment of camshaft and crankshaft tim-

ing marks. Do not reverse rotate crankshaft or

attempt to rotate engine using cam or accessory

shaft attaching screw.

CAUTION: Do not allow oil or solvents to contact the

timing belt as they can deteriorate the rubber and

cause tooth skipping.

Fig. 7 Ignition Cable Cover

Fig. 8 Rocker Arm Shaft Assemblies

Fig. 9 Camshafts Pinned Into Position

Fig. 10 Dial Indicator Located in Number 1 Cylinder

9 - 34 2.2/2.5L ENGINE Ä

Page 1603 of 2438

(2) Install thrust plates and tighten retaining nuts

to6N Im (55 in. lbs.).

(3) Install new camshaft oil seals flush with cylin-

der head surface. Using seal installing special tool C-4680.

CAMSHAFT END PLAY

(1) Using a suitable tool, move camshaft as far

rearward as it will go. (2) Zero dial indicator (Fig. 6).

(3) Move as far forward and backward as camshaft

will go. (4) End play travel: 0.025-0.200mm (.001-.008

inch).

LASH ADJUSTER (TAPPET) NOISE

A tappet-like noise may be produced from several

items. See Lash Adjuster and Tappet Noise-DIAG-

NOSIS in STANDARD SERVICE PROCEDURES,

this Group.

VALVE COMPONENTS REPLACEÐCYLINDER HEAD

NOT REMOVED

ROCKER ARM AND HYDRAULIC LASH

ADJUSTER

REMOVAL

(1) Remove valve cover. Refer to procedure previ-

ously outlined in this section.

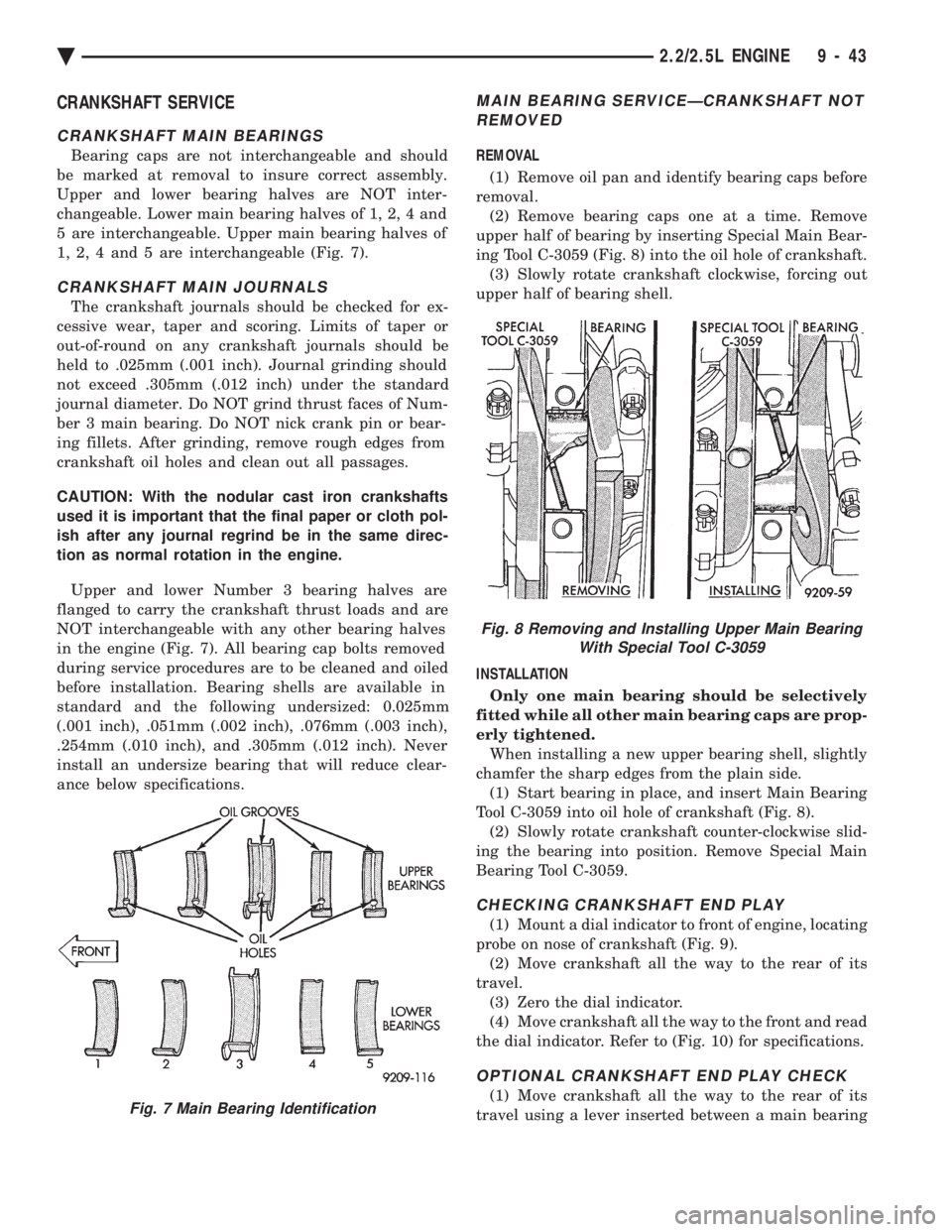

(2) Remove rocker arm shaft(s) in sequence shown

in (Fig. 6). Slide rocker off the shaft. Keep rocker

arms in order for reassembly.

CAUTION: Check lash adjusters for loose or miss-

ing retainers before continuing service procedure.

(3) Remove hydraulic lash adjuster.

Fig. 5 Measuring Camshaft Lobe Wear

Fig. 6 Checking Camshaft End Play

Fig. 7 Rocker Arm ShaftÐRemoval

Fig. 8 Rocker Arm and Lash Adjuster AssemblyÐRight and Left

Ä 2.2/2.5L ENGINE 9 - 37

Page 1609 of 2438

CRANKSHAFT SERVICE

CRANKSHAFT MAIN BEARINGS

Bearing caps are not interchangeable and should

be marked at removal to insure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. Lower main bearing halves of 1, 2, 4 and

5 are interchangeable. Upper main bearing halves of

1, 2, 4 and 5 are interchangeable (Fig. 7).

CRANKSHAFT MAIN JOURNALS

The crankshaft journals should be checked for ex-

cessive wear, taper and scoring. Limits of taper or

out-of-round on any crankshaft journals should be

held to .025mm (.001 inch). Journal grinding should

not exceed .305mm (.012 inch) under the standard

journal diameter. Do NOT grind thrust faces of Num-

ber 3 main bearing. Do NOT nick crank pin or bear-

ing fillets. After grinding, remove rough edges from

crankshaft oil holes and clean out all passages.

CAUTION: With the nodular cast iron crankshafts

used it is important that the final paper or cloth pol-

ish after any journal regrind be in the same direc-

tion as normal rotation in the engine.

Upper and lower Number 3 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 7). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersized: 0.025mm

(.001 inch), .051mm (.002 inch), .076mm (.003 inch),

.254mm (.010 inch), and .305mm (.012 inch). Never

install an undersize bearing that will reduce clear-

ance below specifications.

MAIN BEARING SERVICEÐCRANKSHAFT NOT REMOVED

REMOVAL

(1) Remove oil pan and identify bearing caps before

removal. (2) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059 (Fig. 8) into the oil hole of crankshaft. (3) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION Only one main bearing should be selectively

fitted while all other main bearing caps are prop-

erly tightened. When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side. (1) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 8). (2) Slowly rotate crankshaft counter-clockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locating

probe on nose of crankshaft (Fig. 9). (2) Move crankshaft all the way to the rear of its

travel. (3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and read

the dial indicator. Refer to (Fig. 10) for specifications.

OPTIONAL CRANKSHAFT END PLAY CHECK

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearingFig. 7 Main Bearing Identification

Fig. 8 Removing and Installing Upper Main Bearing With Special Tool C-3059

Ä 2.2/2.5L ENGINE 9 - 43

Page 1654 of 2438

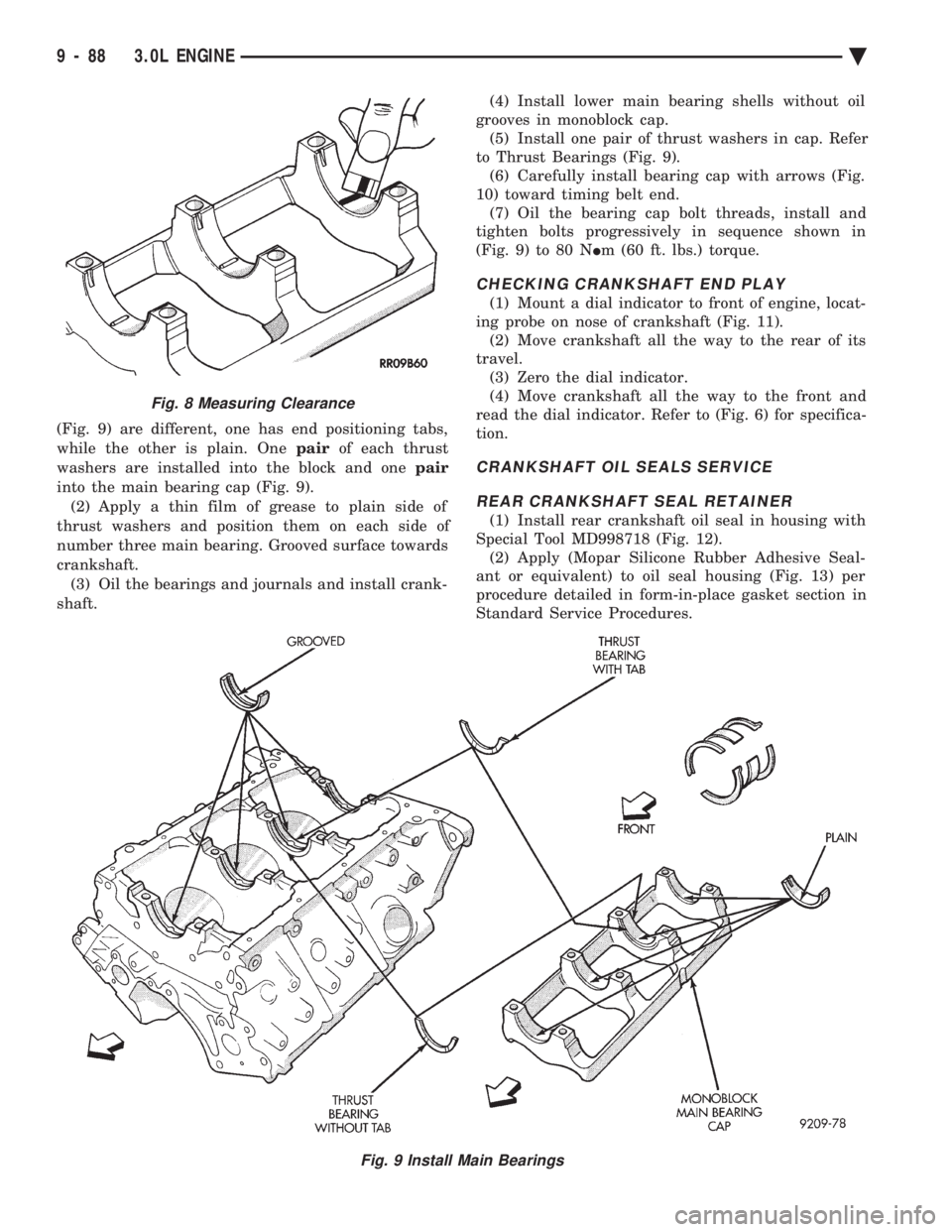

(Fig. 9) are different, one has end positioning tabs,

while the other is plain. One pairof each thrust

washers are installed into the block and one pair

into the main bearing cap (Fig. 9). (2) Apply a thin film of grease to plain side of

thrust washers and position them on each side of

number three main bearing. Grooved surface towards

crankshaft. (3) Oil the bearings and journals and install crank-

shaft. (4) Install lower main bearing shells without oil

grooves in monoblock cap. (5) Install one pair of thrust washers in cap. Refer

to Thrust Bearings (Fig. 9). (6) Carefully install bearing cap with arrows (Fig.

10) toward timing belt end. (7) Oil the bearing cap bolt threads, install and

tighten bolts progressively in sequence shown in

(Fig. 9) to 80 N Im (60 ft. lbs.) torque.

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 11). (2) Move crankshaft all the way to the rear of its

travel. (3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to (Fig. 6) for specifica-

tion.

CRANKSHAFT OIL SEALS SERVICE

REAR CRANKSHAFT SEAL RETAINER

(1) Install rear crankshaft oil seal in housing with

Special Tool MD998718 (Fig. 12). (2) Apply (Mopar Silicone Rubber Adhesive Seal-

ant or equivalent) to oil seal housing (Fig. 13) per

procedure detailed in form-in-place gasket section in

Standard Service Procedures.

Fig. 9 Install Main Bearings

Fig. 8 Measuring Clearance

9 - 88 3.0L ENGINE Ä

Page 1671 of 2438

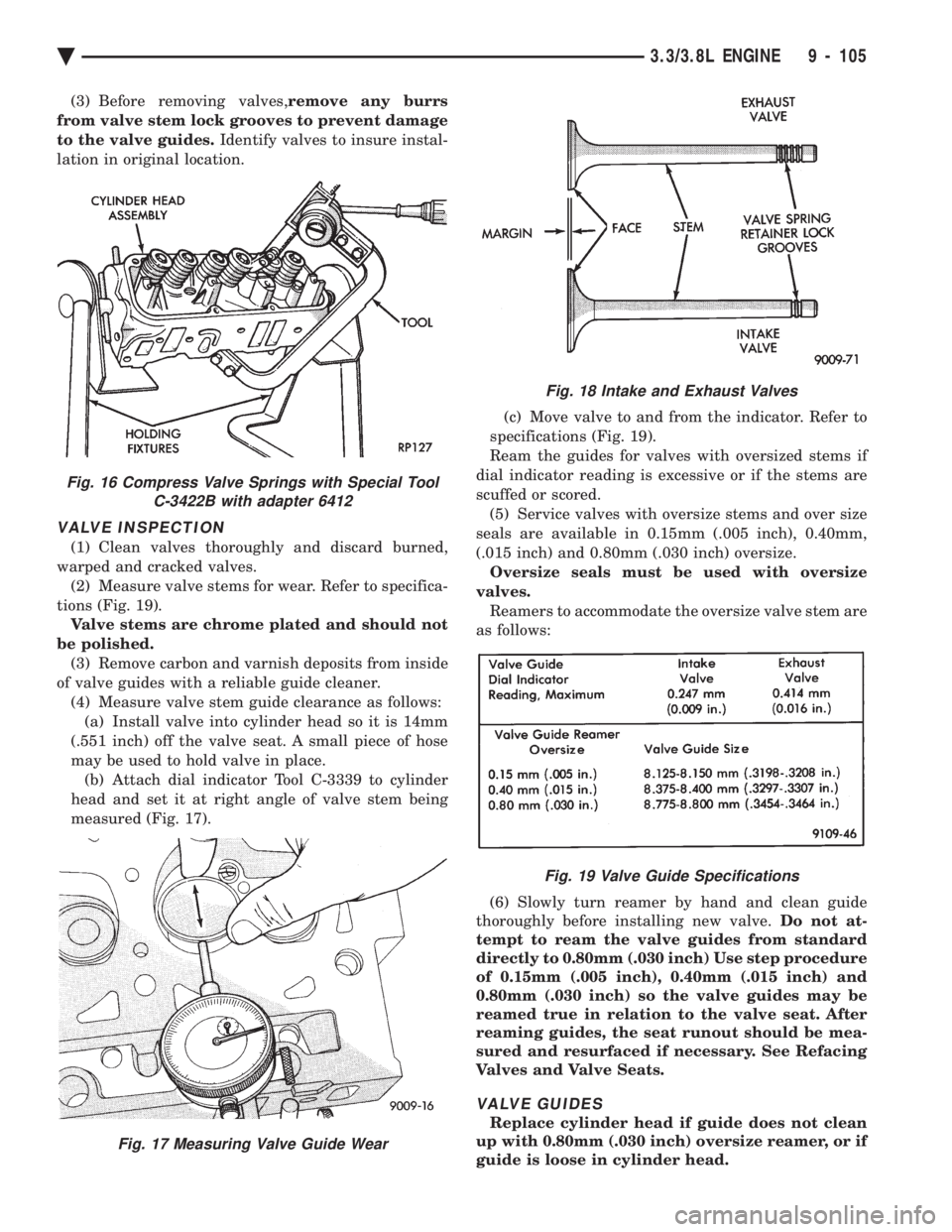

(3) Before removing valves, remove any burrs

from valve stem lock grooves to prevent damage

to the valve guides. Identify valves to insure instal-

lation in original location.

VALVE INSPECTION

(1) Clean valves thoroughly and discard burned,

warped and cracked valves. (2) Measure valve stems for wear. Refer to specifica-

tions (Fig. 19). Valve stems are chrome plated and should not

be polished. (3) Remove carbon and varnish deposits from inside

of valve guides with a reliable guide cleaner. (4) Measure valve stem guide clearance as follows:(a) Install valve into cylinder head so it is 14mm

(.551 inch) off the valve seat. A small piece of hose

may be used to hold valve in place. (b) Attach dial indicator Tool C-3339 to cylinder

head and set it at right angle of valve stem being

measured (Fig. 17). (c) Move valve to and from the indicator. Refer to

specifications (Fig. 19).

Ream the guides for valves with oversized stems if

dial indicator reading is excessive or if the stems are

scuffed or scored. (5) Service valves with oversize stems and over size

seals are available in 0.15mm (.005 inch), 0.40mm,

(.015 inch) and 0.80mm (.030 inch) oversize. Oversize seals must be used with oversize

valves. Reamers to accommodate the oversize valve stem are

as follows:

(6) Slowly turn reamer by hand and clean guide

thoroughly before installing new valve. Do not at-

tempt to ream the valve guides from standard

directly to 0.80mm (.030 inch) Use step procedure

of 0.15mm (.005 inch), 0.40mm (.015 inch) and

0.80mm (.030 inch) so the valve guides may be

reamed true in relation to the valve seat. After

reaming guides, the seat runout should be mea-

sured and resurfaced if necessary. See Refacing

Valves and Valve Seats.

VALVE GUIDES

Replace cylinder head if guide does not clean

up with 0.80mm (.030 inch) oversize reamer, or if

guide is loose in cylinder head.

Fig. 18 Intake and Exhaust Valves

Fig. 19 Valve Guide Specifications

Fig. 16 Compress Valve Springs with Special Tool C-3422B with adapter 6412

Fig. 17 Measuring Valve Guide Wear

Ä 3.3/3.8L ENGINE 9 - 105

Page 1770 of 2438

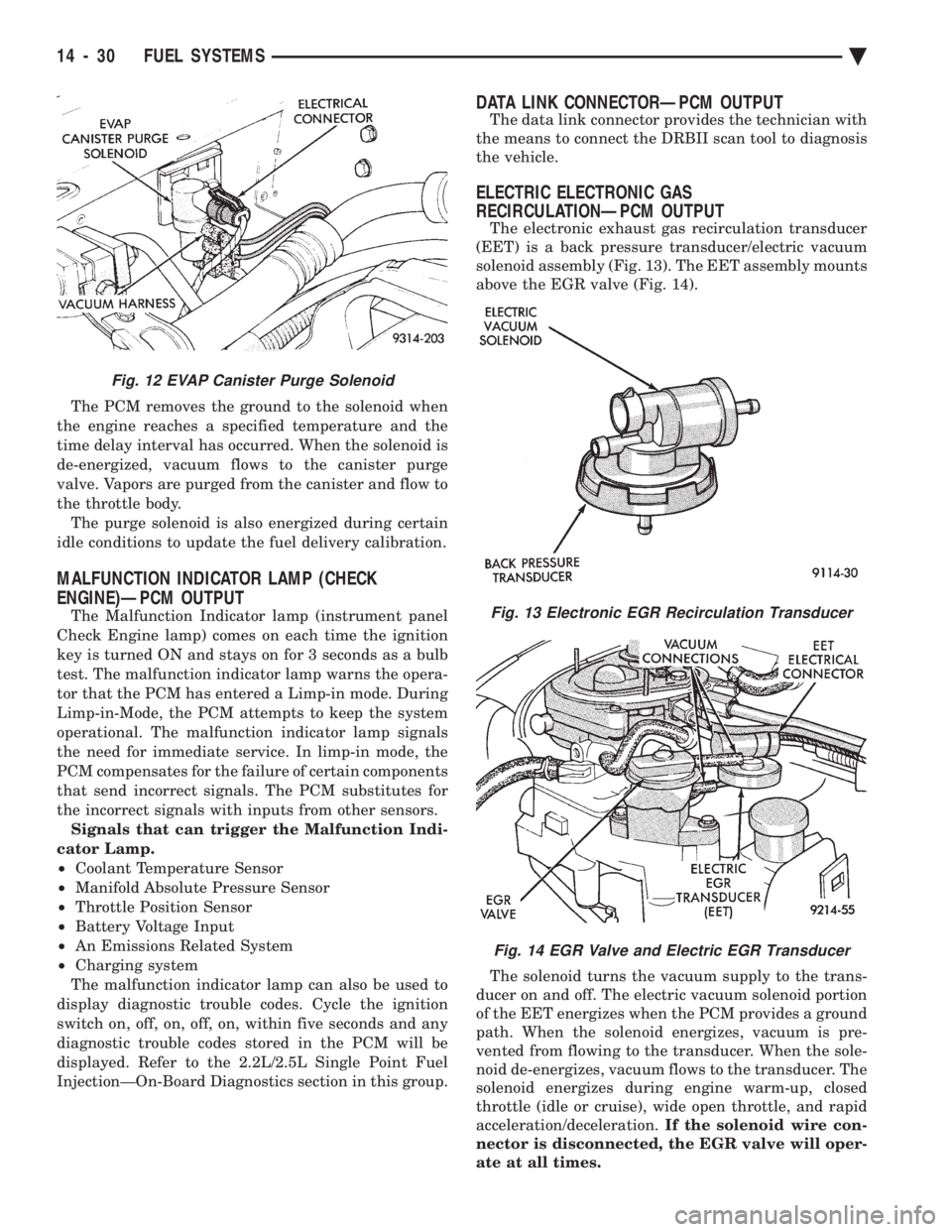

The PCM removes the ground to the solenoid when

the engine reaches a specified temperature and the

time delay interval has occurred. When the solenoid is

de-energized, vacuum flows to the canister purge

valve. Vapors are purged from the canister and flow to

the throttle body. The purge solenoid is also energized during certain

idle conditions to update the fuel delivery calibration.

MALFUNCTION INDICATOR LAMP (CHECK

ENGINE)ÐPCM OUTPUT

The Malfunction Indicator lamp (instrument panel

Check Engine lamp) comes on each time the ignition

key is turned ON and stays on for 3 seconds as a bulb

test. The malfunction indicator lamp warns the opera-

tor that the PCM has entered a Limp-in mode. During

Limp-in-Mode, the PCM attempts to keep the system

operational. The malfunction indicator lamp signals

the need for immediate service. In limp-in mode, the

PCM compensates for the failure of certain components

that send incorrect signals. The PCM substitutes for

the incorrect signals with inputs from other sensors. Signals that can trigger the Malfunction Indi-

cator Lamp.

² Coolant Temperature Sensor

² Manifold Absolute Pressure Sensor

² Throttle Position Sensor

² Battery Voltage Input

² An Emissions Related System

² Charging system

The malfunction indicator lamp can also be used to

display diagnostic trouble codes. Cycle the ignition

switch on, off, on, off, on, within five seconds and any

diagnostic trouble codes stored in the PCM will be

displayed. Refer to the 2.2L/2.5L Single Point Fuel

InjectionÐOn-Board Diagnostics section in this group.

DATA LINK CONNECTORÐPCM OUTPUT

The data link connector provides the technician with

the means to connect the DRBII scan tool to diagnosis

the vehicle.

ELECTRIC ELECTRONIC GAS

RECIRCULATIONÐPCM OUTPUT

The electronic exhaust gas recirculation transducer

(EET) is a back pressure transducer/electric vacuum

solenoid assembly (Fig. 13). The EET assembly mounts

above the EGR valve (Fig. 14).

The solenoid turns the vacuum supply to the trans-

ducer on and off. The electric vacuum solenoid portion

of the EET energizes when the PCM provides a ground

path. When the solenoid energizes, vacuum is pre-

vented from flowing to the transducer. When the sole-

noid de-energizes, vacuum flows to the transducer. The

solenoid energizes during engine warm-up, closed

throttle (idle or cruise), wide open throttle, and rapid

acceleration/deceleration. If the solenoid wire con-

nector is disconnected, the EGR valve will oper-

ate at all times.

Fig. 12 EVAP Canister Purge Solenoid

Fig. 13 Electronic EGR Recirculation Transducer

Fig. 14 EGR Valve and Electric EGR Transducer

14 - 30 FUEL SYSTEMS Ä

Page 1802 of 2438

ter mounting studs (Fig. 12). The top of the solenoid

has the word TOP on it. The solenoid will not oper-

ate unless it is installed correctly.

DATA LINK CONNECTORÐPCM OUTPUT

The data link connector provides the technician

with the means to connect the DRBII scan tool to di-

agnosis the vehicle.

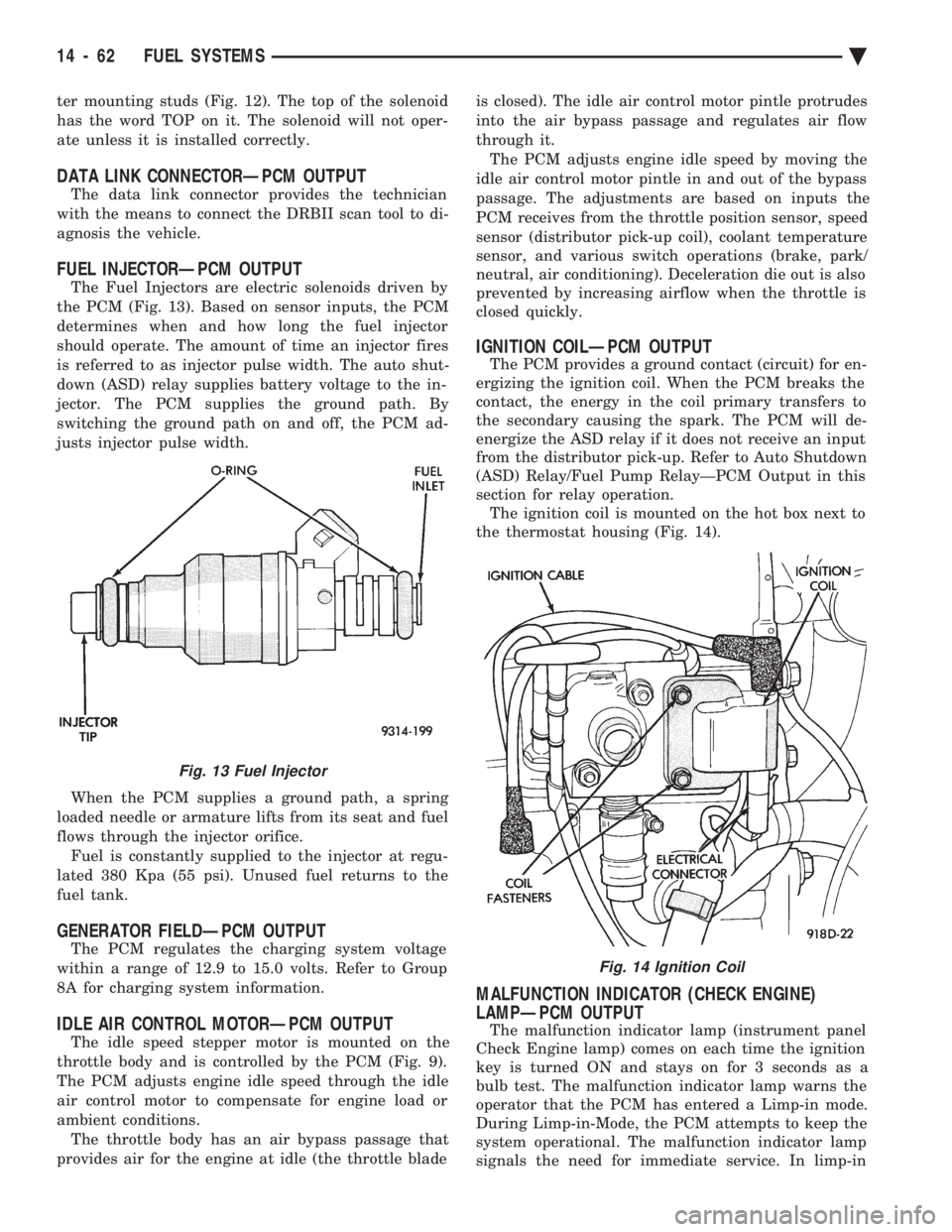

FUEL INJECTORÐPCM OUTPUT

The Fuel Injectors are electric solenoids driven by

the PCM (Fig. 13). Based on sensor inputs, the PCM

determines when and how long the fuel injector

should operate. The amount of time an injector fires

is referred to as injector pulse width. The auto shut-

down (ASD) relay supplies battery voltage to the in-

jector. The PCM supplies the ground path. By

switching the ground path on and off, the PCM ad-

justs injector pulse width.

When the PCM supplies a ground path, a spring

loaded needle or armature lifts from its seat and fuel

flows through the injector orifice. Fuel is constantly supplied to the injector at regu-

lated 380 Kpa (55 psi). Unused fuel returns to the

fuel tank.

GENERATOR FIELDÐPCM OUTPUT

The PCM regulates the charging system voltage

within a range of 12.9 to 15.0 volts. Refer to Group

8A for charging system information.

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The idle speed stepper motor is mounted on the

throttle body and is controlled by the PCM (Fig. 9).

The PCM adjusts engine idle speed through the idle

air control motor to compensate for engine load or

ambient conditions. The throttle body has an air bypass passage that

provides air for the engine at idle (the throttle blade is closed). The idle air control motor pintle protrudes

into the air bypass passage and regulates air flow

through it. The PCM adjusts engine idle speed by moving the

idle air control motor pintle in and out of the bypass

passage. The adjustments are based on inputs the

PCM receives from the throttle position sensor, speed

sensor (distributor pick-up coil), coolant temperature

sensor, and various switch operations (brake, park/

neutral, air conditioning). Deceleration die out is also

prevented by increasing airflow when the throttle is

closed quickly.

IGNITION COILÐPCM OUTPUT

The PCM provides a ground contact (circuit) for en-

ergizing the ignition coil. When the PCM breaks the

contact, the energy in the coil primary transfers to

the secondary causing the spark. The PCM will de-

energize the ASD relay if it does not receive an input

from the distributor pick-up. Refer to Auto Shutdown

(ASD) Relay/Fuel Pump RelayÐPCM Output in this

section for relay operation. The ignition coil is mounted on the hot box next to

the thermostat housing (Fig. 14).

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

The malfunction indicator lamp (instrument panel

Check Engine lamp) comes on each time the ignition

key is turned ON and stays on for 3 seconds as a

bulb test. The malfunction indicator lamp warns the

operator that the PCM has entered a Limp-in mode.

During Limp-in-Mode, the PCM attempts to keep the

system operational. The malfunction indicator lamp

signals the need for immediate service. In limp-in

Fig. 13 Fuel Injector

Fig. 14 Ignition Coil

14 - 62 FUEL SYSTEMS Ä