battery CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1893 of 2438

the PCM determines crankshaft position, it begins

energizing the injectors in sequence.The auto shutdown (ASD) relay supplies battery

voltage to the injectors. The PCM provides the

ground path for the injectors. By switching the

ground path on and off, the PCM adjusts injector

pulse width. Pulse width is the amount of time the

injector is energized. The PCM adjusts injector pulse

width based on inputs it receives.

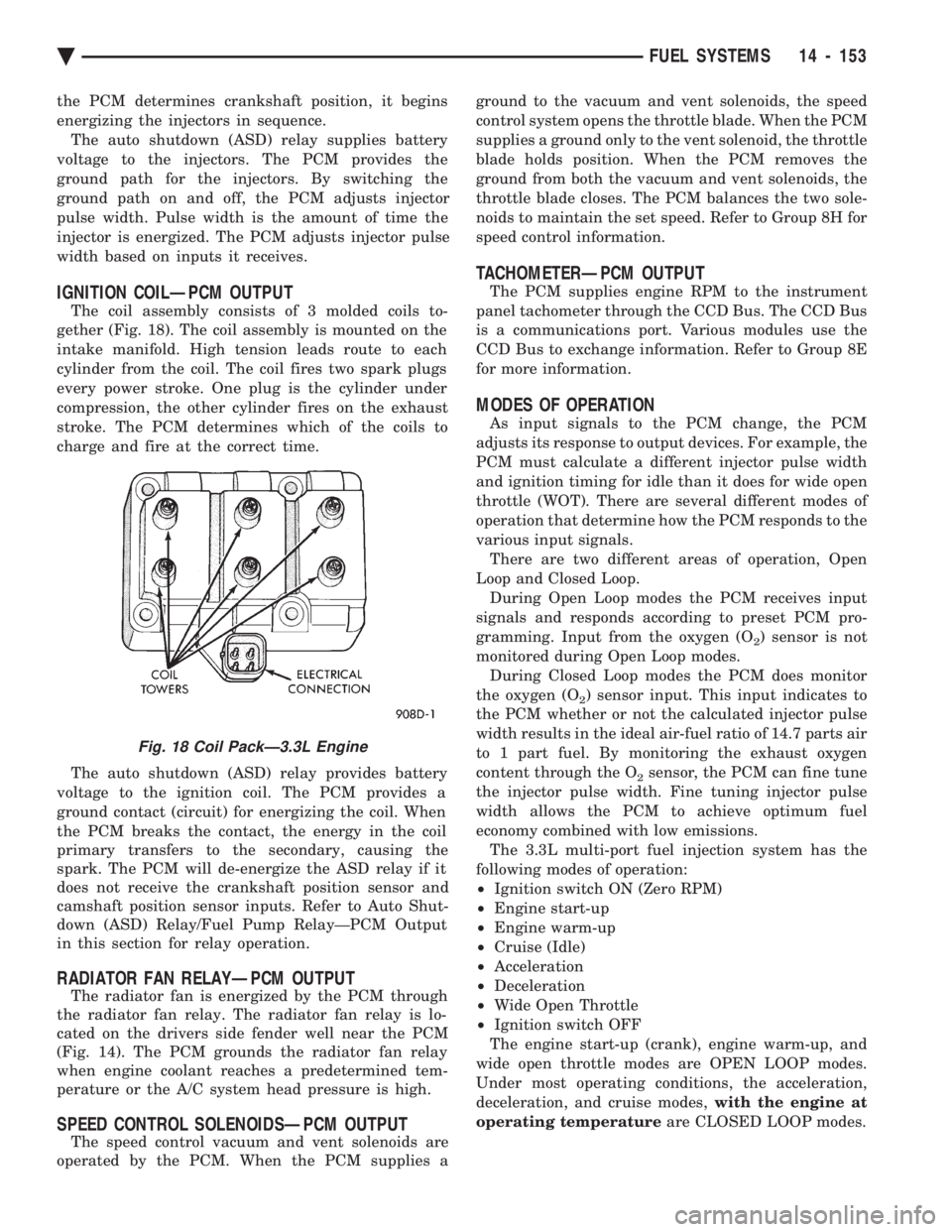

IGNITION COILÐPCM OUTPUT

The coil assembly consists of 3 molded coils to-

gether (Fig. 18). The coil assembly is mounted on the

intake manifold. High tension leads route to each

cylinder from the coil. The coil fires two spark plugs

every power stroke. One plug is the cylinder under

compression, the other cylinder fires on the exhaust

stroke. The PCM determines which of the coils to

charge and fire at the correct time.

The auto shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary, causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) Relay/Fuel Pump RelayÐPCM Output

in this section for relay operation.

RADIATOR FAN RELAYÐPCM OUTPUT

The radiator fan is energized by the PCM through

the radiator fan relay. The radiator fan relay is lo-

cated on the drivers side fender well near the PCM

(Fig. 14). The PCM grounds the radiator fan relay

when engine coolant reaches a predetermined tem-

perature or the A/C system head pressure is high.

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a ground to the vacuum and vent solenoids, the speed

control system opens the throttle blade. When the PCM

supplies a ground only to the vent solenoid, the throttle

blade holds position. When the PCM removes the

ground from both the vacuum and vent solenoids, the

throttle blade closes. The PCM balances the two sole-

noids to maintain the set speed. Refer to Group 8H for

speed control information.

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer through the CCD Bus. The CCD Bus

is a communications port. Various modules use the

CCD Bus to exchange information. Refer to Group 8E

for more information.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example, the

PCM must calculate a different injector pulse width

and ignition timing for idle than it does for wide open

throttle (WOT). There are several different modes of

operation that determine how the PCM responds to the

various input signals. There are two different areas of operation, Open

Loop and Closed Loop. During Open Loop modes the PCM receives input

signals and responds according to preset PCM pro-

gramming. Input from the oxygen (O

2) sensor is not

monitored during Open Loop modes. During Closed Loop modes the PCM does monitor

the oxygen (O

2) sensor input. This input indicates to

the PCM whether or not the calculated injector pulse

width results in the ideal air-fuel ratio of 14.7 parts air

to 1 part fuel. By monitoring the exhaust oxygen

content through the O

2sensor, the PCM can fine tune

the injector pulse width. Fine tuning injector pulse

width allows the PCM to achieve optimum fuel

economy combined with low emissions. The 3.3L multi-port fuel injection system has the

following modes of operation:

² Ignition switch ON (Zero RPM)

² Engine start-up

² Engine warm-up

² Cruise (Idle)

² Acceleration

² Deceleration

² Wide Open Throttle

² Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes.

Under most operating conditions, the acceleration,

deceleration, and cruise modes, with the engine at

operating temperature are CLOSED LOOP modes.

Fig. 18 Coil PackÐ3.3L Engine

Ä FUEL SYSTEMS 14 - 153

Page 1894 of 2438

IGNITION SWITCH ON (ZERO RPM) MODE When the multi-port fuel injection system is acti-

vated by the ignition switch, the following actions oc-

cur:

² The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

² The PCM monitors the coolant temperature sensor

and throttle position sensor input. The PCM modifies

fuel strategy based on this input. When the key is in the ON position and the engine

is not running (zero rpm), the auto shutdown (ASD)

relay and fuel pump relay are not energized. There-

fore battery voltage is not supplied to the fuel pump,

ignition coil, fuel injectors or oxygen sensor heating

element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following ac-

tions occur when the starter motor is engaged. If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the auto shutdown (ASD) relay and fuel pump relay.

These relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil, and oxygen sensor heat-

ing element. If the PCM does not receive the cam-

shaft position sensor and crankshaft position sensor

signals within approximately one second, it de-ener-

gizes the ASD relay and fuel pump relay. The PCM energizes all six injectors until it deter-

mines crankshaft position from the camshaft position

sensor and crankshaft position sensor signals. The

PCM determines crankshaft position within 1 engine

revolution. After determining crankshaft position, the PCM

begins energizing the injectors in sequence. The PCM

adjusts injector pulse width and controls injector syn-

chronization by turning the individual ground paths

to the injectors On and Off. When the engine idles within 664 RPM of its tar-

get RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (Zero RPM) mode. If

the PCM does not detect a minimum difference be-

tween the two values, it sets a MAP fault into mem-

ory. Once the ASD and fuel pump relays have been en-

ergized, the PCM:

² Determines injector pulse width based on battery

voltage, coolant temperature, engine rpm and the

number of engine revolutions since cranking was ini-

tiated.

ENGINE WARM-UP MODE This is a OPEN LOOP mode. The following inputs

are received by the PCM:

² engine coolant temperature ²

manifold absolute pressure (MAP)

² engine speed (crankshaft position sensor)

² throttle position

² A/C switch

² battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off. The PCM adjusts ignition timing and engine idle

speed. Engine idle speed is adjusted through the idle

air control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising speed the

following inputs are received by the PCM:

² engine coolant temperature

² manifold absolute pressure

² engine speed (crankshaft position sensor)

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off. The PCM adjusts engine idle speed and ignition

timing. The PCM adjusts the air/fuel ratio according

to the oxygen content in the exhaust gas.

ACCELERATION MODE This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in throttle position or MAP

pressure as a demand for increased engine output

and vehicle acceleration. The PCM increases injector

pulse width in response to increased fuel demand.

DECELERATION MODE This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

² engine coolant temperature

² manifold absolute pressure

² engine speed

² throttle position

² exhaust gas oxygen content

² A/C control positions

² battery voltage

The PCM may receive a closed throttle input from

the throttle position sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. The PCM will reduce injector

pulse width. This helps maintain better control of the

air-fuel mixture (as sensed through the O

2sensor).

During a closed throttle deceleration condition, the

PCM grounds the exhaust gas recirculation (EGR)

solenoid. When the solenoid is grounded, EGR func-

tion stops.

14 - 154 FUEL SYSTEMS Ä

Page 1895 of 2438

WIDE OPEN THROTTLE MODE This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² battery voltage

² engine coolant temperature

² manifold absolute pressure

² engine speed

² throttle position

When the PCM senses wide open throttle condition

through the throttle position sensor (TPS) it will:

² De-energize the air conditioning relay. This dis-

ables the air conditioning system.

² Provide a ground for the electrical EGR transducer

(EET) solenoid. When the PCM grounds the solenoid,

the EGR system stops operating. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera-

tion. The PCM will adjust injector pulse width to

supply a predetermined amount of additional fuel.

IGNITION SWITCH OFF MODE When the ignition switch is turned to the OFF po-

sition, the following occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

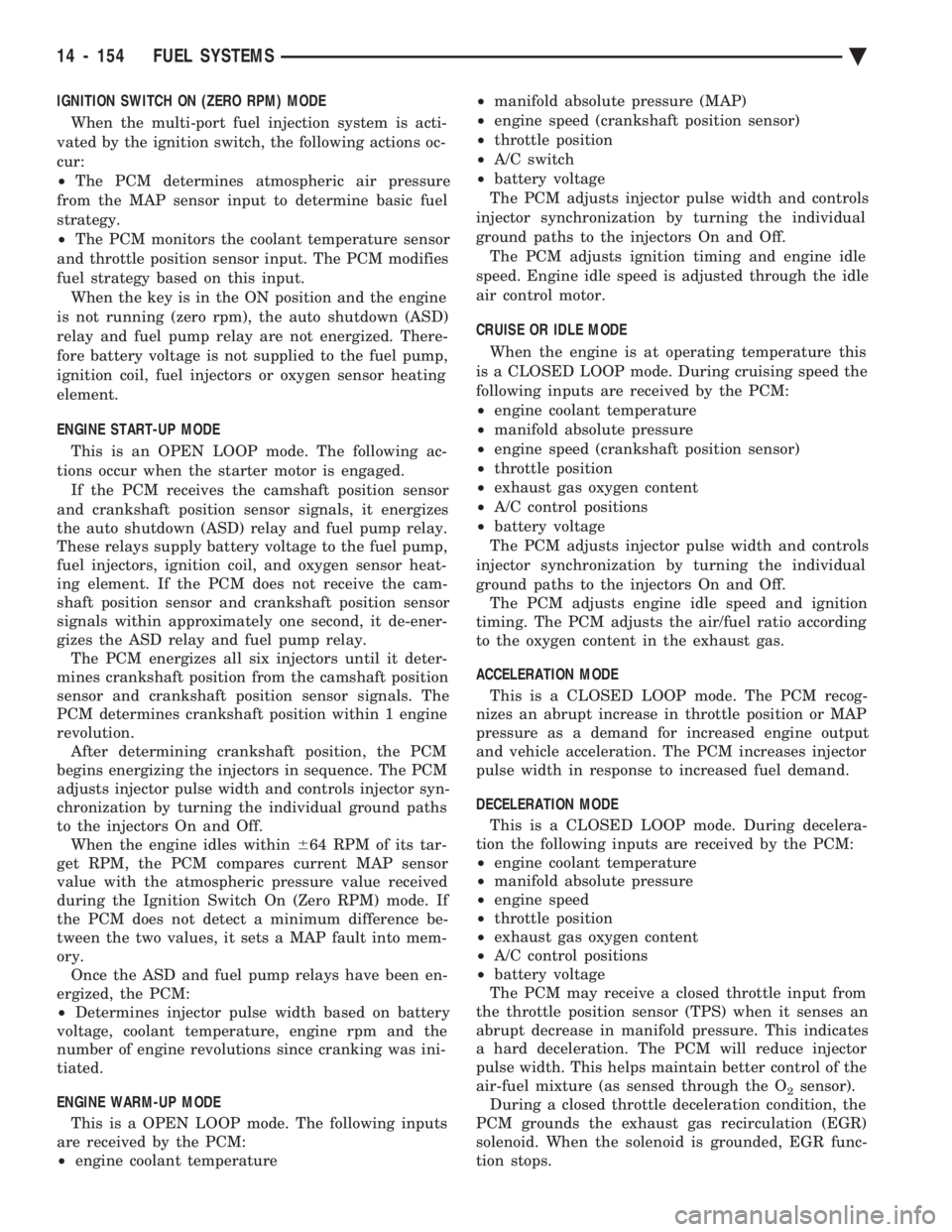

THROTTLE BODY

The throttle body assembly is located on the left

side of the intake manifold plenum (Fig. 19). The

throttle body houses the throttle position sensor and

the idle air control motor. Air flow through the throt- tle body is controlled by a cable operated throttle

blade located in the base of the throttle body.

FUEL SUPPLY CIRCUIT

Fuel is pumped to the fuel rail by an electrical

pump in the fuel tank. The pump inlet is fitted with

a strainer to prevent water and other contaminants

from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The regulator is mounted on the fuel rail. The regu-

lator uses intake manifold pressure as a reference.

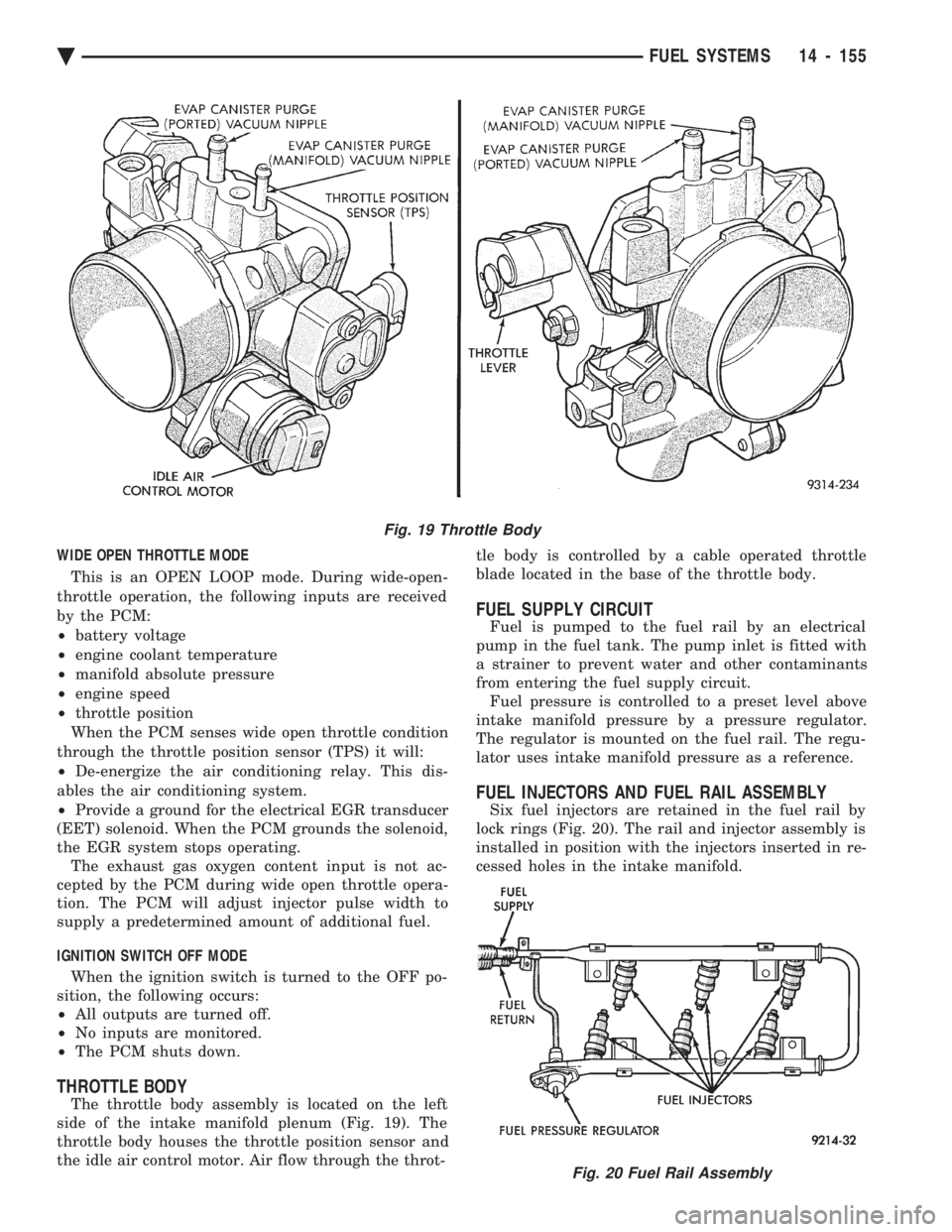

FUEL INJECTORS AND FUEL RAIL ASSEMBLY

Six fuel injectors are retained in the fuel rail by

lock rings (Fig. 20). The rail and injector assembly is

installed in position with the injectors inserted in re-

cessed holes in the intake manifold.

Fig. 19 Throttle Body

Fig. 20 Fuel Rail Assembly

Ä FUEL SYSTEMS 14 - 155

Page 1900 of 2438

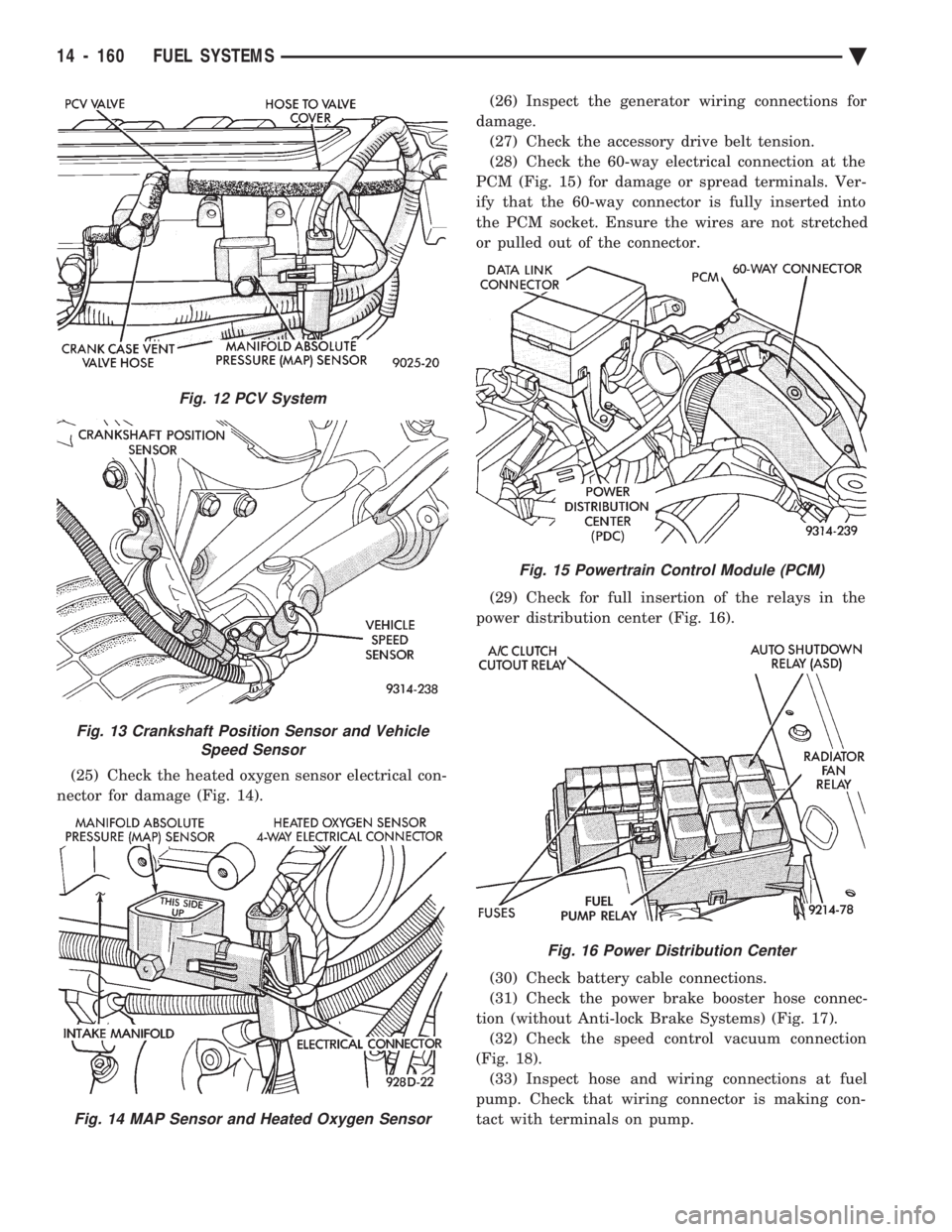

(25) Check the heated oxygen sensor electrical con-

nector for damage (Fig. 14). (26) Inspect the generator wiring connections for

damage. (27) Check the accessory drive belt tension.

(28) Check the 60-way electrical connection at the

PCM (Fig. 15) for damage or spread terminals. Ver-

ify that the 60-way connector is fully inserted into

the PCM socket. Ensure the wires are not stretched

or pulled out of the connector.

(29) Check for full insertion of the relays in the

power distribution center (Fig. 16).

(30) Check battery cable connections.

(31) Check the power brake booster hose connec-

tion (without Anti-lock Brake Systems) (Fig. 17). (32) Check the speed control vacuum connection

(Fig. 18). (33) Inspect hose and wiring connections at fuel

pump. Check that wiring connector is making con-

tact with terminals on pump.

Fig. 12 PCV System

Fig. 13 Crankshaft Position Sensor and Vehicle Speed Sensor

Fig. 14 MAP Sensor and Heated Oxygen Sensor

Fig. 15 Powertrain Control Module (PCM)

Fig. 16 Power Distribution Center

14 - 160 FUEL SYSTEMS Ä

Page 1906 of 2438

S/C Vacuum Solenoid

A/C Clutch Relay

EGR Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Engine Coolant Temperature

Engine Coolant Temp Sensor

Throttle Position

Minimum Throttle

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Spd (speed)

Engine Speed

DIS Sensor Status

Fault #1 Key-On Info

Module Spark Advance

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Speed Control Switch Voltage

Charging System Goal

Theft Alarm Status

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The circuit actuation test mode checks for proper

operation of output circuits or devices which the pow-

ertrain control module (PCM) cannot internally rec-

ognize. The PCM can attempt to activate these

outputs and allow an observer to verify proper oper-

ation. Most of the tests provide an audible or visual

indication of device operation (click of relay contacts,

spray fuel, etc.). Except for intermittent conditions, if

a device functions properly during testing, assume

the device, its associated wiring, and driver circuit

working correctly.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Ignition Coil #2

Ignition Coil #3

Fuel Injector #1

Fuel Injector #2

Fuel Injector #3

Fuel Injector #4

Fuel Injector #5

Fuel Injector #6

Idle Air Control Motor Open/Close

Radiator Fan Relay

A/C Clutch Relay

Auto Shutdown Relay

EVAP Purge Solenoid

S/C Servo Solenoids

Generator Field

EGR Solenoid

All Solenoids/Relays

ASD Fuel System Test

Speed Control Vacuum Solenoid

Speed Control Vent Solenoid

THROTTLE BODY MINIMUM AIR FLOW CHECK

PROCEDURE

(1) Warm engine in Park or Neutral until the cool-

ing fan has cycled on and off at least once. (2) Ensure that all accessories are off.

(3) Shut off engine.

(4) Disconnect the PCV valve hose from the intake

manifold nipple. (5) Attach Air Metering Fitting #6457 (0.125 in.

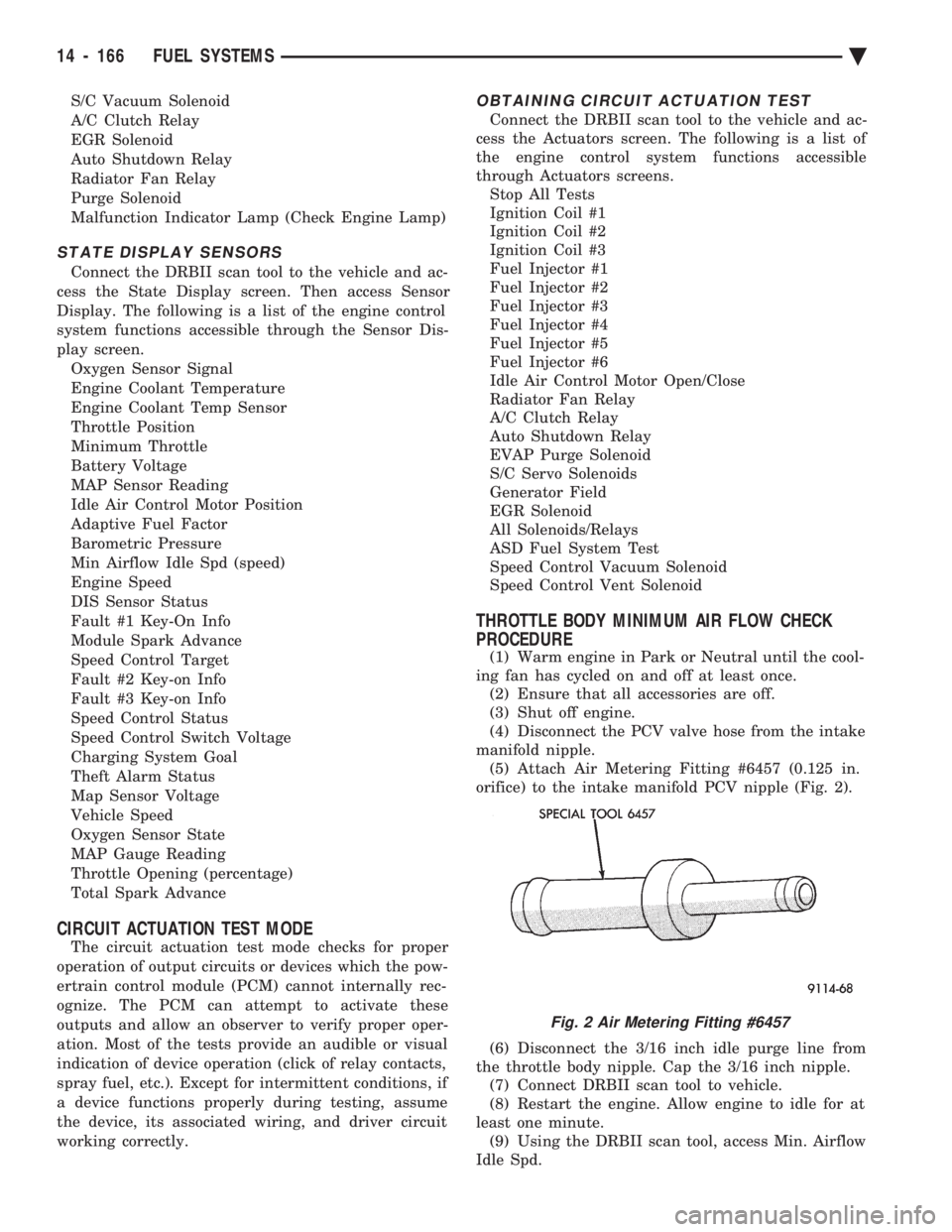

orifice) to the intake manifold PCV nipple (Fig. 2).

(6) Disconnect the 3/16 inch idle purge line from

the throttle body nipple. Cap the 3/16 inch nipple. (7) Connect DRBII scan tool to vehicle.

(8) Restart the engine. Allow engine to idle for at

least one minute. (9) Using the DRBII scan tool, access Min. Airflow

Idle Spd.

Fig. 2 Air Metering Fitting #6457

14 - 166 FUEL SYSTEMS Ä

Page 1909 of 2438

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES INDEX

page page

Camshaft Position Sensor Service ........... 176

Crankshaft Position Sensor ................ 176

EVAP Canister Purge Solenoid Service ....... 175

Fuel Injector ........................... 174

Fuel Injector Rail Assembly ................ 170

Fuel Pressure Regulator .................. 173

Fuel System Pressure Release Procedure ..... 169 Heated Oxygen Sensor (O

2Sensor) Service . . . 177

Idle Air Control Motor .................... 170

Manifold Absolute Pressure (MAP) Sensor ..... 175

PCM Service ........................... 175

Throttle Body ........................... 169

Throttle Body Removal ................... 169

Throttle Position Sensor .................. 169

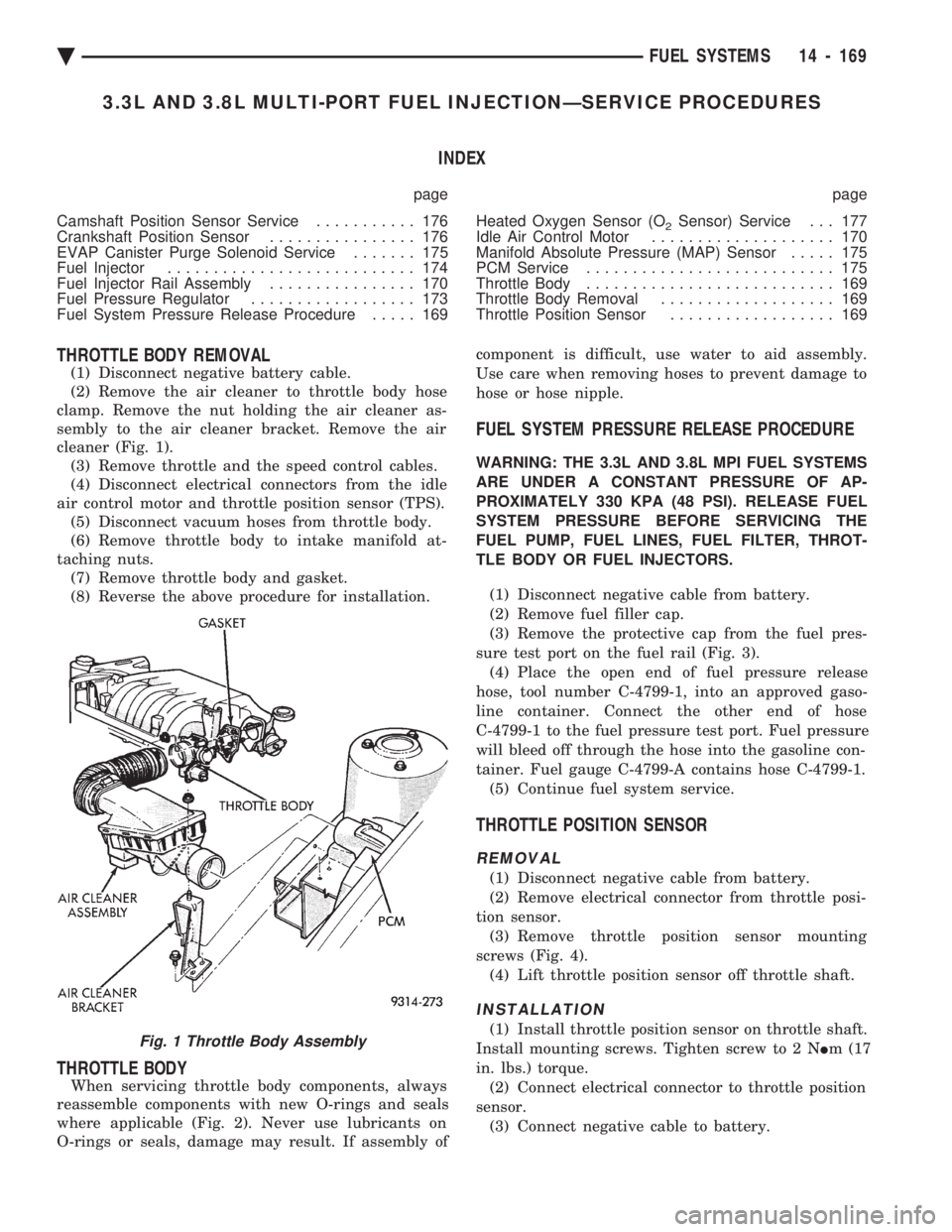

THROTTLE BODY REMOVAL

(1) Disconnect negative battery cable.

(2) Remove the air cleaner to throttle body hose

clamp. Remove the nut holding the air cleaner as-

sembly to the air cleaner bracket. Remove the air

cleaner (Fig. 1). (3) Remove throttle and the speed control cables.

(4) Disconnect electrical connectors from the idle

air control motor and throttle position sensor (TPS). (5) Disconnect vacuum hoses from throttle body.

(6) Remove throttle body to intake manifold at-

taching nuts. (7) Remove throttle body and gasket.

(8) Reverse the above procedure for installation.

THROTTLE BODY

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable (Fig. 2). Never use lubricants on

O-rings or seals, damage may result. If assembly of component is difficult, use water to aid assembly.

Use care when removing hoses to prevent damage to

hose or hose nipple.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING: THE 3.3L AND 3.8L MPI FUEL SYSTEMS

ARE UNDER A CONSTANT PRESSURE OF AP-

PROXIMATELY 330 KPA (48 PSI). RELEASE FUEL

SYSTEM PRESSURE BEFORE SERVICING THE

FUEL PUMP, FUEL LINES, FUEL FILTER, THROT-

TLE BODY OR FUEL INJECTORS.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

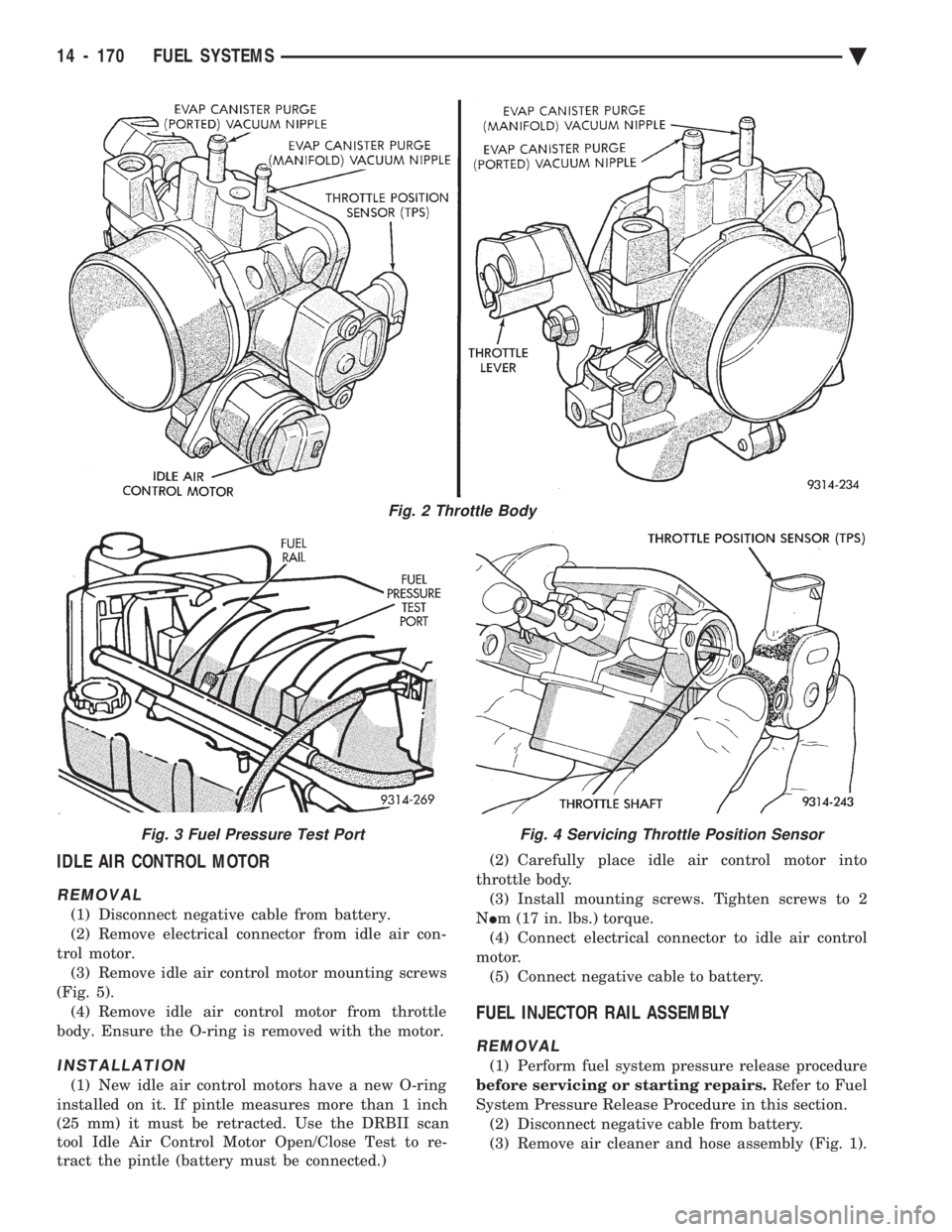

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 3). (4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso-

line container. Connect the other end of hose

C-4799-1 to the fuel pressure test port. Fuel pressure

will bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1. (5) Continue fuel system service.

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from throttle posi-

tion sensor. (3) Remove throttle position sensor mounting

screws (Fig. 4). (4) Lift throttle position sensor off throttle shaft.

INSTALLATION

(1) Install throttle position sensor on throttle shaft.

Install mounting screws. Tighten screw to 2 N Im (17

in. lbs.) torque. (2) Connect electrical connector to throttle position

sensor. (3) Connect negative cable to battery.Fig. 1 Throttle Body Assembly

Ä FUEL SYSTEMS 14 - 169

Page 1910 of 2438

IDLE AIR CONTROL MOTOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air con-

trol motor. (3) Remove idle air control motor mounting screws

(Fig. 5). (4) Remove idle air control motor from throttle

body. Ensure the O-ring is removed with the motor.

INSTALLATION

(1) New idle air control motors have a new O-ring

installed on it. If pintle measures more than 1 inch

(25 mm) it must be retracted. Use the DRBII scan

tool Idle Air Control Motor Open/Close Test to re-

tract the pintle (battery must be connected.) (2) Carefully place idle air control motor into

throttle body. (3) Install mounting screws. Tighten screws to 2

N Im (17 in. lbs.) torque.

(4) Connect electrical connector to idle air control

motor. (5) Connect negative cable to battery.

FUEL INJECTOR RAIL ASSEMBLY

REMOVAL

(1) Perform fuel system pressure release procedure

before servicing or starting repairs. Refer to Fuel

System Pressure Release Procedure in this section. (2) Disconnect negative cable from battery.

(3) Remove air cleaner and hose assembly (Fig. 1).

Fig. 2 Throttle Body

Fig. 3 Fuel Pressure Test PortFig. 4 Servicing Throttle Position Sensor

14 - 170 FUEL SYSTEMS Ä

Page 1913 of 2438

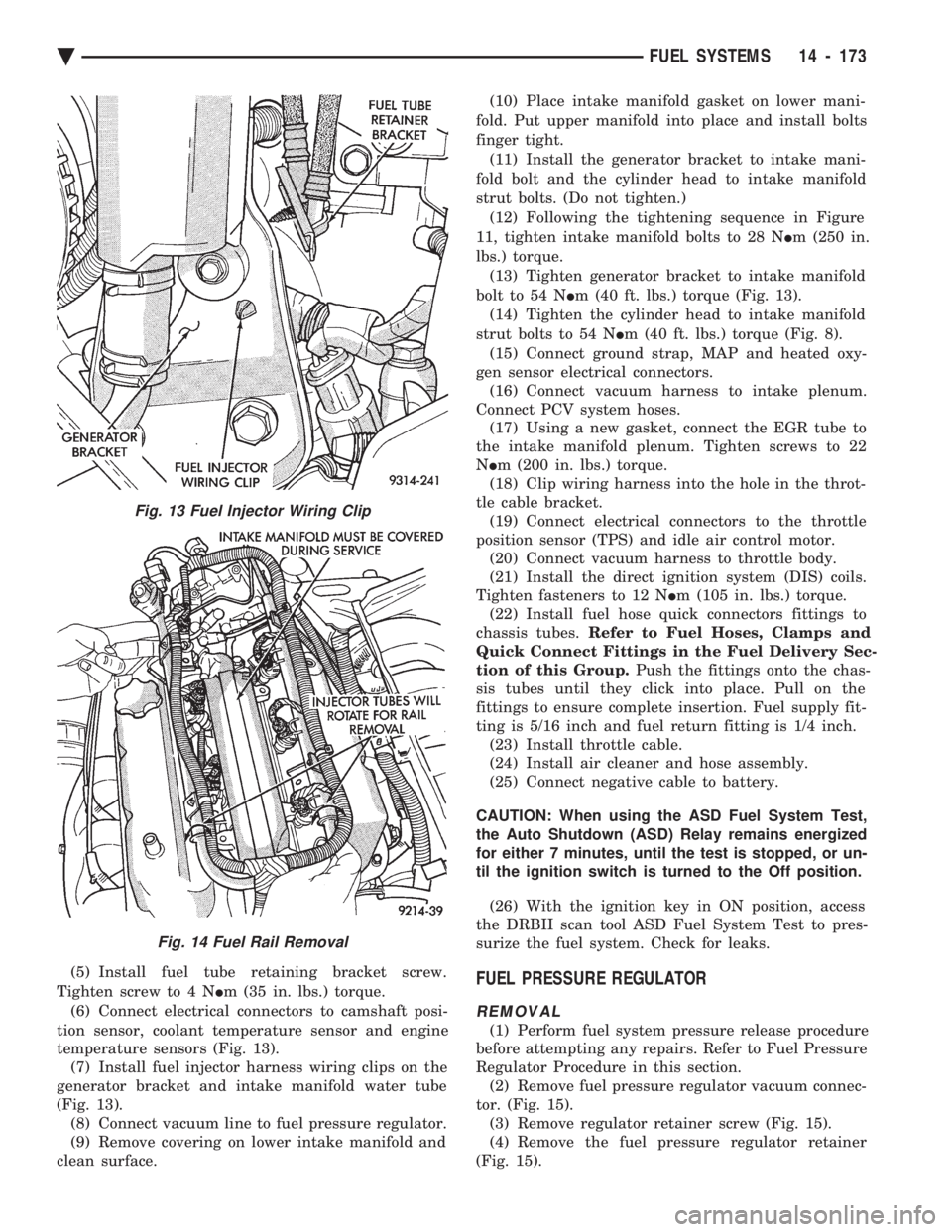

(5) Install fuel tube retaining bracket screw.

Tighten screw to 4 N Im (35 in. lbs.) torque.

(6) Connect electrical connectors to camshaft posi-

tion sensor, coolant temperature sensor and engine

temperature sensors (Fig. 13). (7) Install fuel injector harness wiring clips on the

generator bracket and intake manifold water tube

(Fig. 13). (8) Connect vacuum line to fuel pressure regulator.

(9) Remove covering on lower intake manifold and

clean surface. (10) Place intake manifold gasket on lower mani-

fold. Put upper manifold into place and install bolts

finger tight. (11) Install the generator bracket to intake mani-

fold bolt and the cylinder head to intake manifold

strut bolts. (Do not tighten.) (12) Following the tightening sequence in Figure

11, tighten intake manifold bolts to 28 N Im (250 in.

lbs.) torque. (13) Tighten generator bracket to intake manifold

bolt to 54 N Im (40 ft. lbs.) torque (Fig. 13).

(14) Tighten the cylinder head to intake manifold

strut bolts to 54 N Im (40 ft. lbs.) torque (Fig. 8).

(15) Connect ground strap, MAP and heated oxy-

gen sensor electrical connectors. (16) Connect vacuum harness to intake plenum.

Connect PCV system hoses. (17) Using a new gasket, connect the EGR tube to

the intake manifold plenum. Tighten screws to 22

N Im (200 in. lbs.) torque.

(18) Clip wiring harness into the hole in the throt-

tle cable bracket. (19) Connect electrical connectors to the throttle

position sensor (TPS) and idle air control motor. (20) Connect vacuum harness to throttle body.

(21) Install the direct ignition system (DIS) coils.

Tighten fasteners to 12 N Im (105 in. lbs.) torque.

(22) Install fuel hose quick connectors fittings to

chassis tubes. Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in the Fuel Delivery Sec-

tion of this Group. Push the fittings onto the chas-

sis tubes until they click into place. Pull on the

fittings to ensure complete insertion. Fuel supply fit-

ting is 5/16 inch and fuel return fitting is 1/4 inch. (23) Install throttle cable.

(24) Install air cleaner and hose assembly.

(25) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(26) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.FUEL PRESSURE REGULATOR

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs. Refer to Fuel Pressure

Regulator Procedure in this section. (2) Remove fuel pressure regulator vacuum connec-

tor. (Fig. 15). (3) Remove regulator retainer screw (Fig. 15).

(4) Remove the fuel pressure regulator retainer

(Fig. 15).

Fig. 13 Fuel Injector Wiring Clip

Fig. 14 Fuel Rail Removal

Ä FUEL SYSTEMS 14 - 173

Page 1915 of 2438

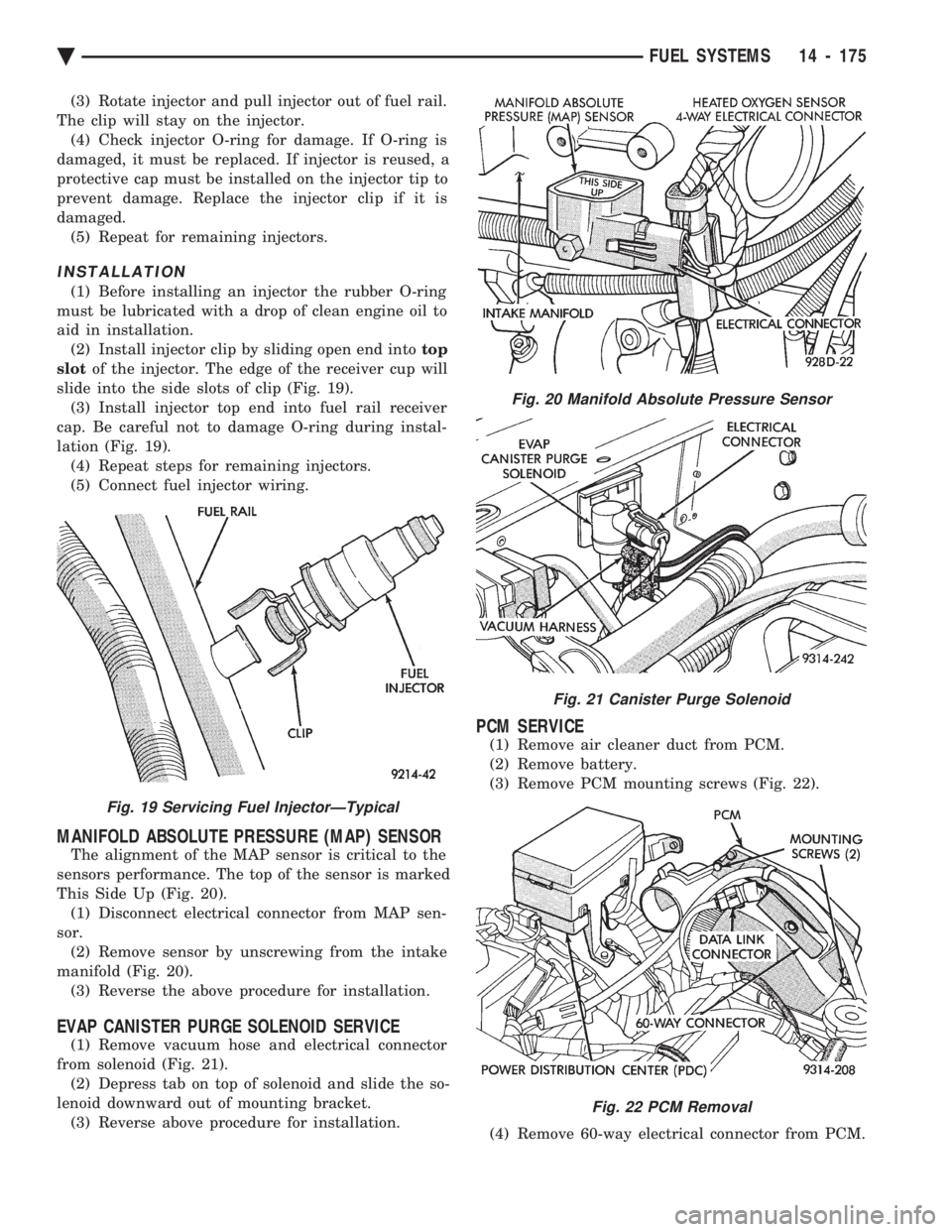

(3) Rotate injector and pull injector out of fuel rail.

The clip will stay on the injector. (4) Check injector O-ring for damage. If O-ring is

damaged, it must be replaced. If injector is reused, a

protective cap must be installed on the injector tip to

prevent damage. Replace the injector clip if it is

damaged. (5) Repeat for remaining injectors.

INSTALLATION

(1) Before installing an injector the rubber O-ring

must be lubricated with a drop of clean engine oil to

aid in installation. (2) Install injector clip by sliding open end into top

slot of the injector. The edge of the receiver cup will

slide into the side slots of clip (Fig. 19). (3) Install injector top end into fuel rail receiver

cap. Be careful not to damage O-ring during instal-

lation (Fig. 19). (4) Repeat steps for remaining injectors.

(5) Connect fuel injector wiring.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The alignment of the MAP sensor is critical to the

sensors performance. The top of the sensor is marked

This Side Up (Fig. 20). (1) Disconnect electrical connector from MAP sen-

sor. (2) Remove sensor by unscrewing from the intake

manifold (Fig. 20). (3) Reverse the above procedure for installation.

EVAP CANISTER PURGE SOLENOID SERVICE

(1) Remove vacuum hose and electrical connector

from solenoid (Fig. 21). (2) Depress tab on top of solenoid and slide the so-

lenoid downward out of mounting bracket. (3) Reverse above procedure for installation.

PCM SERVICE

(1) Remove air cleaner duct from PCM.

(2) Remove battery.

(3) Remove PCM mounting screws (Fig. 22).

(4) Remove 60-way electrical connector from PCM.

Fig. 19 Servicing Fuel InjectorÐTypical

Fig. 20 Manifold Absolute Pressure Sensor

Fig. 21 Canister Purge Solenoid

Fig. 22 PCM Removal

Ä FUEL SYSTEMS 14 - 175

Page 1929 of 2438

INSTALL

(1) Install power steering pressure switch into fit-

ting on power steering pressure hose by hand until

fully seated. Then torque power steering pressure

switch to 12 N Im (106 in. lbs.).

(2) Install vehicle wiring harness connector onto

power steering pressure switch. Be sure latch on wir-

ing harness connector is fully engaged with locking

tab on power steering pressure switch.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(3) Fill power steering pump reservoir to correct

fluid level. (4) Connect negative cable back on negative post of

battery. (5) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING HOSES

Service all power steering hoses with the vehicle

raised on a hoist. Cap all open ends of hoses, power

steering pump fittings and steering gear ports to pre-

vent entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE PARTS

AND EXHAUST SYSTEM MAY BE EXTREMELY HOT

IF ENGINE HAS BEEN RUNNING. DO NOT START

ENGINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

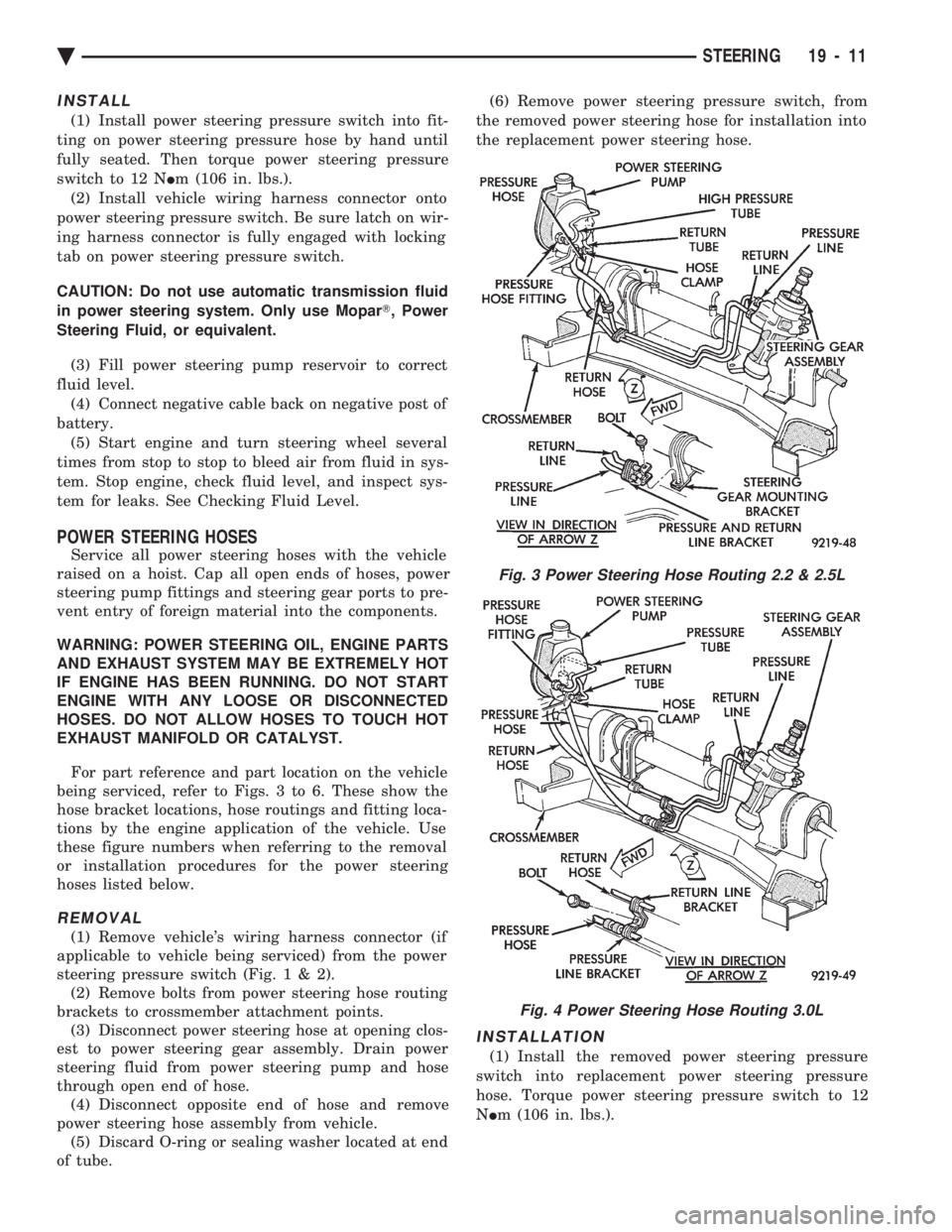

For part reference and part location on the vehicle

being serviced, refer to Figs. 3 to 6. These show the

hose bracket locations, hose routings and fitting loca-

tions by the engine application of the vehicle. Use

these figure numbers when referring to the removal

or installation procedures for the power steering

hoses listed below.

REMOVAL

(1) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig .1&2).

(2) Remove bolts from power steering hose routing

brackets to crossmember attachment points. (3) Disconnect power steering hose at opening clos-

est to power steering gear assembly. Drain power

steering fluid from power steering pump and hose

through open end of hose. (4) Disconnect opposite end of hose and remove

power steering hose assembly from vehicle. (5) Discard O-ring or sealing washer located at end

of tube. (6) Remove power steering pressure switch, from

the removed power steering hose for installation into

the replacement power steering hose.

INSTALLATION

(1) Install the removed power steering pressure

switch into replacement power steering pressure

hose. Torque power steering pressure switch to 12

N Im (106 in. lbs.).

Fig. 3 Power Steering Hose Routing 2.2 & 2.5L

Fig. 4 Power Steering Hose Routing 3.0L

Ä STEERING 19 - 11