battery CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2215 of 2438

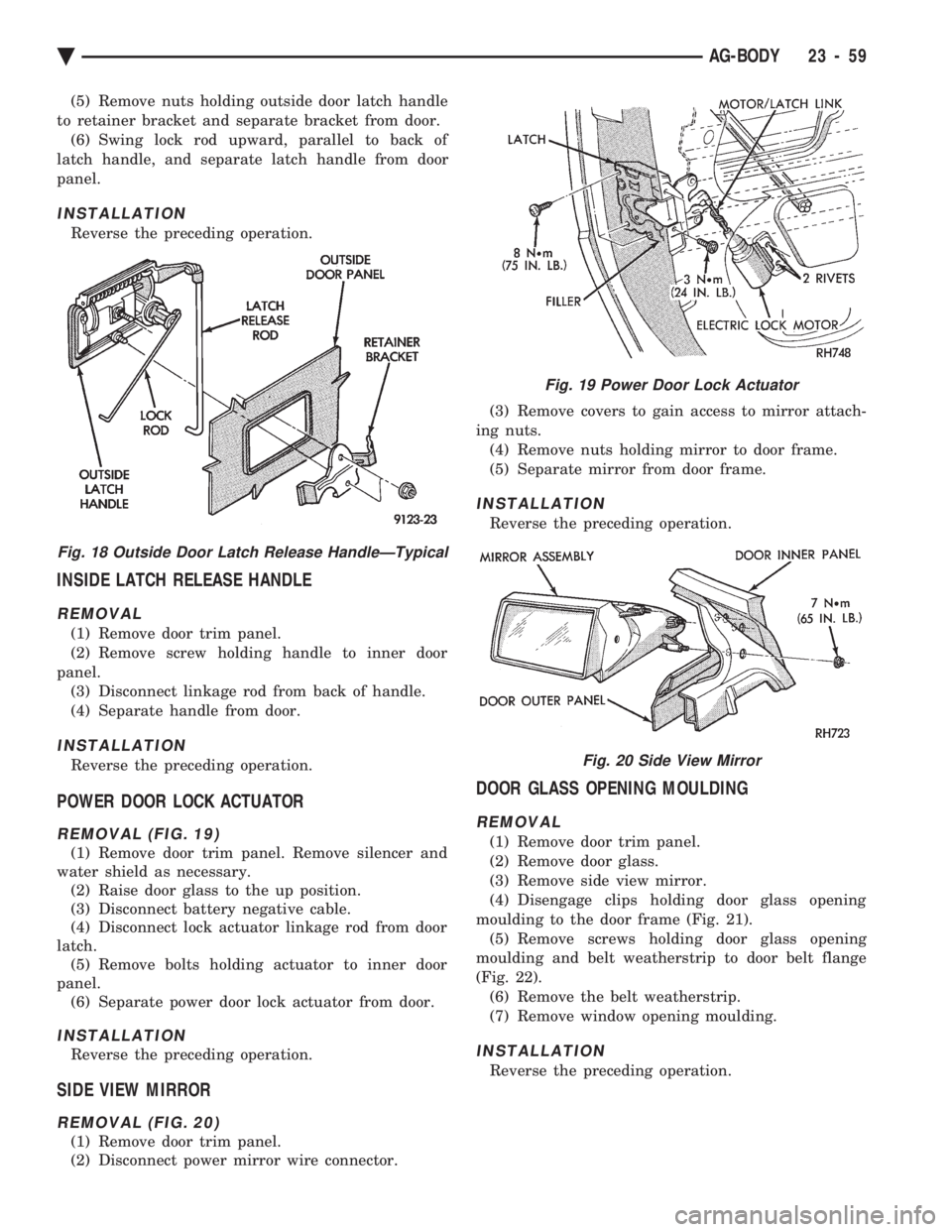

(5) Remove nuts holding outside door latch handle

to retainer bracket and separate bracket from door. (6) Swing lock rod upward, parallel to back of

latch handle, and separate latch handle from door

panel.

INSTALLATION

Reverse the preceding operation.

INSIDE LATCH RELEASE HANDLE

REMOVAL

(1) Remove door trim panel.

(2) Remove screw holding handle to inner door

panel. (3) Disconnect linkage rod from back of handle.

(4) Separate handle from door.

INSTALLATION

Reverse the preceding operation.

POWER DOOR LOCK ACTUATOR

REMOVAL (FIG. 19)

(1) Remove door trim panel. Remove silencer and

water shield as necessary. (2) Raise door glass to the up position.

(3) Disconnect battery negative cable.

(4) Disconnect lock actuator linkage rod from door

latch. (5) Remove bolts holding actuator to inner door

panel. (6) Separate power door lock actuator from door.

INSTALLATION

Reverse the preceding operation.

SIDE VIEW MIRROR

REMOVAL (FIG. 20)

(1) Remove door trim panel.

(2) Disconnect power mirror wire connector. (3) Remove covers to gain access to mirror attach-

ing nuts. (4) Remove nuts holding mirror to door frame.

(5) Separate mirror from door frame.

INSTALLATION

Reverse the preceding operation.

DOOR GLASS OPENING MOULDING

REMOVAL

(1) Remove door trim panel.

(2) Remove door glass.

(3) Remove side view mirror.

(4) Disengage clips holding door glass opening

moulding to the door frame (Fig. 21). (5) Remove screws holding door glass opening

moulding and belt weatherstrip to door belt flange

(Fig. 22). (6) Remove the belt weatherstrip.

(7) Remove window opening moulding.

INSTALLATION

Reverse the preceding operation.

Fig. 18 Outside Door Latch Release HandleÐTypical

Fig. 19 Power Door Lock Actuator

Fig. 20 Side View Mirror

Ä AG-BODY 23 - 59

Page 2221 of 2438

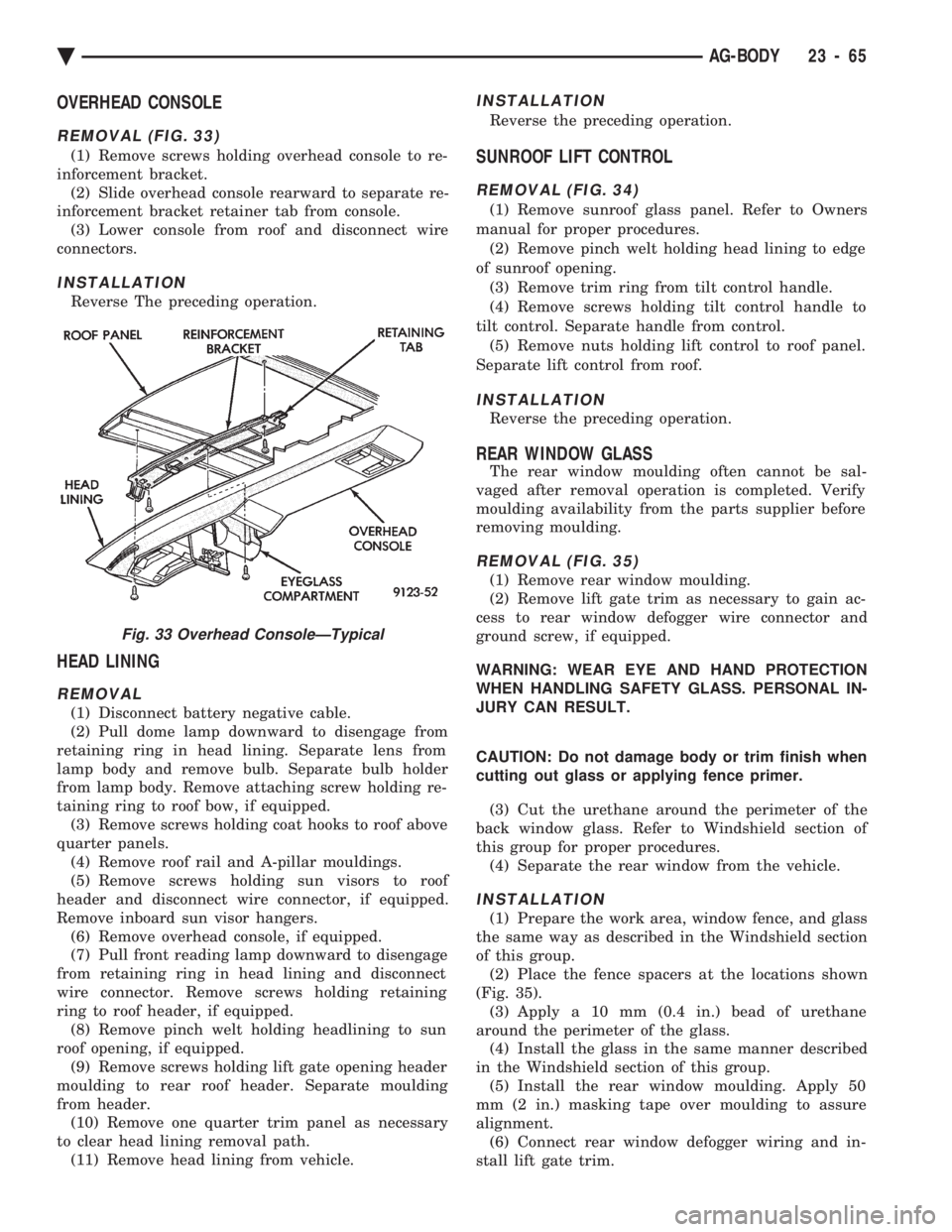

OVERHEAD CONSOLE

REMOVAL (FIG. 33)

(1) Remove screws holding overhead console to re-

inforcement bracket. (2) Slide overhead console rearward to separate re-

inforcement bracket retainer tab from console. (3) Lower console from roof and disconnect wire

connectors.

INSTALLATION

Reverse The preceding operation.

HEAD LINING

REMOVAL

(1) Disconnect battery negative cable.

(2) Pull dome lamp downward to disengage from

retaining ring in head lining. Separate lens from

lamp body and remove bulb. Separate bulb holder

from lamp body. Remove attaching screw holding re-

taining ring to roof bow, if equipped. (3) Remove screws holding coat hooks to roof above

quarter panels. (4) Remove roof rail and A-pillar mouldings.

(5) Remove screws holding sun visors to roof

header and disconnect wire connector, if equipped.

Remove inboard sun visor hangers. (6) Remove overhead console, if equipped.

(7) Pull front reading lamp downward to disengage

from retaining ring in head lining and disconnect

wire connector. Remove screws holding retaining

ring to roof header, if equipped. (8) Remove pinch welt holding headlining to sun

roof opening, if equipped. (9) Remove screws holding lift gate opening header

moulding to rear roof header. Separate moulding

from header. (10) Remove one quarter trim panel as necessary

to clear head lining removal path. (11) Remove head lining from vehicle.

INSTALLATION

Reverse the preceding operation.

SUNROOF LIFT CONTROL

REMOVAL (FIG. 34)

(1) Remove sunroof glass panel. Refer to Owners

manual for proper procedures. (2) Remove pinch welt holding head lining to edge

of sunroof opening. (3) Remove trim ring from tilt control handle.

(4) Remove screws holding tilt control handle to

tilt control. Separate handle from control. (5) Remove nuts holding lift control to roof panel.

Separate lift control from roof.

INSTALLATION

Reverse the preceding operation.

REAR WINDOW GLASS

The rear window moulding often cannot be sal-

vaged after removal operation is completed. Verify

moulding availability from the parts supplier before

removing moulding.

REMOVAL (FIG. 35)

(1) Remove rear window moulding.

(2) Remove lift gate trim as necessary to gain ac-

cess to rear window defogger wire connector and

ground screw, if equipped.

WARNING: WEAR EYE AND HAND PROTECTION

WHEN HANDLING SAFETY GLASS. PERSONAL IN-

JURY CAN RESULT.

CAUTION: Do not damage body or trim finish when

cutting out glass or applying fence primer.

(3) Cut the urethane around the perimeter of the

back window glass. Refer to Windshield section of

this group for proper procedures. (4) Separate the rear window from the vehicle.

INSTALLATION

(1) Prepare the work area, window fence, and glass

the same way as described in the Windshield section

of this group. (2) Place the fence spacers at the locations shown

(Fig. 35). (3) Apply a 10 mm (0.4 in.) bead of urethane

around the perimeter of the glass. (4) Install the glass in the same manner described

in the Windshield section of this group. (5) Install the rear window moulding. Apply 50

mm (2 in.) masking tape over moulding to assure

alignment. (6) Connect rear window defogger wiring and in-

stall lift gate trim.

Fig. 33 Overhead ConsoleÐTypical

Ä AG-BODY 23 - 65

Page 2229 of 2438

(4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

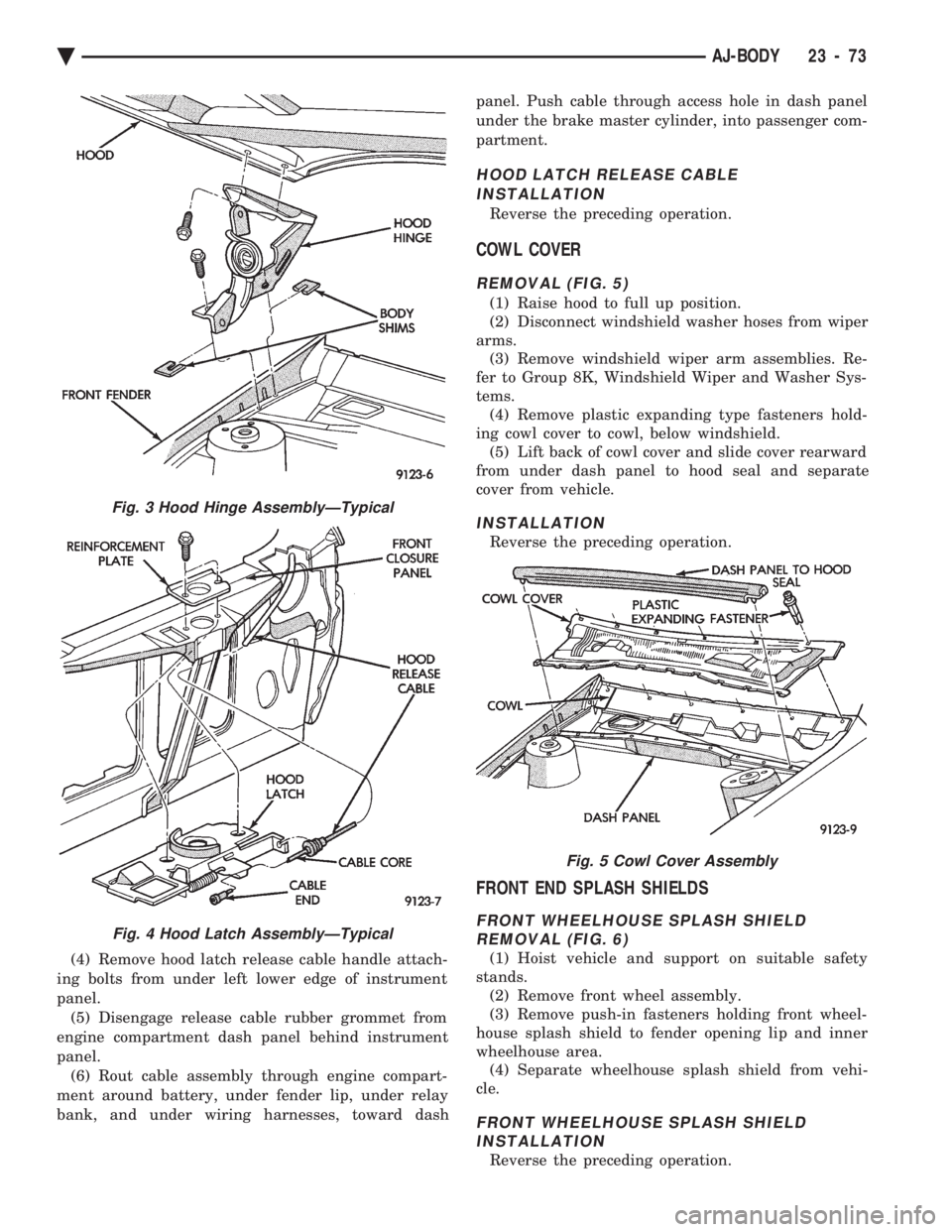

COWL COVER

REMOVAL (FIG. 5)

(1) Raise hood to full up position.

(2) Disconnect windshield washer hoses from wiper

arms. (3) Remove windshield wiper arm assemblies. Re-

fer to Group 8K, Windshield Wiper and Washer Sys-

tems. (4) Remove plastic expanding type fasteners hold-

ing cowl cover to cowl, below windshield. (5) Lift back of cowl cover and slide cover rearward

from under dash panel to hood seal and separate

cover from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELD REMOVAL (FIG. 6)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

Fig. 3 Hood Hinge AssemblyÐTypical

Fig. 4 Hood Latch AssemblyÐTypical

Fig. 5 Cowl Cover Assembly

Ä AJ-BODY 23 - 73

Page 2230 of 2438

TRANSAXLE SPLASH SHIELD REMOVAL (FIG. 6)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 7)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

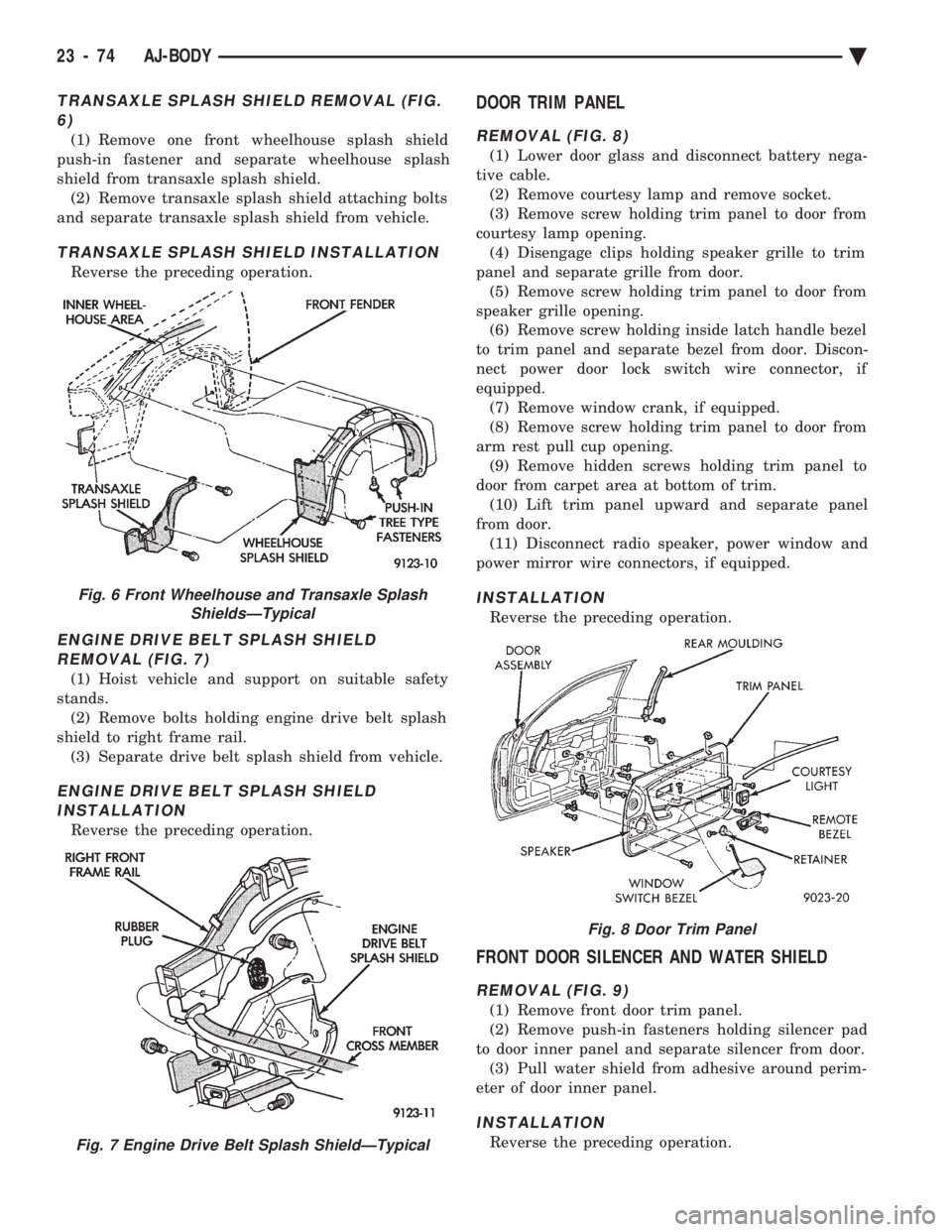

DOOR TRIM PANEL

REMOVAL (FIG. 8)

(1) Lower door glass and disconnect battery nega-

tive cable. (2) Remove courtesy lamp and remove socket.

(3) Remove screw holding trim panel to door from

courtesy lamp opening. (4) Disengage clips holding speaker grille to trim

panel and separate grille from door. (5) Remove screw holding trim panel to door from

speaker grille opening. (6) Remove screw holding inside latch handle bezel

to trim panel and separate bezel from door. Discon-

nect power door lock switch wire connector, if

equipped. (7) Remove window crank, if equipped.

(8) Remove screw holding trim panel to door from

arm rest pull cup opening. (9) Remove hidden screws holding trim panel to

door from carpet area at bottom of trim. (10) Lift trim panel upward and separate panel

from door. (11) Disconnect radio speaker, power window and

power mirror wire connectors, if equipped.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR SILENCER AND WATER SHIELD

REMOVAL (FIG. 9)

(1) Remove front door trim panel.

(2) Remove push-in fasteners holding silencer pad

to door inner panel and separate silencer from door. (3) Pull water shield from adhesive around perim-

eter of door inner panel.

INSTALLATION

Reverse the preceding operation.

Fig. 6 Front Wheelhouse and Transaxle Splash ShieldsÐTypical

Fig. 7 Engine Drive Belt Splash ShieldÐTypical

Fig. 8 Door Trim Panel

23 - 74 AJ-BODY Ä

Page 2232 of 2438

DOOR GLASS

REMOVAL

(1) Remove door trim panel.

(2) Remove silencer and water shield.

(3) Raise door glass 100 mm (4 in.) from down po-

sition. (4) Disconnect battery negative cable if equipped

with power windows. (5) Loosen bolts holding glass stabilizers and guide

hook receiver to top of inner door frame. (6) Remove nuts holding door glass to lift plate.

(7) Separate glass from lift plate and lift glass up-

ward from opening at top of door.

INSTALLATION

Reverse the preceding operation.

DOOR GLASS LIFT PLATE AND GUIDE POST

REMOVAL

(1) Remove door trim panel.

(2) Remove silencer and water shield.

(3) Raise door glass 100 mm (4 in.) from down po-

sition. (4) Disconnect battery negative cable if equipped

with power windows. (5) Remove nuts holding door glass to lift plate

and separate glass from lift plate. Allow glass to

slide downward to the bottom of door. (6) Remove bolts (nuts on AJ-27 body) holding

guide post to inner door panel. (7) Separate lift plate channel from regulator lift

roller. (8) Remove lift plate and guide assemble from door

through access hole in inner door panel.

INSTALLATION

Reverse the preceding operation.

GLASS RUN WEATHERSTRIPÐAJ-21 BODY

REMOVAL

(1) Remove door trim panel.

(2) Remove silencer and water shield as necessary.

(3) Remove side view mirror cover.

(4) Pull glass run weatherstrip from door frame

channel.

INSTALLATION

Reverse the preceding operation.

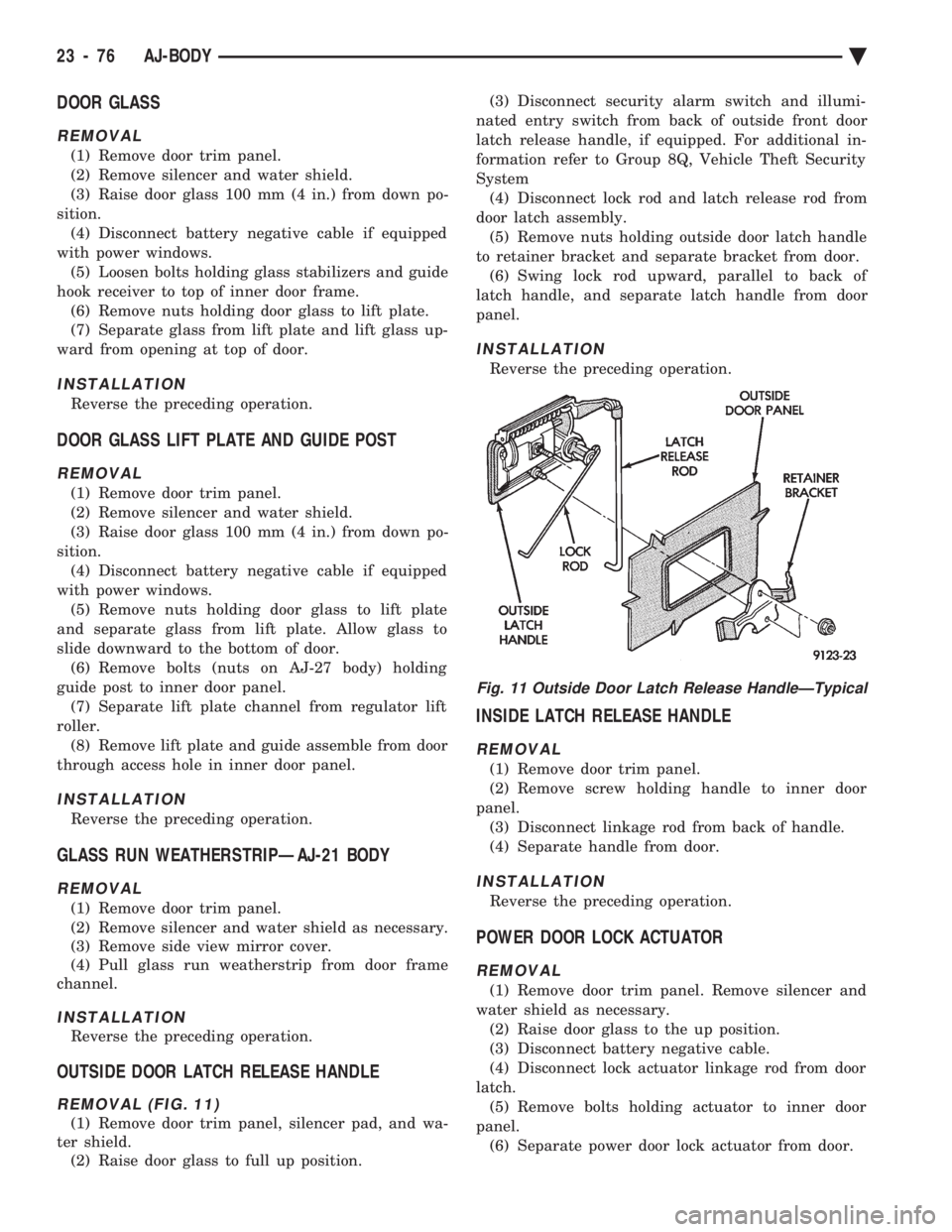

OUTSIDE DOOR LATCH RELEASE HANDLE

REMOVAL (FIG. 11)

(1) Remove door trim panel, silencer pad, and wa-

ter shield. (2) Raise door glass to full up position. (3) Disconnect security alarm switch and illumi-

nated entry switch from back of outside front door

latch release handle, if equipped. For additional in-

formation refer to Group 8Q, Vehicle Theft Security

System (4) Disconnect lock rod and latch release rod from

door latch assembly. (5) Remove nuts holding outside door latch handle

to retainer bracket and separate bracket from door. (6) Swing lock rod upward, parallel to back of

latch handle, and separate latch handle from door

panel.

INSTALLATION

Reverse the preceding operation.

INSIDE LATCH RELEASE HANDLE

REMOVAL

(1) Remove door trim panel.

(2) Remove screw holding handle to inner door

panel. (3) Disconnect linkage rod from back of handle.

(4) Separate handle from door.

INSTALLATION

Reverse the preceding operation.

POWER DOOR LOCK ACTUATOR

REMOVAL

(1) Remove door trim panel. Remove silencer and

water shield as necessary. (2) Raise door glass to the up position.

(3) Disconnect battery negative cable.

(4) Disconnect lock actuator linkage rod from door

latch. (5) Remove bolts holding actuator to inner door

panel. (6) Separate power door lock actuator from door.

Fig. 11 Outside Door Latch Release HandleÐTypical

23 - 76 AJ-BODY Ä

Page 2237 of 2438

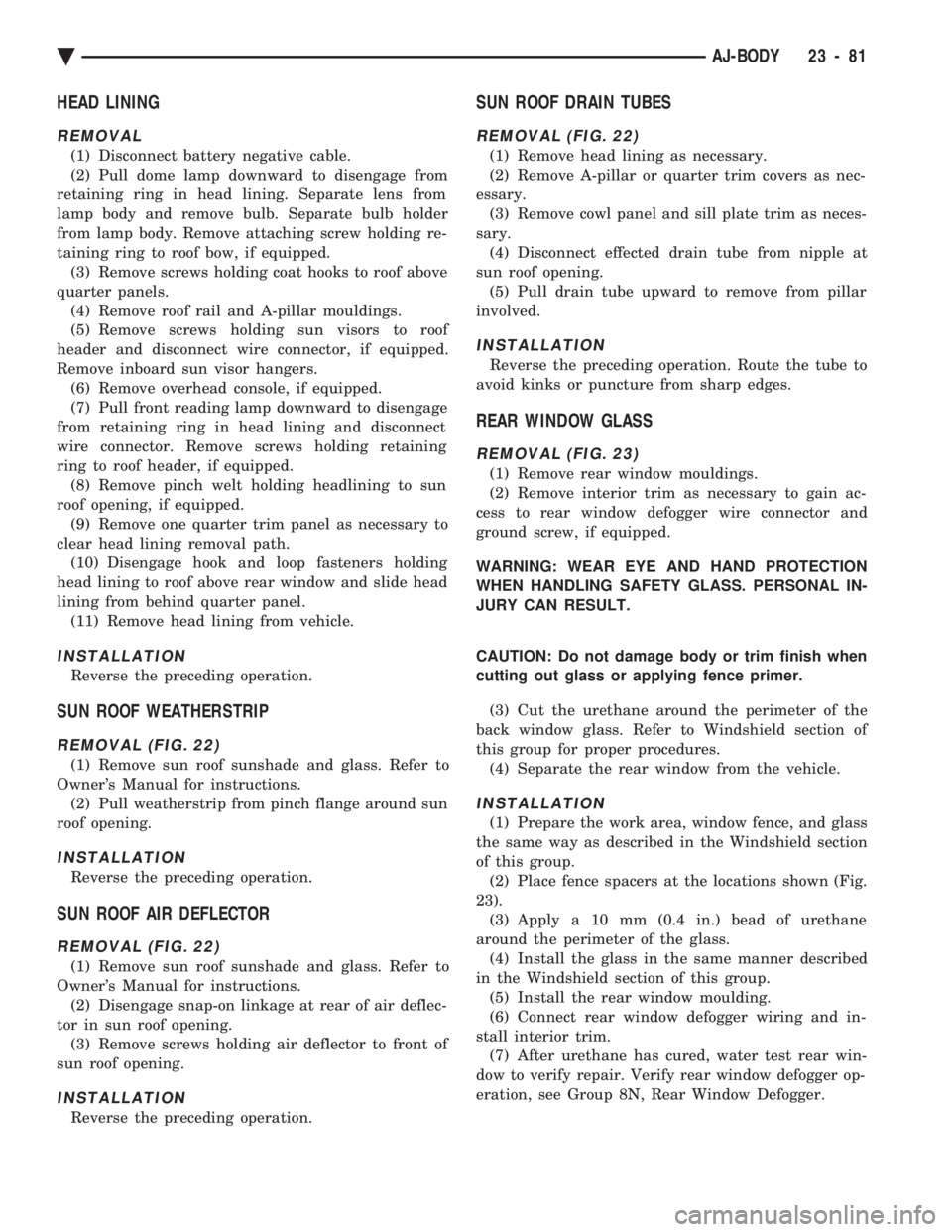

HEAD LINING

REMOVAL

(1) Disconnect battery negative cable.

(2) Pull dome lamp downward to disengage from

retaining ring in head lining. Separate lens from

lamp body and remove bulb. Separate bulb holder

from lamp body. Remove attaching screw holding re-

taining ring to roof bow, if equipped. (3) Remove screws holding coat hooks to roof above

quarter panels. (4) Remove roof rail and A-pillar mouldings.

(5) Remove screws holding sun visors to roof

header and disconnect wire connector, if equipped.

Remove inboard sun visor hangers. (6) Remove overhead console, if equipped.

(7) Pull front reading lamp downward to disengage

from retaining ring in head lining and disconnect

wire connector. Remove screws holding retaining

ring to roof header, if equipped. (8) Remove pinch welt holding headlining to sun

roof opening, if equipped. (9) Remove one quarter trim panel as necessary to

clear head lining removal path. (10) Disengage hook and loop fasteners holding

head lining to roof above rear window and slide head

lining from behind quarter panel. (11) Remove head lining from vehicle.

INSTALLATION

Reverse the preceding operation.

SUN ROOF WEATHERSTRIP

REMOVAL (FIG. 22)

(1) Remove sun roof sunshade and glass. Refer to

Owner's Manual for instructions. (2) Pull weatherstrip from pinch flange around sun

roof opening.

INSTALLATION

Reverse the preceding operation.

SUN ROOF AIR DEFLECTOR

REMOVAL (FIG. 22)

(1) Remove sun roof sunshade and glass. Refer to

Owner's Manual for instructions. (2) Disengage snap-on linkage at rear of air deflec-

tor in sun roof opening. (3) Remove screws holding air deflector to front of

sun roof opening.

INSTALLATION

Reverse the preceding operation.

SUN ROOF DRAIN TUBES

REMOVAL (FIG. 22)

(1) Remove head lining as necessary.

(2) Remove A-pillar or quarter trim covers as nec-

essary. (3) Remove cowl panel and sill plate trim as neces-

sary. (4) Disconnect effected drain tube from nipple at

sun roof opening. (5) Pull drain tube upward to remove from pillar

involved.

INSTALLATION

Reverse the preceding operation. Route the tube to

avoid kinks or puncture from sharp edges.

REAR WINDOW GLASS

REMOVAL (FIG. 23)

(1) Remove rear window mouldings.

(2) Remove interior trim as necessary to gain ac-

cess to rear window defogger wire connector and

ground screw, if equipped.

WARNING: WEAR EYE AND HAND PROTECTION

WHEN HANDLING SAFETY GLASS. PERSONAL IN-

JURY CAN RESULT.

CAUTION: Do not damage body or trim finish when

cutting out glass or applying fence primer.

(3) Cut the urethane around the perimeter of the

back window glass. Refer to Windshield section of

this group for proper procedures. (4) Separate the rear window from the vehicle.

INSTALLATION

(1) Prepare the work area, window fence, and glass

the same way as described in the Windshield section

of this group. (2) Place fence spacers at the locations shown (Fig.

23). (3) Apply a 10 mm (0.4 in.) bead of urethane

around the perimeter of the glass. (4) Install the glass in the same manner described

in the Windshield section of this group. (5) Install the rear window moulding.

(6) Connect rear window defogger wiring and in-

stall interior trim. (7) After urethane has cured, water test rear win-

dow to verify repair. Verify rear window defogger op-

eration, see Group 8N, Rear Window Defogger.

Ä AJ-BODY 23 - 81

Page 2251 of 2438

HYDRAULIC SYSTEMS

The power convertible top hydraulic system con-

sists of;

² Two hydraulic cylinders

² Hydraulic lines

² Electric hydraulic pump and reservoir

² Dual relays

HYDRAULIC SYSTEM TESTS

The convertible top will raise slowly or make ab-

normal noise if the hydraulic fluid level is low. (1) Remove sling well and floor cover.

(2) With the top up and latched, remove the reser-

voir fill plug. (3) Visually inspect fluid level. If low, inspect for

leak in hydraulic system. (4) Repair or replace components, as necessary.

(5) Fill reservoir with Dexron tII, Type A, auto-

matic transmission fluid to the bottom of the fill

hole. (6) Replace fill plug and lower top.

(7) Raise top and verify fluid level.

(8) Install sling well and floor cover.

HYDRAULIC PUMP ASSEMBLY

HYDRAULIC PUMP REMOVAL (FIG. 13)

(1) Disconnect battery negative cable.

(2) Remove sling well and floor cover from behind

rear seat. (3) Disconnect pump wire connector and ground

connection. (4) Disconnect hydraulic lines from pump.

(5) Remove motor pump assembly from vehicle.

The rubber mounts are pressed and locked into the

mounting bracket. Pull up motor assembly to re-

move.

HYDRAULIC PUMP INSTALLATION

Reverse the preceding operation

HYDRAULIC CYLINDER

HYDRAULIC CYLINDER REMOVAL

(1) Disconnect battery negative cable.

(2) Remove interior trim as necessary to gain ac-

cess to hydraulic cylinders. (3) Remove cylinder mounting bracket and nut.

(4) Remove pivot bolt holding cylinder shaft to top

linkage. (5) Disconnect hydraulic lines from the cylinder.

(6) Remove cylinder from vehicle.

HYDRAULIC CYLINDER INSTALLATION

Reverse the preceding operation, and verify each

hydraulic seal is in place when connecting the line to

the cylinder. Replace seal if damaged.

HYDRAULIC PUMP LINE SEALS

HYDRAULIC PUMP LINE SEALS REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect hydraulic lines from pump and re-

move seals.

HYDRAULIC PUMP LINE SEALS INSTALLATION

Reverse the preceding operation.

HYDRAULIC CYLINDER LINE SEALS

REMOVAL

(1) Remove hydraulic cylinder to gain access to hy-

draulic line connections. (2) Disconnect hydraulic lines from cylinder and

remove seals.

INSTALLATION

Reverse the preceding operation.

Ä AJ/27-BODY 23 - 95

Page 2254 of 2438

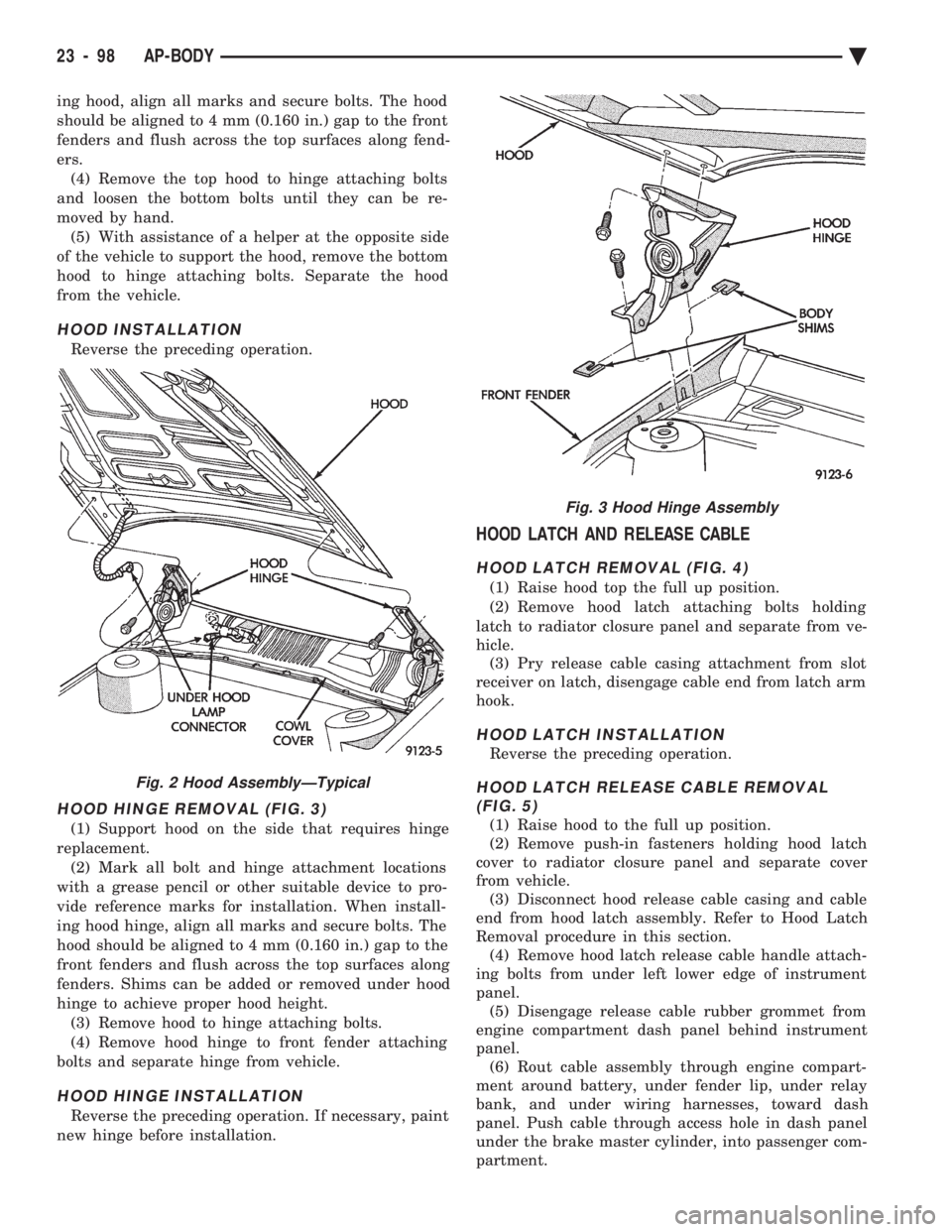

ing hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.(4) Remove the top hood to hinge attaching bolts

and loosen the bottom bolts until they can be re-

moved by hand. (5) With assistance of a helper at the opposite side

of the vehicle to support the hood, remove the bottom

hood to hinge attaching bolts. Separate the hood

from the vehicle.

HOOD INSTALLATION

Reverse the preceding operation.

HOOD HINGE REMOVAL (FIG. 3)

(1) Support hood on the side that requires hinge

replacement. (2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install-

ing hood hinge, align all marks and secure bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders. Shims can be added or removed under hood

hinge to achieve proper hood height. (3) Remove hood to hinge attaching bolts.

(4) Remove hood hinge to front fender attaching

bolts and separate hinge from vehicle.

HOOD HINGE INSTALLATION

Reverse the preceding operation. If necessary, paint

new hinge before installation.

HOOD LATCH AND RELEASE CABLE

HOOD LATCH REMOVAL (FIG. 4)

(1) Raise hood top the full up position.

(2) Remove hood latch attaching bolts holding

latch to radiator closure panel and separate from ve-

hicle. (3) Pry release cable casing attachment from slot

receiver on latch, disengage cable end from latch arm

hook.

HOOD LATCH INSTALLATION

Reverse the preceding operation.

HOOD LATCH RELEASE CABLE REMOVAL (FIG. 5)

(1) Raise hood to the full up position.

(2) Remove push-in fasteners holding hood latch

cover to radiator closure panel and separate cover

from vehicle. (3) Disconnect hood release cable casing and cable

end from hood latch assembly. Refer to Hood Latch

Removal procedure in this section. (4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash

panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

Fig. 2 Hood AssemblyÐTypical

Fig. 3 Hood Hinge Assembly

23 - 98 AP-BODY Ä

Page 2255 of 2438

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELDREMOVAL (FIG. 6)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

TRANSAXLE SPLASH SHIELD REMOVAL (FIG.6)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 7)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

FRONT DOOR TRIM PANELÐAP-24/44 Body

DOOR TRIM PANEL REMOVAL (FIG. 8)

(1) Move glass to down position.

(2) Disconnect battery negative cable.

(3) Remove inside latch release handle bezel. Pull

outward at forward edge and push bezel rearward. (4) Remove screw cover from window crank. Re-

move screw holding crank to regulator and separate

crank from door, if equipped. (5) Remove remote control mirror bezel.

(6) Remove screw covers from arm rest.

Fig. 4 Hood LatchÐTypical

Fig. 5 Hood Latch Release CableÐTypical

Fig. 6 Front Wheelhouse and Transaxle Splash Shields

Ä AP-BODY 23 - 99

Page 2258 of 2438

mately 50 mm (2 in.) up from bottom rearward cor-

ner of glass through opening in inner door panel.

Push handle of tool toward glass to open channel.

Pull upward at front of glass to separate the slide

from the channel. Do not allow upper slide to snap

bank into channel. (5) Rotate front of glass downward and slide glass

forward to separate glass lift channel from regulator

lift arm roller. (6) Remove door glass through opening at top of

door.

INSTALLATION

(1) Lower door glass into opening at top of door.

(2) Tip rear of glass downward and insert window

regulator lift arm roller into glass lift channel. (3) Guide door glass into glass run weatherstrip at

front of door. (4) Push top of glass rearward to snap top slide

into glass run channel. (5) Push downward at front of glass to snap bottom

slide into glass run channel. (6) Install water shield, silencer pad and trim

panel.

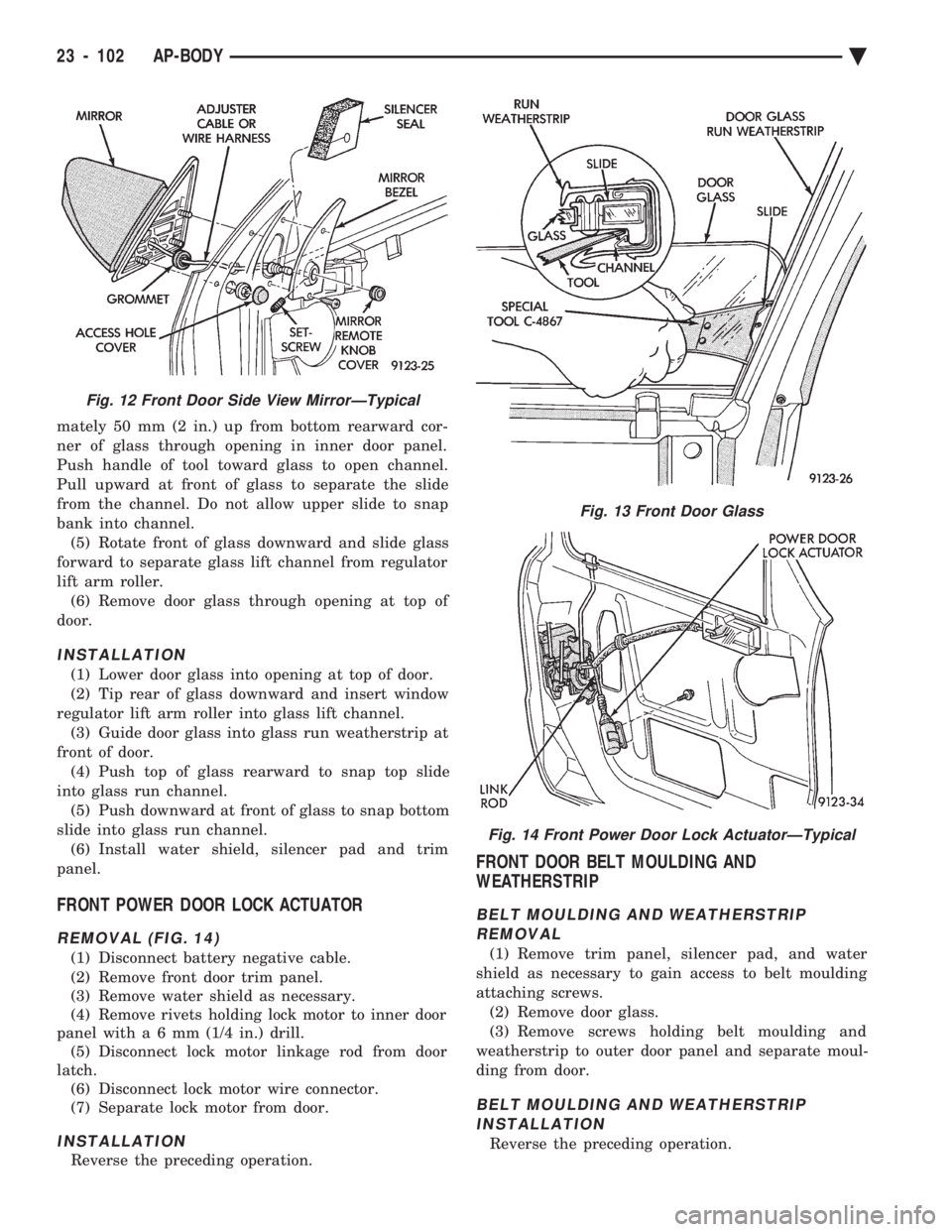

FRONT POWER DOOR LOCK ACTUATOR

REMOVAL (FIG. 14)

(1) Disconnect battery negative cable.

(2) Remove front door trim panel.

(3) Remove water shield as necessary.

(4) Remove rivets holding lock motor to inner door

panel wit ha6mm (1/4 in.) drill.

(5) Disconnect lock motor linkage rod from door

latch. (6) Disconnect lock motor wire connector.

(7) Separate lock motor from door.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR BELT MOULDING AND

WEATHERSTRIP

BELT MOULDING AND WEATHERSTRIP

REMOVAL

(1) Remove trim panel, silencer pad, and water

shield as necessary to gain access to belt moulding

attaching screws. (2) Remove door glass.

(3) Remove screws holding belt moulding and

weatherstrip to outer door panel and separate moul-

ding from door.

BELT MOULDING AND WEATHERSTRIP INSTALLATION

Reverse the preceding operation.

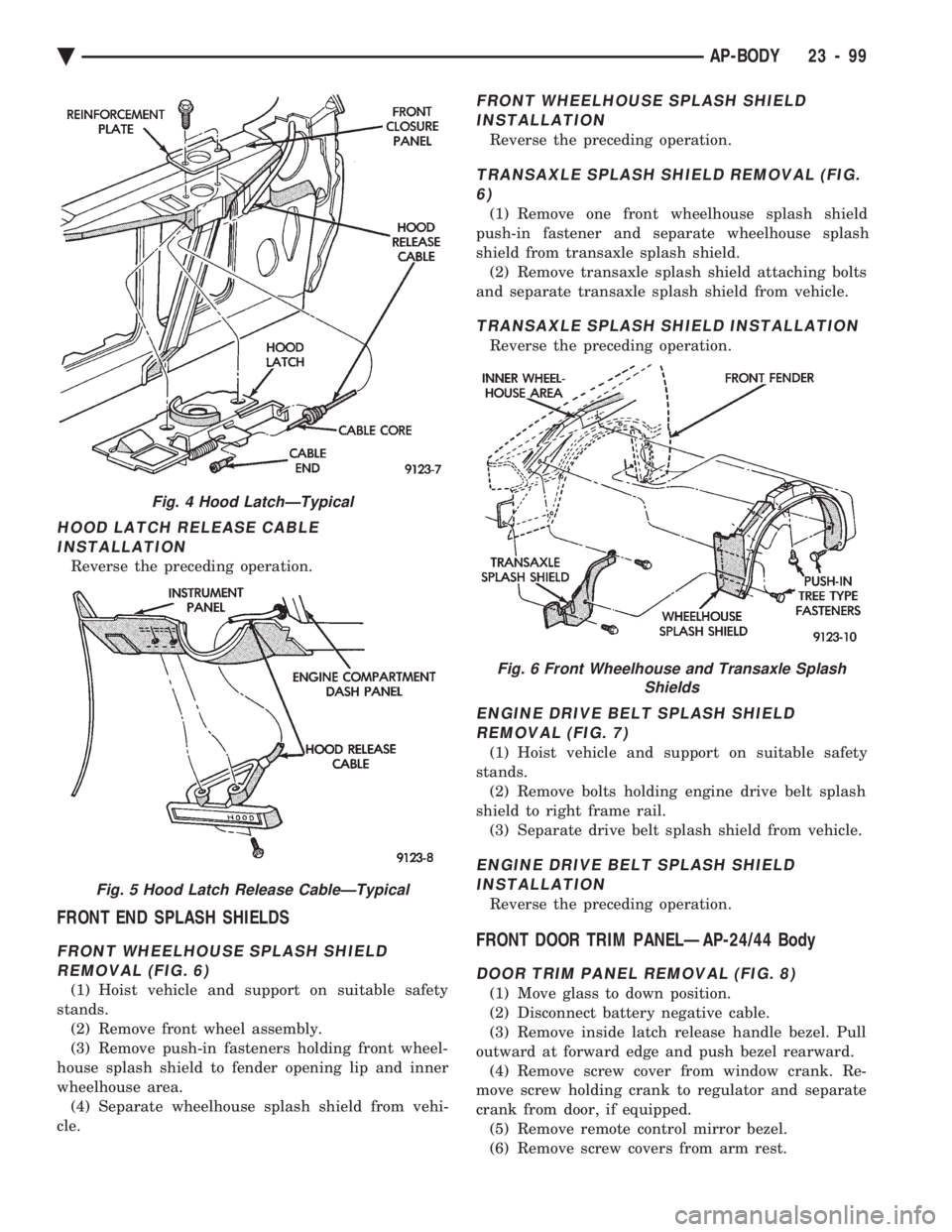

Fig. 12 Front Door Side View MirrorÐTypical

Fig. 13 Front Door Glass

Fig. 14 Front Power Door Lock ActuatorÐTypical

23 - 102 AP-BODY Ä