engine CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1603 of 2438

(2) Install thrust plates and tighten retaining nuts

to6N Im (55 in. lbs.).

(3) Install new camshaft oil seals flush with cylin-

der head surface. Using seal installing special tool C-4680.

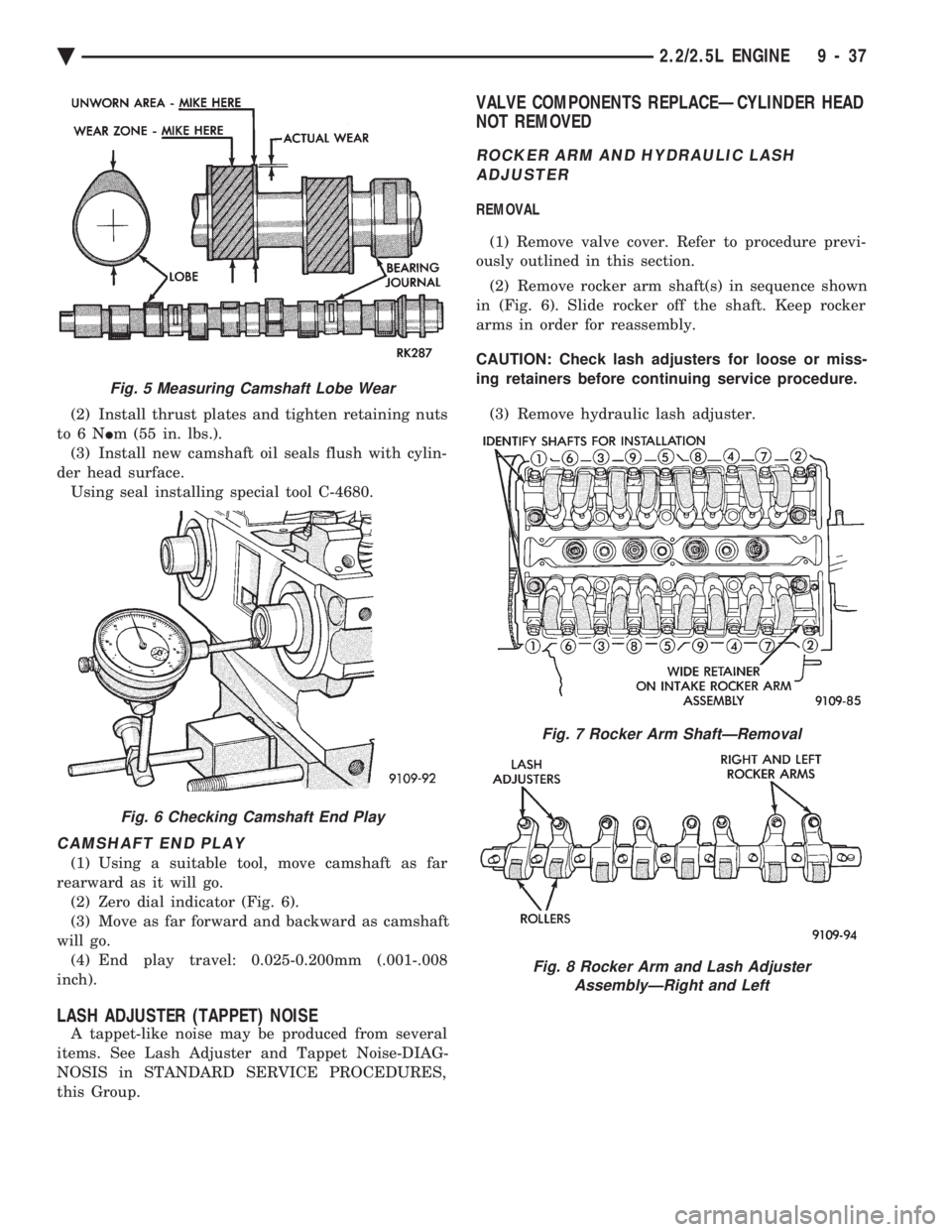

CAMSHAFT END PLAY

(1) Using a suitable tool, move camshaft as far

rearward as it will go. (2) Zero dial indicator (Fig. 6).

(3) Move as far forward and backward as camshaft

will go. (4) End play travel: 0.025-0.200mm (.001-.008

inch).

LASH ADJUSTER (TAPPET) NOISE

A tappet-like noise may be produced from several

items. See Lash Adjuster and Tappet Noise-DIAG-

NOSIS in STANDARD SERVICE PROCEDURES,

this Group.

VALVE COMPONENTS REPLACEÐCYLINDER HEAD

NOT REMOVED

ROCKER ARM AND HYDRAULIC LASH

ADJUSTER

REMOVAL

(1) Remove valve cover. Refer to procedure previ-

ously outlined in this section.

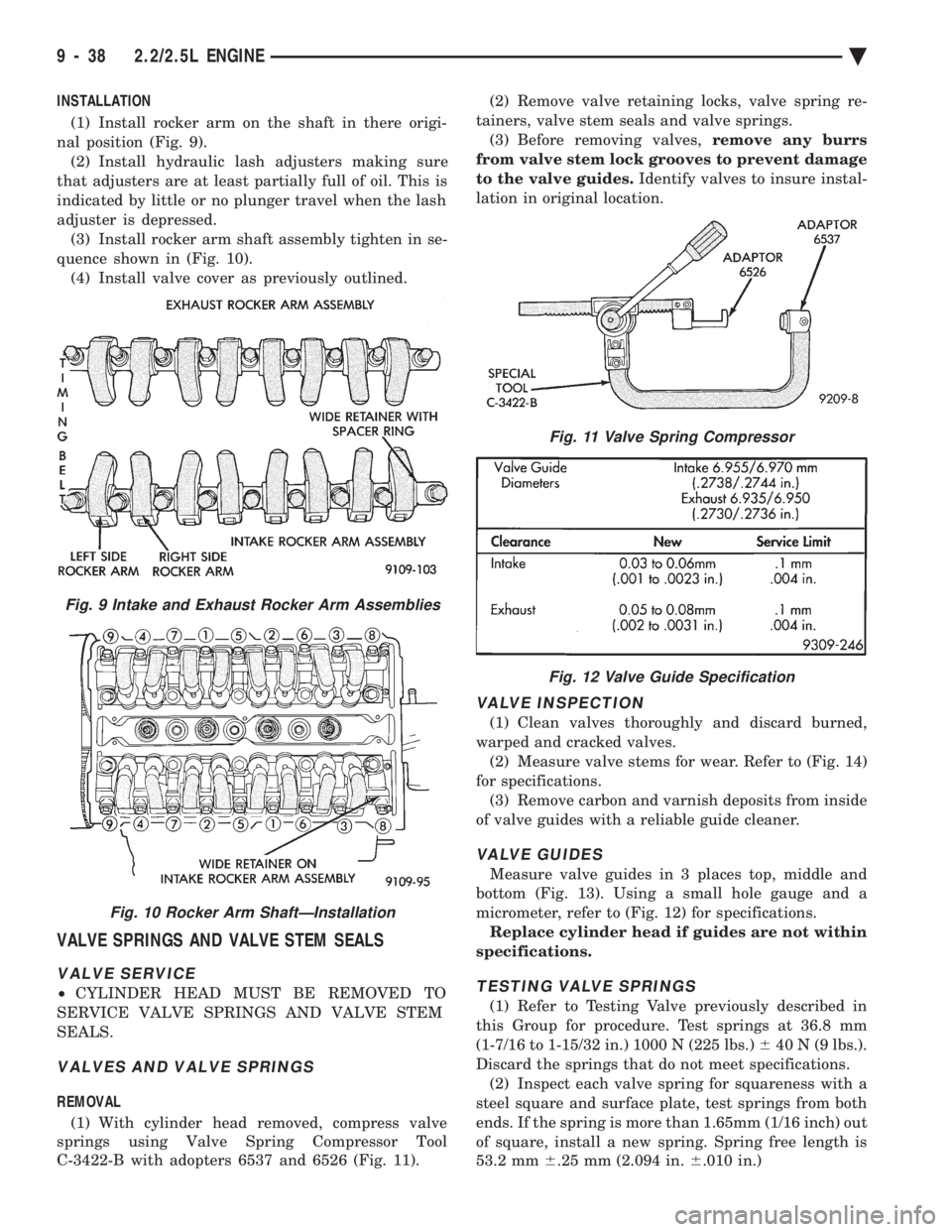

(2) Remove rocker arm shaft(s) in sequence shown

in (Fig. 6). Slide rocker off the shaft. Keep rocker

arms in order for reassembly.

CAUTION: Check lash adjusters for loose or miss-

ing retainers before continuing service procedure.

(3) Remove hydraulic lash adjuster.

Fig. 5 Measuring Camshaft Lobe Wear

Fig. 6 Checking Camshaft End Play

Fig. 7 Rocker Arm ShaftÐRemoval

Fig. 8 Rocker Arm and Lash Adjuster AssemblyÐRight and Left

Ä 2.2/2.5L ENGINE 9 - 37

Page 1604 of 2438

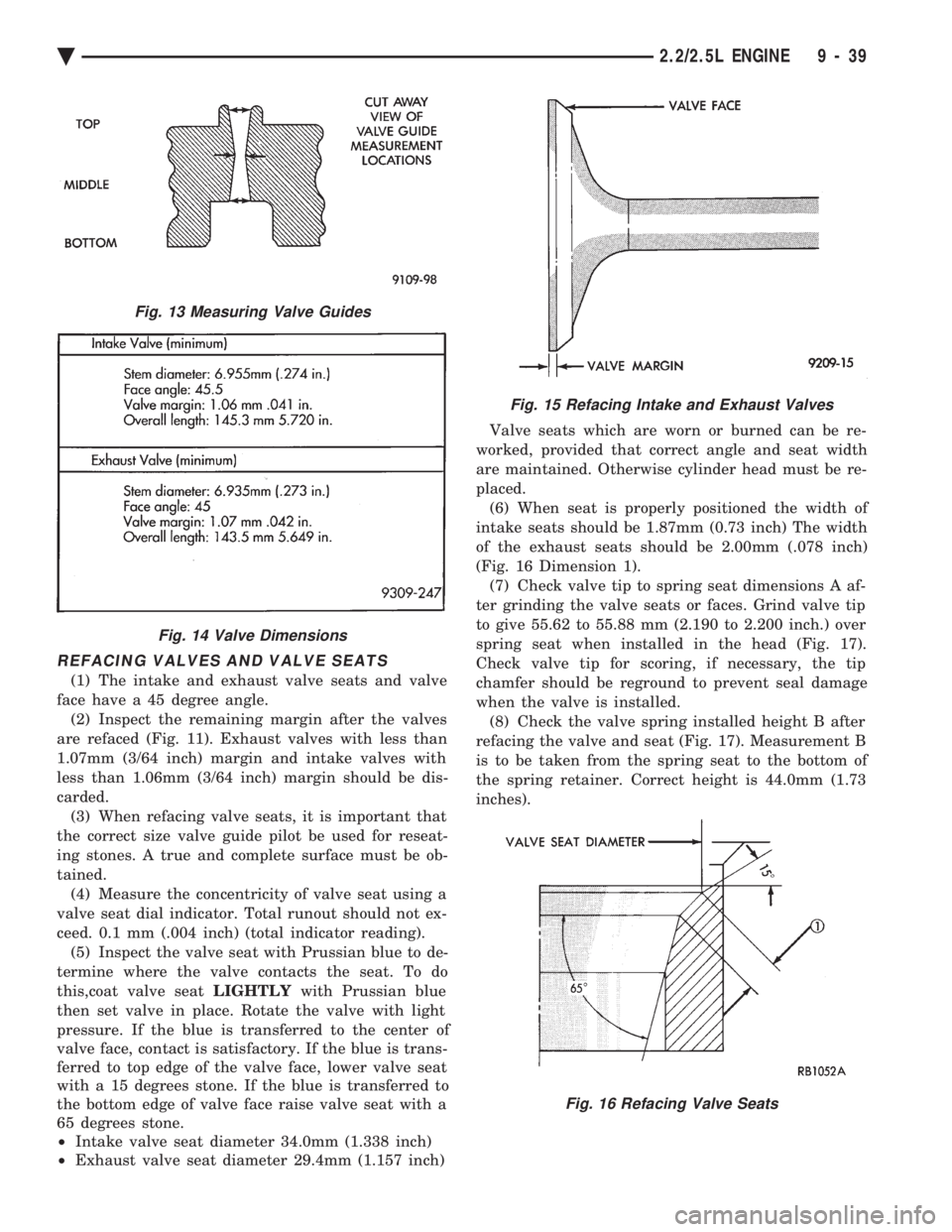

INSTALLATION (1) Install rocker arm on the shaft in there origi-

nal position (Fig. 9). (2) Install hydraulic lash adjusters making sure

that adjusters are at least partially full of oil. This is

indicated by little or no plunger travel when the lash

adjuster is depressed. (3) Install rocker arm shaft assembly tighten in se-

quence shown in (Fig. 10). (4) Install valve cover as previously outlined.

VALVE SPRINGS AND VALVE STEM SEALS

VALVE SERVICE

² CYLINDER HEAD MUST BE REMOVED TO

SERVICE VALVE SPRINGS AND VALVE STEM

SEALS.

VALVES AND VALVE SPRINGS

REMOVAL

(1) With cylinder head removed, compress valve

springs using Valve Spring Compressor Tool

C-3422-B with adopters 6537 and 6526 (Fig. 11). (2) Remove valve retaining locks, valve spring re-

tainers, valve stem seals and valve springs. (3) Before removing valves, remove any burrs

from valve stem lock grooves to prevent damage

to the valve guides. Identify valves to insure instal-

lation in original location.

VALVE INSPECTION

(1) Clean valves thoroughly and discard burned,

warped and cracked valves. (2) Measure valve stems for wear. Refer to (Fig. 14)

for specifications. (3) Remove carbon and varnish deposits from inside

of valve guides with a reliable guide cleaner.

VALVE GUIDES

Measure valve guides in 3 places top, middle and

bottom (Fig. 13). Using a small hole gauge and a

micrometer, refer to (Fig. 12) for specifications. Replace cylinder head if guides are not within

specifications.

TESTING VALVE SPRINGS

(1) Refer to Testing Valve previously described in

this Group for procedure. Test springs at 36.8 mm

(1-7/16 to 1-15/32 in.) 1000 N (225 lbs.) 640 N (9 lbs.).

Discard the springs that do not meet specifications. (2) Inspect each valve spring for squareness with a

steel square and surface plate, test springs from both

ends. If the spring is more than 1.65mm (1/16 inch) out

of square, install a new spring. Spring free length is

53.2 mm 6.25 mm (2.094 in. 6.010 in.)

Fig. 9 Intake and Exhaust Rocker Arm Assemblies

Fig. 10 Rocker Arm ShaftÐInstallation

Fig. 11 Valve Spring Compressor

Fig. 12 Valve Guide Specification

9 - 38 2.2/2.5L ENGINE Ä

Page 1605 of 2438

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle. (2) Inspect the remaining margin after the valves

are refaced (Fig. 11). Exhaust valves with less than

1.07mm (3/64 inch) margin and intake valves with

less than 1.06mm (3/64 inch) margin should be dis-

carded. (3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be ob-

tained. (4) Measure the concentricity of valve seat using a

valve seat dial indicator. Total runout should not ex-

ceed. 0.1 mm (.004 inch) (total indicator reading). (5) Inspect the valve seat with Prussian blue to de-

termine where the valve contacts the seat. To do

this,coat valve seat LIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

² Intake valve seat diameter 34.0mm (1.338 inch)

² Exhaust valve seat diameter 29.4mm (1.157 inch) Valve seats which are worn or burned can be re-

worked, provided that correct angle and seat width

are maintained. Otherwise cylinder head must be re-

placed. (6) When seat is properly positioned the width of

intake seats should be 1.87mm (0.73 inch) The width

of the exhaust seats should be 2.00mm (.078 inch)

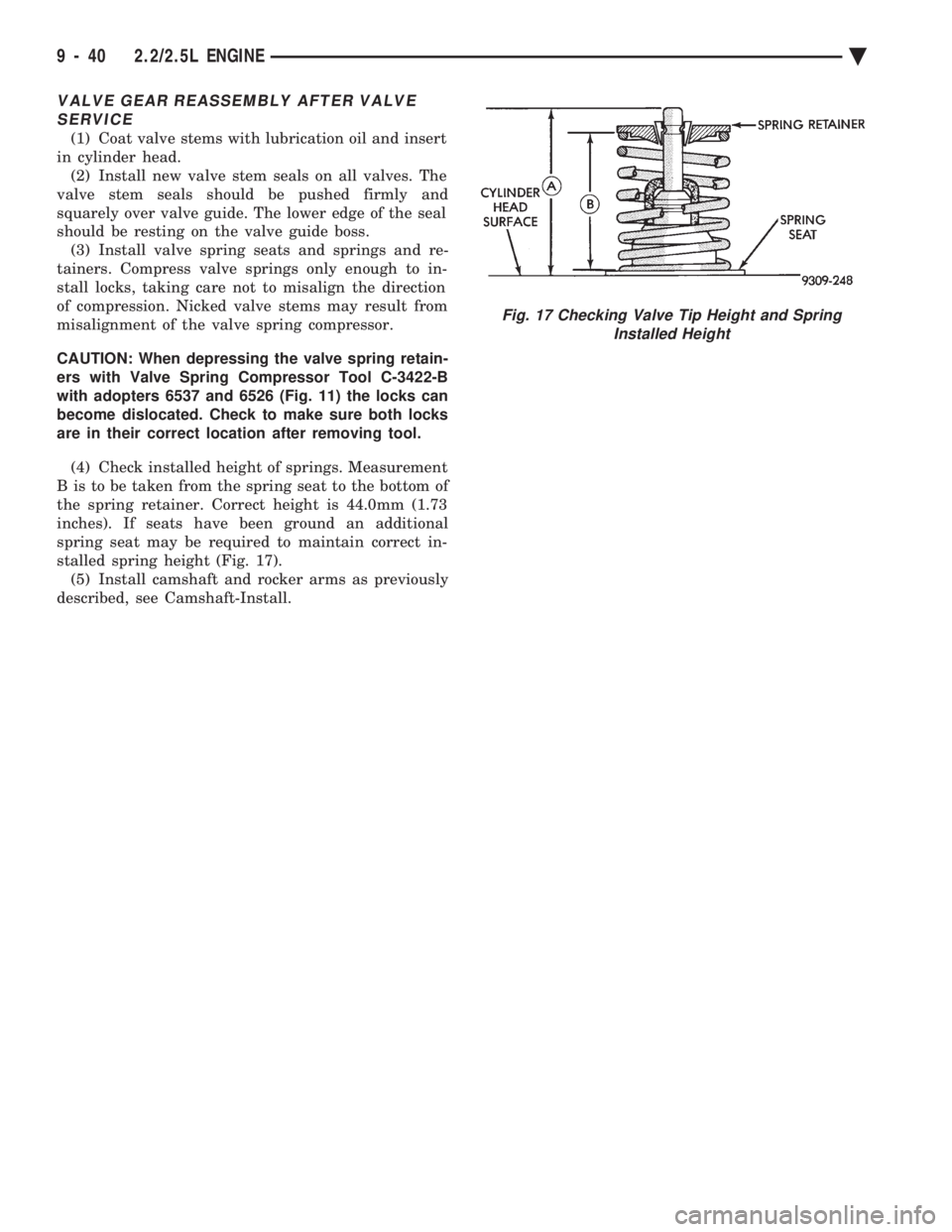

(Fig. 16 Dimension 1). (7) Check valve tip to spring seat dimensions A af-

ter grinding the valve seats or faces. Grind valve tip

to give 55.62 to 55.88 mm (2.190 to 2.200 inch.) over

spring seat when installed in the head (Fig. 17).

Check valve tip for scoring, if necessary, the tip

chamfer should be reground to prevent seal damage

when the valve is installed. (8) Check the valve spring installed height B after

refacing the valve and seat (Fig. 17). Measurement B

is to be taken from the spring seat to the bottom of

the spring retainer. Correct height is 44.0mm (1.73

inches).

Fig. 13 Measuring Valve Guides

Fig. 14 Valve Dimensions

Fig. 15 Refacing Intake and Exhaust Valves

Fig. 16 Refacing Valve Seats

Ä 2.2/2.5L ENGINE 9 - 39

Page 1606 of 2438

VALVE GEAR REASSEMBLY AFTER VALVE SERVICE

(1) Coat valve stems with lubrication oil and insert

in cylinder head. (2) Install new valve stem seals on all valves. The

valve stem seals should be pushed firmly and

squarely over valve guide. The lower edge of the seal

should be resting on the valve guide boss. (3) Install valve spring seats and springs and re-

tainers. Compress valve springs only enough to in-

stall locks, taking care not to misalign the direction

of compression. Nicked valve stems may result from

misalignment of the valve spring compressor.

CAUTION: When depressing the valve spring retain-

ers with Valve Spring Compressor Tool C-3422-B

with adopters 6537 and 6526 (Fig. 11) the locks can

become dislocated. Check to make sure both locks

are in their correct location after removing tool.

(4) Check installed height of springs. Measurement

B is to be taken from the spring seat to the bottom of

the spring retainer. Correct height is 44.0mm (1.73

inches). If seats have been ground an additional

spring seat may be required to maintain correct in-

stalled spring height (Fig. 17). (5) Install camshaft and rocker arms as previously

described, see Camshaft-Install.

Fig. 17 Checking Valve Tip Height and Spring Installed Height

9 - 40 2.2/2.5L ENGINE Ä

Page 1607 of 2438

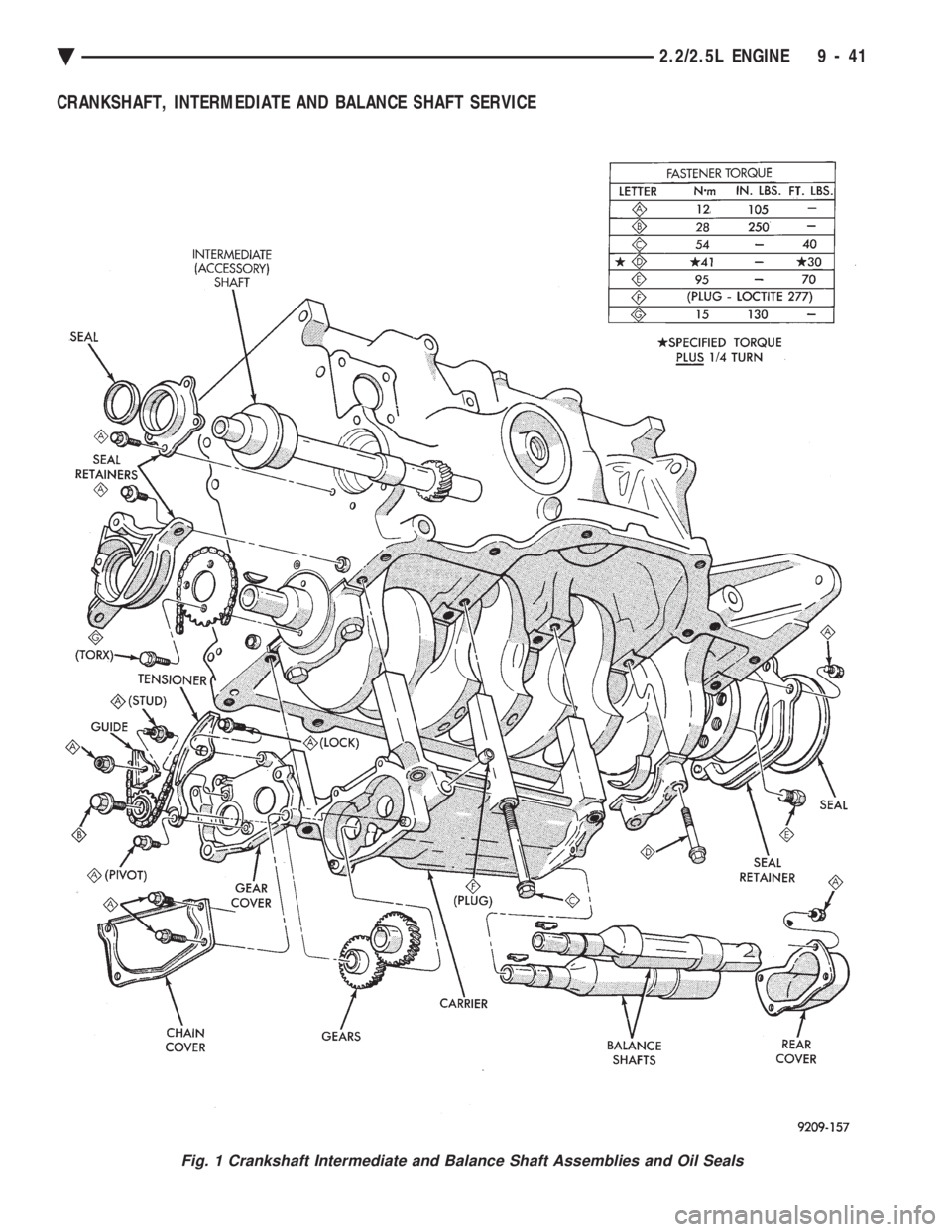

CRANKSHAFT, INTERMEDIATE AND BALANCE SHAFT SERVICE

Fig. 1 Crankshaft Intermediate and Balance Shaft Assemblies and Oil Seals

Ä 2.2/2.5L ENGINE 9 - 41

Page 1608 of 2438

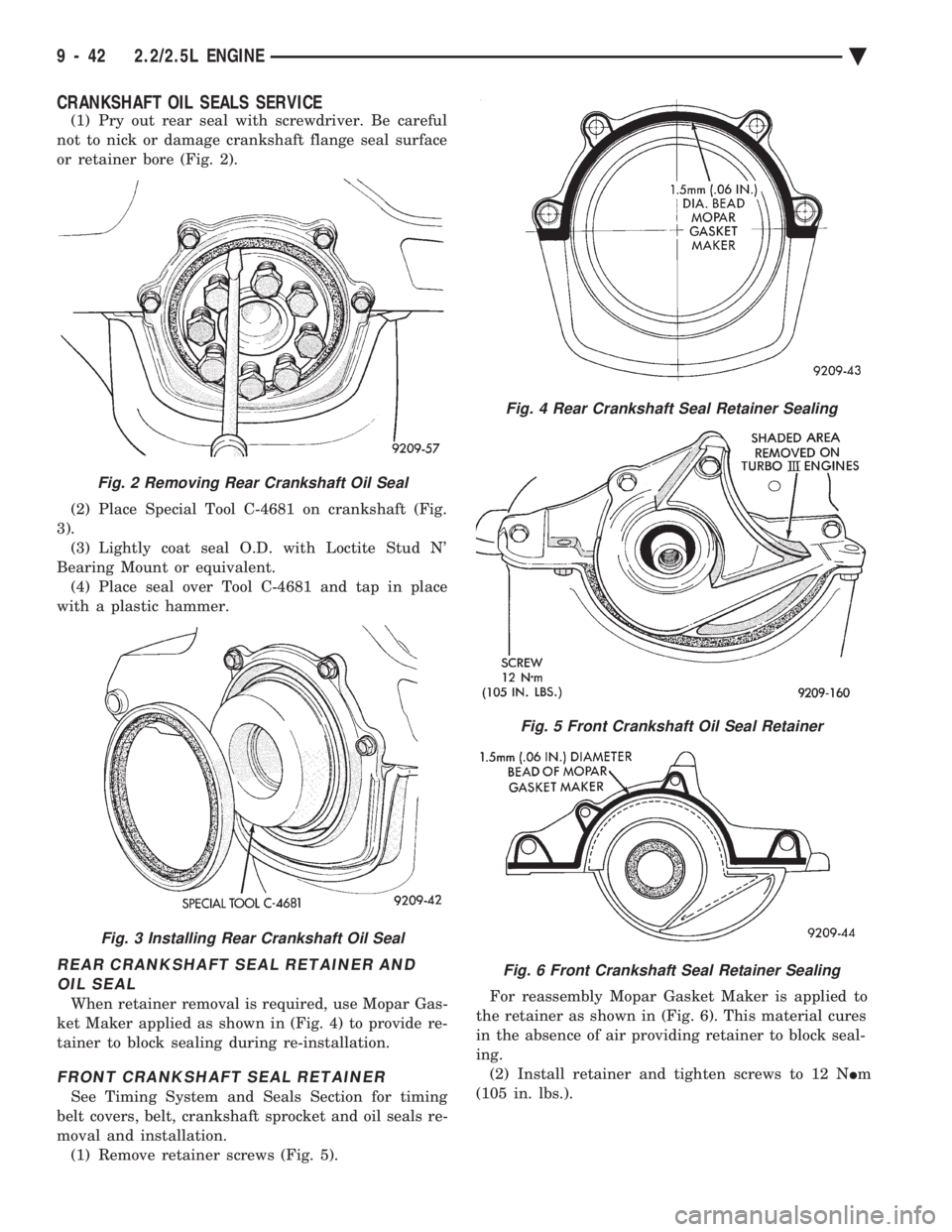

CRANKSHAFT OIL SEALS SERVICE

(1) Pry out rear seal with screwdriver. Be careful

not to nick or damage crankshaft flange seal surface

or retainer bore (Fig. 2).

(2) Place Special Tool C-4681 on crankshaft (Fig.

3). (3) Lightly coat seal O.D. with Loctite Stud N'

Bearing Mount or equivalent. (4) Place seal over Tool C-4681 and tap in place

with a plastic hammer.

REAR CRANKSHAFT SEAL RETAINER AND OIL SEAL

When retainer removal is required, use Mopar Gas-

ket Maker applied as shown in (Fig. 4) to provide re-

tainer to block sealing during re-installation.

FRONT CRANKSHAFT SEAL RETAINER

See Timing System and Seals Section for timing

belt covers, belt, crankshaft sprocket and oil seals re-

moval and installation. (1) Remove retainer screws (Fig. 5). For reassembly Mopar Gasket Maker is applied to

the retainer as shown in (Fig. 6). This material cures

in the absence of air providing retainer to block seal-

ing. (2) Install retainer and tighten screws to 12 N Im

(105 in. lbs.).

Fig. 2 Removing Rear Crankshaft Oil Seal

Fig. 3 Installing Rear Crankshaft Oil Seal

Fig. 4 Rear Crankshaft Seal Retainer Sealing

Fig. 5 Front Crankshaft Oil Seal Retainer

Fig. 6 Front Crankshaft Seal Retainer Sealing

9 - 42 2.2/2.5L ENGINE Ä

Page 1609 of 2438

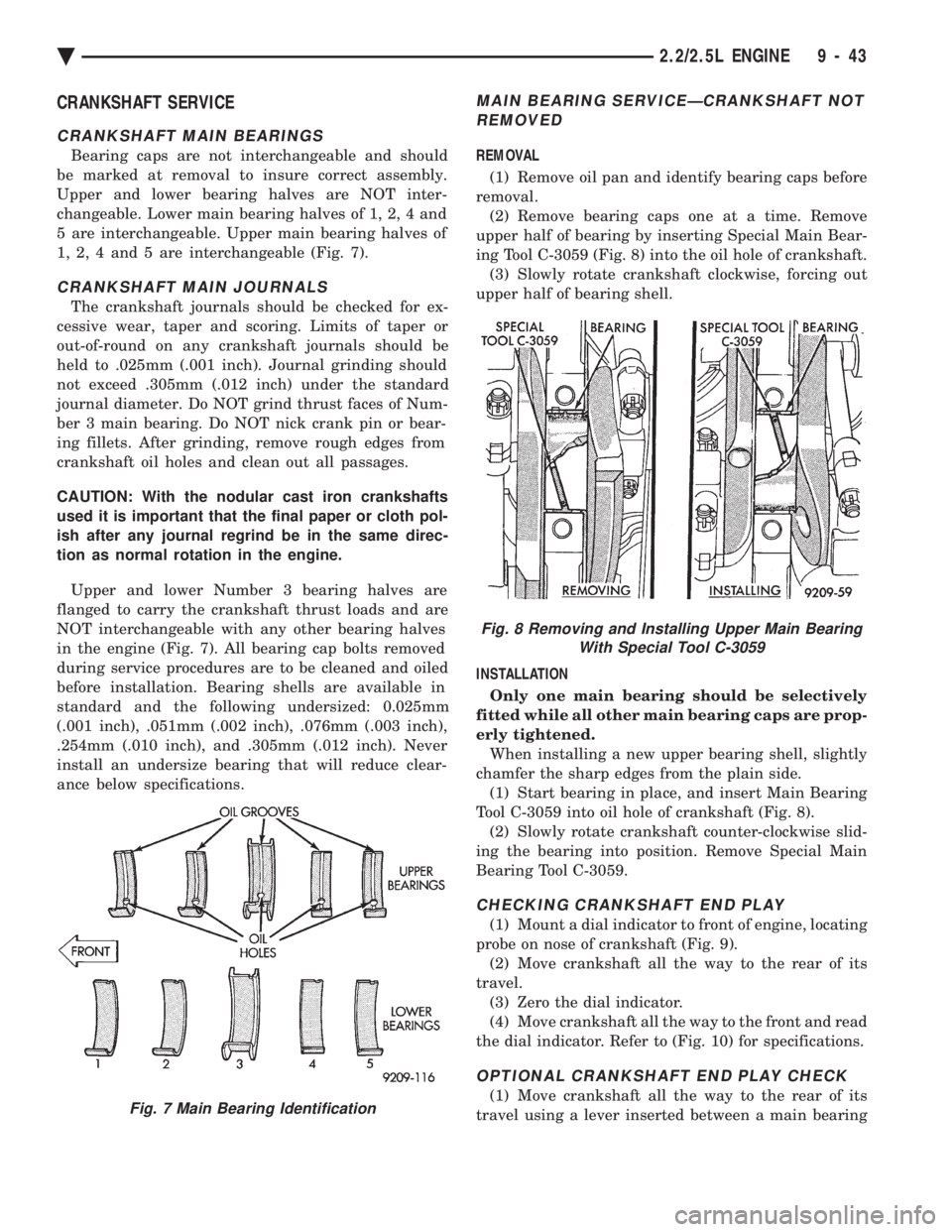

CRANKSHAFT SERVICE

CRANKSHAFT MAIN BEARINGS

Bearing caps are not interchangeable and should

be marked at removal to insure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. Lower main bearing halves of 1, 2, 4 and

5 are interchangeable. Upper main bearing halves of

1, 2, 4 and 5 are interchangeable (Fig. 7).

CRANKSHAFT MAIN JOURNALS

The crankshaft journals should be checked for ex-

cessive wear, taper and scoring. Limits of taper or

out-of-round on any crankshaft journals should be

held to .025mm (.001 inch). Journal grinding should

not exceed .305mm (.012 inch) under the standard

journal diameter. Do NOT grind thrust faces of Num-

ber 3 main bearing. Do NOT nick crank pin or bear-

ing fillets. After grinding, remove rough edges from

crankshaft oil holes and clean out all passages.

CAUTION: With the nodular cast iron crankshafts

used it is important that the final paper or cloth pol-

ish after any journal regrind be in the same direc-

tion as normal rotation in the engine.

Upper and lower Number 3 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 7). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersized: 0.025mm

(.001 inch), .051mm (.002 inch), .076mm (.003 inch),

.254mm (.010 inch), and .305mm (.012 inch). Never

install an undersize bearing that will reduce clear-

ance below specifications.

MAIN BEARING SERVICEÐCRANKSHAFT NOT REMOVED

REMOVAL

(1) Remove oil pan and identify bearing caps before

removal. (2) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059 (Fig. 8) into the oil hole of crankshaft. (3) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION Only one main bearing should be selectively

fitted while all other main bearing caps are prop-

erly tightened. When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side. (1) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 8). (2) Slowly rotate crankshaft counter-clockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locating

probe on nose of crankshaft (Fig. 9). (2) Move crankshaft all the way to the rear of its

travel. (3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and read

the dial indicator. Refer to (Fig. 10) for specifications.

OPTIONAL CRANKSHAFT END PLAY CHECK

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearingFig. 7 Main Bearing Identification

Fig. 8 Removing and Installing Upper Main Bearing With Special Tool C-3059

Ä 2.2/2.5L ENGINE 9 - 43

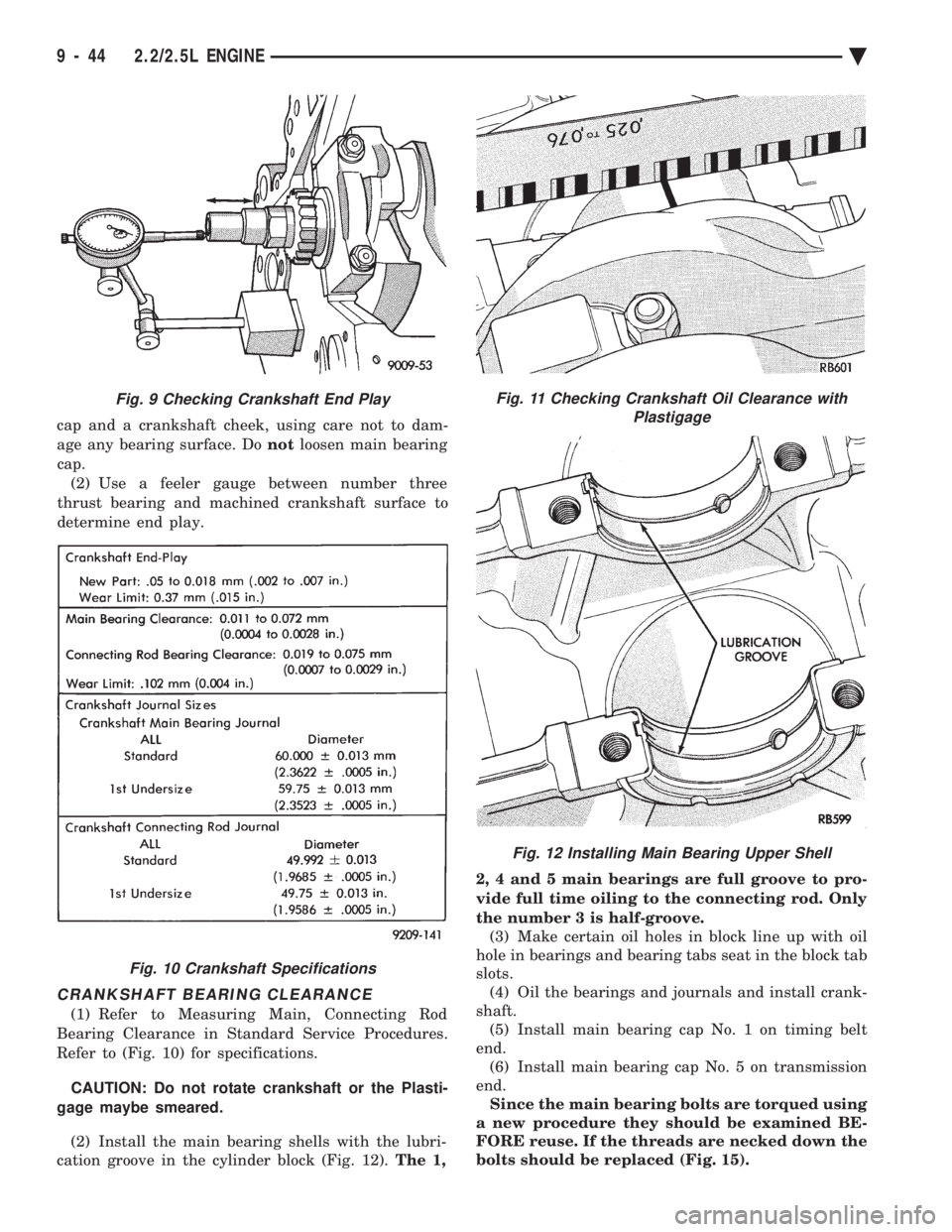

Page 1610 of 2438

cap and a crankshaft cheek, using care not to dam-

age any bearing surface. Do notloosen main bearing

cap. (2) Use a feeler gauge between number three

thrust bearing and machined crankshaft surface to

determine end play.

CRANKSHAFT BEARING CLEARANCE

(1) Refer to Measuring Main, Connecting Rod

Bearing Clearance in Standard Service Procedures.

Refer to (Fig. 10) for specifications.

CAUTION: Do not rotate crankshaft or the Plasti-

gage maybe smeared.

(2) Install the main bearing shells with the lubri-

cation groove in the cylinder block (Fig. 12). The 1, 2, 4 and 5 main bearings are full groove to pro-

vide full time oiling to the connecting rod. Only

the number 3 is half-groove.

(3) Make certain oil holes in block line up with oil

hole in bearings and bearing tabs seat in the block tab

slots. (4) Oil the bearings and journals and install crank-

shaft. (5) Install main bearing cap No. 1 on timing belt

end. (6) Install main bearing cap No. 5 on transmission

end. Since the main bearing bolts are torqued using

a new procedure they should be examined BE-

FORE reuse. If the threads are necked down the

bolts should be replaced (Fig. 15).

Fig. 9 Checking Crankshaft End Play

Fig. 10 Crankshaft Specifications

Fig. 11 Checking Crankshaft Oil Clearance with Plastigage

Fig. 12 Installing Main Bearing Upper Shell

9 - 44 2.2/2.5L ENGINE Ä

Page 1611 of 2438

Necking can be checked by holding a scale or straight

edge against the threads or by running a M11 x 1.50

nut the full length of the thread. If all the threads

do not contact the scale or if the nut does not run

down smoothly the bolt should be replaced. (7) Before installing the bolts the threads should be

oiled with engine oil. (8) Install both bolts in each cap finger tight, then

alternately torque each bolt to assemble the cap prop-

erly. (9) Tighten the bolts to 41 N Im plus 1/4 turn (30

ft.lbs. plus 1/4 turn). (Fig. 14)

BALANCE SHAFTS

2.2L Turbo III and 2.5L engines are equipped with

two counter rotating balance shafts installed in a

carrier attached to the lower crankcase (Fig. 1). The shafts are interconnected through gears. These

gears are driven by a short chain from the crank-

shaft, to rotate at two times crankshaft speed. This

counterbalances certain engine reciprocating forces.

REMOVAL

Refer to Engine Lubrication and Timing System

and Seals Service of this group for removal procedure

of necessary components to repair balance shafts.

(1) Remove chain cover, guide and tensioner (Fig.

16). Also see Carrier Assembly Removal for service

procedures requiring only temporary relocation of as-

sembly. (2) Remove balance shaft gear and chain sprocket

retaining screws and crankshaft chain sprocket torx

screws. Remove chain and sprocket assembly. (Fig.

17) (3) Remove gear cover retaining stud (double

ended to also retain chain guide). Remove cover and

balance shaft gears (Fig. 18). (4) Remove carrier rear cover and balance shafts.

(Fig. 19). (5) Remove six carrier to crankcase attaching bolts

to separate carrier (Fig. 1).

Fig. 16 Chain Cover, Guide and Tensioner

Fig. 13 Main Bearing Caps

Fig. 14 Installing Main Bearing Caps

Fig. 15 Checking Bolts For Stretching (Necked down)

Ä 2.2/2.5L ENGINE 9 - 45

Page 1612 of 2438

BALANCE SHAFTS CARRIER ASSEMBLY

REMOVAL The following components will remain intact dur-

ing carrier removal. Gear cover, gears, balance shafts

and the rear cover. (1) Remove chain cover and driven balance shaft

chain sprocket screw. (2) Loosen tensioner pivot and adjusting screws,

move driven balance shaft inboard through driven

chain sprocket. Sprocket will hang in lower chain

loop. (3) Remove carrier to crankcase attaching bolts to

remove carrier. INSTALLATION

Balance shaft and carrier assembly installation is

the reverse of the removal procedure. During instal-

lation crankshaft to balance shaft timing must be

established.

TIMING

(1) With balance shafts installed in carrier (Fig. 19)

position carrier on crankcase and install six attaching

bolts and tighten to 54 N Im (40 ft. lbs.).

(2) Turn balance shafts until both shaft key ways are

up Parallel to vertical centerline of engine. Install

short hub drive gear on sprocket driven shaft and long

hub gear on gear driven shaft. After installation gear

and balance shaft keyways must be up with gear

timing marks meshed as shown in (Fig. 20). (3) Install gear cover and tighten double ended

stud/washer fastener to 12 N Im (105 in. lbs.).

(4) Install crankshaft sprocket and tighten socket

head torx screws to 13 N Im (130 in. lbs.).

Fig. 20 Gear Timing

Fig. 17 Drive Chain and Sprockets

Fig. 18 Gear Cover and Gears

Fig. 19 Balance Shaft(s) Remove/Install

9 - 46 2.2/2.5L ENGINE Ä