steering CHEVROLET DYNASTY 1993 Manual PDF

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 536 of 2438

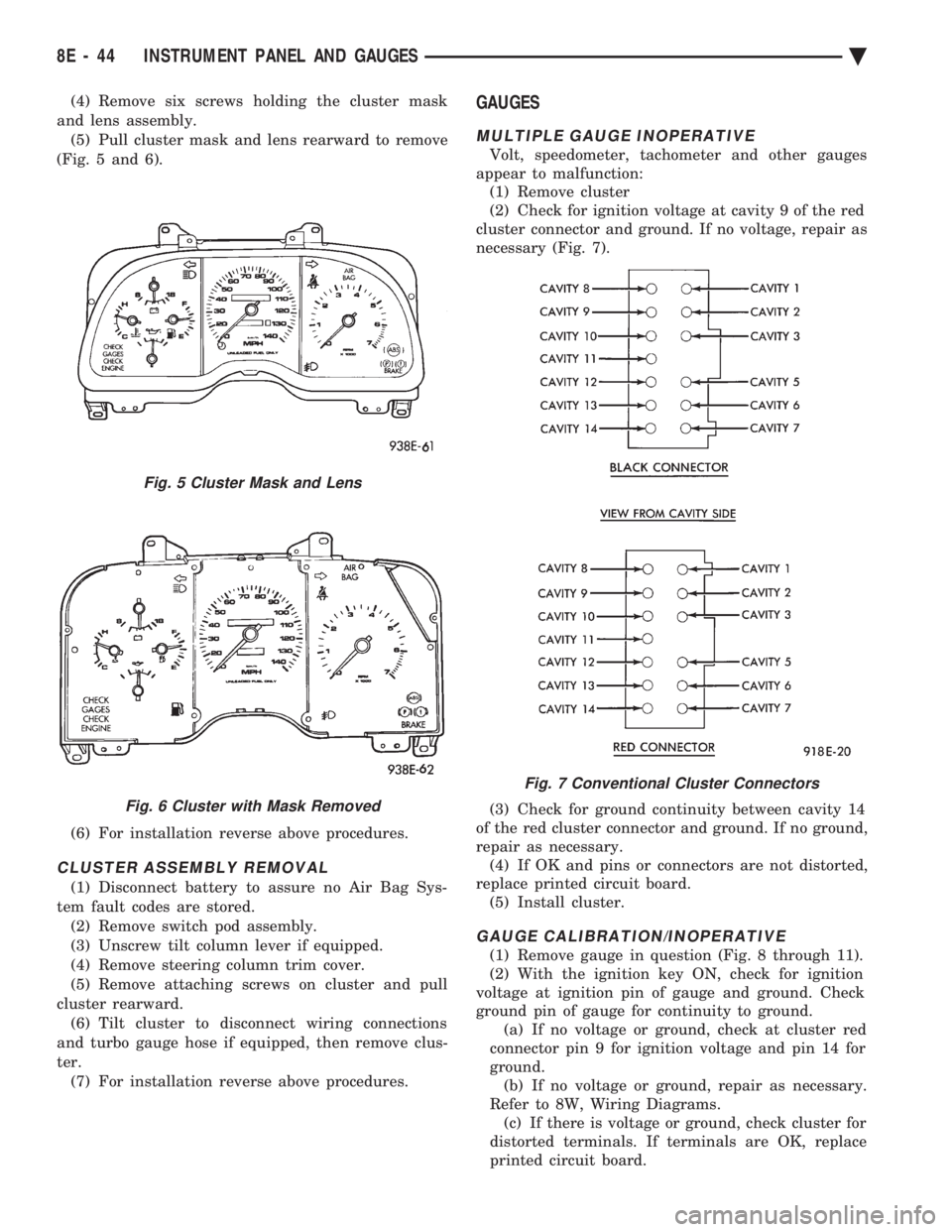

(4) Remove six screws holding the cluster mask

and lens assembly. (5) Pull cluster mask and lens rearward to remove

(Fig. 5 and 6).

(6) For installation reverse above procedures.

CLUSTER ASSEMBLY REMOVAL

(1) Disconnect battery to assure no Air Bag Sys-

tem fault codes are stored. (2) Remove switch pod assembly.

(3) Unscrew tilt column lever if equipped.

(4) Remove steering column trim cover.

(5) Remove attaching screws on cluster and pull

cluster rearward. (6) Tilt cluster to disconnect wiring connections

and turbo gauge hose if equipped, then remove clus-

ter. (7) For installation reverse above procedures.

GAUGES

MULTIPLE GAUGE INOPERATIVE

Volt, speedometer, tachometer and other gauges

appear to malfunction: (1) Remove cluster

(2) Check for ignition voltage at cavity 9 of the red

cluster connector and ground. If no voltage, repair as

necessary (Fig. 7).

(3) Check for ground continuity between cavity 14

of the red cluster connector and ground. If no ground,

repair as necessary. (4) If OK and pins or connectors are not distorted,

replace printed circuit board. (5) Install cluster.

GAUGE CALIBRATION/INOPERATIVE

(1) Remove gauge in question (Fig. 8 through 11).

(2) With the ignition key ON, check for ignition

voltage at ignition pin of gauge and ground. Check

ground pin of gauge for continuity to ground. (a) If no voltage or ground, check at cluster red

connector pin 9 for ignition voltage and pin 14 for

ground. (b) If no voltage or ground, repair as necessary.

Refer to 8W, Wiring Diagrams. (c) If there is voltage or ground, check cluster for

distorted terminals. If terminals are OK, replace

printed circuit board.

Fig. 5 Cluster Mask and Lens

Fig. 6 Cluster with Mask Removed

Fig. 7 Conventional Cluster Connectors

8E - 44 INSTRUMENT PANEL AND GAUGES Ä

Page 538 of 2438

(f) If there is a difference in readings, check

printed circuit board for contact to cluster connec-

tors. (g) If OK and contacts are not distorted, replace

printed circuit board. (h) If everything checks out OK, refer to Sending

Unit Test.

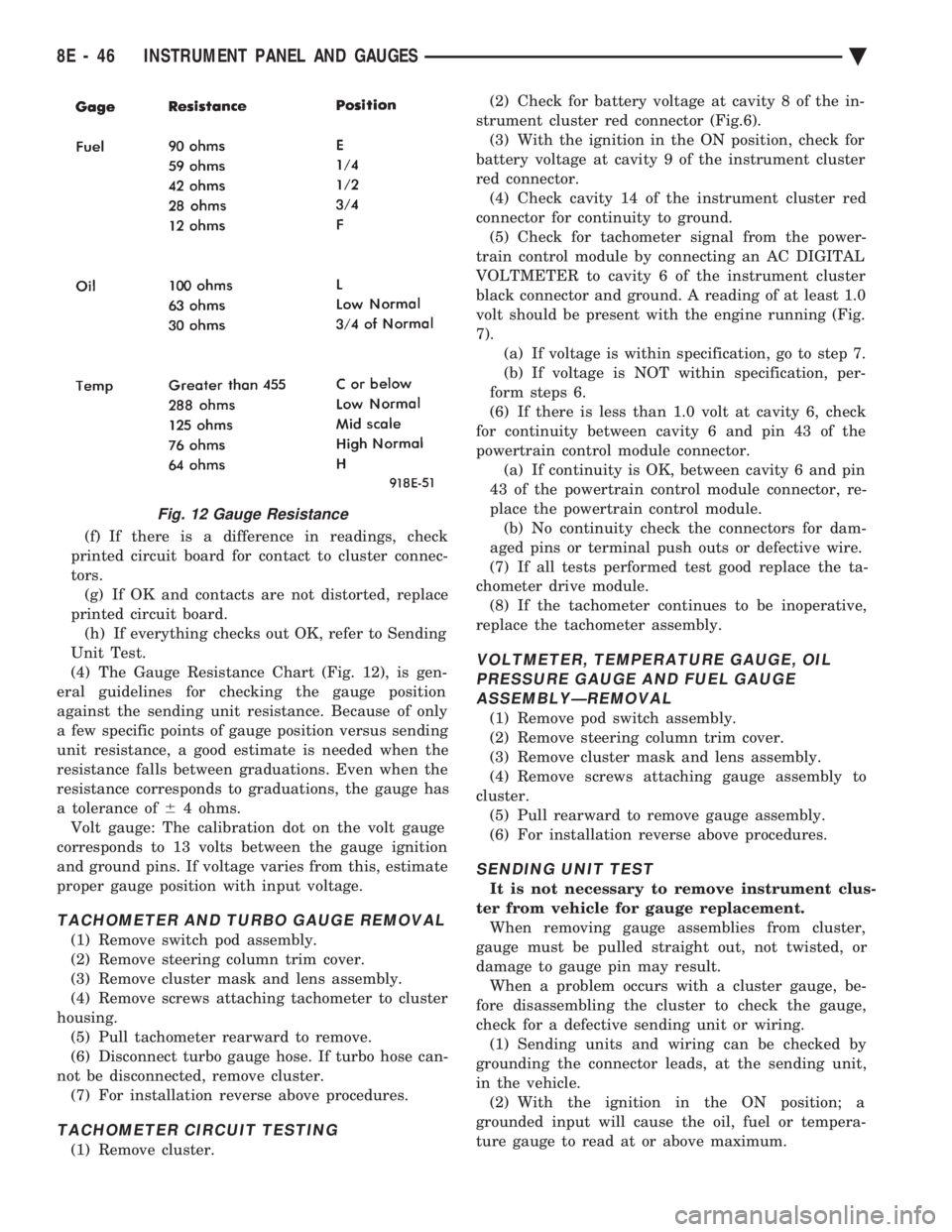

(4) The Gauge Resistance Chart (Fig. 12), is gen-

eral guidelines for checking the gauge position

against the sending unit resistance. Because of only

a few specific points of gauge position versus sending

unit resistance, a good estimate is needed when the

resistance falls between graduations. Even when the

resistance corresponds to graduations, the gauge has

a tolerance of 64 ohms.

Volt gauge: The calibration dot on the volt gauge

corresponds to 13 volts between the gauge ignition

and ground pins. If voltage varies from this, estimate

proper gauge position with input voltage.

TACHOMETER AND TURBO GAUGE REMOVAL

(1) Remove switch pod assembly.

(2) Remove steering column trim cover.

(3) Remove cluster mask and lens assembly.

(4) Remove screws attaching tachometer to cluster

housing. (5) Pull tachometer rearward to remove.

(6) Disconnect turbo gauge hose. If turbo hose can-

not be disconnected, remove cluster. (7) For installation reverse above procedures.

TACHOMETER CIRCUIT TESTING

(1) Remove cluster. (2) Check for battery voltage at cavity 8 of the in-

strument cluster red connector (Fig.6). (3) With the ignition in the ON position, check for

battery voltage at cavity 9 of the instrument cluster

red connector. (4) Check cavity 14 of the instrument cluster red

connector for continuity to ground. (5) Check for tachometer signal from the power-

train control module by connecting an AC DIGITAL

VOLTMETER to cavity 6 of the instrument cluster

black connector and ground. A reading of at least 1.0

volt should be present with the engine running (Fig.

7). (a) If voltage is within specification, go to step 7.

(b) If voltage is NOT within specification, per-

form steps 6.

(6) If there is less than 1.0 volt at cavity 6, check

for continuity between cavity 6 and pin 43 of the

powertrain control module connector. (a) If continuity is OK, between cavity 6 and pin

43 of the powertrain control module connector, re-

place the powertrain control module. (b) No continuity check the connectors for dam-

aged pins or terminal push outs or defective wire.

(7) If all tests performed test good replace the ta-

chometer drive module. (8) If the tachometer continues to be inoperative,

replace the tachometer assembly.

VOLTMETER, TEMPERATURE GAUGE, OIL PRESSURE GAUGE AND FUEL GAUGEASSEMBLYÐREMOVAL

(1) Remove pod switch assembly.

(2) Remove steering column trim cover.

(3) Remove cluster mask and lens assembly.

(4) Remove screws attaching gauge assembly to

cluster. (5) Pull rearward to remove gauge assembly.

(6) For installation reverse above procedures.

SENDING UNIT TEST

It is not necessary to remove instrument clus-

ter from vehicle for gauge replacement. When removing gauge assemblies from cluster,

gauge must be pulled straight out, not twisted, or

damage to gauge pin may result. When a problem occurs with a cluster gauge, be-

fore disassembling the cluster to check the gauge,

check for a defective sending unit or wiring. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position; a

grounded input will cause the oil, fuel or tempera-

ture gauge to read at or above maximum.

Fig. 12 Gauge Resistance

8E - 46 INSTRUMENT PANEL AND GAUGES Ä

Page 546 of 2438

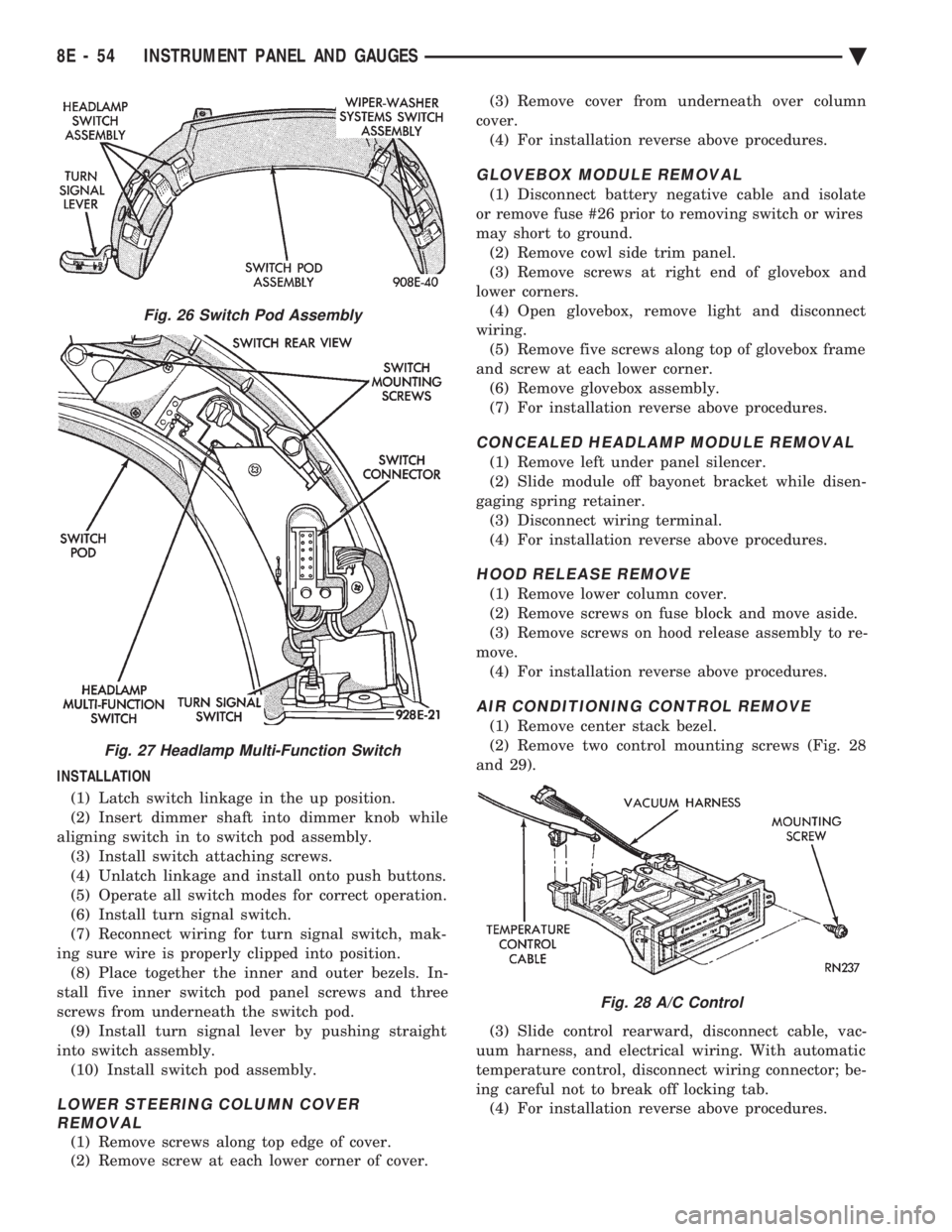

INSTALLATION (1) Latch switch linkage in the up position.

(2) Insert dimmer shaft into dimmer knob while

aligning switch in to switch pod assembly. (3) Install switch attaching screws.

(4) Unlatch linkage and install onto push buttons.

(5) Operate all switch modes for correct operation.

(6) Install turn signal switch.

(7) Reconnect wiring for turn signal switch, mak-

ing sure wire is properly clipped into position. (8) Place together the inner and outer bezels. In-

stall five inner switch pod panel screws and three

screws from underneath the switch pod. (9) Install turn signal lever by pushing straight

into switch assembly. (10) Install switch pod assembly.

LOWER STEERING COLUMN COVER REMOVAL

(1) Remove screws along top edge of cover.

(2) Remove screw at each lower corner of cover. (3) Remove cover from underneath over column

cover. (4) For installation reverse above procedures.

GLOVEBOX MODULE REMOVAL

(1) Disconnect battery negative cable and isolate

or remove fuse #26 prior to removing switch or wires

may short to ground. (2) Remove cowl side trim panel.

(3) Remove screws at right end of glovebox and

lower corners. (4) Open glovebox, remove light and disconnect

wiring. (5) Remove five screws along top of glovebox frame

and screw at each lower corner. (6) Remove glovebox assembly.

(7) For installation reverse above procedures.

CONCEALED HEADLAMP MODULE REMOVAL

(1) Remove left under panel silencer.

(2) Slide module off bayonet bracket while disen-

gaging spring retainer. (3) Disconnect wiring terminal.

(4) For installation reverse above procedures.

HOOD RELEASE REMOVE

(1) Remove lower column cover.

(2) Remove screws on fuse block and move aside.

(3) Remove screws on hood release assembly to re-

move. (4) For installation reverse above procedures.

AIR CONDITIONING CONTROL REMOVE

(1) Remove center stack bezel.

(2) Remove two control mounting screws (Fig. 28

and 29).

(3) Slide control rearward, disconnect cable, vac-

uum harness, and electrical wiring. With automatic

temperature control, disconnect wiring connector; be-

ing careful not to break off locking tab. (4) For installation reverse above procedures.

Fig. 26 Switch Pod Assembly

Fig. 27 Headlamp Multi-Function Switch

Fig. 28 A/C Control

8E - 54 INSTRUMENT PANEL AND GAUGES Ä

Page 548 of 2438

(7) Unscrew lighter receptacle shell from element

and remove. (8) For installation reverse above procedures.

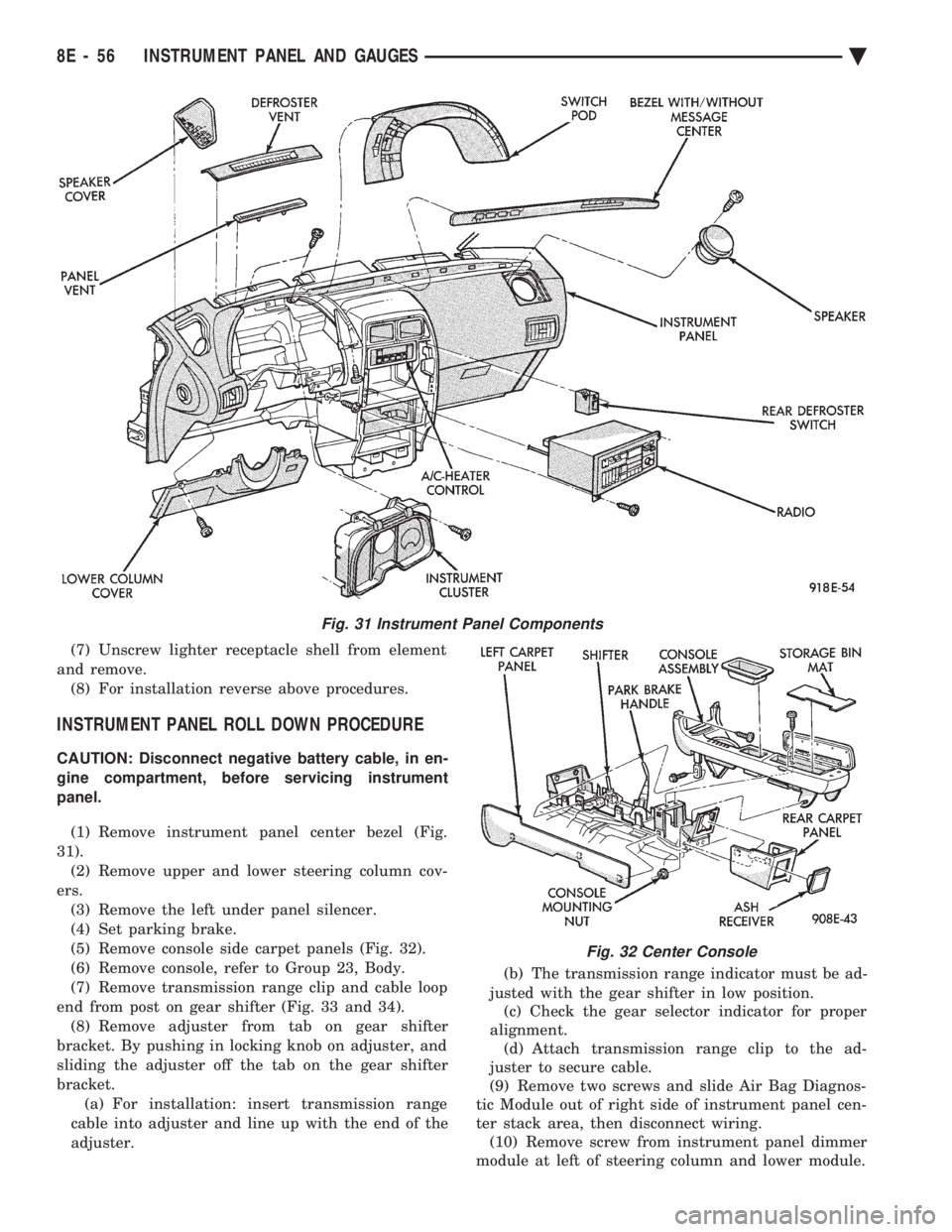

INSTRUMENT PANEL ROLL DOWN PROCEDURE

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel.

(1) Remove instrument panel center bezel (Fig.

31). (2) Remove upper and lower steering column cov-

ers. (3) Remove the left under panel silencer.

(4) Set parking brake.

(5) Remove console side carpet panels (Fig. 32).

(6) Remove console, refer to Group 23, Body.

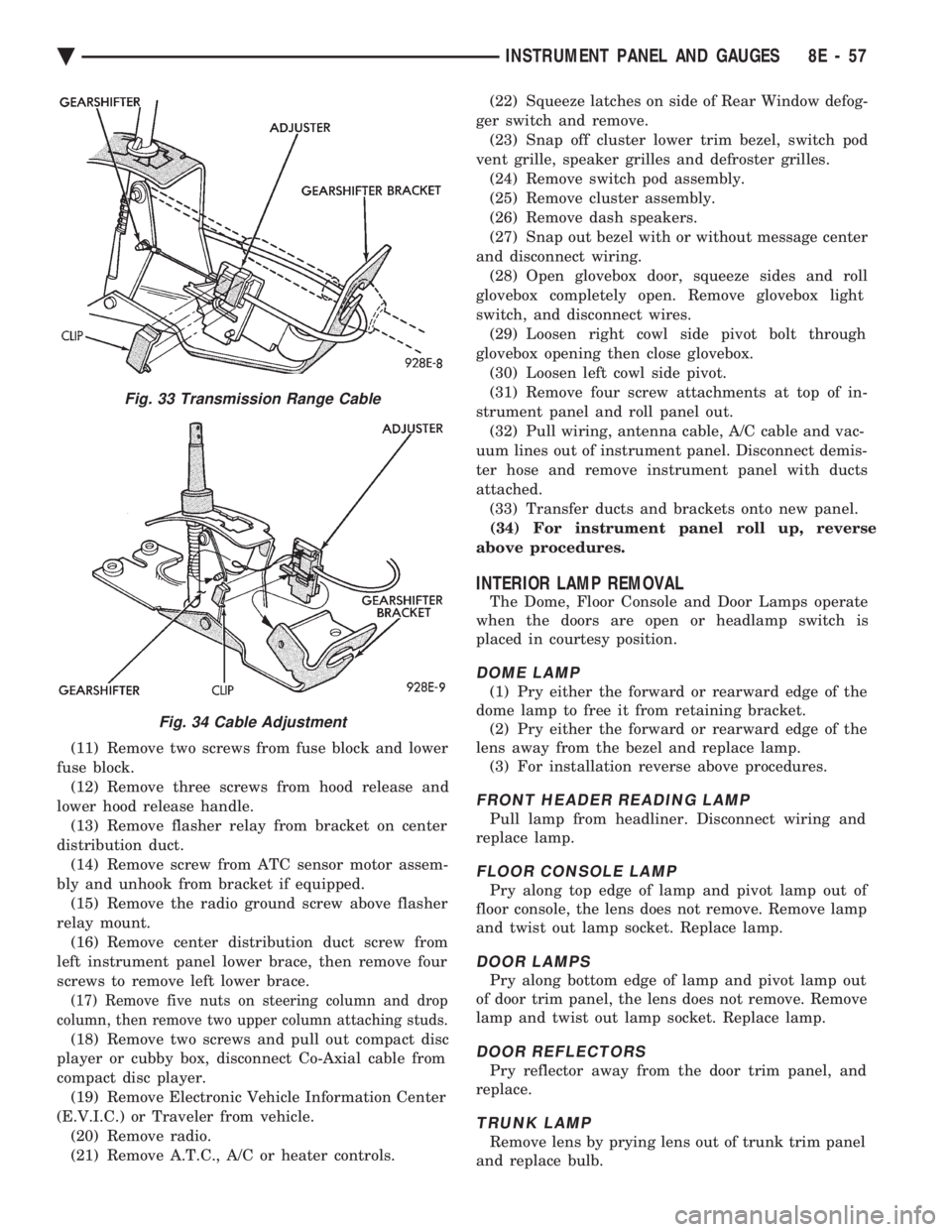

(7) Remove transmission range clip and cable loop

end from post on gear shifter (Fig. 33 and 34). (8) Remove adjuster from tab on gear shifter

bracket. By pushing in locking knob on adjuster, and

sliding the adjuster off the tab on the gear shifter

bracket. (a) For installation: insert transmission range

cable into adjuster and line up with the end of the

adjuster. (b) The transmission range indicator must be ad-

justed with the gear shifter in low position. (c) Check the gear selector indicator for proper

alignment. (d) Attach transmission range clip to the ad-

juster to secure cable.

(9) Remove two screws and slide Air Bag Diagnos-

tic Module out of right side of instrument panel cen-

ter stack area, then disconnect wiring. (10) Remove screw from instrument panel dimmer

module at left of steering column and lower module.

Fig. 31 Instrument Panel Components

Fig. 32 Center Console

8E - 56 INSTRUMENT PANEL AND GAUGES Ä

Page 549 of 2438

(11) Remove two screws from fuse block and lower

fuse block. (12) Remove three screws from hood release and

lower hood release handle. (13) Remove flasher relay from bracket on center

distribution duct. (14) Remove screw from ATC sensor motor assem-

bly and unhook from bracket if equipped. (15) Remove the radio ground screw above flasher

relay mount. (16) Remove center distribution duct screw from

left instrument panel lower brace, then remove four

screws to remove left lower brace.

(17) Remove five nuts on steering column and drop

column, then remove two upper column attaching studs.

(18) Remove two screws and pull out compact disc

player or cubby box, disconnect Co-Axial cable from

compact disc player. (19) Remove Electronic Vehicle Information Center

(E.V.I.C.) or Traveler from vehicle. (20) Remove radio.

(21) Remove A.T.C., A/C or heater controls. (22) Squeeze latches on side of Rear Window defog-

ger switch and remove. (23) Snap off cluster lower trim bezel, switch pod

vent grille, speaker grilles and defroster grilles. (24) Remove switch pod assembly.

(25) Remove cluster assembly.

(26) Remove dash speakers.

(27) Snap out bezel with or without message center

and disconnect wiring. (28) Open glovebox door, squeeze sides and roll

glovebox completely open. Remove glovebox light

switch, and disconnect wires. (29) Loosen right cowl side pivot bolt through

glovebox opening then close glovebox. (30) Loosen left cowl side pivot.

(31) Remove four screw attachments at top of in-

strument panel and roll panel out. (32) Pull wiring, antenna cable, A/C cable and vac-

uum lines out of instrument panel. Disconnect demis-

ter hose and remove instrument panel with ducts

attached. (33) Transfer ducts and brackets onto new panel.

(34) For instrument panel roll up, reverse

above procedures.

INTERIOR LAMP REMOVAL

The Dome, Floor Console and Door Lamps operate

when the doors are open or headlamp switch is

placed in courtesy position.

DOME LAMP

(1) Pry either the forward or rearward edge of the

dome lamp to free it from retaining bracket. (2) Pry either the forward or rearward edge of the

lens away from the bezel and replace lamp. (3) For installation reverse above procedures.

FRONT HEADER READING LAMP

Pull lamp from headliner. Disconnect wiring and

replace lamp.

FLOOR CONSOLE LAMP

Pry along top edge of lamp and pivot lamp out of

floor console, the lens does not remove. Remove lamp

and twist out lamp socket. Replace lamp.

DOOR LAMPS

Pry along bottom edge of lamp and pivot lamp out

of door trim panel, the lens does not remove. Remove

lamp and twist out lamp socket. Replace lamp.

DOOR REFLECTORS

Pry reflector away from the door trim panel, and

replace.

TRUNK LAMP

Remove lens by prying lens out of trunk trim panel

and replace bulb.

Fig. 33 Transmission Range Cable

Fig. 34 Cable Adjustment

Ä INSTRUMENT PANEL AND GAUGES 8E - 57

Page 552 of 2438

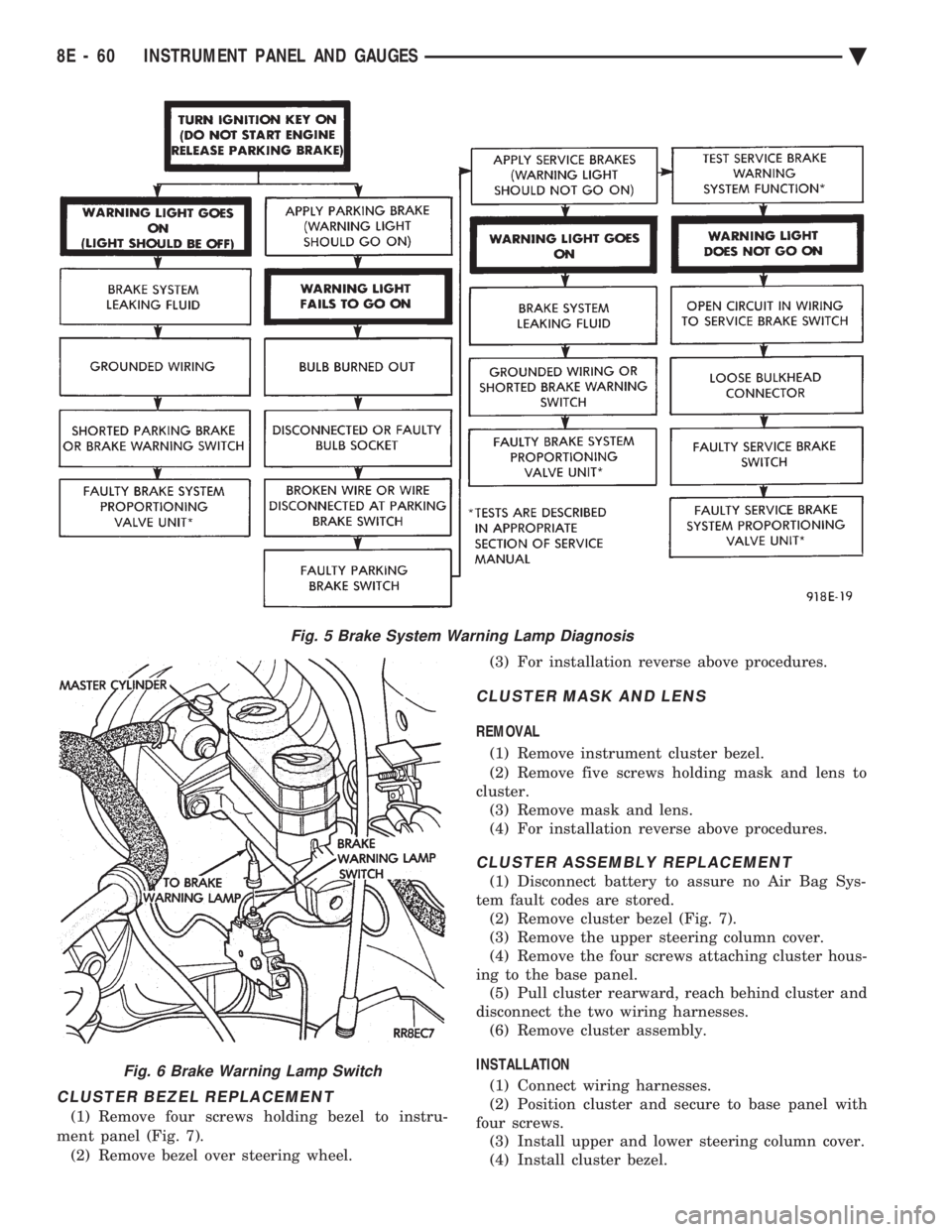

CLUSTER BEZEL REPLACEMENT

(1) Remove four screws holding bezel to instru-

ment panel (Fig. 7). (2) Remove bezel over steering wheel. (3) For installation reverse above procedures.

CLUSTER MASK AND LENS

REMOVAL

(1) Remove instrument cluster bezel.

(2) Remove five screws holding mask and lens to

cluster. (3) Remove mask and lens.

(4) For installation reverse above procedures.

CLUSTER ASSEMBLY REPLACEMENT

(1) Disconnect battery to assure no Air Bag Sys-

tem fault codes are stored. (2) Remove cluster bezel (Fig. 7).

(3) Remove the upper steering column cover.

(4) Remove the four screws attaching cluster hous-

ing to the base panel. (5) Pull cluster rearward, reach behind cluster and

disconnect the two wiring harnesses. (6) Remove cluster assembly.

INSTALLATION (1) Connect wiring harnesses.

(2) Position cluster and secure to base panel with

four screws. (3) Install upper and lower steering column cover.

(4) Install cluster bezel.

Fig. 5 Brake System Warning Lamp Diagnosis

Fig. 6 Brake Warning Lamp Switch

8E - 60 INSTRUMENT PANEL AND GAUGES Ä

Page 559 of 2438

VEHICLE SPEED SENSOR TEST

For testing of the vehicle speed sensor and related

components using DRB II, refer to the appropriate

Powertrain Diagnostics Test Procedure Manual.

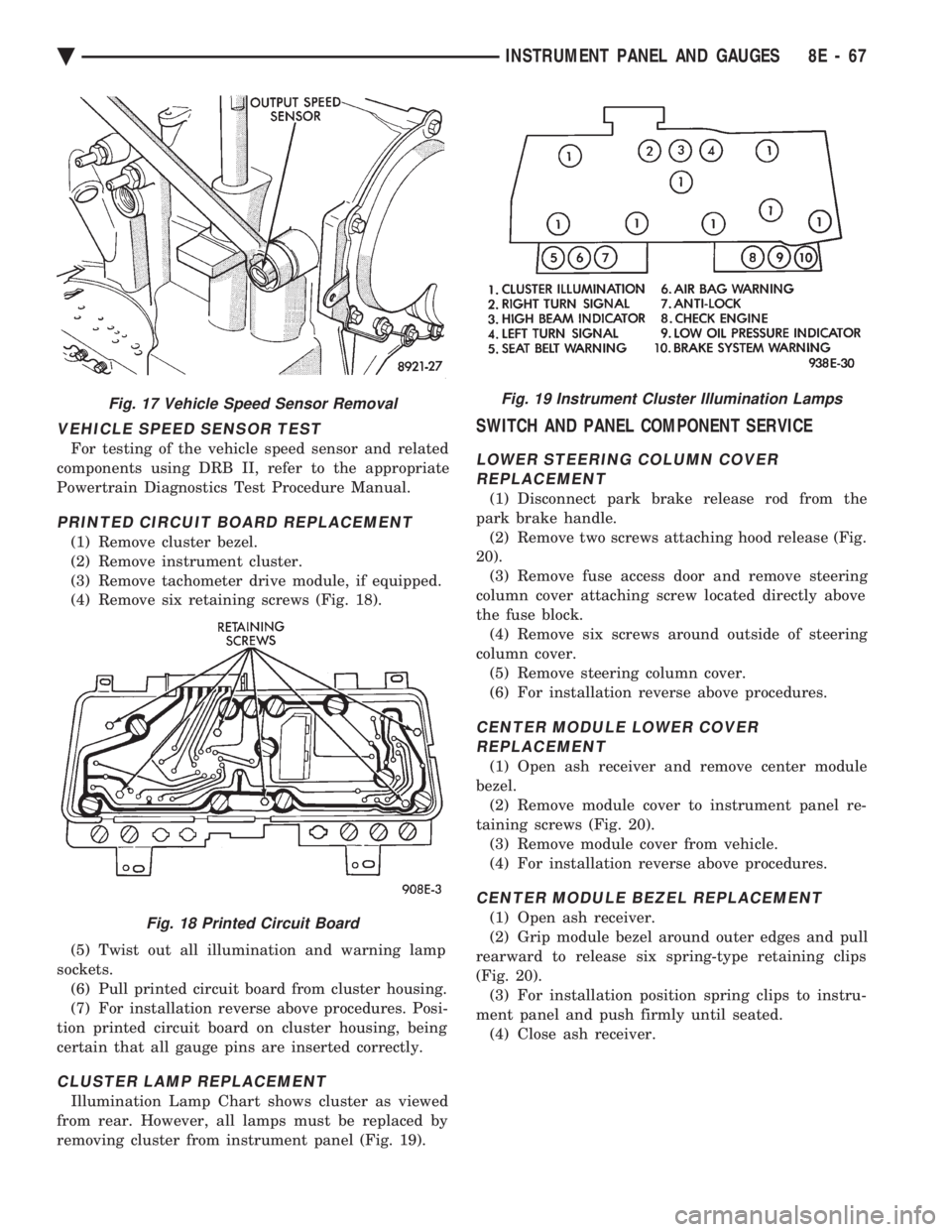

PRINTED CIRCUIT BOARD REPLACEMENT

(1) Remove cluster bezel.

(2) Remove instrument cluster.

(3) Remove tachometer drive module, if equipped.

(4) Remove six retaining screws (Fig. 18).

(5) Twist out all illumination and warning lamp

sockets. (6) Pull printed circuit board from cluster housing.

(7) For installation reverse above procedures. Posi-

tion printed circuit board on cluster housing, being

certain that all gauge pins are inserted correctly.

CLUSTER LAMP REPLACEMENT

Illumination Lamp Chart shows cluster as viewed

from rear. However, all lamps must be replaced by

removing cluster from instrument panel (Fig. 19).

SWITCH AND PANEL COMPONENT SERVICE

LOWER STEERING COLUMN COVER REPLACEMENT

(1) Disconnect park brake release rod from the

park brake handle. (2) Remove two screws attaching hood release (Fig.

20). (3) Remove fuse access door and remove steering

column cover attaching screw located directly above

the fuse block. (4) Remove six screws around outside of steering

column cover. (5) Remove steering column cover.

(6) For installation reverse above procedures.

CENTER MODULE LOWER COVER REPLACEMENT

(1) Open ash receiver and remove center module

bezel. (2) Remove module cover to instrument panel re-

taining screws (Fig. 20). (3) Remove module cover from vehicle.

(4) For installation reverse above procedures.

CENTER MODULE BEZEL REPLACEMENT

(1) Open ash receiver.

(2) Grip module bezel around outer edges and pull

rearward to release six spring-type retaining clips

(Fig. 20). (3) For installation position spring clips to instru-

ment panel and push firmly until seated. (4) Close ash receiver.

Fig. 17 Vehicle Speed Sensor Removal

Fig. 18 Printed Circuit Board

Fig. 19 Instrument Cluster Illumination Lamps

Ä INSTRUMENT PANEL AND GAUGES 8E - 67

Page 562 of 2438

CIGAR LIGHTER REPLACEMENT

(1) Remove center bezel assembly (Fig. 23).

(2) Remove center module lower cover or open for-

ward console lid. (3) Unscrew lighter receptacle shell from recepta-

cle and remove from base instrument panel. (4) Disconnect wiring connectors from lighter re-

ceptacle and remove from vehicle. (5) For installation reverse above procedures.

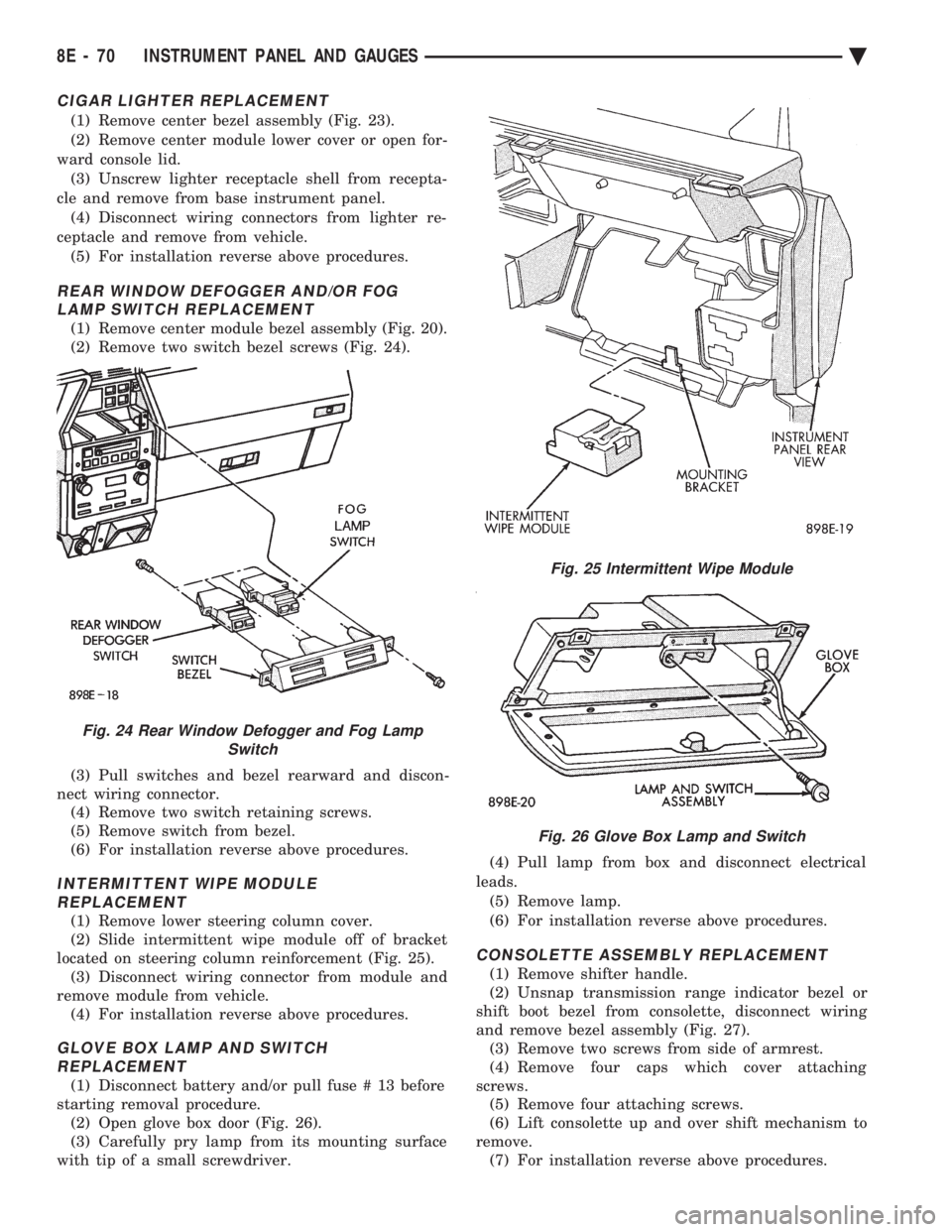

REAR WINDOW DEFOGGER AND/OR FOG LAMP SWITCH REPLACEMENT

(1) Remove center module bezel assembly (Fig. 20).

(2) Remove two switch bezel screws (Fig. 24).

(3) Pull switches and bezel rearward and discon-

nect wiring connector. (4) Remove two switch retaining screws.

(5) Remove switch from bezel.

(6) For installation reverse above procedures.

INTERMITTENT WIPE MODULE REPLACEMENT

(1) Remove lower steering column cover.

(2) Slide intermittent wipe module off of bracket

located on steering column reinforcement (Fig. 25). (3) Disconnect wiring connector from module and

remove module from vehicle. (4) For installation reverse above procedures.

GLOVE BOX LAMP AND SWITCHREPLACEMENT

(1) Disconnect battery and/or pull fuse # 13 before

starting removal procedure. (2) Open glove box door (Fig. 26).

(3) Carefully pry lamp from its mounting surface

with tip of a small screwdriver. (4) Pull lamp from box and disconnect electrical

leads. (5) Remove lamp.

(6) For installation reverse above procedures.

CONSOLETTE ASSEMBLY REPLACEMENT

(1) Remove shifter handle.

(2) Unsnap transmission range indicator bezel or

shift boot bezel from consolette, disconnect wiring

and remove bezel assembly (Fig. 27). (3) Remove two screws from side of armrest.

(4) Remove four caps which cover attaching

screws. (5) Remove four attaching screws.

(6) Lift consolette up and over shift mechanism to

remove. (7) For installation reverse above procedures.

Fig. 24 Rear Window Defogger and Fog Lamp Switch

Fig. 25 Intermittent Wipe Module

Fig. 26 Glove Box Lamp and Switch

8E - 70 INSTRUMENT PANEL AND GAUGES Ä

Page 564 of 2438

(2) Pry cover up and forward until released from

instrument panel pad. (3) Lift top cover upward and rearward to remove

from vehicle. (4) For installation place top cover on panel open-

ing. Be certain that blades of top cover are located in

the retaining spring clips. (5) Push forward and down to engage in pad.

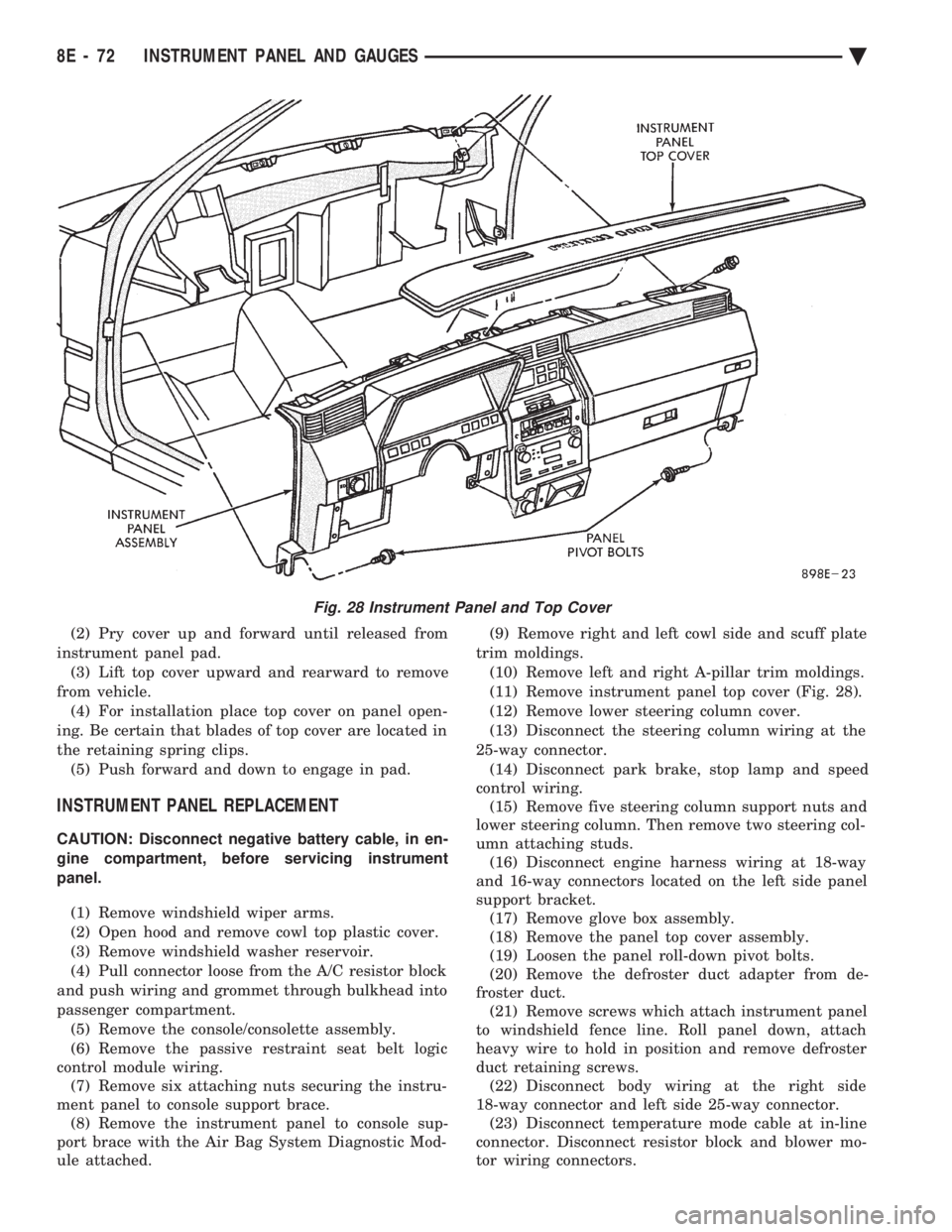

INSTRUMENT PANEL REPLACEMENT

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel.

(1) Remove windshield wiper arms.

(2) Open hood and remove cowl top plastic cover.

(3) Remove windshield washer reservoir.

(4) Pull connector loose from the A/C resistor block

and push wiring and grommet through bulkhead into

passenger compartment. (5) Remove the console/consolette assembly.

(6) Remove the passive restraint seat belt logic

control module wiring. (7) Remove six attaching nuts securing the instru-

ment panel to console support brace. (8) Remove the instrument panel to console sup-

port brace with the Air Bag System Diagnostic Mod-

ule attached. (9) Remove right and left cowl side and scuff plate

trim moldings. (10) Remove left and right A-pillar trim moldings.

(11) Remove instrument panel top cover (Fig. 28).

(12) Remove lower steering column cover.

(13) Disconnect the steering column wiring at the

25-way connector. (14) Disconnect park brake, stop lamp and speed

control wiring. (15) Remove five steering column support nuts and

lower steering column. Then remove two steering col-

umn attaching studs. (16) Disconnect engine harness wiring at 18-way

and 16-way connectors located on the left side panel

support bracket. (17) Remove glove box assembly.

(18) Remove the panel top cover assembly.

(19) Loosen the panel roll-down pivot bolts.

(20) Remove the defroster duct adapter from de-

froster duct. (21) Remove screws which attach instrument panel

to windshield fence line. Roll panel down, attach

heavy wire to hold in position and remove defroster

duct retaining screws. (22) Disconnect body wiring at the right side

18-way connector and left side 25-way connector. (23) Disconnect temperature mode cable at in-line

connector. Disconnect resistor block and blower mo-

tor wiring connectors.

Fig. 28 Instrument Panel and Top Cover

8E - 72 INSTRUMENT PANEL AND GAUGES Ä

Page 597 of 2438

HORNS

CONTENTS

page page

GENERAL INFORMATION .................. 1

HORN SWITCH REPLACEMENT ............ 3 TESTING HORN SYSTEM

................. 1

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AIR

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

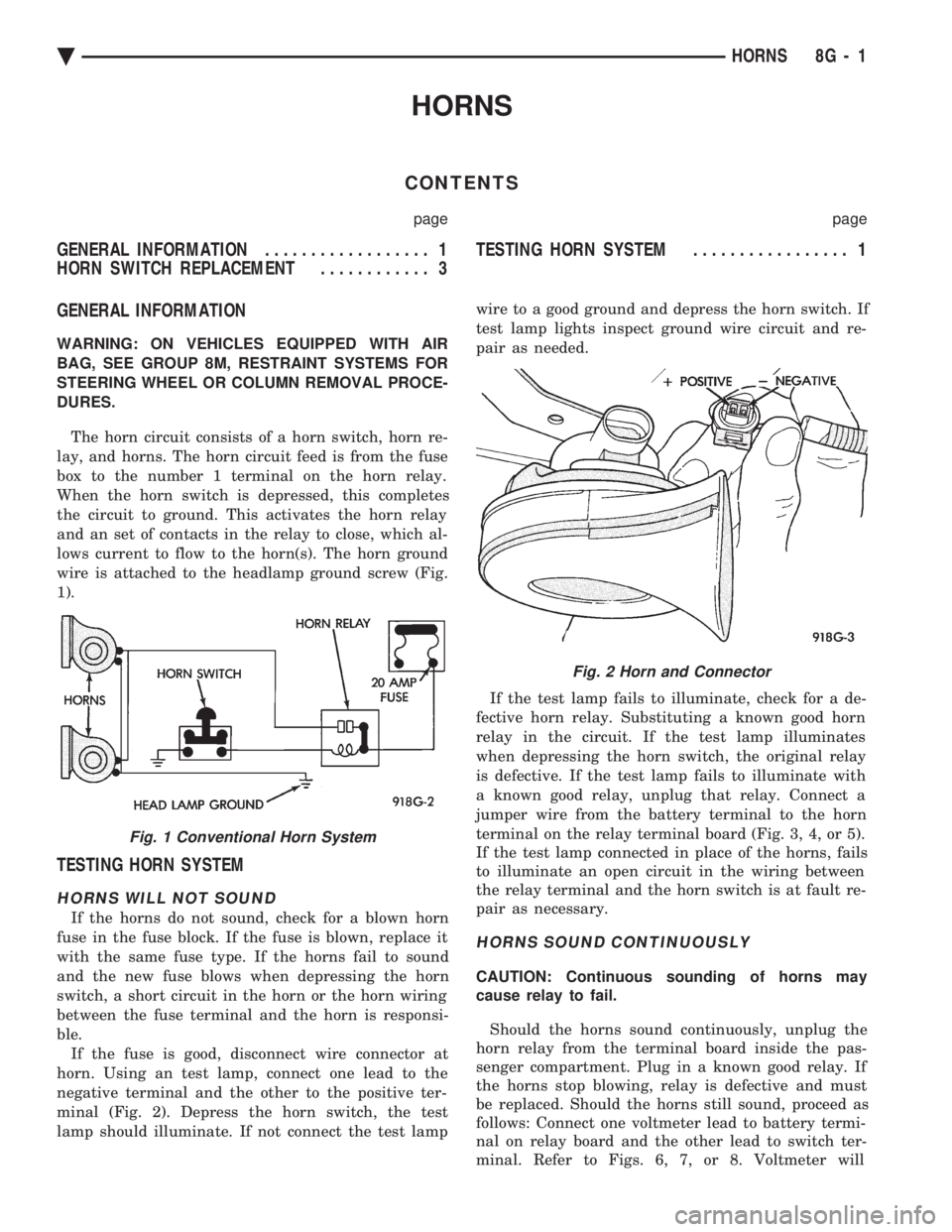

The horn circuit consists of a horn switch, horn re-

lay, and horns. The horn circuit feed is from the fuse

box to the number 1 terminal on the horn relay.

When the horn switch is depressed, this completes

the circuit to ground. This activates the horn relay

and an set of contacts in the relay to close, which al-

lows current to flow to the horn(s). The horn ground

wire is attached to the headlamp ground screw (Fig.

1).

TESTING HORN SYSTEM

HORNS WILL NOT SOUND

If the horns do not sound, check for a blown horn

fuse in the fuse block. If the fuse is blown, replace it

with the same fuse type. If the horns fail to sound

and the new fuse blows when depressing the horn

switch, a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble. If the fuse is good, disconnect wire connector at

horn. Using an test lamp, connect one lead to the

negative terminal and the other to the positive ter-

minal (Fig. 2). Depress the horn switch, the test

lamp should illuminate. If not connect the test lamp wire to a good ground and depress the horn switch. If

test lamp lights inspect ground wire circuit and re-

pair as needed.

If the test lamp fails to illuminate, check for a de-

fective horn relay. Substituting a known good horn

relay in the circuit. If the test lamp illuminates

when depressing the horn switch, the original relay

is defective. If the test lamp fails to illuminate with

a known good relay, unplug that relay. Connect a

jumper wire from the battery terminal to the horn

terminal on the relay terminal board (Fig. 3, 4, or 5).

If the test lamp connected in place of the horns, fails

to illuminate an open circuit in the wiring between

the relay terminal and the horn switch is at fault re-

pair as necessary.

HORNS SOUND CONTINUOUSLY

CAUTION: Continuous sounding of horns may

cause relay to fail.

Should the horns sound continuously, unplug the

horn relay from the terminal board inside the pas-

senger compartment. Plug in a known good relay. If

the horns stop blowing, relay is defective and must

be replaced. Should the horns still sound, proceed as

follows: Connect one voltmeter lead to battery termi-

nal on relay board and the other lead to switch ter-

minal. Refer to Figs. 6, 7, or 8. Voltmeter will

Fig. 1 Conventional Horn System

Fig. 2 Horn and Connector

Ä HORNS 8G - 1