brakes CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 186 of 2438

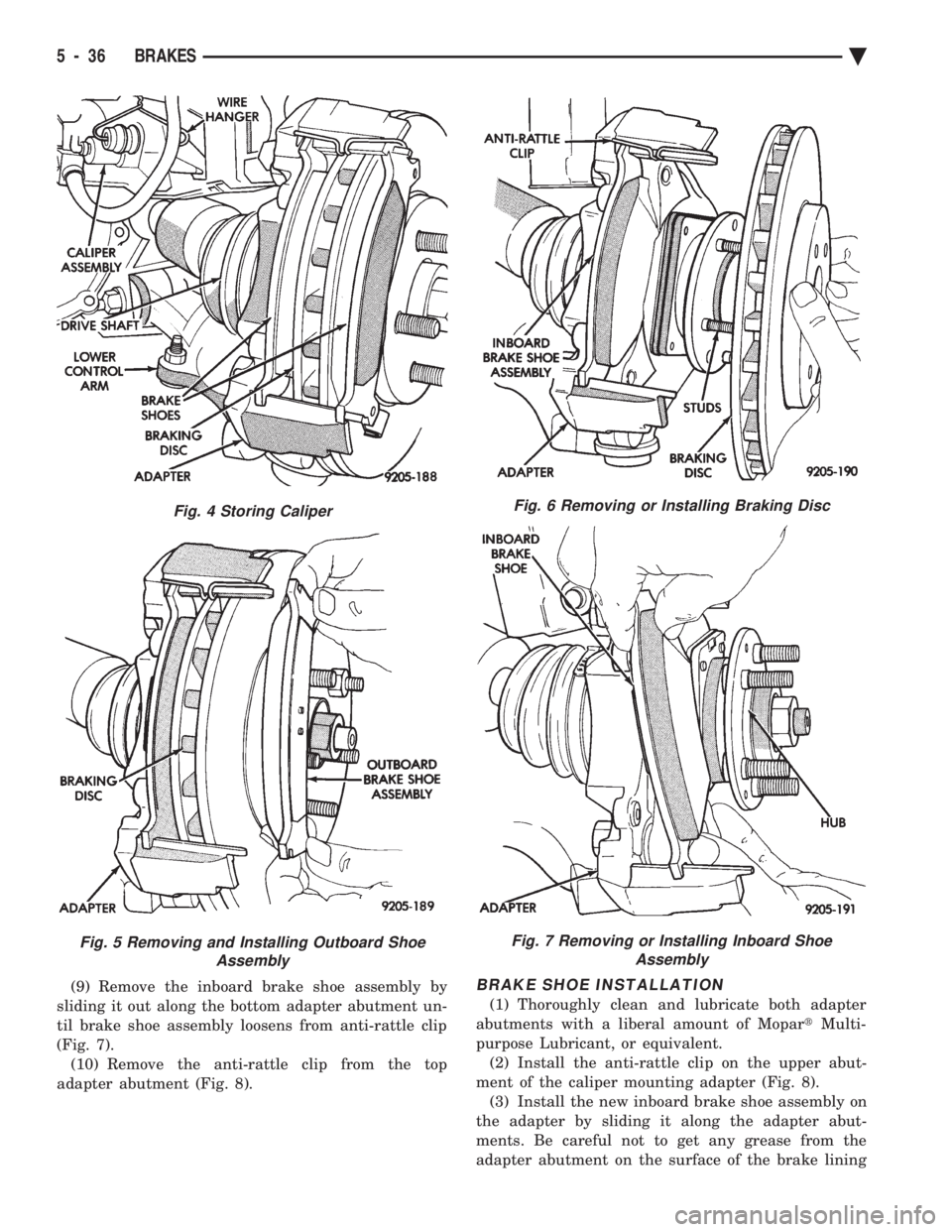

(9) Remove the inboard brake shoe assembly by

sliding it out along the bottom adapter abutment un-

til brake shoe assembly loosens from anti-rattle clip

(Fig. 7). (10) Remove the anti-rattle clip from the top

adapter abutment (Fig. 8).BRAKE SHOE INSTALLATION

(1) Thoroughly clean and lubricate both adapter

abutments with a liberal amount of Mopar tMulti-

purpose Lubricant, or equivalent. (2) Install the anti-rattle clip on the upper abut-

ment of the caliper mounting adapter (Fig. 8). (3) Install the new inboard brake shoe assembly on

the adapter by sliding it along the adapter abut-

ments. Be careful not to get any grease from the

adapter abutment on the surface of the brake lining

Fig. 4 Storing Caliper

Fig. 5 Removing and Installing Outboard Shoe Assembly

Fig. 6 Removing or Installing Braking Disc

Fig. 7 Removing or Installing Inboard ShoeAssembly

5 - 36 BRAKES Ä

Page 187 of 2438

material, (Fig. 7). Be sure inboard brake shoe assem-

bly is correctly positioned against anti-rattle clip

(Fig. 6). (4) Reinstall the Braking Disk on the hub, by in-

stalling it over the wheel studs until it is seated

against the face of the hub (Fig. 6). (5) Slide the new outboard brake shoe assembly on

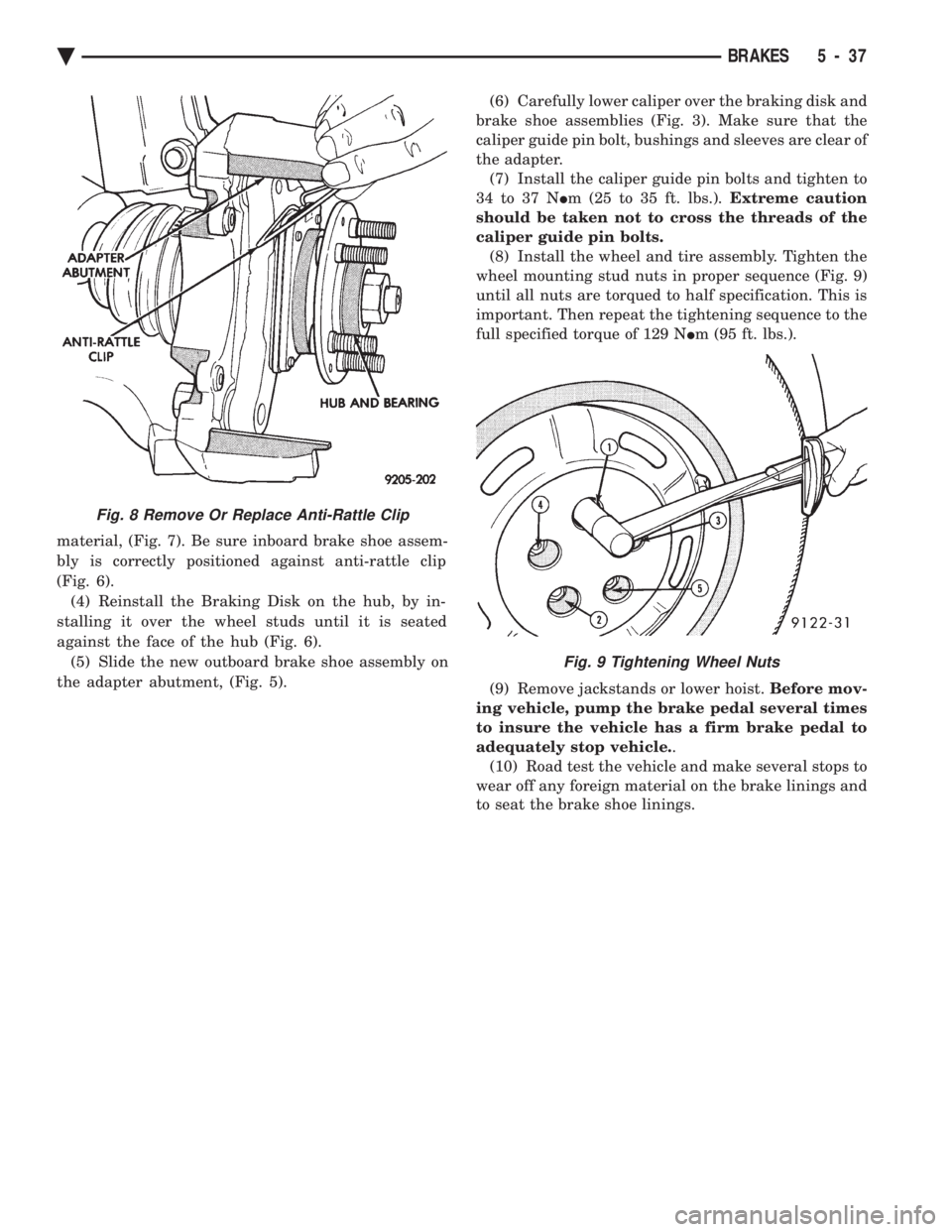

the adapter abutment, (Fig. 5). (6) Carefully lower caliper over the braking disk and

brake shoe assemblies (Fig. 3). Make sure that the

caliper guide pin bolt, bushings and sleeves are clear of

the adapter. (7) Install the caliper guide pin bolts and tighten to

34 to 37 N Im (25 to 35 ft. lbs.). Extreme caution

should be taken not to cross the threads of the

caliper guide pin bolts. (8) Install the wheel and tire assembly. Tighten the

wheel mounting stud nuts in proper sequence (Fig. 9)

until all nuts are torqued to half specification. This is

important. Then repeat the tightening sequence to the

full specified torque of 129 N Im (95 ft. lbs.).

(9) Remove jackstands or lower hoist. Before mov-

ing vehicle, pump the brake pedal several times

to insure the vehicle has a firm brake pedal to

adequately stop vehicle. .

(10) Road test the vehicle and make several stops to

wear off any foreign material on the brake linings and

to seat the brake shoe linings.

Fig. 8 Remove Or Replace Anti-Rattle Clip

Fig. 9 Tightening Wheel Nuts

Ä BRAKES 5 - 37

Page 188 of 2438

KELSEY HAYES DOUBLE PIN NON-FAMILY CALIPER INDEX

page page

Assembling Disc Brake Caliper .............. 42

Cleaning and Inspection of Brake Caliper ...... 41 Disc Brake Caliper Disassembly

............. 40

Service Procedures ....................... 38

SERVICE PROCEDURES

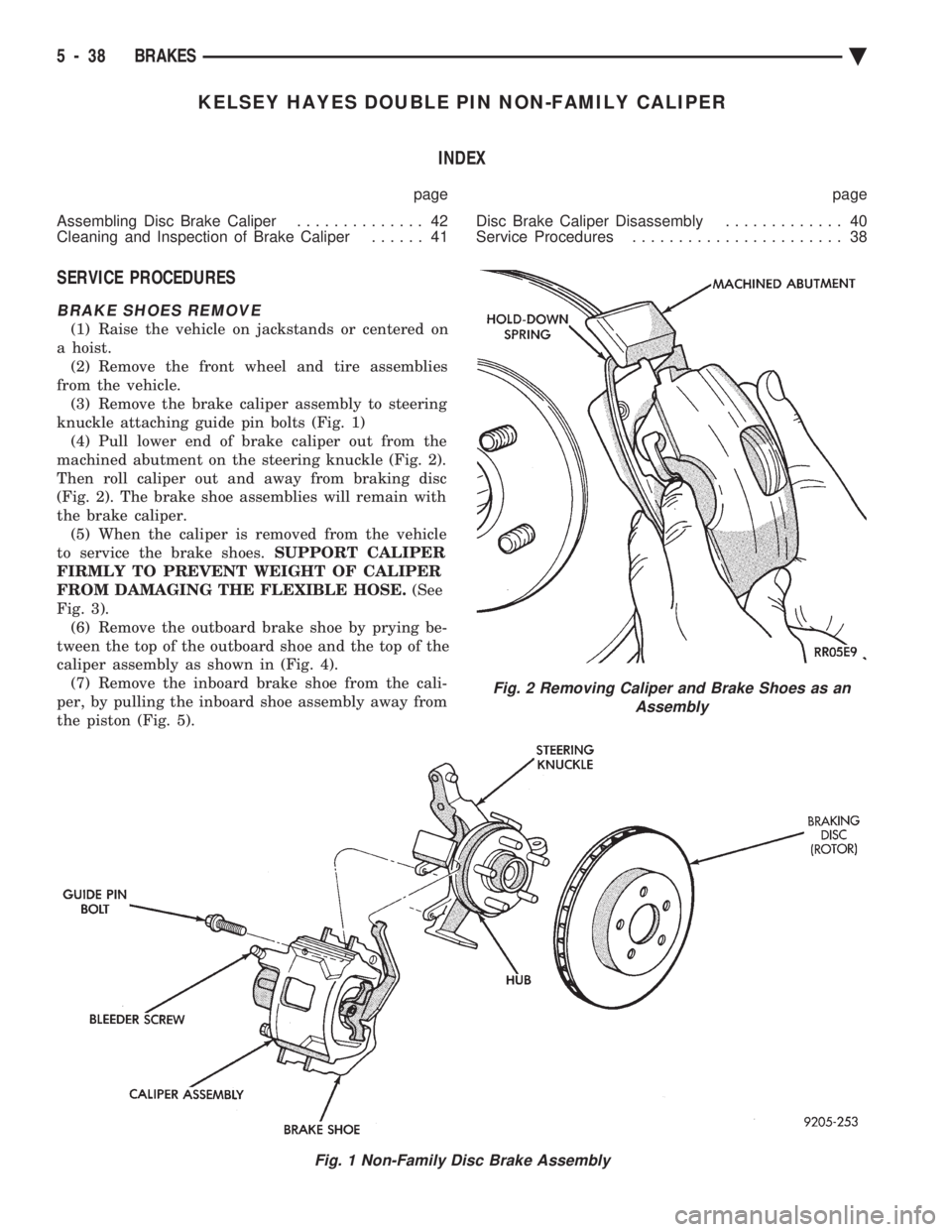

BRAKE SHOES REMOVE

(1) Raise the vehicle on jackstands or centered on

a hoist. (2) Remove the front wheel and tire assemblies

from the vehicle. (3) Remove the brake caliper assembly to steering

knuckle attaching guide pin bolts (Fig. 1) (4) Pull lower end of brake caliper out from the

machined abutment on the steering knuckle (Fig. 2).

Then roll caliper out and away from braking disc

(Fig. 2). The brake shoe assemblies will remain with

the brake caliper. (5) When the caliper is removed from the vehicle

to service the brake shoes. SUPPORT CALIPER

FIRMLY TO PREVENT WEIGHT OF CALIPER

FROM DAMAGING THE FLEXIBLE HOSE. (See

Fig. 3). (6) Remove the outboard brake shoe by prying be-

tween the top of the outboard shoe and the top of the

caliper assembly as shown in (Fig. 4). (7) Remove the inboard brake shoe from the cali-

per, by pulling the inboard shoe assembly away from

the piston (Fig. 5).

Fig. 1 Non-Family Disc Brake Assembly

Fig. 2 Removing Caliper and Brake Shoes as an Assembly

5 - 38 BRAKES Ä

Page 189 of 2438

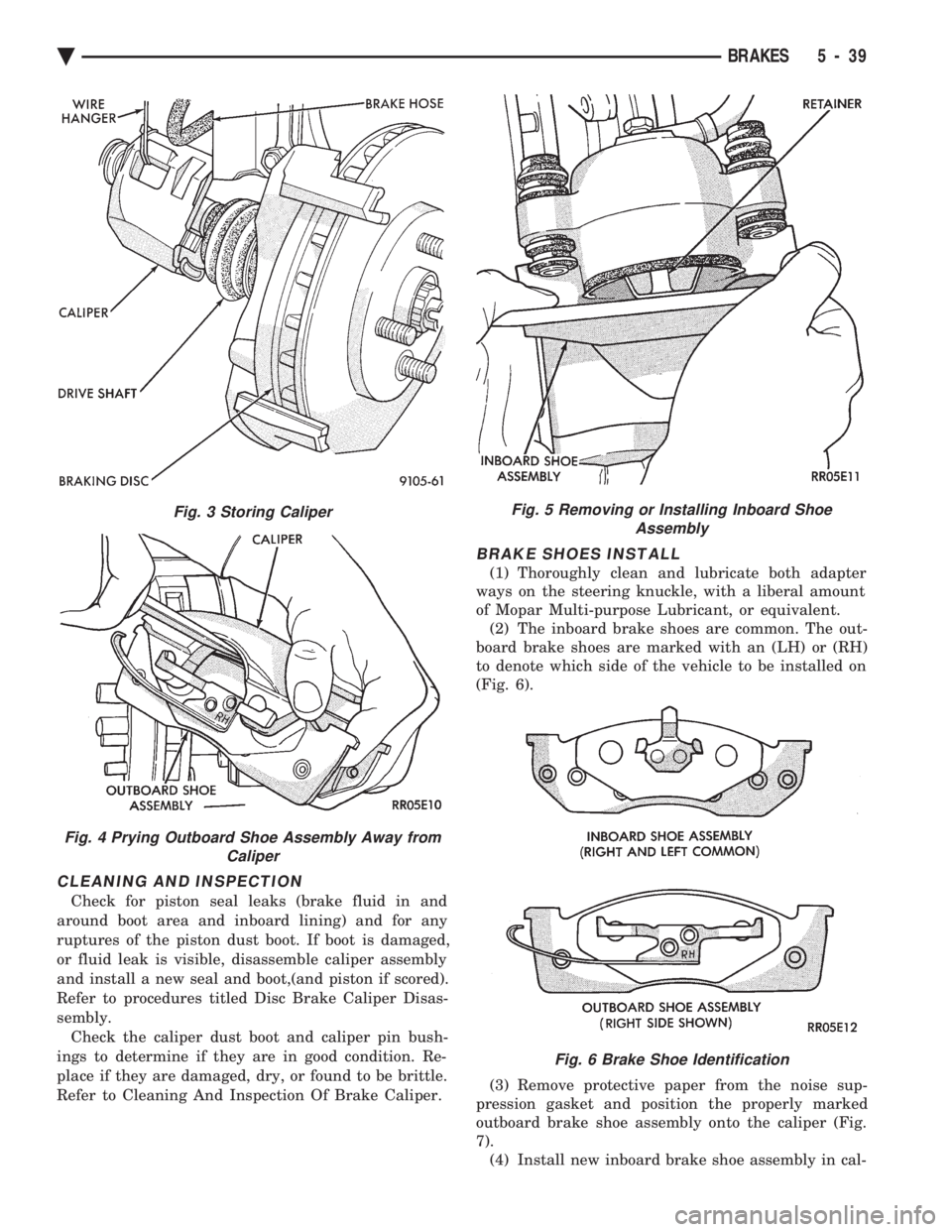

CLEANING AND INSPECTION

Check for piston seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of the piston dust boot. If boot is damaged,

or fluid leak is visible, disassemble caliper assembly

and install a new seal and boot,(and piston if scored).

Refer to procedures titled Disc Brake Caliper Disas-

sembly. Check the caliper dust boot and caliper pin bush-

ings to determine if they are in good condition. Re-

place if they are damaged, dry, or found to be brittle.

Refer to Cleaning And Inspection Of Brake Caliper.

BRAKE SHOES INSTALL

(1) Thoroughly clean and lubricate both adapter

ways on the steering knuckle, with a liberal amount

of Mopar Multi-purpose Lubricant, or equivalent. (2) The inboard brake shoes are common. The out-

board brake shoes are marked with an (LH) or (RH)

to denote which side of the vehicle to be installed on

(Fig. 6).

(3) Remove protective paper from the noise sup-

pression gasket and position the properly marked

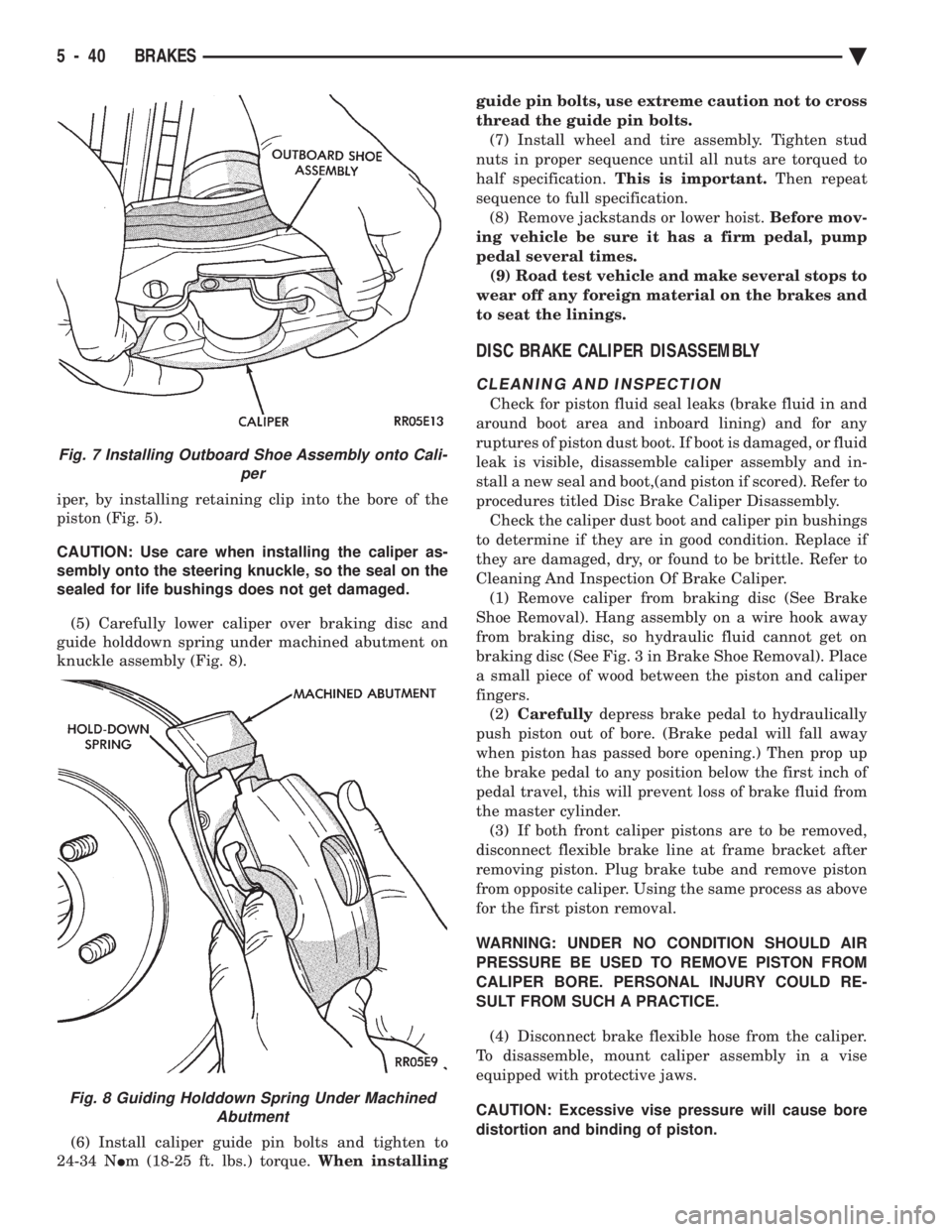

outboard brake shoe assembly onto the caliper (Fig.

7). (4) Install new inboard brake shoe assembly in cal-

Fig. 3 Storing Caliper

Fig. 4 Prying Outboard Shoe Assembly Away from Caliper

Fig. 5 Removing or Installing Inboard ShoeAssembly

Fig. 6 Brake Shoe Identification

Ä BRAKES 5 - 39

Page 190 of 2438

iper, by installing retaining clip into the bore of the

piston (Fig. 5).

CAUTION: Use care when installing the caliper as-

sembly onto the steering knuckle, so the seal on the

sealed for life bushings does not get damaged.

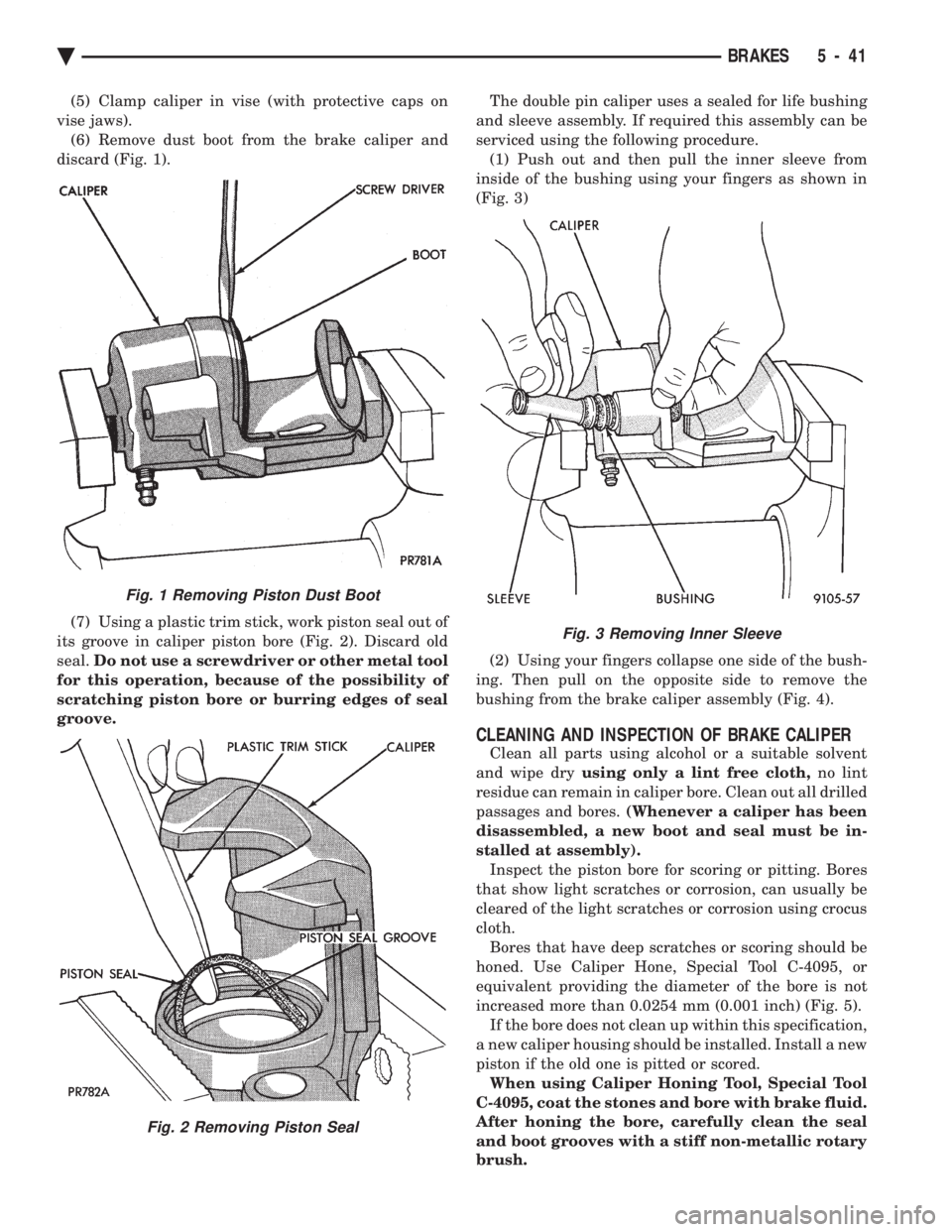

(5) Carefully lower caliper over braking disc and

guide holddown spring under machined abutment on

knuckle assembly (Fig. 8).

(6) Install caliper guide pin bolts and tighten to

24-34 N Im (18-25 ft. lbs.) torque. When installing guide pin bolts, use extreme caution not to cross

thread the guide pin bolts.

(7) Install wheel and tire assembly. Tighten stud

nuts in proper sequence until all nuts are torqued to

half specification. This is important. Then repeat

sequence to full specification. (8) Remove jackstands or lower hoist. Before mov-

ing vehicle be sure it has a firm pedal, pump

pedal several times. (9) Road test vehicle and make several stops to

wear off any foreign material on the brakes and

to seat the linings.

DISC BRAKE CALIPER DISASSEMBLY

CLEANING AND INSPECTION

Check for piston fluid seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If boot is damaged, or fluid

leak is visible, disassemble caliper assembly and in-

stall a new seal and boot,(and piston if scored). Refer to

procedures titled Disc Brake Caliper Disassembly. Check the caliper dust boot and caliper pin bushings

to determine if they are in good condition. Replace if

they are damaged, dry, or found to be brittle. Refer to

Cleaning And Inspection Of Brake Caliper. (1) Remove caliper from braking disc (See Brake

Shoe Removal). Hang assembly on a wire hook away

from braking disc, so hydraulic fluid cannot get on

braking disc (See Fig. 3 in Brake Shoe Removal). Place

a small piece of wood between the piston and caliper

fingers. (2) Carefully depress brake pedal to hydraulically

push piston out of bore. (Brake pedal will fall away

when piston has passed bore opening.) Then prop up

the brake pedal to any position below the first inch of

pedal travel, this will prevent loss of brake fluid from

the master cylinder. (3) If both front caliper pistons are to be removed,

disconnect flexible brake line at frame bracket after

removing piston. Plug brake tube and remove piston

from opposite caliper. Using the same process as above

for the first piston removal.

WARNING: UNDER NO CONDITION SHOULD AIR

PRESSURE BE USED TO REMOVE PISTON FROM

CALIPER BORE. PERSONAL INJURY COULD RE-

SULT FROM SUCH A PRACTICE.

(4) Disconnect brake flexible hose from the caliper.

To disassemble, mount caliper assembly in a vise

equipped with protective jaws.

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston.

Fig. 7 Installing Outboard Shoe Assembly onto Cali- per

Fig. 8 Guiding Holddown Spring Under MachinedAbutment

5 - 40 BRAKES Ä

Page 191 of 2438

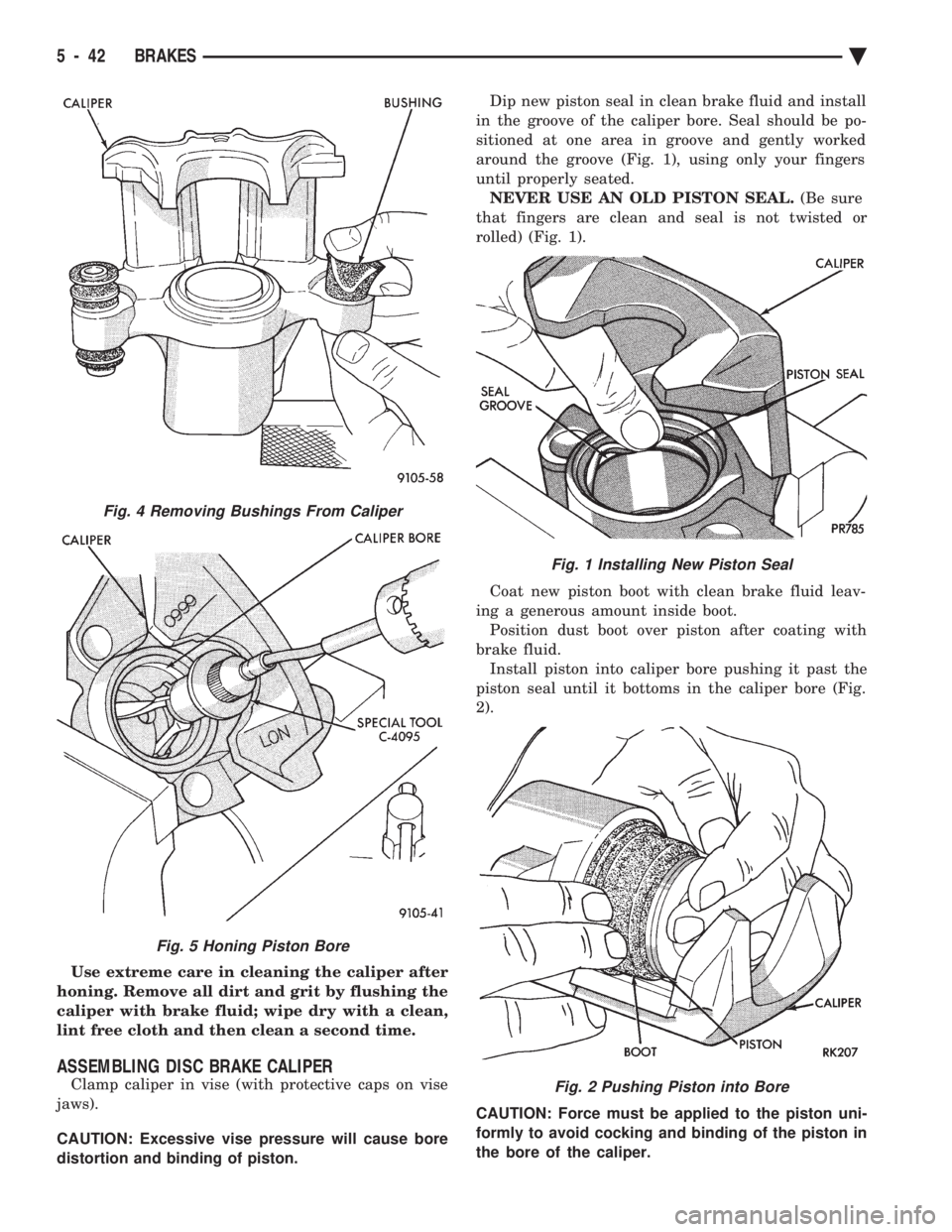

(5) Clamp caliper in vise (with protective caps on

vise jaws). (6) Remove dust boot from the brake caliper and

discard (Fig. 1).

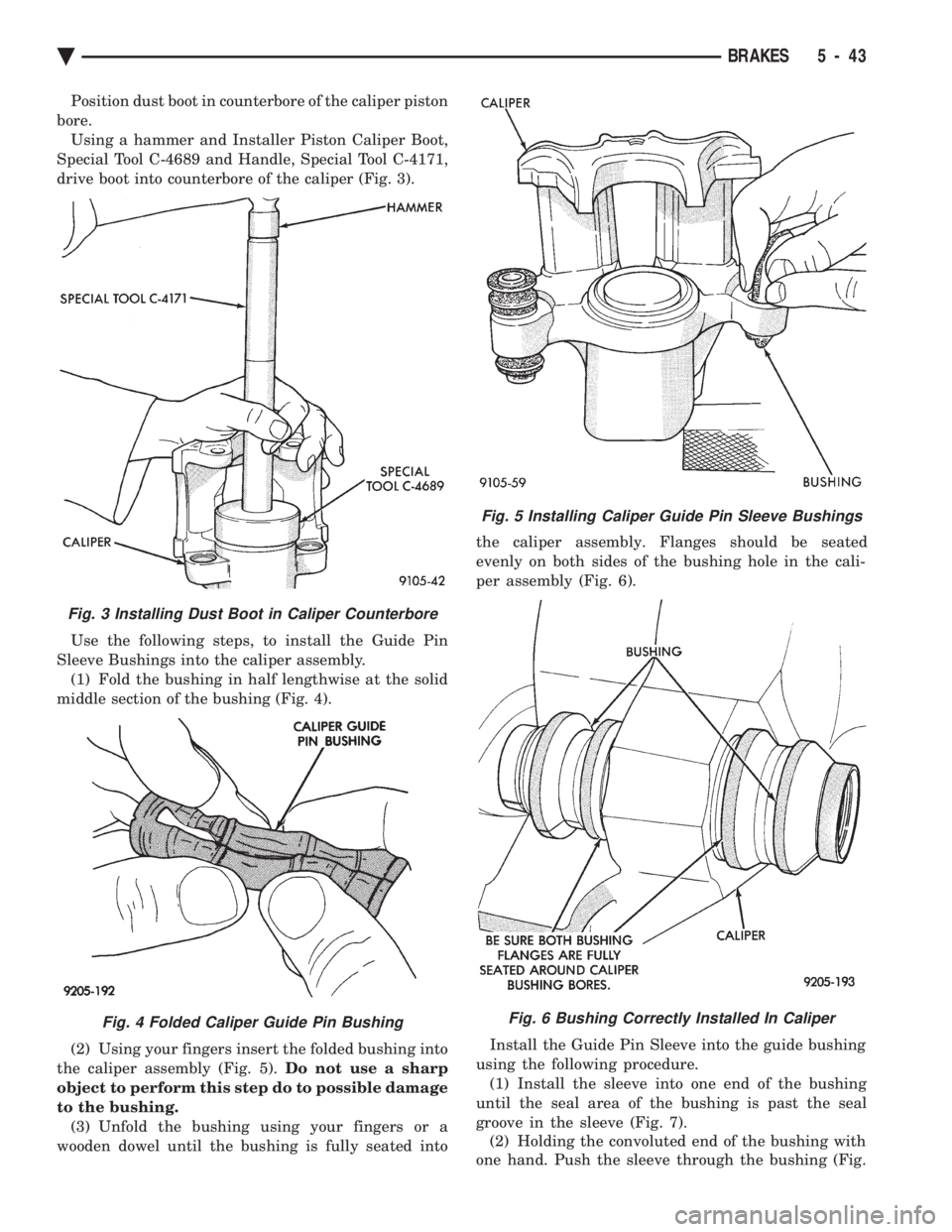

(7) Using a plastic trim stick, work piston seal out of

its groove in caliper piston bore (Fig. 2). Discard old

seal. Do not use a screwdriver or other metal tool

for this operation, because of the possibility of

scratching piston bore or burring edges of seal

groove. The double pin caliper uses a sealed for life bushing

and sleeve assembly. If required this assembly can be

serviced using the following procedure. (1) Push out and then pull the inner sleeve from

inside of the bushing using your fingers as shown in

(Fig. 3)

(2) Using your fingers collapse one side of the bush-

ing. Then pull on the opposite side to remove the

bushing from the brake caliper assembly (Fig. 4).

CLEANING AND INSPECTION OF BRAKE CALIPER

Clean all parts using alcohol or a suitable solvent

and wipe dry using only a lint free cloth, no lint

residue can remain in caliper bore. Clean out all drilled

passages and bores. (Whenever a caliper has been

disassembled, a new boot and seal must be in-

stalled at assembly). Inspect the piston bore for scoring or pitting. Bores

that show light scratches or corrosion, can usually be

cleared of the light scratches or corrosion using crocus

cloth. Bores that have deep scratches or scoring should be

honed. Use Caliper Hone, Special Tool C-4095, or

equivalent providing the diameter of the bore is not

increased more than 0.0254 mm (0.001 inch) (Fig. 5). If the bore does not clean up within this specification,

a new caliper housing should be installed. Install a new

piston if the old one is pitted or scored. When using Caliper Honing Tool, Special Tool

C-4095, coat the stones and bore with brake fluid.

After honing the bore, carefully clean the seal

and boot grooves with a stiff non-metallic rotary

brush.

Fig. 1 Removing Piston Dust Boot

Fig. 2 Removing Piston Seal

Fig. 3 Removing Inner Sleeve

Ä BRAKES 5 - 41

Page 192 of 2438

Use extreme care in cleaning the caliper after

honing. Remove all dirt and grit by flushing the

caliper with brake fluid; wipe dry with a clean,

lint free cloth and then clean a second time.

ASSEMBLING DISC BRAKE CALIPER

Clamp caliper in vise (with protective caps on vise

jaws).

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston. Dip new piston seal in clean brake fluid and install

in the groove of the caliper bore. Seal should be po-

sitioned at one area in groove and gently worked

around the groove (Fig. 1), using only your fingers

until properly seated. NEVER USE AN OLD PISTON SEAL. (Be sure

that fingers are clean and seal is not twisted or

rolled) (Fig. 1).

Coat new piston boot with clean brake fluid leav-

ing a generous amount inside boot. Position dust boot over piston after coating with

brake fluid. Install piston into caliper bore pushing it past the

piston seal until it bottoms in the caliper bore (Fig.

2).

CAUTION: Force must be applied to the piston uni-

formly to avoid cocking and binding of the piston in

the bore of the caliper.

Fig. 1 Installing New Piston Seal

Fig. 2 Pushing Piston into Bore

Fig. 4 Removing Bushings From Caliper

Fig. 5 Honing Piston Bore

5 - 42 BRAKES Ä

Page 193 of 2438

Position dust boot in counterbore of the caliper piston

bore. Using a hammer and Installer Piston Caliper Boot,

Special Tool C-4689 and Handle, Special Tool C-4171,

drive boot into counterbore of the caliper (Fig. 3).

Use the following steps, to install the Guide Pin

Sleeve Bushings into the caliper assembly. (1) Fold the bushing in half lengthwise at the solid

middle section of the bushing (Fig. 4).

(2) Using your fingers insert the folded bushing into

the caliper assembly (Fig. 5). Do not use a sharp

object to perform this step do to possible damage

to the bushing. (3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated into the caliper assembly. Flanges should be seated

evenly on both sides of the bushing hole in the cali-

per assembly (Fig. 6).

Install the Guide Pin Sleeve into the guide bushing

using the following procedure. (1) Install the sleeve into one end of the bushing

until the seal area of the bushing is past the seal

groove in the sleeve (Fig. 7). (2) Holding the convoluted end of the bushing with

one hand. Push the sleeve through the bushing (Fig.

Fig. 5 Installing Caliper Guide Pin Sleeve Bushings

Fig. 6 Bushing Correctly Installed In Caliper

Fig. 3 Installing Dust Boot in Caliper Counterbore

Fig. 4 Folded Caliper Guide Pin Bushing

Ä BRAKES 5 - 43

Page 194 of 2438

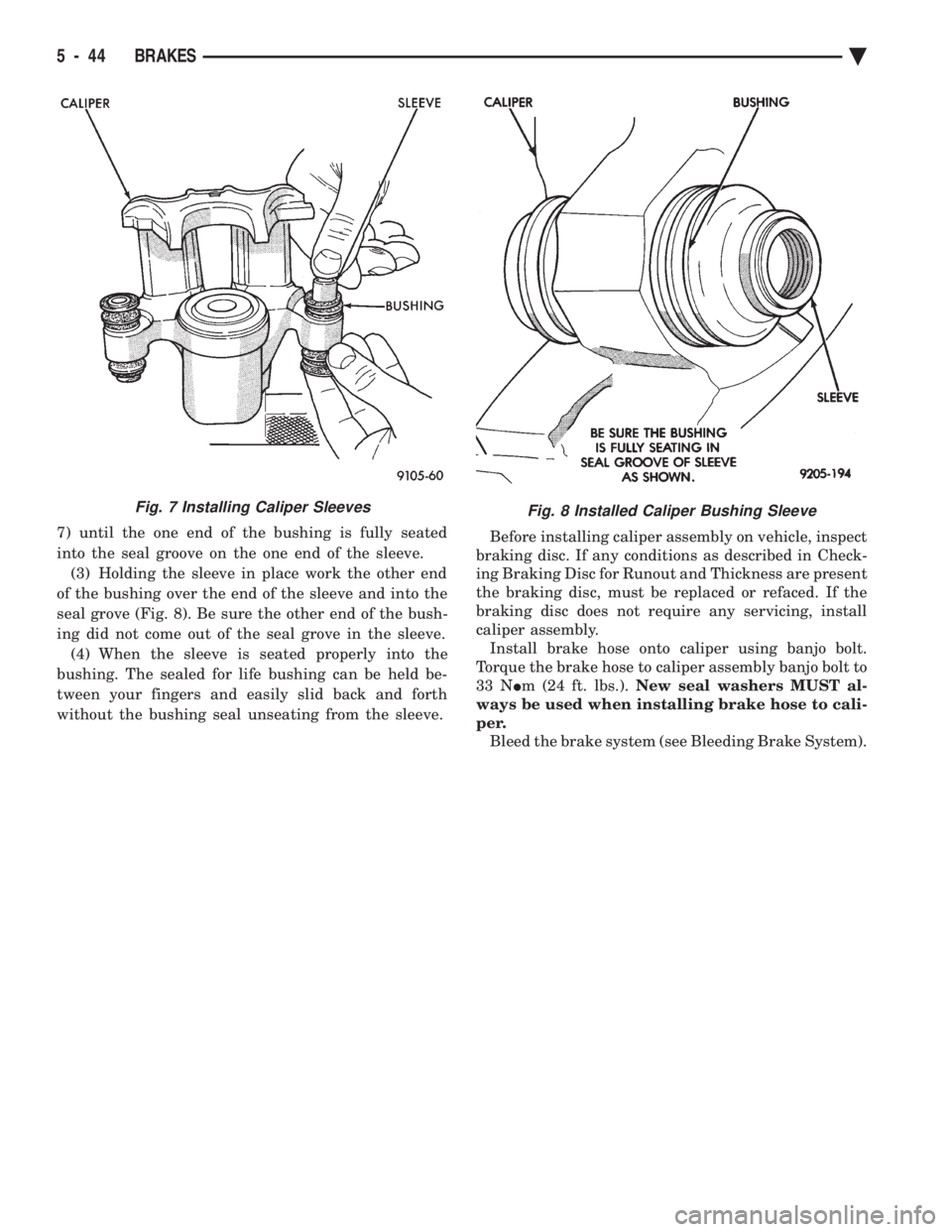

7) until the one end of the bushing is fully seated

into the seal groove on the one end of the sleeve. (3) Holding the sleeve in place work the other end

of the bushing over the end of the sleeve and into the

seal grove (Fig. 8). Be sure the other end of the bush-

ing did not come out of the seal grove in the sleeve. (4) When the sleeve is seated properly into the

bushing. The sealed for life bushing can be held be-

tween your fingers and easily slid back and forth

without the bushing seal unseating from the sleeve. Before installing caliper assembly on vehicle, inspect

braking disc. If any conditions as described in Check-

ing Braking Disc for Runout and Thickness are present

the braking disc, must be replaced or refaced. If the

braking disc does not require any servicing, install

caliper assembly. Install brake hose onto caliper using banjo bolt.

Torque the brake hose to caliper assembly banjo bolt to

33 N Im (24 ft. lbs.). New seal washers MUST al-

ways be used when installing brake hose to cali-

per. Bleed the brake system (see Bleeding Brake System).

Fig. 7 Installing Caliper SleevesFig. 8 Installed Caliper Bushing Sleeve

5 - 44 BRAKES Ä

Page 195 of 2438

REAR DISC BRAKES INDEX

page page

Assembling Rear Disc Brake Caliper .......... 49

Brake Shoe Removal ..................... 46

Cleaning and Inspection ................... 49

Disassembling Rear Caliper Assembly ......... 48 General Information

....................... 45

Lining Wear ............................. 45

Service Precautions ....................... 46

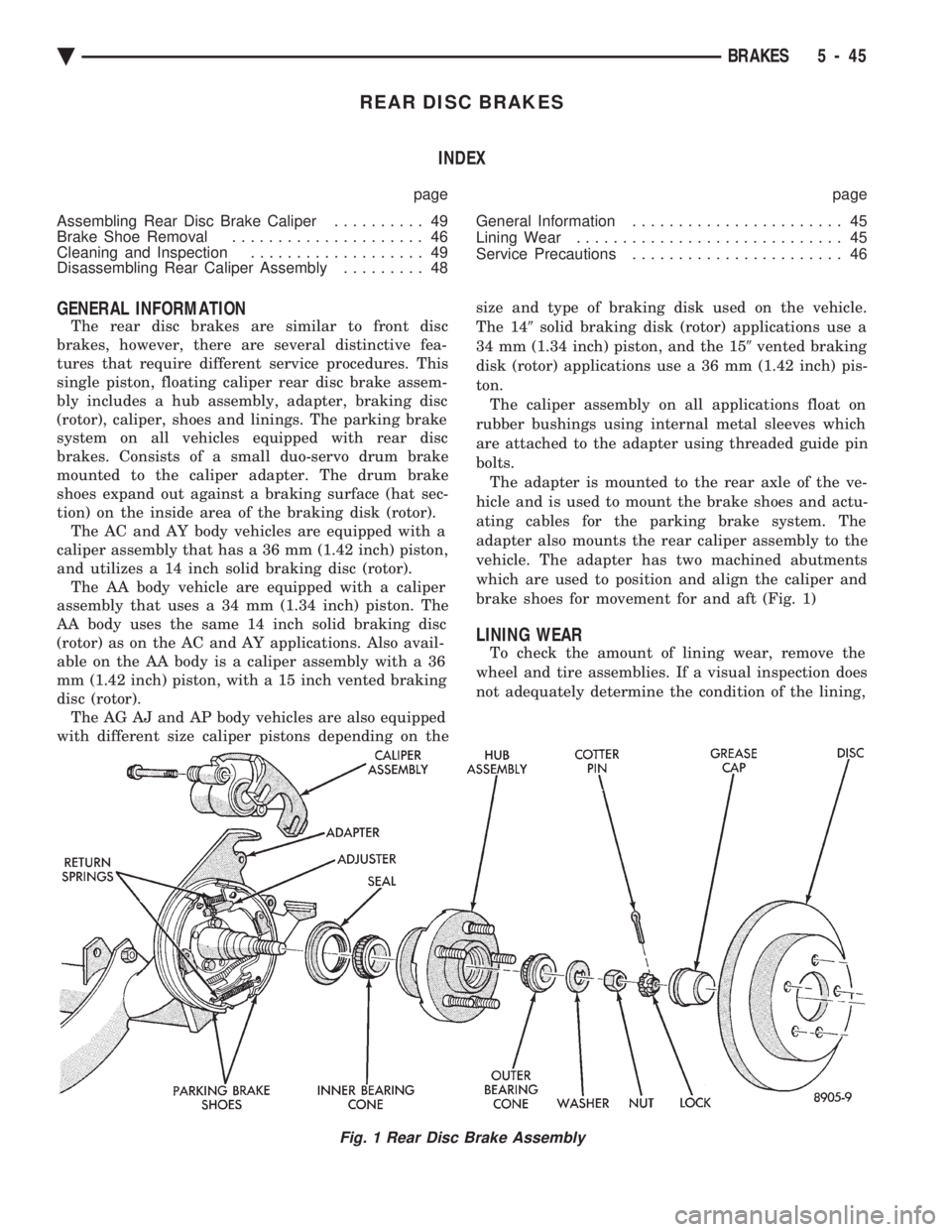

GENERAL INFORMATION

The rear disc brakes are similar to front disc

brakes, however, there are several distinctive fea-

tures that require different service procedures. This

single piston, floating caliper rear disc brake assem-

bly includes a hub assembly, adapter, braking disc

(rotor), caliper, shoes and linings. The parking brake

system on all vehicles equipped with rear disc

brakes. Consists of a small duo-servo drum brake

mounted to the caliper adapter. The drum brake

shoes expand out against a braking surface (hat sec-

tion) on the inside area of the braking disk (rotor). The AC and AY body vehicles are equipped with a

caliper assembly that has a 36 mm (1.42 inch) piston,

and utilizes a 14 inch solid braking disc (rotor). The AA body vehicle are equipped with a caliper

assembly that uses a 34 mm (1.34 inch) piston. The

AA body uses the same 14 inch solid braking disc

(rotor) as on the AC and AY applications. Also avail-

able on the AA body is a caliper assembly with a 36

mm (1.42 inch) piston, with a 15 inch vented braking

disc (rotor). The AG AJ and AP body vehicles are also equipped

with different size caliper pistons depending on the size and type of braking disk used on the vehicle.

The 14 9solid braking disk (rotor) applications use a

34 mm (1.34 inch) piston, and the 15 9vented braking

disk (rotor) applications use a 36 mm (1.42 inch) pis-

ton. The caliper assembly on all applications float on

rubber bushings using internal metal sleeves which

are attached to the adapter using threaded guide pin

bolts. The adapter is mounted to the rear axle of the ve-

hicle and is used to mount the brake shoes and actu-

ating cables for the parking brake system. The

adapter also mounts the rear caliper assembly to the

vehicle. The adapter has two machined abutments

which are used to position and align the caliper and

brake shoes for movement for and aft (Fig. 1)

LINING WEAR

To check the amount of lining wear, remove the

wheel and tire assemblies. If a visual inspection does

not adequately determine the condition of the lining,

Fig. 1 Rear Disc Brake Assembly

Ä BRAKES 5 - 45