brakes CHEVROLET DYNASTY 1993 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 196 of 2438

removal will be necessary. Remove the shoe and lin-

ing assemblies (see Brake Shoe Removal).Combined shoe and lining thickness should be

measured at the thinnest part of the assembly. When a shoe and lining assembly is worn to a

thickness of approximately 7.0 mm (9/32 inch) it

should be replaced. Replace both shoe assemblies (inboard and out-

board) on both wheels whenever shoe assemblies on

either side are replaced. If a shoe assembly does not require replacement.

Reinstall it, making sure each shoe assembly is re-

turned to its original position on the wheel of the ve-

hicle from which it was removed. (See Brake Shoe

Installation).

SERVICE PRECAUTIONS

WARNING: DUST AND DIRT ON BRAKE PARTS

GENERATED DURING THE NORMAL USE AND

WEAR OF MOTOR VEHICLE BRAKE SYSTEMS CAN

CONTAIN ASBESTOS FIBERS. BREATHING EXCES-

SIVE CONCENTRATIONS OF ASBESTOS FIBERS

CAN CAUSE SERIOUS BODILY HARM, SUCH AS

ASBESTOSIS AND CANCER. EXTREME CARE

SHOULD BE EXERCISED WHILE SERVICING

BRAKE ASSEMBLIES OR COMPONENTS. DO NOT CLEAN BRAKE ASSEMBLIES OR COM-

PONENTS WITH COMPRESSED AIR OR BY DRY

BRUSHING; USE A VACUUM CLEANER SPECIFI-

CALLY RECOMMENDED FOR USE WITH ASBES-

TOS FIBERS. IF A SUITABLE VACUUM CLEANER IS

NOT AVAILABLE, CLEANING SHOULD BE DONE

WET USING A WATER DAMPENED CLOTH. DO NOT CREATE DUST BY SANDING, GRINDIN-

G,AND/OR SHAVING BRAKE LININGS OR PADS

UNLESS SUCH OPERATION IS DONE WHILE USING

PROPERLY EXHAUST VENTILATED EQUIPMENT. DISPOSE OF ALL DUST AND DIRT SUSPECTED

TO CONTAIN ANY ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS TO MINIMIZE DUST EXPO-

SURE TO YOURSELF AND OTHERS. FOLLOW ALL RECOMMENDED PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION AND THE ENVIRON-

MENTAL PROTECTION AGENCY. FOR THE HAN-

DLING, PROCESSING, AND DISPOSITION OF DUST

OR DIRT WHICH MAY CONTAIN ASBESTOS FI-

BERS. IT IS RECOMMENDED NOT TO BREATH ANY

TYPE OF BRAKE LINING MATERIAL DUST EVEN

ASBESTOS FREE, DUE TO THE FIBROUS NATURE

OF THE MATERIALS BEING USED.

Grease or any other foreign material must be kept

off the caliper assembly, surfaces of the braking disc

and external surfaces of the hub, during service pro-

cedures. Handling the braking disc and caliper should be done

in such a way as to avoid deformation of the disc and

scratching or nicking the brake linings (pads). During removal and installation of a wheel and tire

assembly, use care not to strike the caliper. Before vehicle is moved after any brake service

work, be sure to obtain a firm brake pedal.

BRAKE SHOE REMOVAL

(1) Raise vehicle on jackstands or centered on a

hoist. (2) Remove rear wheel and tire assemblies.

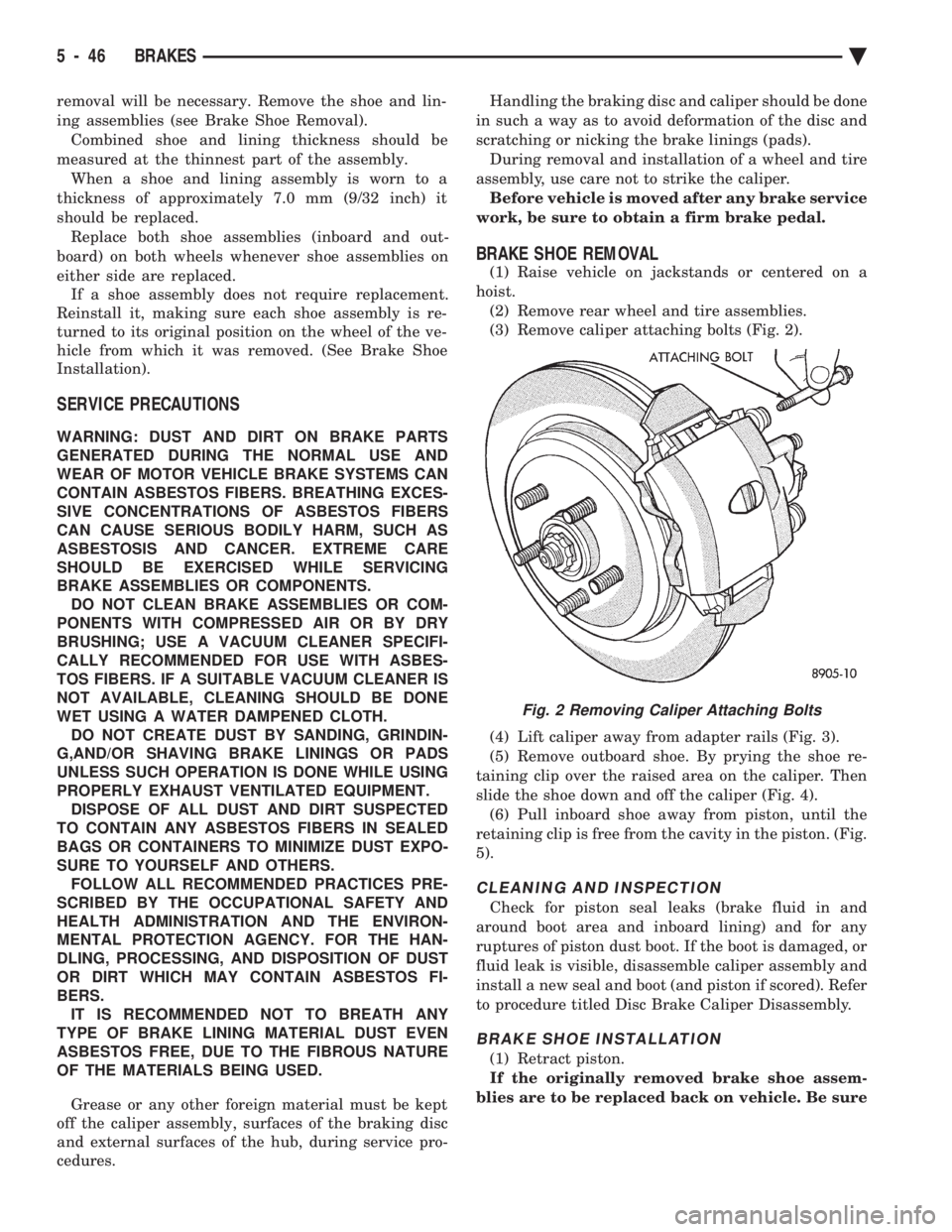

(3) Remove caliper attaching bolts (Fig. 2).

(4) Lift caliper away from adapter rails (Fig. 3).

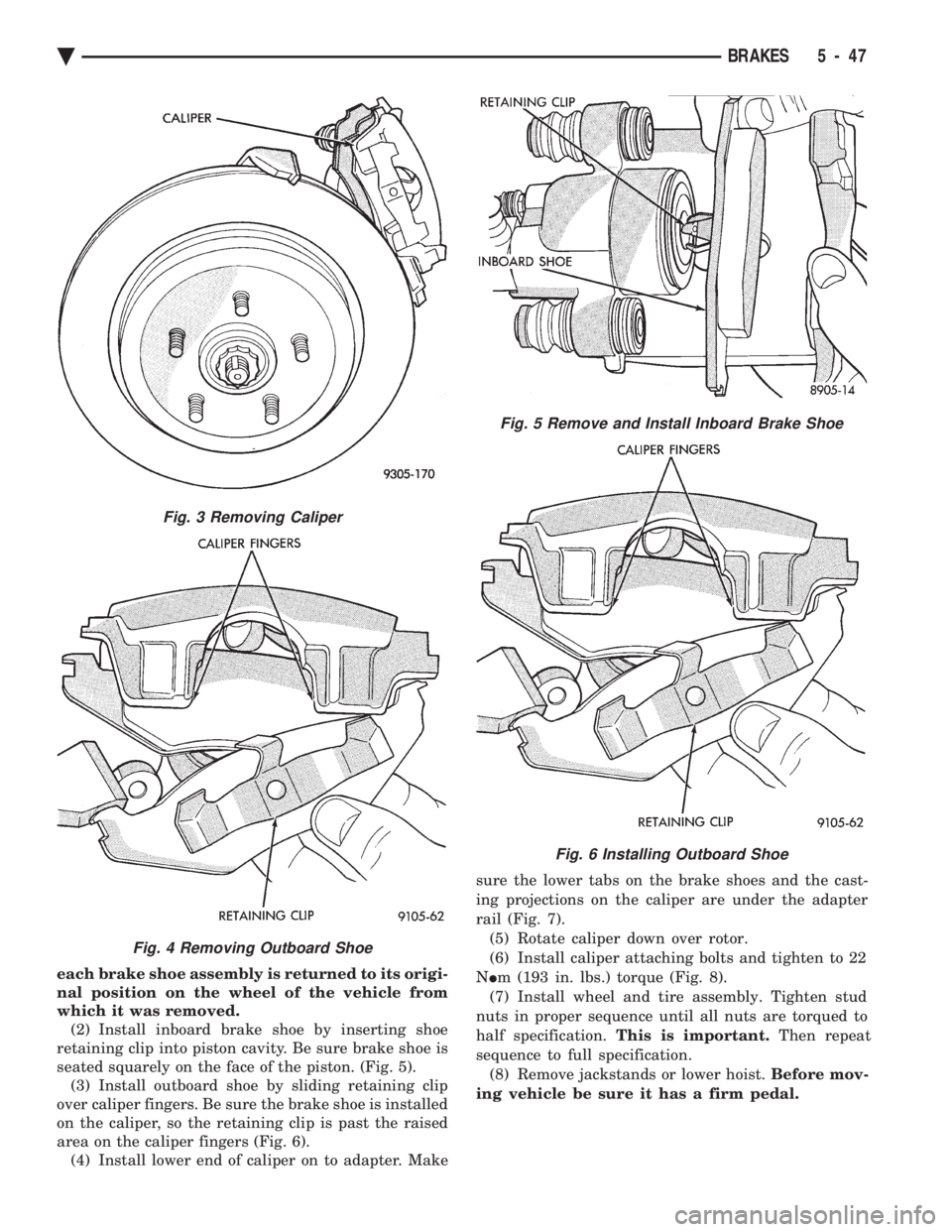

(5) Remove outboard shoe. By prying the shoe re-

taining clip over the raised area on the caliper. Then

slide the shoe down and off the caliper (Fig. 4). (6) Pull inboard shoe away from piston, until the

retaining clip is free from the cavity in the piston. (Fig.

5).

CLEANING AND INSPECTION

Check for piston seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If the boot is damaged, or

fluid leak is visible, disassemble caliper assembly and

install a new seal and boot (and piston if scored). Refer

to procedure titled Disc Brake Caliper Disassembly.

BRAKE SHOE INSTALLATION

(1) Retract piston.

If the originally removed brake shoe assem-

blies are to be replaced back on vehicle. Be sure

Fig. 2 Removing Caliper Attaching Bolts

5 - 46 BRAKES Ä

Page 197 of 2438

each brake shoe assembly is returned to its origi-

nal position on the wheel of the vehicle from

which it was removed. (2) Install inboard brake shoe by inserting shoe

retaining clip into piston cavity. Be sure brake shoe is

seated squarely on the face of the piston. (Fig. 5). (3) Install outboard shoe by sliding retaining clip

over caliper fingers. Be sure the brake shoe is installed

on the caliper, so the retaining clip is past the raised

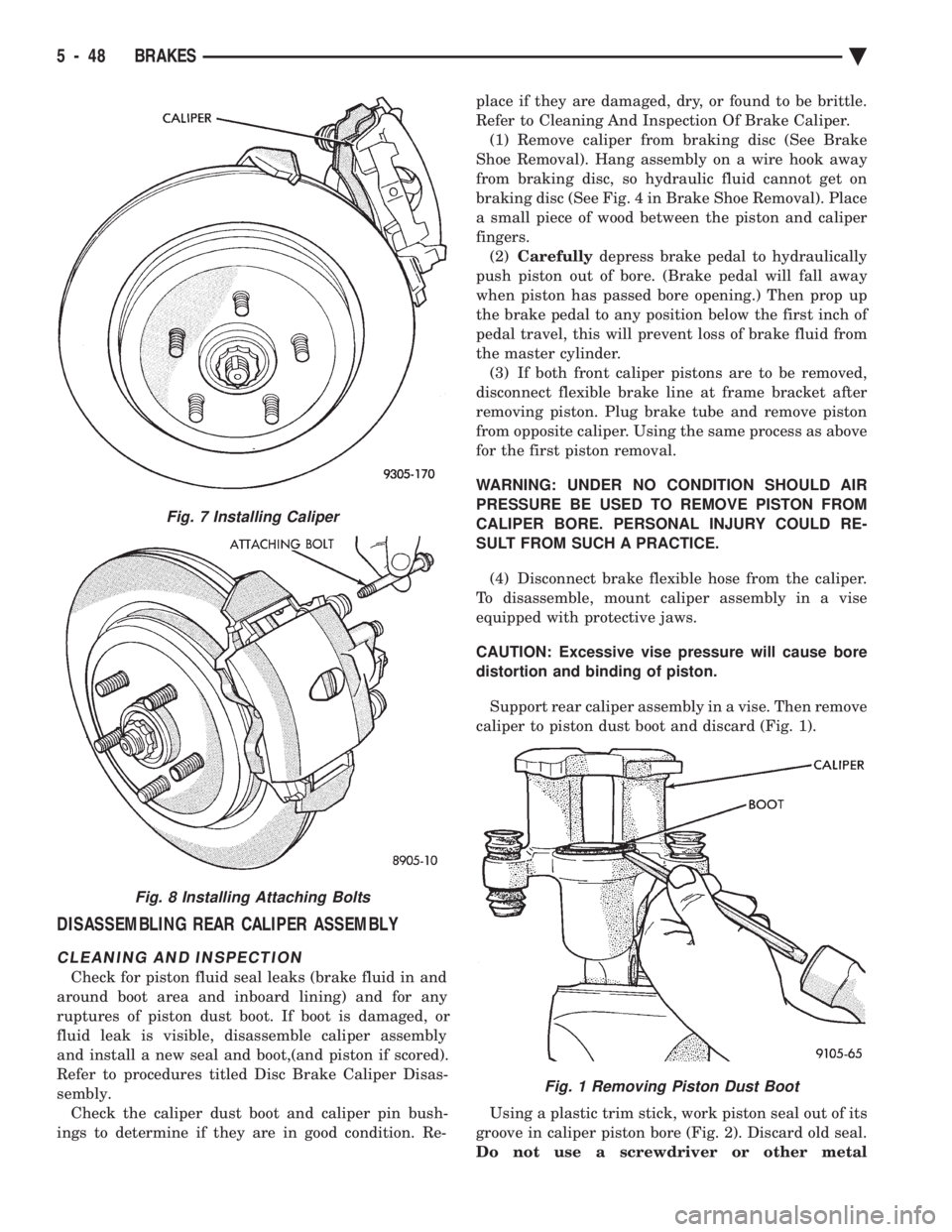

area on the caliper fingers (Fig. 6). (4) Install lower end of caliper on to adapter. Make sure the lower tabs on the brake shoes and the cast-

ing projections on the caliper are under the adapter

rail (Fig. 7). (5) Rotate caliper down over rotor.

(6) Install caliper attaching bolts and tighten to 22

N Im (193 in. lbs.) torque (Fig. 8).

(7) Install wheel and tire assembly. Tighten stud

nuts in proper sequence until all nuts are torqued to

half specification. This is important. Then repeat

sequence to full specification. (8) Remove jackstands or lower hoist. Before mov-

ing vehicle be sure it has a firm pedal.

Fig. 5 Remove and Install Inboard Brake Shoe

Fig. 6 Installing Outboard Shoe

Fig. 3 Removing Caliper

Fig. 4 Removing Outboard Shoe

Ä BRAKES 5 - 47

Page 198 of 2438

DISASSEMBLING REAR CALIPER ASSEMBLY

CLEANING AND INSPECTION

Check for piston fluid seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If boot is damaged, or

fluid leak is visible, disassemble caliper assembly

and install a new seal and boot,(and piston if scored).

Refer to procedures titled Disc Brake Caliper Disas-

sembly. Check the caliper dust boot and caliper pin bush-

ings to determine if they are in good condition. Re- place if they are damaged, dry, or found to be brittle.

Refer to Cleaning And Inspection Of Brake Caliper. (1) Remove caliper from braking disc (See Brake

Shoe Removal). Hang assembly on a wire hook away

from braking disc, so hydraulic fluid cannot get on

braking disc (See Fig. 4 in Brake Shoe Removal). Place

a small piece of wood between the piston and caliper

fingers. (2) Carefully depress brake pedal to hydraulically

push piston out of bore. (Brake pedal will fall away

when piston has passed bore opening.) Then prop up

the brake pedal to any position below the first inch of

pedal travel, this will prevent loss of brake fluid from

the master cylinder. (3) If both front caliper pistons are to be removed,

disconnect flexible brake line at frame bracket after

removing piston. Plug brake tube and remove piston

from opposite caliper. Using the same process as above

for the first piston removal.

WARNING: UNDER NO CONDITION SHOULD AIR

PRESSURE BE USED TO REMOVE PISTON FROM

CALIPER BORE. PERSONAL INJURY COULD RE-

SULT FROM SUCH A PRACTICE.

(4) Disconnect brake flexible hose from the caliper.

To disassemble, mount caliper assembly in a vise

equipped with protective jaws.

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston.

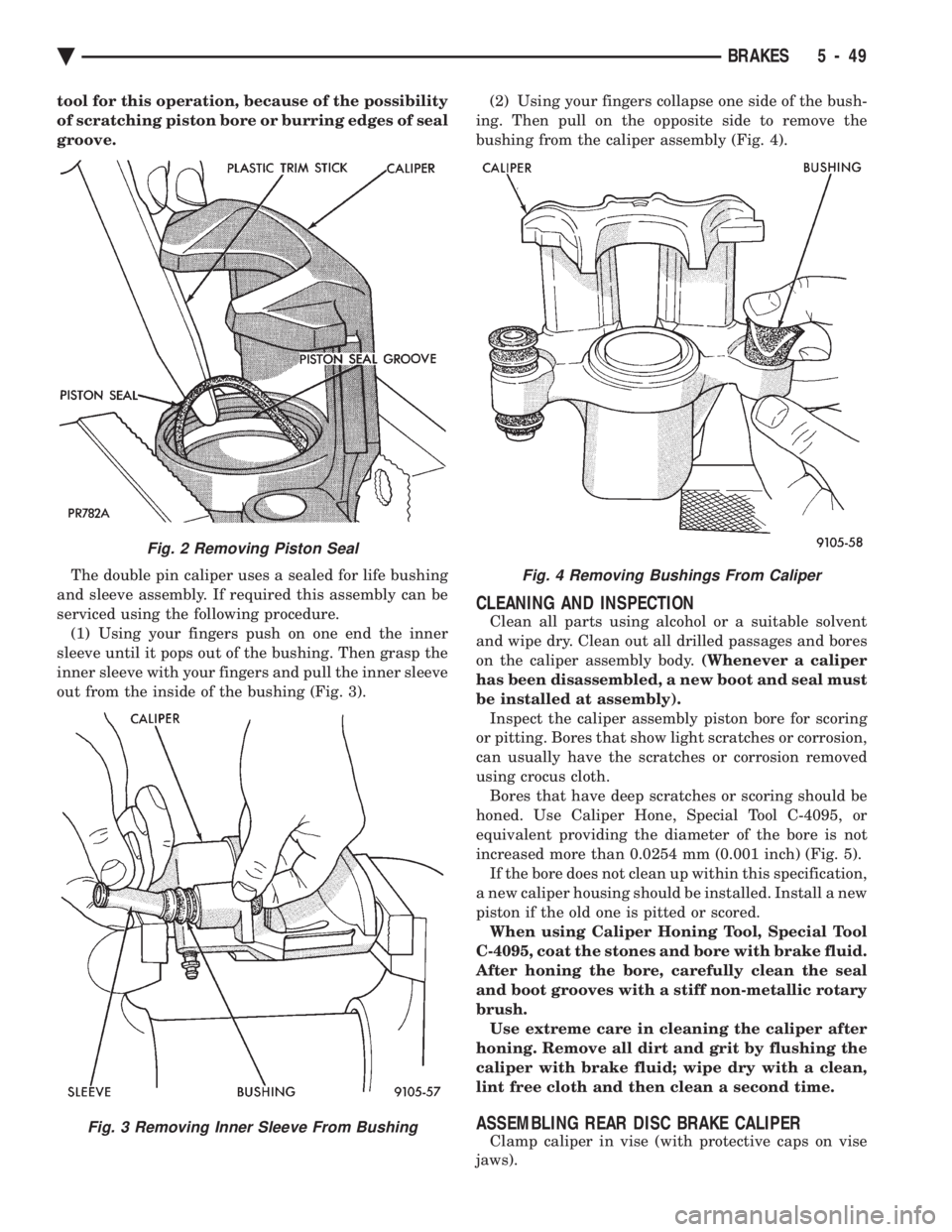

Support rear caliper assembly in a vise. Then remove

caliper to piston dust boot and discard (Fig. 1).

Using a plastic trim stick, work piston seal out of its

groove in caliper piston bore (Fig. 2). Discard old seal.

Do not use a screwdriver or other metal

Fig. 7 Installing Caliper

Fig. 8 Installing Attaching Bolts

Fig. 1 Removing Piston Dust Boot

5 - 48 BRAKES Ä

Page 199 of 2438

tool for this operation, because of the possibility

of scratching piston bore or burring edges of seal

groove. The double pin caliper uses a sealed for life bushing

and sleeve assembly. If required this assembly can be

serviced using the following procedure. (1) Using your fingers push on one end the inner

sleeve until it pops out of the bushing. Then grasp the

inner sleeve with your fingers and pull the inner sleeve

out from the inside of the bushing (Fig. 3). (2) Using your fingers collapse one side of the bush-

ing. Then pull on the opposite side to remove the

bushing from the caliper assembly (Fig. 4).

CLEANING AND INSPECTION

Clean all parts using alcohol or a suitable solvent

and wipe dry. Clean out all drilled passages and bores

on the caliper assembly body. (Whenever a caliper

has been disassembled, a new boot and seal must

be installed at assembly). Inspect the caliper assembly piston bore for scoring

or pitting. Bores that show light scratches or corrosion,

can usually have the scratches or corrosion removed

using crocus cloth. Bores that have deep scratches or scoring should be

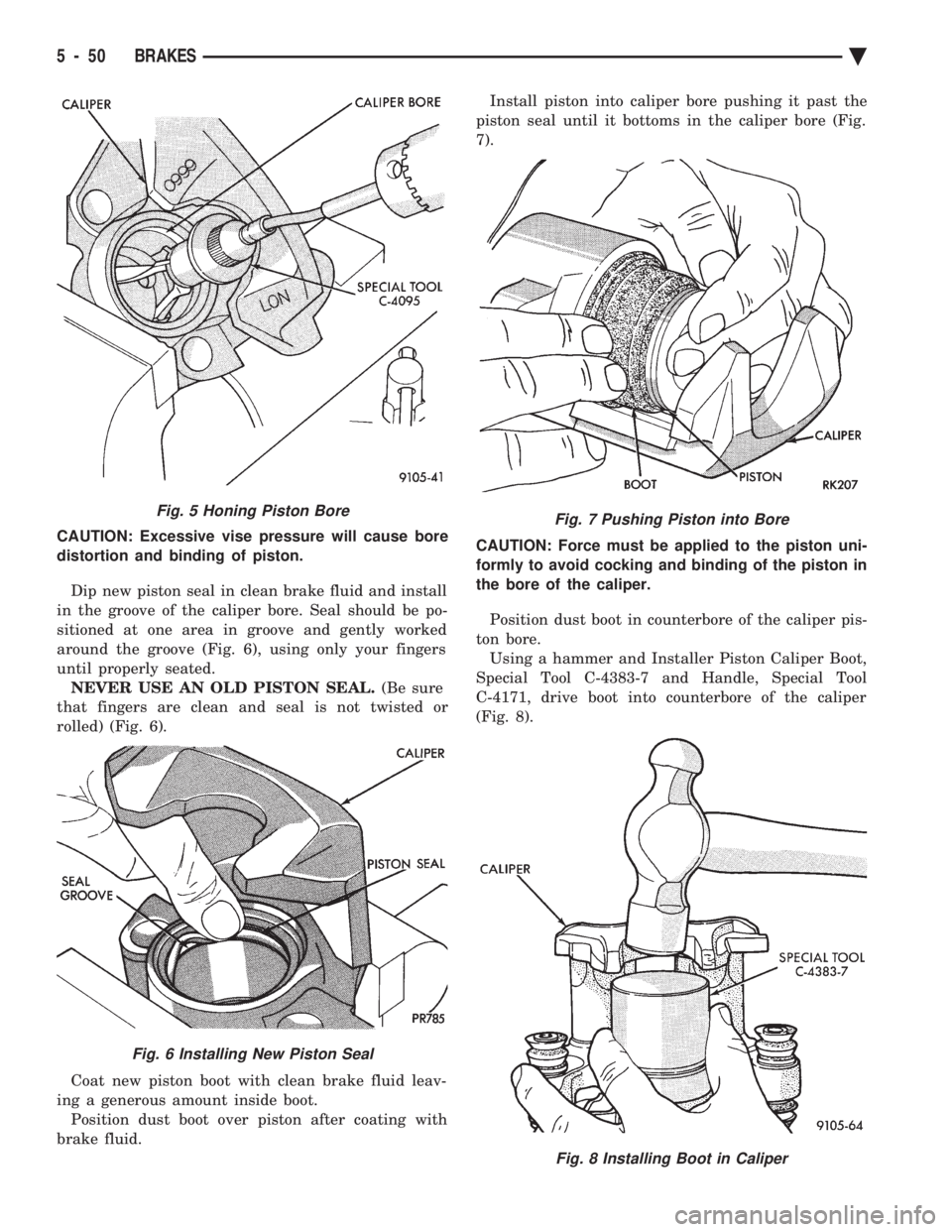

honed. Use Caliper Hone, Special Tool C-4095, or

equivalent providing the diameter of the bore is not

increased more than 0.0254 mm (0.001 inch) (Fig. 5). If the bore does not clean up within this specification,

a new caliper housing should be installed. Install a new

piston if the old one is pitted or scored. When using Caliper Honing Tool, Special Tool

C-4095, coat the stones and bore with brake fluid.

After honing the bore, carefully clean the seal

and boot grooves with a stiff non-metallic rotary

brush. Use extreme care in cleaning the caliper after

honing. Remove all dirt and grit by flushing the

caliper with brake fluid; wipe dry with a clean,

lint free cloth and then clean a second time.

ASSEMBLING REAR DISC BRAKE CALIPER

Clamp caliper in vise (with protective caps on vise

jaws).

Fig. 2 Removing Piston Seal

Fig. 3 Removing Inner Sleeve From Bushing

Fig. 4 Removing Bushings From Caliper

Ä BRAKES 5 - 49

Page 200 of 2438

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston. Dip new piston seal in clean brake fluid and install

in the groove of the caliper bore. Seal should be po-

sitioned at one area in groove and gently worked

around the groove (Fig. 6), using only your fingers

until properly seated. NEVER USE AN OLD PISTON SEAL. (Be sure

that fingers are clean and seal is not twisted or

rolled) (Fig. 6).

Coat new piston boot with clean brake fluid leav-

ing a generous amount inside boot. Position dust boot over piston after coating with

brake fluid. Install piston into caliper bore pushing it past the

piston seal until it bottoms in the caliper bore (Fig.

7).

CAUTION: Force must be applied to the piston uni-

formly to avoid cocking and binding of the piston in

the bore of the caliper.

Position dust boot in counterbore of the caliper pis-

ton bore. Using a hammer and Installer Piston Caliper Boot,

Special Tool C-4383-7 and Handle, Special Tool

C-4171, drive boot into counterbore of the caliper

(Fig. 8).

Fig. 5 Honing Piston Bore

Fig. 6 Installing New Piston Seal

Fig. 7 Pushing Piston into Bore

Fig. 8 Installing Boot in Caliper

5 - 50 BRAKES Ä

Page 201 of 2438

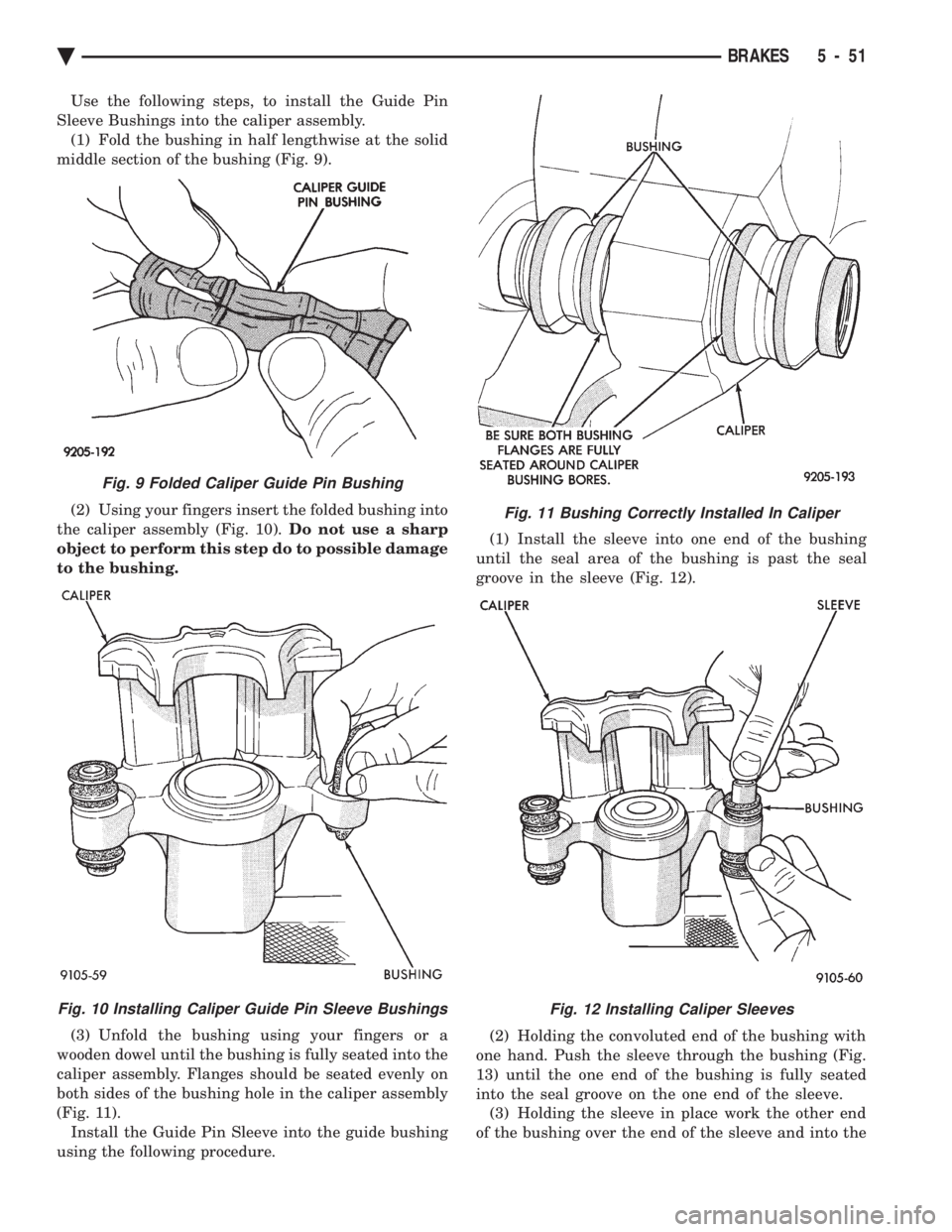

Use the following steps, to install the Guide Pin

Sleeve Bushings into the caliper assembly. (1) Fold the bushing in half lengthwise at the solid

middle section of the bushing (Fig. 9).

(2) Using your fingers insert the folded bushing into

the caliper assembly (Fig. 10). Do not use a sharp

object to perform this step do to possible damage

to the bushing.

(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated into the

caliper assembly. Flanges should be seated evenly on

both sides of the bushing hole in the caliper assembly

(Fig. 11). Install the Guide Pin Sleeve into the guide bushing

using the following procedure. (1) Install the sleeve into one end of the bushing

until the seal area of the bushing is past the seal

groove in the sleeve (Fig. 12).

(2) Holding the convoluted end of the bushing with

one hand. Push the sleeve through the bushing (Fig.

13) until the one end of the bushing is fully seated

into the seal groove on the one end of the sleeve. (3) Holding the sleeve in place work the other end

of the bushing over the end of the sleeve and into the

Fig. 11 Bushing Correctly Installed In Caliper

Fig. 12 Installing Caliper Sleeves

Fig. 9 Folded Caliper Guide Pin Bushing

Fig. 10 Installing Caliper Guide Pin Sleeve Bushings

Ä BRAKES 5 - 51

Page 202 of 2438

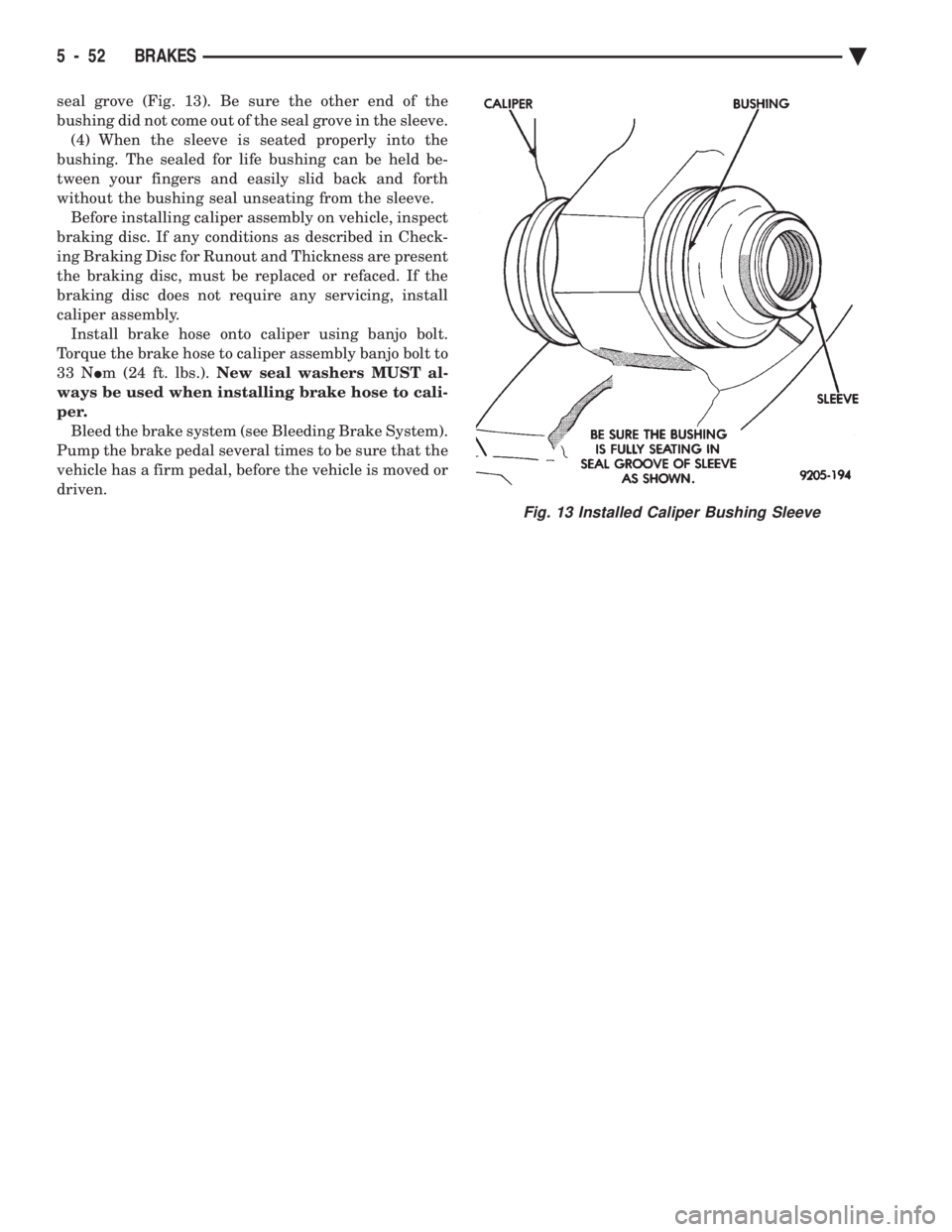

seal grove (Fig. 13). Be sure the other end of the

bushing did not come out of the seal grove in the sleeve.(4) When the sleeve is seated properly into the

bushing. The sealed for life bushing can be held be-

tween your fingers and easily slid back and forth

without the bushing seal unseating from the sleeve. Before installing caliper assembly on vehicle, inspect

braking disc. If any conditions as described in Check-

ing Braking Disc for Runout and Thickness are present

the braking disc, must be replaced or refaced. If the

braking disc does not require any servicing, install

caliper assembly. Install brake hose onto caliper using banjo bolt.

Torque the brake hose to caliper assembly banjo bolt to

33 N Im (24 ft. lbs.). New seal washers MUST al-

ways be used when installing brake hose to cali-

per. Bleed the brake system (see Bleeding Brake System).

Pump the brake pedal several times to be sure that the

vehicle has a firm pedal, before the vehicle is moved or

driven.

Fig. 13 Installed Caliper Bushing Sleeve

5 - 52 BRAKES Ä

Page 203 of 2438

BRAKE DISC (ROTOR) INDEX

page page

Braking Disc Removal ..................... 54

General Information ....................... 53

Inspection Diagnosis ...................... 53 Installing Braking Disc

..................... 54

Refinishing Braking Disc ................... 55

Service Procedures ....................... 53

GENERAL INFORMATION

Any servicing of the braking disc requires extreme

care to maintain the braking disc within service toler-

ances to ensure proper brake action.

CAUTION: If the braking disk (rotor) needs to be

replaced with a new part. The protective coating on

the braking surfaces of the rotor MUST BE REMOVED

with an appropriate solvent, to avoid contamination

of the brake shoe linings.

When replacing a rotor with a new part do NOT

reface the new rotor. Rotor already has the re-

quired micro finish when manufactured, only

remove the protective coating.

INSPECTION DIAGNOSIS

Before refinishing or refacing a braking disc, the disc

should be checked and inspected for the following

conditions: Braking surface scoring, rust, impregnation of lining

material and worn ridges. Excessive lateral rotor runout or wobble.

Thickness variation (Parallelism).

Dishing or distortion (Flatness).

If a vehicle has not been driven for a period of time.

The discs will rust in the area not covered by the brake

lining and cause noise and chatter when the brakes are

applied. Excessive wear and scoring of the disc can cause

temporary improper lining contact if ridges are not

removed before installation of new brake shoe assem-

blies. Some discoloration or wear of the disc surface is

normal and does not require resurfacing when linings

are replaced. Excessive runout or wobble in a disc can increase

pedal travel due to piston knock back. This will in-

crease guide pin bushing wear due to tendency of

caliper to follow disc wobble. Thickness variation in a disc can also result in pedal

pulsation, chatter and surge due to variation in brake

output. This can also be caused by excessive runout in

braking disc or hub. Dishing or distortion can be caused by extreme heat

and abuse of the brakes.

SERVICE PROCEDURES

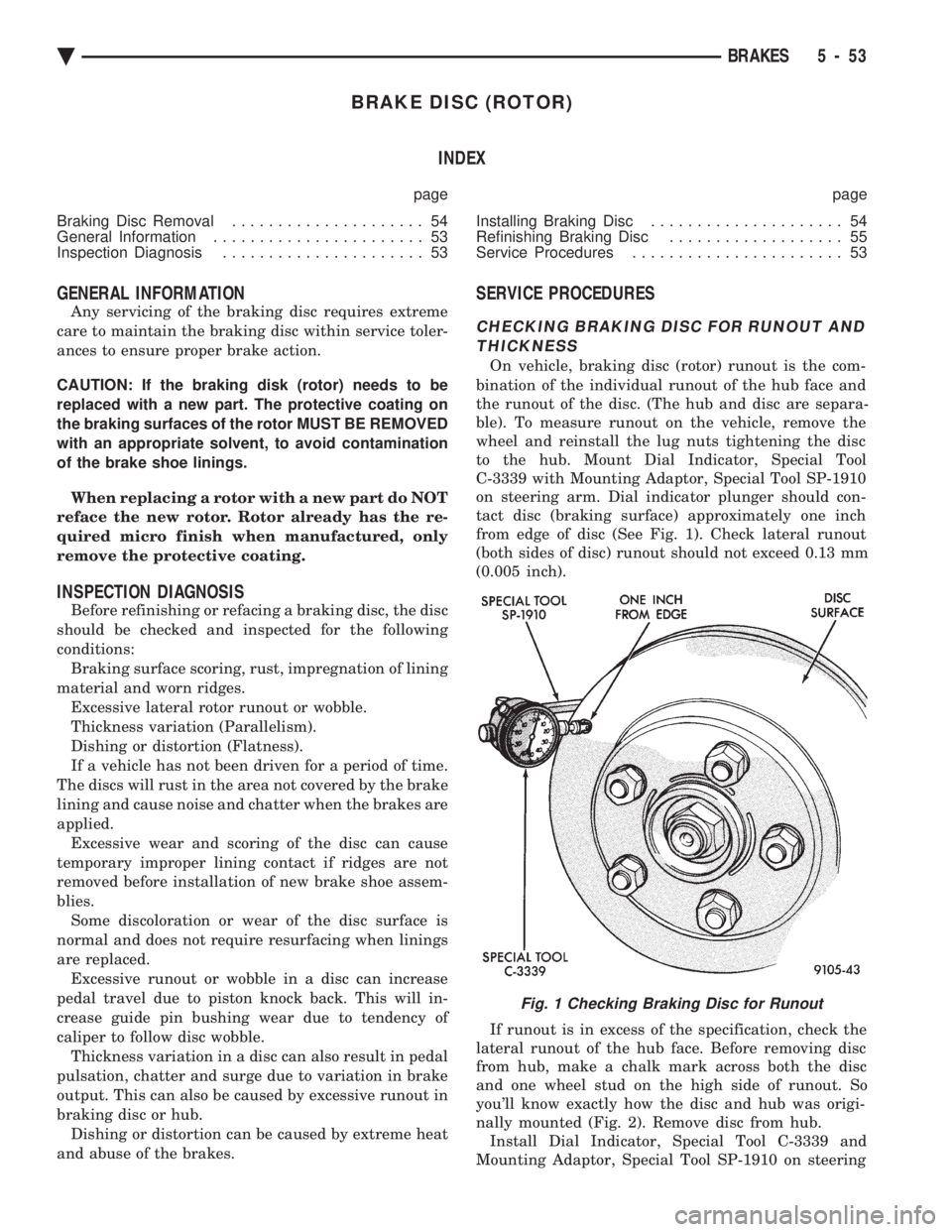

CHECKING BRAKING DISC FOR RUNOUT AND THICKNESS

On vehicle, braking disc (rotor) runout is the com-

bination of the individual runout of the hub face and

the runout of the disc. (The hub and disc are separa-

ble). To measure runout on the vehicle, remove the

wheel and reinstall the lug nuts tightening the disc

to the hub. Mount Dial Indicator, Special Tool

C-3339 with Mounting Adaptor, Special Tool SP-1910

on steering arm. Dial indicator plunger should con-

tact disc (braking surface) approximately one inch

from edge of disc (See Fig. 1). Check lateral runout

(both sides of disc) runout should not exceed 0.13 mm

(0.005 inch).

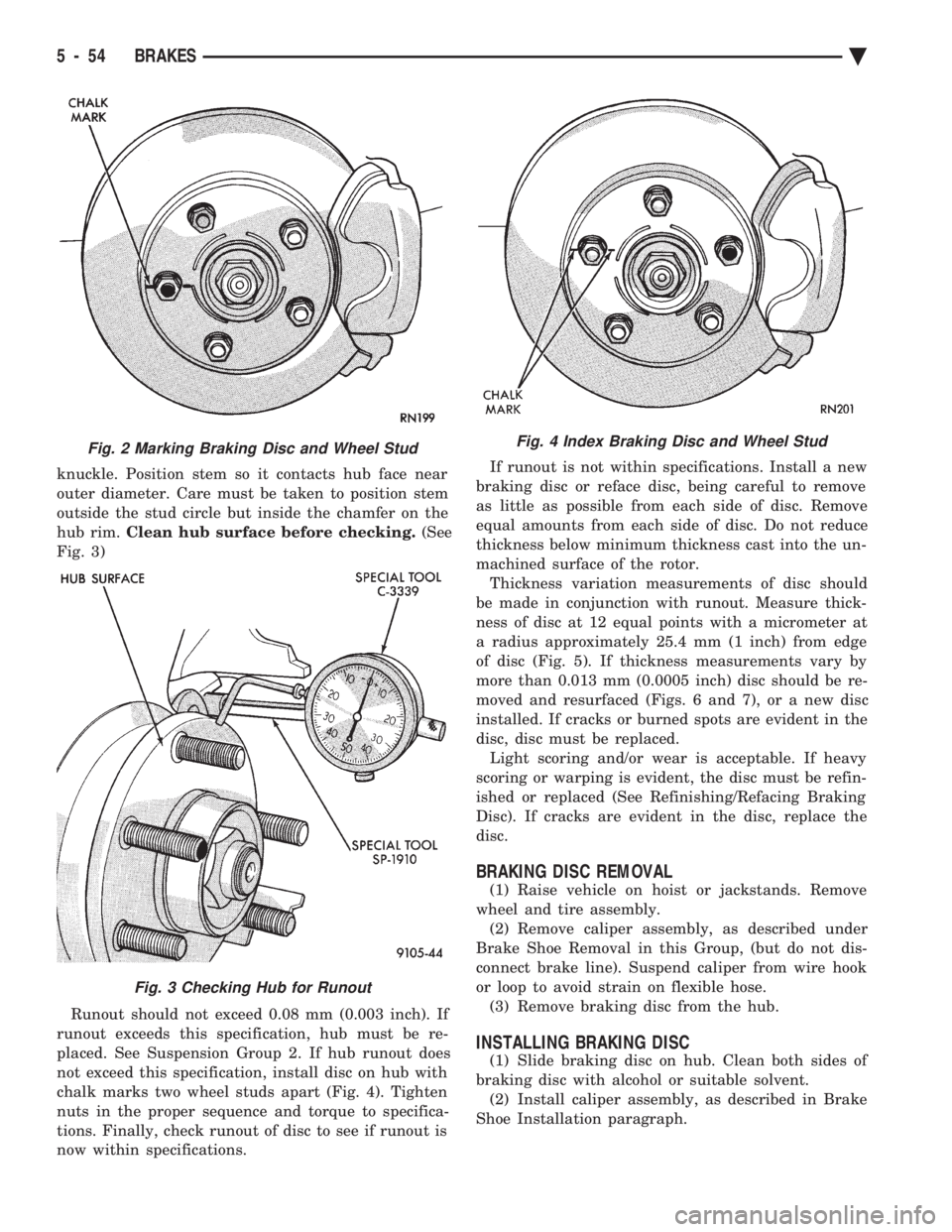

If runout is in excess of the specification, check the

lateral runout of the hub face. Before removing disc

from hub, make a chalk mark across both the disc

and one wheel stud on the high side of runout. So

you'll know exactly how the disc and hub was origi-

nally mounted (Fig. 2). Remove disc from hub. Install Dial Indicator, Special Tool C-3339 and

Mounting Adaptor, Special Tool SP-1910 on steering

Fig. 1 Checking Braking Disc for Runout

Ä BRAKES 5 - 53

Page 204 of 2438

knuckle. Position stem so it contacts hub face near

outer diameter. Care must be taken to position stem

outside the stud circle but inside the chamfer on the

hub rim. Clean hub surface before checking. (See

Fig. 3)

Runout should not exceed 0.08 mm (0.003 inch). If

runout exceeds this specification, hub must be re-

placed. See Suspension Group 2. If hub runout does

not exceed this specification, install disc on hub with

chalk marks two wheel studs apart (Fig. 4). Tighten

nuts in the proper sequence and torque to specifica-

tions. Finally, check runout of disc to see if runout is

now within specifications. If runout is not within specifications. Install a new

braking disc or reface disc, being careful to remove

as little as possible from each side of disc. Remove

equal amounts from each side of disc. Do not reduce

thickness below minimum thickness cast into the un-

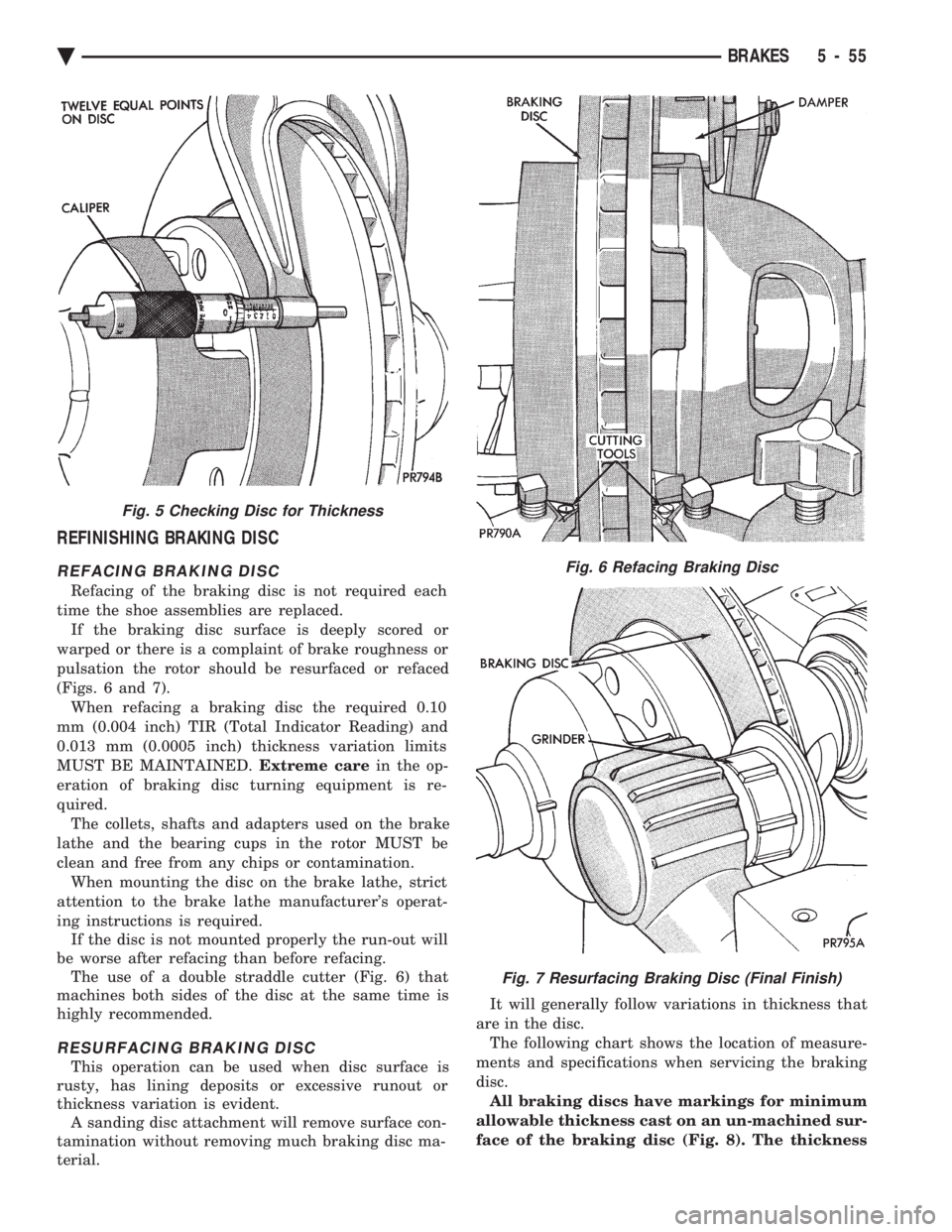

machined surface of the rotor. Thickness variation measurements of disc should

be made in conjunction with runout. Measure thick-

ness of disc at 12 equal points with a micrometer at

a radius approximately 25.4 mm (1 inch) from edge

of disc (Fig. 5). If thickness measurements vary by

more than 0.013 mm (0.0005 inch) disc should be re-

moved and resurfaced (Figs. 6 and 7), or a new disc

installed. If cracks or burned spots are evident in the

disc, disc must be replaced. Light scoring and/or wear is acceptable. If heavy

scoring or warping is evident, the disc must be refin-

ished or replaced (See Refinishing/Refacing Braking

Disc). If cracks are evident in the disc, replace the

disc.

BRAKING DISC REMOVAL

(1) Raise vehicle on hoist or jackstands. Remove

wheel and tire assembly. (2) Remove caliper assembly, as described under

Brake Shoe Removal in this Group, (but do not dis-

connect brake line). Suspend caliper from wire hook

or loop to avoid strain on flexible hose. (3) Remove braking disc from the hub.

INSTALLING BRAKING DISC

(1) Slide braking disc on hub. Clean both sides of

braking disc with alcohol or suitable solvent. (2) Install caliper assembly, as described in Brake

Shoe Installation paragraph.

Fig. 2 Marking Braking Disc and Wheel Stud

Fig. 3 Checking Hub for Runout

Fig. 4 Index Braking Disc and Wheel Stud

5 - 54 BRAKES Ä

Page 205 of 2438

REFINISHING BRAKING DISC

REFACING BRAKING DISC

Refacing of the braking disc is not required each

time the shoe assemblies are replaced. If the braking disc surface is deeply scored or

warped or there is a complaint of brake roughness or

pulsation the rotor should be resurfaced or refaced

(Figs. 6 and 7). When refacing a braking disc the required 0.10

mm (0.004 inch) TIR (Total Indicator Reading) and

0.013 mm (0.0005 inch) thickness variation limits

MUST BE MAINTAINED. Extreme carein the op-

eration of braking disc turning equipment is re-

quired. The collets, shafts and adapters used on the brake

lathe and the bearing cups in the rotor MUST be

clean and free from any chips or contamination. When mounting the disc on the brake lathe, strict

attention to the brake lathe manufacturer's operat-

ing instructions is required. If the disc is not mounted properly the run-out will

be worse after refacing than before refacing. The use of a double straddle cutter (Fig. 6) that

machines both sides of the disc at the same time is

highly recommended.

RESURFACING BRAKING DISC

This operation can be used when disc surface is

rusty, has lining deposits or excessive runout or

thickness variation is evident. A sanding disc attachment will remove surface con-

tamination without removing much braking disc ma-

terial. It will generally follow variations in thickness that

are in the disc. The following chart shows the location of measure-

ments and specifications when servicing the braking

disc. All braking discs have markings for minimum

allowable thickness cast on an un-machined sur-

face of the braking disc (Fig. 8). The thickness

Fig. 5 Checking Disc for Thickness

Fig. 6 Refacing Braking Disc

Fig. 7 Resurfacing Braking Disc (Final Finish)

Ä BRAKES 5 - 55