trunk CHEVROLET DYNASTY 1993 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2285 of 2438

INSTALLATION

Reverse the preceding operation.

REAR SEAT BELT RETRACTOR

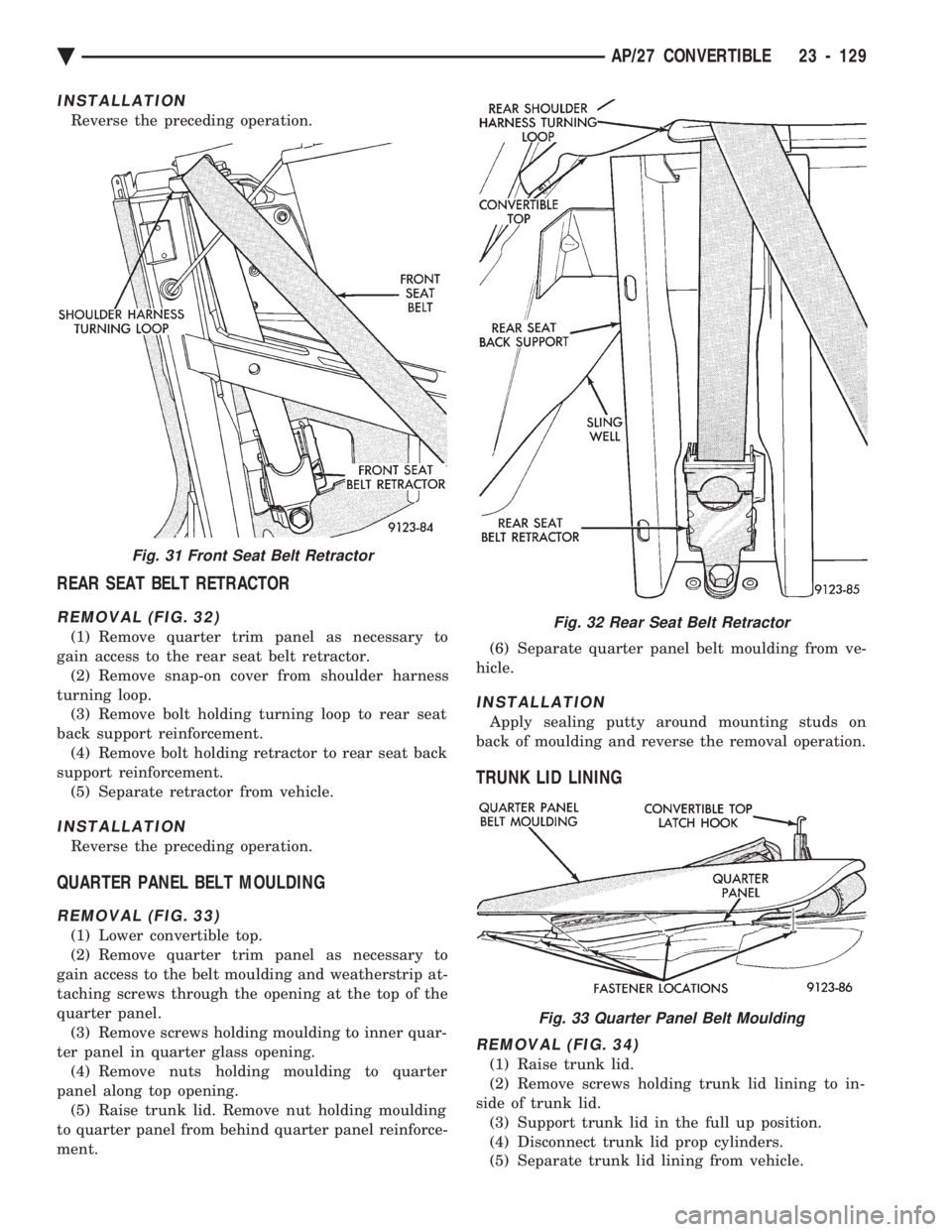

REMOVAL (FIG. 32)

(1) Remove quarter trim panel as necessary to

gain access to the rear seat belt retractor. (2) Remove snap-on cover from shoulder harness

turning loop. (3) Remove bolt holding turning loop to rear seat

back support reinforcement. (4) Remove bolt holding retractor to rear seat back

support reinforcement. (5) Separate retractor from vehicle.

INSTALLATION

Reverse the preceding operation.

QUARTER PANEL BELT MOULDING

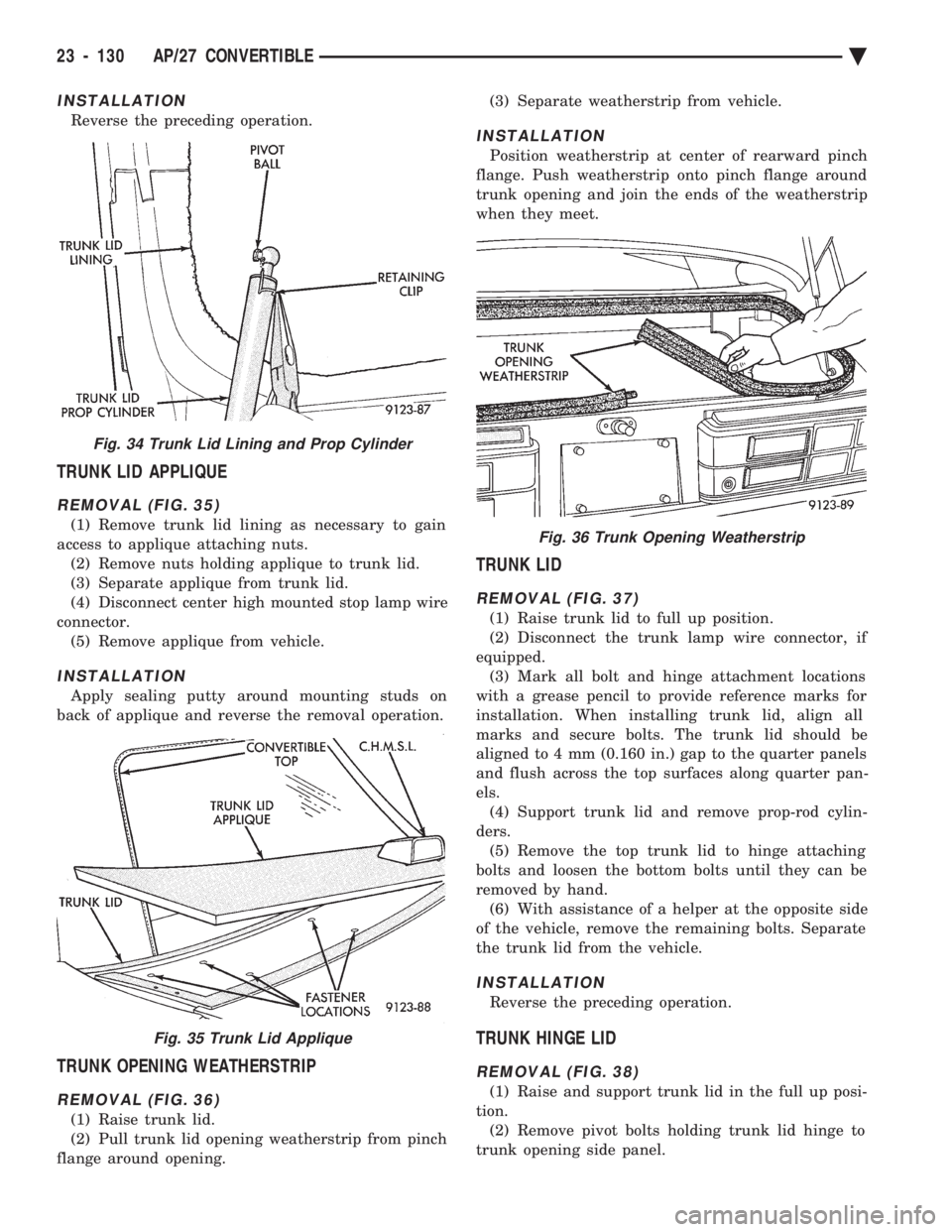

REMOVAL (FIG. 33)

(1) Lower convertible top.

(2) Remove quarter trim panel as necessary to

gain access to the belt moulding and weatherstrip at-

taching screws through the opening at the top of the

quarter panel. (3) Remove screws holding moulding to inner quar-

ter panel in quarter glass opening. (4) Remove nuts holding moulding to quarter

panel along top opening. (5) Raise trunk lid. Remove nut holding moulding

to quarter panel from behind quarter panel reinforce-

ment. (6) Separate quarter panel belt moulding from ve-

hicle.

INSTALLATION

Apply sealing putty around mounting studs on

back of moulding and reverse the removal operation.

TRUNK LID LINING

REMOVAL (FIG. 34)

(1) Raise trunk lid.

(2) Remove screws holding trunk lid lining to in-

side of trunk lid. (3) Support trunk lid in the full up position.

(4) Disconnect trunk lid prop cylinders.

(5) Separate trunk lid lining from vehicle.

Fig. 31 Front Seat Belt Retractor

Fig. 32 Rear Seat Belt Retractor

Fig. 33 Quarter Panel Belt Moulding

Ä AP/27 CONVERTIBLE 23 - 129

Page 2286 of 2438

INSTALLATION

Reverse the preceding operation.

TRUNK LID APPLIQUE

REMOVAL (FIG. 35)

(1) Remove trunk lid lining as necessary to gain

access to applique attaching nuts. (2) Remove nuts holding applique to trunk lid.

(3) Separate applique from trunk lid.

(4) Disconnect center high mounted stop lamp wire

connector. (5) Remove applique from vehicle.

INSTALLATION

Apply sealing putty around mounting studs on

back of applique and reverse the removal operation.

TRUNK OPENING WEATHERSTRIP

REMOVAL (FIG. 36)

(1) Raise trunk lid.

(2) Pull trunk lid opening weatherstrip from pinch

flange around opening. (3) Separate weatherstrip from vehicle.

INSTALLATION

Position weatherstrip at center of rearward pinch

flange. Push weatherstrip onto pinch flange around

trunk opening and join the ends of the weatherstrip

when they meet.

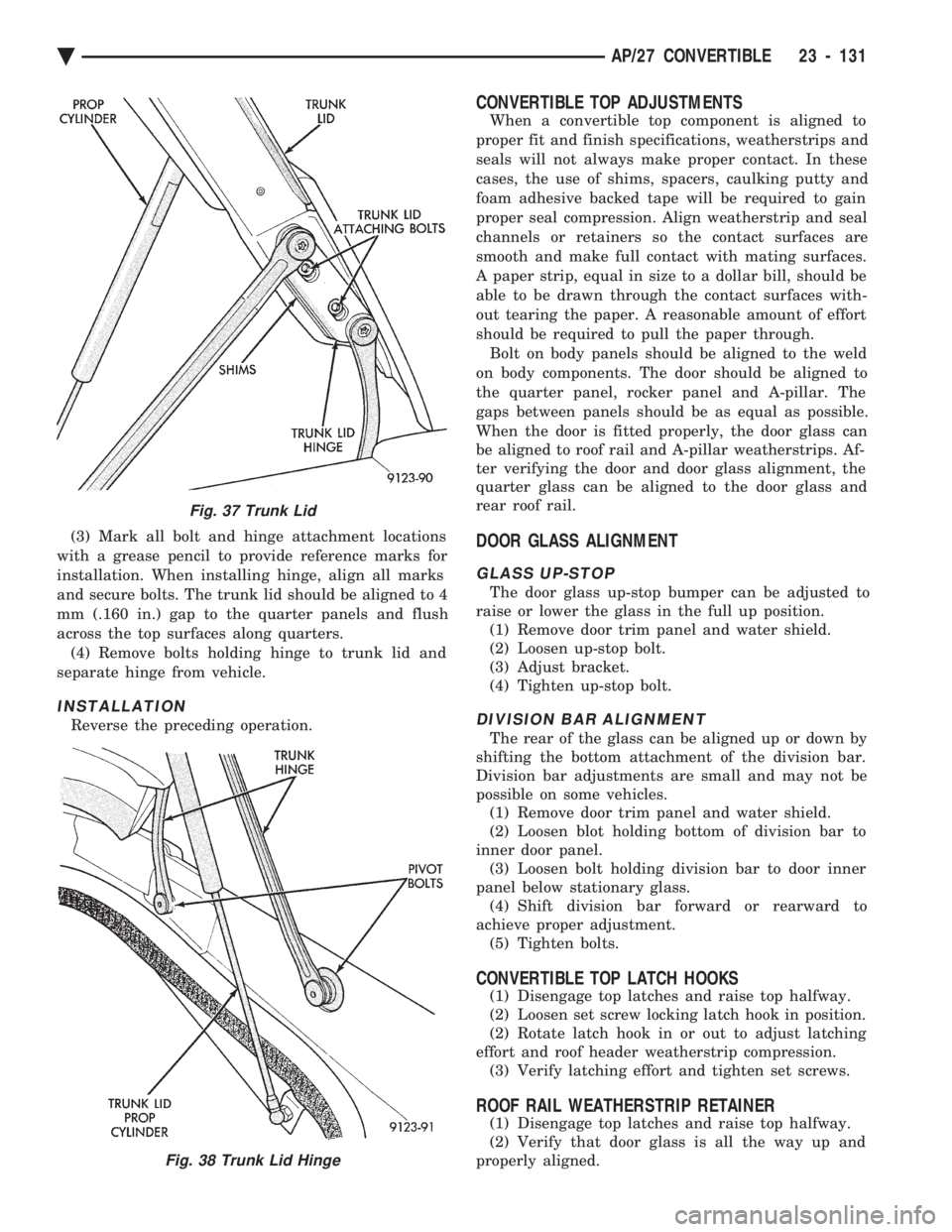

TRUNK LID

REMOVAL (FIG. 37)

(1) Raise trunk lid to full up position.

(2) Disconnect the trunk lamp wire connector, if

equipped. (3) Mark all bolt and hinge attachment locations

with a grease pencil to provide reference marks for

installation. When installing trunk lid, align all

marks and secure bolts. The trunk lid should be

aligned to 4 mm (0.160 in.) gap to the quarter panels

and flush across the top surfaces along quarter pan-

els. (4) Support trunk lid and remove prop-rod cylin-

ders. (5) Remove the top trunk lid to hinge attaching

bolts and loosen the bottom bolts until they can be

removed by hand. (6) With assistance of a helper at the opposite side

of the vehicle, remove the remaining bolts. Separate

the trunk lid from the vehicle.

INSTALLATION

Reverse the preceding operation.

TRUNK HINGE LID

REMOVAL (FIG. 38)

(1) Raise and support trunk lid in the full up posi-

tion. (2) Remove pivot bolts holding trunk lid hinge to

trunk opening side panel.

Fig. 34 Trunk Lid Lining and Prop Cylinder

Fig. 35 Trunk Lid Applique

Fig. 36 Trunk Opening Weatherstrip

23 - 130 AP/27 CONVERTIBLE Ä

Page 2287 of 2438

(3) Mark all bolt and hinge attachment locations

with a grease pencil to provide reference marks for

installation. When installing hinge, align all marks

and secure bolts. The trunk lid should be aligned to 4

mm (.160 in.) gap to the quarter panels and flush

across the top surfaces along quarters. (4) Remove bolts holding hinge to trunk lid and

separate hinge from vehicle.

INSTALLATION

Reverse the preceding operation.

CONVERTIBLE TOP ADJUSTMENTS

When a convertible top component is aligned to

proper fit and finish specifications, weatherstrips and

seals will not always make proper contact. In these

cases, the use of shims, spacers, caulking putty and

foam adhesive backed tape will be required to gain

proper seal compression. Align weatherstrip and seal

channels or retainers so the contact surfaces are

smooth and make full contact with mating surfaces.

A paper strip, equal in size to a dollar bill, should be

able to be drawn through the contact surfaces with-

out tearing the paper. A reasonable amount of effort

should be required to pull the paper through. Bolt on body panels should be aligned to the weld

on body components. The door should be aligned to

the quarter panel, rocker panel and A-pillar. The

gaps between panels should be as equal as possible.

When the door is fitted properly, the door glass can

be aligned to roof rail and A-pillar weatherstrips. Af-

ter verifying the door and door glass alignment, the

quarter glass can be aligned to the door glass and

rear roof rail.

DOOR GLASS ALIGNMENT

GLASS UP-STOP

The door glass up-stop bumper can be adjusted to

raise or lower the glass in the full up position. (1) Remove door trim panel and water shield.

(2) Loosen up-stop bolt.

(3) Adjust bracket.

(4) Tighten up-stop bolt.

DIVISION BAR ALIGNMENT

The rear of the glass can be aligned up or down by

shifting the bottom attachment of the division bar.

Division bar adjustments are small and may not be

possible on some vehicles. (1) Remove door trim panel and water shield.

(2) Loosen blot holding bottom of division bar to

inner door panel. (3) Loosen bolt holding division bar to door inner

panel below stationary glass. (4) Shift division bar forward or rearward to

achieve proper adjustment. (5) Tighten bolts.

CONVERTIBLE TOP LATCH HOOKS

(1) Disengage top latches and raise top halfway.

(2) Loosen set screw locking latch hook in position.

(2) Rotate latch hook in or out to adjust latching

effort and roof header weatherstrip compression. (3) Verify latching effort and tighten set screws.

ROOF RAIL WEATHERSTRIP RETAINER

(1) Disengage top latches and raise top halfway.

(2) Verify that door glass is all the way up and

properly aligned.

Fig. 37 Trunk Lid

Fig. 38 Trunk Lid Hinge

Ä AP/27 CONVERTIBLE 23 - 131

Page 2289 of 2438

AY-VEHICLE BODY COMPONENT SERVICE INDEX

page page

A-Pillar and Roof Rail Mouldings ............ 143

B-Pillar Trim Panel ...................... 143

Body Mouldings ......................... 146

Cowl Panel Trim and Scuff Plates ........... 143

Door Frame Trim Moulding ................ 137

Front Door and Hinge .................... 137

Front Door Glass ........................ 139

Front Door Latch ........................ 138

Front Door Silencer and Water Shield ........ 137

Front Door Trim Panel .................... 136

Front Door Window Regulator .............. 138

Front End Splash Shields ................. 136

Front Seat Belts ........................ 144

Front Seats ............................ 145

Grille AY/P Body ........................ 133

Grille AY/S Body ........................ 133

Grille Opening Panel AY/P Body ............ 134

Grille Opening Panel AY/S Body ............ 134

Head Lining ............................ 142

Hood and Hinges ....................... 134

Hood Latch and Release Cable ............. 135

Hood Ornament AY/P-S .................. 134

Outside Door Handle ..................... 138

Overhead Console ....................... 142 Quarter Trim Panel

...................... 143

Rear Deck Filler Panel ................... 146

Rear Door and Hinge .................... 140

Rear Door Fixed Glass Outer Cover ÐAY-S Body ......................... 141

Rear Door Fixed Window Module ........... 142

Rear Door Frame Trim Moulding ............ 139

Rear Door Glass ........................ 141

Rear Door Glass Lift Plate and Guide Bar ..... 141

Rear Door Latch ........................ 140

Rear Door Outer CoverÐAY-P Body ......... 141

Rear Door Outside Handle ................ 140

Rear Door Silencer and Water Shield ........ 140

Rear Door Trim Panel .................... 139

Rear Door Window Regulator .............. 141

Rear Seat Belts ......................... 144

Rear Seats ............................ 145

Rear Shelf Trim Panel .................... 144

Rear Window Glass ...................... 147

Side View Mirror Trim Cover ............... 137

Trunk Lid .............................. 147

Trunk Lid Hinge ........................ 147

Trunk Lid Torsion Bar .................... 148

Vinyl Roof Bonnet ....................... 146

GRILLE AY/P BODY

REMOVAL (FIG. 1)

(1) Remove screws holding grille to opening panel.

(2) Push top of grille downward and pull forward.

(3) Separate grille from vehicle.

INSTALLATION

Reverse the preceding operation.

GRILLE AY/S BODY

REMOVAL (FIG. 2)

(1) Loosen hidden screws holding grille to grille

opening panel at corners of grille. The screws are

captured in a clearance hole covered by a bracket be-

hind the grille. (2) Pull grille forward from grille opening panel.

INSTALLATION

Reverse the preceding operation.

Fig. 1 GrilleÐAY/P Body

Fig. 2 GrilleÐAY/S Body

Ä AY-BODY 23 - 133

Page 2302 of 2438

(3) Remove cushion from vehicle.

REAR SEAT CUSHION INSTALLATION

Reverse the preceding operation.

REAR SEAT BACK REMOVAL

(1) Remove rear seat cushion assembly.

(2) Remove bolts holding seat back to rear floor

kick-up. (3) Lift seat back upward to disengage upper hooks

from shelf support panel. (4) Separate seat back from vehicle.

REAR SEAT BACK INSTALLATION

Reverse the preceding operation.

BODY MOULDINGS

STICK-ON BODY SIDE MOULDING REMOVALAND INSTALLATION

(1) Warm the effected stick-on moulding and body

metal to approximately 38ÉC (100ÉF) using a suitable

heat lamp or heat gun. (2) Pull stick-on moulding from painted surface.

(3) Remove adhesive tape residue from painted

surface of vehicle. (4) If moulding is to be reused, Remove tape resi-

due from moulding. Clean back of moulding with Mo-

par, Super Kleen solvent or equivalent. Wipe

moulding dry with lint free cloth. Apply new body

side moulding (two sided adhesive) tape to back of

moulding. (5) Clean body surface with Mopar, Super Kleen

solvent or equivalent. Wipe surface dry with lint free

cloth. (6) Apply a length of masking tape on the body,

parallel to the top edge of the moulding to use as a

guide, if necessary. (7) Remove protective cover from tape on back of

moulding. Apply moulding to body below the mask-

ing tape guide. (8) Remove masking tape guide and heat body and

moulding, see step one. Firmly press moulding to

body surface to assure adhesion.

FRONT WHEEL OPENING MOULDING REMOVAL

(1) Remove screws holding wheel opening mould-

ing to front fender. (2) Separate moulding from fender.

FRONT WHEEL OPENING MOULDINGINSTALLATION

(1) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (2) Install screws around wheel opening.

REAR WHEEL OPENING MOULDING REMOVAL

(1) Remove screws holding wheel opening mould-

ing to quarter panel. (2) Separate wheel opening moulding from quarter

panel.

REAR WHEEL OPENING MOULDING INSTALLATION

(1) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (2) Install screws around wheel opening.

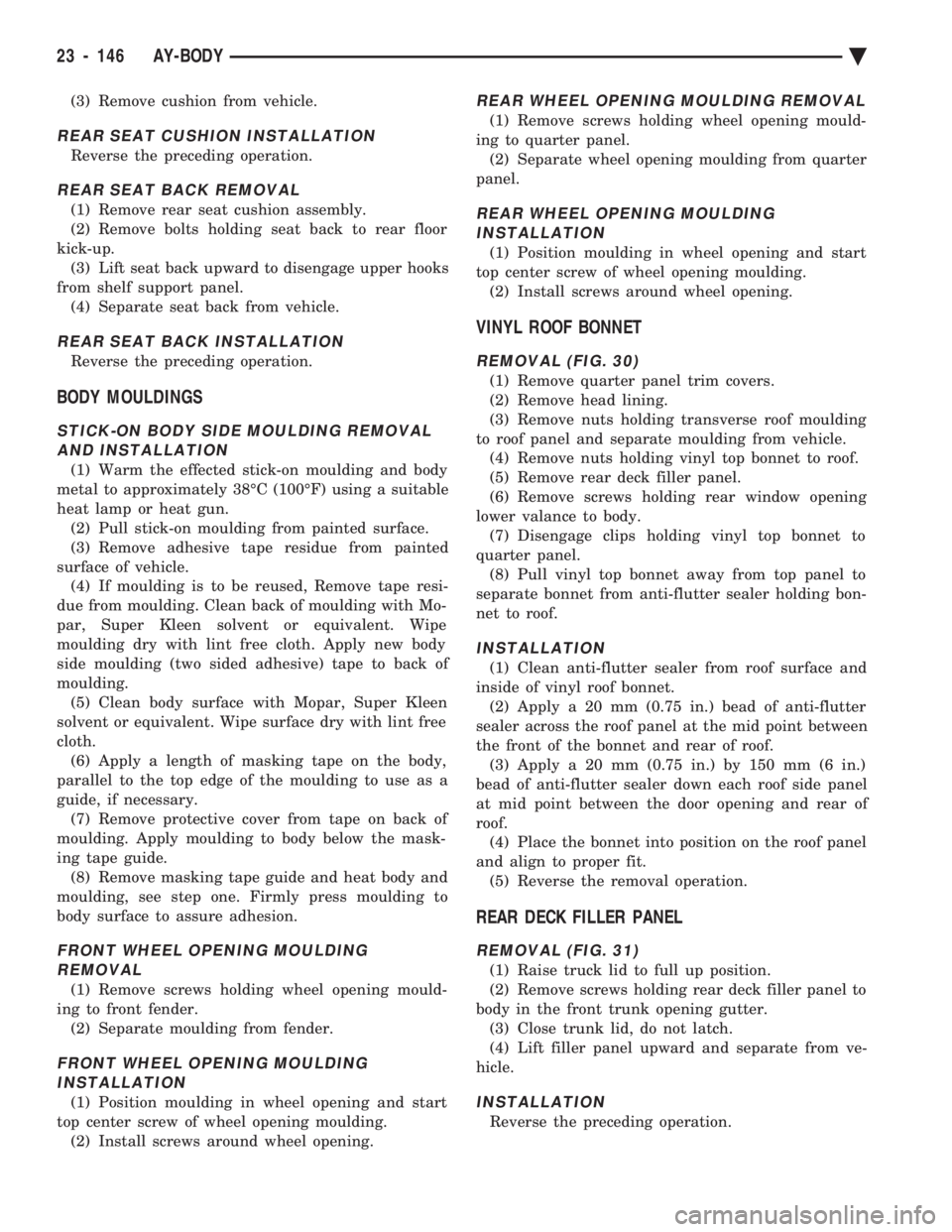

VINYL ROOF BONNET

REMOVAL (FIG. 30)

(1) Remove quarter panel trim covers.

(2) Remove head lining.

(3) Remove nuts holding transverse roof moulding

to roof panel and separate moulding from vehicle. (4) Remove nuts holding vinyl top bonnet to roof.

(5) Remove rear deck filler panel.

(6) Remove screws holding rear window opening

lower valance to body. (7) Disengage clips holding vinyl top bonnet to

quarter panel. (8) Pull vinyl top bonnet away from top panel to

separate bonnet from anti-flutter sealer holding bon-

net to roof.

INSTALLATION

(1) Clean anti-flutter sealer from roof surface and

inside of vinyl roof bonnet. (2) Apply a 20 mm (0.75 in.) bead of anti-flutter

sealer across the roof panel at the mid point between

the front of the bonnet and rear of roof. (3) Apply a 20 mm (0.75 in.) by 150 mm (6 in.)

bead of anti-flutter sealer down each roof side panel

at mid point between the door opening and rear of

roof. (4) Place the bonnet into position on the roof panel

and align to proper fit. (5) Reverse the removal operation.

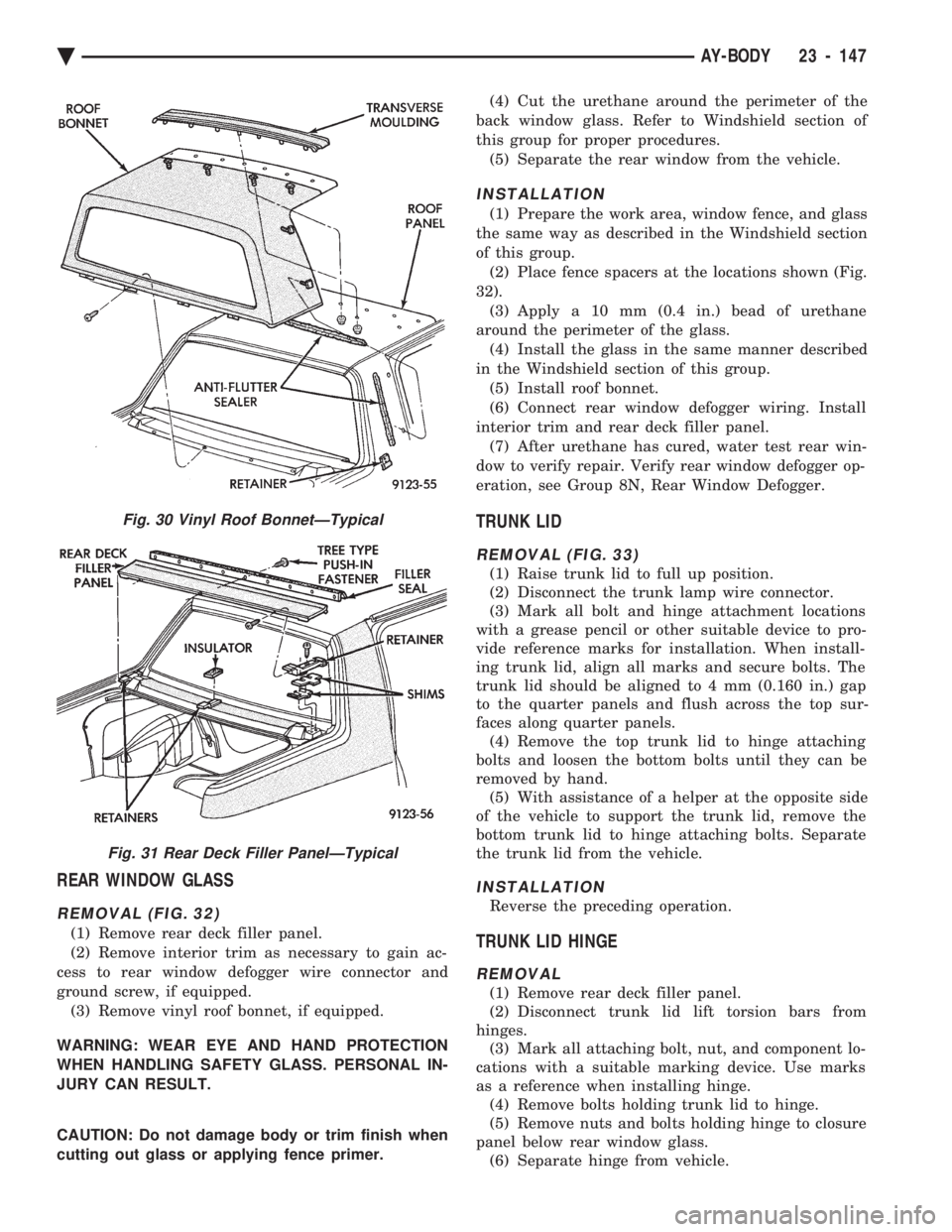

REAR DECK FILLER PANEL

REMOVAL (FIG. 31)

(1) Raise truck lid to full up position.

(2) Remove screws holding rear deck filler panel to

body in the front trunk opening gutter. (3) Close trunk lid, do not latch.

(4) Lift filler panel upward and separate from ve-

hicle.

INSTALLATION

Reverse the preceding operation.

23 - 146 AY-BODY Ä

Page 2303 of 2438

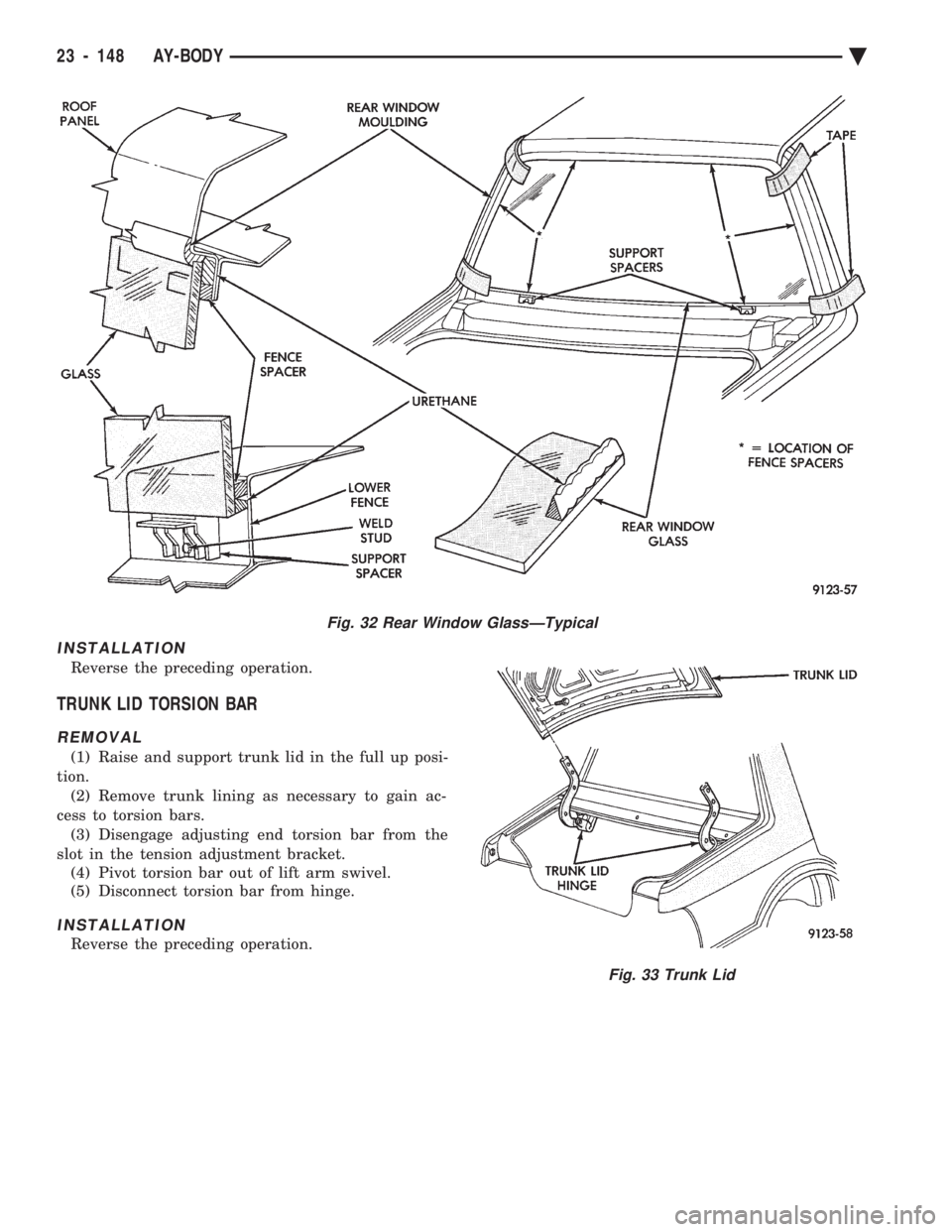

REAR WINDOW GLASS

REMOVAL (FIG. 32)

(1) Remove rear deck filler panel.

(2) Remove interior trim as necessary to gain ac-

cess to rear window defogger wire connector and

ground screw, if equipped. (3) Remove vinyl roof bonnet, if equipped.

WARNING: WEAR EYE AND HAND PROTECTION

WHEN HANDLING SAFETY GLASS. PERSONAL IN-

JURY CAN RESULT.

CAUTION: Do not damage body or trim finish when

cutting out glass or applying fence primer. (4) Cut the urethane around the perimeter of the

back window glass. Refer to Windshield section of

this group for proper procedures. (5) Separate the rear window from the vehicle.

INSTALLATION

(1) Prepare the work area, window fence, and glass

the same way as described in the Windshield section

of this group. (2) Place fence spacers at the locations shown (Fig.

32). (3) Apply a 10 mm (0.4 in.) bead of urethane

around the perimeter of the glass. (4) Install the glass in the same manner described

in the Windshield section of this group. (5) Install roof bonnet.

(6) Connect rear window defogger wiring. Install

interior trim and rear deck filler panel. (7) After urethane has cured, water test rear win-

dow to verify repair. Verify rear window defogger op-

eration, see Group 8N, Rear Window Defogger.

TRUNK LID

REMOVAL (FIG. 33)

(1) Raise trunk lid to full up position.

(2) Disconnect the trunk lamp wire connector.

(3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install-

ing trunk lid, align all marks and secure bolts. The

trunk lid should be aligned to 4 mm (0.160 in.) gap

to the quarter panels and flush across the top sur-

faces along quarter panels. (4) Remove the top trunk lid to hinge attaching

bolts and loosen the bottom bolts until they can be

removed by hand. (5) With assistance of a helper at the opposite side

of the vehicle to support the trunk lid, remove the

bottom trunk lid to hinge attaching bolts. Separate

the trunk lid from the vehicle.

INSTALLATION

Reverse the preceding operation.

TRUNK LID HINGE

REMOVAL

(1) Remove rear deck filler panel.

(2) Disconnect trunk lid lift torsion bars from

hinges. (3) Mark all attaching bolt, nut, and component lo-

cations with a suitable marking device. Use marks

as a reference when installing hinge. (4) Remove bolts holding trunk lid to hinge.

(5) Remove nuts and bolts holding hinge to closure

panel below rear window glass. (6) Separate hinge from vehicle.

Fig. 30 Vinyl Roof BonnetÐTypical

Fig. 31 Rear Deck Filler PanelÐTypical

Ä AY-BODY 23 - 147

Page 2304 of 2438

INSTALLATION

Reverse the preceding operation.

TRUNK LID TORSION BAR

REMOVAL

(1) Raise and support trunk lid in the full up posi-

tion. (2) Remove trunk lining as necessary to gain ac-

cess to torsion bars. (3) Disengage adjusting end torsion bar from the

slot in the tension adjustment bracket. (4) Pivot torsion bar out of lift arm swivel.

(5) Disconnect torsion bar from hinge.

INSTALLATION

Reverse the preceding operation.

Fig. 32 Rear Window GlassÐTypical

Fig. 33 Trunk Lid

23 - 148 AY-BODY Ä