maintenance CHEVROLET KODIAK 2007 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2007, Model line: KODIAK, Model: CHEVROLET KODIAK 2007Pages: 430, PDF Size: 6.06 MB

Page 311 of 430

Rear Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant and when to

change it. SeeScheduled Maintenance on

page 363.

Notice:If you drive your vehicle through deep

water that is higher than the front or rear

axle, water may enter the axle housing and

cause the axle lubricant to break down.

This could damage the gears inside. Avoid

driving your vehicle through deep water.

You should avoid driving your vehicle through

deep puddles or standing water. If you must drive

through water that is higher than the front or

rear axle, see your dealer immediately afterward

to have the condition of the axle lubricant checked.

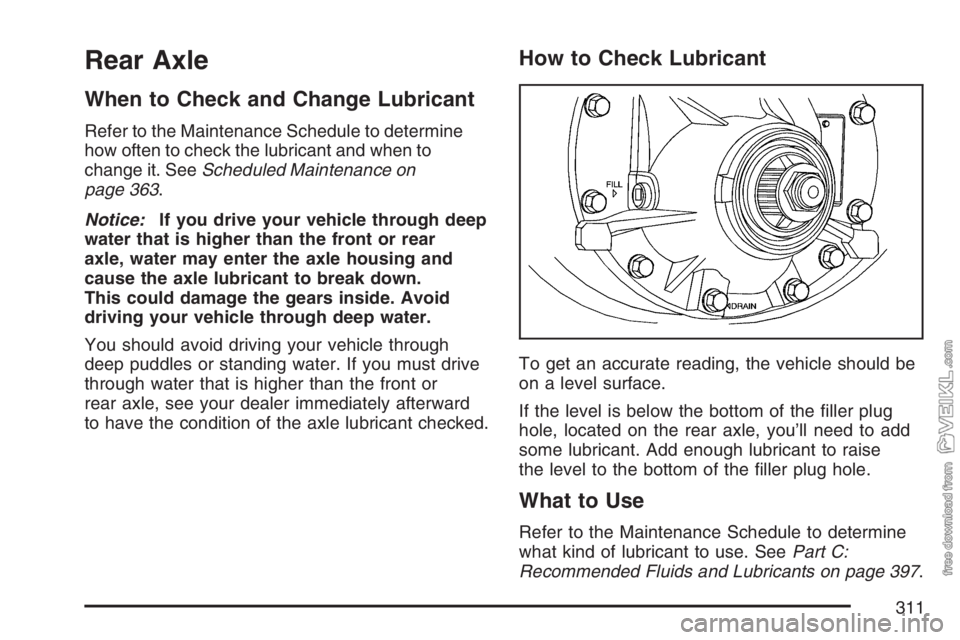

How to Check Lubricant

To get an accurate reading, the vehicle should be

on a level surface.

If the level is below the bottom of the filler plug

hole, located on the rear axle, you’ll need to add

some lubricant. Add enough lubricant to raise

the level to the bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine

what kind of lubricant to use. SeePart C:

Recommended Fluids and Lubricants on page 397.

311

Page 312 of 430

Rear Axle Shift Motor

When to Check and Change Fluid

If you have an optional air-shift two-speed,

controlled traction, or locking differential type rear

axle, a good time to check the fluid level in the axle

shift motor is when the rear axle lubricant is

checked.

How to Check Fluid

Remove the plug on the front plate of the axle

shift motor, add enough fluid to raise the level to

the bottom of the filler plug hole, then replace

the plug.

What to Use

Refer to your Maintenance Schedule to determine

what kind of lubricant to use. SeePart C:

Recommended Fluids and Lubricants on page 397.

Four-Wheel Drive

Transfer Case

When to Check Lubricant

It is not necessary to regularly check transfer case

fluid unless you suspect there is a leak or you

hear an unusual noise. A fluid loss could indicate

a problem. Have it inspected and repaired.

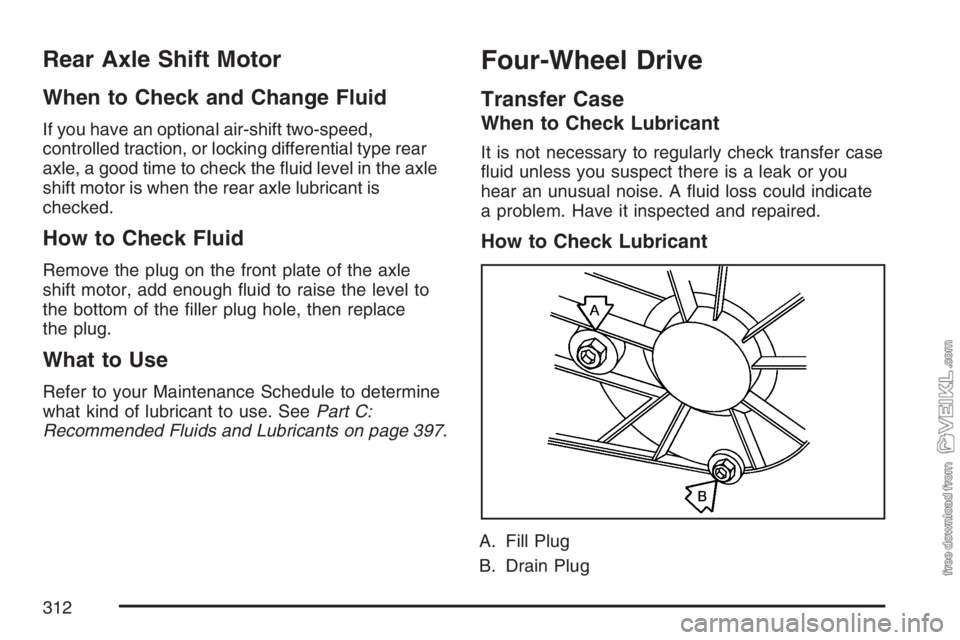

How to Check Lubricant

A. Fill Plug

B. Drain Plug

312

Page 313 of 430

To get an accurate reading, the vehicle should be

on a level surface.

If the level is below the bottom of the fill plug hole,

located on the transfer case, you’ll need to add

some lubricant. Add enough lubricant to raise the

level to the bottom of the fill plug hole. Use

care not to overtighten the plug.

When to Change Lubricant

Refer to the Maintenance Schedule to determine

how often to change the lubricant. See

Scheduled Maintenance on page 363.

What to Use

Refer to the Maintenance Schedule to determine

what kind of lubricant to use. SeePart C:

Recommended Fluids and Lubricants on page 397.

Front Axle

When to Check Lubricant

It is not necessary to regularly check front axle

fluid unless you suspect there is a leak or you hear

an unusual noise. A fluid loss could indicate a

problem. Have it inspected and repaired.

Notice:If you drive your vehicle through deep

water that is higher than the front or rear

axle, water may enter the axle housing and

cause the axle lubricant to break down.

This could damage the gears inside. Avoid

driving your vehicle through deep water.

You should avoid driving your vehicle through

deep puddles or standing water. If you must drive

through water that is higher than the front or

rear axle, see your dealer immediately afterward

to have the condition of the axle lubricant checked.

313

Page 314 of 430

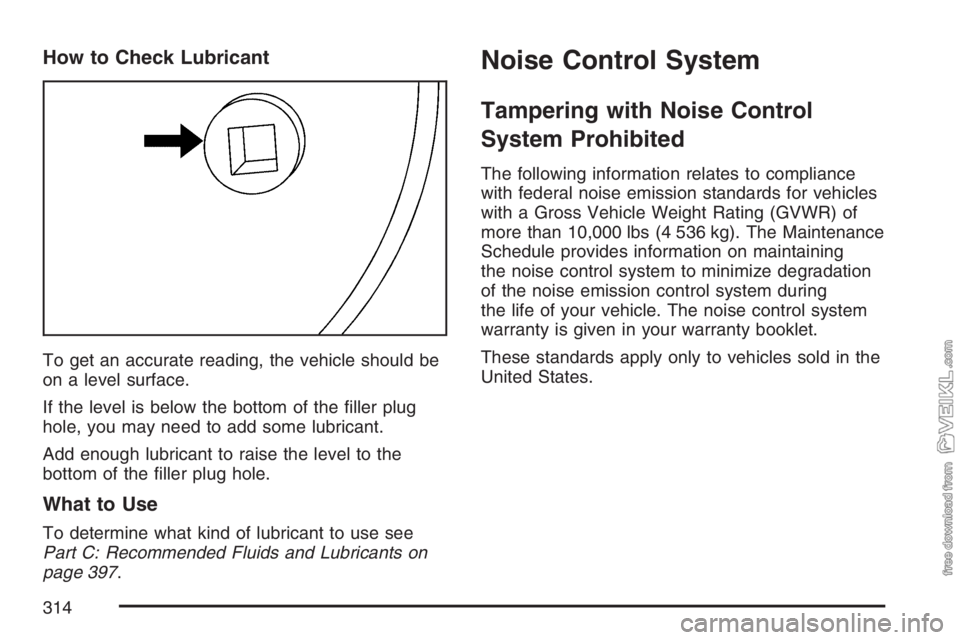

How to Check Lubricant

To get an accurate reading, the vehicle should be

on a level surface.

If the level is below the bottom of the filler plug

hole, you may need to add some lubricant.

Add enough lubricant to raise the level to the

bottom of the filler plug hole.

What to Use

To determine what kind of lubricant to use see

Part C: Recommended Fluids and Lubricants on

page 397.

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance

with federal noise emission standards for vehicles

with a Gross Vehicle Weight Rating (GVWR) of

more than 10,000 lbs (4 536 kg). The Maintenance

Schedule provides information on maintaining

the noise control system to minimize degradation

of the noise emission control system during

the life of your vehicle. The noise control system

warranty is given in your warranty booklet.

These standards apply only to vehicles sold in the

United States.

314

Page 315 of 430

Federal law prohibits the following acts or the

causing thereof:

1. The removal or rendering inoperative by any

person, other than for purposes of

maintenance, repair or replacement, of any

device or element of design incorporated into

any new vehicle for the purpose of noise

control, prior to its sale or delivery to

the ultimate purchaser or while it is in use; or

2. The use of the vehicle after such device or

element of design has been removed or

rendered inoperative by any person.

Among those acts presumed to constitute

tampering are the acts listed below.

Insulation:

•

Removal of the noise shields or any

underhood insulation.

Engine:

•

Removal or rendering engine speed governor,

if the vehicle has one, inoperative so as to

allow engine speed to exceed manufacturer

specifications.

Fan and Drive:

•

Removal of fan clutch, if the vehicle has one,

or rendering clutch inoperative.

•Removal of the fan shroud, if the vehicle

has one.

Air Intake:

•

Removal of the air cleaner silencer.

•Modification of the air cleaner.

Exhaust:

•

Removal of the muffler and/or resonator.

•Removal of the exhaust pipes and exhaust

pipe clamps.

Bulb Replacement

It is recommended that all bulbs be replaced by

your dealer.

315

Page 317 of 430

Other Service Items

Fuel Filter

Fuel Filter/Pressure Regulator

(Gasoline Engines)

The steel fuel filter/pressure regulator is located

near the engine compartment on the driver’s

side frame rail. If your vehicle has a rear steel fuel

tank, the fuel filter/pressure regulator is located

near the rear fuel tank, on the driver’s side frame

rail. SeeScheduled Maintenance on page 363

for recommended service intervals.

If your vehicle is equipped with the optional Davco

spin-on type filter, it is located on the driver’s

side frame rail.

Fuel Filter (Diesel Engines)

If you have a diesel engine, your fuel filter is

located in the engine compartment on the driver’s

side of the vehicle, or along the driver’s side

frame rail. See “Fuel Filter Replacement” earlier in

this section for further information.

Also seeScheduled Maintenance on page 363for

recommended service intervals.

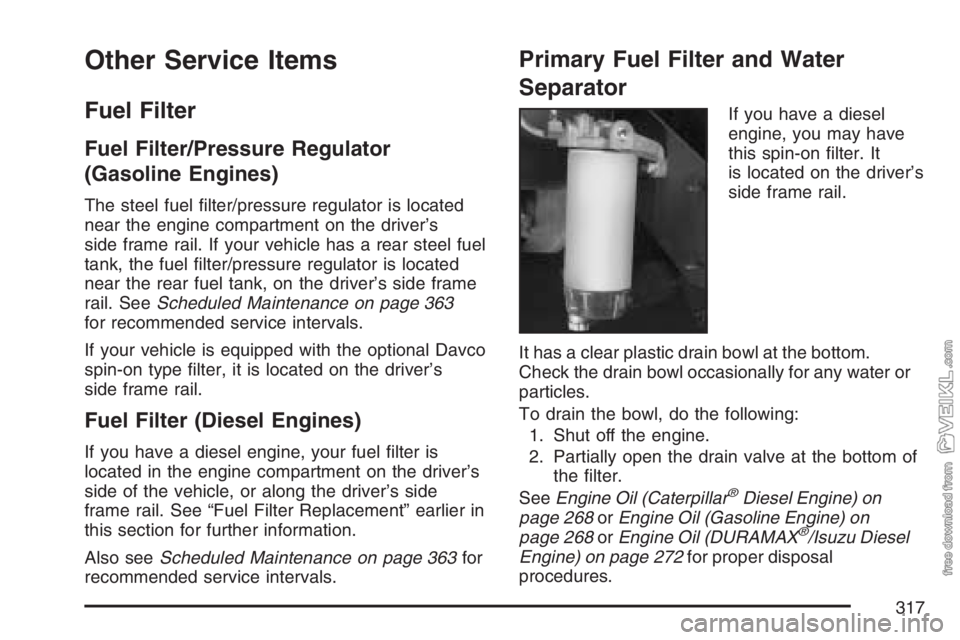

Primary Fuel Filter and Water

Separator

If you have a diesel

engine, you may have

this spin-on filter. It

is located on the driver’s

side frame rail.

It has a clear plastic drain bowl at the bottom.

Check the drain bowl occasionally for any water or

particles.

To drain the bowl, do the following:

1. Shut off the engine.

2. Partially open the drain valve at the bottom of

the filter.

SeeEngine Oil (Caterpillar

®Diesel Engine) on

page 268orEngine Oil (Gasoline Engine) on

page 268orEngine Oil (DURAMAX

®/Isuzu Diesel

Engine) on page 272for proper disposal

procedures.

317

Page 320 of 430

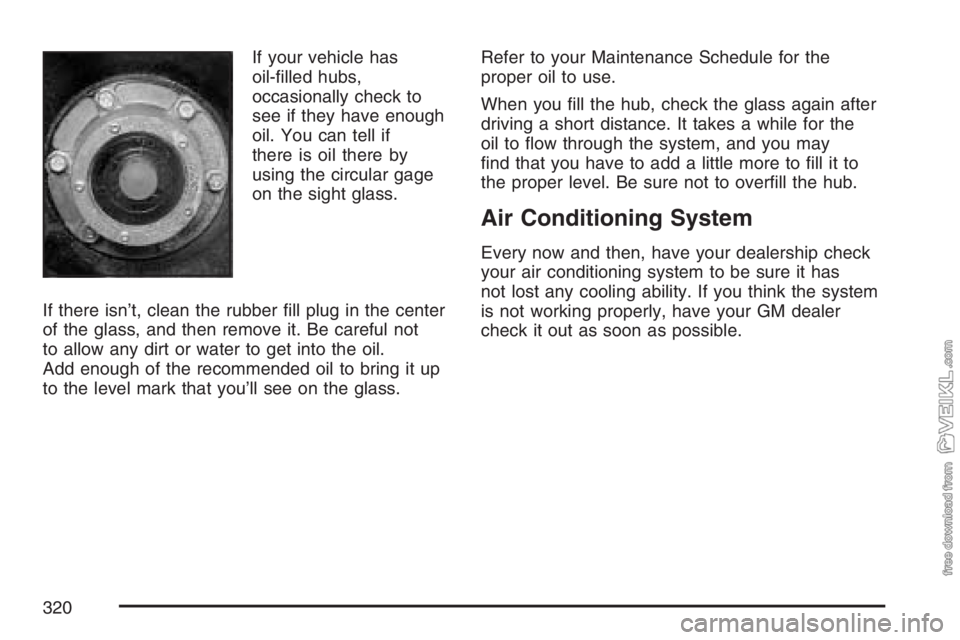

If your vehicle has

oil-filled hubs,

occasionally check to

see if they have enough

oil. You can tell if

there is oil there by

using the circular gage

on the sight glass.

If there isn’t, clean the rubber fill plug in the center

of the glass, and then remove it. Be careful not

to allow any dirt or water to get into the oil.

Add enough of the recommended oil to bring it up

to the level mark that you’ll see on the glass.Refer to your Maintenance Schedule for the

proper oil to use.

When you fill the hub, check the glass again after

driving a short distance. It takes a while for the

oil to flow through the system, and you may

find that you have to add a little more to fill it to

the proper level. Be sure not to overfill the hub.

Air Conditioning System

Every now and then, have your dealership check

your air conditioning system to be sure it has

not lost any cooling ability. If you think the system

is not working properly, have your GM dealer

check it out as soon as possible.

320

Page 328 of 430

How Often to Check

Wheel tightness is so important you should have a

technician check nut tightness on all wheels with a

torque wrench after your first 100 miles (160 km),

and then 1,000 miles (1 600 km) after that. Be sure

to repeat this service whenever you have a tire

removed or serviced. SeeScheduled Maintenance

on page 363for further information.

Wheel Replacement

Replace any wheel that is bent, cracked or badly

rusted or corroded. If wheel nuts keep coming

loose, replace the wheel. If the wheel leaks

air, replace it.

Your dealer will know the kind of wheel you need.

Each new wheel should have the same

load-carrying capacity, diameter, width, offset and

be mounted the same way as the one it replaces.If you need to replace any of your wheels, wheel

bolts or wheel nuts, replace them only with

new GM original equipment parts. This way, you

will be sure to have the right wheel, wheel

bolts and wheel nuts for your vehicle.

{CAUTION:

A leaking wheel could fail without warning.

A wheel designed for tubeless tires could

be leaking because it is damaged. Do not

use an inner tube or some other thing to try

to stop the leaking. Get a new wheel of the

proper type.

328

Page 338 of 430

Finish Damage

Any stone chips, fractures or deep scratches in

the finish should be repaired right away. Bare

metal will corrode quickly and may develop into

major repair expense.

Minor chips and scratches can be repaired with

touch-up materials available from your dealer.

Larger areas of finish damage can be corrected in

your dealer’s body and paint shop.

Underbody Maintenance

Chemicals used for ice and snow removal and

dust control can collect on the underbody. If these

are not removed, corrosion and rust can develop

on the underbody parts such as fuel lines,

frame, floor pan, and exhaust system even though

they have corrosion protection.

At least every spring, flush these materials from the

underbody with plain water. Clean any areas where

mud and debris can collect. Dirt packed in close

areas of the frame should be loosened before being

flushed. Your dealer or an underbody car washing

system can do this for you.

Chemical Paint Spotting

Some weather and atmospheric conditions can

create a chemical fallout. Airborne pollutants can

fall upon and attack painted surfaces on the

vehicle. This damage can take two forms: blotchy,

ring-shaped discolorations, and small, irregular

dark spots etched into the paint surface.

Although no defect in the paint job causes this,

GM will repair, at no charge to the owner, the

surfaces of new vehicles damaged by this fallout

condition within 12 months or 12,000 miles

(20 000 km) of purchase, whichever occurs first.

338

Page 351 of 430

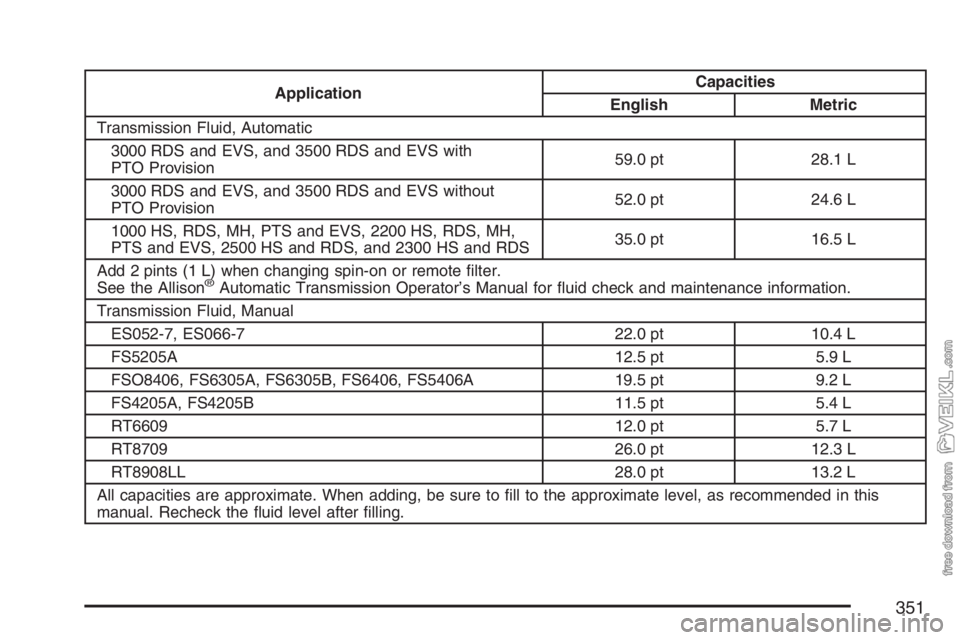

ApplicationCapacities

English Metric

Transmission Fluid, Automatic

3000 RDS and EVS, and 3500 RDS and EVS with

PTO Provision59.0 pt 28.1 L

3000 RDS and EVS, and 3500 RDS and EVS without

PTO Provision52.0 pt 24.6 L

1000 HS, RDS, MH, PTS and EVS, 2200 HS, RDS, MH,

PTS and EVS, 2500 HS and RDS, and 2300 HS and RDS35.0 pt 16.5 L

Add 2 pints (1 L) when changing spin-on or remote filter.

See the Allison

®Automatic Transmission Operator’s Manual for fluid check and maintenance information.

Transmission Fluid, Manual

ES052-7, ES066-7 22.0 pt 10.4 L

FS5205A 12.5 pt 5.9 L

FSO8406, FS6305A, FS6305B, FS6406, FS5406A 19.5 pt 9.2 L

FS4205A, FS4205B 11.5 pt 5.4 L

RT6609 12.0 pt 5.7 L

RT8709 26.0 pt 12.3 L

RT8908LL 28.0 pt 13.2 L

All capacities are approximate. When adding, be sure to fill to the approximate level, as recommended in this

manual. Recheck the fluid level after filling.

351