CHEVROLET PLYMOUTH ACCLAIM 1993 Owners Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 91 of 2438

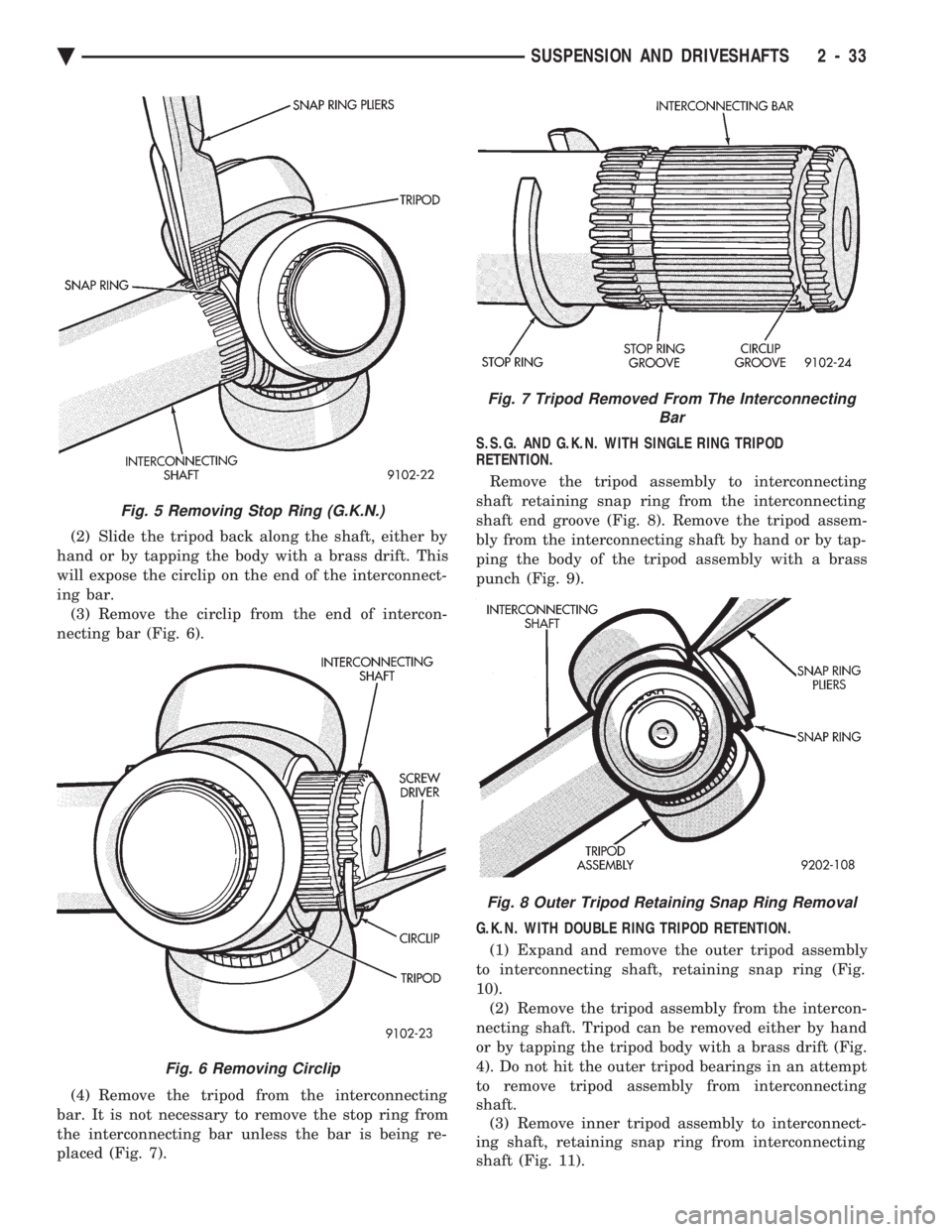

(2) Slide the tripod back along the shaft, either by

hand or by tapping the body with a brass drift. This

will expose the circlip on the end of the interconnect-

ing bar. (3) Remove the circlip from the end of intercon-

necting bar (Fig. 6).

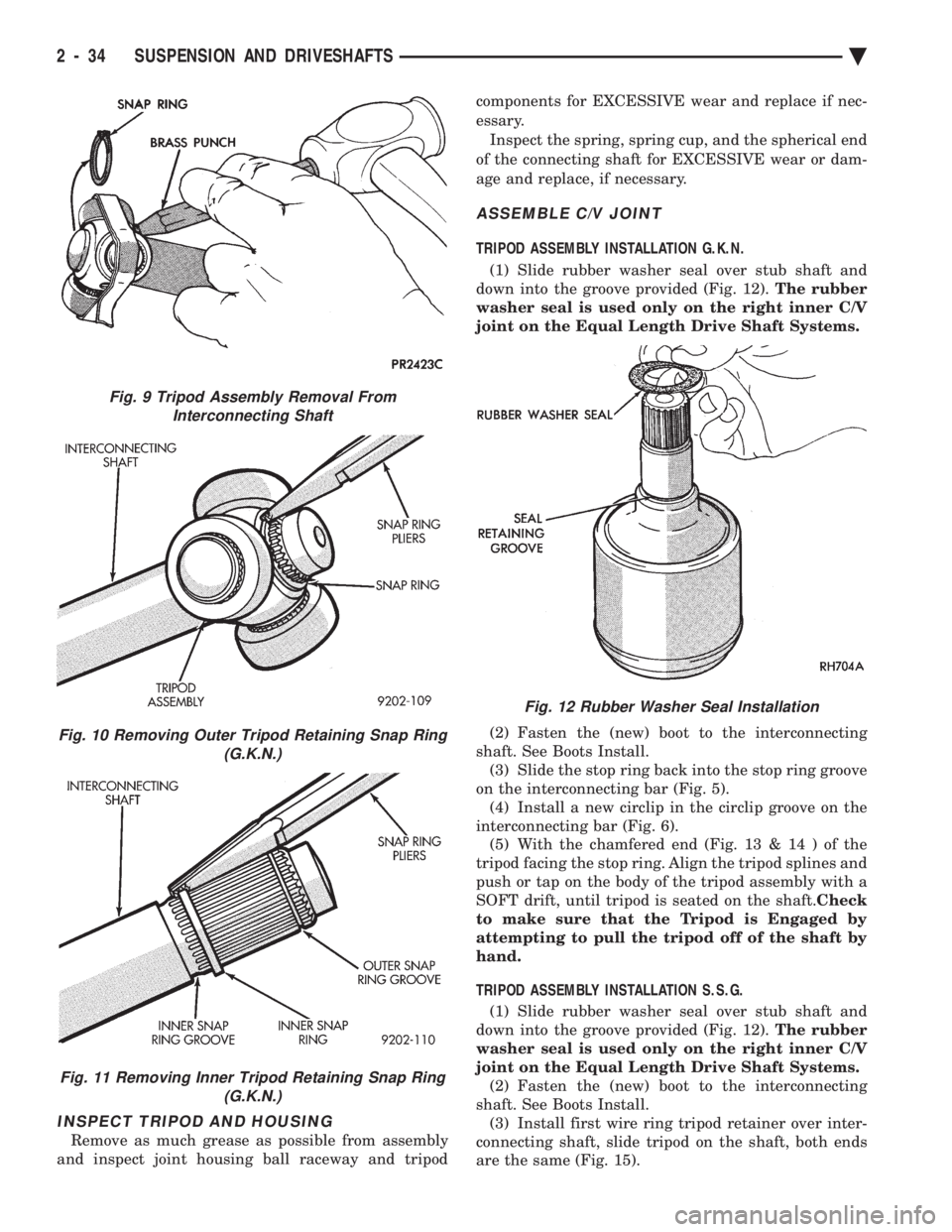

(4) Remove the tripod from the interconnecting

bar. It is not necessary to remove the stop ring from

the interconnecting bar unless the bar is being re-

placed (Fig. 7). S.S.G. AND G.K.N. WITH SINGLE RING TRIPOD

RETENTION.

Remove the tripod assembly to interconnecting

shaft retaining snap ring from the interconnecting

shaft end groove (Fig. 8). Remove the tripod assem-

bly from the interconnecting shaft by hand or by tap-

ping the body of the tripod assembly with a brass

punch (Fig. 9).

G.K.N. WITH DOUBLE RING TRIPOD RETENTION. (1) Expand and remove the outer tripod assembly

to interconnecting shaft, retaining snap ring (Fig.

10). (2) Remove the tripod assembly from the intercon-

necting shaft. Tripod can be removed either by hand

or by tapping the tripod body with a brass drift (Fig.

4). Do not hit the outer tripod bearings in an attempt

to remove tripod assembly from interconnecting

shaft. (3) Remove inner tripod assembly to interconnect-

ing shaft, retaining snap ring from interconnecting

shaft (Fig. 11).

Fig. 5 Removing Stop Ring (G.K.N.)

Fig. 6 Removing Circlip

Fig. 7 Tripod Removed From The Interconnecting Bar

Fig. 8 Outer Tripod Retaining Snap Ring Removal

Ä SUSPENSION AND DRIVESHAFTS 2 - 33

Page 92 of 2438

INSPECT TRIPOD AND HOUSING

Remove as much grease as possible from assembly

and inspect joint housing ball raceway and tripod components for EXCESSIVE wear and replace if nec-

essary.

Inspect the spring, spring cup, and the spherical end

of the connecting shaft for EXCESSIVE wear or dam-

age and replace, if necessary.

ASSEMBLE C/V JOINT

TRIPOD ASSEMBLY INSTALLATION G.K.N.

(1) Slide rubber washer seal over stub shaft and

down into the groove provided (Fig. 12). The rubber

washer seal is used only on the right inner C/V

joint on the Equal Length Drive Shaft Systems.

(2) Fasten the (new) boot to the interconnecting

shaft. See Boots Install. (3) Slide the stop ring back into the stop ring groove

on the interconnecting bar (Fig. 5). (4) Install a new circlip in the circlip groove on the

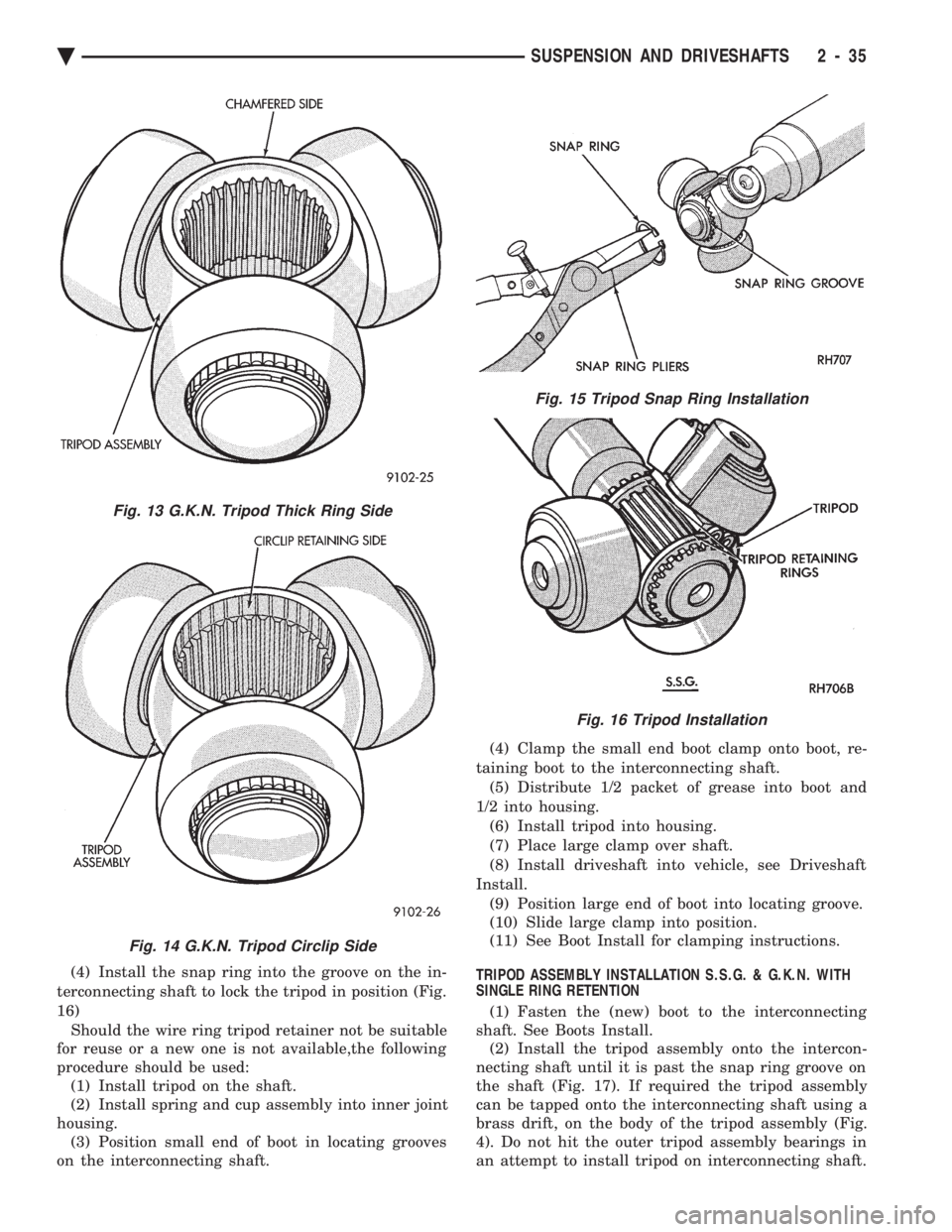

interconnecting bar (Fig. 6). (5) With the chamfered end (Fig. 13 & 14 ) of the

tripod facing the stop ring. Align the tripod splines and

push or tap on the body of the tripod assembly with a

SOFT drift, until tripod is seated on the shaft. Check

to make sure that the Tripod is Engaged by

attempting to pull the tripod off of the shaft by

hand.

TRIPOD ASSEMBLY INSTALLATION S.S.G. (1) Slide rubber washer seal over stub shaft and

down into the groove provided (Fig. 12). The rubber

washer seal is used only on the right inner C/V

joint on the Equal Length Drive Shaft Systems. (2) Fasten the (new) boot to the interconnecting

shaft. See Boots Install. (3) Install first wire ring tripod retainer over inter-

connecting shaft, slide tripod on the shaft, both ends

are the same (Fig. 15).

Fig. 9 Tripod Assembly Removal From Interconnecting Shaft

Fig. 10 Removing Outer Tripod Retaining Snap Ring (G.K.N.)

Fig. 11 Removing Inner Tripod Retaining Snap Ring(G.K.N.)

Fig. 12 Rubber Washer Seal Installation

2 - 34 SUSPENSION AND DRIVESHAFTS Ä

Page 93 of 2438

(4) Install the snap ring into the groove on the in-

terconnecting shaft to lock the tripod in position (Fig.

16) Should the wire ring tripod retainer not be suitable

for reuse or a new one is not available,the following

procedure should be used: (1) Install tripod on the shaft.

(2) Install spring and cup assembly into inner joint

housing. (3) Position small end of boot in locating grooves

on the interconnecting shaft. (4) Clamp the small end boot clamp onto boot, re-

taining boot to the interconnecting shaft. (5) Distribute 1/2 packet of grease into boot and

1/2 into housing. (6) Install tripod into housing.

(7) Place large clamp over shaft.

(8) Install driveshaft into vehicle, see Driveshaft

Install. (9) Position large end of boot into locating groove.

(10) Slide large clamp into position.

(11) See Boot Install for clamping instructions.

TRIPOD ASSEMBLY INSTALLATION S.S.G. & G.K.N. WITH

SINGLE RING RETENTION

(1) Fasten the (new) boot to the interconnecting

shaft. See Boots Install. (2) Install the tripod assembly onto the intercon-

necting shaft until it is past the snap ring groove on

the shaft (Fig. 17). If required the tripod assembly

can be tapped onto the interconnecting shaft using a

brass drift, on the body of the tripod assembly (Fig.

4). Do not hit the outer tripod assembly bearings in

an attempt to install tripod on interconnecting shaft.

Fig. 13 G.K.N. Tripod Thick Ring Side

Fig. 14 G.K.N. Tripod Circlip Side

Fig. 15 Tripod Snap Ring Installation

Fig. 16 Tripod Installation

Ä SUSPENSION AND DRIVESHAFTS 2 - 35

Page 94 of 2438

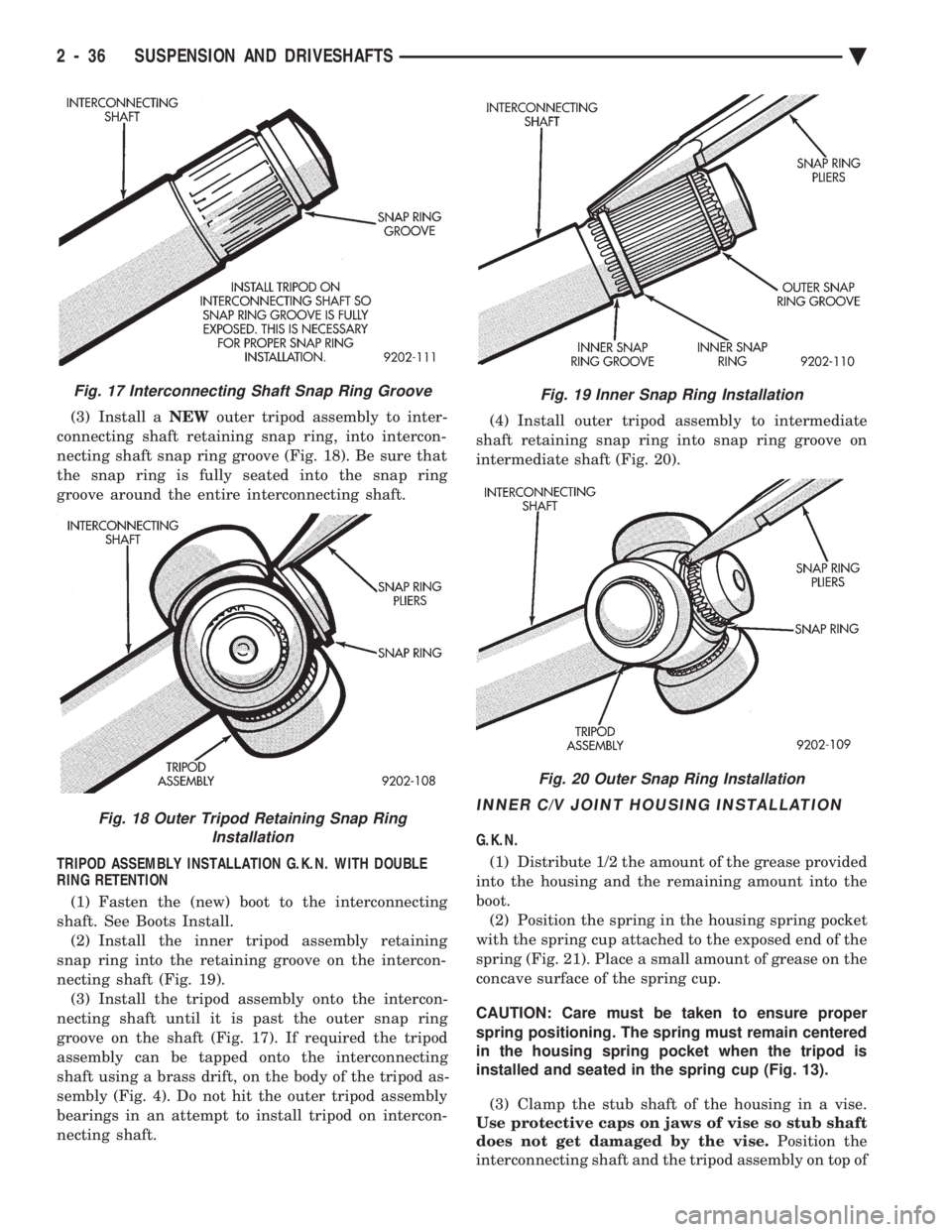

(3) Install a NEWouter tripod assembly to inter-

connecting shaft retaining snap ring, into intercon-

necting shaft snap ring groove (Fig. 18). Be sure that

the snap ring is fully seated into the snap ring

groove around the entire interconnecting shaft.

TRIPOD ASSEMBLY INSTALLATION G.K.N. WITH DOUBLE

RING RETENTION

(1) Fasten the (new) boot to the interconnecting

shaft. See Boots Install. (2) Install the inner tripod assembly retaining

snap ring into the retaining groove on the intercon-

necting shaft (Fig. 19). (3) Install the tripod assembly onto the intercon-

necting shaft until it is past the outer snap ring

groove on the shaft (Fig. 17). If required the tripod

assembly can be tapped onto the interconnecting

shaft using a brass drift, on the body of the tripod as-

sembly (Fig. 4). Do not hit the outer tripod assembly

bearings in an attempt to install tripod on intercon-

necting shaft. (4) Install outer tripod assembly to intermediate

shaft retaining snap ring into snap ring groove on

intermediate shaft (Fig. 20).

INNER C/V JOINT HOUSING INSTALLATION

G.K.N.

(1) Distribute 1/2 the amount of the grease provided

into the housing and the remaining amount into the

boot. (2) Position the spring in the housing spring pocket

with the spring cup attached to the exposed end of the

spring (Fig. 21). Place a small amount of grease on the

concave surface of the spring cup.

CAUTION: Care must be taken to ensure proper

spring positioning. The spring must remain centered

in the housing spring pocket when the tripod is

installed and seated in the spring cup (Fig. 13).

(3) Clamp the stub shaft of the housing in a vise.

Use protective caps on jaws of vise so stub shaft

does not get damaged by the vise. Position the

interconnecting shaft and the tripod assembly on top of

Fig. 17 Interconnecting Shaft Snap Ring Groove

Fig. 18 Outer Tripod Retaining Snap Ring Installation

Fig. 19 Inner Snap Ring Installation

Fig. 20 Outer Snap Ring Installation

2 - 36 SUSPENSION AND DRIVESHAFTS Ä

Page 95 of 2438

the plastic retaining collar. Carefully insert each of the

tripod rollers into the retaining collar, one at a time

while holding the interconnecting shaft on an angle.

Carefully push down on the shaft until the rollers are

locked into retaining collar in the housing.(4) Position the boot over the boot retaining groove

in the housing and clamp in place. See Boots Install.

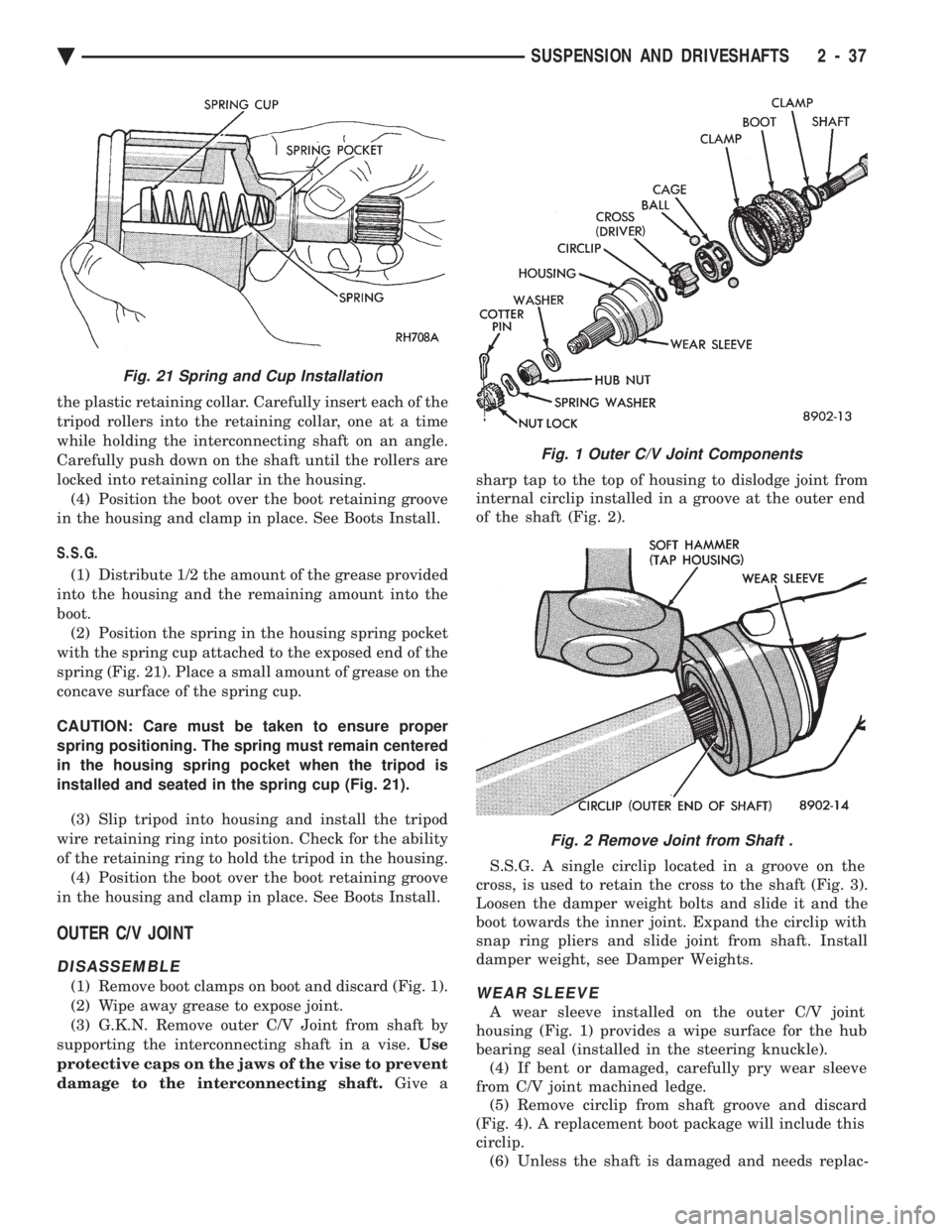

S.S.G.

(1) Distribute 1/2 the amount of the grease provided

into the housing and the remaining amount into the

boot. (2) Position the spring in the housing spring pocket

with the spring cup attached to the exposed end of the

spring (Fig. 21). Place a small amount of grease on the

concave surface of the spring cup.

CAUTION: Care must be taken to ensure proper

spring positioning. The spring must remain centered

in the housing spring pocket when the tripod is

installed and seated in the spring cup (Fig. 21).

(3) Slip tripod into housing and install the tripod

wire retaining ring into position. Check for the ability

of the retaining ring to hold the tripod in the housing. (4) Position the boot over the boot retaining groove

in the housing and clamp in place. See Boots Install.

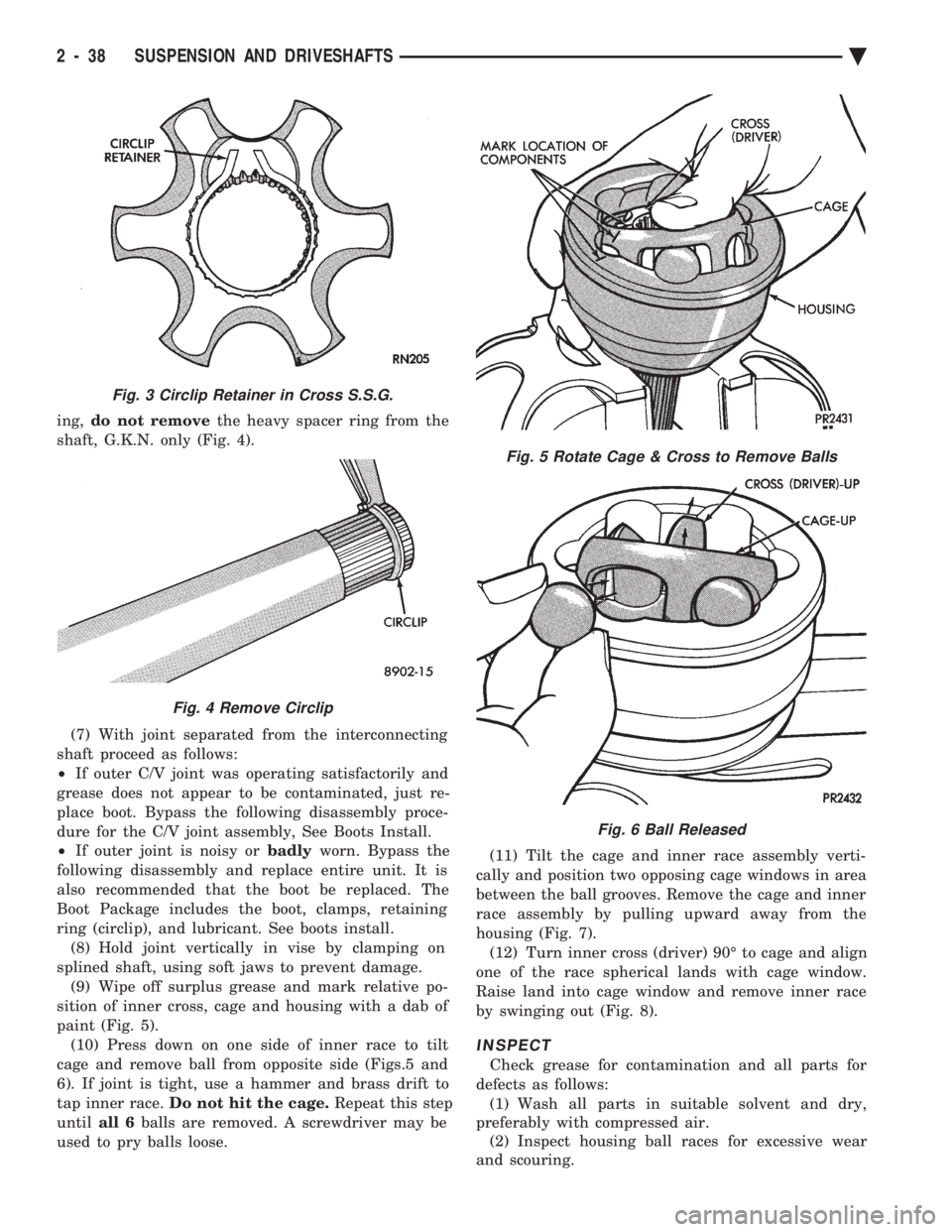

OUTER C/V JOINT

DISASSEMBLE

(1) Remove boot clamps on boot and discard (Fig. 1).

(2) Wipe away grease to expose joint.

(3) G.K.N. Remove outer C/V Joint from shaft by

supporting the interconnecting shaft in a vise. Use

protective caps on the jaws of the vise to prevent

damage to the interconnecting shaft. Give a sharp tap to the top of housing to dislodge joint from

internal circlip installed in a groove at the outer end

of the shaft (Fig. 2).

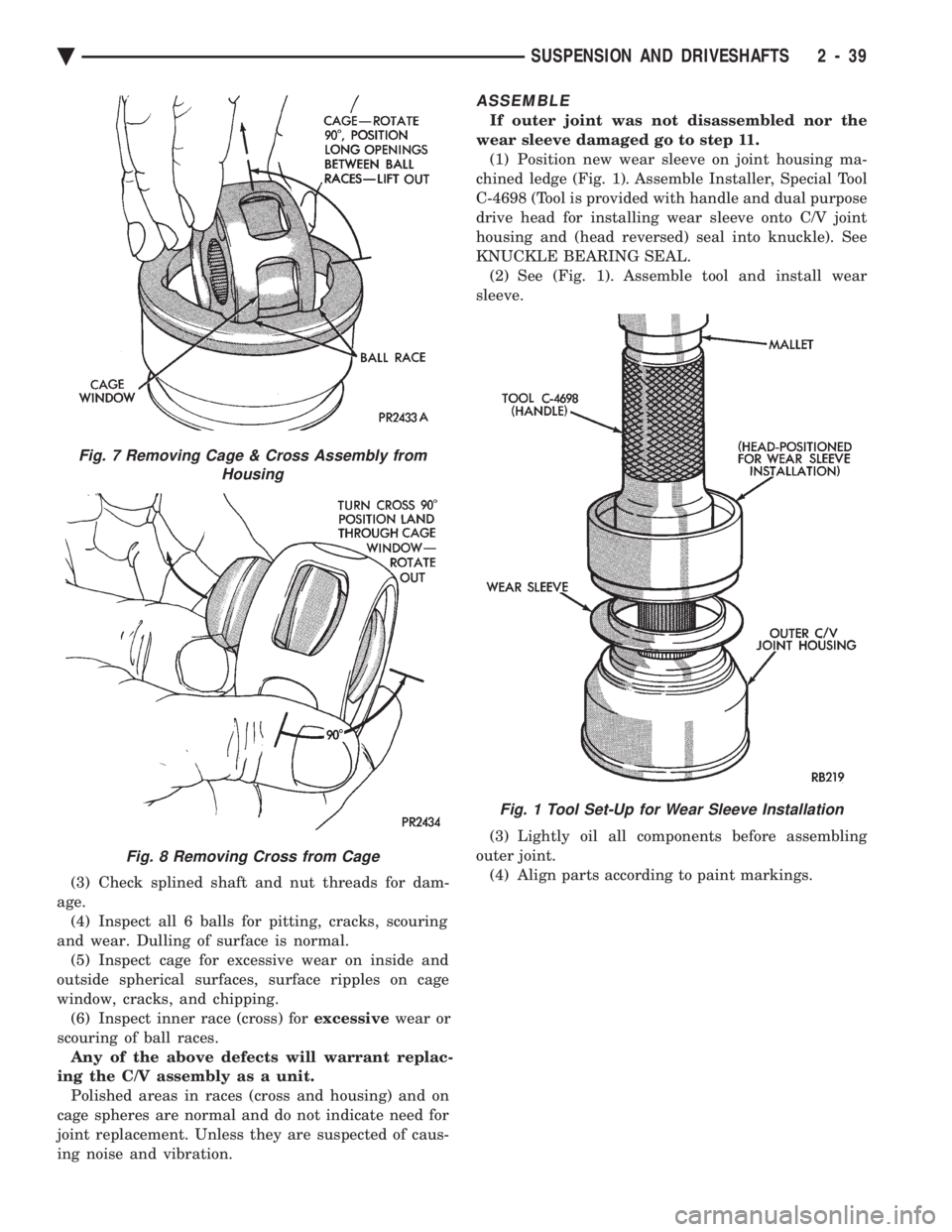

S.S.G. A single circlip located in a groove on the

cross, is used to retain the cross to the shaft (Fig. 3).

Loosen the damper weight bolts and slide it and the

boot towards the inner joint. Expand the circlip with

snap ring pliers and slide joint from shaft. Install

damper weight, see Damper Weights.WEAR SLEEVE

A wear sleeve installed on the outer C/V joint

housing (Fig. 1) provides a wipe surface for the hub

bearing seal (installed in the steering knuckle). (4) If bent or damaged, carefully pry wear sleeve

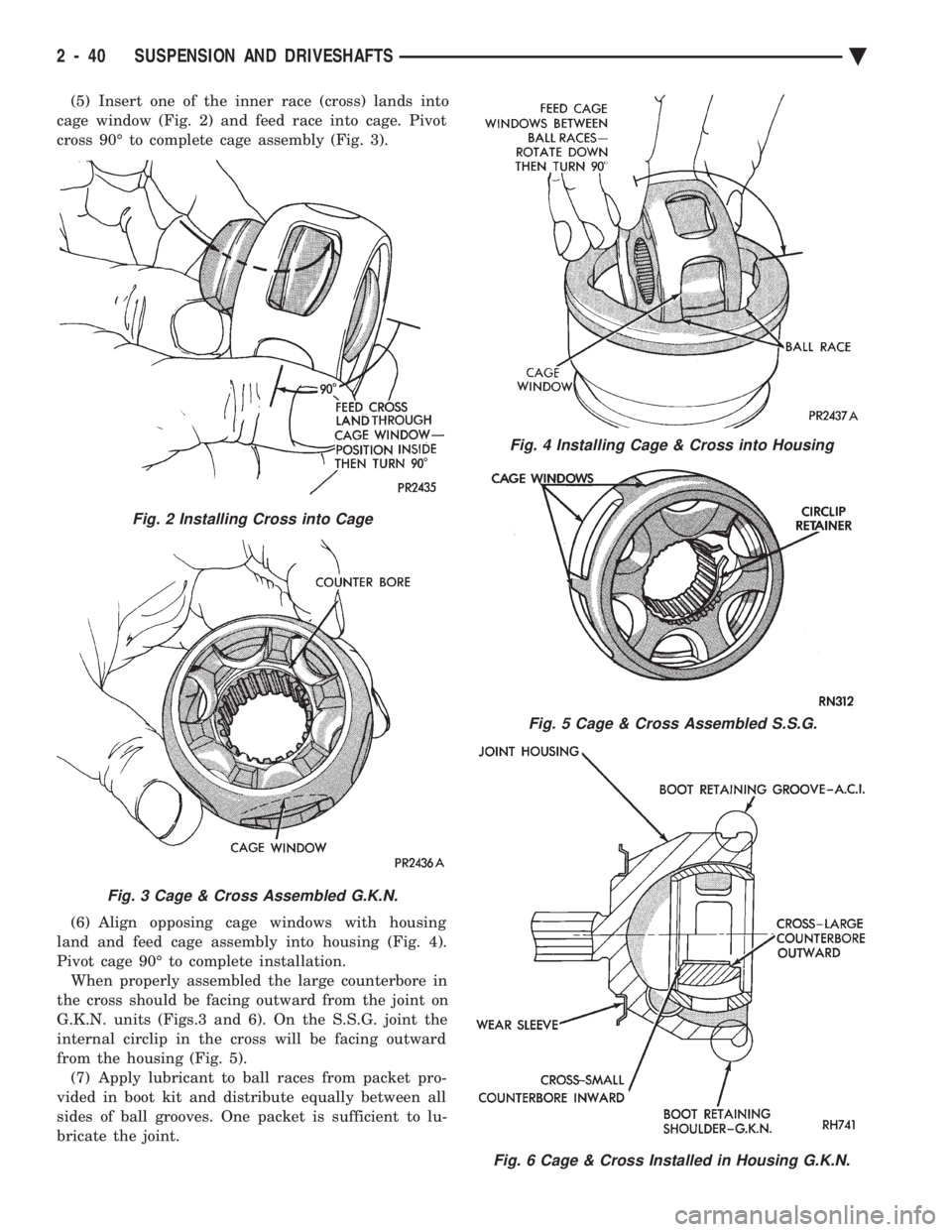

from C/V joint machined ledge. (5) Remove circlip from shaft groove and discard

(Fig. 4). A replacement boot package will include this

circlip. (6) Unless the shaft is damaged and needs replac-

Fig. 1 Outer C/V Joint Components

Fig. 2 Remove Joint from Shaft .

Fig. 21 Spring and Cup Installation

Ä SUSPENSION AND DRIVESHAFTS 2 - 37

Page 96 of 2438

ing, do not remove the heavy spacer ring from the

shaft, G.K.N. only (Fig. 4).

(7) With joint separated from the interconnecting

shaft proceed as follows:

² If outer C/V joint was operating satisfactorily and

grease does not appear to be contaminated, just re-

place boot. Bypass the following disassembly proce-

dure for the C/V joint assembly, See Boots Install.

² If outer joint is noisy or badlyworn. Bypass the

following disassembly and replace entire unit. It is

also recommended that the boot be replaced. The

Boot Package includes the boot, clamps, retaining

ring (circlip), and lubricant. See boots install. (8) Hold joint vertically in vise by clamping on

splined shaft, using soft jaws to prevent damage. (9) Wipe off surplus grease and mark relative po-

sition of inner cross, cage and housing with a dab of

paint (Fig. 5). (10) Press down on one side of inner race to tilt

cage and remove ball from opposite side (Figs.5 and

6). If joint is tight, use a hammer and brass drift to

tap inner race. Do not hit the cage. Repeat this step

until all 6 balls are removed. A screwdriver may be

used to pry balls loose. (11) Tilt the cage and inner race assembly verti-

cally and position two opposing cage windows in area

between the ball grooves. Remove the cage and inner

race assembly by pulling upward away from the

housing (Fig. 7). (12) Turn inner cross (driver) 90É to cage and align

one of the race spherical lands with cage window.

Raise land into cage window and remove inner race

by swinging out (Fig. 8).

INSPECT

Check grease for contamination and all parts for

defects as follows: (1) Wash all parts in suitable solvent and dry,

preferably with compressed air. (2) Inspect housing ball races for excessive wear

and scouring.

Fig. 3 Circlip Retainer in Cross S.S.G.

Fig. 4 Remove Circlip

Fig. 5 Rotate Cage & Cross to Remove Balls

Fig. 6 Ball Released

2 - 38 SUSPENSION AND DRIVESHAFTS Ä

Page 97 of 2438

(3) Check splined shaft and nut threads for dam-

age. (4) Inspect all 6 balls for pitting, cracks, scouring

and wear. Dulling of surface is normal. (5) Inspect cage for excessive wear on inside and

outside spherical surfaces, surface ripples on cage

window, cracks, and chipping. (6) Inspect inner race (cross) for excessivewear or

scouring of ball races. Any of the above defects will warrant replac-

ing the C/V assembly as a unit. Polished areas in races (cross and housing) and on

cage spheres are normal and do not indicate need for

joint replacement. Unless they are suspected of caus-

ing noise and vibration.

ASSEMBLE

If outer joint was not disassembled nor the

wear sleeve damaged go to step 11. (1) Position new wear sleeve on joint housing ma-

chined ledge (Fig. 1). Assemble Installer, Special Tool

C-4698 (Tool is provided with handle and dual purpose

drive head for installing wear sleeve onto C/V joint

housing and (head reversed) seal into knuckle). See

KNUCKLE BEARING SEAL. (2) See (Fig. 1). Assemble tool and install wear

sleeve.

(3) Lightly oil all components before assembling

outer joint. (4) Align parts according to paint markings.

Fig. 7 Removing Cage & Cross Assembly from Housing

Fig. 8 Removing Cross from Cage

Fig. 1 Tool Set-Up for Wear Sleeve Installation

Ä SUSPENSION AND DRIVESHAFTS 2 - 39

Page 98 of 2438

(5) Insert one of the inner race (cross) lands into

cage window (Fig. 2) and feed race into cage. Pivot

cross 90É to complete cage assembly (Fig. 3).

(6) Align opposing cage windows with housing

land and feed cage assembly into housing (Fig. 4).

Pivot cage 90É to complete installation. When properly assembled the large counterbore in

the cross should be facing outward from the joint on

G.K.N. units (Figs.3 and 6). On the S.S.G. joint the

internal circlip in the cross will be facing outward

from the housing (Fig. 5). (7) Apply lubricant to ball races from packet pro-

vided in boot kit and distribute equally between all

sides of ball grooves. One packet is sufficient to lu-

bricate the joint.

Fig. 4 Installing Cage & Cross into Housing

Fig. 5 Cage & Cross Assembled S.S.G.

Fig. 6 Cage & Cross Installed in Housing G.K.N.

Fig. 2 Installing Cross into Cage

Fig. 3 Cage & Cross Assembled G.K.N.

2 - 40 SUSPENSION AND DRIVESHAFTS Ä

Page 99 of 2438

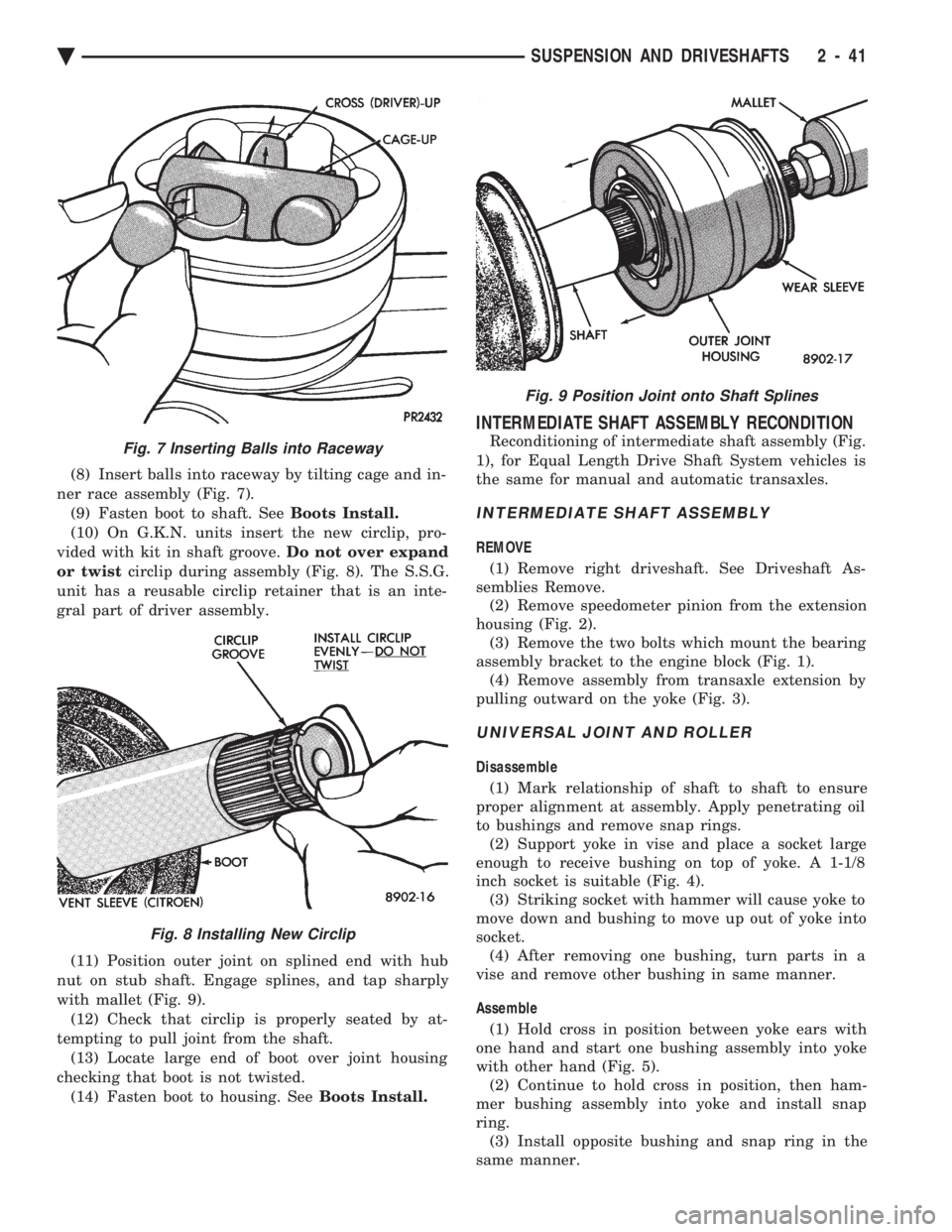

(8) Insert balls into raceway by tilting cage and in-

ner race assembly (Fig. 7). (9) Fasten boot to shaft. See Boots Install.

(10) On G.K.N. units insert the new circlip, pro-

vided with kit in shaft groove. Do not over expand

or twist circlip during assembly (Fig. 8). The S.S.G.

unit has a reusable circlip retainer that is an inte-

gral part of driver assembly.

(11) Position outer joint on splined end with hub

nut on stub shaft. Engage splines, and tap sharply

with mallet (Fig. 9). (12) Check that circlip is properly seated by at-

tempting to pull joint from the shaft. (13) Locate large end of boot over joint housing

checking that boot is not twisted. (14) Fasten boot to housing. See Boots Install.

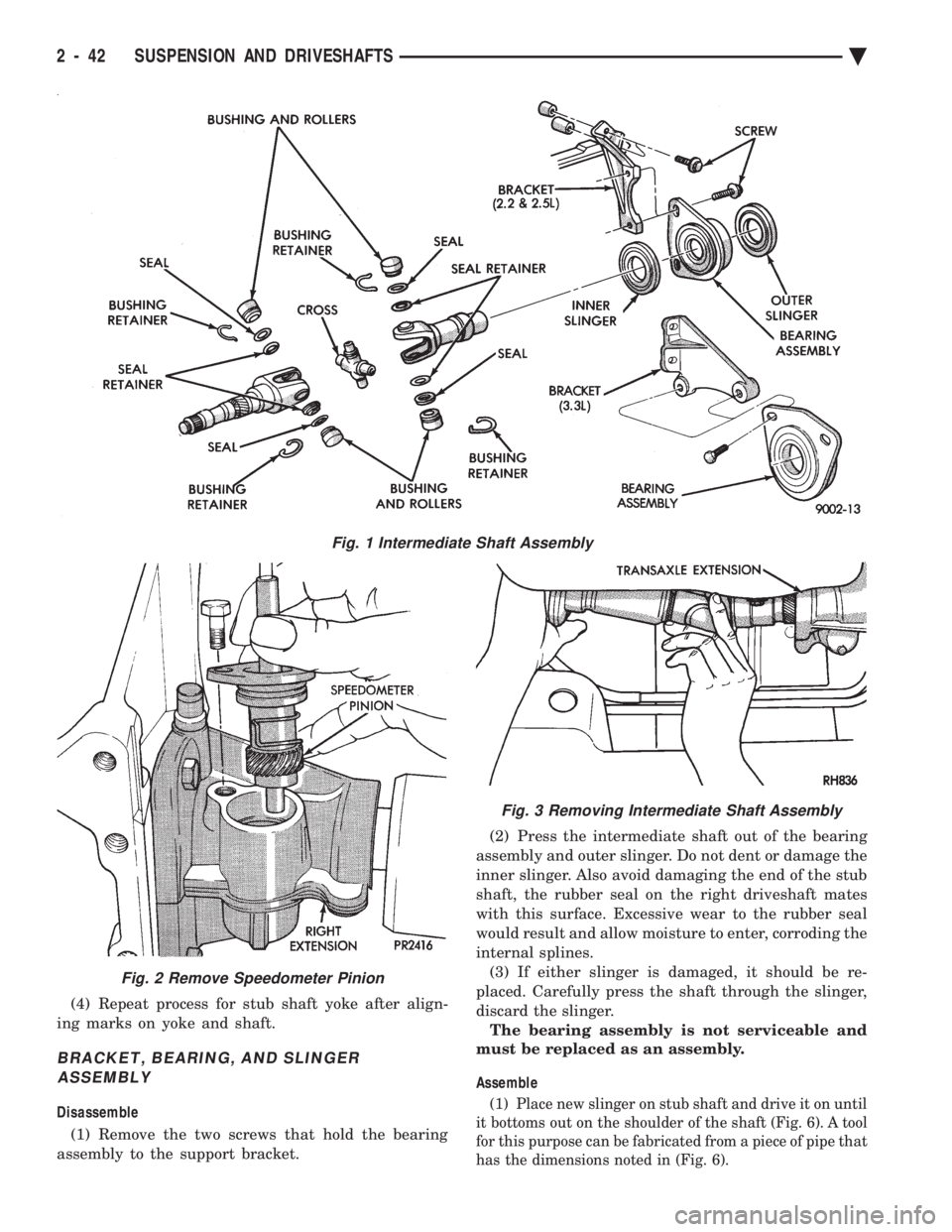

INTERMEDIATE SHAFT ASSEMBLY RECONDITION

Reconditioning of intermediate shaft assembly (Fig.

1), for Equal Length Drive Shaft System vehicles is

the same for manual and automatic transaxles.

INTERMEDIATE SHAFT ASSEMBLY

REMOVE

(1) Remove right driveshaft. See Driveshaft As-

semblies Remove. (2) Remove speedometer pinion from the extension

housing (Fig. 2). (3) Remove the two bolts which mount the bearing

assembly bracket to the engine block (Fig. 1). (4) Remove assembly from transaxle extension by

pulling outward on the yoke (Fig. 3).

UNIVERSAL JOINT AND ROLLER

Disassemble

(1) Mark relationship of shaft to shaft to ensure

proper alignment at assembly. Apply penetrating oil

to bushings and remove snap rings. (2) Support yoke in vise and place a socket large

enough to receive bushing on top of yoke. A 1-1/8

inch socket is suitable (Fig. 4). (3) Striking socket with hammer will cause yoke to

move down and bushing to move up out of yoke into

socket. (4) After removing one bushing, turn parts in a

vise and remove other bushing in same manner.

Assemble (1) Hold cross in position between yoke ears with

one hand and start one bushing assembly into yoke

with other hand (Fig. 5). (2) Continue to hold cross in position, then ham-

mer bushing assembly into yoke and install snap

ring. (3) Install opposite bushing and snap ring in the

same manner.

Fig. 7 Inserting Balls into Raceway

Fig. 8 Installing New Circlip

Fig. 9 Position Joint onto Shaft Splines

Ä SUSPENSION AND DRIVESHAFTS 2 - 41

Page 100 of 2438

(4) Repeat process for stub shaft yoke after align-

ing marks on yoke and shaft.

BRACKET, BEARING, AND SLINGER ASSEMBLY

Disassemble

(1) Remove the two screws that hold the bearing

assembly to the support bracket. (2) Press the intermediate shaft out of the bearing

assembly and outer slinger. Do not dent or damage the

inner slinger. Also avoid damaging the end of the stub

shaft, the rubber seal on the right driveshaft mates

with this surface. Excessive wear to the rubber seal

would result and allow moisture to enter, corroding the

internal splines. (3) If either slinger is damaged, it should be re-

placed. Carefully press the shaft through the slinger,

discard the slinger. The bearing assembly is not serviceable and

must be replaced as an assembly.

Assemble(1) Place new slinger on stub shaft and drive it on until

it bottoms out on the shoulder of the shaft (Fig. 6). A tool

for this purpose can be fabricated from a piece of pipe that

has the dimensions noted in (Fig. 6).

Fig. 1 Intermediate Shaft Assembly

Fig. 2 Remove Speedometer Pinion

Fig. 3 Removing Intermediate Shaft Assembly

2 - 42 SUSPENSION AND DRIVESHAFTS Ä