CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 1651 of 2438

(2) Tighten nuts to 52 N Im (38 ft. lbs.).

(3) Remove connecting rod cap and measure Plas-

tigage (Fig. 16).

CAUTION: Do not rotate crankshaft or the Plasti-

gage may be smeared.

CONNECTING ROD SIDE CLEARANCE

Using a feeler gauge, check connecting rod side

clearance (Fig. 17). Refer to (Fig. 18) for specifica-

tion.

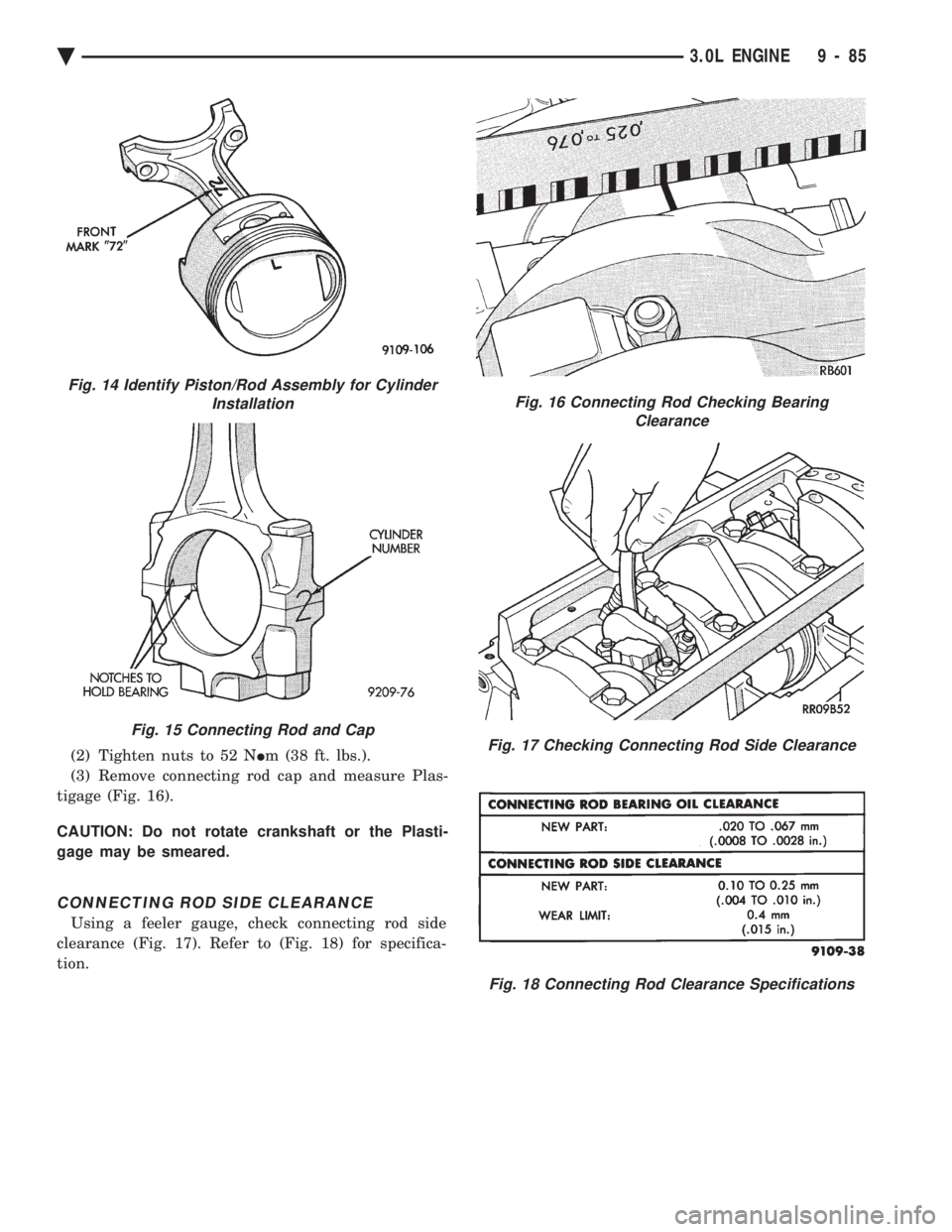

Fig. 14 Identify Piston/Rod Assembly for Cylinder Installation

Fig. 15 Connecting Rod and Cap

Fig. 16 Connecting Rod Checking BearingClearance

Fig. 17 Checking Connecting Rod Side Clearance

Fig. 18 Connecting Rod Clearance Specifications

Ä 3.0L ENGINE 9 - 85

Page 1652 of 2438

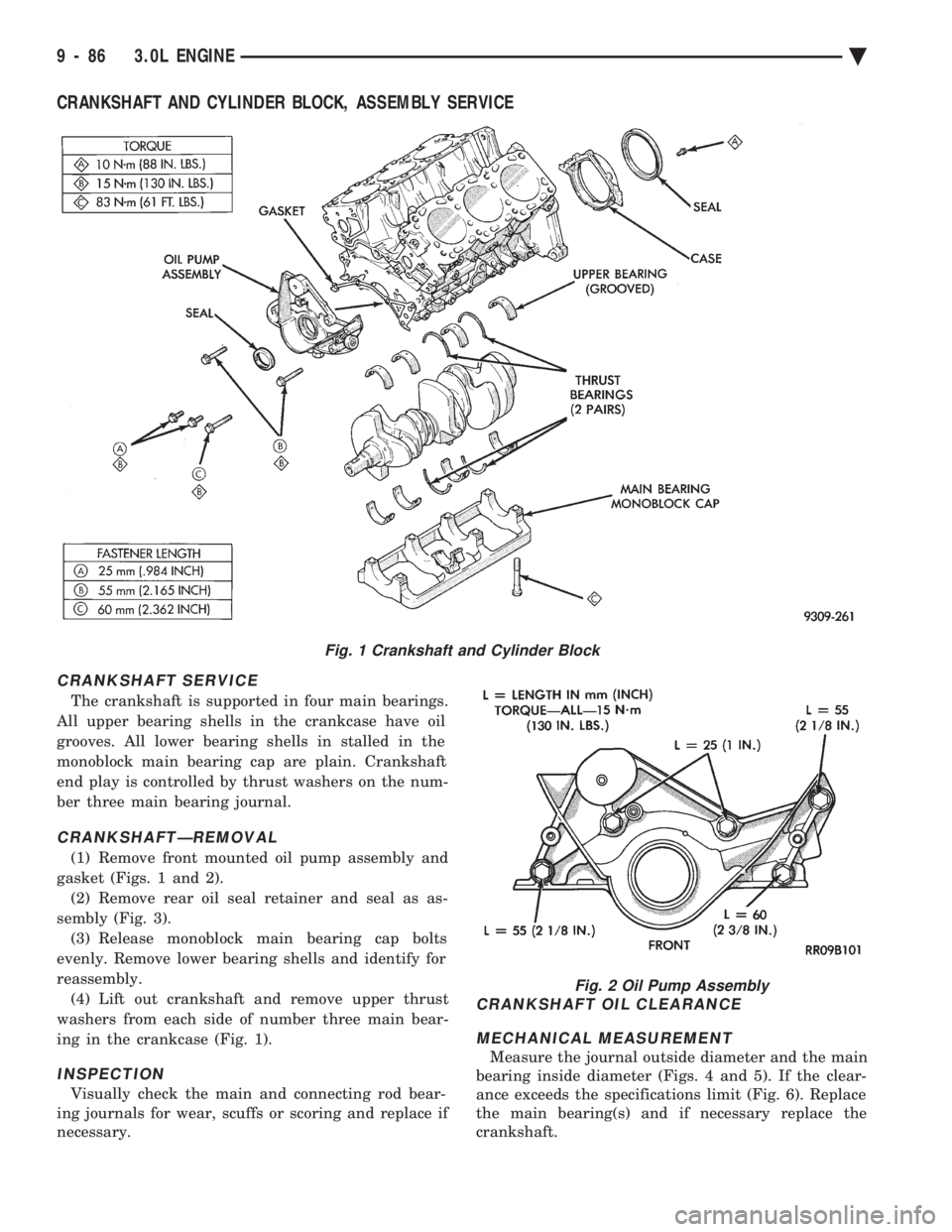

CRANKSHAFT AND CYLINDER BLOCK, ASSEMBLY SERVICE

CRANKSHAFT SERVICE

The crankshaft is supported in four main bearings.

All upper bearing shells in the crankcase have oil

grooves. All lower bearing shells in stalled in the

monoblock main bearing cap are plain. Crankshaft

end play is controlled by thrust washers on the num-

ber three main bearing journal.

CRANKSHAFTÐREMOVAL

(1) Remove front mounted oil pump assembly and

gasket (Figs. 1 and 2). (2) Remove rear oil seal retainer and seal as as-

sembly (Fig. 3). (3) Release monoblock main bearing cap bolts

evenly. Remove lower bearing shells and identify for

reassembly. (4) Lift out crankshaft and remove upper thrust

washers from each side of number three main bear-

ing in the crankcase (Fig. 1).

INSPECTION

Visually check the main and connecting rod bear-

ing journals for wear, scuffs or scoring and replace if

necessary.

CRANKSHAFT OIL CLEARANCE

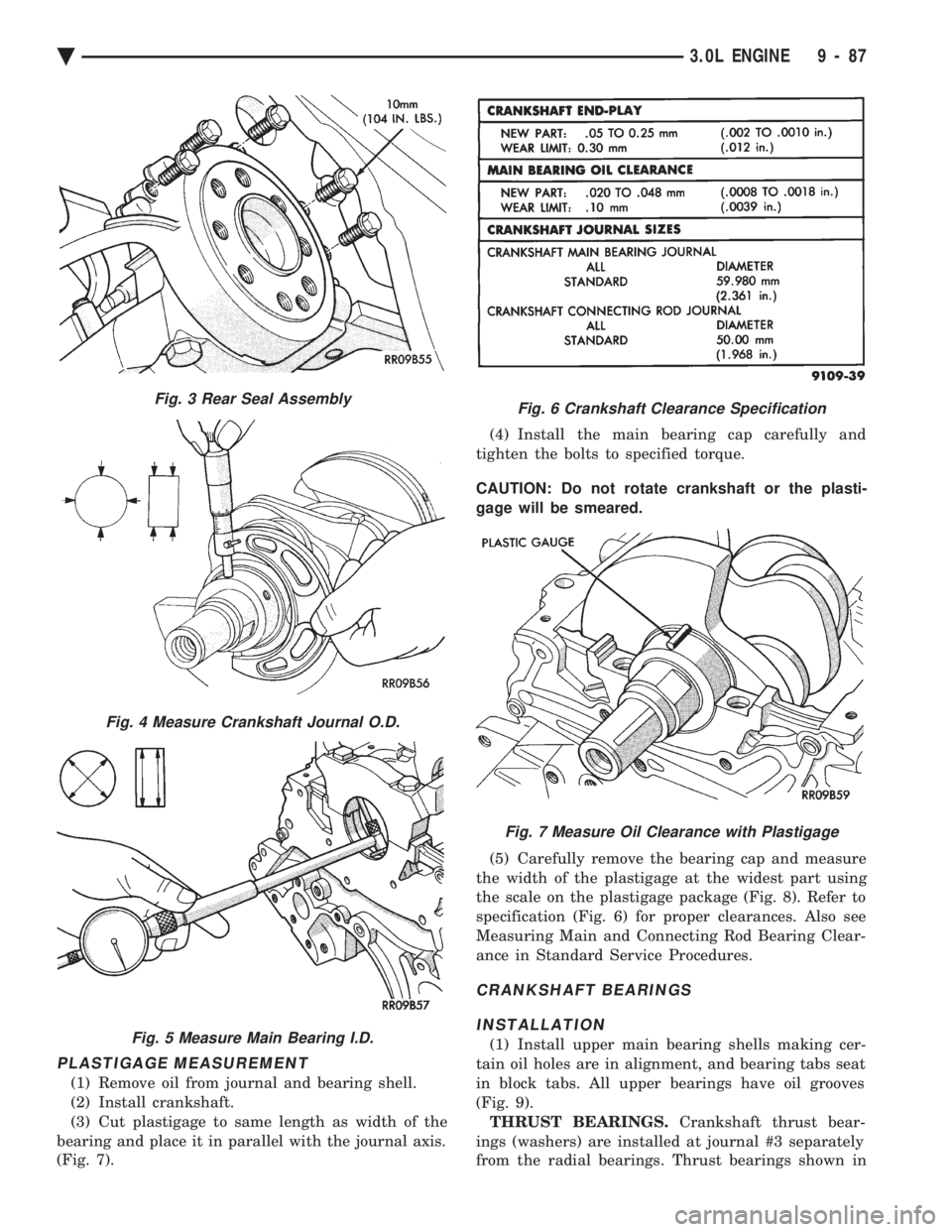

MECHANICAL MEASUREMENT

Measure the journal outside diameter and the main

bearing inside diameter (Figs. 4 and 5). If the clear-

ance exceeds the specifications limit (Fig. 6). Replace

the main bearing(s) and if necessary replace the

crankshaft.

Fig. 1 Crankshaft and Cylinder Block

Fig. 2 Oil Pump Assembly

9 - 86 3.0L ENGINE Ä

Page 1653 of 2438

PLASTIGAGE MEASUREMENT

(1) Remove oil from journal and bearing shell.

(2) Install crankshaft.

(3) Cut plastigage to same length as width of the

bearing and place it in parallel with the journal axis.

(Fig. 7). (4) Install the main bearing cap carefully and

tighten the bolts to specified torque.

CAUTION: Do not rotate crankshaft or the plasti-

gage will be smeared.

(5) Carefully remove the bearing cap and measure

the width of the plastigage at the widest part using

the scale on the plastigage package (Fig. 8). Refer to

specification (Fig. 6) for proper clearances. Also see

Measuring Main and Connecting Rod Bearing Clear-

ance in Standard Service Procedures.

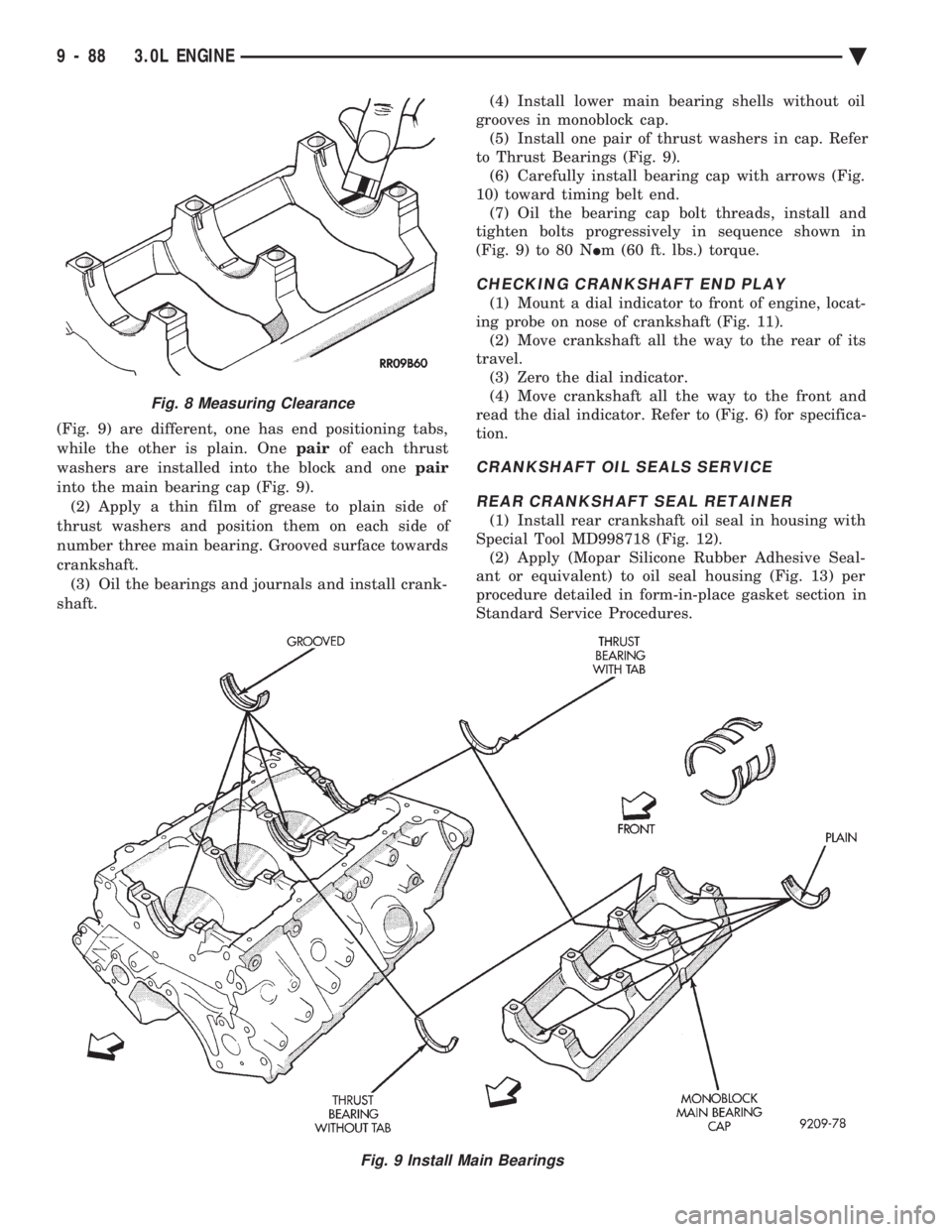

CRANKSHAFT BEARINGS

INSTALLATION

(1) Install upper main bearing shells making cer-

tain oil holes are in alignment, and bearing tabs seat

in block tabs. All upper bearings have oil grooves

(Fig. 9). THRUST BEARINGS. Crankshaft thrust bear-

ings (washers) are installed at journal #3 separately

from the radial bearings. Thrust bearings shown in

Fig. 3 Rear Seal Assembly

Fig. 4 Measure Crankshaft Journal O.D.

Fig. 5 Measure Main Bearing I.D.

Fig. 6 Crankshaft Clearance Specification

Fig. 7 Measure Oil Clearance with Plastigage

Ä 3.0L ENGINE 9 - 87

Page 1654 of 2438

(Fig. 9) are different, one has end positioning tabs,

while the other is plain. One pairof each thrust

washers are installed into the block and one pair

into the main bearing cap (Fig. 9). (2) Apply a thin film of grease to plain side of

thrust washers and position them on each side of

number three main bearing. Grooved surface towards

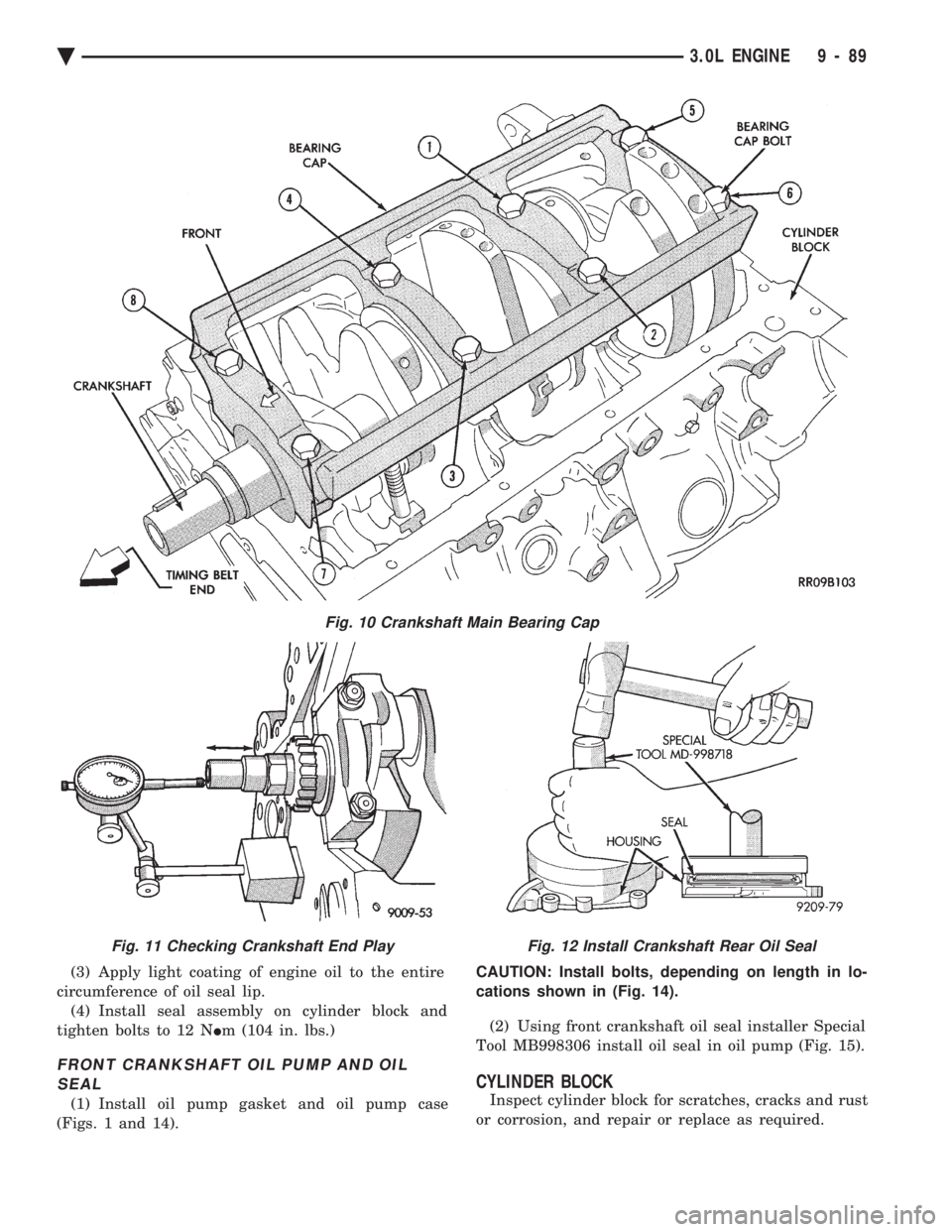

crankshaft. (3) Oil the bearings and journals and install crank-

shaft. (4) Install lower main bearing shells without oil

grooves in monoblock cap. (5) Install one pair of thrust washers in cap. Refer

to Thrust Bearings (Fig. 9). (6) Carefully install bearing cap with arrows (Fig.

10) toward timing belt end. (7) Oil the bearing cap bolt threads, install and

tighten bolts progressively in sequence shown in

(Fig. 9) to 80 N Im (60 ft. lbs.) torque.

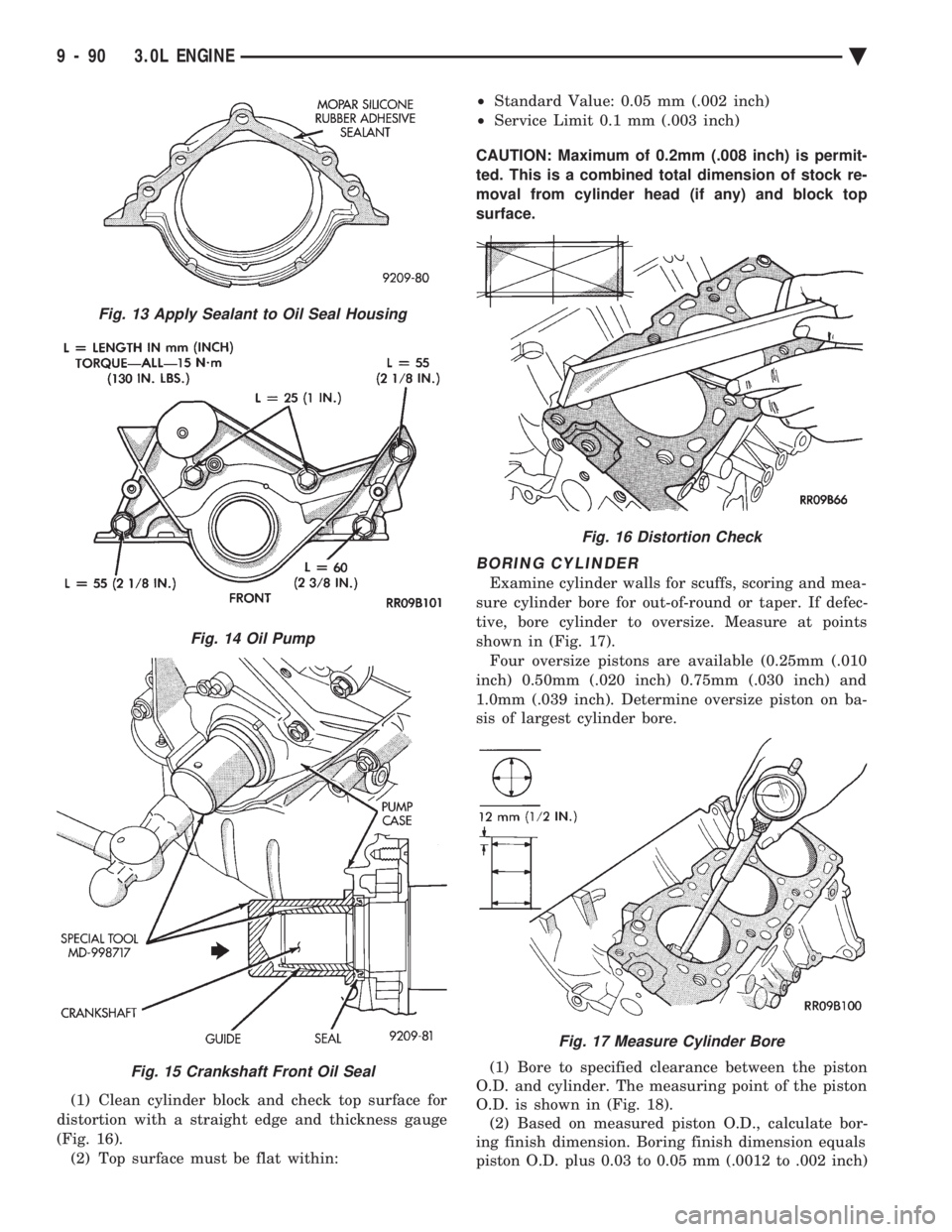

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 11). (2) Move crankshaft all the way to the rear of its

travel. (3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to (Fig. 6) for specifica-

tion.

CRANKSHAFT OIL SEALS SERVICE

REAR CRANKSHAFT SEAL RETAINER

(1) Install rear crankshaft oil seal in housing with

Special Tool MD998718 (Fig. 12). (2) Apply (Mopar Silicone Rubber Adhesive Seal-

ant or equivalent) to oil seal housing (Fig. 13) per

procedure detailed in form-in-place gasket section in

Standard Service Procedures.

Fig. 9 Install Main Bearings

Fig. 8 Measuring Clearance

9 - 88 3.0L ENGINE Ä

Page 1655 of 2438

(3) Apply light coating of engine oil to the entire

circumference of oil seal lip. (4) Install seal assembly on cylinder block and

tighten bolts to 12 N Im (104 in. lbs.)

FRONT CRANKSHAFT OIL PUMP AND OIL

SEAL

(1) Install oil pump gasket and oil pump case

(Figs. 1 and 14). CAUTION: Install bolts, depending on length in lo-

cations shown in (Fig. 14).

(2) Using front crankshaft oil seal installer Special

Tool MB998306 install oil seal in oil pump (Fig. 15).

CYLINDER BLOCK

Inspect cylinder block for scratches, cracks and rust

or corrosion, and repair or replace as required.

Fig. 10 Crankshaft Main Bearing Cap

Fig. 11 Checking Crankshaft End PlayFig. 12 Install Crankshaft Rear Oil Seal

Ä 3.0L ENGINE 9 - 89

Page 1656 of 2438

(1) Clean cylinder block and check top surface for

distortion with a straight edge and thickness gauge

(Fig. 16). (2) Top surface must be flat within: ²

Standard Value: 0.05 mm (.002 inch)

² Service Limit 0.1 mm (.003 inch)

CAUTION: Maximum of 0.2mm (.008 inch) is permit-

ted. This is a combined total dimension of stock re-

moval from cylinder head (if any) and block top

surface.

BORING CYLINDER

Examine cylinder walls for scuffs, scoring and mea-

sure cylinder bore for out-of-round or taper. If defec-

tive, bore cylinder to oversize. Measure at points

shown in (Fig. 17). Four oversize pistons are available (0.25mm (.010

inch) 0.50mm (.020 inch) 0.75mm (.030 inch) and

1.0mm (.039 inch). Determine oversize piston on ba-

sis of largest cylinder bore.

(1) Bore to specified clearance between the piston

O.D. and cylinder. The measuring point of the piston

O.D. is shown in (Fig. 18). (2) Based on measured piston O.D., calculate bor-

ing finish dimension. Boring finish dimension equals

piston O.D. plus 0.03 to 0.05 mm (.0012 to .002 inch)

Fig. 13 Apply Sealant to Oil Seal Housing

Fig. 14 Oil Pump

Fig. 15 Crankshaft Front Oil Seal

Fig. 16 Distortion Check

Fig. 17 Measure Cylinder Bore

9 - 90 3.0L ENGINE Ä

Page 1657 of 2438

(clearance between piston O.D. and cylinder) minus

0.02 mm which is the boring margin. (3) Bore all cylinders to calculated boring finish di-

mension. Then bore the final finish dimension (piston

O.D. plus cylinder clearance). (4) Check clearance between piston and cylinder,

clearance should be 0.03 to 0.05 mm (.0012 to .002

inch).

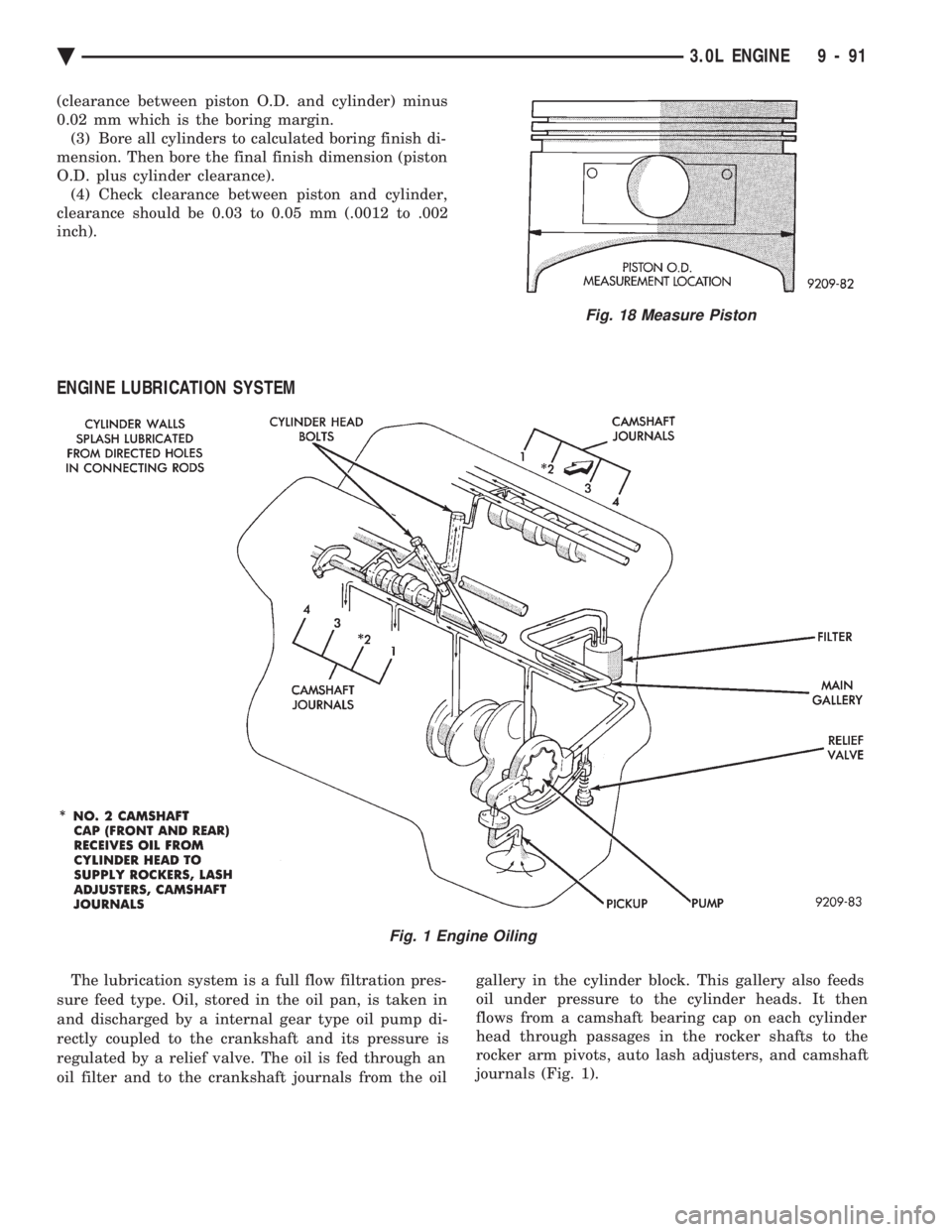

ENGINE LUBRICATION SYSTEM

The lubrication system is a full flow filtration pres-

sure feed type. Oil, stored in the oil pan, is taken in

and discharged by a internal gear type oil pump di-

rectly coupled to the crankshaft and its pressure is

regulated by a relief valve. The oil is fed through an

oil filter and to the crankshaft journals from the oil gallery in the cylinder block. This gallery also feeds

oil under pressure to the cylinder heads. It then

flows from a camshaft bearing cap on each cylinder

head through passages in the rocker shafts to the

rocker arm pivots, auto lash adjusters, and camshaft

journals (Fig. 1).

Fig. 18 Measure Piston

Fig. 1 Engine Oiling

Ä 3.0L ENGINE 9 - 91

Page 1658 of 2438

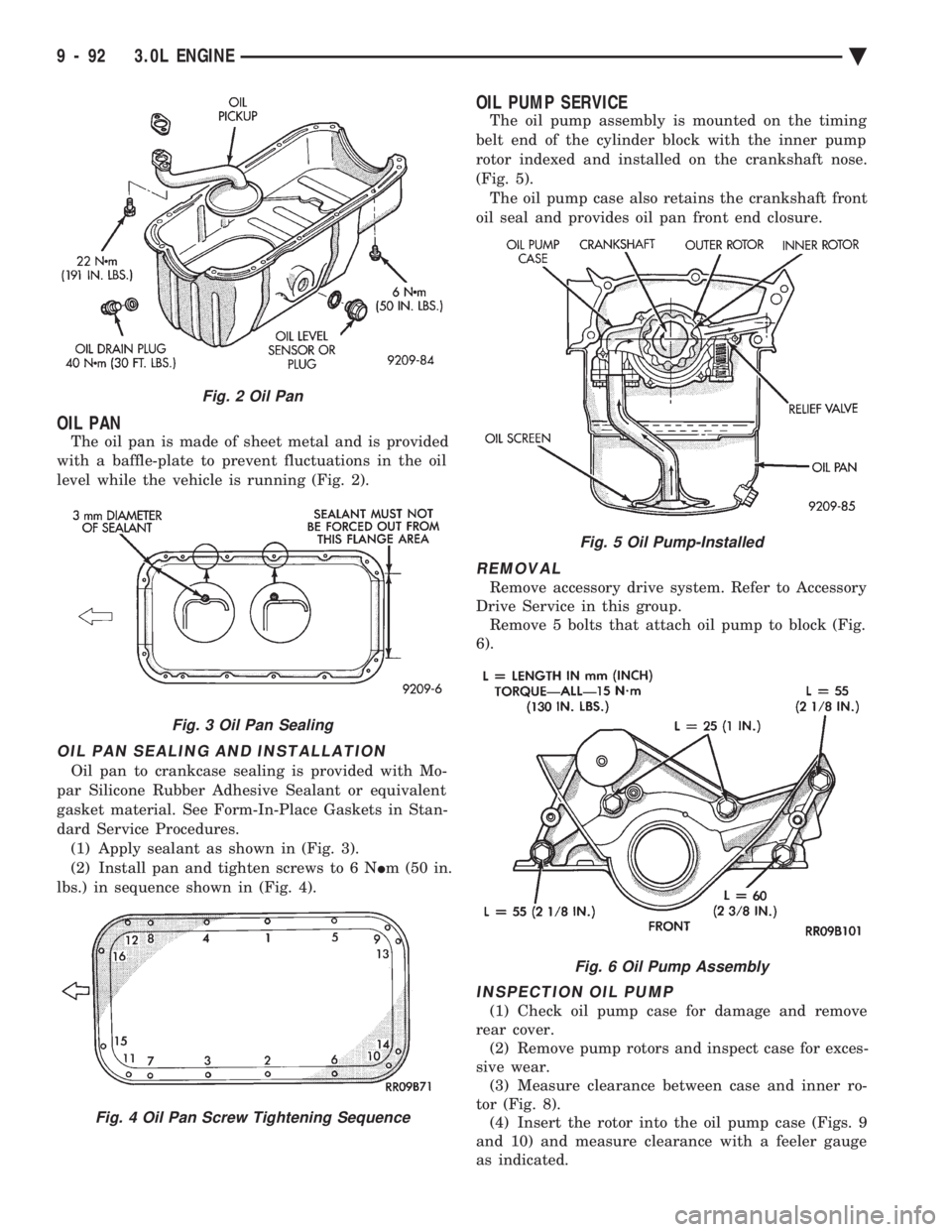

OIL PAN

The oil pan is made of sheet metal and is provided

with a baffle-plate to prevent fluctuations in the oil

level while the vehicle is running (Fig. 2).

OIL PAN SEALING AND INSTALLATION

Oil pan to crankcase sealing is provided with Mo-

par Silicone Rubber Adhesive Sealant or equivalent

gasket material. See Form-In-Place Gaskets in Stan-

dard Service Procedures. (1) Apply sealant as shown in (Fig. 3).

(2) Install pan and tighten screws to 6 N Im (50 in.

lbs.) in sequence shown in (Fig. 4).

OIL PUMP SERVICE

The oil pump assembly is mounted on the timing

belt end of the cylinder block with the inner pump

rotor indexed and installed on the crankshaft nose.

(Fig. 5). The oil pump case also retains the crankshaft front

oil seal and provides oil pan front end closure.

REMOVAL

Remove accessory drive system. Refer to Accessory

Drive Service in this group. Remove 5 bolts that attach oil pump to block (Fig.

6).

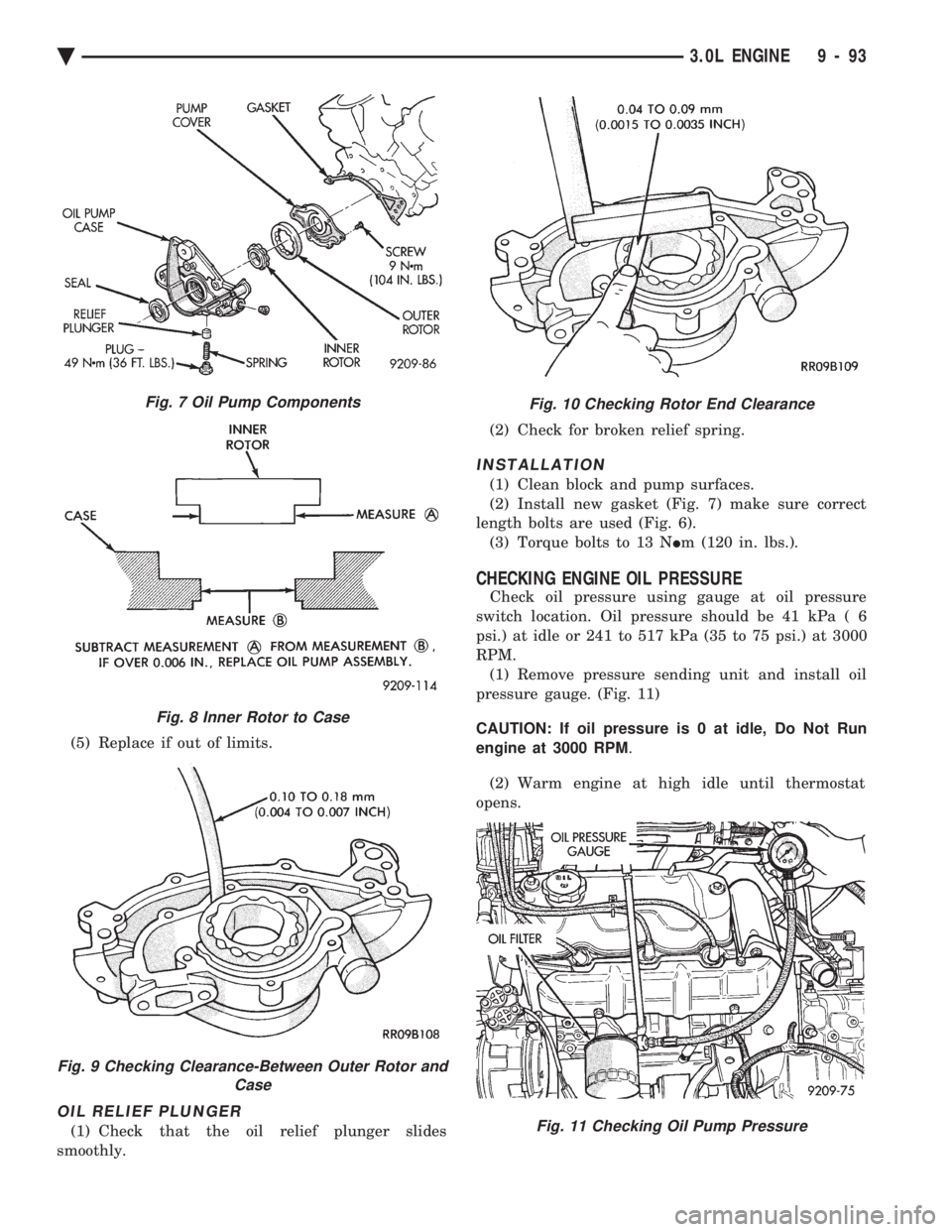

INSPECTION OIL PUMP

(1) Check oil pump case for damage and remove

rear cover. (2) Remove pump rotors and inspect case for exces-

sive wear. (3) Measure clearance between case and inner ro-

tor (Fig. 8). (4) Insert the rotor into the oil pump case (Figs. 9

and 10) and measure clearance with a feeler gauge

as indicated.

Fig. 2 Oil Pan

Fig. 3 Oil Pan Sealing

Fig. 4 Oil Pan Screw Tightening Sequence

Fig. 5 Oil Pump-Installed

Fig. 6 Oil Pump Assembly

9 - 92 3.0L ENGINE Ä

Page 1659 of 2438

(5) Replace if out of limits.

OIL RELIEF PLUNGER

(1) Check that the oil relief plunger slides

smoothly. (2) Check for broken relief spring.

INSTALLATION

(1) Clean block and pump surfaces.

(2) Install new gasket (Fig. 7) make sure correct

length bolts are used (Fig. 6). (3) Torque bolts to 13 N Im (120 in. lbs.).

CHECKING ENGINE OIL PRESSURE

Check oil pressure using gauge at oil pressure

switch location. Oil pressure should be 41 kPa ( 6

psi.) at idle or 241 to 517 kPa (35 to 75 psi.) at 3000

RPM. (1) Remove pressure sending unit and install oil

pressure gauge. (Fig. 11)

CAUTION: If oil pressure is 0 at idle, Do Not Run

engine at 3000 RPM .

(2) Warm engine at high idle until thermostat

opens.

Fig. 7 Oil Pump Components

Fig. 8 Inner Rotor to Case

Fig. 9 Checking Clearance-Between Outer Rotor and Case

Fig. 10 Checking Rotor End Clearance

Fig. 11 Checking Oil Pump Pressure

Ä 3.0L ENGINE 9 - 93

Page 1660 of 2438

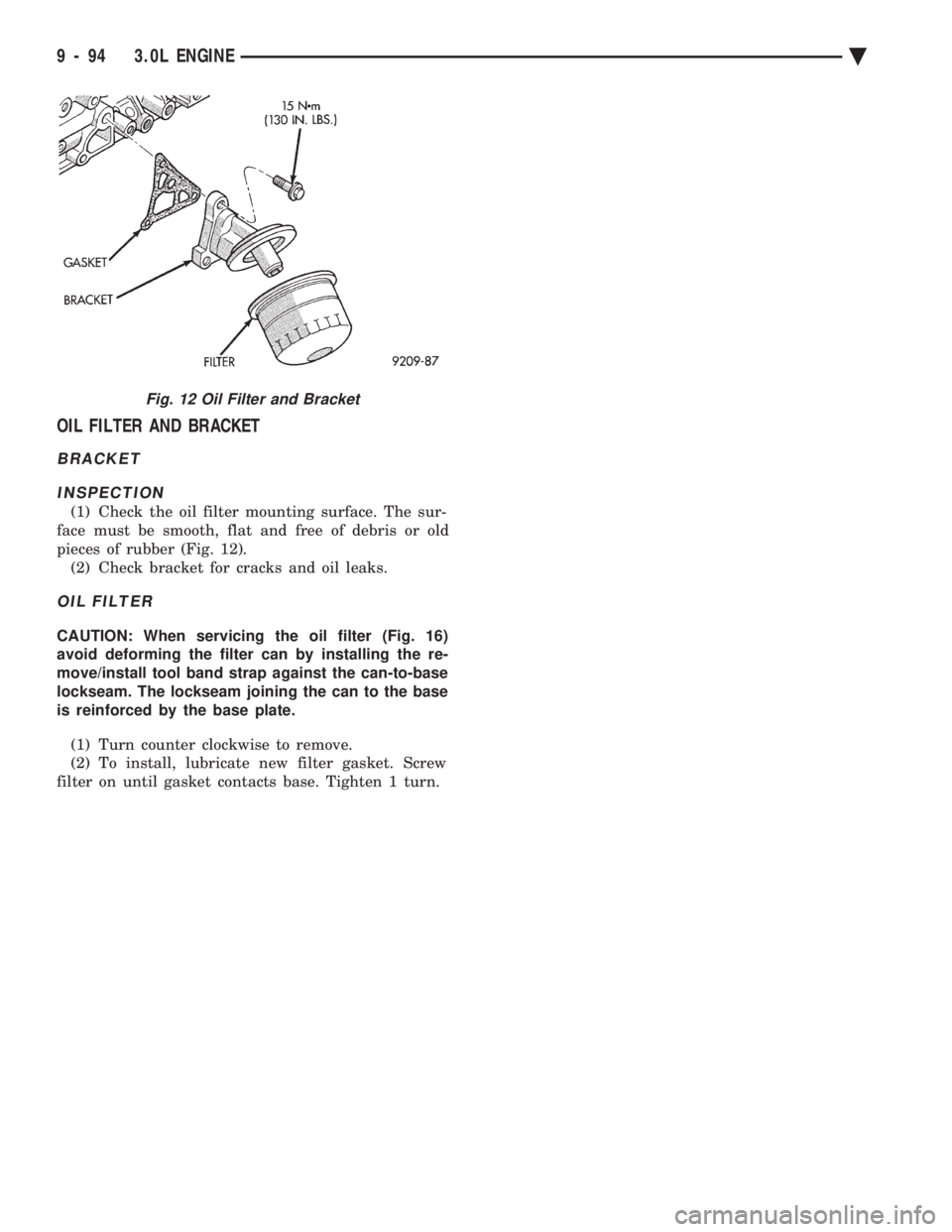

OIL FILTER AND BRACKET

BRACKET INSPECTION

(1) Check the oil filter mounting surface. The sur-

face must be smooth, flat and free of debris or old

pieces of rubber (Fig. 12). (2) Check bracket for cracks and oil leaks.

OIL FILTER

CAUTION: When servicing the oil filter (Fig. 16)

avoid deforming the filter can by installing the re-

move/install tool band strap against the can-to-base

lockseam. The lockseam joining the can to the base

is reinforced by the base plate.

(1) Turn counter clockwise to remove.

(2) To install, lubricate new filter gasket. Screw

filter on until gasket contacts base. Tighten 1 turn.

Fig. 12 Oil Filter and Bracket

9 - 94 3.0L ENGINE Ä