transmission CHEVROLET PLYMOUTH ACCLAIM 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 610 of 2438

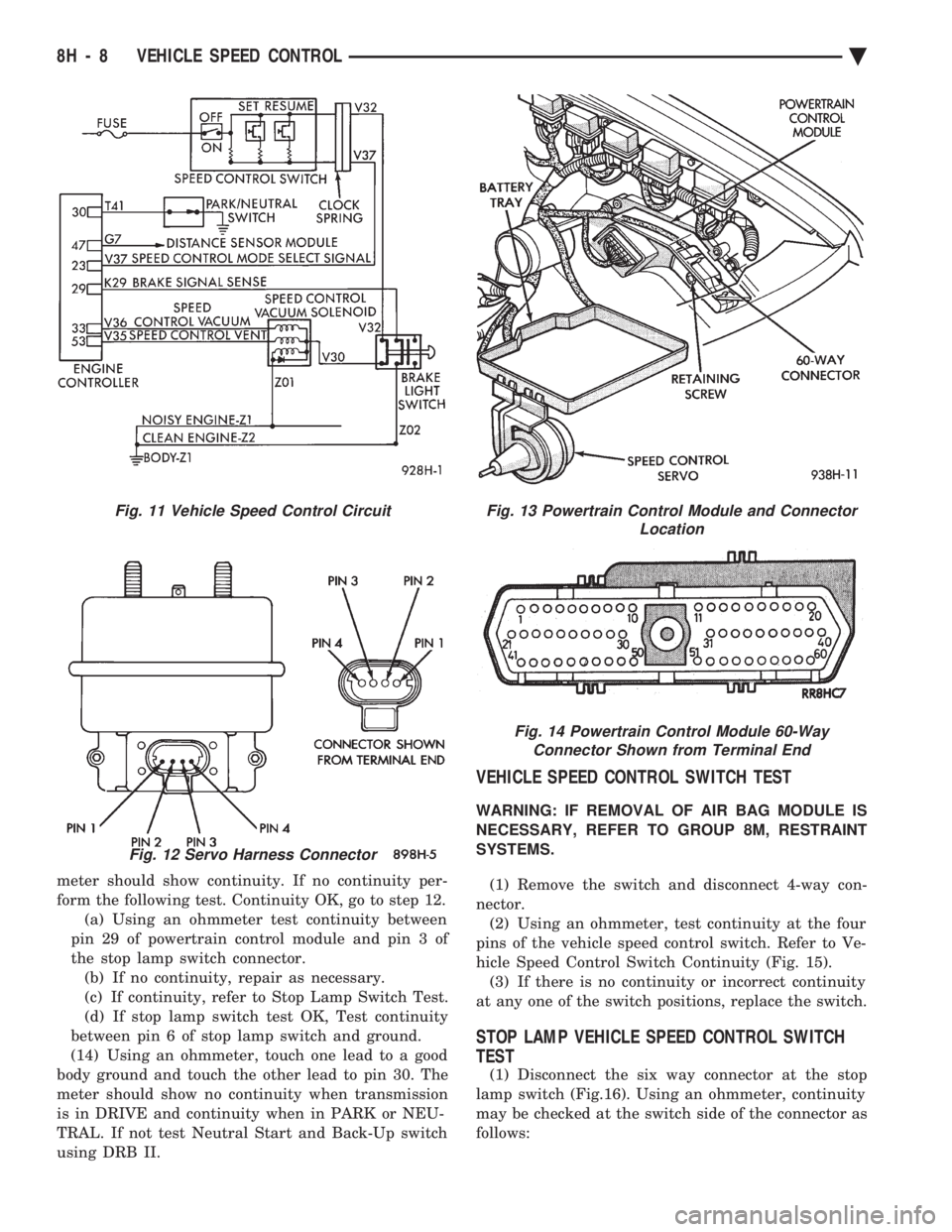

meter should show continuity. If no continuity per-

form the following test. Continuity OK, go to step 12.(a) Using an ohmmeter test continuity between

pin 29 of powertrain control module and pin 3 of

the stop lamp switch connector. (b) If no continuity, repair as necessary.

(c) If continuity, refer to Stop Lamp Switch Test.

(d) If stop lamp switch test OK, Test continuity

between pin 6 of stop lamp switch and ground.

(14) Using an ohmmeter, touch one lead to a good

body ground and touch the other lead to pin 30. The

meter should show no continuity when transmission

is in DRIVE and continuity when in PARK or NEU-

TRAL. If not test Neutral Start and Back-Up switch

using DRB II.

VEHICLE SPEED CONTROL SWITCH TEST

WARNING: IF REMOVAL OF AIR BAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

(1) Remove the switch and disconnect 4-way con-

nector. (2) Using an ohmmeter, test continuity at the four

pins of the vehicle speed control switch. Refer to Ve-

hicle Speed Control Switch Continuity (Fig. 15). (3) If there is no continuity or incorrect continuity

at any one of the switch positions, replace the switch.

STOP LAMP VEHICLE SPEED CONTROL SWITCH

TEST

(1) Disconnect the six way connector at the stop

lamp switch (Fig.16). Using an ohmmeter, continuity

may be checked at the switch side of the connector as

follows:

Fig. 11 Vehicle Speed Control Circuit

Fig. 12 Servo Harness Connector

Fig. 13 Powertrain Control Module and Connector Location

Fig. 14 Powertrain Control Module 60-WayConnector Shown from Terminal End

8H - 8 VEHICLE SPEED CONTROL Ä

Page 707 of 2438

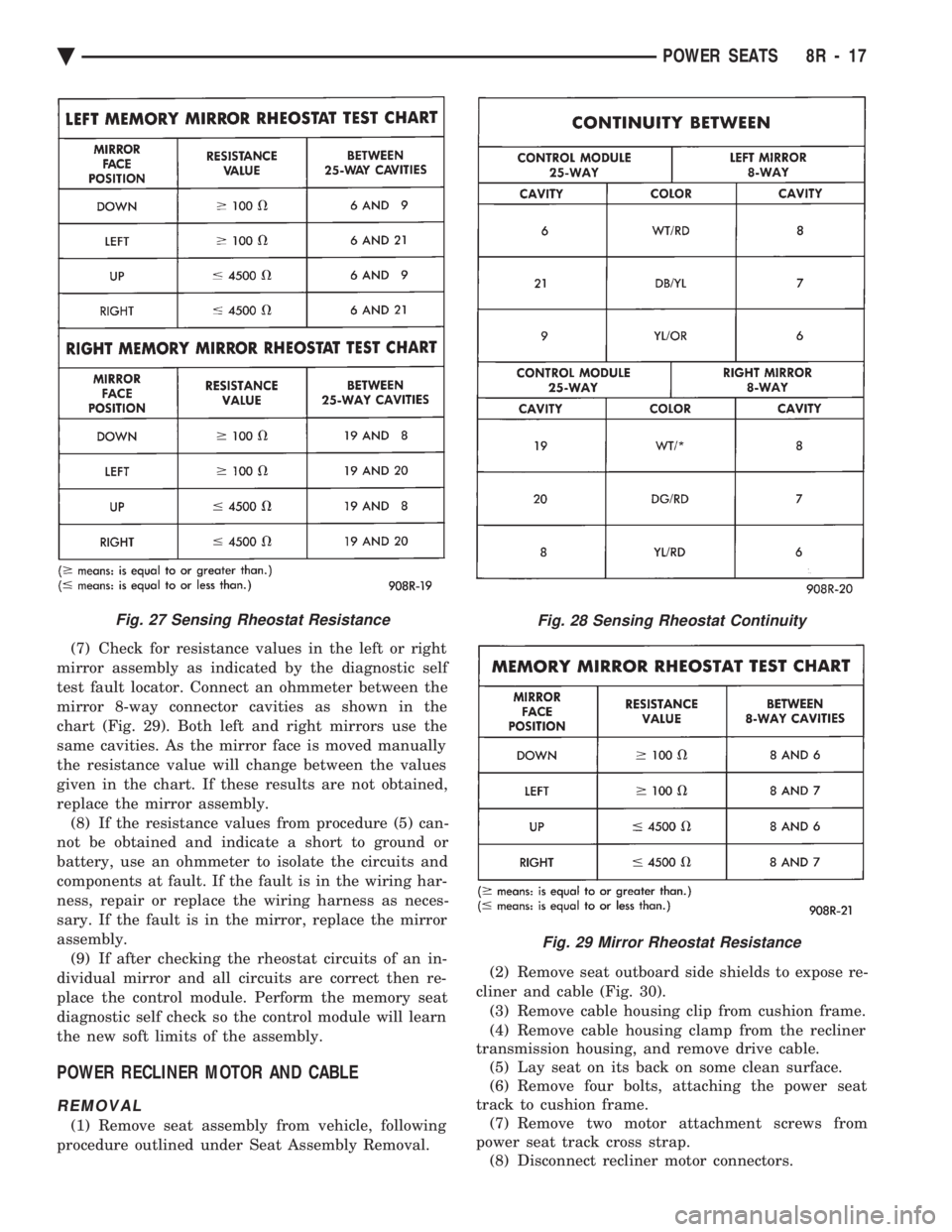

POWER SEATS

CONTENTS

page page

ADJUSTER ............................. 3

CIRCUIT BREAKER TEST .................. 1

ENTHUSIAST SEAT ....................... 4

GENERAL INFORMATION .................. 1

HARNESS VOLTAGE TEST ................. 1

HORIZONTAL AND VERTICAL TRANSMISSIONS ....................... 3

MEMORY CONTROL MODULE REPLACEMENT ....................... 19

MOTOR ................................ 3

MOTOR TESTS .......................... 1

POWER MEMORY SEAT, RECLINER AND MIRRORS ............................. 5 POWER MEMORY SEAT, RECLINER AND

MIRRORS DIAGNOSIS ................... 9

POWER RECLINER MECHANISM ........... 18

POWER RECLINER MOTOR AND CABLE ..... 17

RECLINER SWITCH REPLACEMENT ......... 19

RECLINER SWITCH TEST ................. 19

SEAT ASSEMBLY ........................ 3

SWITCH REPLACEMENT REMOVAL .......... 5

SWITCH TEST ........................... 5

SWITCH TEST ........................... 3

TEST PROCEDURES ...................... 6

TEST PROCEDURES ...................... 1

GENERAL INFORMATION

Power seats can be adjusted in six different direc-

tions up, down, forward, back, tilt forward, or tilt

rearward. A three armature permanent magnet reversible mo-

tor is coupled through cables to worm gear box assem-

blies located in the seat tracks, providing the various

seat movements. The electrical circuit is protected by a 30 amp circuit

breaker located on the fuse block.

TEST PROCEDURES

Before any testing is attempted the battery should be

carefully charged and all connections and terminals

cleaned and tightened to insure proper continuity and

grounds. With dome lamp on, apply switch in direction of

failure. If dome lamp dims the seat motor is trying to

work indicating mechanical jamming. If dome lamp

does not dim, then proceed with the following electrical

tests.

CIRCUIT BREAKER TEST

Find correct circuit breaker on fuse block. Pull out

slightly but be sure that circuit breaker terminals still

contact terminals in fuse block. Connect ground wire of

voltmeter to a good ground. With probe of voltmeter

positive wire, check both terminals of circuit breaker

for battery voltage. If only one terminal checks at

battery voltage, circuit breaker is defective and must

be replaced. If neither terminal shows battery voltage,

check for open or shorted circuit to circuit breaker.

HARNESS VOLTAGE TEST

The following test will determine whether or not

voltage is continuous through the body harness to the

switch. (1) Remove power seat switch from mounting posi-

tion and disconnect switch from wiring harness. (2) Connect one lead of test light to ground terminal,

black wire (BK) of center section, and touch other test

light lead to red wire (RD) terminal. (3) If test light comes on, harness to switch is good.

If test light does not come on, perform circuit breaker

test.

MOTOR TESTS

AA BODY

(1) Remove switch from mounting position and dis-

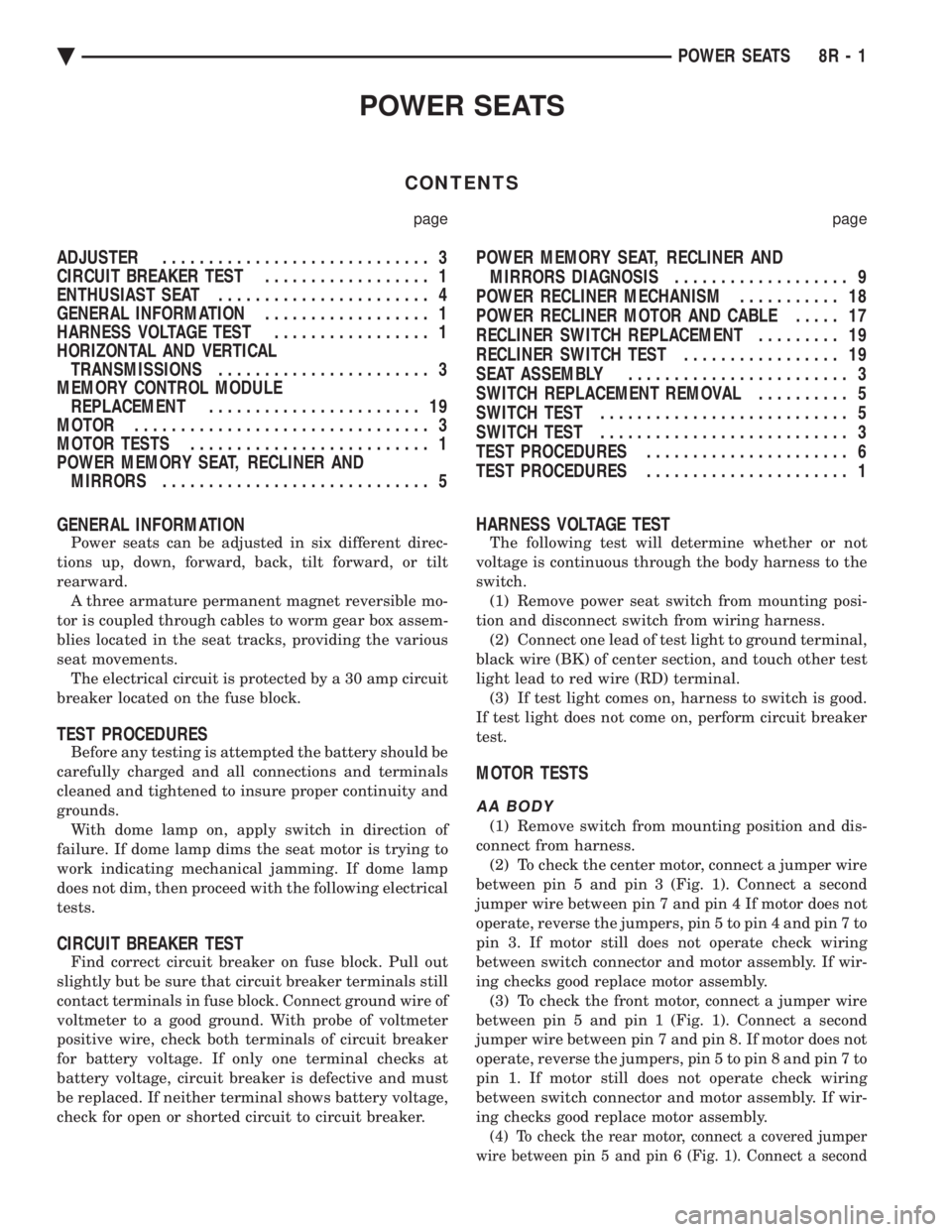

connect from harness. (2) To check the center motor, connect a jumper wire

between pin 5 and pin 3 (Fig. 1). Connect a second

jumper wire between pin 7 and pin 4 If motor does not

operate, reverse the jumpers, pin 5 to pin 4 and pin 7 to

pin 3. If motor still does not operate check wiring

between switch connector and motor assembly. If wir-

ing checks good replace motor assembly. (3) To check the front motor, connect a jumper wire

between pin 5 and pin 1 (Fig. 1). Connect a second

jumper wire between pin 7 and pin 8. If motor does not

operate, reverse the jumpers, pin 5 to pin 8 and pin 7 to

pin 1. If motor still does not operate check wiring

between switch connector and motor assembly. If wir-

ing checks good replace motor assembly.

(4) To check the rear motor, connect a covered jumper

wire between pin 5 and pin 6 (Fig. 1). Connect a second

Ä POWER SEATS 8R - 1

Page 709 of 2438

switch connector and motor assembly. If wiring

checks good replace motor assembly.(4) To check the rear motor, connect a jumper wire

between cavity number 3 and cavity number 4. Con-

nect a second jumper wire between cavity number 6

and cavity number 13. If the motor does not operate,

reverse the jumpers, 3 to 13 and 6 to 4. If the motor

still does not operate check the wiring between

switch connector and motor assembly. If wiring

checks good replace motor assembly. (5) If all motors and the seat operate properly, per-

form Switch Test.

SWITCH TEST

To check the switch, remove the switch from its

mounting position. Using an ohmmeter, perform

switch continuity test (Fig. 5, 6 and 7). If there is no

continuity at any one of the switch positions, replace

the switch.

SEAT ASSEMBLY

REMOVAL

(1) Remove plastic covers.

(2) Remove adjuster attaching bolts and nuts from

floor pan. Move adjuster as required for access. (3) Disconnect battery negative cable.

(4) Disconnect wiring harness power lead at car-

pet. (5) Remove seat assembly from vehicle.

INSTALLATION

(1) Position seat assembly in vehicle.

(2) Connect wiring harness.

(3) Install and tighten mounting bolts and nuts to

28 N Im (250 in. lbs.) torque.

(4) Connect battery negative cable and check seat

operation. (5) Install plastic covers.

HORIZONTAL AND VERTICAL TRANSMISSIONS

Transmissions are not removable and no mainte-

nance is required. If transmission fails replace entire

seat adjuster assembly.

ADJUSTER

REMOVAL

(1) Remove seat assembly from vehicle following

procedure outlined under Seat Assembly Removal. (2) Lay seat on its back on some clean surface.

(3) Remove bolts attaching adjuster to seat assem-

bly (Fig. 8 Through 11). (4) Disconnect wiring harness at switch if seat

mounted switch is used. (5) Remove tie straps holding cable housing to seat

for power bench seat adjuster only.

INSTALLATION

(1) Lay seat on its back on a clean surface.

(2) Position adjuster to seat assembly and install

attaching bolts. (3) Connect wiring harness at switch and replace

tie straps where removed. (4) Install seat following procedure outlined under

Seat Assembly Installation.

MOTOR

REMOVAL

Anytime the motor, cable and housing assemblies,

or vertical and horizontal transmission assemblies,

require maintenance, the assemblies must be syn-

chronized to insure easy and proper operation. (1) Remove seat assembly from vehicle following

procedure outlined under Seat Assembly Removal

(Fig. 8 through 11). (2) Lay seat assembly on its back on a clean sur-

face.

Fig. 3 Left Power Seat SwitchÐAC & AY Bodies

Fig. 4 Right Power Seat SwitchÐAC & AY Bodies

Ä POWER SEATS 8R - 3

Page 723 of 2438

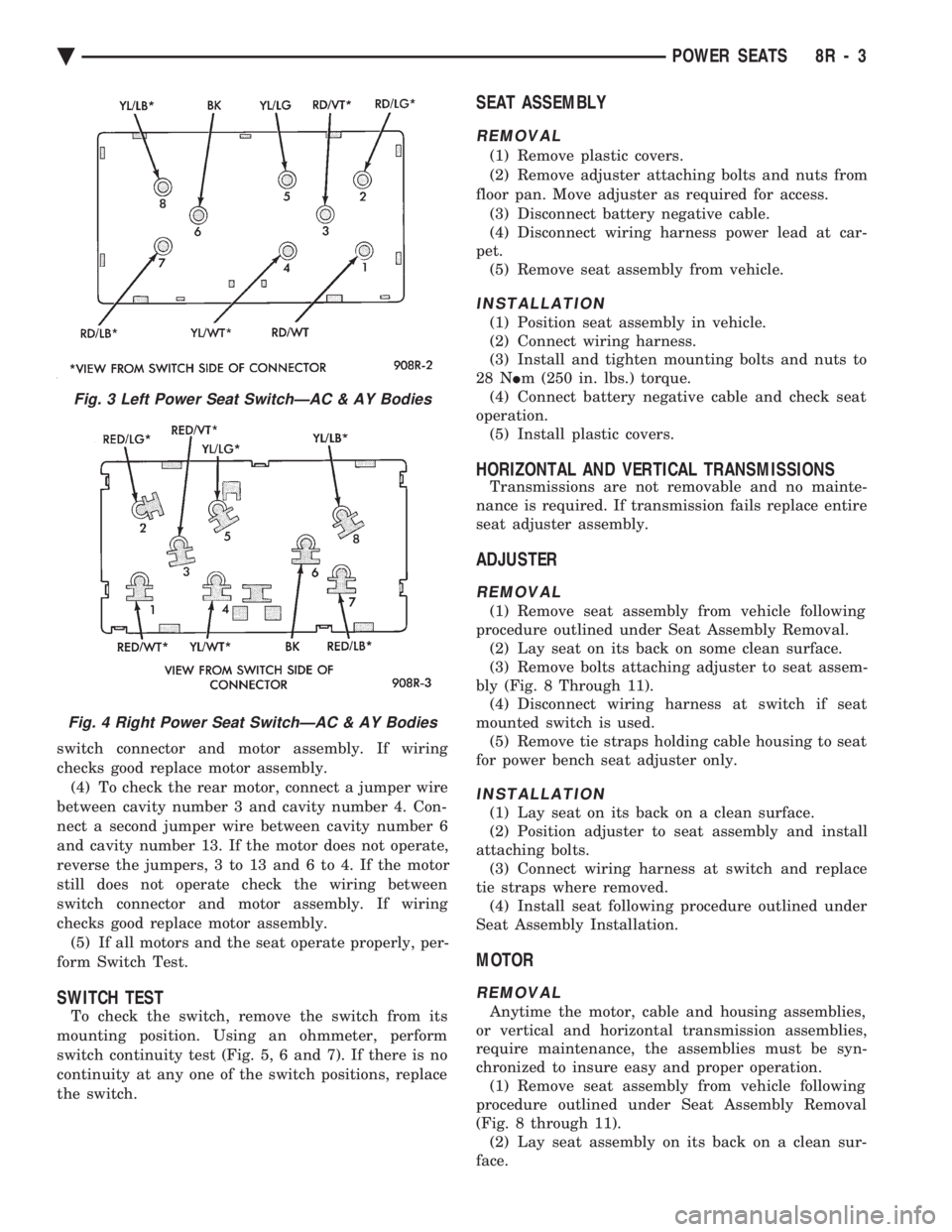

(7) Check for resistance values in the left or right

mirror assembly as indicated by the diagnostic self

test fault locator. Connect an ohmmeter between the

mirror 8-way connector cavities as shown in the

chart (Fig. 29). Both left and right mirrors use the

same cavities. As the mirror face is moved manually

the resistance value will change between the values

given in the chart. If these results are not obtained,

replace the mirror assembly. (8) If the resistance values from procedure (5) can-

not be obtained and indicate a short to ground or

battery, use an ohmmeter to isolate the circuits and

components at fault. If the fault is in the wiring har-

ness, repair or replace the wiring harness as neces-

sary. If the fault is in the mirror, replace the mirror

assembly. (9) If after checking the rheostat circuits of an in-

dividual mirror and all circuits are correct then re-

place the control module. Perform the memory seat

diagnostic self check so the control module will learn

the new soft limits of the assembly.

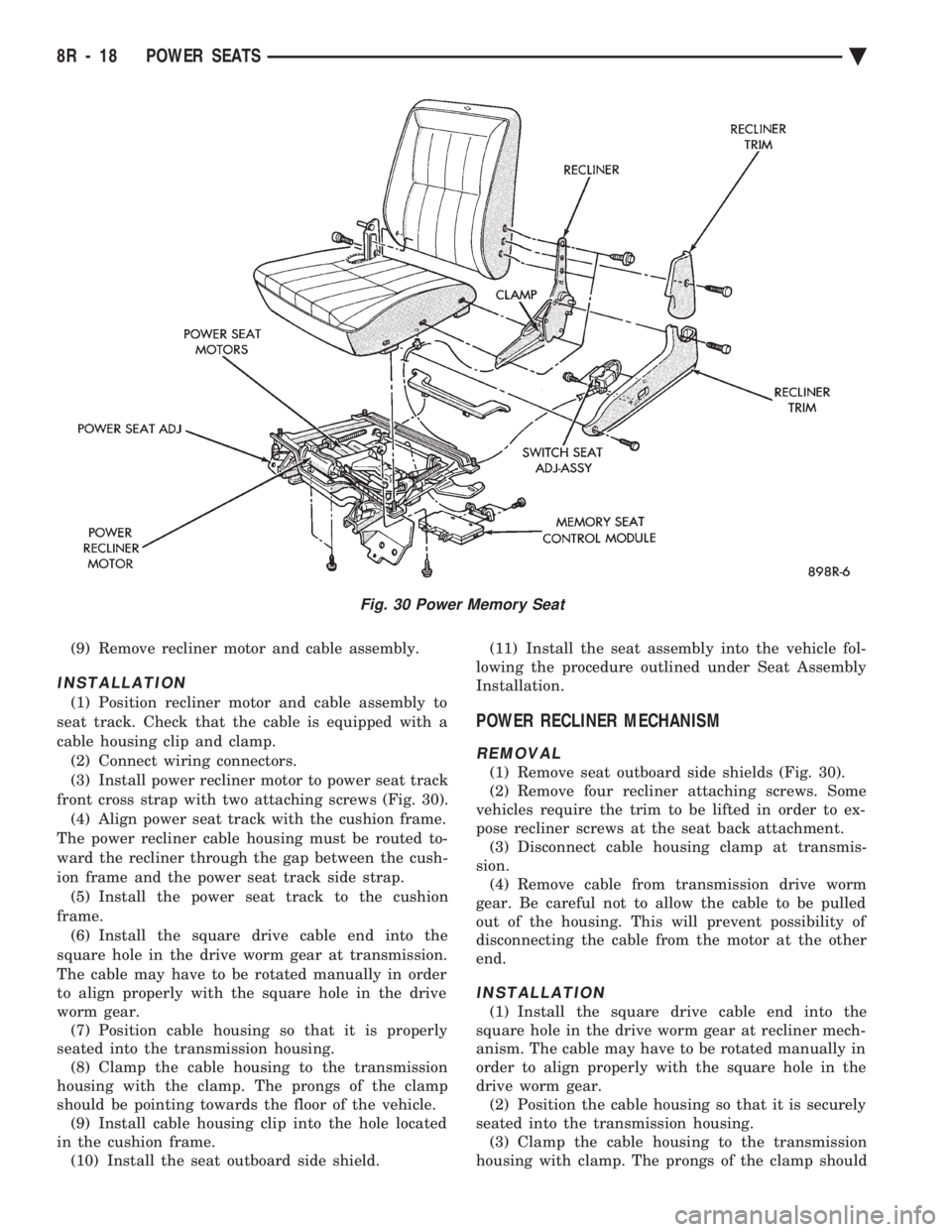

POWER RECLINER MOTOR AND CABLE

REMOVAL

(1) Remove seat assembly from vehicle, following

procedure outlined under Seat Assembly Removal. (2) Remove seat outboard side shields to expose re-

cliner and cable (Fig. 30). (3) Remove cable housing clip from cushion frame.

(4) Remove cable housing clamp from the recliner

transmission housing, and remove drive cable. (5) Lay seat on its back on some clean surface.

(6) Remove four bolts, attaching the power seat

track to cushion frame. (7) Remove two motor attachment screws from

power seat track cross strap. (8) Disconnect recliner motor connectors.

Fig. 27 Sensing Rheostat ResistanceFig. 28 Sensing Rheostat Continuity

Fig. 29 Mirror Rheostat Resistance

Ä POWER SEATS 8R - 17

Page 724 of 2438

(9) Remove recliner motor and cable assembly.

INSTALLATION

(1) Position recliner motor and cable assembly to

seat track. Check that the cable is equipped with a

cable housing clip and clamp. (2) Connect wiring connectors.

(3) Install power recliner motor to power seat track

front cross strap with two attaching screws (Fig. 30). (4) Align power seat track with the cushion frame.

The power recliner cable housing must be routed to-

ward the recliner through the gap between the cush-

ion frame and the power seat track side strap. (5) Install the power seat track to the cushion

frame. (6) Install the square drive cable end into the

square hole in the drive worm gear at transmission.

The cable may have to be rotated manually in order

to align properly with the square hole in the drive

worm gear. (7) Position cable housing so that it is properly

seated into the transmission housing. (8) Clamp the cable housing to the transmission

housing with the clamp. The prongs of the clamp

should be pointing towards the floor of the vehicle. (9) Install cable housing clip into the hole located

in the cushion frame. (10) Install the seat outboard side shield. (11) Install the seat assembly into the vehicle fol-

lowing the procedure outlined under Seat Assembly

Installation.

POWER RECLINER MECHANISM

REMOVAL

(1) Remove seat outboard side shields (Fig. 30).

(2) Remove four recliner attaching screws. Some

vehicles require the trim to be lifted in order to ex-

pose recliner screws at the seat back attachment. (3) Disconnect cable housing clamp at transmis-

sion. (4) Remove cable from transmission drive worm

gear. Be careful not to allow the cable to be pulled

out of the housing. This will prevent possibility of

disconnecting the cable from the motor at the other

end.

INSTALLATION

(1) Install the square drive cable end into the

square hole in the drive worm gear at recliner mech-

anism. The cable may have to be rotated manually in

order to align properly with the square hole in the

drive worm gear. (2) Position the cable housing so that it is securely

seated into the transmission housing. (3) Clamp the cable housing to the transmission

housing with clamp. The prongs of the clamp should

Fig. 30 Power Memory Seat

8R - 18 POWER SEATS Ä

Page 743 of 2438

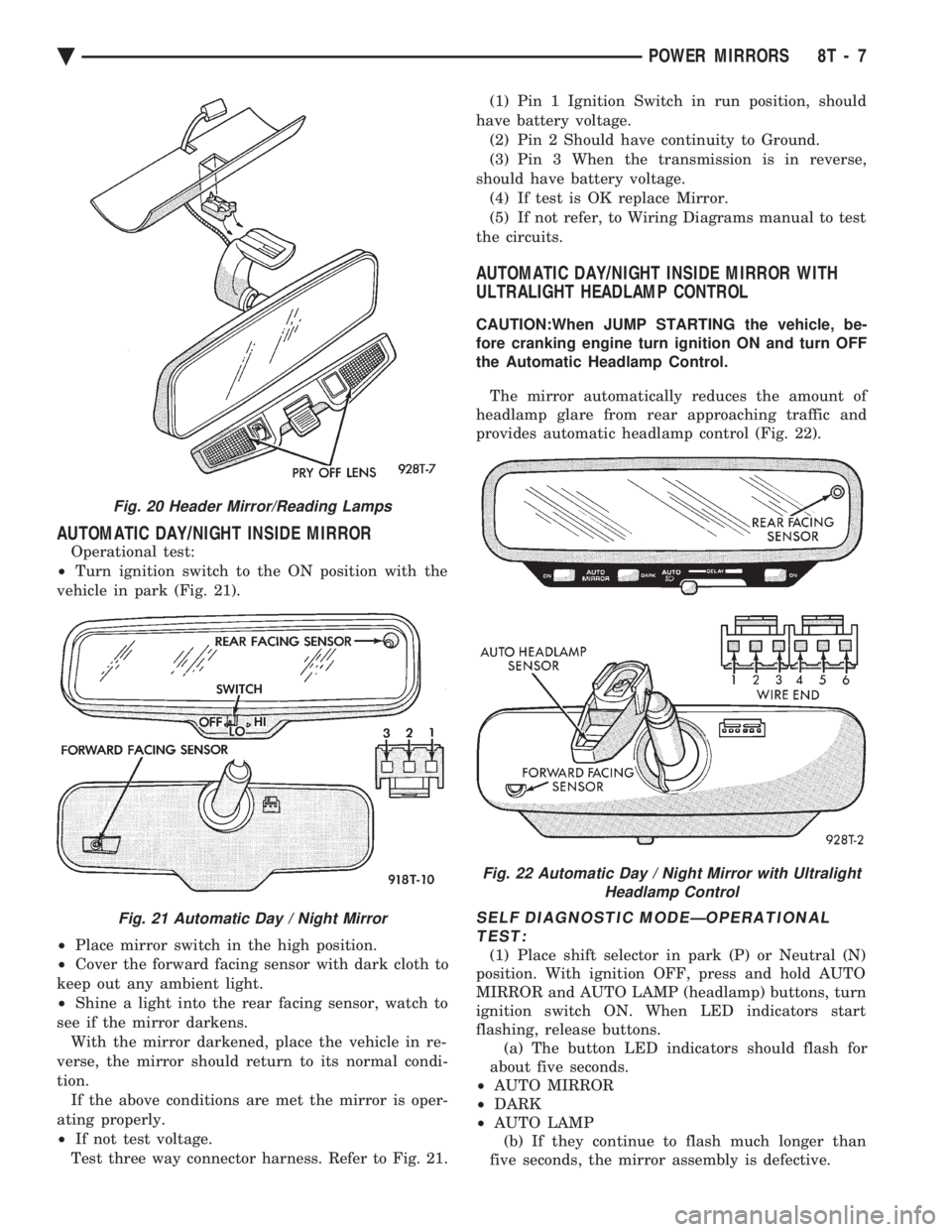

AUTOMATIC DAY/NIGHT INSIDE MIRROR

Operational test:

² Turn ignition switch to the ON position with the

vehicle in park (Fig. 21).

² Place mirror switch in the high position.

² Cover the forward facing sensor with dark cloth to

keep out any ambient light.

² Shine a light into the rear facing sensor, watch to

see if the mirror darkens. With the mirror darkened, place the vehicle in re-

verse, the mirror should return to its normal condi-

tion. If the above conditions are met the mirror is oper-

ating properly.

² If not test voltage.

Test three way connector harness. Refer to Fig. 21. (1) Pin 1 Ignition Switch in run position, should

have battery voltage. (2) Pin 2 Should have continuity to Ground.

(3) Pin 3 When the transmission is in reverse,

should have battery voltage. (4) If test is OK replace Mirror.

(5) If not refer, to Wiring Diagrams manual to test

the circuits.

AUTOMATIC DAY/NIGHT INSIDE MIRROR WITH

ULTRALIGHT HEADLAMP CONTROL

CAUTION:When JUMP STARTING the vehicle, be-

fore cranking engine turn ignition ON and turn OFF

the Automatic Headlamp Control.

The mirror automatically reduces the amount of

headlamp glare from rear approaching traffic and

provides automatic headlamp control (Fig. 22).

SELF DIAGNOSTIC MODEÐOPERATIONAL TEST:

(1) Place shift selector in park (P) or Neutral (N)

position. With ignition OFF, press and hold AUTO

MIRROR and AUTO LAMP (headlamp) buttons, turn

ignition switch ON. When LED indicators start

flashing, release buttons. (a) The button LED indicators should flash for

about five seconds.

² AUTO MIRROR

² DARK

² AUTO LAMP

(b) If they continue to flash much longer than

five seconds, the mirror assembly is defective.

Fig. 20 Header Mirror/Reading Lamps

Fig. 21 Automatic Day / Night Mirror

Fig. 22 Automatic Day / Night Mirror with Ultralight Headlamp Control

Ä POWER MIRRORS 8T - 7

Page 754 of 2438

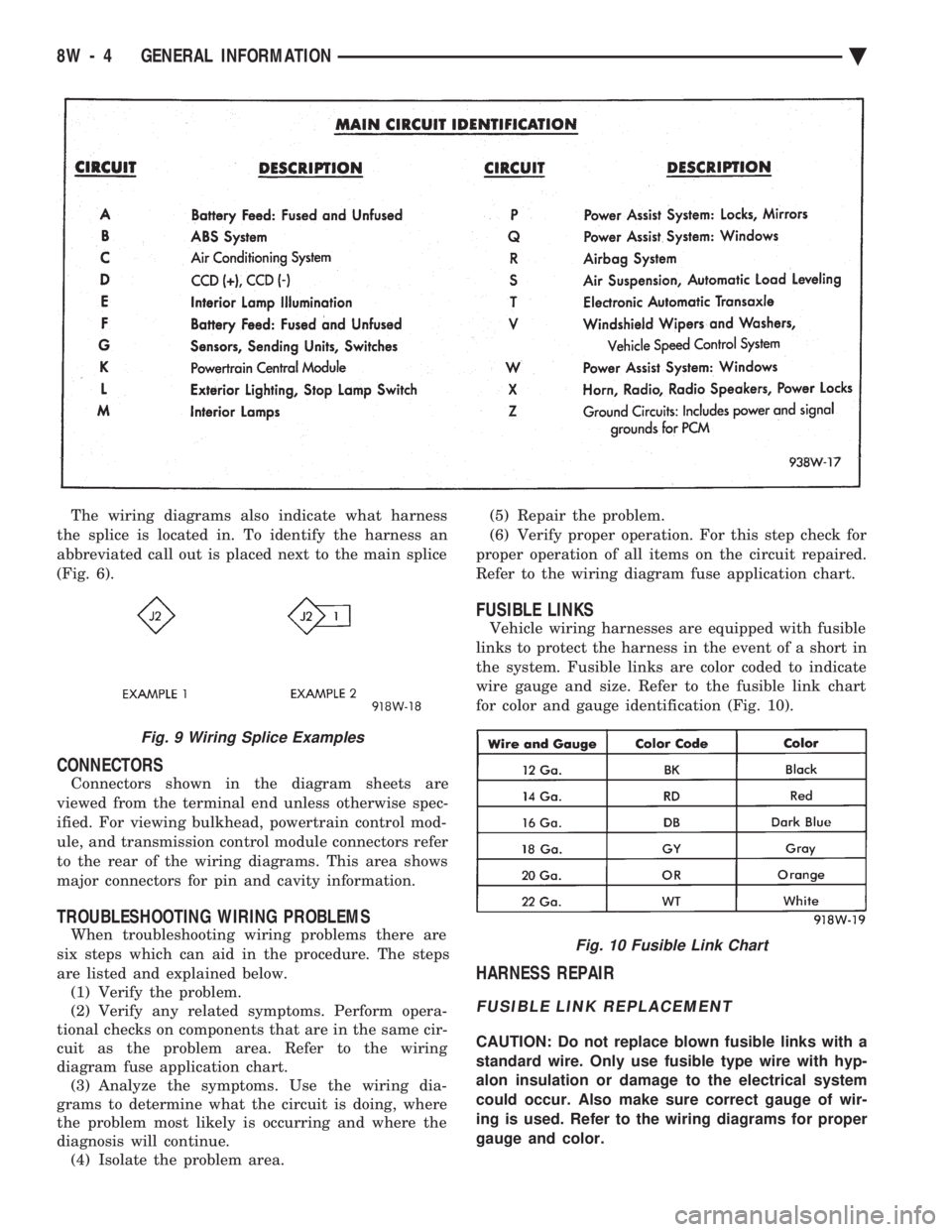

The wiring diagrams also indicate what harness

the splice is located in. To identify the harness an

abbreviated call out is placed next to the main splice

(Fig. 6).

CONNECTORS

Connectors shown in the diagram sheets are

viewed from the terminal end unless otherwise spec-

ified. For viewing bulkhead, powertrain control mod-

ule, and transmission control module connectors refer

to the rear of the wiring diagrams. This area shows

major connectors for pin and cavity information.

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. (1) Verify the problem.

(2) Verify any related symptoms. Perform opera-

tional checks on components that are in the same cir-

cuit as the problem area. Refer to the wiring

diagram fuse application chart. (3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue. (4) Isolate the problem area. (5) Repair the problem.

(6) Verify proper operation. For this step check for

proper operation of all items on the circuit repaired.

Refer to the wiring diagram fuse application chart.

FUSIBLE LINKS

Vehicle wiring harnesses are equipped with fusible

links to protect the harness in the event of a short in

the system. Fusible links are color coded to indicate

wire gauge and size. Refer to the fusible link chart

for color and gauge identification (Fig. 10).

HARNESS REPAIR

FUSIBLE LINK REPLACEMENT

CAUTION: Do not replace blown fusible links with a

standard wire. Only use fusible type wire with hyp-

alon insulation or damage to the electrical system

could occur. Also make sure correct gauge of wir-

ing is used. Refer to the wiring diagrams for proper

gauge and color.

Fig. 9 Wiring Splice Examples

Fig. 10 Fusible Link Chart

8W - 4 GENERAL INFORMATION Ä

Page 769 of 2438

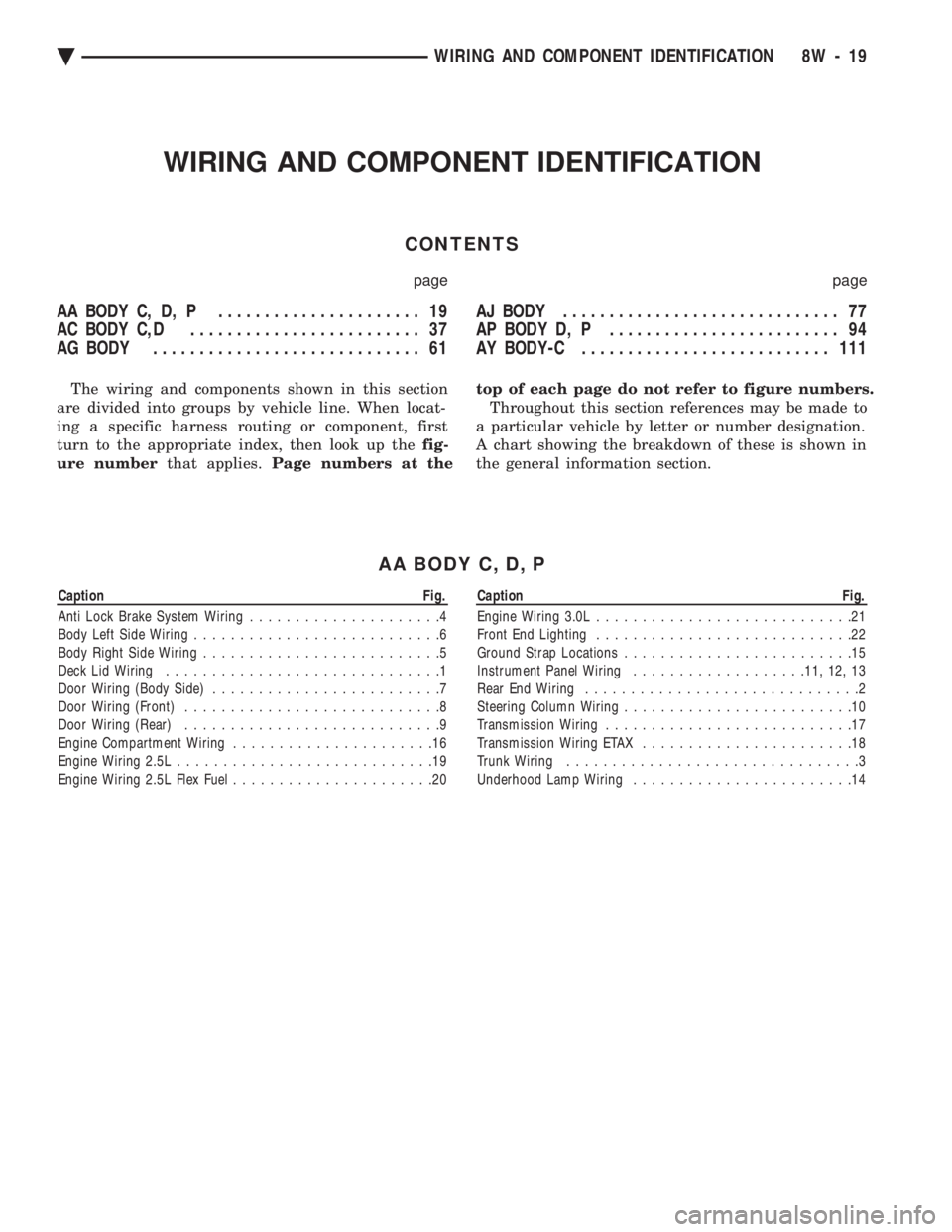

WIRING AND COMPONENT IDENTIFICATION

CONTENTS

page page

AA BODY C, D, P ...................... 19

AC BODY C,D ......................... 37

AG BODY ............................. 61 AJ BODY

.............................. 77

AP BODY D, P ......................... 94

AY BODY-C ........................... 111

The wiring and components shown in this section

are divided into groups by vehicle line. When locat-

ing a specific harness routing or component, first

turn to the appropriate index, then look up the fig-

ure number that applies.Page numbers at the top of each page do not refer to figure numbers.

Throughout this section references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these is shown in

the general information section.

AA BODY C, D, P

Caption Fig.

Anti Lock Brake System Wiring .....................4

Body Left Side Wiring ...........................6

Body Right Side Wiring ..........................5

Deck Lid Wiring ..............................1

Door Wiring (Body Side) .........................7

Door Wiring (Front) ............................8

Door Wiring (Rear) ............................9

Engine Compartment Wiring ......................16

Engine Wiring 2.5L ............................19

Engine Wiring 2.5L Flex Fuel ......................20Caption Fig.

Engine Wiring 3.0L ............................21

Front End Lighting ............................22

Ground Strap Locations .........................15

Instrument Panel Wiring .................. .11, 12, 13

Rear End Wiring ..............................2

Steering Column Wiring .........................10

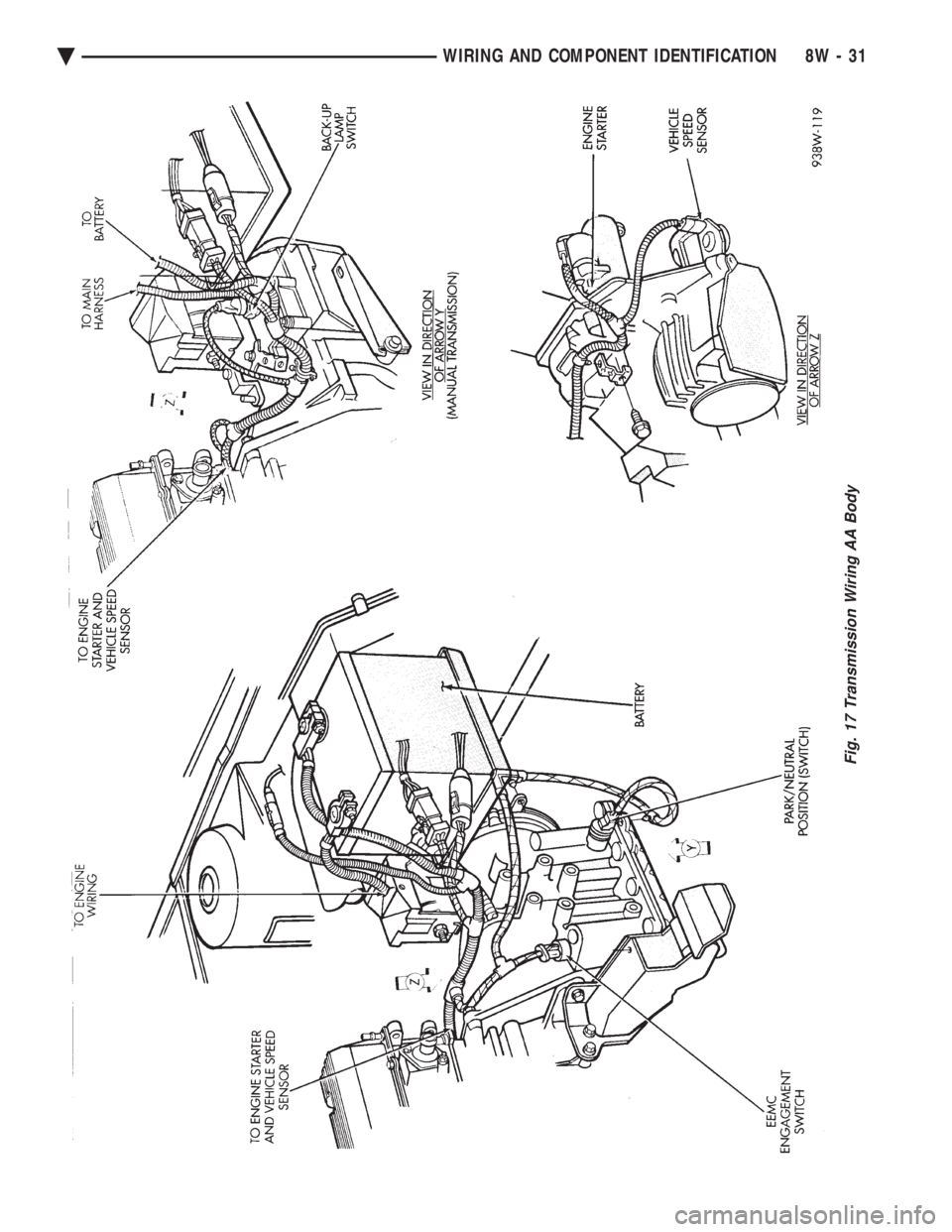

Transmission Wiring ...........................17

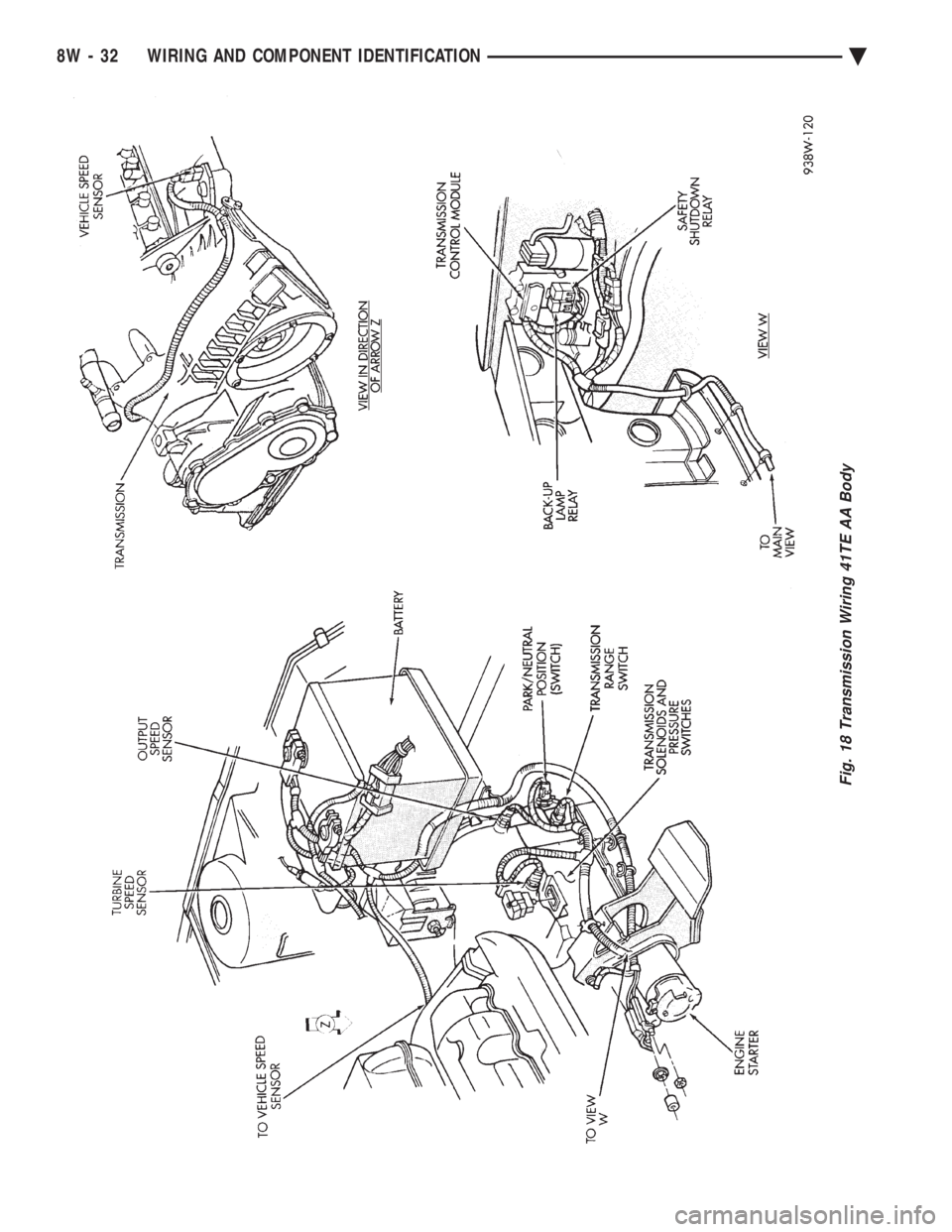

Transmission Wiring ETAX .......................18

Trunk Wiring ................................3

Underhood Lamp Wiring ........................14

Ä WIRING AND COMPONENT IDENTIFICATION 8W - 19

Page 781 of 2438

Fig. 17 Transmission Wiring AA Body

Ä WIRING AND COMPONENT IDENTIFICATION 8W - 31

Page 782 of 2438

Fig. 18 Transmission Wiring 41TE AA Body

8W - 32 WIRING AND COMPONENT IDENTIFICATION Ä