CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 701 of 2438

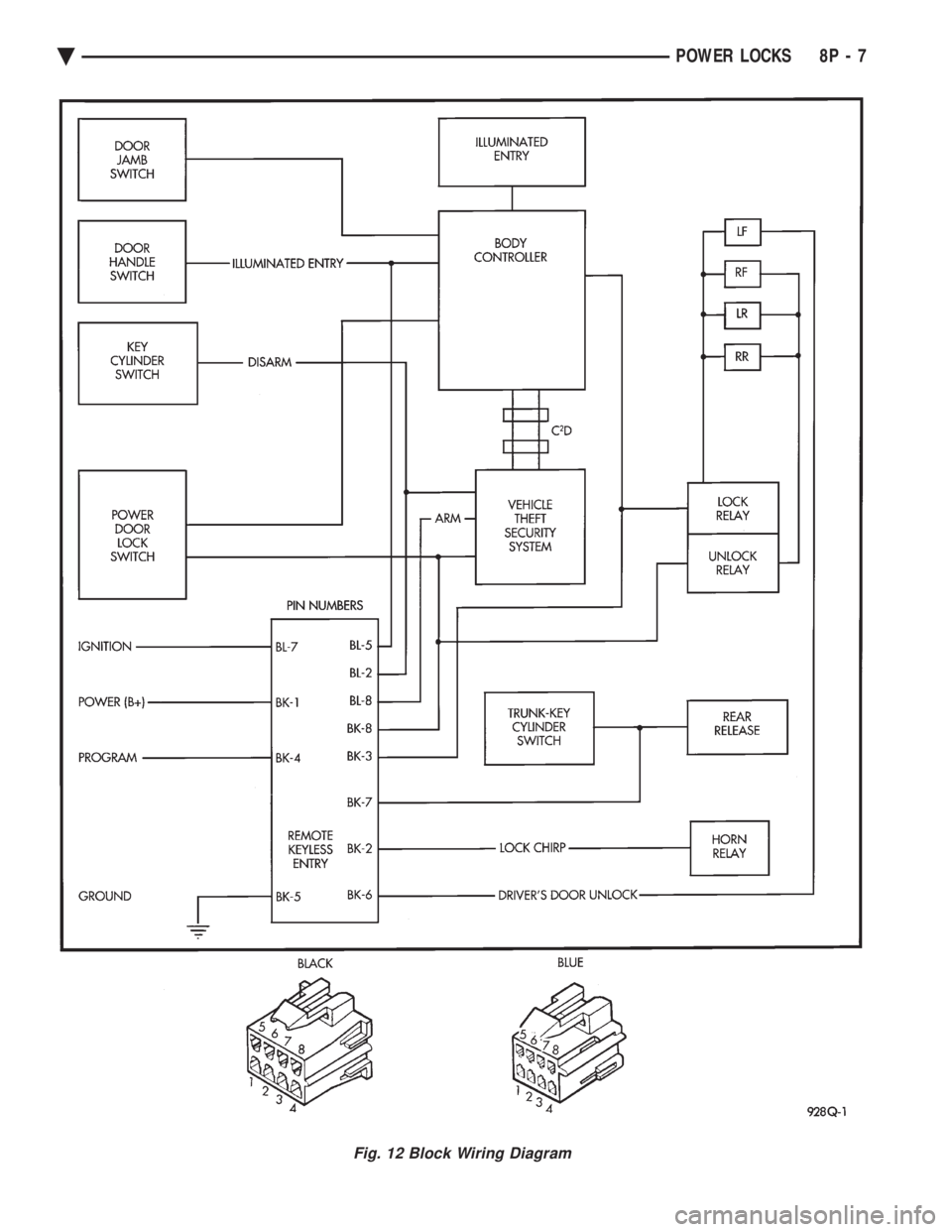

Fig. 12 Block Wiring Diagram

Ä POWER LOCKS 8P - 7

Page 702 of 2438

AA BODY

Uses a power door lock inhibit relay. The relay is

located above the glove box compartment.

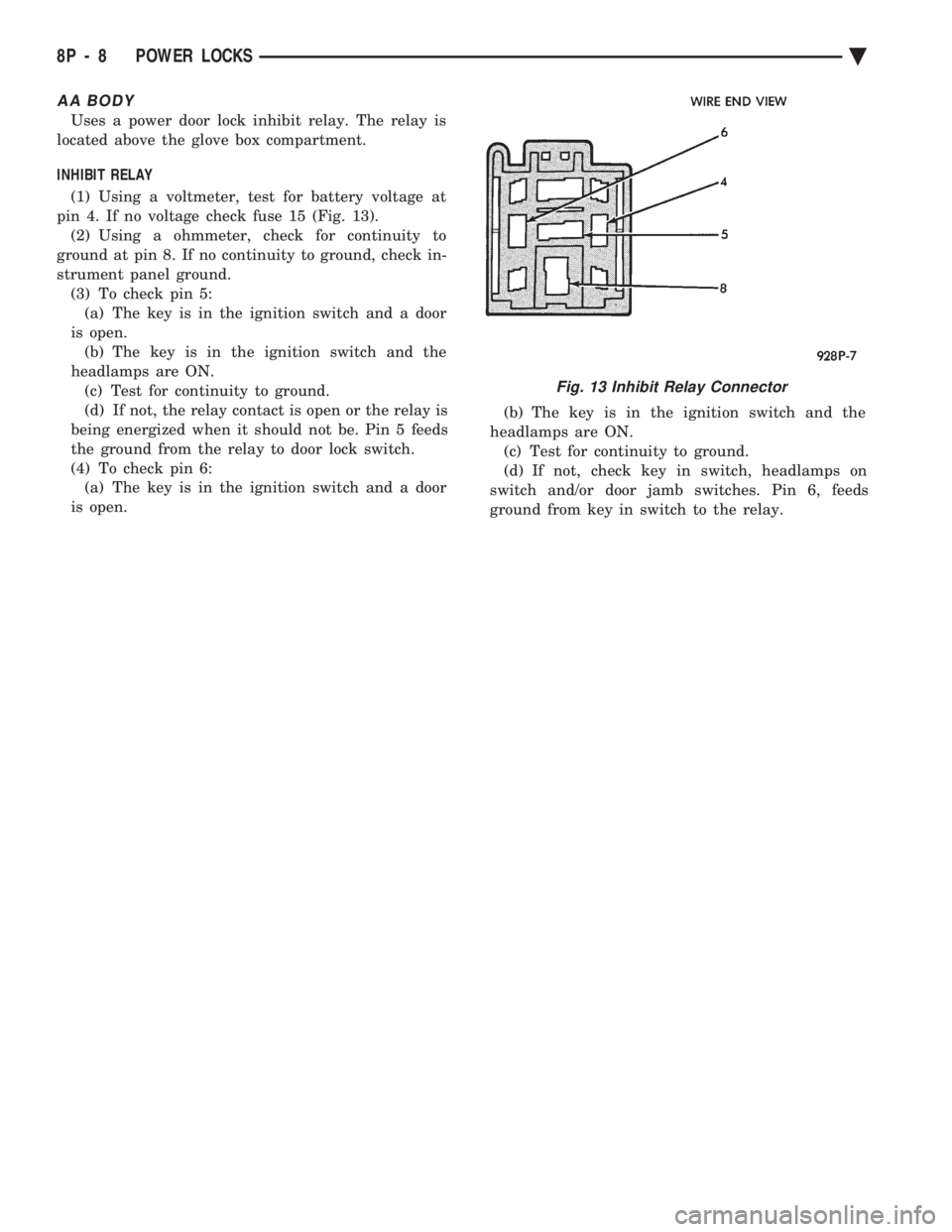

INHIBIT RELAY

(1) Using a voltmeter, test for battery voltage at

pin 4. If no voltage check fuse 15 (Fig. 13). (2) Using a ohmmeter, check for continuity to

ground at pin 8. If no continuity to ground, check in-

strument panel ground. (3) To check pin 5:(a) The key is in the ignition switch and a door

is open. (b) The key is in the ignition switch and the

headlamps are ON. (c) Test for continuity to ground.

(d) If not, the relay contact is open or the relay is

being energized when it should not be. Pin 5 feeds

the ground from the relay to door lock switch.

(4) To check pin 6: (a) The key is in the ignition switch and a door

is open. (b) The key is in the ignition switch and the

headlamps are ON. (c) Test for continuity to ground.

(d) If not, check key in switch, headlamps on

switch and/or door jamb switches. Pin 6, feeds

ground from key in switch to the relay.

Fig. 13 Inhibit Relay Connector

8P - 8 POWER LOCKS Ä

Page 703 of 2438

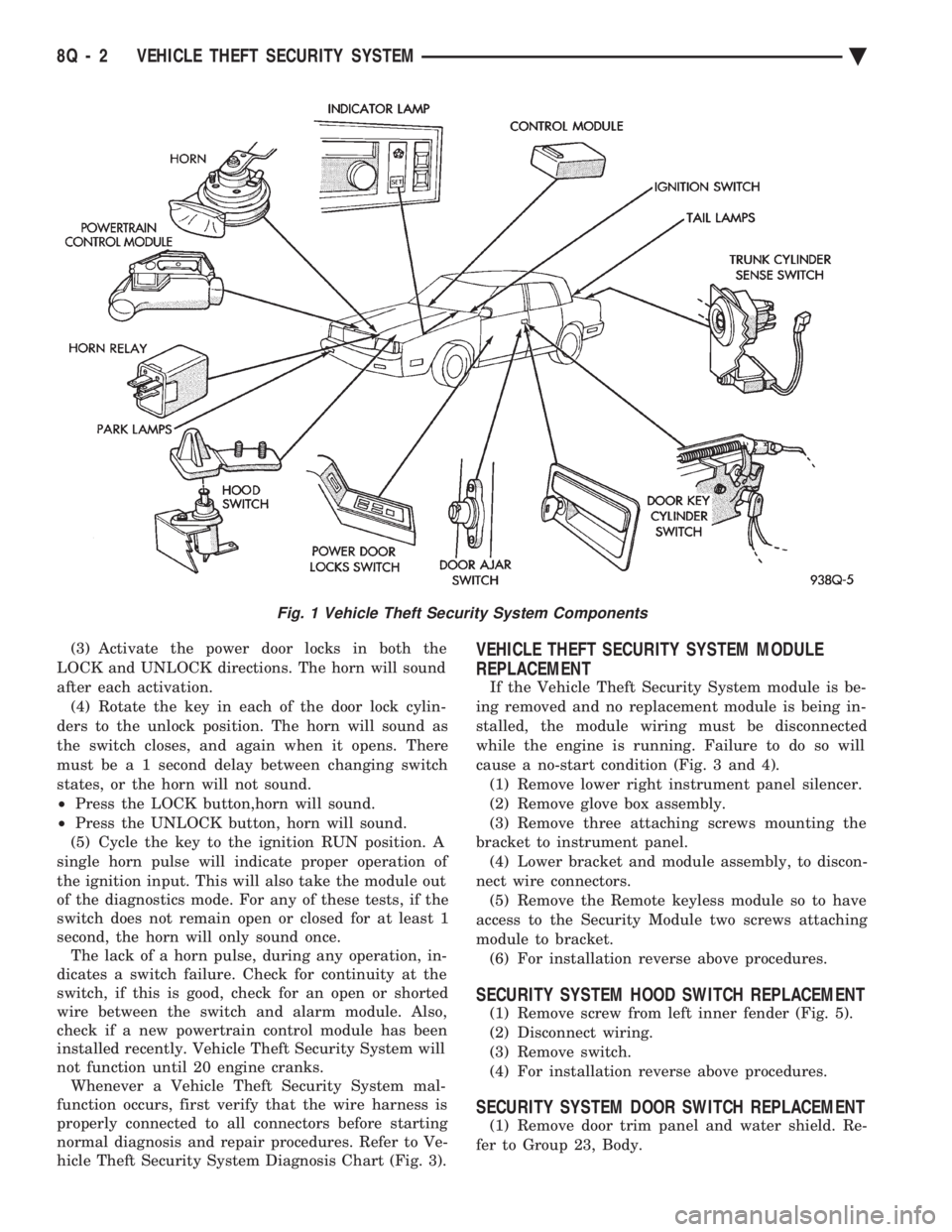

VEHICLE THEFT SECURITY SYSTEM

CONTENTS

page page

GENERAL INFORMATION .................. 1

SECURITY SYSTEM DOOR SWITCH REPLACEMENT ........................ 2

SECURITY SYSTEM HOOD SWITCH REPLACEMENT ........................ 2 SYSTEM SELF-TESTS

.................... 1

VEHICLE THEFT SECURITY SYSTEM MODULE REPLACEMENT ........................ 2

WHAT WILL TRIGGER THE SYSTEM ........ 1

GENERAL INFORMATION

JUMP-STARTING, VEHICLE EQUIPPED

WITH THEFT SECURITY SYSTEM . After the

booster battery has been connected, the Theft System

must be turned OFF. Using the key, lock then un-

lock either front door. This turns the Theft System

OFF and the remainder of the Jump-Starting proce-

dure can be followed. If this procedure is not followed, the Theft System

electronics will prevent the engine from starting. If a new Powertrain Control Module is installed,

the engine has to be cranked 20 times before the

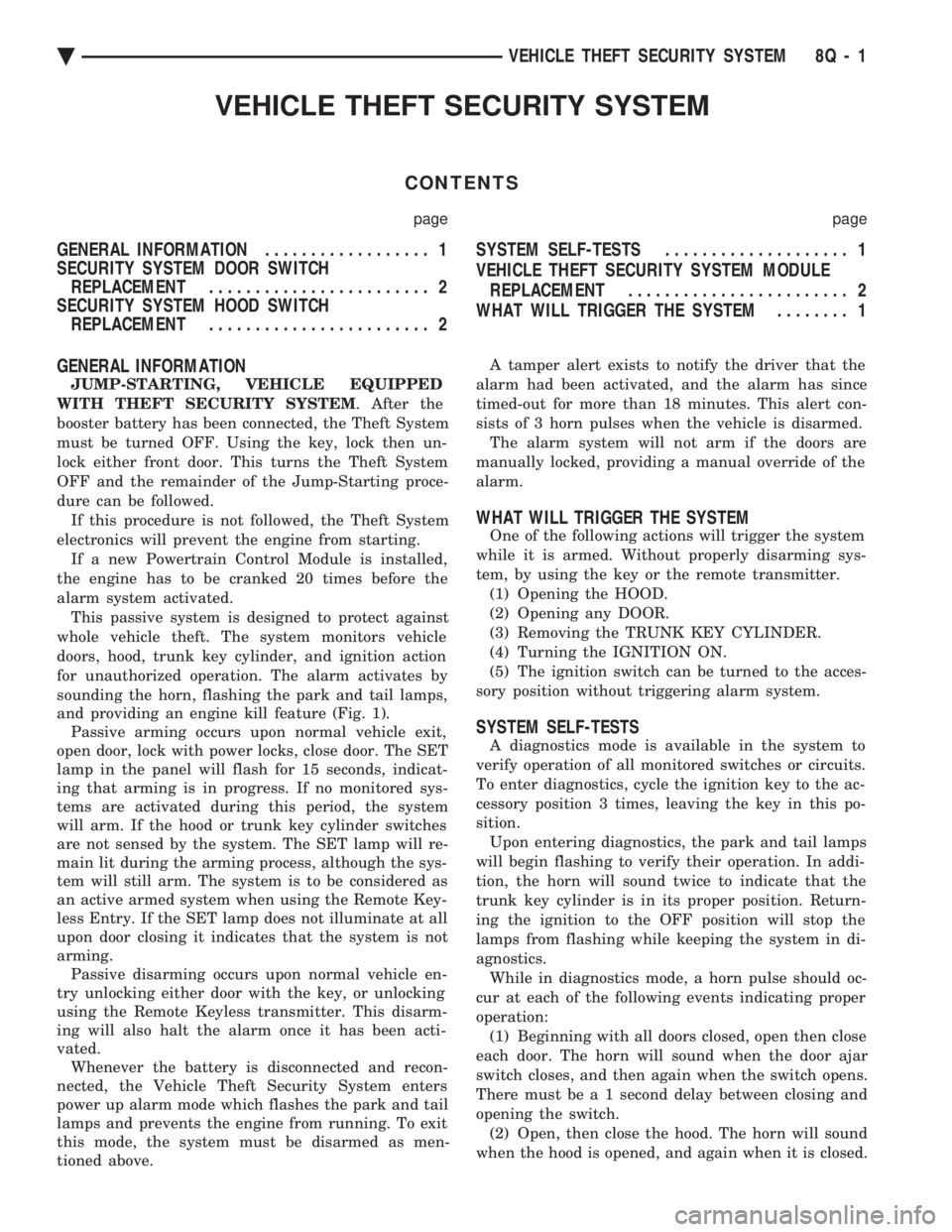

alarm system activated. This passive system is designed to protect against

whole vehicle theft. The system monitors vehicle

doors, hood, trunk key cylinder, and ignition action

for unauthorized operation. The alarm activates by

sounding the horn, flashing the park and tail lamps,

and providing an engine kill feature (Fig. 1). Passive arming occurs upon normal vehicle exit,

open door, lock with power locks, close door. The SET

lamp in the panel will flash for 15 seconds, indicat-

ing that arming is in progress. If no monitored sys-

tems are activated during this period, the system

will arm. If the hood or trunk key cylinder switches

are not sensed by the system. The SET lamp will re-

main lit during the arming process, although the sys-

tem will still arm. The system is to be considered as

an active armed system when using the Remote Key-

less Entry. If the SET lamp does not illuminate at all

upon door closing it indicates that the system is not

arming. Passive disarming occurs upon normal vehicle en-

try unlocking either door with the key, or unlocking

using the Remote Keyless transmitter. This disarm-

ing will also halt the alarm once it has been acti-

vated. Whenever the battery is disconnected and recon-

nected, the Vehicle Theft Security System enters

power up alarm mode which flashes the park and tail

lamps and prevents the engine from running. To exit

this mode, the system must be disarmed as men-

tioned above. A tamper alert exists to notify the driver that the

alarm had been activated, and the alarm has since

timed-out for more than 18 minutes. This alert con-

sists of 3 horn pulses when the vehicle is disarmed. The alarm system will not arm if the doors are

manually locked, providing a manual override of the

alarm.

WHAT WILL TRIGGER THE SYSTEM

One of the following actions will trigger the system

while it is armed. Without properly disarming sys-

tem, by using the key or the remote transmitter. (1) Opening the HOOD.

(2) Opening any DOOR.

(3) Removing the TRUNK KEY CYLINDER.

(4) Turning the IGNITION ON.

(5) The ignition switch can be turned to the acces-

sory position without triggering alarm system.

SYSTEM SELF-TESTS

A diagnostics mode is available in the system to

verify operation of all monitored switches or circuits.

To enter diagnostics, cycle the ignition key to the ac-

cessory position 3 times, leaving the key in this po-

sition. Upon entering diagnostics, the park and tail lamps

will begin flashing to verify their operation. In addi-

tion, the horn will sound twice to indicate that the

trunk key cylinder is in its proper position. Return-

ing the ignition to the OFF position will stop the

lamps from flashing while keeping the system in di-

agnostics. While in diagnostics mode, a horn pulse should oc-

cur at each of the following events indicating proper

operation: (1) Beginning with all doors closed, open then close

each door. The horn will sound when the door ajar

switch closes, and then again when the switch opens.

There must b e a 1 second delay between closing and

opening the switch. (2) Open, then close the hood. The horn will sound

when the hood is opened, and again when it is closed.

Ä VEHICLE THEFT SECURITY SYSTEM 8Q - 1

Page 704 of 2438

(3) Activate the power door locks in both the

LOCK and UNLOCK directions. The horn will sound

after each activation. (4) Rotate the key in each of the door lock cylin-

ders to the unlock position. The horn will sound as

the switch closes, and again when it opens. There

must b e a 1 second delay between changing switch

states, or the horn will not sound.

² Press the LOCK button,horn will sound.

² Press the UNLOCK button, horn will sound.

(5) Cycle the key to the ignition RUN position. A

single horn pulse will indicate proper operation of

the ignition input. This will also take the module out

of the diagnostics mode. For any of these tests, if the

switch does not remain open or closed for at least 1

second, the horn will only sound once. The lack of a horn pulse, during any operation, in-

dicates a switch failure. Check for continuity at the

switch, if this is good, check for an open or shorted

wire between the switch and alarm module. Also,

check if a new powertrain control module has been

installed recently. Vehicle Theft Security System will

not function until 20 engine cranks. Whenever a Vehicle Theft Security System mal-

function occurs, first verify that the wire harness is

properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to Ve-

hicle Theft Security System Diagnosis Chart (Fig. 3).VEHICLE THEFT SECURITY SYSTEM MODULE

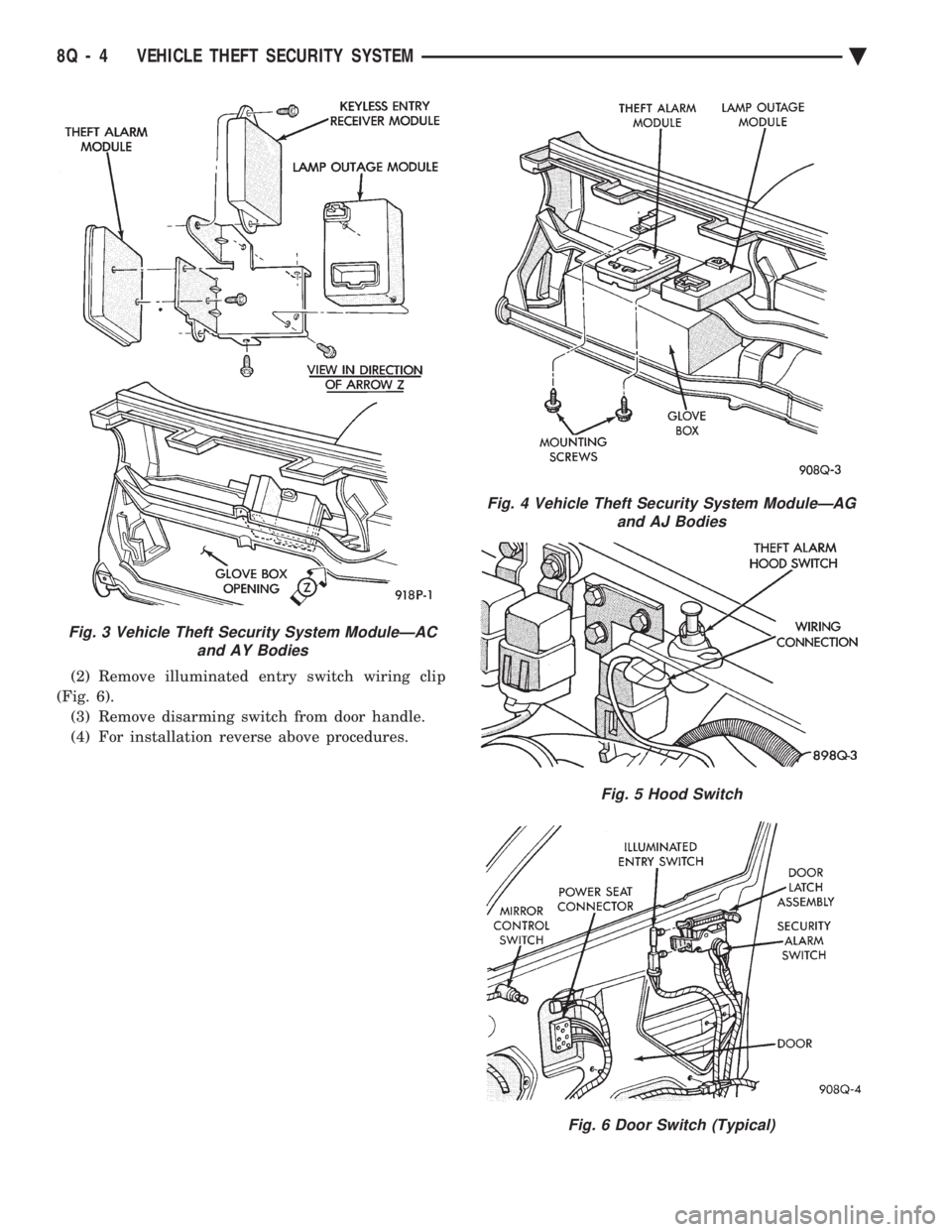

REPLACEMENT

If the Vehicle Theft Security System module is be-

ing removed and no replacement module is being in-

stalled, the module wiring must be disconnected

while the engine is running. Failure to do so will

cause a no-start condition (Fig. 3 and 4). (1) Remove lower right instrument panel silencer.

(2) Remove glove box assembly.

(3) Remove three attaching screws mounting the

bracket to instrument panel. (4) Lower bracket and module assembly, to discon-

nect wire connectors. (5) Remove the Remote keyless module so to have

access to the Security Module two screws attaching

module to bracket. (6) For installation reverse above procedures.

SECURITY SYSTEM HOOD SWITCH REPLACEMENT

(1) Remove screw from left inner fender (Fig. 5).

(2) Disconnect wiring.

(3) Remove switch.

(4) For installation reverse above procedures.

SECURITY SYSTEM DOOR SWITCH REPLACEMENT

(1) Remove door trim panel and water shield. Re-

fer to Group 23, Body.

Fig. 1 Vehicle Theft Security System Components

8Q - 2 VEHICLE THEFT SECURITY SYSTEM Ä

Page 705 of 2438

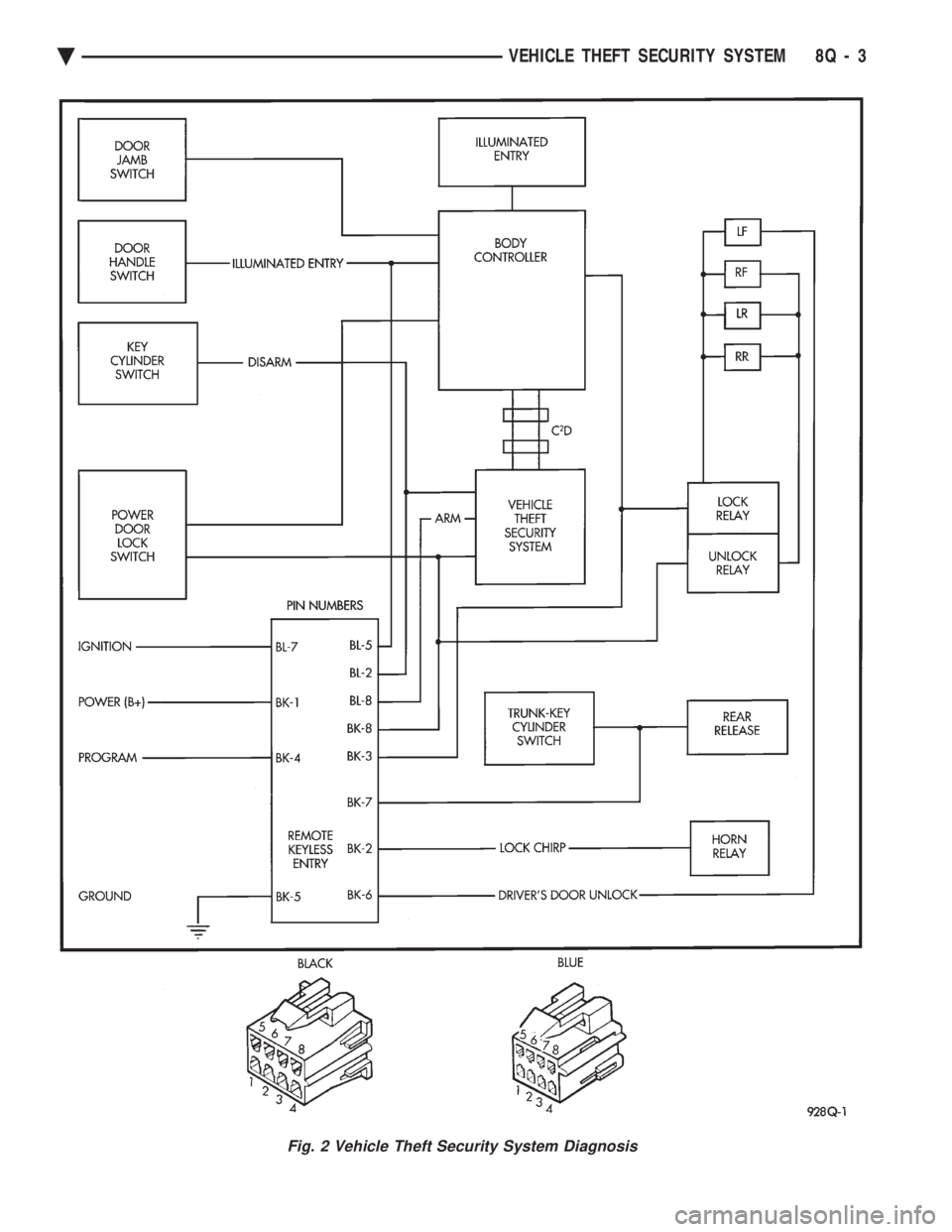

Fig. 2 Vehicle Theft Security System Diagnosis

Ä VEHICLE THEFT SECURITY SYSTEM 8Q - 3

Page 706 of 2438

(2) Remove illuminated entry switch wiring clip

(Fig. 6). (3) Remove disarming switch from door handle.

(4) For installation reverse above procedures.

Fig. 3 Vehicle Theft Security System ModuleÐAC and AY Bodies

Fig. 4 Vehicle Theft Security System ModuleÐAG and AJ Bodies

Fig. 5 Hood Switch

Fig. 6 Door Switch (Typical)

8Q - 4 VEHICLE THEFT SECURITY SYSTEM Ä

Page 707 of 2438

POWER SEATS

CONTENTS

page page

ADJUSTER ............................. 3

CIRCUIT BREAKER TEST .................. 1

ENTHUSIAST SEAT ....................... 4

GENERAL INFORMATION .................. 1

HARNESS VOLTAGE TEST ................. 1

HORIZONTAL AND VERTICAL TRANSMISSIONS ....................... 3

MEMORY CONTROL MODULE REPLACEMENT ....................... 19

MOTOR ................................ 3

MOTOR TESTS .......................... 1

POWER MEMORY SEAT, RECLINER AND MIRRORS ............................. 5 POWER MEMORY SEAT, RECLINER AND

MIRRORS DIAGNOSIS ................... 9

POWER RECLINER MECHANISM ........... 18

POWER RECLINER MOTOR AND CABLE ..... 17

RECLINER SWITCH REPLACEMENT ......... 19

RECLINER SWITCH TEST ................. 19

SEAT ASSEMBLY ........................ 3

SWITCH REPLACEMENT REMOVAL .......... 5

SWITCH TEST ........................... 5

SWITCH TEST ........................... 3

TEST PROCEDURES ...................... 6

TEST PROCEDURES ...................... 1

GENERAL INFORMATION

Power seats can be adjusted in six different direc-

tions up, down, forward, back, tilt forward, or tilt

rearward. A three armature permanent magnet reversible mo-

tor is coupled through cables to worm gear box assem-

blies located in the seat tracks, providing the various

seat movements. The electrical circuit is protected by a 30 amp circuit

breaker located on the fuse block.

TEST PROCEDURES

Before any testing is attempted the battery should be

carefully charged and all connections and terminals

cleaned and tightened to insure proper continuity and

grounds. With dome lamp on, apply switch in direction of

failure. If dome lamp dims the seat motor is trying to

work indicating mechanical jamming. If dome lamp

does not dim, then proceed with the following electrical

tests.

CIRCUIT BREAKER TEST

Find correct circuit breaker on fuse block. Pull out

slightly but be sure that circuit breaker terminals still

contact terminals in fuse block. Connect ground wire of

voltmeter to a good ground. With probe of voltmeter

positive wire, check both terminals of circuit breaker

for battery voltage. If only one terminal checks at

battery voltage, circuit breaker is defective and must

be replaced. If neither terminal shows battery voltage,

check for open or shorted circuit to circuit breaker.

HARNESS VOLTAGE TEST

The following test will determine whether or not

voltage is continuous through the body harness to the

switch. (1) Remove power seat switch from mounting posi-

tion and disconnect switch from wiring harness. (2) Connect one lead of test light to ground terminal,

black wire (BK) of center section, and touch other test

light lead to red wire (RD) terminal. (3) If test light comes on, harness to switch is good.

If test light does not come on, perform circuit breaker

test.

MOTOR TESTS

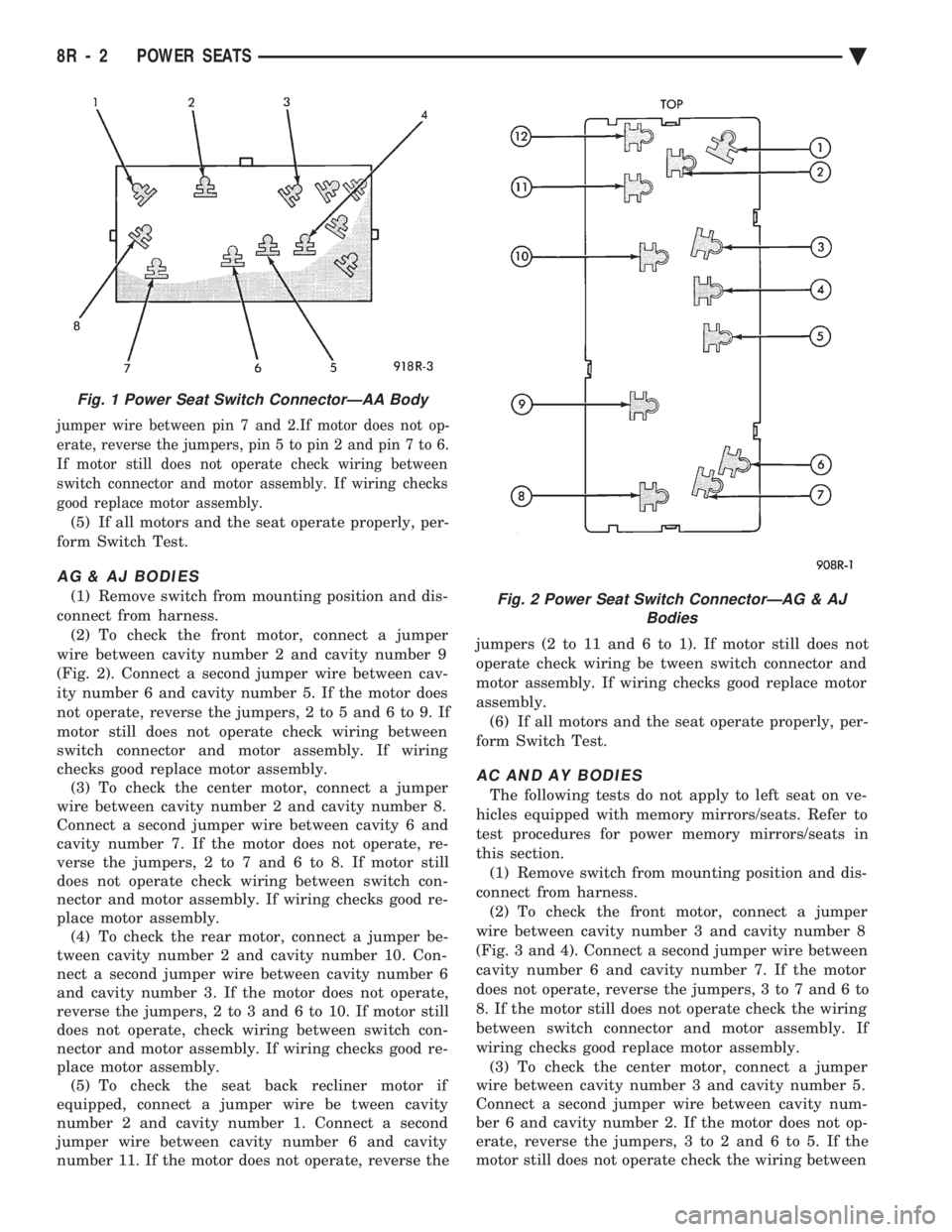

AA BODY

(1) Remove switch from mounting position and dis-

connect from harness. (2) To check the center motor, connect a jumper wire

between pin 5 and pin 3 (Fig. 1). Connect a second

jumper wire between pin 7 and pin 4 If motor does not

operate, reverse the jumpers, pin 5 to pin 4 and pin 7 to

pin 3. If motor still does not operate check wiring

between switch connector and motor assembly. If wir-

ing checks good replace motor assembly. (3) To check the front motor, connect a jumper wire

between pin 5 and pin 1 (Fig. 1). Connect a second

jumper wire between pin 7 and pin 8. If motor does not

operate, reverse the jumpers, pin 5 to pin 8 and pin 7 to

pin 1. If motor still does not operate check wiring

between switch connector and motor assembly. If wir-

ing checks good replace motor assembly.

(4) To check the rear motor, connect a covered jumper

wire between pin 5 and pin 6 (Fig. 1). Connect a second

Ä POWER SEATS 8R - 1

Page 708 of 2438

jumper wire between pin 7 and 2.If motor does not op-

erate, reverse the jumpers, pin 5 to pin 2 and pin 7 to 6.

If motor still does not operate check wiring between

switch connector and motor assembly. If wiring checks

good replace motor assembly.

(5) If all motors and the seat operate properly, per-

form Switch Test.

AG & AJ BODIES

(1) Remove switch from mounting position and dis-

connect from harness. (2) To check the front motor, connect a jumper

wire between cavity number 2 and cavity number 9

(Fig. 2). Connect a second jumper wire between cav-

ity number 6 and cavity number 5. If the motor does

not operate, reverse the jumpers, 2 to 5 and 6 to 9. If

motor still does not operate check wiring between

switch connector and motor assembly. If wiring

checks good replace motor assembly. (3) To check the center motor, connect a jumper

wire between cavity number 2 and cavity number 8.

Connect a second jumper wire between cavity 6 and

cavity number 7. If the motor does not operate, re-

verse the jumpers, 2 to 7 and 6 to 8. If motor still

does not operate check wiring between switch con-

nector and motor assembly. If wiring checks good re-

place motor assembly. (4) To check the rear motor, connect a jumper be-

tween cavity number 2 and cavity number 10. Con-

nect a second jumper wire between cavity number 6

and cavity number 3. If the motor does not operate,

reverse the jumpers, 2 to 3 and 6 to 10. If motor still

does not operate, check wiring between switch con-

nector and motor assembly. If wiring checks good re-

place motor assembly. (5) To check the seat back recliner motor if

equipped, connect a jumper wire be tween cavity

number 2 and cavity number 1. Connect a second

jumper wire between cavity number 6 and cavity

number 11. If the motor does not operate, reverse the jumpers (2 to 11 and 6 to 1). If motor still does not

operate check wiring be tween switch connector and

motor assembly. If wiring checks good replace motor

assembly.

(6) If all motors and the seat operate properly, per-

form Switch Test.

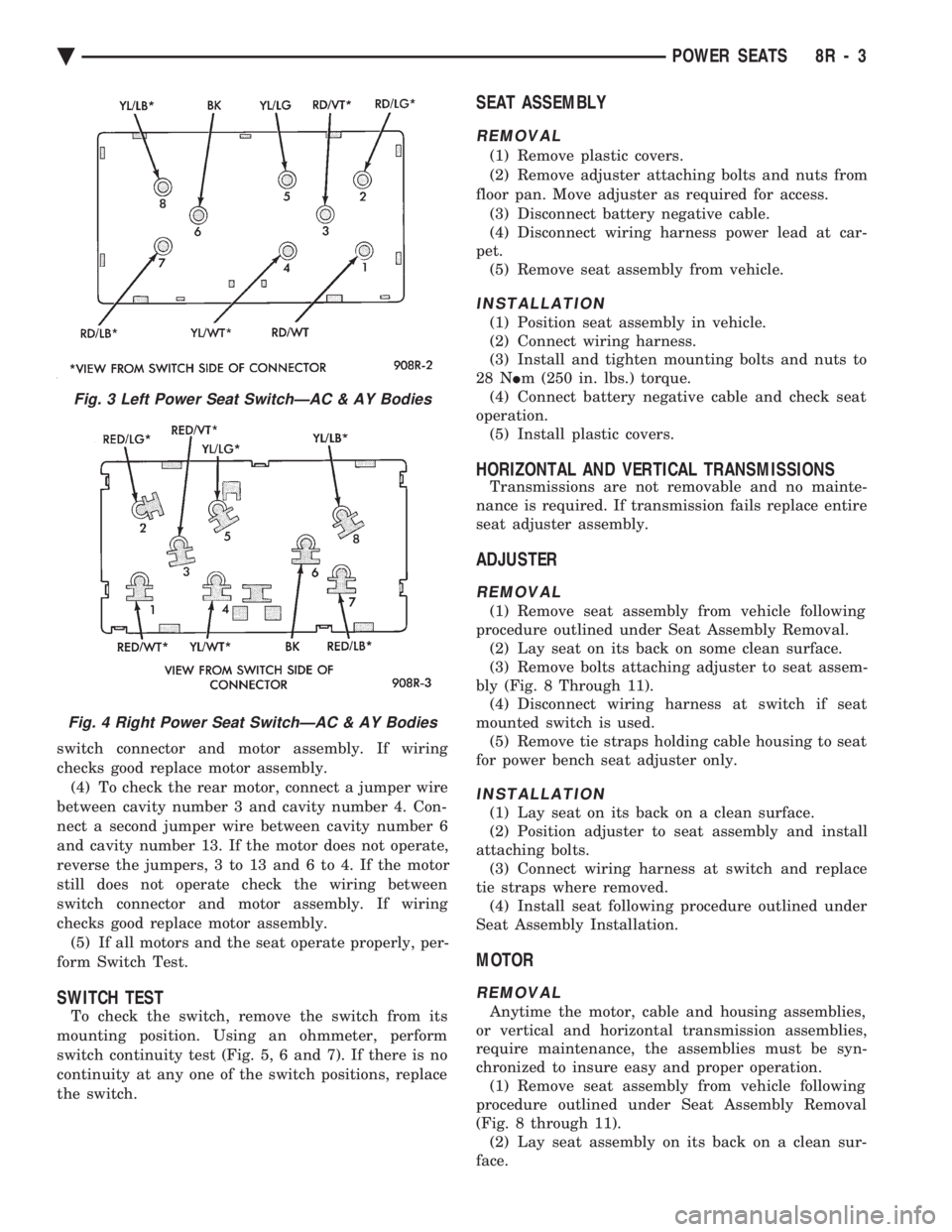

AC AND AY BODIES

The following tests do not apply to left seat on ve-

hicles equipped with memory mirrors/seats. Refer to

test procedures for power memory mirrors/seats in

this section. (1) Remove switch from mounting position and dis-

connect from harness. (2) To check the front motor, connect a jumper

wire between cavity number 3 and cavity number 8

(Fig. 3 and 4). Connect a second jumper wire between

cavity number 6 and cavity number 7. If the motor

does not operate, reverse the jumpers, 3 to 7 and 6 to

8. If the motor still does not operate check the wiring

between switch connector and motor assembly. If

wiring checks good replace motor assembly. (3) To check the center motor, connect a jumper

wire between cavity number 3 and cavity number 5.

Connect a second jumper wire between cavity num-

ber 6 and cavity number 2. If the motor does not op-

erate, reverse the jumpers, 3 to 2 and 6 to 5. If the

motor still does not operate check the wiring between

Fig. 1 Power Seat Switch ConnectorÐAA Body

Fig. 2 Power Seat Switch ConnectorÐAG & AJ Bodies

8R - 2 POWER SEATS Ä

Page 709 of 2438

switch connector and motor assembly. If wiring

checks good replace motor assembly.(4) To check the rear motor, connect a jumper wire

between cavity number 3 and cavity number 4. Con-

nect a second jumper wire between cavity number 6

and cavity number 13. If the motor does not operate,

reverse the jumpers, 3 to 13 and 6 to 4. If the motor

still does not operate check the wiring between

switch connector and motor assembly. If wiring

checks good replace motor assembly. (5) If all motors and the seat operate properly, per-

form Switch Test.

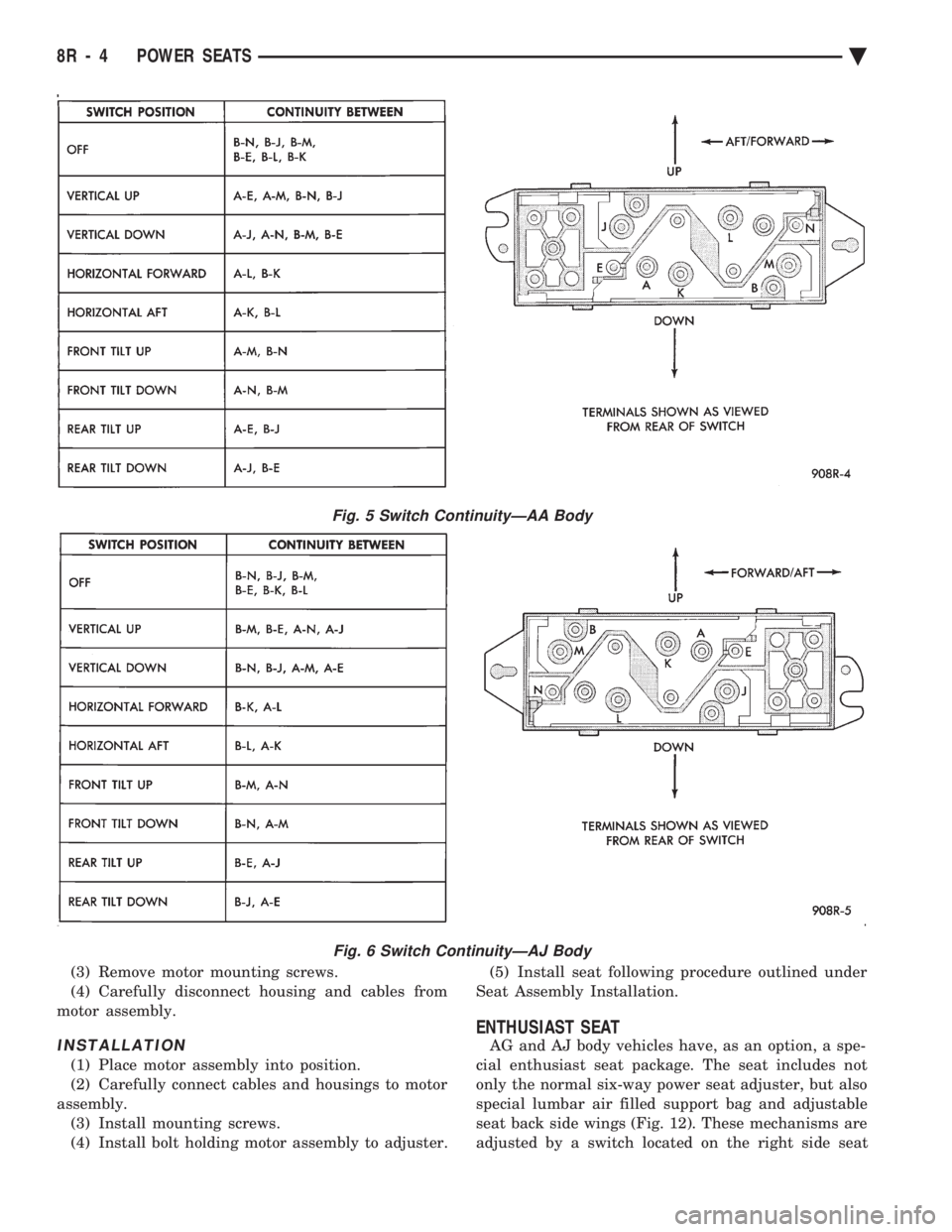

SWITCH TEST

To check the switch, remove the switch from its

mounting position. Using an ohmmeter, perform

switch continuity test (Fig. 5, 6 and 7). If there is no

continuity at any one of the switch positions, replace

the switch.

SEAT ASSEMBLY

REMOVAL

(1) Remove plastic covers.

(2) Remove adjuster attaching bolts and nuts from

floor pan. Move adjuster as required for access. (3) Disconnect battery negative cable.

(4) Disconnect wiring harness power lead at car-

pet. (5) Remove seat assembly from vehicle.

INSTALLATION

(1) Position seat assembly in vehicle.

(2) Connect wiring harness.

(3) Install and tighten mounting bolts and nuts to

28 N Im (250 in. lbs.) torque.

(4) Connect battery negative cable and check seat

operation. (5) Install plastic covers.

HORIZONTAL AND VERTICAL TRANSMISSIONS

Transmissions are not removable and no mainte-

nance is required. If transmission fails replace entire

seat adjuster assembly.

ADJUSTER

REMOVAL

(1) Remove seat assembly from vehicle following

procedure outlined under Seat Assembly Removal. (2) Lay seat on its back on some clean surface.

(3) Remove bolts attaching adjuster to seat assem-

bly (Fig. 8 Through 11). (4) Disconnect wiring harness at switch if seat

mounted switch is used. (5) Remove tie straps holding cable housing to seat

for power bench seat adjuster only.

INSTALLATION

(1) Lay seat on its back on a clean surface.

(2) Position adjuster to seat assembly and install

attaching bolts. (3) Connect wiring harness at switch and replace

tie straps where removed. (4) Install seat following procedure outlined under

Seat Assembly Installation.

MOTOR

REMOVAL

Anytime the motor, cable and housing assemblies,

or vertical and horizontal transmission assemblies,

require maintenance, the assemblies must be syn-

chronized to insure easy and proper operation. (1) Remove seat assembly from vehicle following

procedure outlined under Seat Assembly Removal

(Fig. 8 through 11). (2) Lay seat assembly on its back on a clean sur-

face.

Fig. 3 Left Power Seat SwitchÐAC & AY Bodies

Fig. 4 Right Power Seat SwitchÐAC & AY Bodies

Ä POWER SEATS 8R - 3

Page 710 of 2438

(3) Remove motor mounting screws.

(4) Carefully disconnect housing and cables from

motor assembly.

INSTALLATION

(1) Place motor assembly into position.

(2) Carefully connect cables and housings to motor

assembly. (3) Install mounting screws.

(4) Install bolt holding motor assembly to adjuster. (5) Install seat following procedure outlined under

Seat Assembly Installation.

ENTHUSIAST SEAT

AG and AJ body vehicles have, as an option, a spe-

cial enthusiast seat package. The seat includes not

only the normal six-way power seat adjuster, but also

special lumbar air filled support bag and adjustable

seat back side wings (Fig. 12). These mechanisms are

adjusted by a switch located on the right side seat

Fig. 5 Switch ContinuityÐAA Body

Fig. 6 Switch ContinuityÐAJ Body

8R - 4 POWER SEATS Ä