CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 671 of 2438

PROBLEM

Headlamp door or doors fit poorly, rattle, or bang

when coming open or closed.

CHECK:

² Headlamp door fascia mounting bracket or adjust-

able stops for improper alignment.

² Headlamp door pivot brackets or door/crank lateral

adjustment for improperly aligned collar.

² For missing or worn pivot bushings.

² For defective motor.

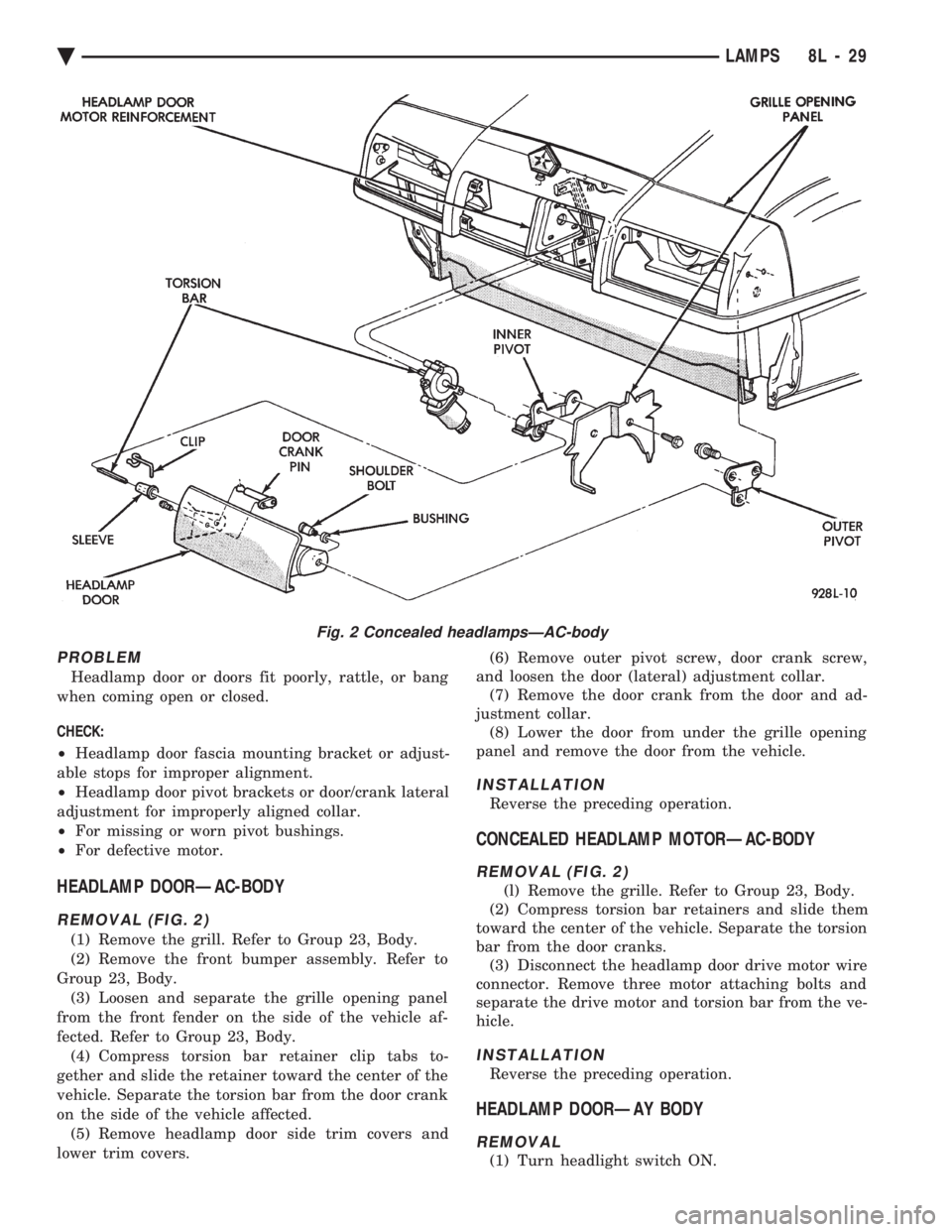

HEADLAMP DOORÐAC-BODY

REMOVAL (FIG. 2)

(1) Remove the grill. Refer to Group 23, Body.

(2) Remove the front bumper assembly. Refer to

Group 23, Body. (3) Loosen and separate the grille opening panel

from the front fender on the side of the vehicle af-

fected. Refer to Group 23, Body. (4) Compress torsion bar retainer clip tabs to-

gether and slide the retainer toward the center of the

vehicle. Separate the torsion bar from the door crank

on the side of the vehicle affected. (5) Remove headlamp door side trim covers and

lower trim covers. (6) Remove outer pivot screw, door crank screw,

and loosen the door (lateral) adjustment collar. (7) Remove the door crank from the door and ad-

justment collar. (8) Lower the door from under the grille opening

panel and remove the door from the vehicle.

INSTALLATION

Reverse the preceding operation.

CONCEALED HEADLAMP MOTORÐAC-BODY

REMOVAL (FIG. 2)

(l) Remove the grille. Refer to Group 23, Body.

(2) Compress torsion bar retainers and slide them

toward the center of the vehicle. Separate the torsion

bar from the door cranks. (3) Disconnect the headlamp door drive motor wire

connector. Remove three motor attaching bolts and

separate the drive motor and torsion bar from the ve-

hicle.

INSTALLATION

Reverse the preceding operation.

HEADLAMP DOORÐAY BODY

REMOVAL

(1) Turn headlight switch ON.

Fig. 2 Concealed headlampsÐAC-body

Ä LAMPS 8L - 29

Page 672 of 2438

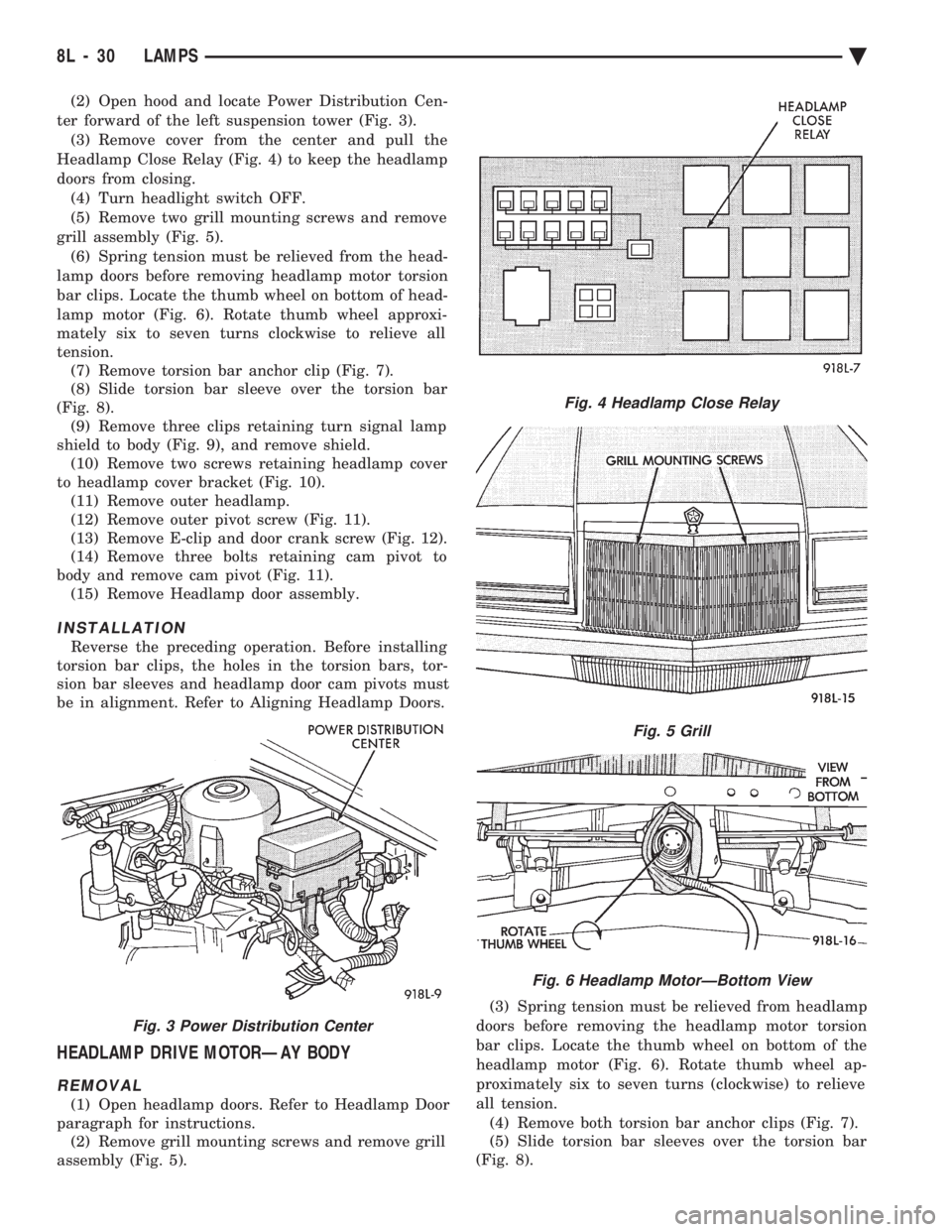

(2) Open hood and locate Power Distribution Cen-

ter forward of the left suspension tower (Fig. 3). (3) Remove cover from the center and pull the

Headlamp Close Relay (Fig. 4) to keep the headlamp

doors from closing. (4) Turn headlight switch OFF.

(5) Remove two grill mounting screws and remove

grill assembly (Fig. 5). (6) Spring tension must be relieved from the head-

lamp doors before removing headlamp motor torsion

bar clips. Locate the thumb wheel on bottom of head-

lamp motor (Fig. 6). Rotate thumb wheel approxi-

mately six to seven turns clockwise to relieve all

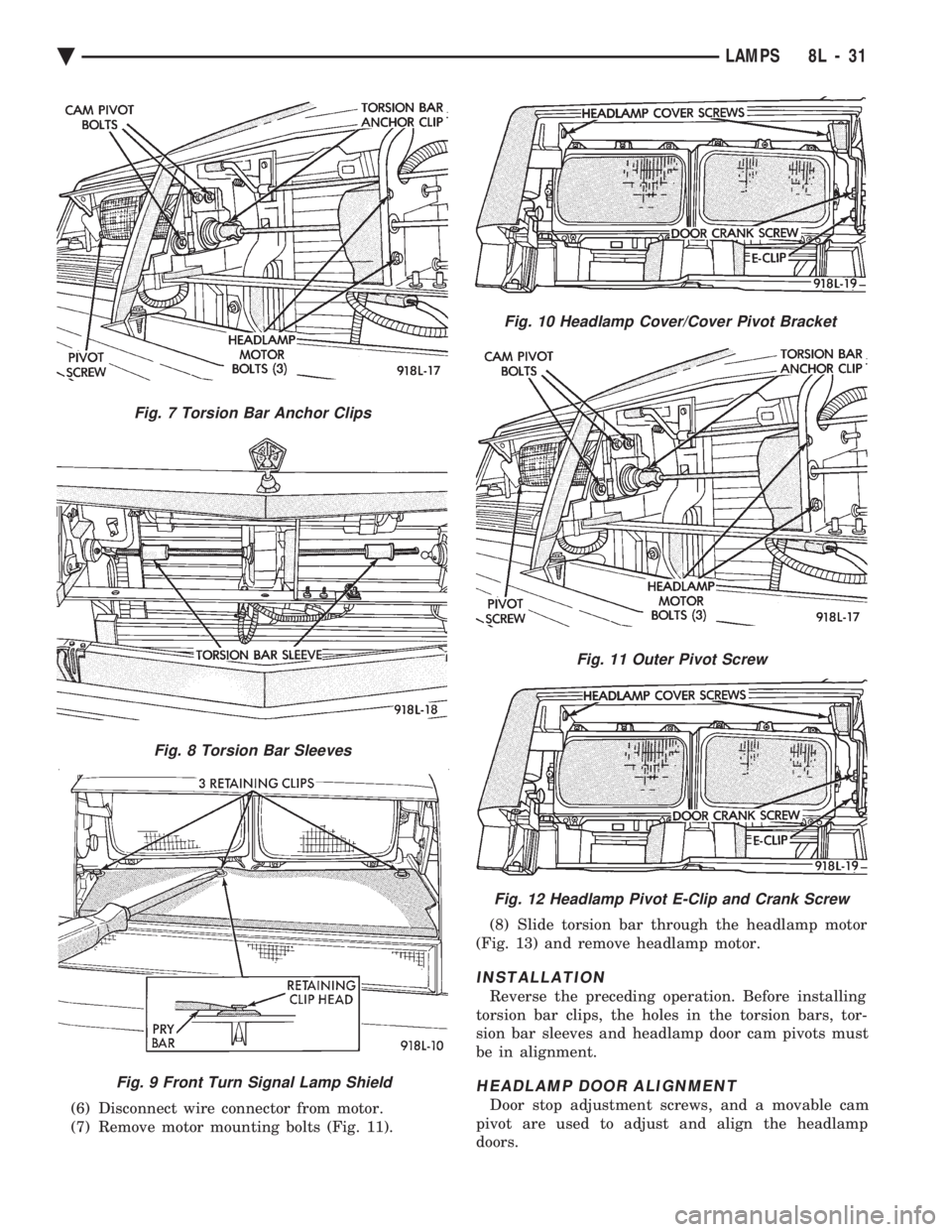

tension. (7) Remove torsion bar anchor clip (Fig. 7).

(8) Slide torsion bar sleeve over the torsion bar

(Fig. 8). (9) Remove three clips retaining turn signal lamp

shield to body (Fig. 9), and remove shield. (10) Remove two screws retaining headlamp cover

to headlamp cover bracket (Fig. 10). (11) Remove outer headlamp.

(12) Remove outer pivot screw (Fig. 11).

(13) Remove E-clip and door crank screw (Fig. 12).

(14) Remove three bolts retaining cam pivot to

body and remove cam pivot (Fig. 11). (15) Remove Headlamp door assembly.

INSTALLATION

Reverse the preceding operation. Before installing

torsion bar clips, the holes in the torsion bars, tor-

sion bar sleeves and headlamp door cam pivots must

be in alignment. Refer to Aligning Headlamp Doors.

HEADLAMP DRIVE MOTORÐAY BODY

REMOVAL

(1) Open headlamp doors. Refer to Headlamp Door

paragraph for instructions. (2) Remove grill mounting screws and remove grill

assembly (Fig. 5). (3) Spring tension must be relieved from headlamp

doors before removing the headlamp motor torsion

bar clips. Locate the thumb wheel on bottom of the

headlamp motor (Fig. 6). Rotate thumb wheel ap-

proximately six to seven turns (clockwise) to relieve

all tension. (4) Remove both torsion bar anchor clips (Fig. 7).

(5) Slide torsion bar sleeves over the torsion bar

(Fig. 8).

Fig. 3 Power Distribution Center

Fig. 4 Headlamp Close Relay

Fig. 5 Grill

Fig. 6 Headlamp MotorÐBottom View

8L - 30 LAMPS Ä

Page 673 of 2438

(6) Disconnect wire connector from motor.

(7) Remove motor mounting bolts (Fig. 11). (8) Slide torsion bar through the headlamp motor

(Fig. 13) and remove headlamp motor.

INSTALLATION

Reverse the preceding operation. Before installing

torsion bar clips, the holes in the torsion bars, tor-

sion bar sleeves and headlamp door cam pivots must

be in alignment.

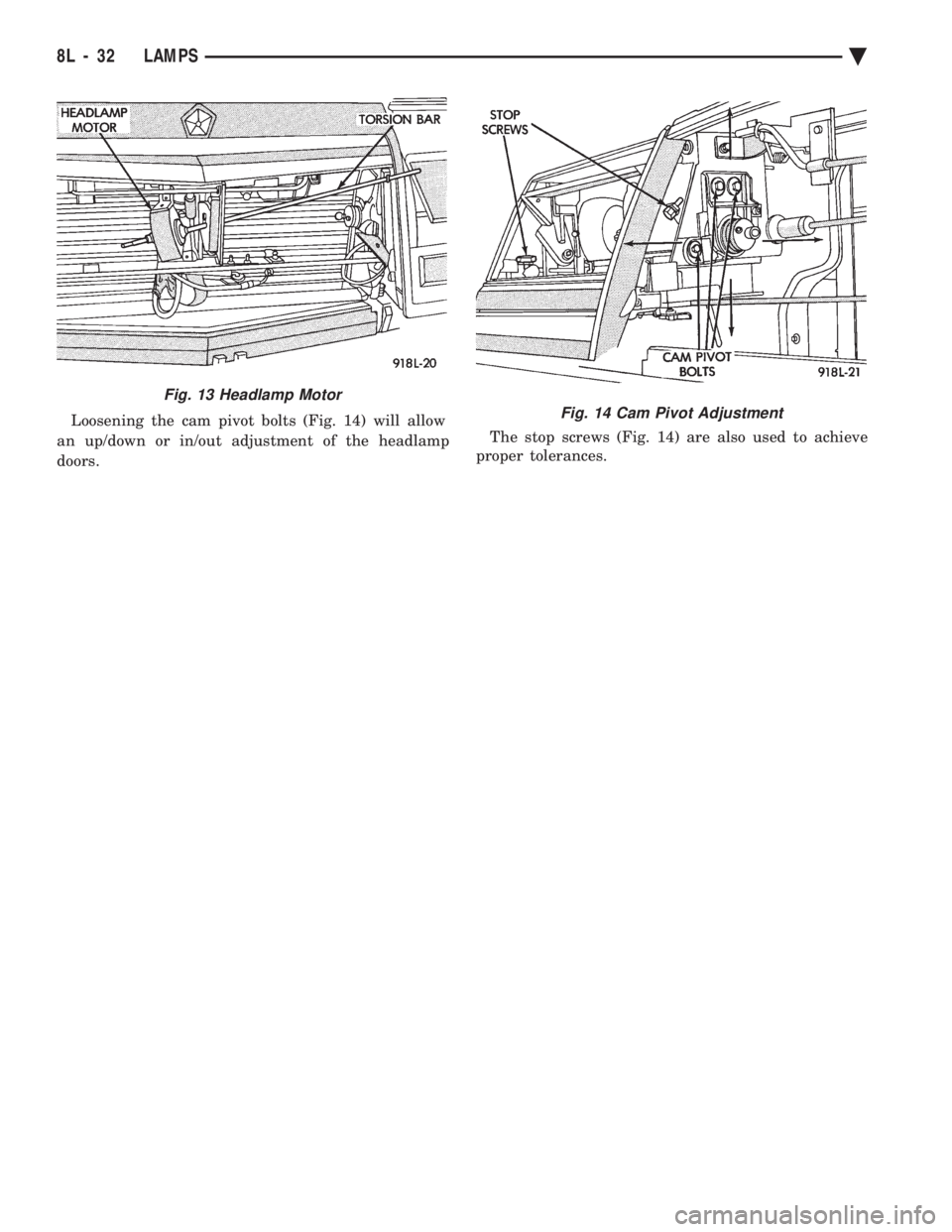

HEADLAMP DOOR ALIGNMENT

Door stop adjustment screws, and a movable cam

pivot are used to adjust and align the headlamp

doors.

Fig. 9 Front Turn Signal Lamp Shield

Fig. 10 Headlamp Cover/Cover Pivot Bracket

Fig. 7 Torsion Bar Anchor Clips

Fig. 8 Torsion Bar Sleeves

Fig. 11 Outer Pivot Screw

Fig. 12 Headlamp Pivot E-Clip and Crank Screw

Ä LAMPS 8L - 31

Page 674 of 2438

Loosening the cam pivot bolts (Fig. 14) will allow

an up/down or in/out adjustment of the headlamp

doors. The stop screws (Fig. 14) are also used to achieve

proper tolerances.

Fig. 13 Headlamp Motor

Fig. 14 Cam Pivot Adjustment

8L - 32 LAMPS Ä

Page 675 of 2438

ILLUMINATED ENTRY SYSTEM INDEX

page page

Body Controller ComputerÐAC, AG, AJ and AY-Body ............................. 34

Diagnostic ProceduresÐAA-Body ............ 33 Diagnostic ProceduresÐAC, AG, AJ and AY-Body . 33

General Information ....................... 33

Illuminated Entry ModuleÐAA-Body ........... 34

GENERAL INFORMATION

AA-BODY

The Illuminated Entry System (on AA Body) actu-

ates the interior courtesy and/or dome lamps (except

for the illuminated ignition switch) by lifting either

front door exterior handle. Lamp illumination is terminated 35 seconds ( 68

seconds later when battery voltage is normal), or by

turning the ignition switch to the run position,

whichever occurs first. When testing the system, all

vehicle doors must be closed to prevent the door jam

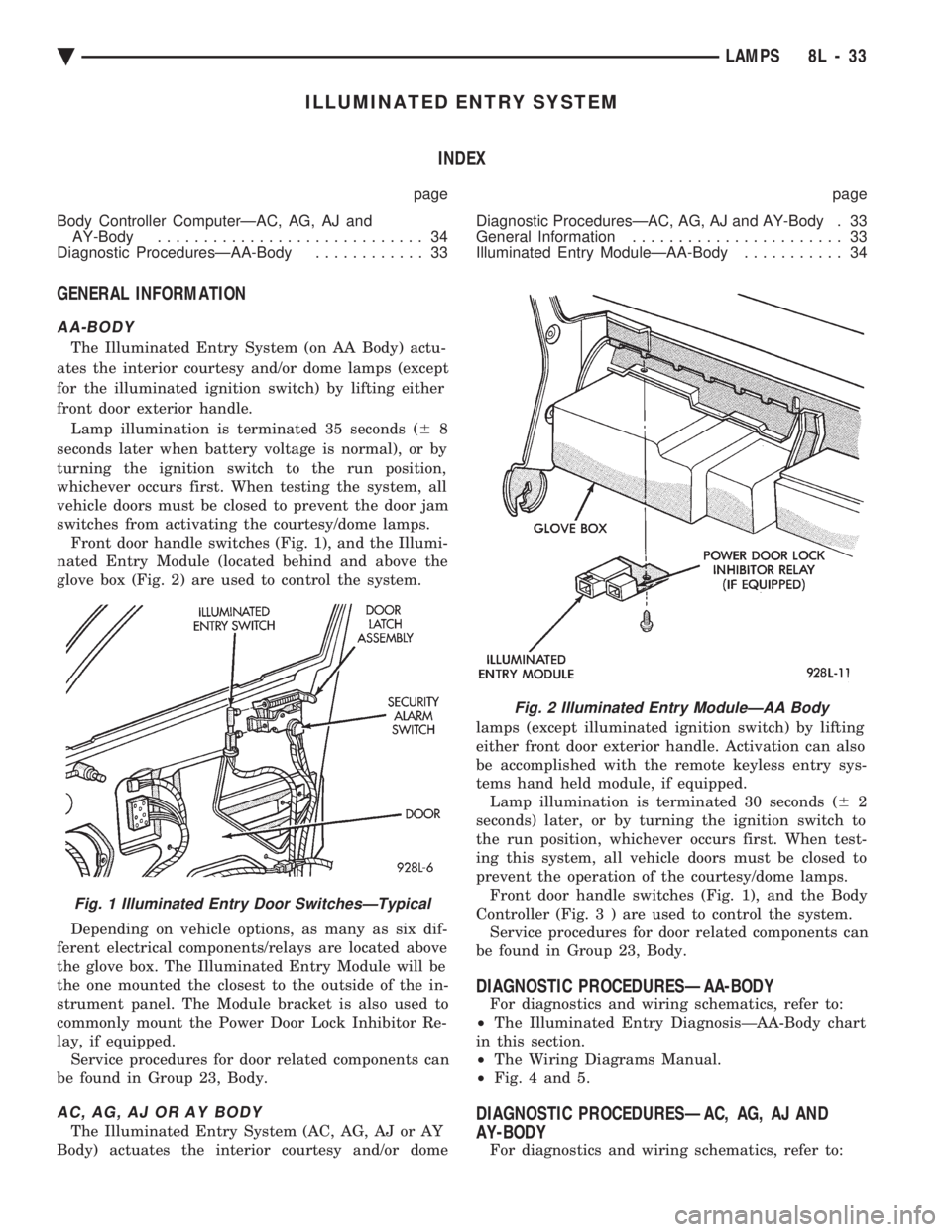

switches from activating the courtesy/dome lamps. Front door handle switches (Fig. 1), and the Illumi-

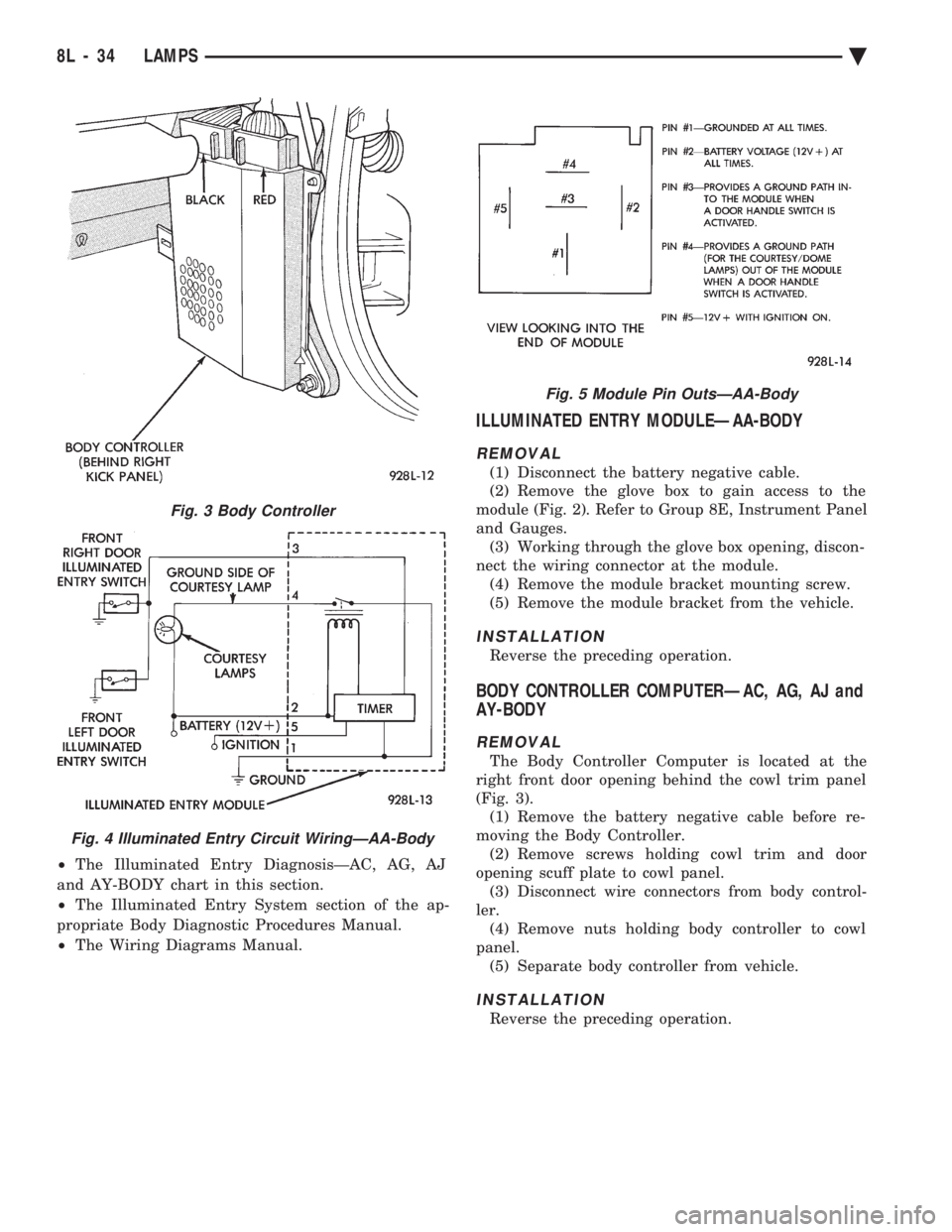

nated Entry Module (located behind and above the

glove box (Fig. 2) are used to control the system.

Depending on vehicle options, as many as six dif-

ferent electrical components/relays are located above

the glove box. The Illuminated Entry Module will be

the one mounted the closest to the outside of the in-

strument panel. The Module bracket is also used to

commonly mount the Power Door Lock Inhibitor Re-

lay, if equipped. Service procedures for door related components can

be found in Group 23, Body.

AC, AG, AJ OR AY BODY

The Illuminated Entry System (AC, AG, AJ or AY

Body) actuates the interior courtesy and/or dome lamps (except illuminated ignition switch) by lifting

either front door exterior handle. Activation can also

be accomplished with the remote keyless entry sys-

tems hand held module, if equipped. Lamp illumination is terminated 30 seconds ( 62

seconds) later, or by turning the ignition switch to

the run position, whichever occurs first. When test-

ing this system, all vehicle doors must be closed to

prevent the operation of the courtesy/dome lamps. Front door handle switches (Fig. 1), and the Body

Controller (Fig . 3 ) are used to control the system.

Service procedures for door related components can

be found in Group 23, Body.

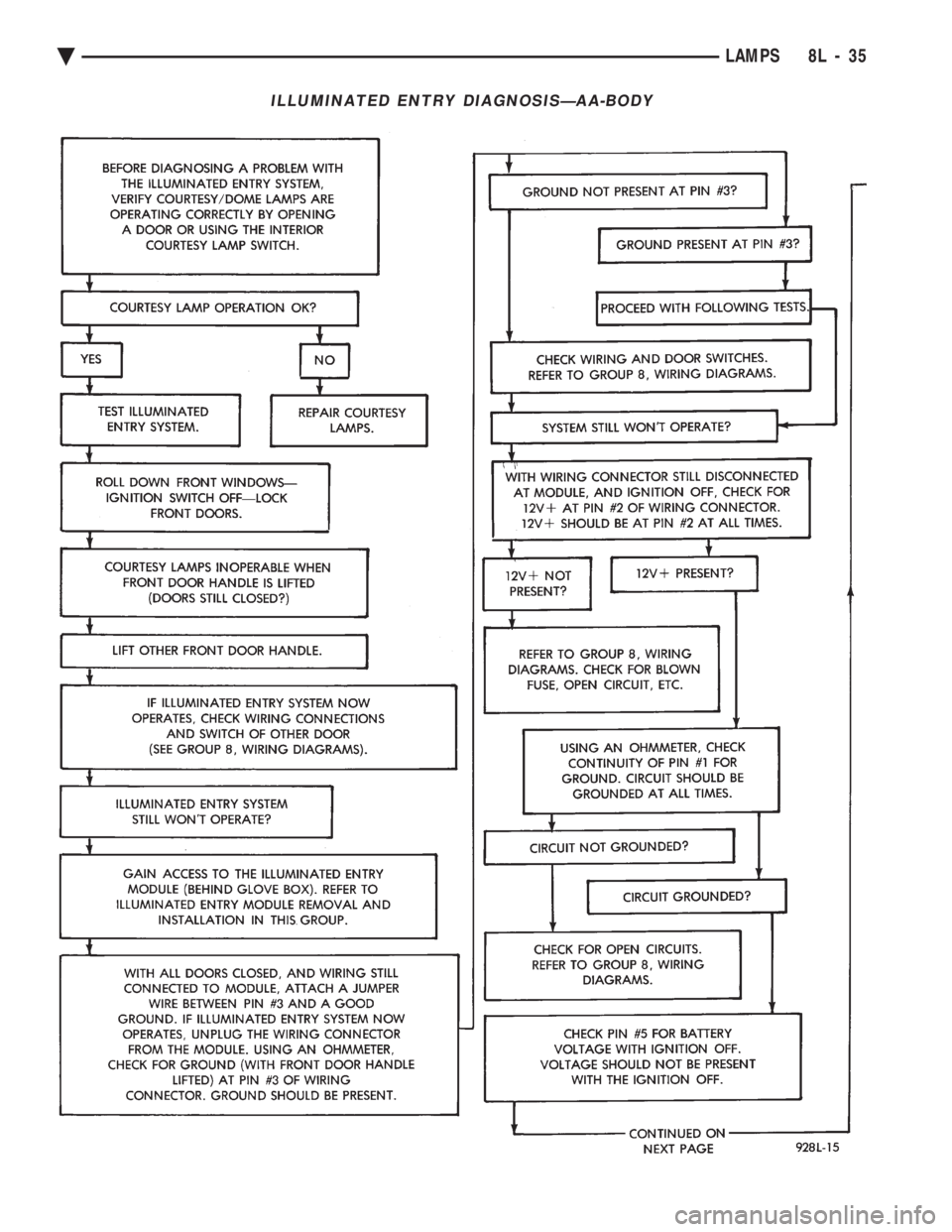

DIAGNOSTIC PROCEDURESÐAA-BODY

For diagnostics and wiring schematics, refer to:

² The Illuminated Entry DiagnosisÐAA-Body chart

in this section.

² The Wiring Diagrams Manual.

² Fig. 4 and 5.

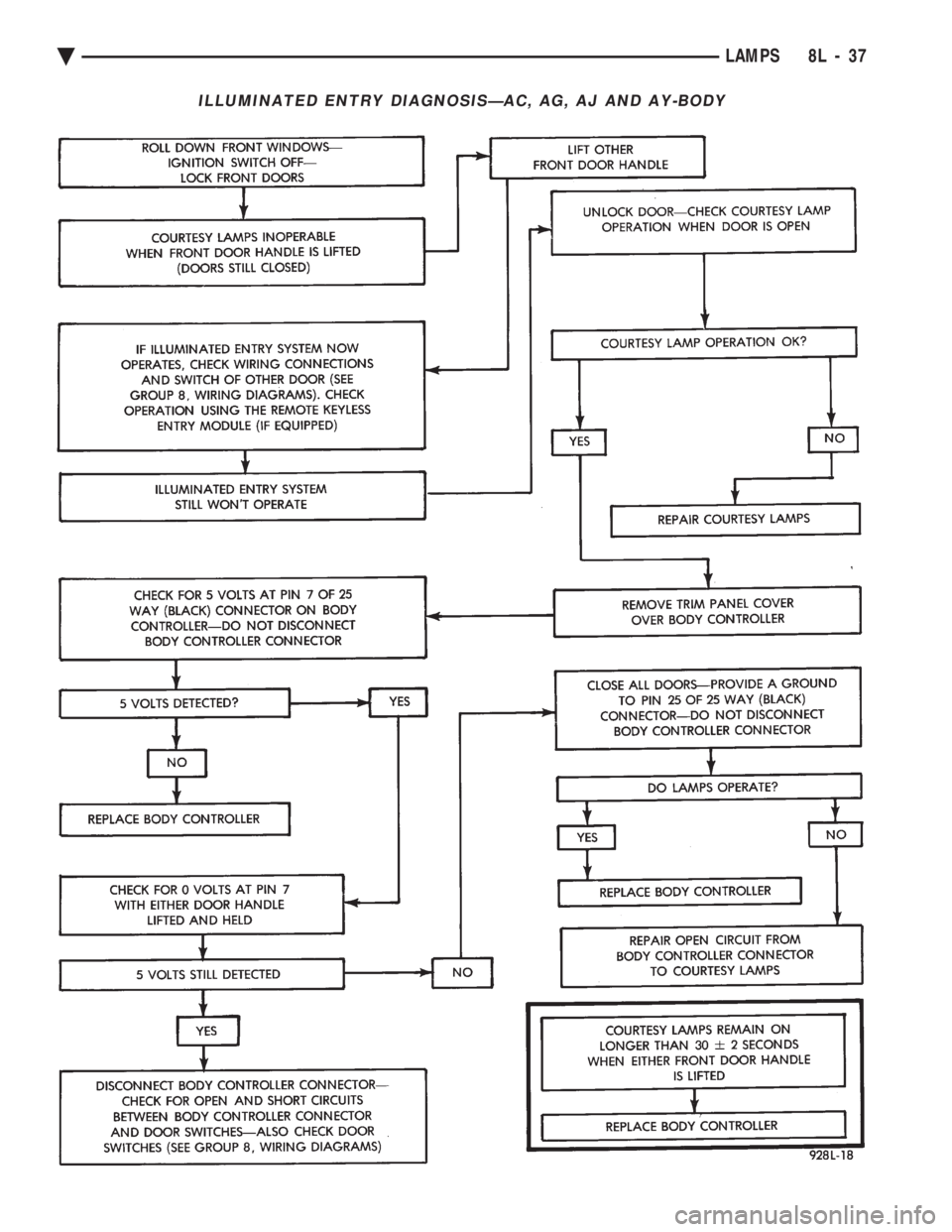

DIAGNOSTIC PROCEDURESÐAC, AG, AJ AND

AY-BODY

For diagnostics and wiring schematics, refer to:

Fig. 1 Illuminated Entry Door SwitchesÐTypical

Fig. 2 Illuminated Entry ModuleÐAA Body

Ä LAMPS 8L - 33

Page 676 of 2438

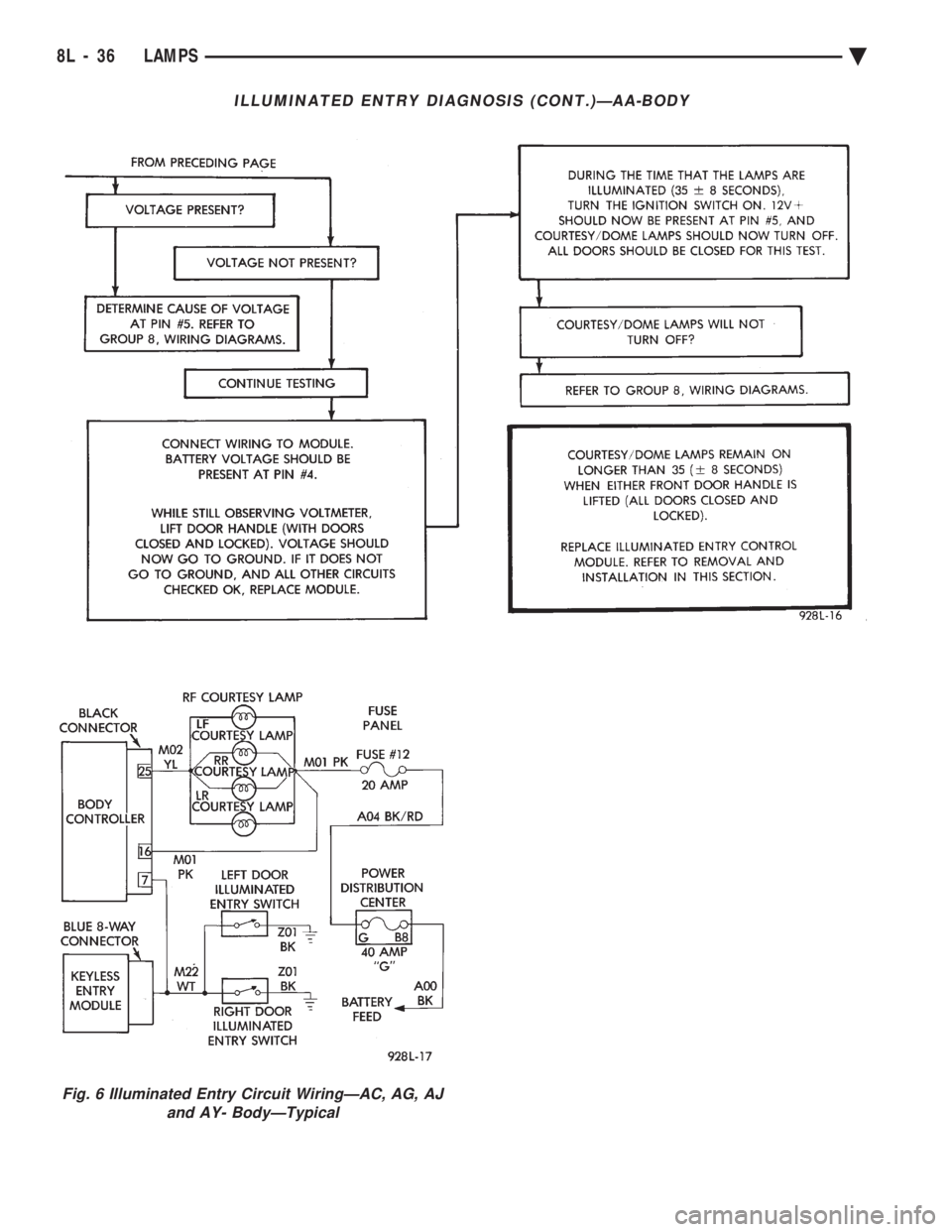

² The Illuminated Entry DiagnosisÐAC, AG, AJ

and AY-BODY chart in this section.

² The Illuminated Entry System section of the ap-

propriate Body Diagnostic Procedures Manual.

² The Wiring Diagrams Manual.

ILLUMINATED ENTRY MODULEÐAA-BODY

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the glove box to gain access to the

module (Fig. 2). Refer to Group 8E, Instrument Panel

and Gauges. (3) Working through the glove box opening, discon-

nect the wiring connector at the module. (4) Remove the module bracket mounting screw.

(5) Remove the module bracket from the vehicle.

INSTALLATION

Reverse the preceding operation.

BODY CONTROLLER COMPUTERÐAC, AG, AJ and

AY-BODY

REMOVAL

The Body Controller Computer is located at the

right front door opening behind the cowl trim panel

(Fig. 3). (1) Remove the battery negative cable before re-

moving the Body Controller. (2) Remove screws holding cowl trim and door

opening scuff plate to cowl panel. (3) Disconnect wire connectors from body control-

ler. (4) Remove nuts holding body controller to cowl

panel. (5) Separate body controller from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 3 Body Controller

Fig. 4 Illuminated Entry Circuit WiringÐAA-Body

Fig. 5 Module Pin OutsÐAA-Body

8L - 34 LAMPS Ä

Page 677 of 2438

ILLUMINATED ENTRY DIAGNOSISÐAA-BODY

Ä LAMPS 8L - 35

Page 678 of 2438

ILLUMINATED ENTRY DIAGNOSIS (CONT.)ÐAA-BODY

Fig. 6 Illuminated Entry Circuit WiringÐAC, AG, AJ and AY- BodyÐTypical

8L - 36 LAMPS Ä

Page 679 of 2438

ILLUMINATED ENTRY DIAGNOSISÐAC, AG, AJ AND AY-BODY

Ä LAMPS 8L - 37

Page 680 of 2438

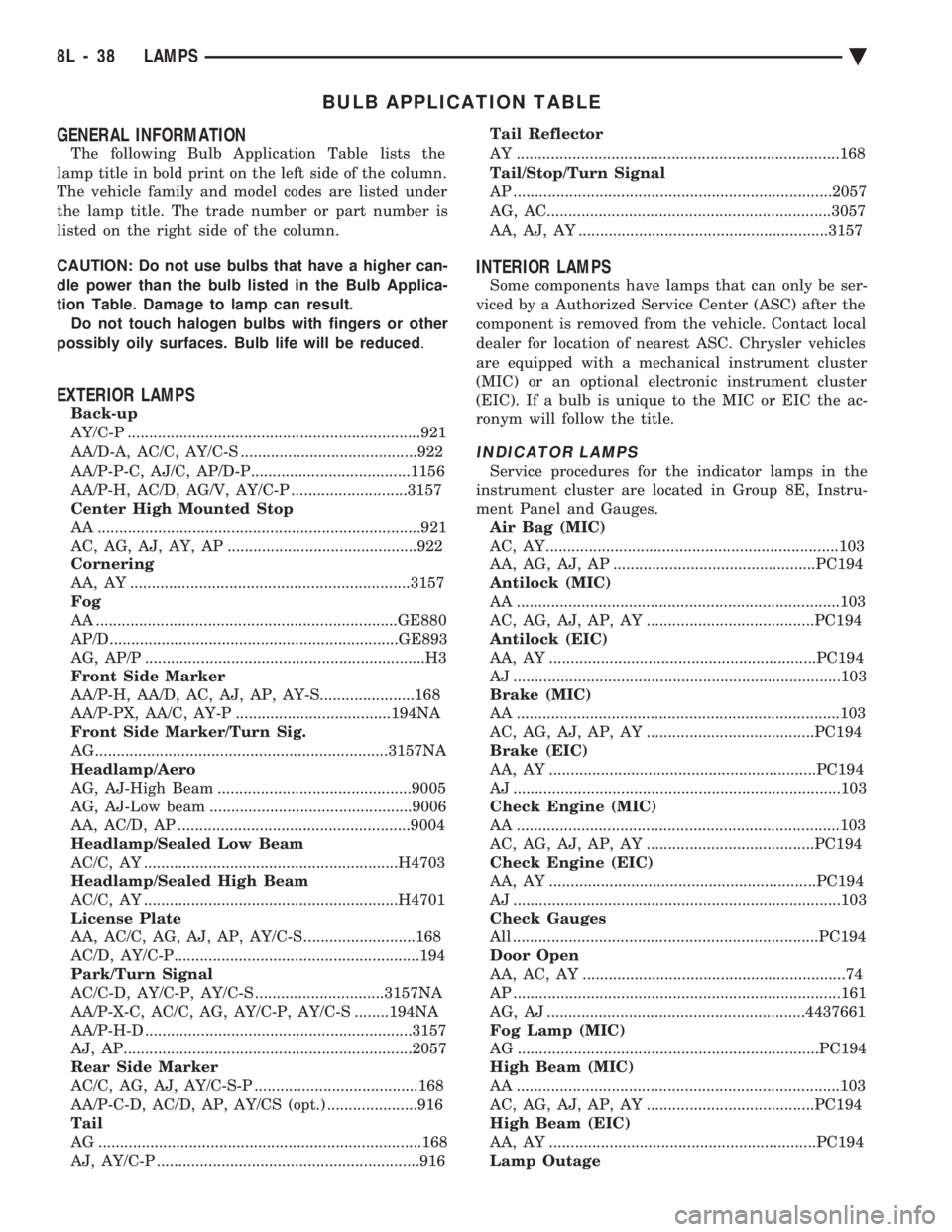

BULB APPLICATION TABLE

GENERAL INFORMATION

The following Bulb Application Table lists the

lamp title in bold print on the left side of the column.

The vehicle family and model codes are listed under

the lamp title. The trade number or part number is

listed on the right side of the column.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the Bulb Applica-

tion Table. Damage to lamp can result. Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced .

EXTERIOR LAMPS

Back-up

AY/C-P ....................................................................921

AA/D-A, AC/C, AY/C-S .........................................922

AA/P-P-C, AJ/C, AP/D-P.....................................1156

AA/P-H, AC/D, AG/V, AY/C-P ...........................3157

Center High Mounted Stop

AA ...........................................................................921

AC, AG, AJ, AY, AP ............................................922

Cornering

AA, AY .................................................................3157

Fog

AA ......................................................................GE880

AP/D...................................................................GE893

AG, AP/P .................................................................H3

Front Side Marker

AA/P-H, AA/D, AC, AJ, AP, AY-S......................168

AA/P-PX, AA/C, AY-P ....................................194NA

Front Side Marker/Turn Sig.

AG....................................................................3157NA

Headlamp/Aero

AG, AJ-High Beam .............................................9005

AG, AJ-Low beam ...............................................9006

AA, AC/D, AP ......................................................9004

Headlamp/Sealed Low Beam

AC/C, AY ...........................................................H4703

Headlamp/Sealed High Beam

AC/C, AY ...........................................................H4701

License Plate

AA, AC/C, AG, AJ, AP, AY/C-S ..........................168

AC/D, AY/C-P.........................................................194

Park/Turn Signal

AC/C-D, AY/C-P, AY/C-S ..............................3157NA

AA/P-X-C, AC/C, AG, AY/C-P, AY/C-S ........194NA

AA/P-H-D ..............................................................3157

AJ, AP...................................................................2057

Rear Side Marker

AC/C, AG, AJ, AY/C-S-P ......................................168

AA/P-C-D, AC/D, AP, AY/CS (opt.) .....................916

Tail

AG ...........................................................................168

AJ, AY/C-P .............................................................916 Tail Reflector

AY ...........................................................................168

Tail/Stop/Turn Signal

AP ..........................................................................2057

AG, AC..................................................................3057

AA, AJ, AY ..........................................................3157

INTERIOR LAMPS

Some components have lamps that can only be ser-

viced by a Authorized Service Center (ASC) after the

component is removed from the vehicle. Contact local

dealer for location of nearest ASC. Chrysler vehicles

are equipped with a mechanical instrument cluster

(MIC) or an optional electronic instrument cluster

(EIC). If a bulb is unique to the MIC or EIC the ac-

ronym will follow the title.

INDICATOR LAMPS

Service procedures for the indicator lamps in the

instrument cluster are located in Group 8E, Instru-

ment Panel and Gauges. Air Bag (MIC)

AC, AY....................................................................103

AA, AG, AJ, AP ...............................................PC194

Antilock (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Antilock (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

Brake (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Brake (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

Check Engine (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Check Engine (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

Check Gauges

All .......................................................................PC194

Door Open

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Fog Lamp (MIC)

AG ......................................................................PC194

High Beam (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

High Beam (EIC)

AA, AY ..............................................................PC194

Lamp Outage

8L - 38 LAMPS Ä