CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 661 of 2438

EXTERIOR LAMPSÐAP BODY INDEX

page page

Center High Mounted Stop Lamp (CHMSL)Ð AP/24-44-Body ......................... 21

Center High Mounted Stop Lamp BulbÐ AP/24-44-Body ......................... 21

Fog Lamp Bulb .......................... 21

Fog Lamps ............................. 21

Front Side Marker Lamp or Bulb ............. 20

Headlamp Bulb .......................... 19 Headlamp Diagnosis

...................... 19

Headlamp Housing ....................... 19

License Plate Lamp or Bulb ................ 20

Park and Turn Signal Lamp or Bulb .......... 20

Tail, Stop, Turn Signal, Back-Up and Side Marker Lamp ................................ 20

Tail, Stop, Turn Signal, Back-Up and Side Marker Lamp Bulbs ........................... 20

HEADLAMP DIAGNOSIS

For headlamp diagnosis, refer to the headlamp di-

agnosis chart at the beginning of this group. Refer to

Wiring Diagrams manual for circuit and component

locations.

HEADLAMP BULB

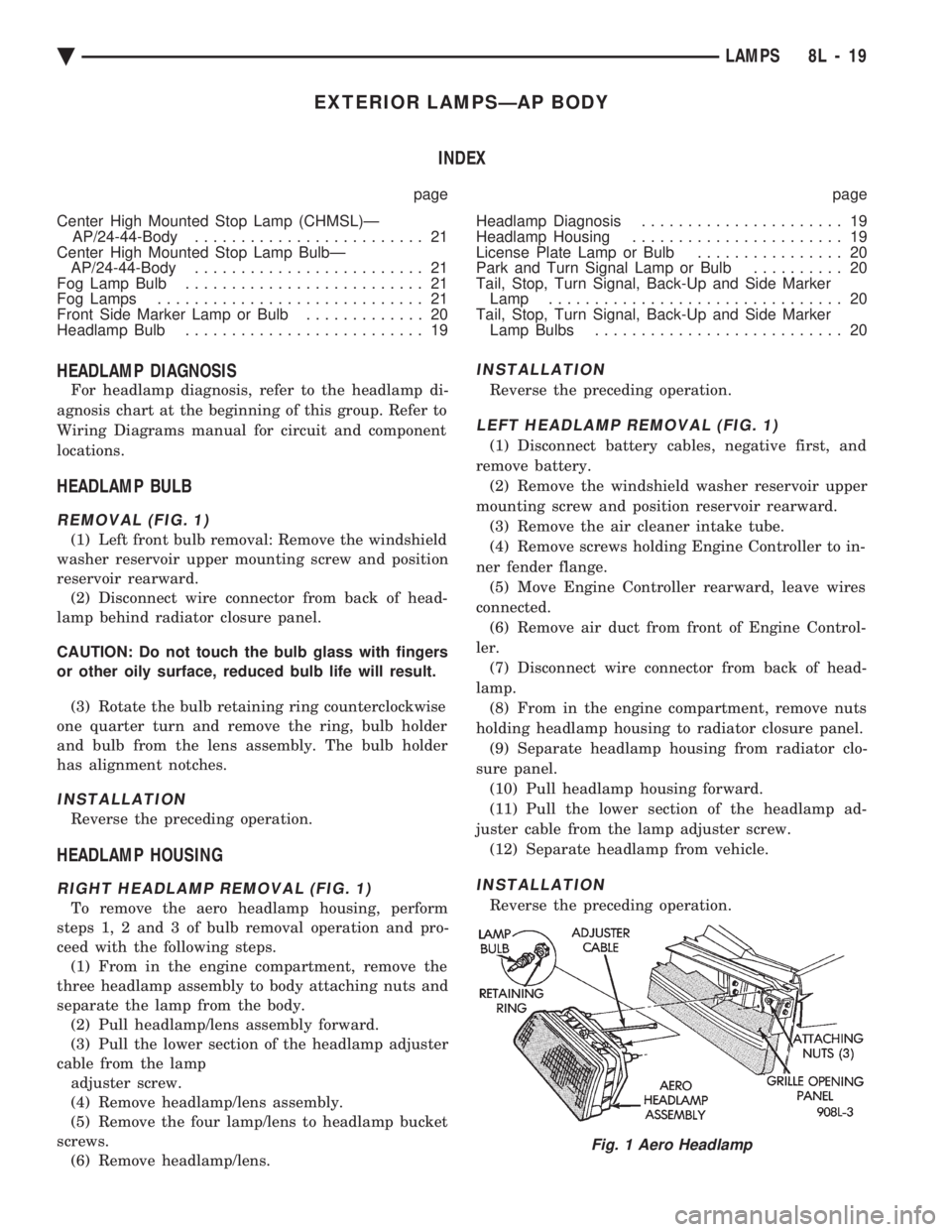

REMOVAL (FIG. 1)

(1) Left front bulb removal: Remove the windshield

washer reservoir upper mounting screw and position

reservoir rearward. (2) Disconnect wire connector from back of head-

lamp behind radiator closure panel.

CAUTION: Do not touch the bulb glass with fingers

or other oily surface, reduced bulb life will result.

(3) Rotate the bulb retaining ring counterclockwise

one quarter turn and remove the ring, bulb holder

and bulb from the lens assembly. The bulb holder

has alignment notches.

INSTALLATION

Reverse the preceding operation.

HEADLAMP HOUSING

RIGHT HEADLAMP REMOVAL (FIG. 1)

To remove the aero headlamp housing, perform

steps 1, 2 and 3 of bulb removal operation and pro-

ceed with the following steps. (1) From in the engine compartment, remove the

three headlamp assembly to body attaching nuts and

separate the lamp from the body. (2) Pull headlamp/lens assembly forward.

(3) Pull the lower section of the headlamp adjuster

cable from the lamp adjuster screw.

(4) Remove headlamp/lens assembly.

(5) Remove the four lamp/lens to headlamp bucket

screws. (6) Remove headlamp/lens.

INSTALLATION

Reverse the preceding operation.

LEFT HEADLAMP REMOVAL (FIG. 1)

(1) Disconnect battery cables, negative first, and

remove battery. (2) Remove the windshield washer reservoir upper

mounting screw and position reservoir rearward. (3) Remove the air cleaner intake tube.

(4) Remove screws holding Engine Controller to in-

ner fender flange. (5) Move Engine Controller rearward, leave wires

connected. (6) Remove air duct from front of Engine Control-

ler. (7) Disconnect wire connector from back of head-

lamp. (8) From in the engine compartment, remove nuts

holding headlamp housing to radiator closure panel. (9) Separate headlamp housing from radiator clo-

sure panel. (10) Pull headlamp housing forward.

(11) Pull the lower section of the headlamp ad-

juster cable from the lamp adjuster screw. (12) Separate headlamp from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 1 Aero Headlamp

Ä LAMPS 8L - 19

Page 662 of 2438

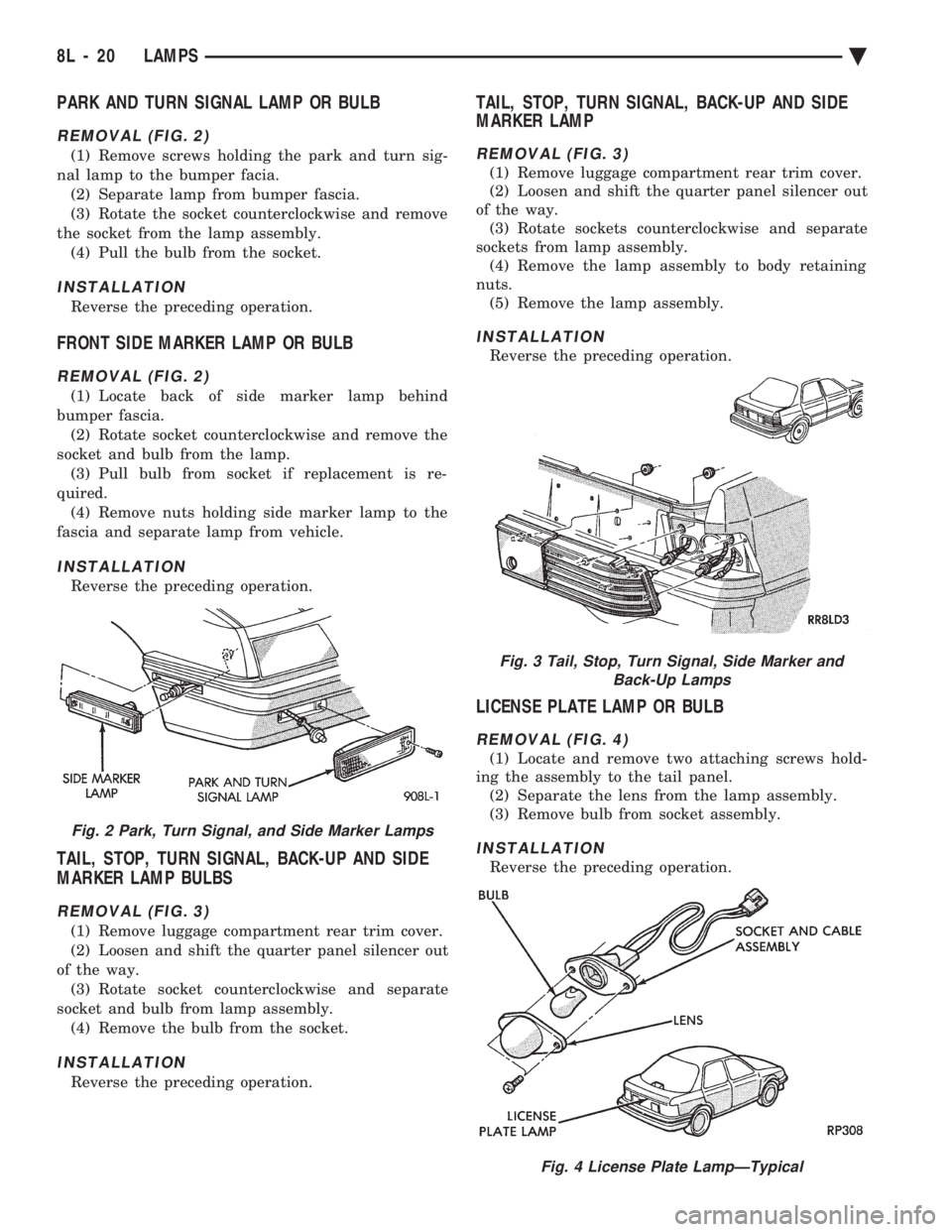

PARK AND TURN SIGNAL LAMP OR BULB

REMOVAL (FIG. 2)

(1) Remove screws holding the park and turn sig-

nal lamp to the bumper facia. (2) Separate lamp from bumper fascia.

(3) Rotate the socket counterclockwise and remove

the socket from the lamp assembly. (4) Pull the bulb from the socket.

INSTALLATION

Reverse the preceding operation.

FRONT SIDE MARKER LAMP OR BULB

REMOVAL (FIG. 2)

(1) Locate back of side marker lamp behind

bumper fascia. (2) Rotate socket counterclockwise and remove the

socket and bulb from the lamp. (3) Pull bulb from socket if replacement is re-

quired. (4) Remove nuts holding side marker lamp to the

fascia and separate lamp from vehicle.

INSTALLATION

Reverse the preceding operation.

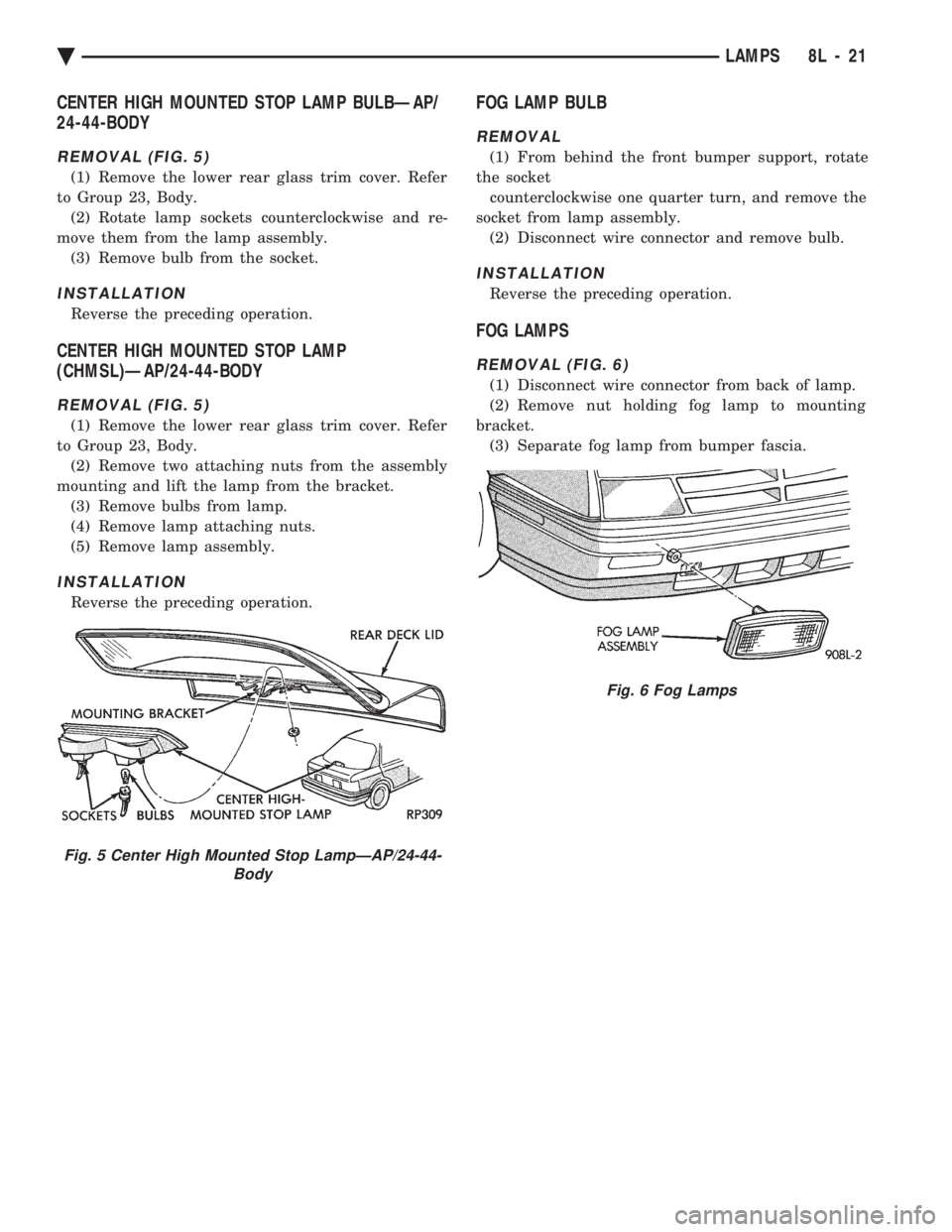

TAIL, STOP, TURN SIGNAL, BACK-UP AND SIDE

MARKER LAMP BULBS

REMOVAL (FIG. 3)

(1) Remove luggage compartment rear trim cover.

(2) Loosen and shift the quarter panel silencer out

of the way. (3) Rotate socket counterclockwise and separate

socket and bulb from lamp assembly. (4) Remove the bulb from the socket.

INSTALLATION

Reverse the preceding operation.

TAIL, STOP, TURN SIGNAL, BACK-UP AND SIDE

MARKER LAMP

REMOVAL (FIG. 3)

(1) Remove luggage compartment rear trim cover.

(2) Loosen and shift the quarter panel silencer out

of the way. (3) Rotate sockets counterclockwise and separate

sockets from lamp assembly. (4) Remove the lamp assembly to body retaining

nuts. (5) Remove the lamp assembly.

INSTALLATION

Reverse the preceding operation.

LICENSE PLATE LAMP OR BULB

REMOVAL (FIG. 4)

(1) Locate and remove two attaching screws hold-

ing the assembly to the tail panel. (2) Separate the lens from the lamp assembly.

(3) Remove bulb from socket assembly.

INSTALLATION

Reverse the preceding operation.

Fig. 2 Park, Turn Signal, and Side Marker Lamps

Fig. 3 Tail, Stop, Turn Signal, Side Marker and Back-Up Lamps

Fig. 4 License Plate LampÐTypical

8L - 20 LAMPS Ä

Page 663 of 2438

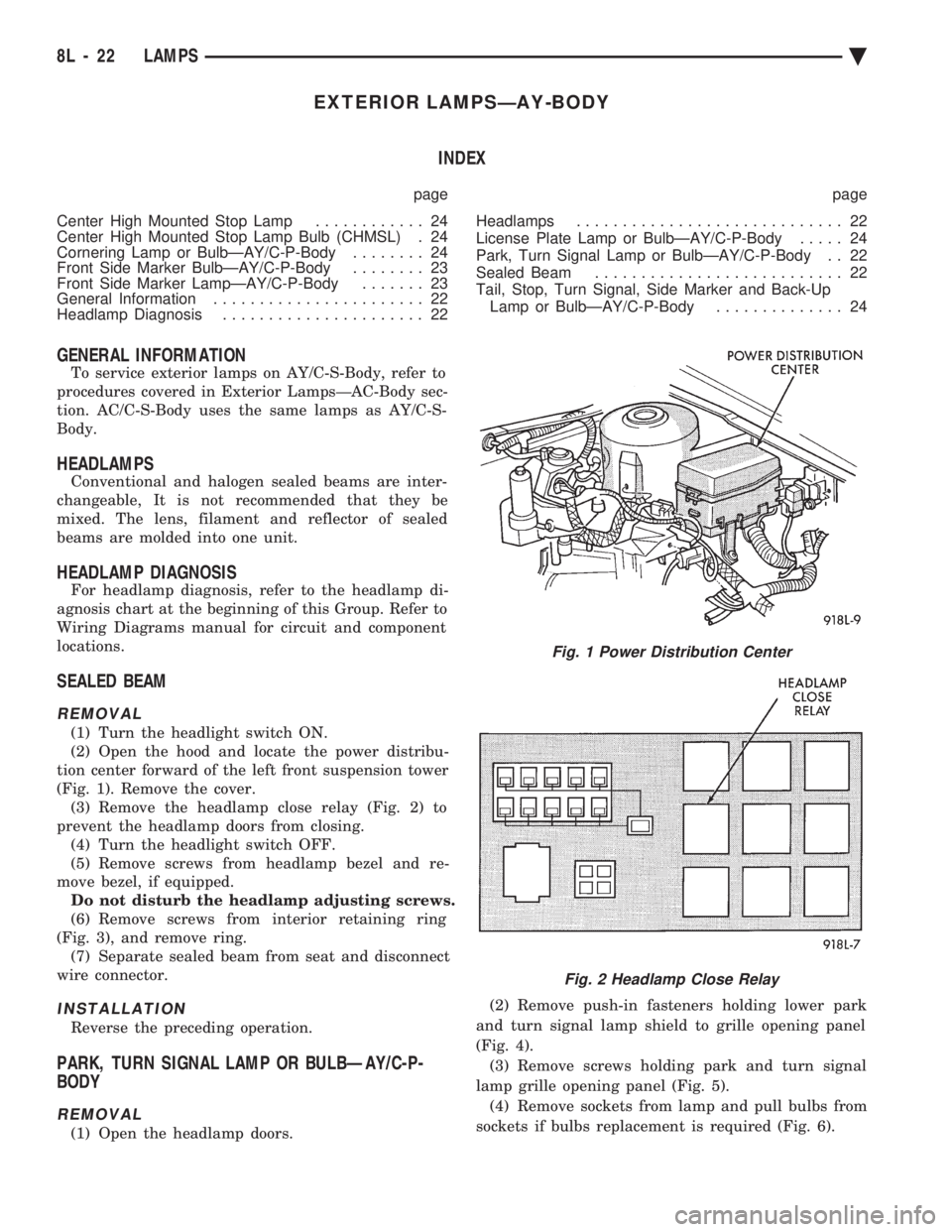

CENTER HIGH MOUNTED STOP LAMP BULBÐAP/

24-44-BODY

REMOVAL (FIG. 5)

(1) Remove the lower rear glass trim cover. Refer

to Group 23, Body. (2) Rotate lamp sockets counterclockwise and re-

move them from the lamp assembly. (3) Remove bulb from the socket.

INSTALLATION

Reverse the preceding operation.

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐAP/24-44-BODY

REMOVAL (FIG. 5)

(1) Remove the lower rear glass trim cover. Refer

to Group 23, Body. (2) Remove two attaching nuts from the assembly

mounting and lift the lamp from the bracket. (3) Remove bulbs from lamp.

(4) Remove lamp attaching nuts.

(5) Remove lamp assembly.

INSTALLATION

Reverse the preceding operation.

FOG LAMP BULB

REMOVAL

(1) From behind the front bumper support, rotate

the socket counterclockwise one quarter turn, and remove the

socket from lamp assembly. (2) Disconnect wire connector and remove bulb.

INSTALLATION

Reverse the preceding operation.

FOG LAMPS

REMOVAL (FIG. 6)

(1) Disconnect wire connector from back of lamp.

(2) Remove nut holding fog lamp to mounting

bracket. (3) Separate fog lamp from bumper fascia.

Fig. 5 Center High Mounted Stop LampÐAP/24-44- Body

Fig. 6 Fog Lamps

Ä LAMPS 8L - 21

Page 664 of 2438

EXTERIOR LAMPSÐAY-BODY INDEX

page page

Center High Mounted Stop Lamp ............ 24

Center High Mounted Stop Lamp Bulb (CHMSL) . 24

Cornering Lamp or BulbÐAY/C-P-Body ........ 24

Front Side Marker BulbÐAY/C-P-Body ........ 23

Front Side Marker LampÐAY/C-P-Body ....... 23

General Information ....................... 22

Headlamp Diagnosis ...................... 22 Headlamps

............................. 22

License Plate Lamp or BulbÐAY/C-P-Body ..... 24

Park, Turn Signal Lamp or BulbÐAY/C-P-Body . . 22

Sealed Beam ........................... 22

Tail, Stop, Turn Signal, Side Marker and Back-Up Lamp or BulbÐAY/C-P-Body .............. 24

GENERAL INFORMATION

To service exterior lamps on AY/C-S-Body, refer to

procedures covered in Exterior LampsÐAC-Body sec-

tion. AC/C-S-Body uses the same lamps as AY/C-S-

Body.

HEADLAMPS

Conventional and halogen sealed beams are inter-

changeable, It is not recommended that they be

mixed. The lens, filament and reflector of sealed

beams are molded into one unit.

HEADLAMP DIAGNOSIS

For headlamp diagnosis, refer to the headlamp di-

agnosis chart at the beginning of this Group. Refer to

Wiring Diagrams manual for circuit and component

locations.

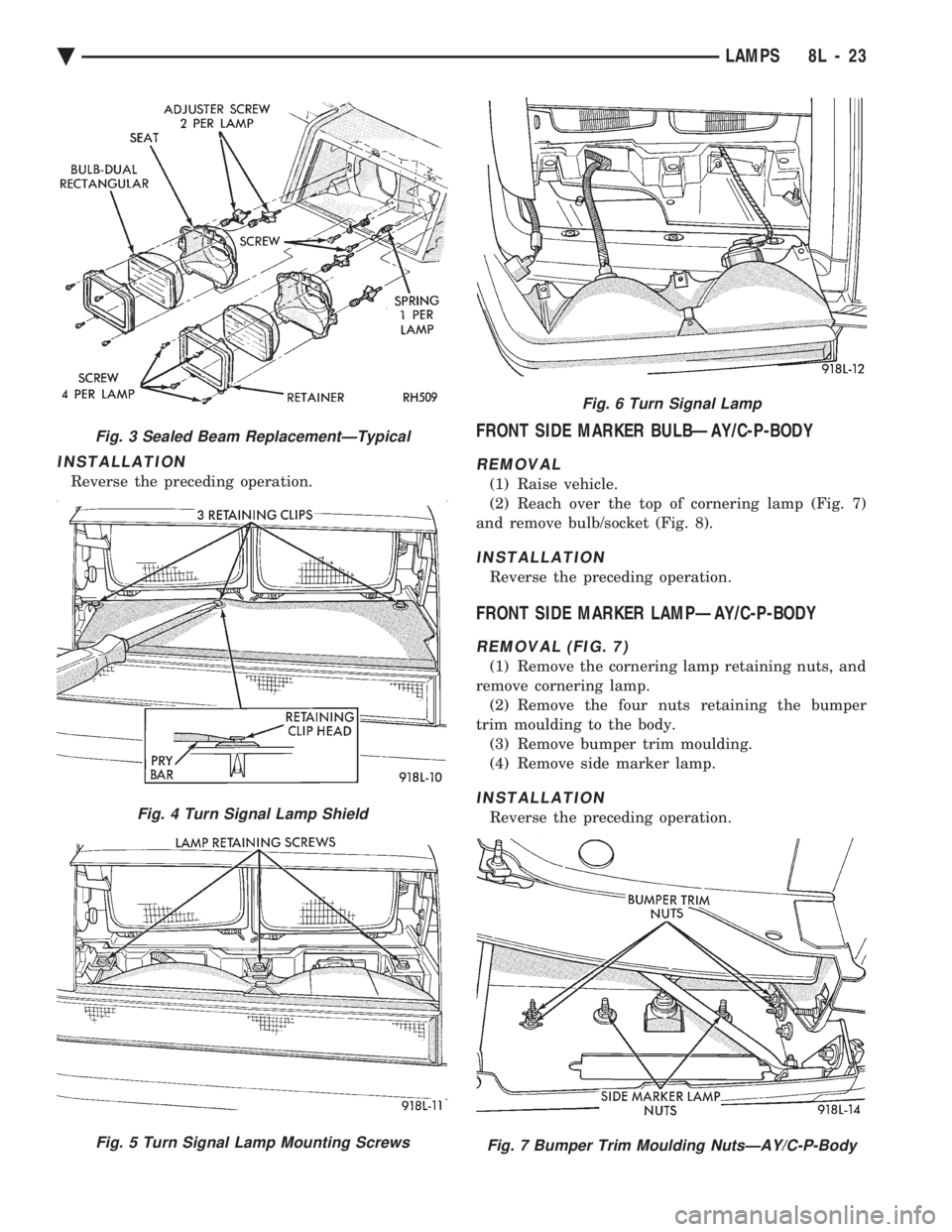

SEALED BEAM

REMOVAL

(1) Turn the headlight switch ON.

(2) Open the hood and locate the power distribu-

tion center forward of the left front suspension tower

(Fig. 1). Remove the cover. (3) Remove the headlamp close relay (Fig. 2) to

prevent the headlamp doors from closing. (4) Turn the headlight switch OFF.

(5) Remove screws from headlamp bezel and re-

move bezel, if equipped. Do not disturb the headlamp adjusting screws.

(6) Remove screws from interior retaining ring

(Fig. 3), and remove ring. (7) Separate sealed beam from seat and disconnect

wire connector.

INSTALLATION

Reverse the preceding operation.

PARK, TURN SIGNAL LAMP OR BULBÐAY/C-P-

BODY

REMOVAL

(1) Open the headlamp doors. (2) Remove push-in fasteners holding lower park

and turn signal lamp shield to grille opening panel

(Fig. 4). (3) Remove screws holding park and turn signal

lamp grille opening panel (Fig. 5). (4) Remove sockets from lamp and pull bulbs from

sockets if bulbs replacement is required (Fig. 6).

Fig. 1 Power Distribution Center

Fig. 2 Headlamp Close Relay

8L - 22 LAMPS Ä

Page 665 of 2438

INSTALLATION

Reverse the preceding operation.

FRONT SIDE MARKER BULBÐAY/C-P-BODY

REMOVAL

(1) Raise vehicle.

(2) Reach over the top of cornering lamp (Fig. 7)

and remove bulb/socket (Fig. 8).

INSTALLATION

Reverse the preceding operation.

FRONT SIDE MARKER LAMPÐAY/C-P-BODY

REMOVAL (FIG. 7)

(1) Remove the cornering lamp retaining nuts, and

remove cornering lamp. (2) Remove the four nuts retaining the bumper

trim moulding to the body. (3) Remove bumper trim moulding.

(4) Remove side marker lamp.

INSTALLATION

Reverse the preceding operation.

Fig. 3 Sealed Beam ReplacementÐTypical

Fig. 4 Turn Signal Lamp Shield

Fig. 5 Turn Signal Lamp Mounting Screws

Fig. 6 Turn Signal Lamp

Fig. 7 Bumper Trim Moulding NutsÐAY/C-P-Body

Ä LAMPS 8L - 23

Page 666 of 2438

CORNERING LAMP OR BULBÐAY/C-P-BODY

REMOVAL (FIG. 8)

(1) Raise vehicle.

(2) Remove bulb.

(3) To remove lamp assembly, remove the two re-

taining nuts.

INSTALLATION

Reverse the preceding operation.

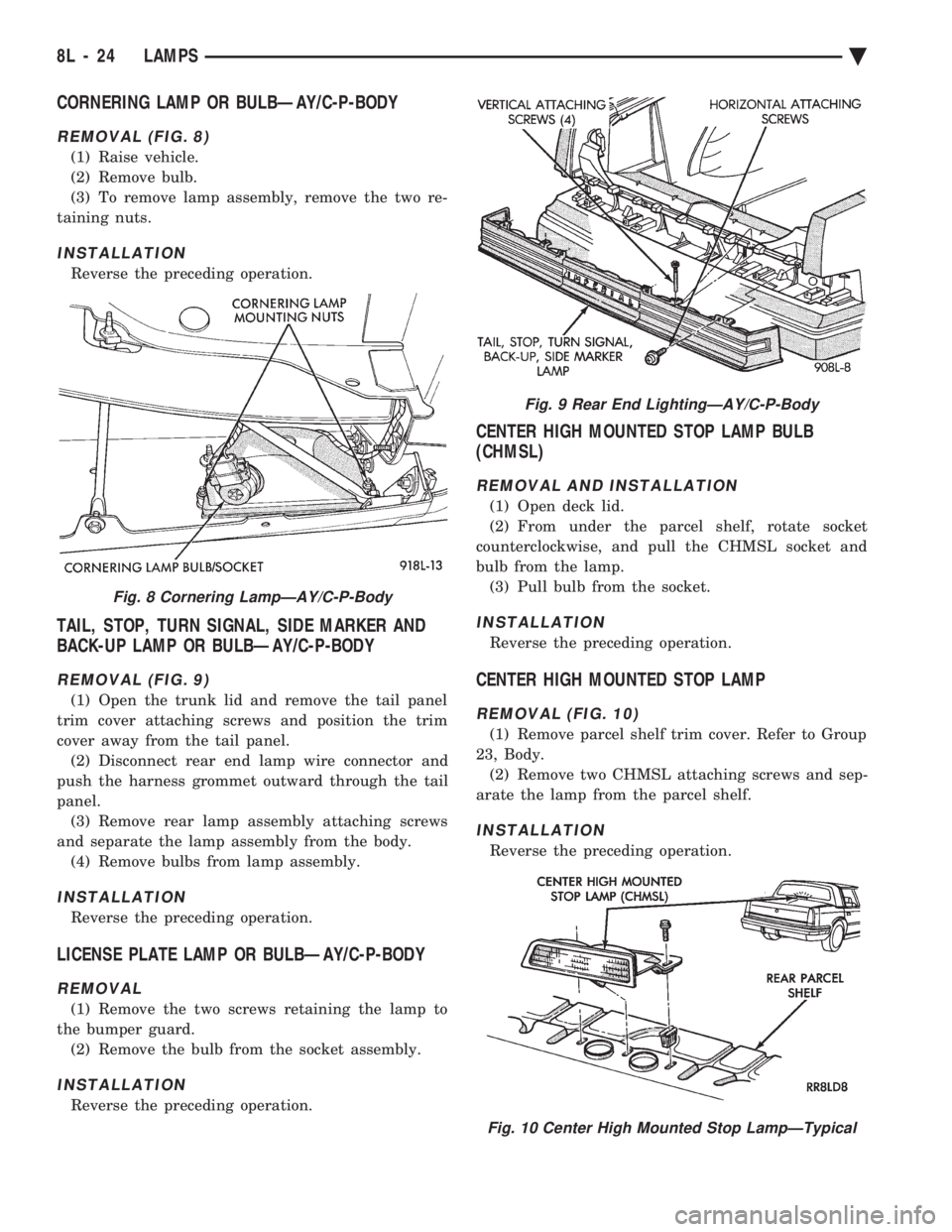

TAIL, STOP, TURN SIGNAL, SIDE MARKER AND

BACK-UP LAMP OR BULBÐAY/C-P-BODY

REMOVAL (FIG. 9)

(1) Open the trunk lid and remove the tail panel

trim cover attaching screws and position the trim

cover away from the tail panel. (2) Disconnect rear end lamp wire connector and

push the harness grommet outward through the tail

panel. (3) Remove rear lamp assembly attaching screws

and separate the lamp assembly from the body. (4) Remove bulbs from lamp assembly.

INSTALLATION

Reverse the preceding operation.

LICENSE PLATE LAMP OR BULBÐAY/C-P-BODY

REMOVAL

(1) Remove the two screws retaining the lamp to

the bumper guard. (2) Remove the bulb from the socket assembly.

INSTALLATION

Reverse the preceding operation.

CENTER HIGH MOUNTED STOP LAMP BULB

(CHMSL)

REMOVAL AND INSTALLATION

(1) Open deck lid.

(2) From under the parcel shelf, rotate socket

counterclockwise, and pull the CHMSL socket and

bulb from the lamp. (3) Pull bulb from the socket.

INSTALLATION

Reverse the preceding operation.

CENTER HIGH MOUNTED STOP LAMP

REMOVAL (FIG. 10)

(1) Remove parcel shelf trim cover. Refer to Group

23, Body. (2) Remove two CHMSL attaching screws and sep-

arate the lamp from the parcel shelf.

INSTALLATION

Reverse the preceding operation.

Fig. 8 Cornering LampÐAY/C-P-Body

Fig. 9 Rear End LightingÐAY/C-P-Body

Fig. 10 Center High Mounted Stop LampÐTypical

8L - 24 LAMPS Ä

Page 667 of 2438

EXTERIOR LAMP SYSTEMS INDEX

page page

Daytime Running LampÐCanada Only ........ 25

Headlamp Time Delay System .............. 26

Lamp Outage ModuleÐAA-Body ............. 25 Lamp Outage ModuleÐAll Except AA-Body

..... 25

Lamp Outage System ..................... 25

Removal (Fig. 4) ......................... 25

LAMP OUTAGE SYSTEM

Diagnostics and component relationships for AC,

AG, AJ or AY-Bodies can be found in the Body Di-

agnostic Procedures Manual, Electronic Vehicle In-

formation Center (EVIC) section. For circuit and component locations on AA-body,

refer to the Wiring Diagrams Manual.

LAMP OUTAGE MODULEÐALL EXCEPT AA-BODY

REMOVAL

(1) Remove battery negative cable.

(2) Remove the glove box assembly. Refer to Group

8E, Instrument Panel. (3) Disconnect the wire connector from the lamp

outage module. (4) Remove lamp outage module attaching screw

and remove the module from the vehicle (Figs. 1, 2

or 3).

INSTALLATION

Reverse the preceding operation.

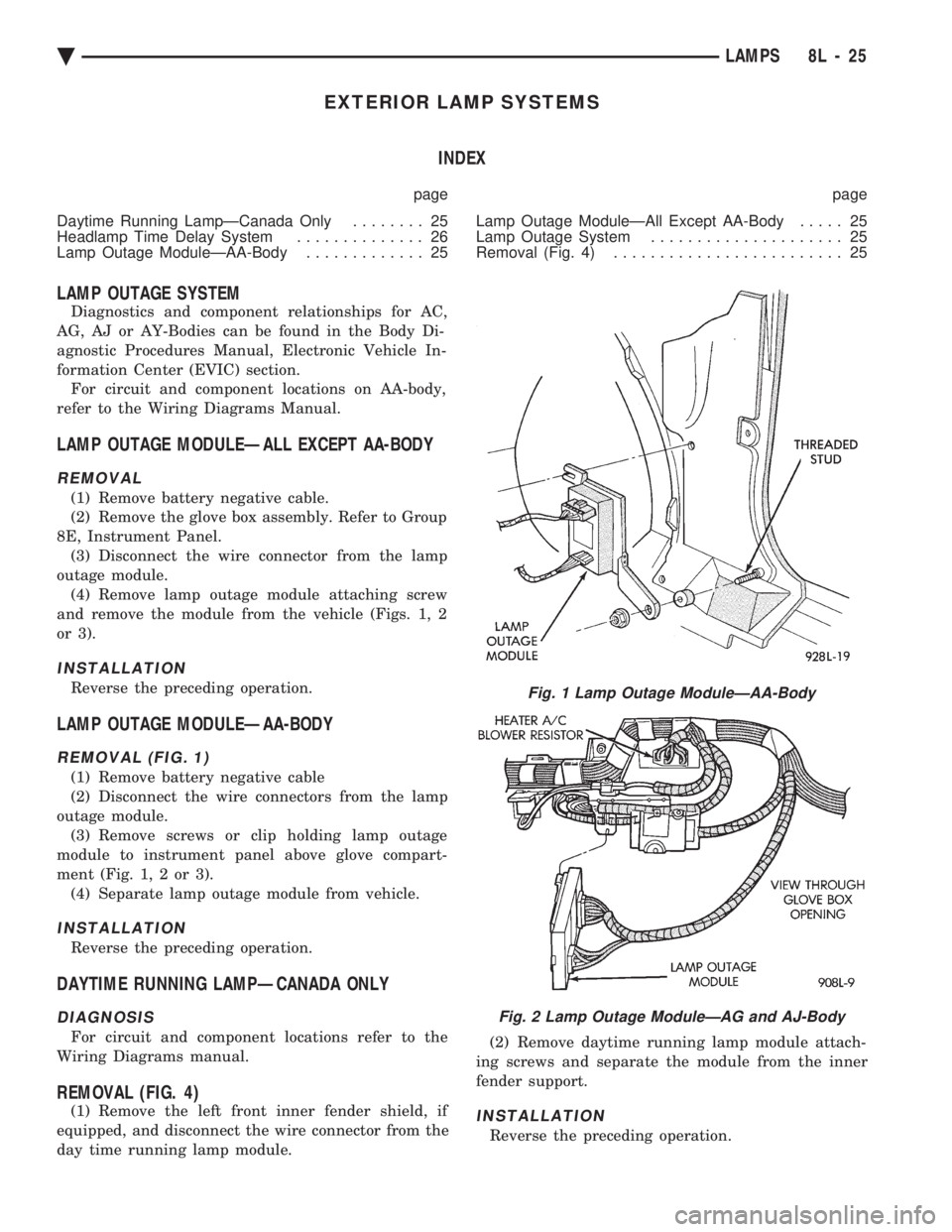

LAMP OUTAGE MODULEÐAA-BODY

REMOVAL (FIG. 1)

(1) Remove battery negative cable

(2) Disconnect the wire connectors from the lamp

outage module. (3) Remove screws or clip holding lamp outage

module to instrument panel above glove compart-

ment (Fig. 1, 2 or 3). (4) Separate lamp outage module from vehicle.

INSTALLATION

Reverse the preceding operation.

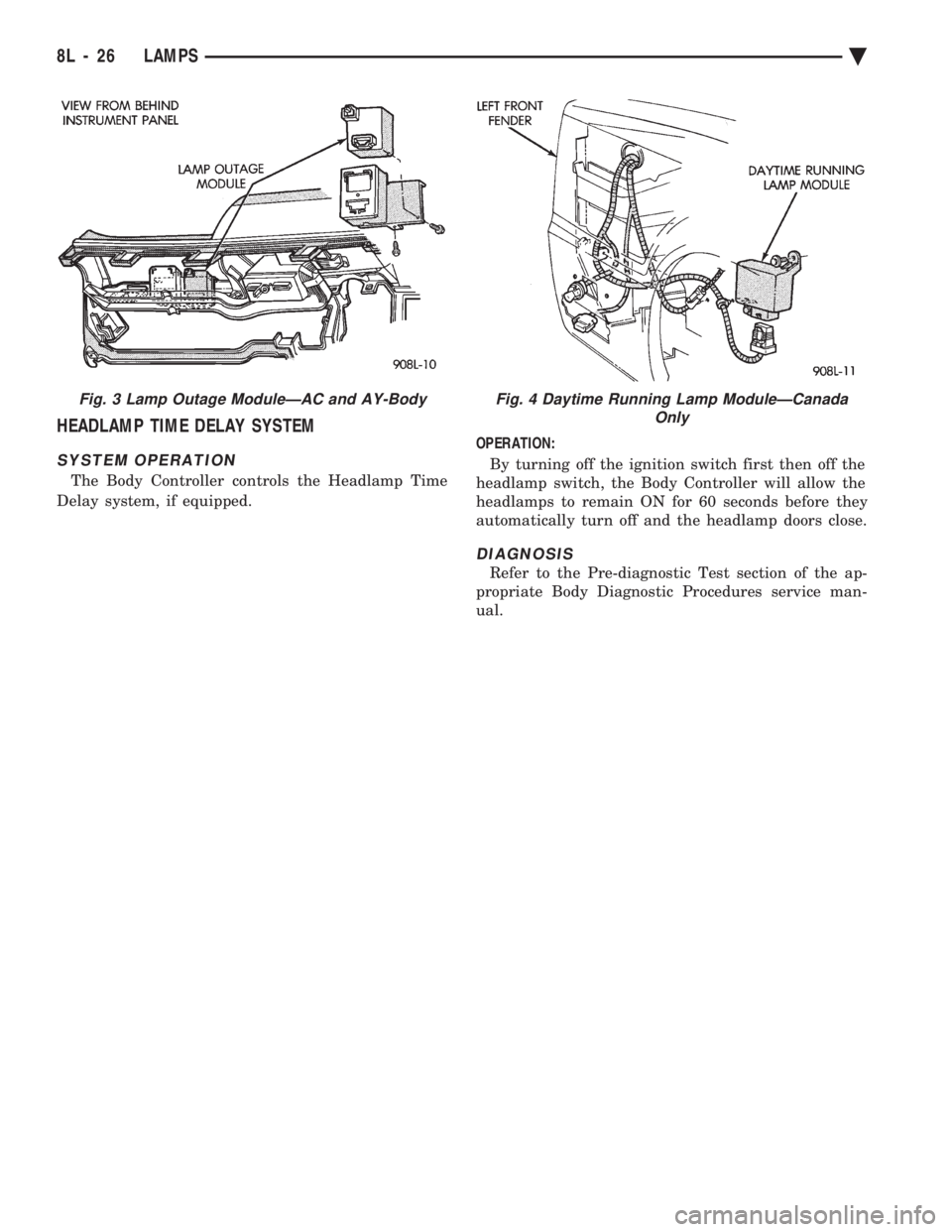

DAYTIME RUNNING LAMPÐCANADA ONLY

DIAGNOSIS

For circuit and component locations refer to the

Wiring Diagrams manual.

REMOVAL (FIG. 4)

(1) Remove the left front inner fender shield, if

equipped, and disconnect the wire connector from the

day time running lamp module. (2) Remove daytime running lamp module attach-

ing screws and separate the module from the inner

fender support.INSTALLATION

Reverse the preceding operation.

Fig. 1 Lamp Outage ModuleÐAA-Body

Fig. 2 Lamp Outage ModuleÐAG and AJ-Body

Ä LAMPS 8L - 25

Page 668 of 2438

HEADLAMP TIME DELAY SYSTEM

SYSTEM OPERATION

The Body Controller controls the Headlamp Time

Delay system, if equipped. OPERATION:

By turning off the ignition switch first then off the

headlamp switch, the Body Controller will allow the

headlamps to remain ON for 60 seconds before they

automatically turn off and the headlamp doors close.

DIAGNOSIS

Refer to the Pre-diagnostic Test section of the ap-

propriate Body Diagnostic Procedures service man-

ual.

Fig. 3 Lamp Outage ModuleÐAC and AY-BodyFig. 4 Daytime Running Lamp ModuleÐCanada Only

8L - 26 LAMPS Ä

Page 669 of 2438

CONCEALED HEADLAMPS INDEX

page page

Concealed Headlamp MotorÐAC-Body ........ 29

Diagnostic Procedures ..................... 27

General Information ....................... 27 Headlamp DoorÐAC-Body

................. 29

Headlamp DoorÐAY Body ................. 29

Headlamp Drive MotorÐAY Body ............ 30

GENERAL INFORMATION

For proper operation of the Concealed Headlamp

System, refer to the Owner's Manual provided with

the vehicle.

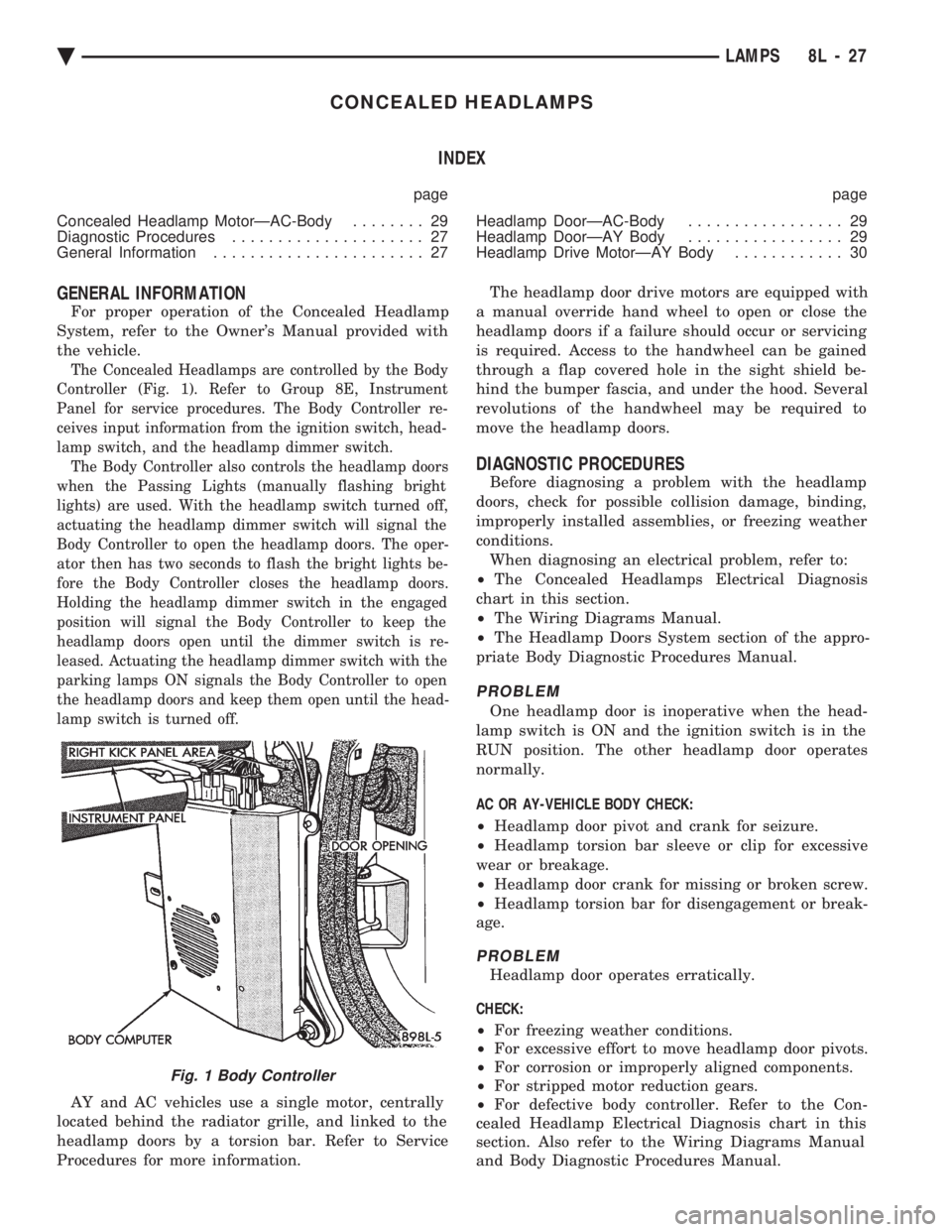

The Concealed Headlamps are controlled by the Body

Controller (Fig. 1). Refer to Group 8E, Instrument

Panel for service procedures. The Body Controller re-

ceives input information from the ignition switch, head-

lamp switch, and the headlamp dimmer switch. The Body Controller also controls the headlamp doors

when the Passing Lights (manually flashing bright

lights) are used. With the headlamp switch turned off,

actuating the headlamp dimmer switch will signal the

Body Controller to open the headlamp doors. The oper-

ator then has two seconds to flash the bright lights be-

fore the Body Controller closes the headlamp doors.

Holding the headlamp dimmer switch in the engaged

position will signal the Body Controller to keep the

headlamp doors open until the dimmer switch is re-

leased. Actuating the headlamp dimmer switch with the

parking lamps ON signals the Body Controller to open

the headlamp doors and keep them open until the head-

lamp switch is turned off.

AY and AC vehicles use a single motor, centrally

located behind the radiator grille, and linked to the

headlamp doors by a torsion bar. Refer to Service

Procedures for more information. The headlamp door drive motors are equipped with

a manual override hand wheel to open or close the

headlamp doors if a failure should occur or servicing

is required. Access to the handwheel can be gained

through a flap covered hole in the sight shield be-

hind the bumper fascia, and under the hood. Several

revolutions of the handwheel may be required to

move the headlamp doors.

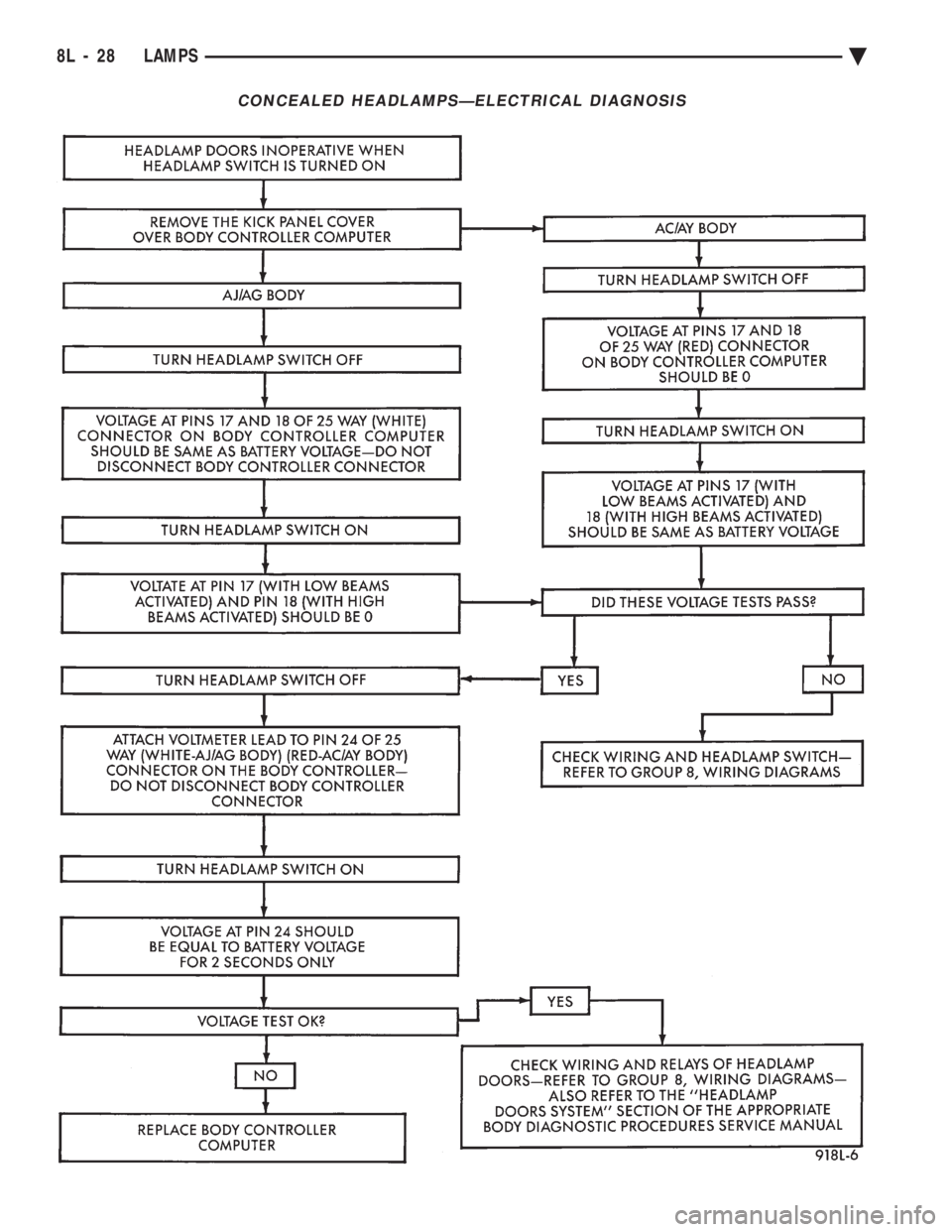

DIAGNOSTIC PROCEDURES

Before diagnosing a problem with the headlamp

doors, check for possible collision damage, binding,

improperly installed assemblies, or freezing weather

conditions. When diagnosing an electrical problem, refer to:

² The Concealed Headlamps Electrical Diagnosis

chart in this section.

² The Wiring Diagrams Manual.

² The Headlamp Doors System section of the appro-

priate Body Diagnostic Procedures Manual.

PROBLEM

One headlamp door is inoperative when the head-

lamp switch is ON and the ignition switch is in the

RUN position. The other headlamp door operates

normally.

AC OR AY-VEHICLE BODY CHECK:

² Headlamp door pivot and crank for seizure.

² Headlamp torsion bar sleeve or clip for excessive

wear or breakage.

² Headlamp door crank for missing or broken screw.

² Headlamp torsion bar for disengagement or break-

age.

PROBLEM

Headlamp door operates erratically.

CHECK:

² For freezing weather conditions.

² For excessive effort to move headlamp door pivots.

² For corrosion or improperly aligned components.

² For stripped motor reduction gears.

² For defective body controller. Refer to the Con-

cealed Headlamp Electrical Diagnosis chart in this

section. Also refer to the Wiring Diagrams Manual

and Body Diagnostic Procedures Manual.

Fig. 1 Body Controller

Ä LAMPS 8L - 27

Page 670 of 2438

CONCEALED HEADLAMPSÐELECTRICAL DIAGNOSIS

8L - 28 LAMPS Ä