ECU CHRYSLER CARAVAN 2003 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 542 of 2177

AUTOMATIC SPEED CONTROL OVERSPEED

REDUCTION

DESCRIPTION

Transmission control software includes an auto-

matic speed control overspeed reduction feature. This

maintains vehicle speed at the selected set point

when descending a grade.

OPERATION

The TCM (on SBEC vehicles) (PCM on NGC vehi-

cles) first senses that the speed control is set. If the

set speed is exceeded by more than 4 mph (6.5

km/hr) and the throttle is closed, the TCM (on SBEC

vehicles) (PCM on NGC vehicles) causes the trans-

axle to downshift to THIRD gear. After downshifting,

the automatic speed control resumes normal opera-

tion. To ensure that an upshift is appropriate after

the set speed is reached, the TCM (on SBEC vehi-

cles) (PCM on NGC vehicles) waits until the speed

control system opens the throttle at least 6 degrees

before upshifting to OVERDRIVE again.

If the driver applies the brakes, canceling auto-

matic speed control operation with the transaxle still

in THIRD gear, the TCM (on SBEC vehicles) (PCM

on NGC vehicles) maintains this gear until the driver

opens the throttle at least 6 degrees to avoid an inap-

propriate upshift. The upshift is also delayed for 2.5

seconds after reaching the 6 degrees throttle opening

in anticipation that the driver might open the throt-

tle enough to require THIRD gear. This will avoid

unnecessary and disturbing transmission cycling. If

the automatic speed control RESUME feature is used

after braking, the upshift is delayed until the set

speed is achieved to reduce cycling and provide bet-

ter response.

DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road test

should include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to the Instru-

ment Cluster for speedometer diagnosis.

If a road test verifies an inoperative system, and

the speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose or corroded electrical connections at the

servo. Corrosion should be removed from electrical

terminals and a light coating of Mopar Multipurpose

Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment at both ends of the speed

control servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Conduct electrical test at PCM.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SPECIFICATIONS - TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Servo Mounting Bracket

Nuts14 10.3 123.9

Servo Mounting Bracket

Bolts14 10.3 123.9

Servo Mounting Nuts 6.7 60

RSSPEED CONTROL8P-3

SPEED CONTROL (Continued)

ProCarManuals.com

Page 546 of 2177

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

IMMOBILIZER SYSTEM..................3

DIAGNOSIS AND TESTING - VEHICLE

THEFT SECURITY SYSTEM..............3

HOOD AJAR SWITCH - EXPORT

REMOVAL.............................3INSTALLATION..........................3

TRANSPONDER KEY

DESCRIPTION..........................3

OPERATION............................3

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING.......................4

VTSS/SKIS INDICATOR LAMP

DESCRIPTION..........................5

OPERATION............................5

VEHICLE THEFT SECURITY

DESCRIPTION

VEHICLE THEFT SECURITY SYSTEM

The Vehicle Theft Security System (VTSS) is

designed to protect against whole vehicle theft. The

system monitors vehicle doors, and ignition action for

unauthorized operation (hood and liftgate for RG -

Export). The alarm activates:

²Sounding of the horn

²Flashing of the headlamps/park/tail lamps

²Flashing of the headlamps

²An engine kill feature (with SKIS)

SENTRY KEY IMMOBILIZER SYSTEM

The Sentry Key Immobilizer System (SKIS) is

available as a factory-installed option on this vehicle.

It is designed to provide passive protection against

unauthorized vehicle use by disabling the engine,

after two (2) seconds of running, whenever an invalid

key is used to start the vehicle. The SKIS is active

whenever the ignition is on and does not require any

customer intervention. The primary components of

the system are the Sentry Key Immobilizer Module

(SKIM), Sentry Key (ignition key with a transponder

molded into the head), indicator light, Body Control

Module (BCM), and the Powertrain Control Module

(PCM). The SKIM is mounted to the steering column

with the molded, integral antenna mounted on the

ignition housing. The indicator light, is located in the

Mechanical Instrument Cluster (MIC).

OPERATION

VEHICLE THEFT SECURITY SYSTEM

Upon failure of proper SKIM communication to the

PCM, the PCM will shut off fuel after two seconds of

run time. The engine will not re-crank on the key

cycle that the failure occurred, a full key down

sequence must be performed for the engine to crank

again. After six consecutive fuel shut-offs, the engine

will no longer crank on subsequent key cycles. The

failure must be corrected and a valid communication

process between the SKIM and the PCM must occur

for the engine to crank and start again.

The electronics for the VTSS are part of the Body

Control Module (BCM). The system is armed when

the vehicle is locked using the:

²Power door lock switches (with any door ajar)

²Remote Keyless Entry transmitter.

²Door Cylinder Lock Switches.

For vehicles equipped with SKIS, the doors do not

have to be locked to enable the fuel shut off feature.

After the vehicle is locked and the last door is

closed, the set LED indicator in the Mechanical

Instrument Cluster (MIC) will flash quickly for 16

seconds, indicating that arming is in progress. If no

monitored systems are activated during this period,

the system will arm. The LED will extinguish unless

the liftgate is open. If the liftgate is open, the LED

will flash at a slower rate.

This indicates that the system is armed. If fault is

detected on the driver key cylinder input, the indica-

tor LED will remain solid during the arming process,

although the system will still arm. If the indicator

LED does not illuminate at all upon door closing it

indicates that the system is not arming.

Passive disarming occurs upon normal vehicle

entry by unlocking either door with the ignition key/

RSVEHICLE THEFT SECURITY8Q-1

ProCarManuals.com

Page 547 of 2177

remote transmitter. This disarming will also halt the

alarm once it has been activated.

A tamper alert exists to notify the driver that the

VTSS had been activated. This alert consists of 3

horn pulses when the vehicle is disarmed.

NOTE: The VTSS will not arm by pushing down the

door lock mechanism. This will manually override

the system.

For Door Cylinder Lock Switch Removal and

Installation, refer to Electrical, Power Locks, Door

Cylinder Lock Switch.

If the VTSS is triggered, the horn will pulse, head-

lamps/marker lamps will flash, and the VTSS warn-

ing lamp will flash. If BCM determines the threat to

be false and the VTSS is not triggered again, the sys-

tem will shut down and rearm itself after three min-

utes. If a trigger is still active, the alarm will

continue for an additional 15 minutes without the

horn. The VTSS monitors the passenger compart-

ment (for RG - Export it also monitors the engine

compartment. If a malfunction occurs in the engine

compartment, the passenger compartment would still

arm and function normally).

NOTE: System will not arm if passenger compart-

ment is not secure.

NOTE: (RG - Export - If hood is not secure during

the arming sequence, the lamp will stay lit and not

flash. The system will arm with hood not secured

and the liftgate open).

ARMING THE VTSS - METHOD A

(1) With the key removed from the ignition lock

and any door open (excluding liftgate), actuate one of

the following:

²Power door lock button to LOCK,

²Key fob LOCK button

²Driver door lock key cylinder to locked position.

(2) Close all opened doors. Liftgate can remain

open.

(3) After the last door is closed, an arming time-

out period of sixteen seconds will start, then the

VTSS will become armed.

ARMING THE VTSS - METHOD B

Actuating the key fob transmitter LOCK button,

key locking the front doors with the doors closed and

the ignition locked will begin the arming time-out

period. If method A, 16 second time-out sequence was

in process when method B was actuated, the 16 sec-

ond time-out will restart from the time of the second

actuation.If the security lamp does not illuminate at all upon

final door closure, it indicates that the system is not

arming.

The current VTSS status armed or disarmed shall

be maintained in memory to prevent battery discon-

nects from disarming the system.

TRIGGERING THE VTSS

After the VTSS is armed, the following actions will

trigger the alarm:

²Opening any door (excluding liftgate).

²Opening the hood (RG - Export)

²Turning the ignition to the RUN position.

NOTE: When the VTSS is ARMED, the interior

power door lock switch ªUNLOCKº will be disabled

until the vehicle is disarmed.

CAUTION: The VTSS indicator LED will trigger and

engine will continue to run if the vehicle is

equipped with SKIS and the proper key is used to

start the vehicle. This condition will occur if the

VTSS has been triggered. If valid key is used, VTSS

will disarm

SENTRY KEY IMMOBILIZER SYSTEM

The SKIS includes keys from the factory which are

pre-programmed. Each SKIM will recognize a maxi-

mum of eight Sentry Keys. If the customer would

like to own additional keys other than those provided

with the vehicle, they can be purchased from any

authorized dealer. These keys must be programmed

to the SKIM on the vehicle in order for the system to

recognize them as valid keys. This can be done by

the dealer with a DRB IIItscan tool or by a cus-

tomer if this feature is available in their market and

they have two (2) valid keys already available to

them. Refer to the Service Procedures portion of this

system for additional details. The SKIS performs a

self-test each time the ignition switch is turned to

the ON position and will store Diagnostic Trouble

Codes (DTC's) if a system malfunction is detected.

The SKIS can be diagnosed and any stored DTC's

can be retrieved using a DRB IIItscan tool as

described in the appropriate Body Diagnostic Proce-

dures manual.

8Q - 2 VEHICLE THEFT SECURITYRS

VEHICLE THEFT SECURITY (Continued)

ProCarManuals.com

Page 548 of 2177

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS,

WARNINGS, BEFORE ATTEMPTING COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Sentry Key Immobilizer System involves the use of

a DRB IIITscan tool. Refer to the proper Body Diag-

nostic Procedures Manual.

The Sentry Key Immobilizer System (SKIS) and

the Programmable Communication Interface (PCI)

bus network should be diagnosed using a DRB IIIt

scan tool. The DRB IIItwill allow confirmation that

the PCI bus is functional, that the Sentry Key Immo-

bilizer Module (SKIM) is placing the proper messages

on the PCI bus, and that the Powertrain Control

Module (PCM) is receiving the PCI bus messages.

Refer to the proper Body Diagnostic Procedures man-

ual, and Wiring Diagrams for complete circuit

descriptions and diagrams.

(1) Check the fuses in the Integrated Power Mod-

ule (IPM). If OK, go to Step 2. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(2) Disconnect and isolate the battery negative

remote cable from the remote terminal. Unplug the

wire harness connector at the SKIM. Check for con-

tinuity between the ground circuit cavity of the

SKIM wire harness connector and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the open circuit to ground as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKIM wire harness connector. If OK, go to Step 4. If

not OK, repair the open circuit to the fuse in the

IPM as required.

(4) Turn the ignition switch to the ON position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the SKIM wire

harness connector. If OK, use a DRB IIItscan tool

and the proper Body Diagnostic Procedures manual

to complete the diagnosis of the SKIS. If not OK,

repair the open circuit to the fuse in the IPM as

required.

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Using a DRB

IIItscan tool. Refer to the proper Body Diagnostic

Procedures Manual for test procedures.

HOOD AJAR SWITCH -

EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a small flat blade screwdriver, pry trig-

ger switch from the bracket on the left fender well.

(3) Disconnect the hood ajar switch from the wire

connector and remove from vehicle.

INSTALLATION

(1) Connect the hood ajar switch to the wire conec-

tor.

(2) Press the hood ajar switch into position on the

bracket located on the left inner fender well.

(3) Reconnect the battery negative cable.

(4) Close the hood and check for proper operation.

TRANSPONDER KEY

DESCRIPTION

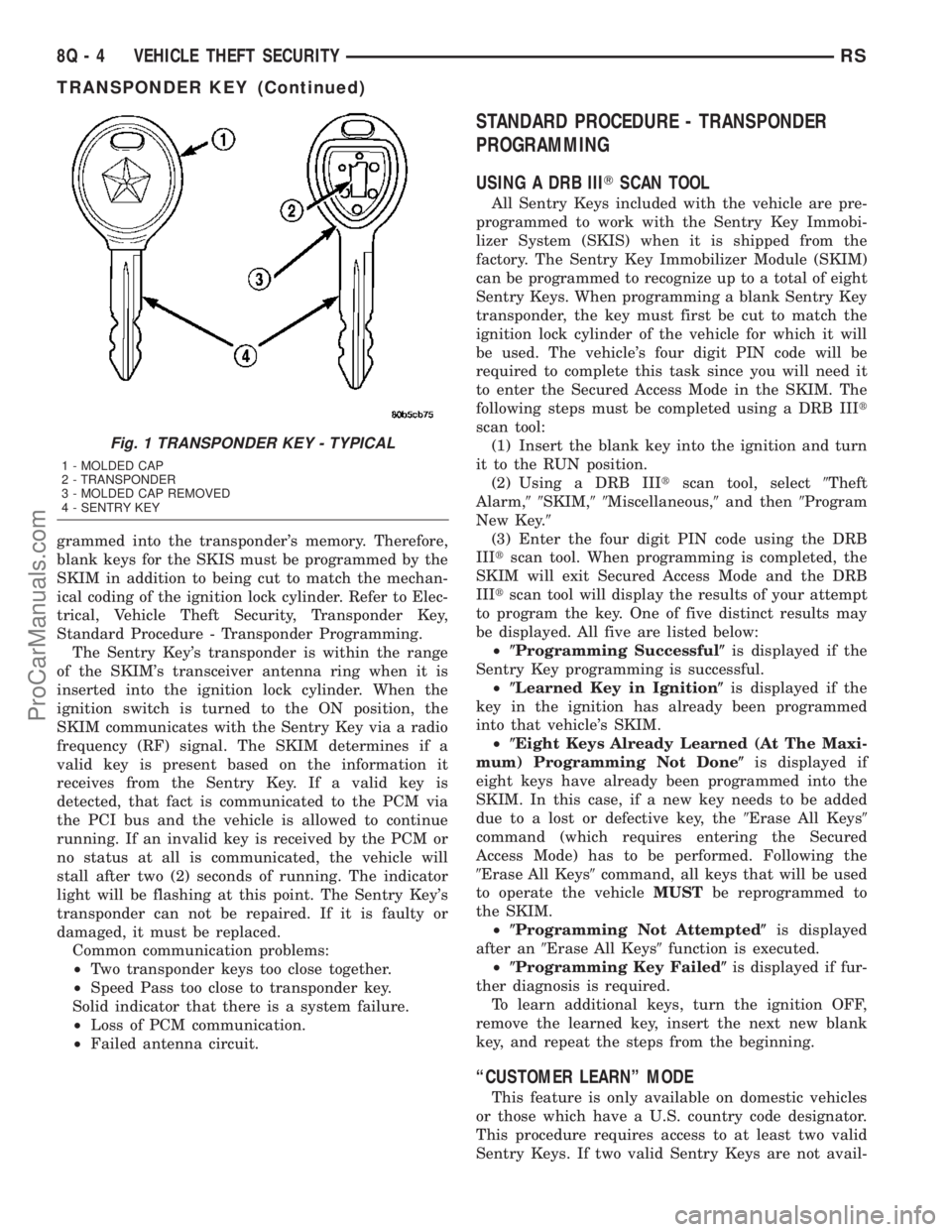

The Sentry Key Immobilizer System (SKIS) uses a

transponder chip that is integral to each ignition key

(Fig. 1) to communicate with the Sentry Key Immo-

bilizer Module (SKIM). Ignition keys are supplied

with the vehicle when it is shipped from the factory.

The transponder chip is undermolded within the

head of the key. This undermold is hidden beneath

an overmolded rubber cap.

OPERATION

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the SKIM has a unique

9Secret Key9code programmed into it by the manu-

facturer as well. When a Sentry Key is programmed

into the memory of the SKIM, the SKIM stores the

transponder identification code from the Sentry Key,

and the Sentry Key learns the9Secret Key9code from

the SKIM. Once the Sentry Key learns the9Secret

Key9code of the SKIM, it is also permanently pro-

RSVEHICLE THEFT SECURITY8Q-3

VEHICLE THEFT SECURITY (Continued)

ProCarManuals.com

Page 549 of 2177

grammed into the transponder's memory. Therefore,

blank keys for the SKIS must be programmed by the

SKIM in addition to being cut to match the mechan-

ical coding of the ignition lock cylinder. Refer to Elec-

trical, Vehicle Theft Security, Transponder Key,

Standard Procedure - Transponder Programming.

The Sentry Key's transponder is within the range

of the SKIM's transceiver antenna ring when it is

inserted into the ignition lock cylinder. When the

ignition switch is turned to the ON position, the

SKIM communicates with the Sentry Key via a radio

frequency (RF) signal. The SKIM determines if a

valid key is present based on the information it

receives from the Sentry Key. If a valid key is

detected, that fact is communicated to the PCM via

the PCI bus and the vehicle is allowed to continue

running. If an invalid key is received by the PCM or

no status at all is communicated, the vehicle will

stall after two (2) seconds of running. The indicator

light will be flashing at this point. The Sentry Key's

transponder can not be repaired. If it is faulty or

damaged, it must be replaced.

Common communication problems:

²Two transponder keys too close together.

²Speed Pass too close to transponder key.

Solid indicator that there is a system failure.

²Loss of PCM communication.

²Failed antenna circuit.

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING

USING A DRB IIITSCAN TOOL

All Sentry Keys included with the vehicle are pre-

programmed to work with the Sentry Key Immobi-

lizer System (SKIS) when it is shipped from the

factory. The Sentry Key Immobilizer Module (SKIM)

can be programmed to recognize up to a total of eight

Sentry Keys. When programming a blank Sentry Key

transponder, the key must first be cut to match the

ignition lock cylinder of the vehicle for which it will

be used. The vehicle's four digit PIN code will be

required to complete this task since you will need it

to enter the Secured Access Mode in the SKIM. The

following steps must be completed using a DRB IIIt

scan tool:

(1) Insert the blank key into the ignition and turn

it to the RUN position.

(2) Using a DRB IIItscan tool, select9Theft

Alarm,99SKIM,99Miscellaneous,9and then9Program

New Key.9

(3) Enter the four digit PIN code using the DRB

IIItscan tool. When programming is completed, the

SKIM will exit Secured Access Mode and the DRB

IIItscan tool will display the results of your attempt

to program the key. One of five distinct results may

be displayed. All five are listed below:

²(Programming Successful(is displayed if the

Sentry Key programming is successful.

²(Learned Key in Ignition(is displayed if the

key in the ignition has already been programmed

into that vehicle's SKIM.

²(Eight Keys Already Learned (At The Maxi-

mum) Programming Not Done(is displayed if

eight keys have already been programmed into the

SKIM. In this case, if a new key needs to be added

due to a lost or defective key, the9Erase All Keys9

command (which requires entering the Secured

Access Mode) has to be performed. Following the

9Erase All Keys9command, all keys that will be used

to operate the vehicleMUSTbe reprogrammed to

the SKIM.

²(Programming Not Attempted(is displayed

after an9Erase All Keys9function is executed.

²(Programming Key Failed(is displayed if fur-

ther diagnosis is required.

To learn additional keys, turn the ignition OFF,

remove the learned key, insert the next new blank

key, and repeat the steps from the beginning.

ªCUSTOMER LEARNº MODE

This feature is only available on domestic vehicles

or those which have a U.S. country code designator.

This procedure requires access to at least two valid

Sentry Keys. If two valid Sentry Keys are not avail-

Fig. 1 TRANSPONDER KEY - TYPICAL

1 - MOLDED CAP

2 - TRANSPONDER

3 - MOLDED CAP REMOVED

4 - SENTRY KEY

8Q - 4 VEHICLE THEFT SECURITYRS

TRANSPONDER KEY (Continued)

ProCarManuals.com

Page 550 of 2177

able, Sentry Key programming will require the use of

a DRB IIItscan tool.

The steps required to program Sentry Keys with

two valid Sentry Keys follows:

(1) Obtain the blank Sentry Key(s) that need to be

programmed. Cut the keys to match the ignition lock

cylinder mechanical key codes.

(2) Insert one of the two valid Sentry Keys into the

ignition switch and turn the ignition switch to the

ON position.

(3) After the ignition switch has been in the ON

position for longer than three seconds, but no more

than fifteen seconds, cycle the ignition switch back to

the OFF position. Replace the first valid Sentry Key

in the ignition lock cylinder with the second valid

Sentry Key and turn the ignition switch back to the

ON position. The second valid Sentry Key must be

inserted within 15 seconds of removing the first valid

Sentry key.

(4) About ten seconds after the completion of Step

3, the indicator light will start to flash and a single

audible chime tone will sound to indicate that the

system has entered the9Customer Learn9program-

ming mode.

(5) Within sixty seconds of entering the9Customer

Learn9programming mode, turn the ignition switch

to the OFF position, replace the valid Sentry Key

with a blank Sentry Key transponder, and turn the

ignition switch back to the ON position.

(6) About ten seconds after the completion of Step

5, a single audible chime tone will sound and the

indicator light will stop flashing and stay on solid for

three seconds and then turn off to indicate that the

blank Sentry Key has been successfully programmed.

The SKIS will immediately exit the9Customer

Learn9programming mode and the vehicle may be

started using the newly programmed Sentry Key.

These steps must be completed in their entirety for

each additional Sentry Key to be programmed. If any

of the above steps are not completed in the given

sequence, or within the allotted time, the SKIS will

exit the9Customer Learn9programming mode and

the programming will be unsuccessful. The SKIS will

also automatically exit the9Customer Learn9pro-

gramming mode if:

²It sees a non-blank Sentry Key when it should

see a blank.

²If it has already programmed eight (8) valid

Sentry Keys.

²If the ignition switch is turned to the OFF posi-

tion for more than about fifty (50) seconds.

NOTE: If you attempt to start the vehicle while in

ªCustomer Learnº mode (LED flashing), the vehiclewill behave as though an invalid key is being used

(i.e. the engine will stall after two (2) seconds of

running). No faults will be logged.

NOTE: Once a Sentry Key has been programmed to

a particular vehicle, it cannot be used on any other

vehicle.

VTSS/SKIS INDICATOR LAMP

DESCRIPTION

The Sentry Key Immobilizer System (SKIS) uses

an indicator light to convey information on the status

of the system to the customer. This light is shared

with the Vehicle Theft Security System (VTSS). The

light is located in the Mechanical Instrument Cluster

(MIC). The indicator light is controlled by the Body

Control Module (BCM), via Programmable Communi-

cation Interface (PCI) data bus communication with

the MIC, based upon messages it receives from the

Sentry Key Immobilizer Module (SKIM) on the PCI

data bus.

OPERATION

The Mechanical Instrument Cluster (MIC) per-

forms a four second bulb check via PCI communica-

tion with the Sentry Key Immobilizer Module

(SKIM). After the bulb check, the lamp is controlled

according to SKIM messages. Then, the SKIM sends

messages to the BCM to operate the light based upon

the results of the SKIS self tests. The light may be

actuated in two possible ways, flashing or on solid. If

the light comes on and stays on solid after a pow-

er-up test, this indicates that the SKIM has detected

a system malfunction. If the SKIM detects an invalid

key when the ignition switch is moved to the ON

position, it sends a message on the PCI bus to the

BCM, to flash the light. The SKIM can also send a

message to flash the light and generate a single audi-

ble chime at the same time. These two events occur-

ring simultaneously indicate that the SKIS has been

placed into the9Customer Learn9mode. Refer to

Electrical, Vehicle Theft Security, Transponder Key,

Standard Procedure - Transponder Programming for

more information on the9Customer Learn9mode. If

the light comes on and stays on after the power-up

test, diagnosis of the SKIS should be performed

using a DRB IIItscan tool and the appropriate Body

Diagnostic Procedures manual. The light is not a ser-

viceable component.

RSVEHICLE THEFT SECURITY8Q-5

TRANSPONDER KEY (Continued)

ProCarManuals.com

Page 569 of 2177

INSTALLATION

(1) Connect the wire harness connector.

(2) Install the linkage on the wiper unit.

(3) Install the nut holding the linkage to the wiper

unit.

(4)

Install the cowl cover brackets to the wiper nut.

(5) Install the front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(6) Install the cowl cover.

(7) Install the wiper arms and blades.

WIPER MODULE

REMOVAL

(1) Release the hood latch and open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the wiper arms.

(4) Remove the cowl cover (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL).

(5) Disconnect the positive lock on the wiper mod-

ule wire connector (Fig. 8).

(6) Disconnect the wiper module wire connector

from the engine compartment wire harness.

(7) Disconnect the windshield washer hose from

coupling outside the module.

(8) Disconnect the drain tubes from nipples on bot-

tom of the wiper module.

(9) Remove nuts holding wiper module to lower

windshield fence.

(10) Remove bolts holding the wiper module to the

dash panel (Fig. 9).(11) Lift wiper module from weld-studs on lower

windshield fence.

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.

(12) Remove wiper module.

INSTALLATION

(1) Position the wiper module into the cowl.

(2) Install the bolts that secure the wiper module

to the dash (Fig. 9).

(3) Install the nuts that retain the wiper module.

(4) Connect the drain tubes to the nipples on the

wiper module.

(5) Connect the windshield washer tube.

(6) Connect the wire harness connector to the

wiper module (Fig. 9).

(7) Connect the positive lock on the wiper module

wire connector (Fig. 8).

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.

(8) Install the cowl cover (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION).

(9) Install the wiper arms and blades.

(10) Connect the battery negative cable.

(11) Close the hood.

Fig. 8 WIPER MODULE WIRE CONNECTOR

1 - WIPER SYSTEM WIRE CONNECTOR

2 - LOCK TAB

3 - POSITIVE LOCK

4 - WIPER MODULE

Fig. 9 WIPER MODULE

1 - BOLT

2 - NUTS

3 - BOLT

4 - WIPER MODULE

5 - WINDSHIELD

8R - 18 WIPERS/WASHERSRS

WIPER LINKAGE (Continued)

ProCarManuals.com

Page 570 of 2177

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1

MESSAGE CENTER................... 8W-46-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

POWER SUNROOF................... 8W-64-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION SYSTEM........ 8W-97-1 RSWIRING

8W-1

ProCarManuals.com

Page 774 of 2177

8W-39 VEHICLE THEFT SECURITY SYSTEM

Component Page

Body Control Module.... 8W-39-2, 3, 4, 7, 8, 9, 10,

11, 12, 13, 14, 15

Clockspring........................ 8W-39-6

Driver Door Lock Switch........... 8W-39-12, 13

Front Control Module............... 8W-39-4, 6

Front Intrusion Sensor................ 8W-39-5

Fuse 8............................ 8W-39-6

Fuse 14............................ 8W-39-2

G102.............................. 8W-39-6

G200.............................. 8W-39-3

G300........... 8W-39-7, 8, 9, 10, 11, 12, 13, 14

G301.............. 8W-39-7, 8, 9, 10, 11, 12, 13

G302............................. 8W-39-15

G303.......................... 8W-39-14, 15

High Note Horn..................... 8W-39-6

Hood Ajar Switch................... 8W-39-14

Horn Relay......................... 8W-39-6

Horn Switch........................ 8W-39-6

Ignition Switch.................... 8W-39-3, 4

Integrated Power Module.......... 8W-39-2, 4, 6

Left Cylinder Lock Switch......... 8W-39-12, 13

Left Front Door Ajar Switch............ 8W-39-7

Left Front Door Lock Motor/Ajar

Switch........................ 8W-39-7, 8

Left Sliding Door Control Module..... 8W-39-9, 10

Left Sliding Door Latch Sensing Switch . . . 8W-39-9Component Page

Left Sliding Door Lock Motor.......... 8W-39-10

Left Sliding Door Lock Motor/Ajar

Switch.......................... 8W-39-11

Liftgate Ajar Switch................. 8W-39-15

Liftgate Cinch/Release Motor.......... 8W-39-15

Liftgate Cylinder Lock Switch......... 8W-39-14

Low Note Horn...................... 8W-39-6

Passenger Door Lock Switch........ 8W-39-12, 13

Power Liftgate Module............... 8W-39-15

Rear Intrusion Sensor................ 8W-39-5

Remote Keyless Entry Module.......... 8W-39-2

Right Cylinder Lock Switch........ 8W-39-12, 13

Right Front Door Ajar Switch........... 8W-39-7

Right Front Door Lock Motor/Ajar

Switch........................ 8W-39-7, 8

Right Sliding Door Control Module.... 8W-39-9, 10

Right Sliding Door Latch Sensing

Switch.......................... 8W-39-9

Right Sliding Door Lock Motor......... 8W-39-10

Right Sliding Door Lock Motor/Ajar

Switch.......................... 8W-39-11

Sentry Key Immobilizer Module....... 8W-39-2, 3

Siren............................. 8W-39-4

Thatcham Alarm Indicator............. 8W-39-5

Thatcham Alarm Module............ 8W-39-4, 5

RS8W-39 VEHICLE THEFT SECURITY SYSTEM8W-39-1

ProCarManuals.com

Page 1174 of 2177

8W-97 POWER DISTRIBUTION SYSTEM

TABLE OF CONTENTS

page page

POWER DISTRIBUTION SYSTEM

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........2

ACCESSORY RELAY

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - ACCESSORY

RELAY...............................2

REMOVAL.............................3

INSTALLATION..........................3

INTEGRATED POWER MODULE

DESCRIPTION..........................3OPERATION............................3

REMOVAL.............................4

INSTALLATION..........................4

IOD FUSE

DESCRIPTION..........................4

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................5

POWER OUTLET

DESCRIPTION..........................5

OPERATION............................5

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET . . 6

REMOVAL.............................6

INSTALLATION..........................6

POWER DISTRIBUTION

SYSTEM

DESCRIPTION

This group covers the various standard and

optional power distribution components used on this

model. The power distribution system for this vehicle

consists of the following components:

²Integrated Power Module (IPM)

²Front Control Module (FCM)

²Power Outlets

Refer to Wiring Diagrams for complete circuit sche-

matics.

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Bus bars

²Cartridge fuses

²Circuit splice blocks

²Flashers

²Fusible links

²RelaysFollowing are general descriptions of the major

components in the power distribution system. See the

owner's manual in the vehicle glove box for more

information on the features and use of all of the

power distribution system components.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide the

electrical current needed to operate many accessories

that the vehicle owner may choose to have installed

in the aftermarket.

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-1

ProCarManuals.com