ECU CHRYSLER CARAVAN 2003 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 473 of 2177

TRANSVERSE BRACKET

DESCRIPTION

Vehicles equipped with a power liftgate utilize a

transverse bracket (Fig. 15) to support and secure

the power liftgate gear/motor assembly to the left

rear body D-pillar.

The transverse bracket is a serviceable power lift-

gate component. Consult your MoparŸ parts catalog

for a specific part number.

OPERATION

The power liftgate transverse bracket supports the

gear motor assembly by supplying an additional

attachment point. Located on the leading edge of the

gear motor assembly, one end of the transverse

bracket attaches to the motor assembly the other to

the leading edge of the vehicles D-pillar.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the left D-pillar trim from the vehicle.

Refer to Body for the procedure.

(3) Disconnect the gear motor assembly electrical

connector and disengage retaining pushpin.

(4) Loosen the gear motor assembly retaining bolts

to allow room for transverse bracket to be removed.

(5) Remove the transverse bracket retaining bolts

(Fig. 12).

(6) Remove the transverse bracket from the vehi-

cle.

INSTALLATION

(1) Position the transverse bracket in the vehicle.

Be certain the transverse bracket is properly posi-

tioned. The bracket should just touch the engage

actuator arm and be positioned between the actuator

arm and the motor housing.

(2) Torque the transverse bracket retaining bolts

to the gear motor assembly to 9.5 N´m (85 in. lbs.).

Do not tighten the transverse bracket retaining bolt,

located under the window actuator at this time.

(3) Torque the gear motor assembly retaining bolts

to 9.5 N´m (85 in. lbs.).

(4) Torque the final transverse bracket retaining

bolt to 9.5 N´m (85 in. lbs.).

(5) Connect the gear motor assembly electrical con-

nector and engage retaining pushpin.

(6) Install the appropriate D-pillar trim from the

vehicle. Refer to Body for the procedure.

Fig. 15 LIFTGATE GEAR/MOTOR ASSEMBLY

1 - TRANSVERSE BRACKET

2 - ENGAGE ACTUATOR

3 - LIFT GEAR AND ROD ASSEMBLY

4 - LIFTGATE MOTOR

8N - 18 POWER LIFTGATE SYSTEMRS

ProCarManuals.com

Page 483 of 2177

STANDARD PROCEDURE

STANDARD PROCEDURE - POWER DOOR

LEARN CYCLE

Any time a power side door component is removed,

replaced, door adjustment is performed or diagnostic

trouble codes are addressed and erased, a learn cycle

mustbe performed. This learn cycle enables the

power side door control module to learn or relearn its

critical information (travel limits, resistance to door

travel, etc.) which allows it to perform properly and

safely. It also tells the technician that the system is

performing properly and is able to be returned to ser-

vice. To perform a power door learn cycle do the fol-

lowing:

(1) Obtain a DRB IIItscan tool.

Connect the DRB IIItto the vehicle and check for

any power side door system stored diagnostic trouble

codes, erase any stored codes. Operate the system

and check to see if any trouble codes return. If any

diagnostic trouble codes return, diagnose, correct and

erase the codes before performing the learn cycle. If a

DRB IIItscan tool is not available, the learn cycle

can be performed by opening and closing the power

side door using any of the normal open/close com-

mand switches. Be certain to cycle the side door

through a complete openandclose cycle or the pro-

cedure will not be complete.

(2) Using the DRB IIIt, Go into Test Routine

Menu and select a power open command.

(3) Select a power close command.

(4) The power side door learn cycle is complete.

NOTE: If the power side door will not complete a

full cycle, a problem exists with the power side

door system. Refer to Power Side Door Diagnosis

and Testing.

STANDARD PROCEDURE - PUSH-PIN

GROMMET REPLACEMENT

Vehicles equipped with a power sliding door utilize

push-pin grommets. These push-pin grommets are

used to hold and isolate the power sliding door motor

to and from the door inner panel. This secures the

door motor assembly to the inner panel and keeps

the audible motor vibrations to a minimum. If a

push-pin grommet shows signs of wear, it must be

replaced. Follow the procedure below if replacement

is necessary.

(1) Remove the door motor from the door inner

panel. (Refer to 8 - ELECTRICAL/POWER DOORS/

MOTOR - REMOVAL).(2) Using a trim panel tool (special tool #C-4755)

or equivalent, remove the push-pin grommets from

the inner panel by pulling them straight out (Fig. 4).

(3) Install the replacement push-pin grommets in

the inner panel and install the door motor(Refer to 8

- ELECTRICAL/POWER DOORS/MOTOR - INSTAL-

LATION).

STANDARD PROCEDURE - SLIDING DOOR

ADJUSTMENT

In order for the power sliding door system to func-

tion properly the door must move freely and

smoothly. The power sliding door system can accom-

modate for some minor changes in the effort required

to move the door. However, in extreme conditions the

door may need to be mechanically adjusted for proper

fit. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS).

If a problem exists with the power sliding door and

it is suspected to be extreme effort, check for proper

door alignment and adjustment first, then check the

door tracks and drive unit for free manual operation.

Use a known good vehicle for side door comparison

data. Refer to the Side Door Adjustment procedure in

the Body section of the service manual for detailed

instructions.

Fig. 4 Side Door Motor push-pin grommets

1 - Push-Pin Grommets

2 - Side Door Inner Panel

8N - 28 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 486 of 2177

(2) Remove the door trim panel from the appropri-

ate side door. Refer to the Body section for the pro-

cedure.

(3) Remove water shield as necessary to gain

access to motor assembly.

(4) Remove retaining clip holding flex drive assem-

bly to the motor (Fig. 8). Pull flex drive cable straight

out of the motor assembly.

(5) Disconnect door motor electrical connector.

(6) Using a trim stick (special tool #C-4755) or

equivalent, gently pry out push-pin fasteners retain-

ing motor.

(7) Remove the motor assembly from the vehicle.

INSTALLATION

(1) Position the motor assembly on the door inner

panel.

(2) Install the push-pin fasteners retaining the

motor assembly to the sliding door.

NOTE: Push in on the push-pins at the clutch hous-

ing (plastic side) until you hear one click. Push in

on the push-pin fasteners at the motor mount

(sheet metal side) until you hear two clicks. This

assures proper installation/attachment of the motor

to the sliding door.

(3) Install the flex shaft by lining up the square

shaped drive shaft with corresponding hole in motor

drive unit and push straight in.(4) Install the E-clip to secure flex-shaft.

(5) Connect the negative battery cable.

(6) Install the weather shield. Refer to the Body

section of the service manual for the procedure.

(7) Install the door trim panel on the side door.

Refer to Body for the procedure.

FULL OPEN SWITCH

DESCRIPTION

Vehicles equipped with a power sliding door utilize

a full open switch. This switch is located in the hold

open latch (Fig. 9) under the side door lower hinge.

When the power side door module receives a ground

signal input from the full open switch, and as long as

the cinching latch actuator is not in power mode or

the handle switch is open, the signal indicates that

the door is at the full open position.

The full open switch is incorporated into the hold

open latch. If the full open switch proves faulty, the

entire hold open latch assembly must be replaced.

OPERATION

The full open switch is triggered by a pawl lever in

the hold open latch. When the full open switch is

closed (circuit to ground) the ratchet has engaged on

the hold open striker and the pawl lever has engaged

on the ratchet, locking the latch from opening and

holding the door in the full open position.

Fig. 8 Flex Drive Retaining Clip

1 - Flex Drive Cable Retaining Clip

2 - Flex Drive Cable

3 - Side Door Motor Assembly

Fig. 9 Full Open Switch Position & Orientation

1 - Hold Open Latch Assembly

2 - Hold Open Latch Cable

3 - Full Open Switch

RSPOWER SLIDING DOOR SYSTEM8N-31

SLIDING DOOR MOTOR (Continued)

ProCarManuals.com

Page 491 of 2177

(11) Remove the wire harness assembly from the

vehicle.

INSTALLATION

(1) Position the wire harness assembly in the vehi-

cle.

(2) Connect the wire harness connector located at

the rearward edge of the B-pillar.

(3) Install the side door lower sill plate. Refer to

the Body section for the procedure.

(4) Snap the wire harness retaining pushpins in

the rocker panel.

(5) Slide the wire harness on the lower drive unit

stud.

(6) Install the wire harness retaining clip on the

lower drive unit stud.

(7) Connect the power side door electrical connec-

tor, located just behind the lower drive unit.

(8) Install the lower drive unit cover and retaining

screws.

(9) Install the appropriate door trim panel on the

sliding side door. Refer to the Body section for the

procedure.

(10) Connect the negative battery cable.

FLEX DRIVE

DESCRIPTION

Vehicles equipped with a power sliding side door

utilize a flex drive assembly. The flex drive assembly

is located in the lower portion of the door (Fig. 18)

and is used to connect the door motor to the lower

drive unit. An E-clip is used to secure the flexdrive to

the motor assembly, while the flex drive collar is

used to secure the drive to the lower drive unit. The

flex drive assembly is basically a flexible drive shaft

for the power side door system.

The flex drive assembly is a replaceable compo-

nent. Consult your Mopar parts catalog for specific

part numbers.

OPERATION

With one end of the flex drive attached to the door

motor and the other attached to the lower drive unit,

the flex drive transfers the power and torque from

the motor to the drive unit. A square shaped drive

cable, inside the flex drive assembly engages the

motor drive and rotates to move the door accordingly.

Fig. 17 Lower Hinge/Drive Assembly

1 - Lower Drive Unit Cover

2 - Lower Drive Unit Cover Retaining Screws

3 - Sliding Door

4 - Lower Hinge Arm Bracket

Fig. 18 Side Door Components

1 - Sliding Door Control Module

2 - Module Retaining Screw

3 - Module Electrical Connectors

4 - Door Motor Assembly

5 - Flex Drive Assembly

6 - Door Motor Retaining Fasteners

7 - Door Motor Electrical Connector

8N - 36 POWER SLIDING DOOR SYSTEMRS

WIRING HARNESS (Continued)

ProCarManuals.com

Page 493 of 2177

POWER LOCKS

TABLE OF CONTENTS

page page

POWER LOCKS

DESCRIPTION.........................38

OPERATION...........................39

DOOR CYLINDER LOCK SWITCH

DESCRIPTION.........................40

OPERATION...........................40

DIAGNOSIS AND TESTING - DOOR

CYLINDER LOCK SWITCH..............40

REMOVAL.............................41

INSTALLATION.........................41

DOOR LOCK MOTOR

DIAGNOSIS AND TESTING - DOOR LOCK

MOTOR .............................41

DOOR LOCK SWITCH

DIAGNOSIS AND TESTING - DOOR LOCK

SWITCH............................41

REMOVAL.............................42

INSTALLATION.........................42

KEYLESS ENTRY TRANSMITTER

DIAGNOSIS AND TESTING - KEYLESS ENTRY

TRANSMITTER.......................42STANDARD PROCEDURE

STANDARD PROCEDURE - HORN CHIRP

PREFERENCE........................42

STANDARD PROCEDURE - BATTERY

REPLACEMENT.......................42

STANDARD PROCEDURE - RKE

TRANSMITTER PROGRAMING...........43

SPECIFICATIONS

RANGE.............................43

BATTERY...........................43

REMOTE KEYLESS ENTRY MODULE

DESCRIPTION.........................43

OPERATION...........................43

DIAGNOSIS AND TESTING - REMOTE

KEYLESS ENTRY MODULE..............43

REMOVAL.............................44

INSTALLATION.........................44

SLIDING DOOR LOCK MOTOR

REMOVAL.............................44

INSTALLATION.........................44

POWER LOCKS

DESCRIPTION

POWER DOOR LOCK SYSTEM

The front doors, sliding door(s) and liftgate are

equipped with actuator motors to lock or unlock the

latch mechanisms. The door lock actuator motor is

not serviced separately from the door latch, except

for the sliding door(s).

AUTOMATIC DOOR LOCK

The vehicle comes with two options for power door

locks:

²Rolling automatic lock (ENABLE), doors auto-

matically lock at approximately at 25.7 Km/h (16

mph).

²No rolling automatic lock (DISABLE), doors do

not automatically lock when the vehicle is moving.

AUTOMATIC DOOR UNLOCK

The doors will unlock automatically on vehicles

equipped with power door locks if:

²Auto door locks feature is enabled and automatic

unlock is enabled.²The transmission was in gear and speed was

above zero.

²The transmission in park or neutral and speed

is zero.

²Any door (excluding liftgate) opens.

DOOR LOCK INHIBIT

The BCM cancels out the door lock switch actua-

tion, when the key is in the Ignition Switch and

either front door is open.

Pressing the key fob RKE lock/unlock under these

conditions results in normal lock/unlock activation.

CENTRAL LOCKING

If equipped with Vehicle Theft Security System

(VTSS), all the doors can be locked with the key by

using the driver door lock cylinder. Turning the key

to the lock position will lock all the doors.

DOOR LOCK CIRCUIT PROTECTION

The door lock system is protected by a 40 amp fuse

located in the IPM. The BCM receives lock/unlock

input and will turn on the appropriate drivers and

provide a voltage level to the door lock motor for a

specific time. The IPM is located along the side of the

vehicle battery in the engine compartment.

8N - 38 POWER LOCKSRS

ProCarManuals.com

Page 494 of 2177

REMOTE KEYLESS ENTRY SYSTEM

The key fob transmitter (Fig. 1) has six buttons.

Three of them, LOCK, UNLOCK, and PANIC, are

used to actuate parts of, and program the Remote

Keyless Entry (RKE) system via the customer pro-

gramming mode. It is not necessary to use the

PANIC button with the DRB IIItscan tool mode of

programming.

OPERATION

POWER DOOR LOCK SYSTEM

The Body Control Module (BCM) locks or unlocks

the doors when an actuation input signal from a door

lock switch or Remote Keyless Entry Module (RKE)

is received. The BCM turns on the output drivers

and provides a voltage level to the door lock motor

for a specified time. The BCM locks the doors auto-

matically when the vehicle is driven beyond the

speed of 25.7 Km/h (16 mph). The rolling door lock

feature can be disabled if desired. All doors and lift-

gate can be locked or unlocked using mechanical but-

ton or key cylinder methods (Liftgate cylinder does

not lock/unlock vehicle. It only unlocks the liftgate).

AUTOMATIC DOOR LOCKS

The BCM is equipped with a disable feature to

stop the speed sensitive automatic door locks from

functioning. The DISABLE feature can be switchedON or OFF as desired. When the system is DIS-

ABLED the door locks will operate normally, but will

not lock automatically when the vehicle is rolling.

When the door locks are ENABLED the door locks

will automatically lock when the vehicle is moving at

about 25.7 Km/h (16 mph). All doors are closed, the

PCM has set the ªOK TO LOCKº bit, and doors were

not previously locked.

DOOR LOCK INHIBIT

If the key is in the ignition, in any position, and

either front door is ajar, all power door lock function-

ing shall be disabled when activating either door lock

switch. Also, if the Vehicle Theft Alarm (VTA) is

armed, the door lock switch ªUNLOCKº feature will

be disabled until the vehicle is disarmed. Pressing

the RKE lock/unlock button under these conditions

will result in a normal lock/unlock activation.

After the key is removed from the Ignition Switch,

or the doors are closed, the power door locks will

operate normally.

CENTRAL LOCKING

If equipped with Vehicle Theft Security System

(VTSS), all the doors can be locked with the key by

using any of the door lock cylinders. Turning the key

to the LOCK position will lock all the doors.

When the driver door key cylinder switch is

detected active, the BCM will activate the illumi-

nated entry feature and the individual front doors

will become mechanically unlocked. To central unlock

all doors, a second transition from OFF to UNLOCK

has to occur within 2 seconds of the first complete

UNLOCK cycle.

To central unlock the driver door, turn the key to

the rear of the vehicle. This indicates an unlock sig-

nal to the BCM. When key cylinder switch is

detected as active, the BCM will activate the illumi-

nated entry feature. The individual doors will become

mechanically unlocked.

To central lock the vehicle, the driver door lock cyl-

inder is turned toward the front of the vehicle. When

a lock input from either key cylinder is detected as

active, the BCM will cancel the illuminated entry

feature and perform the central lock operation.

DOOR LOCK CIRCUIT PROTECTION

The BCM controls the door lock output drivers. If

the door lock switch is actuated continuously for

more than one second the BCM will turn the output

driver OFF (the BCM would consider the switch

stuck). The lock motors are protected with Positive

Temperature Coefficient (PTC) device that prevents

motor burn out.

Fig. 1 KEY FOB

1 - LEFT SLIDING DOOR BUTTON

2 - RIGHT SLIDING DOOR BUTTON

3 - LIFTGATE SWITCH

RSPOWER LOCKS8N-39

POWER LOCKS (Continued)

ProCarManuals.com

Page 495 of 2177

REMOTE KEYLESS ENTRY SYSTEM

²LOCK: Pressing the LOCK button locks all

doors and sounds horn (chirp) and arm the Vehicle

Theft Security System, if equipped. The chirp verifies

that the RKE receiver has sent a message to the

BCM for door lock operation. If a door has not been

closed before pressing the LOCK button, the vehicle

may not be secured and the VTSS will not arm until

the door is closed.

²UNLOCK: Pressing the UNLOCK button once

will unlock the driver's side doors and activate the

illuminated entry system and disarm Vehicle Theft

Security System, if equipped. Pressing the UNLOCK

button twice within five seconds will unlock all doors

and activate the illuminated entry system.

²LEFT SLIDING DOOR: Pressing the LEFT

SLIDING DOOR BUTTON opens/closes the left

power sliding door remotely.

²RIGHT SLIDING DOOR: Pressing the RIGHT

SLIDING DOOR BUTTON opens/closes the right

power sliding door remotely.

²LIFTGATE: Pressing the LIFTGATE BUTTON

opens/closes the liftgate remotely, if equipped.If not

equipped with power liftgate, pressing the liftgate

button will allow a one time 30 second access to lift-

gate.

²PANIC: Pressing the PANIC button sounds the

horns at half second intervals, flashes the exterior

lamps, and turns ON the interior lamps. The panic

alarm will remain on for three minutes, or until the

PANIC button is actuated again or the ignition

switch is turned to the RUN position.

The Remote Keyless Entry Module is capable of

retaining the transmitter Vehicle Access Code(s)

(VAC) in its memory even after vehicle power has

been interrupted.

NOTE: Additional features available to the customer

are described in the Vehicle Owners Manual.

The RKE system activates the optional memory

seat, mirror system and adjustable pedals, if

equipped. Two primary key fob transmitters can be

programmed to actuate memory seat and mirror set-

ting 1 or 2. Two additional key fob transmitters can

be added, but they will not be able to operate the

memory seat and mirror system (Refer to 8 - ELEC-

TRICAL/POWER SEATS - OPERATION) and (Refer

to 8 - ELECTRICAL/POWER MIRRORS - OPERA-

TION).

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

The Door Cylinder Lock Switch is used to:

²Unlock/Lock all the doors via the Central Lock-

ing feature.

²Arm/Disarm the Vehicle Theft Security System.

²Trigger the Illuminated Entry feature.

The door cylinder lock switch is mounted to the

rear of the driver door lock cylinder. When installed

on the rear of the cylinder, there is a tab on the lock

cylinder that aligns with the switch to prevent it

from turning. An anti-rotating device. The door cylin-

der lock switch is a one time use switch. Once it is

removed from the rear of the door lock cylinder, it

may not be reinstalled and a new switch must be

used.

OPERATION

When the Door Cylinder Lock Switch is turned

either way using the door key cylinder, the BCM

reads a direct message signal from the switch.

If turning the key cylinder once, toward the front

of the vehicle, this will:

(1) Mechanically unlock the door lock.

(2) Disarm the Vehicle Theft Security System (if

equipped).

(3) Turn on the Illuminated Entry (if equipped) for

approximately 30 seconds.

If the key cylinder is turned to the unlock position

(toward the front of vehicle) twice within two sec-

onds, all the doors and liftgate will unlock (if

equipped with the central locking feature).

To lock the vehicle using the door cylinder lock

switch, turn the key cylinder toward the rear of the

vehicle once. This will lock the door that you are

using the key on. If equipped with the central locking

feature, this will lock all the other doors and liftgate.

Furthermore, this will arm the vehicle theft security

system and turn off the illuminated entry.

DIAGNOSIS AND TESTING - DOOR CYLINDER

LOCK SWITCH

(1) Visually inspect the switch for proper installa-

tion. Make sure it is seated on the rear of the key

cylinder, with the tab of the door key cylinder prop-

erly aligned with the slot on the door cylinder lock

switch.

(2) Disconnect the switch at the harness connector

and check the resistance in each switch position.

8N - 40 POWER LOCKSRS

POWER LOCKS (Continued)

ProCarManuals.com

Page 498 of 2177

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMING

(1) Using a functional key fob transmitter, unlock

the vehicle and disarm the Vehicle Theft Security

System.

(2) Insert ignition key into the ignition switch.

(3) Turn the ignition switch to RUN position with-

out starting engine.

(4) Using a functional key fob transmitter, press

and hold the UNLOCK button for a minimum five

seconds (maximum ten seconds).

(5) While still holding UNLOCK button, and

before ten seconds passes, press the PANIC button

and release both at the same time. A single chime

will sound to indicate that the transmitter program-

ming mode has been entered (allow 3 seconds for

chime to sound).

(6) Within 30 seconds of the chime, press and

release the ªLOCKº and ªUNLOCKº buttons on the

transmitter at the same time. Then press and release

any button on the same transmitter and a chime will

sound after successfully programming the transmit-

ter.

(7) Repeat steps 5 and 6 for all transmitters that

will be used with this vehicle (up to 4 total).

(8) Turn ignition to the OFF position. Transmitter

programming mode will discontinue after 60 seconds.

All transmitter programming must be com-

pleted within time specified.

SPECIFICATIONS

RANGE

Normal operation range is up to a distance of 7

meters (23 ft.) of the vehicle. Range may be better or

worse depending on the environment around the

vehicle. Closeness to a radio frequency transmitter

such as a radio station tower that is broadcasting on

105 MHz FM or a 156 MHz 2±way communication

station, may degrade operational range, while range

in an open field will be enhanced.

BATTERY

The batteries can be removed without special tools

and are readily available at local retail stores. Therecommended battery is Duracell DL 2016 or equiva-

lent, TWO cells are required. Battery life is about

three years minimum.

CAUTION: Do not touch the battery terminals or

handle the batteries any more than necessary.

Hands must be clean and dry.

REMOTE KEYLESS ENTRY

MODULE

DESCRIPTION

The RKE module is capable of retaining up to four

different Vehicle Access Codes.

OPERATION

Whenever the vehicle battery power is interrupted

the RKE Module will retain all vehicle access codes

in its memory. When replacing or adding a key fob

transmitter (maximum 4) a DRB IIItscan tool is

required to program the RKE Module to accept the

new Vehicle Access Code if a customer owned trans-

mitter is not available. Refer to Electrical, Remote

Keyless Entry Module, Standard Procedure - Pro-

gramming RKE Module or the Proper Body Diagnos-

tic Procedures manual.

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY MODULE

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Refer to the

proper Body Diagnostic Procedures Manual for test-

ing the Remote Keyless Entry system using a

DRB IIItscan tool. Also refer to other interrelated

systems groups within this manual:

²Vehicle Theft Security System

²Power Seats

²Power Mirrors

RSPOWER LOCKS8N-43

KEYLESS ENTRY TRANSMITTER (Continued)

ProCarManuals.com

Page 507 of 2177

Refer toHeated Seat Systemfor more informa-

tion on the heated seat system. Refer toRemote

Keyless Entry Systemin Power Lock Systems for

more information on the RKE system.

Refer toWiring Diagramsfor complete circuit

diagrams. Following are descriptions, theory of oper-

ation, diagnosis/testing procedures and removal/in-

stallation procedures of the major components in the

memory and power seat systems.

OPERATION

OPERATION - POWER SEAT SYSTEM

The power seat system receives battery current

through fuse #22 in the Intelligent Power Module

and a circuit breaker under the front seats, regard-

less of the ignition switch position.

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the appropri-

ate power seat track adjuster motor. The selected

adjuster motor operates to move the seat track

through its drive unit in the selected direction until

the switch is released, or until the travel limit of the

seat track is reached. When the switch is moved in

the opposite direction, the battery feed and ground

path to the motor are reversed through the switch

contacts. This causes the adjuster motor to run in the

opposite direction.

No power seat switch should be held applied in any

direction after the seat track has reached its travel

limit. The power seat track each contain a self-reset-

ting circuit breaker to protect them from overload.

However, consecutive or frequent resetting of the cir-

cuit breaker must not be allowed to continue, or the

motor may be damaged. Refer to the owner's manual

in the vehicle glove box for more information on the

features, use and operation of the power seat system.

OPERATION - MEMORY SYSTEM

The Memory Seat Mirror Module (MSMM) receives

battery current through fuse #22 in the Intelligent

Power Module and the power seat system circuit

breaker, located under the driver side front seat near

the rear edge of the seat cushion pan. The memory

system does not operate with the Ignition-Off Draw

(IOD) fuse removed. The MSMM will drive a maxi-

mum of 2 motors at a time in a given direction. If

conflicting directions are requested, the priority for

response will be approximately as follows:

²Seat Track Rearward or Forward

²Seat Front Down or Up

²Seat Rear Down or Up

²Recliner Rearward or ForwardThe inputs from these switches to the MSMM is a

current limited battery source fed by the MSMM.

This protects the MSMM printed circuit board traces

from acting as fuses. All of these switch contact

inputs to the MSMM are normally closed to ground,

except when actuated.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory system. For diagnosis of the MSMM,

the PCI data bus, or the other electronic modules on

the PCI data bus that provide inputs and outputs for

the memory system, the use of a DRBIIItscan tool

and the proper Diagnostic Procedures manual are

recommended.

ELECTRONIC VEHICLE INFORMATION CENTER

The Electronic Vehicle Information Center (EVIC)

serves as the user interface for the memory system.

It displays memory system status messages and pro-

vides the user with the means for enabling and dis-

abling the many customer programmable features

available on the vehicle, including those for the mem-

ory system.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EVIC. Refer toElectronic Vehicle Informa-

tion Centerin Overhead Console Systems for more

information on the EVIC.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power seat

system. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing of

the driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBIIItscan tool

and the proper Diagnostic Procedures manual. The

DRBIIItscan tool can provide confirmation that the

PCI data bus is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages on the PCI data bus, and that the memory sys-

tem is receiving the proper hard wired inputs and

relaying the proper hard wired outputs to perform its

driver side power seat functions.

8N - 52 POWER SEAT SYSTEMRS

POWER SEAT SYSTEM (Continued)

ProCarManuals.com

Page 508 of 2177

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) If the vehicle is equipped with the memory sys-

tem and the driver side power seat exhibits a inter-

rupted or jerky motion, there is a possibility that the

wires leading from the memory seat module to the

memory seat motor are mis-wired. To check the con-

cern, obtain a DRBIIItscan tool and energize each

axis one at a time. If any axis stops in approximately

2 seconds (without hitting the end of travel), the

feedback for that axis may have an open, short or be

mis-wired. Check the wiring to that axis (module to

motor). Fix any wiring problems and retry that axis.

(2) If any power seat is not operational in any

direction, check the power seat circuit breaker,

located under the trailing edge of the driver side

power seat. Refer to the Power Distribution section of

this service manual for the circuit breaker diagnosis

and testing procedure.

(3) If the power seat circuit breaker is OK, check

for proper battery and ground connections at the

power seat switch and/or memory seat module. Fix

any wiring problems and retry.

(4) Check the power seat system wire harness con-

nections and pins to ensure proper circuit continuity

and ground paths. For complete circuit diagrams,

refer toWiring Diagrams.

(5) With the dome lamp on, apply the power seat

switch in the direction of the failure. If the dome

lamp dims, the seat may be jamming. Check under

and behind the seat for binding or obstructions. If

the dome lamp does not dim, proceed with testing of

the individual components and circuits in the power

seat system.

DIAGNOSIS AND TESTING - MEMORY SYSTEM

In order to obtain conclusive testing of the memory

system, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the memory system requires the use of a

DRB IIItscan tool and the proper Diagnostic Proce-

dures manual. The DRB IIItscan tool can provideconfirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the memory system is receiving the proper hard

wired inputs and relaying the proper hard wired out-

puts to perform its functions.

(1) If the driver power seat exhibits a interrupted

or jerky motion, there is a possibility that the wires

leading from the memory seat module to the memory

seat motor are mis-wired. To check the concern,

obtain a DRB IIItscan tool and energize each axis

one at a time. If any axis stops in approximately 2

seconds (without hitting the end of travel), the feed-

back for that axis may have an open, short or be mis-

wired. Check the wiring to that axis (module to

motor). Fix any wiring problems and retry that axis.

Refer to Wiring Diagrams for complete circuit sche-

matic or connector pin-out information.

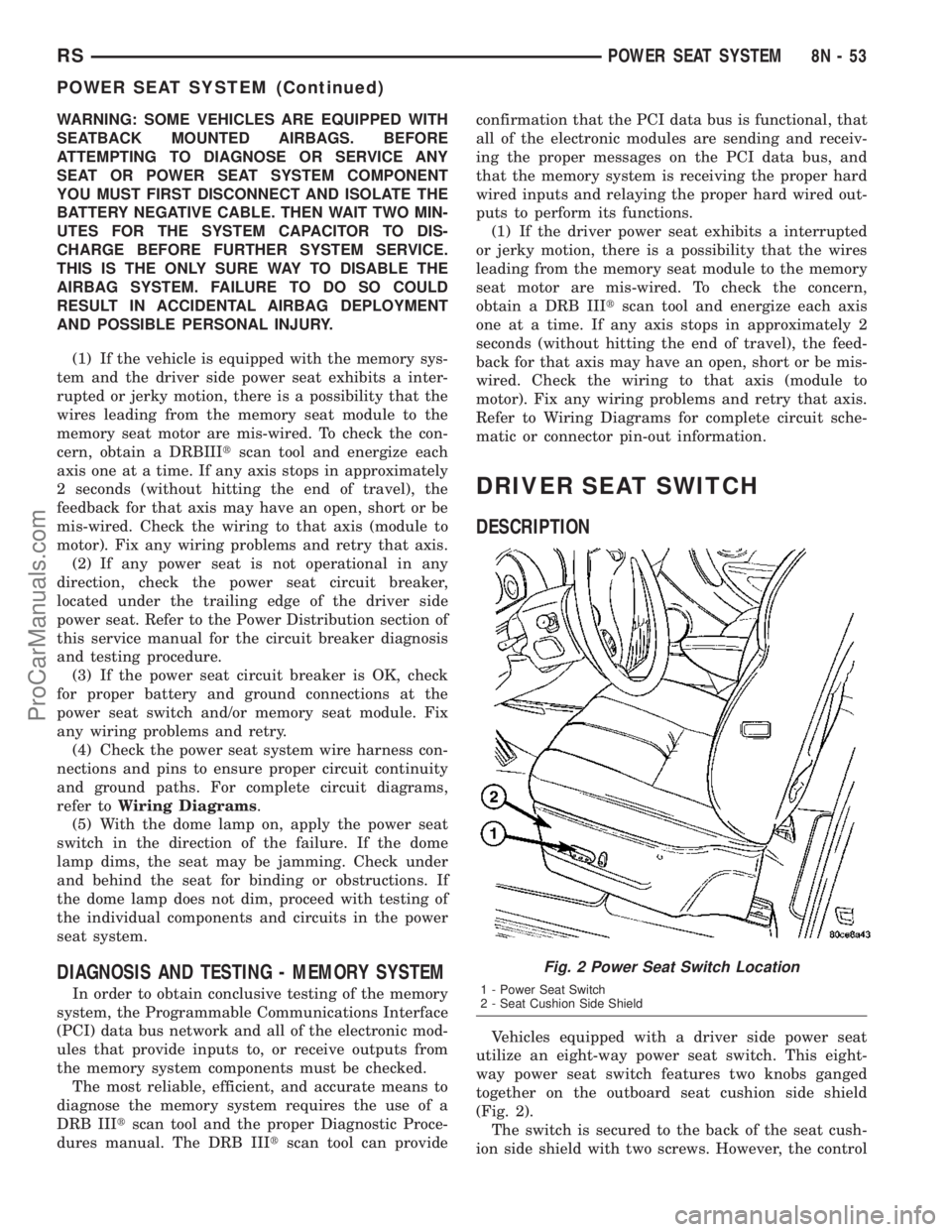

DRIVER SEAT SWITCH

DESCRIPTION

Vehicles equipped with a driver side power seat

utilize an eight-way power seat switch. This eight-

way power seat switch features two knobs ganged

together on the outboard seat cushion side shield

(Fig. 2).

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

Fig. 2 Power Seat Switch Location

1 - Power Seat Switch

2 - Seat Cushion Side Shield

RSPOWER SEAT SYSTEM8N-53

POWER SEAT SYSTEM (Continued)

ProCarManuals.com