ECU CHRYSLER CARAVAN 2003 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 341 of 2177

²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

²Battery Thermowrap- The battery thermow-

rap insulates the battery to protect it from engine

compartment temperature extremes.

²Battery Tray- The battery tray provides a

secure mounting location in the vehicle for the bat-

tery and an anchor point for the battery holddown

hardware.

For battery system maintenance schedules and

jump starting procedure, see the owner's manual in

the vehicle glove box. Optionally, refer to the Lubri-

cation and Maintenance section of this manual for

the recommended battery maintenance schedules and

for the proper battery jump starting procedure. While

battery charging can be considered a maintenance

procedure, the battery charging procedure and

related information are located later in this section of

this service manual. This was done because the bat-

tery must be fully-charged before any battery system

diagnosis or testing procedures can be performed.

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle acces-

sory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging sys-

tem for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING - BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be tested

as a complete system. In order for the engine to start

and the battery to maintain its charge properly, all of

the components that are used in these systems must

perform within specifications. It is important that

the battery, starting, and charging systems be thor-

oughly tested and inspected any time a battery needs

to be charged or replaced. The cause of abnormal bat-

tery discharge, overcharging or early battery failure

must be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it eas-

ier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interde-

pendency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmme-

ter, a battery charger, a carbon pile rheostat (load

tester) and a 12-volt test lamp may be required. All

OBD-sensed systems are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for any failure it detects. Refer to

Charging System for the proper charging system on-

board diagnostic test procedures.

MICRO 420 BATTERY TESTER

The Micro 420 automotive battery system tester is

designed to help the dealership technicians diagnose

the cause of a defective battery. Follow the instruc-

tion manual supplied with the tester to properly

diagnose a vehicle. If the instruction manual is not

available refer to the standard procedure in this sec-

tion, which includes the directions for using the

Micro 420 battery tester.

8F - 2 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)

ProCarManuals.com

Page 353 of 2177

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.

(4) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Integrated Power Module (IPM), one

at a time until the amperage reading becomes very

low, or nonexistent. Refer to the appropriate wiring

information in this service manual for complete Inte-

grated Power Module fuse, circuit breaker, and cir-

cuit identification. This will isolate each circuit and

identify the circuit that is the source of the high-am-

perage IOD. If the amperage reading remains high

after removing and replacing each fuse and circuit

breaker, disconnect the wire harness from the gener-

ator. If the amperage reading now becomes very low

or nonexistent, refer to Charging System for the

proper charging system diagnosis and testing proce-

dures. After the high-amperage IOD has been cor-

rected, switch the multi-meter to progressively lower

amperage scales and, if necessary, repeat the fuse

and circuit breaker remove-and-replace process to

identify and correct all sources of excessive IOD. It is

now safe to select the lowest milliampere scale of the

multi-meter to check the low-amperage IOD.

CAUTION: Do not open any doors, or turn on any

electrical accessories with the lowest milliampere

scale selected, or the multi-meter may be damaged.

(5) Allow twenty minutes for the IOD to stabilize

and observe the multi-meter reading. The low-amper-

age IOD should not exceed twenty-five milliamperes

(0.025 ampere). If the current draw exceeds twenty-

five milliamperes, isolate each circuit using the fuse

and circuit breaker remove-and-replace process in

Step 4. The multi-meter reading will drop to within

the acceptable limit when the source of the excessive

current draw is disconnected. Repair this circuit as

required; whether a wiring short, incorrect switch

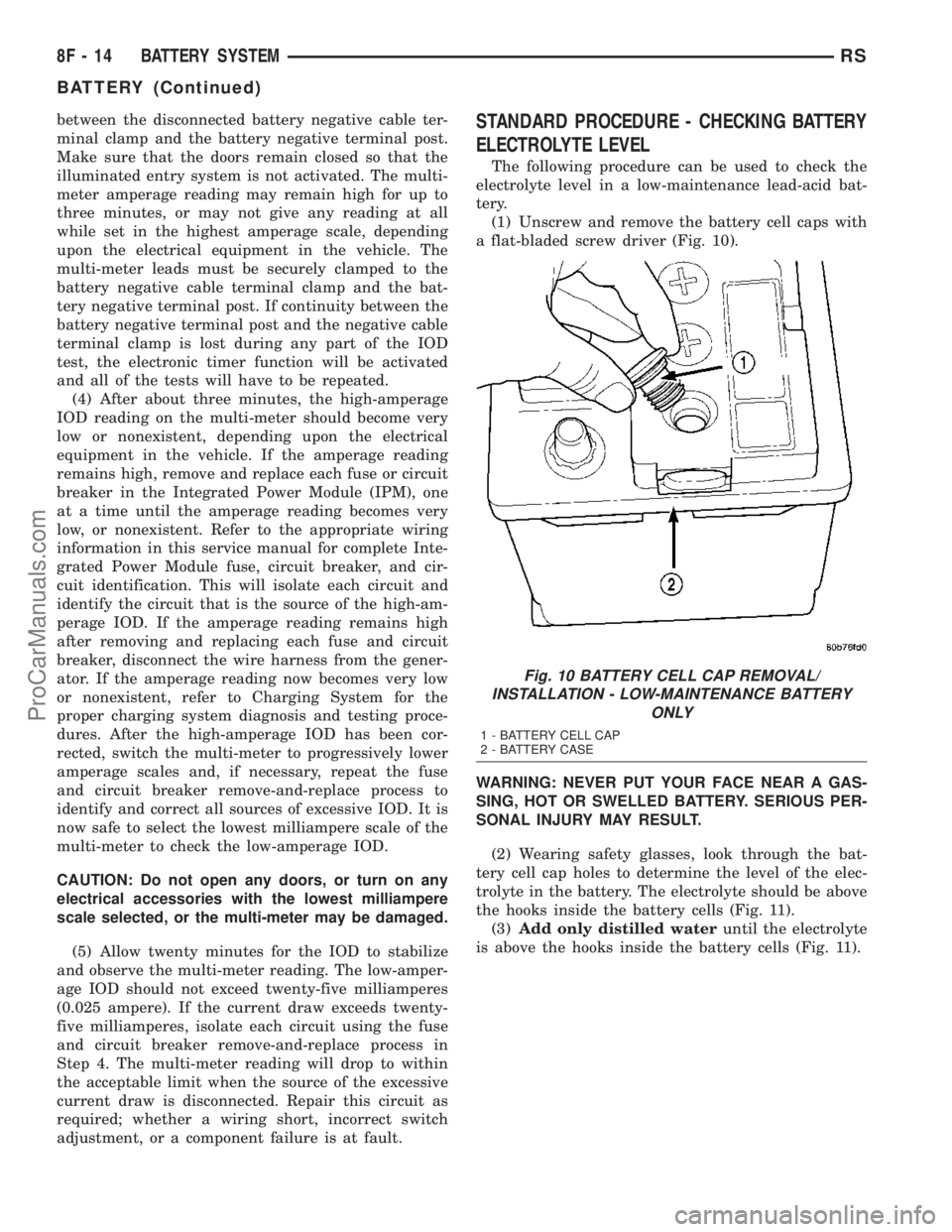

adjustment, or a component failure is at fault.STANDARD PROCEDURE - CHECKING BATTERY

ELECTROLYTE LEVEL

The following procedure can be used to check the

electrolyte level in a low-maintenance lead-acid bat-

tery.

(1) Unscrew and remove the battery cell caps with

a flat-bladed screw driver (Fig. 10).

WARNING: NEVER PUT YOUR FACE NEAR A GAS-

SING, HOT OR SWELLED BATTERY. SERIOUS PER-

SONAL INJURY MAY RESULT.

(2) Wearing safety glasses, look through the bat-

tery cell cap holes to determine the level of the elec-

trolyte in the battery. The electrolyte should be above

the hooks inside the battery cells (Fig. 11).

(3)Add only distilled wateruntil the electrolyte

is above the hooks inside the battery cells (Fig. 11).

Fig. 10 BATTERY CELL CAP REMOVAL/

INSTALLATION - LOW-MAINTENANCE BATTERY

ONLY

1 - BATTERY CELL CAP

2 - BATTERY CASE

8F - 14 BATTERY SYSTEMRS

BATTERY (Continued)

ProCarManuals.com

Page 354 of 2177

REMOVAL - BATTERY

WARNING: A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES AND SAFETY GLASSES SHOULD

BE WORN WHEN REMOVING OR SERVICING A

BATTERY.

WARNING: REMOVE METALLIC JEWELRY TO

AVOID INJURY BY ACCIDENTAL ARCING OF BAT-

TERY CURRENT.

(1) Verify that the ignition switch and all accesso-

ries are OFF.

(2) Disconnect the battery cables from the battery

posts, negative first (Fig. 12).

(3) Remove the battery hold down retaining nut.

(4) Remove the battery hold down bracket.

(5) Remove the battery from the vehicle.

INSTALLATION

(1) Position the battery in the battery tray.

(2) Install the battery hold down bracket and

retaining nut. Torque the nut to 20 N´m (180 in. lbs.).

(3) Connect the battery cables to the battery posts,

positive cable first. Torque terminal fasteners to 5

N´m (40 in. lbs.).

BATTERY HOLDDOWN

DESCRIPTION

The battery hold down hardware consists of a

molded plastic lip that is integral to the outboard

edge of the battery tray and support unit, a molded

steel hold down bracket and a single hex nut with a

coned washer.

When installing a battery into the battery tray, be

certain that the hold down hardware is properly

installed and that the fasteners are tightened to the

proper specifications. Improper hold down fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle or both. Refer to

Battery Hold Downsin this section of this service

manual for the location of the proper battery hold

down installation procedures, including the proper

hold down fastener tightness specifications.

OPERATION

The battery holddown secures the battery in the

battery tray. This holddown is designed to prevent

battery movement during the most extreme vehicle

operation conditions. Periodic removal and lubrica-

tion of the battery holddown hardware is recom-

mended to prevent hardware seizure at a later date.

Fig. 11 HOOK INSIDE BATTERY CELLS - LOW-

MAINTENANCE BATTERY ONLY

1 - TOP OF BATTERY

2 - HOOK INSIDE BATTERY CELLS

Fig. 12 BATTERY POSITION & ORIENTATION

1 - BATTERY THERMOWRAP (IF EQUIPPED)

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

RSBATTERY SYSTEM8F-15

BATTERY (Continued)

ProCarManuals.com

Page 355 of 2177

NOTE: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

All of the battery hold down hardware can be ser-

viced without removal of the battery or the battery

tray and support unit.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Remove the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit.

(3) Remove the battery hold down bracket from

the battery tray and support unit.

INSTALLATION

(1) Install the battery hold down bracket in the

battery tray and support unit.

(2) Install the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit. Torque to 20 N´m (180 in. lbs.).

BATTERY CABLES

DESCRIPTION

The battery cables are large gauge, stranded cop-

per wires sheathed within a heavy plastic or syn-

thetic rubber insulating jacket. The wire used in the

battery cables combines excellent flexibility and reli-

ability with high electrical current carrying capacity.

Refer toWiring Diagramsin the index of this ser-

vice manual for the location of the proper battery

cable wire gauge information.

A clamping type female battery terminal made of

stamped metal is attached to one end of the battery

cable wire. A square headed pinch-bolt and hex nut

are installed at the open end of the female battery

terminal clamp. Large eyelet type terminals are

crimped onto the opposite end of the battery cable

wire and then solder-dipped. The battery positive

cable wires have a red insulating jacket to provide

visual identification and feature a larger female bat-

tery terminal clamp to allow connection to the larger

battery positive terminal post. The battery negative

cable wires have a black insulating jacket and a

smaller female battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer toWiring Diagramsin theindex of this service manual for the location of more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is

attached to the ends of two wires. One wire has an

eyelet terminal that connects the battery positive

cable to the B(+) terminal stud of the Integrated

Power Module (IPM), and the other wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the engine starter motor

solenoid. The battery negative cable terminal clamp

is also attached to the ends of two wires. One wire

has an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the left side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the left front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLE

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

8F - 16 BATTERY SYSTEMRS

BATTERY HOLDDOWN (Continued)

ProCarManuals.com

Page 357 of 2177

REMOVAL

The battery cables on this model may include por-

tions of wiring circuits for the generator and other

components on the vehicle. If battery cable replace-

ment is required, it will be necessary to extract the

cables out of the engine wire harness assembly. Use

care not to damage the other wires and circuits

which are also packaged into the engine wire harness

assembly.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Disconnect and isolate the negative battery

cable terminal.

(3) Remove the battery thermowrap (if equipped)

from the battery tray.

(4) Remove the tape from the engine wire harness

assembly, to access the desired battery cable.(5) One at a time, trace and disconnect the battery

cable retaining fasteners and routing clips until the

desired cable is free from the vehicle.

(6) Feed the battery cable out of the vehicle.

INSTALLATION

(1) Position the battery cable in the vehicle.

(2) One at a time, trace and install the battery

cable retaining fasteners and routing clips until the

desired cable is properly installed in the engine wire

harness assembly.

(3) Install the tape on the engine wire harness

assembly.

(4) Install the battery thermowrap (if equipped) on

the battery tray.

(5) Connect the negative battery cable terminal.

BATTERY TRAY

DESCRIPTION

The battery is mounted in a molded plastic battery

tray and support unit located in the left front corner

of the engine compartment. The battery tray and

support unit is secured with two nuts, one is located

directly under the battery and the other is located on

the right side of the tray which also serves as a cool-

ant bottle neck retaining bolt. An additional bolt is

located directly under the battery.

Fig. 15 Testing Battery Positive Cable Resistance

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

Fig. 16 Testing Ground Circuit Resistance

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 17 RS BATTERY TRAY

1 - ENGINE VACUUM RESERVOIR

2 - BATTERY TRAY ASSEMBLY

3 - DRAINAGE HOSE

8F - 18 BATTERY SYSTEMRS

BATTERY CABLES (Continued)

ProCarManuals.com

Page 358 of 2177

The battery tray and support unit also includes a

engine vacuum reservoir, located in the rear of the

unit (Fig. 17). And a drainage hose, located in the

front of the unit (Fig. 17).

OPERATION

The battery tray provides a secure mounting loca-

tion and supports the battery. The battery tray also

provides the anchor point for the battery holddown

hardware. The battery tray and the battery hold-

down hardware combine to secure and stabilize the

battery in the engine compartment, which prevents

battery movement during vehicle operation. Unre-

strained battery movement during vehicle operation

could result in damage to the vehicle, the battery, or

both.

The battery tray used on this model also includes a

engine vacuum reservoir and drainage hose. The vac-

uum reservoir provides a storage container for engine

vacuum. Refer to the engine section of the service

manual for more engine vacuum information. The

drainage hose provides means for any liquid that

might collect in the bottom of the battery tray to

drain under the vehicle.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the battery from the vehicle. Refer to

the procedure in this section.

(3) Remove the battery tray retaining fasteners

(Fig. 18).

(4) Pull battery tray up far enough to disconnect

the engine vacuum harness hose from the battery

tray mounted, vacuum reservoir.

(5) Remove the battery tray from the vehicle.

INSTALLATION

(1) Position the battery tray in the vehicle.

(2) Connect the engine vacuum harness hose on

the battery tray mounted vacuum reservoir.

(3) Position drainage hose and install the battery

tray retaining fasteners (Fig. 18).

(4) Install the battery in the vehicle. Refer to the

procedure in this section.

(5) Connect the negative battery cable.

THERMOWRAP

DESCRIPTION

A one-piece slip-on thermowrap unit shields the

battery case from engine compartment heat. The

thermowrap slips over the battery case and due to its

one piece design, the battery cables must be removed

in order to install or remove the thermowrap.

OPERATION

The thermowrap protects the battery from engine

compartment temperature extremes. The tempera-

ture of the battery can affect battery life. The air

trapped in the padded material of the thermowrap

creates a dead air space, which helps to insulate the

sides of the battery case from the air temperature

found in the surrounding engine compartment.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Disconnect the positive battery cable.

(3) Lift the battery thermowrap straight up to

remove from the battery.

INSTALLATION

(1) Position the thermowrap on the battery.

(2) Connect the negative and positive battery

cables.

Fig. 18 BATTERY TRAY POSITION & ORIENTATION

1 - BATTERY TRAY RETAINING FASTENERS

RSBATTERY SYSTEM8F-19

BATTERY TRAY (Continued)

ProCarManuals.com

Page 379 of 2177

(6) For a terminal replacement, apply a thin layer

of epoxy to area where terminal was fastened.

(7) Apply a thin layer of epoxy on terminal and

place terminal on desired location. To prevent termi-

nal from falling off use a wooden wedge to secure it.

(8) Carefully remove masking tape from grid line.

CAUTION: Do not allow the laminated windshield

glass surface to exceed 82É C (180É F) or the glass

may fracture. The rear window glass surface should

not exceed 204É C (400É F).

(9) Allow epoxy to cure 24 hours at room tempera-

ture.

(10) After epoxy is properly cured remove wedge

from terminal and check the operation of the rear

window defogger.

Fig. 5 Grid Line Repair

1 - BREAK

2 - GRID LINE

3 - MASKING TAPE

8G - 4 HEATED GLASSRS

WINDSHIELD GRID (Continued)

ProCarManuals.com

Page 385 of 2177

(4) Reconnect the instrument panel switch bank

and test the heated seat system for proper operation.

If the system is still inoperative proceed with check-

ing remaining components.

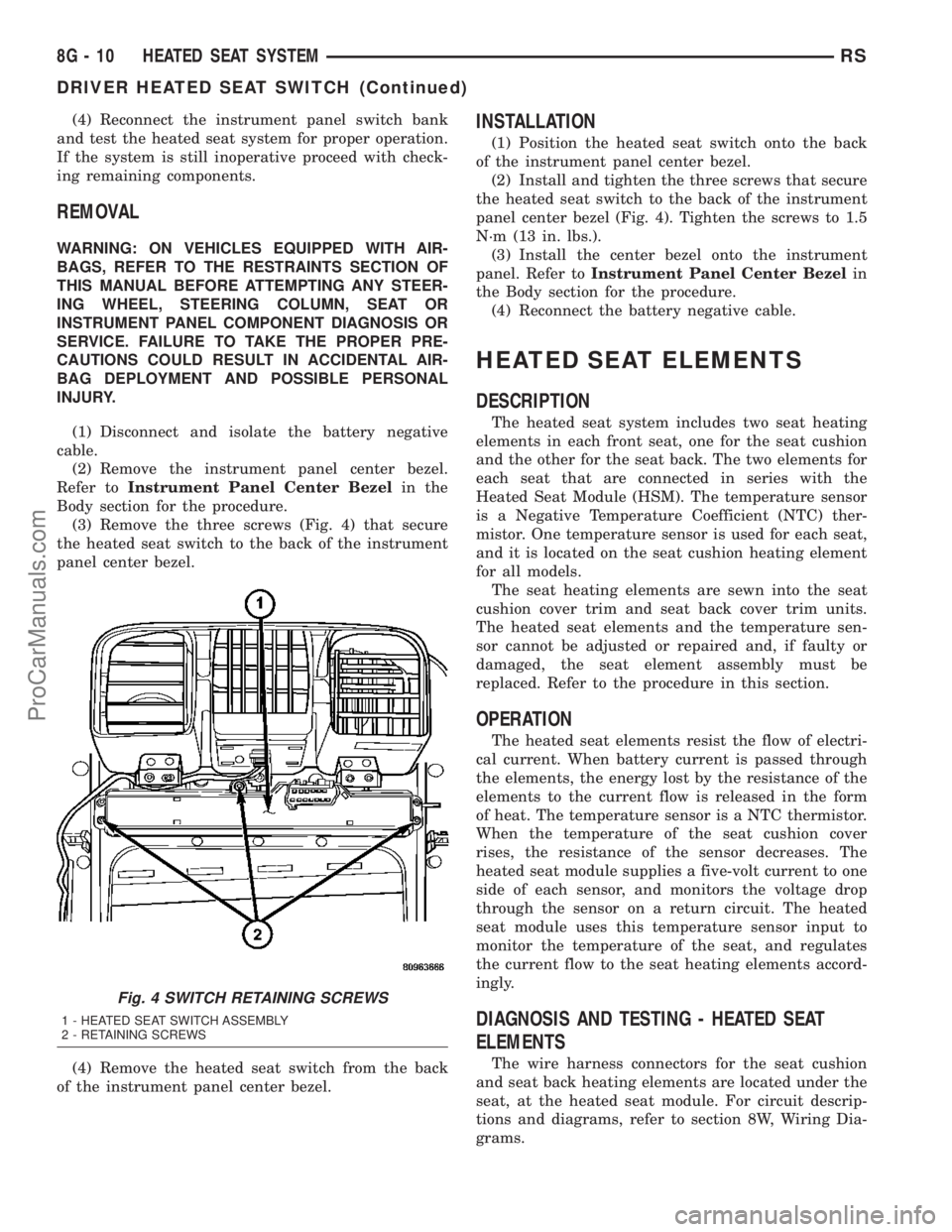

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

(3) Remove the three screws (Fig. 4) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

(2) Install and tighten the three screws that secure

the heated seat switch to the back of the instrument

panel center bezel (Fig. 4). Tighten the screws to 1.5

N´m (13 in. lbs.).

(3) Install the center bezel onto the instrument

panel. Refer toInstrument Panel Center Bezelin

the Body section for the procedure.

(4) Reconnect the battery negative cable.

HEATED SEAT ELEMENTS

DESCRIPTION

The heated seat system includes two seat heating

elements in each front seat, one for the seat cushion

and the other for the seat back. The two elements for

each seat that are connected in series with the

Heated Seat Module (HSM). The temperature sensor

is a Negative Temperature Coefficient (NTC) ther-

mistor. One temperature sensor is used for each seat,

and it is located on the seat cushion heating element

for all models.

The seat heating elements are sewn into the seat

cushion cover trim and seat back cover trim units.

The heated seat elements and the temperature sen-

sor cannot be adjusted or repaired and, if faulty or

damaged, the seat element assembly must be

replaced. Refer to the procedure in this section.

OPERATION

The heated seat elements resist the flow of electri-

cal current. When battery current is passed through

the elements, the energy lost by the resistance of the

elements to the current flow is released in the form

of heat. The temperature sensor is a NTC thermistor.

When the temperature of the seat cushion cover

rises, the resistance of the sensor decreases. The

heated seat module supplies a five-volt current to one

side of each sensor, and monitors the voltage drop

through the sensor on a return circuit. The heated

seat module uses this temperature sensor input to

monitor the temperature of the seat, and regulates

the current flow to the seat heating elements accord-

ingly.

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENTS

The wire harness connectors for the seat cushion

and seat back heating elements are located under the

seat, at the heated seat module. For circuit descrip-

tions and diagrams, refer to section 8W, Wiring Dia-

grams.

Fig. 4 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 10 HEATED SEAT SYSTEMRS

DRIVER HEATED SEAT SWITCH (Continued)

ProCarManuals.com

Page 386 of 2177

In order to access and test the heated seat ele-

ments it will be necessary to remove the appropriate

front seat retaining bolts and lay the seat rearward,

up against one of the rear seats. It is not necessary

to disconnect the seat electrical connectors, just use

care not to damage the attached wire harnesses

while testing.

NOTE: When checking heated seat elements for

continuity, be certain to move the heating element

being checked. Moving the element, such as sitting

in the seat will eliminate the possibility of an inter-

mittent open in the element which would only be

evident if the element was in a certain position.

Failure to check the element in various positions

could result in an incomplete test.

SEAT CUSHION ELEMENT

(1) From under the vehicle, remove the appropri-

ate seats four retaining nuts.

(2) From inside the vehicle, pull the seat up, off

the mounting studs and lay it back, up against one of

the rear seats.

(3) Locate the heated seat module, attached to the

bottom of the seat cushion pan. Remove the heated

seat module from the seat cushion pan. Do not dis-

connect the electrical connectors at this time.

(4) Locate the green 4-way electrical connector,

connected to the heated seat module. Disconnect the

green 4-way connector from the heated seat module.

(5) Check for continuity between the two outboard

circuit cavities of the wire harness connector (Pins

1&4). There should be continuity. If OK, refer to

Heated Seat Module Diagnosis and Testing in the

Electronic Control Modules section of the service

manual for complete system testing procedures. If

not OK, install a replacement heated seat cushion

element. Refer to the procedure in this section.

SEAT BACK ELEMENT

(1) From under the vehicle, remove the appropri-

ate seats four retaining nuts.

(2) From inside the vehicle, pull the seat up and

off the mounting studs and lay it back, up against

one of the rear seats.

(3) Locate the heated seat module, attached to the

bottom of the seat cushion pan. Remove the heated

seat module from the seat cushion pan. Do not dis-

connect the electrical connectors at this time.

(4) Locate the gray 2-way electrical connector, con-

nected to the heated seat module. Disconnect the

2-way connector from the heated seat module.

(5) Check for continuity between the two circuit

cavities of the 2-way wire harness connector. There

should be continuity. If OK, refer to Heated Seat

Module Diagnosis and Testing in the Electronic Con-trol Modules section of the service manual for com-

plete system testing procedures. If not OK, install a

replacement heated seat back element. Refer to the

procedure in this section.

REMOVAL

Do not remove the OEM heating element from the

seat or seat back cushion/trim covers. The original

element is permanently attached and cannot be

removed without permanent damage. The service

replacement heating element is designed to be

applied directly on the seat cushion.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate seat cushion or seat

back trim cover. Refer to the Body section of the ser-

vice manual for the procedures.

(3) Disconnect the inoperative heated seat cushion

or seat back element electrical connectors.

(4) Locate the wires leading from the inoperative

heating element and cut them off flush with the edge

of the original heating element.

INSTALLATION

(1) Peel off the adhesive backing on the back of the

replacement heating element and stick directly on

the foam cushion.

CAUTION: During the installation of the replace-

ment heating element, be careful not to fold or

crease the element assembly. Folds or creases will

cause premature failure.

(2) Connect the new heating element electrical

connectors (Fig. 5).

(3) Connect the negative battery cable.

(4) Verify heated seat system operation.

(5) Install the appropriate seat cushion or seat

back trim cover. Make certain the seat wire harness

is correctly routed through the seat and seat back.

The excess wire between the cushion and back ele-

ments should be securely tucked between the rear of

the cushion foam and the rear carpet flap of the trim

cover.

HEATED SEAT SENSOR

DESCRIPTION

Two heated seat sensors are used per vehicle, one

in each front seat cushion heating element. The

heated seat temperature sensor is a Negative Tem-

perature Coefficient (NTC) thermistor.

The heated seat sensors cannot be repaired or

adjusted and if found to be faulty, the complete

heated seat cushion element must be replaced.

RSHEATED SEAT SYSTEM8G-11

HEATED SEAT ELEMENTS (Continued)

ProCarManuals.com

Page 389 of 2177

(4) Reconnect the instrument panel switch bank

and test the heated seat system for proper operation.

If the system is still inoperative proceed with check-

ing remaining components.

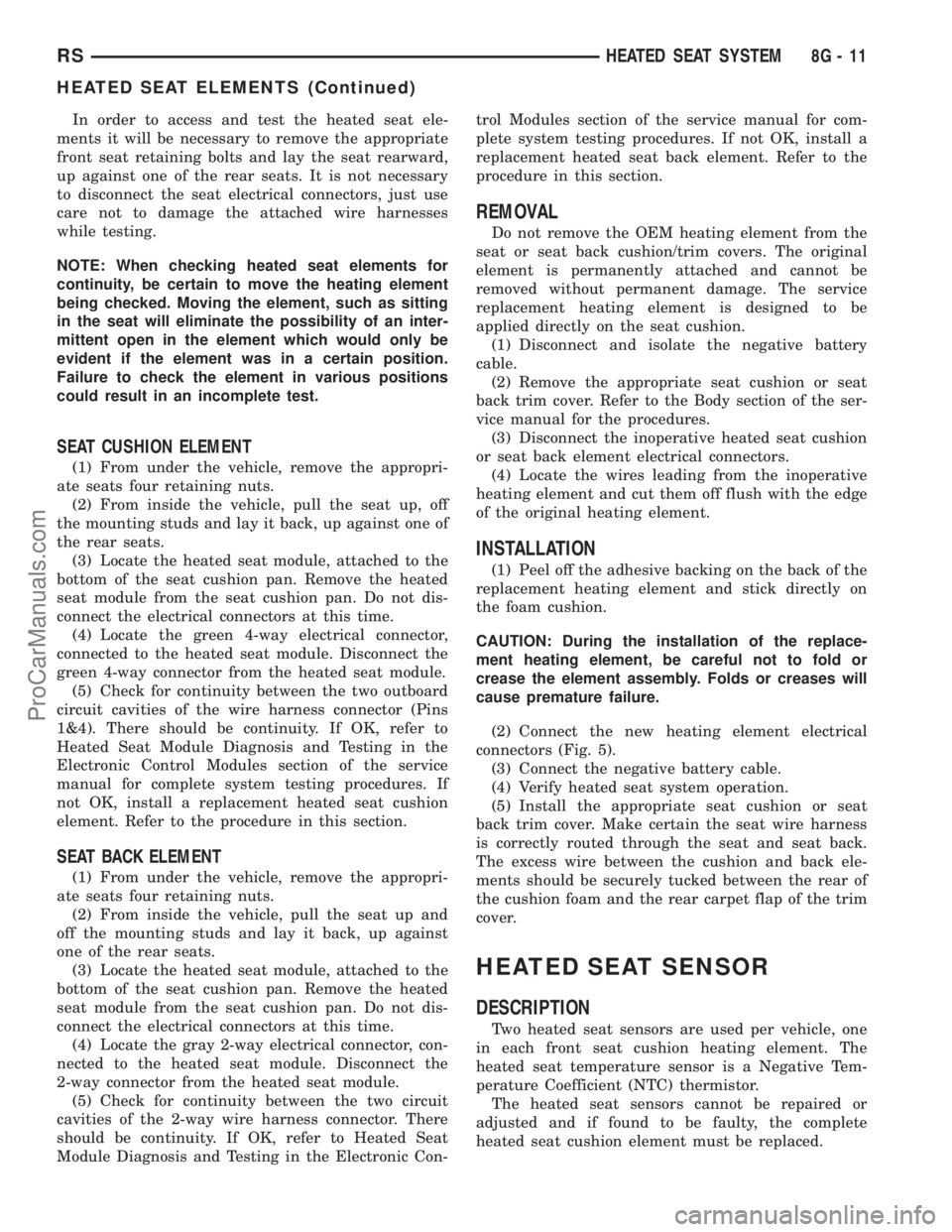

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

(3) Remove the three screws (Fig. 8) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

(2) Install and tighten the three screws that secure

the heated seat switch to the back of the instrumentpanel center bezel (Fig. 8). Tighten the screws to 1.5

N´m (13 in. lbs.).

(3) Install the center bezel onto the instrument

panel. Refer toInstrument Panel Center Bezelin

the Body section for the procedure.

(4) Reconnect the battery negative cable.

Fig. 8 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 14 HEATED SEAT SYSTEMRS

PASSENGER HEATED SEAT SWITCH (Continued)

ProCarManuals.com