location CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1172 of 2339

Fig. 49 LIFTGATE

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-59

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1173 of 2339

Fig. 50 HEADLINER

8W - 91 - 60 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1176 of 2339

(5) Connect the negative and positive battery

cables.

(6) Using a scan tool, check for any stored diagnos-

tic trouble codes. Ensure that all vehicle options are

operational.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed from its normal

cavity in the Integrated Power Module (IPM) when

the vehicle is shipped from the factory. Dealer per-

sonnel are to remove the IOD fuse from the storage

location and install it into the IPM fuse cavity

marked IOD as part of the preparation procedures

performed just prior to new vehicle delivery.

The IOD fuse is a 20 ampere blade-type mini fuse

and, when removed, it is stored in a fuse cavity adja-

cent to the washer fuse within the IPM.

OPERATION

The term ignition-off draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position.

The IOD fuse feeds the memory and sleep mode func-

tions for some of the electronic modules in the vehicle

as well as various other accessories that require bat-

tery current when the ignition switch is in the Off

position, including the clock. The only reason the

IOD fuse is removed is to reduce the normal IOD of

the vehicle electrical system during new vehicle

transportation and pre-delivery storage to reduce

battery depletion, while still allowing vehicle opera-

tion so that the vehicle can be loaded, unloaded and

moved as needed by both vehicle transportation com-

pany and dealer personnel.

The IOD fuse is removed from the Integrated

Power Module (IPM) fuse cavity when the vehicle is

shipped from the assembly plant. Dealer personnel

must install the IOD fuse when the vehicle is being

prepared for delivery in order to restore full electrical

system operation. Once the vehicle is prepared for

delivery, the IOD function of this fuse becomes trans-

parent and the fuse that has been assigned the IOD

designation becomes only another Fused B(+) circuit

fuse. The IOD fuse serves no useful purpose to the

dealer technician in the service or diagnosis of any

vehicle system or condition, other than the same pur-

pose as that of any other standard circuit protection

device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed approximately thirty days. However, it mustbe remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than thirty days,

the battery negative cable should be disconnected to

eliminate normal IOD; and, the battery should be

tested and recharged at regular intervals during the

vehicle storage period to prevent the battery from

becoming discharged or damaged.

POWER OUTLET

DESCRIPTION

Two power outlets are installed in the instrument

panel center lower bezel. Two additional power out-

lets are incorporated into the left rear C-pillar and

the center console (if equipped). The power outlets

bases are secured by a snap fit. A hinged plug flips

closed to conceal and protect the power outlet base

when not in use.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the ON position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-3

INTEGRATED POWER MODULE (Continued)

Page 1180 of 2339

REMOVAL - CAMSHAFT SPROCKETS.....66

REMOVAL - CRANKSHAFT SPROCKET....66

CLEANING............................67

INSTALLATION

INSTALLATION - CRANKSHAFT SPROCKET . 67

INSTALLATION - CAMSHAFT SPROCKETS . . 67

INSTALLATION - TIMING BELT...........67

TIMING BELT TENSIONER & PULLEY

REMOVAL.............................69INSTALLATION.........................70

BALANCE SHAFTS AND CARRIER ASSEMBLY

DESCRIPTION.........................71

OPERATION...........................71

REMOVAL.............................71

INSTALLATION.........................73

ENGINE 2.4L

DESCRIPTION

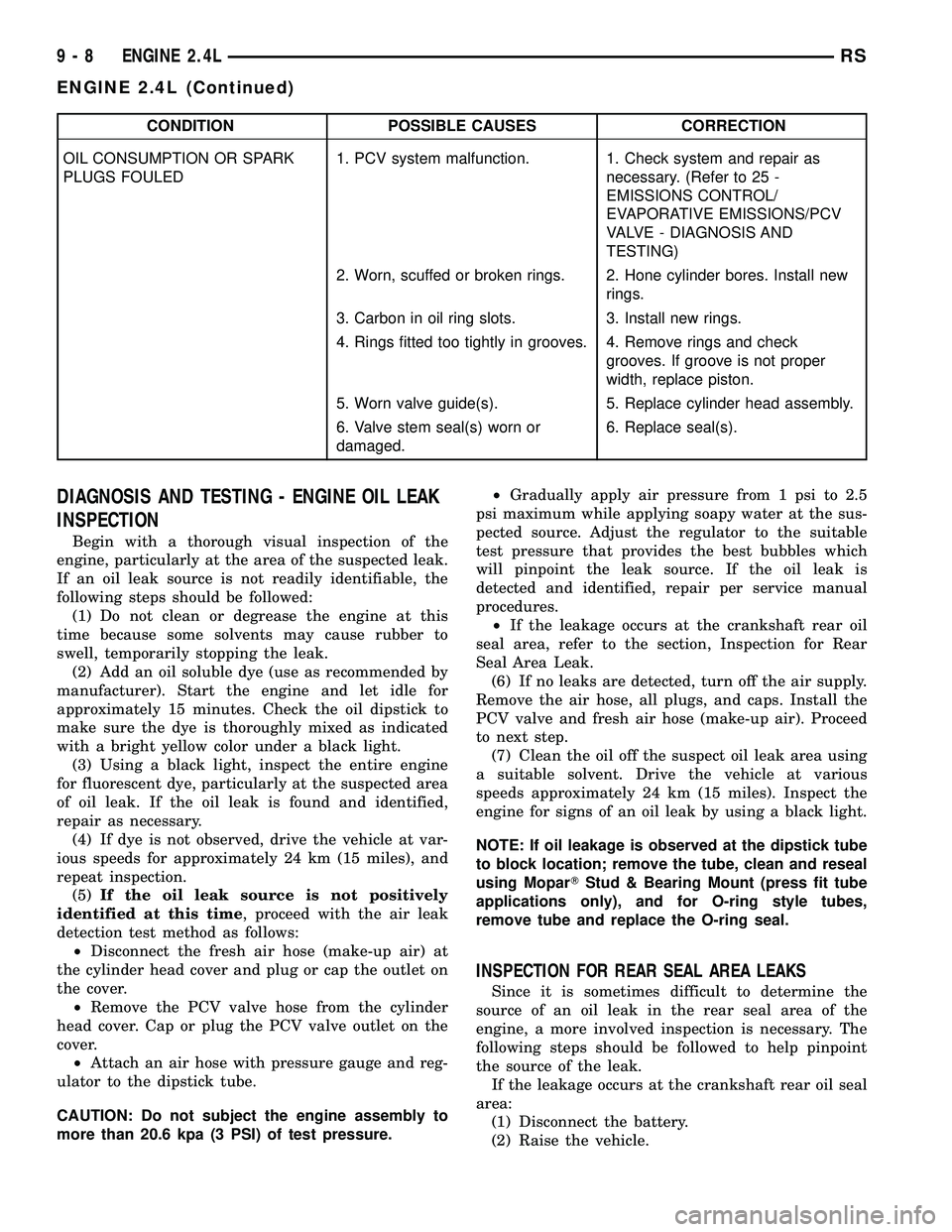

The 2.4 Liter (148 cu. in.) in-line four cylinder

engine is a double over head camshaft with hydraulic

lash adjusters and four valve per cylinder design.

The engine is free-wheeling; meaning it has provi-

sions for piston-to-valve clearance. However valve-to-

valve interference can occur, if camshafts are rotated

independently.

The cylinders are numbered from front of the

engine to the rear. The firing order is 1±3±4±2.

The engine identification number is located on the

rear of the cylinder block (Fig. 1).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).

For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Hydraulic Lash Adjuster Noise Diagnosis

²Engine Oil Leak Inspection

Fig. 1 Engine Identification

1 - ENGINE IDENTIFICATION LOCATION

RSENGINE 2.4L9-3

Page 1185 of 2339

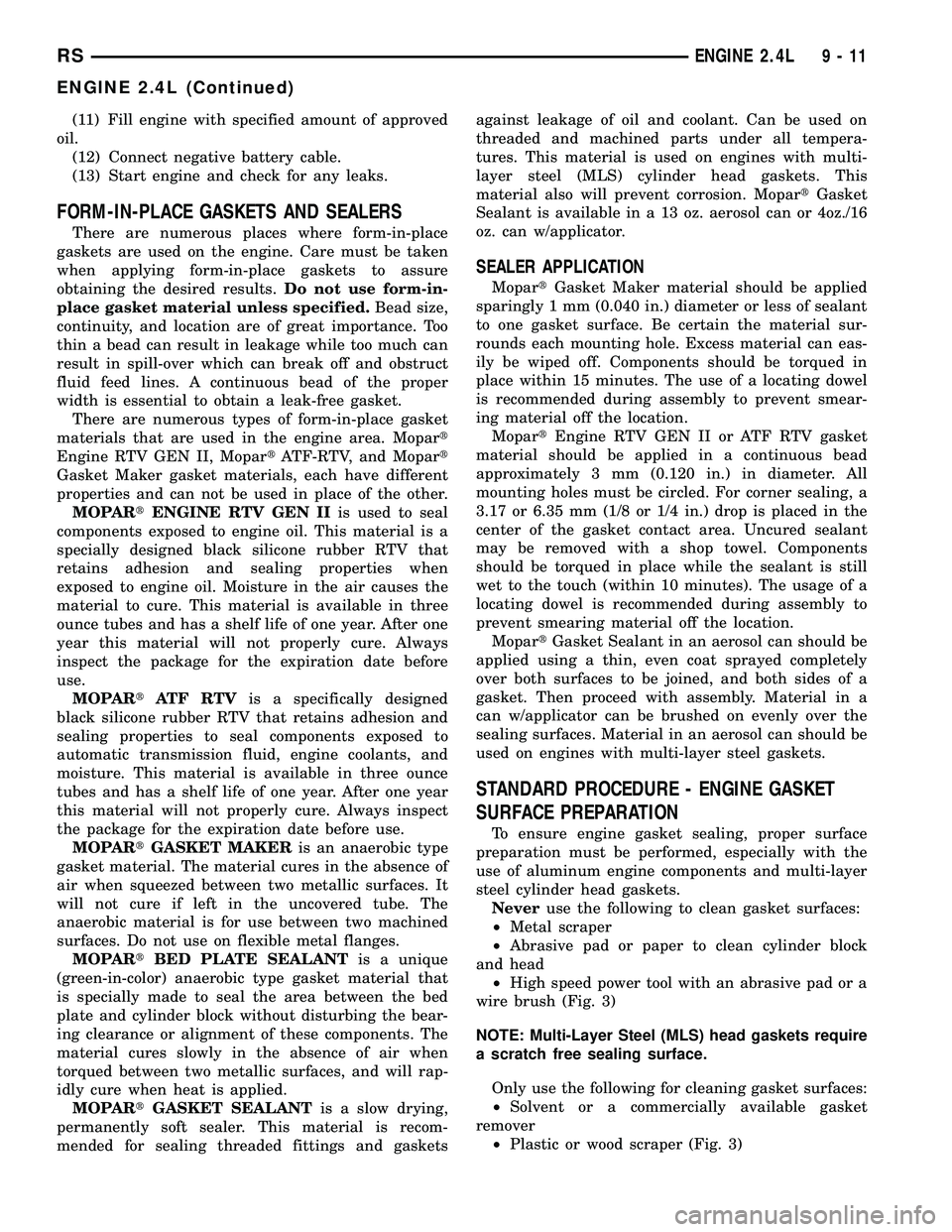

CONDITION POSSIBLE CAUSES CORRECTION

OIL CONSUMPTION OR SPARK

PLUGS FOULED1. PCV system malfunction. 1. Check system and repair as

necessary. (Refer to 25 -

EMISSIONS CONTROL/

EVAPORATIVE EMISSIONS/PCV

VALVE - DIAGNOSIS AND

TESTING)

2. Worn, scuffed or broken rings. 2. Hone cylinder bores. Install new

rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check

grooves. If groove is not proper

width, replace piston.

5. Worn valve guide(s). 5. Replace cylinder head assembly.

6. Valve stem seal(s) worn or

damaged.6. Replace seal(s).

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair as necessary.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (make-up air) at

the cylinder head cover and plug or cap the outlet on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve outlet on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and fresh air hose (make-up air). Proceed

to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

NOTE: If oil leakage is observed at the dipstick tube

to block location; remove the tube, clean and reseal

using MoparTStud & Bearing Mount (press fit tube

applications only), and for O-ring style tubes,

remove tube and replace the O-ring seal.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

9 - 8 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1188 of 2339

(11) Fill engine with specified amount of approved

oil.

(12) Connect negative battery cable.

(13) Start engine and check for any leaks.

FORM-IN-PLACE GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

anaerobic material is for use between two machined

surfaces. Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANTis a unique

(green-in-color) anaerobic type gasket material that

is specially made to seal the area between the bed

plate and cylinder block without disturbing the bear-

ing clearance or alignment of these components. The

material cures slowly in the absence of air when

torqued between two metallic surfaces, and will rap-

idly cure when heat is applied.

MOPARtGASKET SEALANTis a slow drying,

permanently soft sealer. This material is recom-

mended for sealing threaded fittings and gasketsagainst leakage of oil and coolant. Can be used on

threaded and machined parts under all tempera-

tures. This material is used on engines with multi-

layer steel (MLS) cylinder head gaskets. This

material also will prevent corrosion. MopartGasket

Sealant is available in a 13 oz. aerosol can or 4oz./16

oz. can w/applicator.

SEALER APPLICATION

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 3)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 3)

RSENGINE 2.4L9-11

ENGINE 2.4L (Continued)

Page 1204 of 2339

INSPECTION

(1) Cylinder head must be flat within 0.1 mm

(0.004 in.) (Fig. 14).

(2) Inspect camshaft bearing journals for scoring.

(3) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(4) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 15). (Refer to 9 - ENGINE - SPECIFICA-

TIONS) Replace guides if they are not within

specification.

(5) Check valve guide height (Fig. 16).

INSTALLATION - CYLINDER HEAD

NOTE: The Cylinder head bolts should be examined

BEFORE reuse. If the threads are necked down, the

bolts must be replaced (Fig. 17).Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale, the bolt should be replaced.

(1) Before installing the bolts, the threads should

be coated with engine oil.

(2) Position cylinder head gasket on engine block

(Fig. 18).

(3) Install cylinder head on engine block.

(4) Tighten the cylinder head bolts in the sequence

shown in (Fig. 19). Using the 4 step torque turn

method, tighten according to the following values:

²First All to 34 N´m (25 ft. lbs.)

²Second All to 68 N´m (50 ft. lbs.)

²Third All to 68 N´m (50 ft. lbs.)

CAUTION: Do not use a torque wrench for the fol-

lowing step.

²Fourth Turn an additional 1/4 Turn,

Fig. 14 Checking Cylinder Head Flatness

1 - FEELER GAUGE

2 - STRAIGHT EDGE

Fig. 15 Checking Wear on Valve GuideÐTypical

1-TOP

2 - MIDDLE

3 - BOTTOM

4 - CUT AWAY VIEW OF VALVE GUIDE MEASUREMENT

LOCATIONS

Fig. 16 Valve Guide Height

1 - VALVE GUIDE

2 - 13.25 - 13.75 MM (0.521 - 0.541 IN.)

3 - SPRING SEAT

Fig. 17 Checking Bolts for Stretching (Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

RSENGINE 2.4L9-27

CYLINDER HEAD (Continued)

Page 1207 of 2339

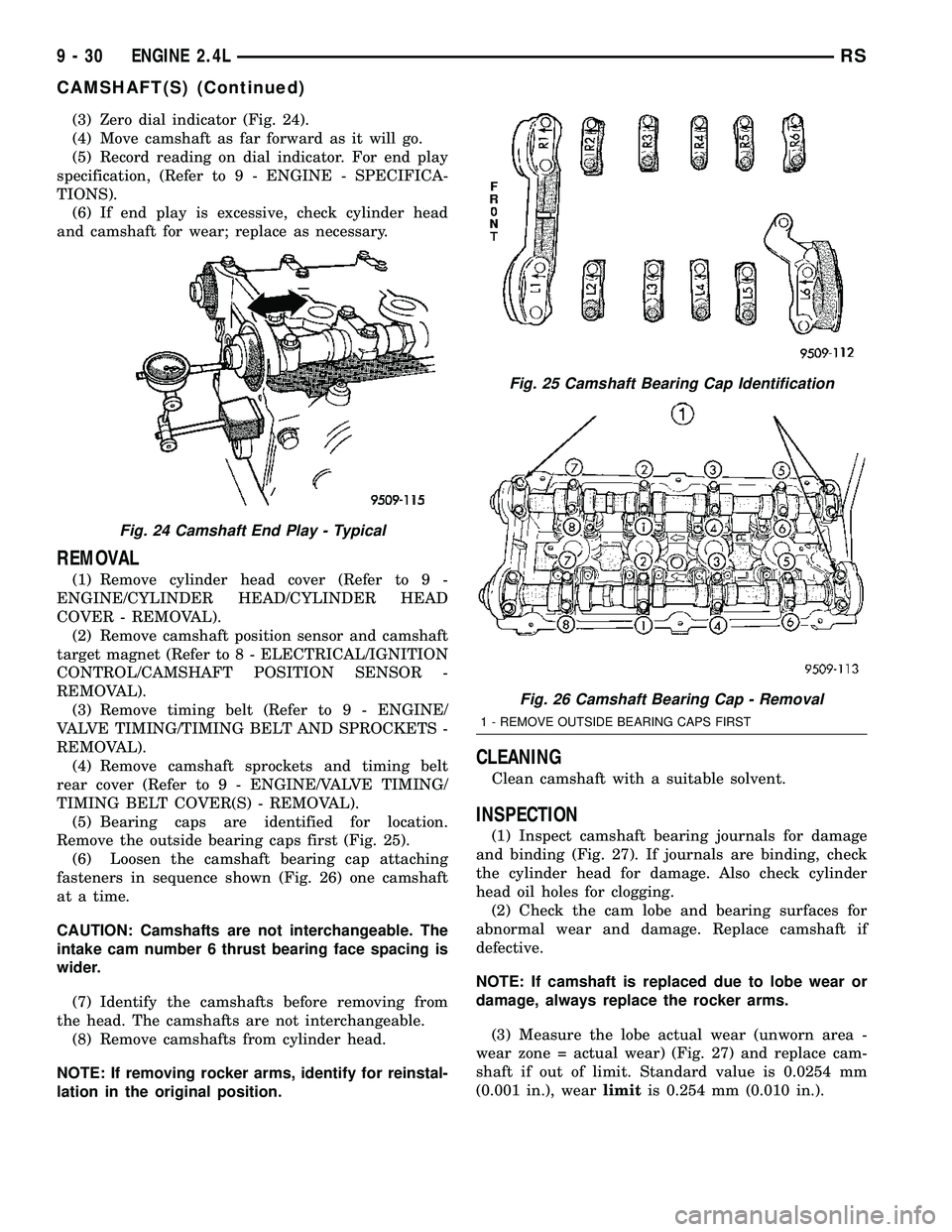

(3) Zero dial indicator (Fig. 24).

(4) Move camshaft as far forward as it will go.

(5) Record reading on dial indicator. For end play

specification, (Refer to 9 - ENGINE - SPECIFICA-

TIONS).

(6) If end play is excessive, check cylinder head

and camshaft for wear; replace as necessary.

REMOVAL

(1) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER - REMOVAL).

(2) Remove camshaft position sensor and camshaft

target magnet (Refer to 8 - ELECTRICAL/IGNITION

CONTROL/CAMSHAFT POSITION SENSOR -

REMOVAL).

(3) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

REMOVAL).

(4) Remove camshaft sprockets and timing belt

rear cover (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT COVER(S) - REMOVAL).

(5) Bearing caps are identified for location.

Remove the outside bearing caps first (Fig. 25).

(6) Loosen the camshaft bearing cap attaching

fasteners in sequence shown (Fig. 26) one camshaft

at a time.

CAUTION: Camshafts are not interchangeable. The

intake cam number 6 thrust bearing face spacing is

wider.

(7) Identify the camshafts before removing from

the head. The camshafts are not interchangeable.

(8) Remove camshafts from cylinder head.

NOTE: If removing rocker arms, identify for reinstal-

lation in the original position.

CLEANING

Clean camshaft with a suitable solvent.

INSPECTION

(1) Inspect camshaft bearing journals for damage

and binding (Fig. 27). If journals are binding, check

the cylinder head for damage. Also check cylinder

head oil holes for clogging.

(2) Check the cam lobe and bearing surfaces for

abnormal wear and damage. Replace camshaft if

defective.

NOTE: If camshaft is replaced due to lobe wear or

damage, always replace the rocker arms.

(3) Measure the lobe actual wear (unworn area -

wear zone = actual wear) (Fig. 27) and replace cam-

shaft if out of limit. Standard value is 0.0254 mm

(0.001 in.), wearlimitis 0.254 mm (0.010 in.).

Fig. 24 Camshaft End Play - Typical

Fig. 25 Camshaft Bearing Cap Identification

Fig. 26 Camshaft Bearing Cap - Removal

1 - REMOVE OUTSIDE BEARING CAPS FIRST

9 - 30 ENGINE 2.4LRS

CAMSHAFT(S) (Continued)

Page 1209 of 2339

INSTALLATION

NOTE: Replace spark plug well seals and bolt

assemblies when installing a new cylinder head

cover gasket.

(1) Install new cylinder head cover gaskets and

spark plug well seals (Fig. 30).

(2) Replace cylinder head cover bolt assemblies.

CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.

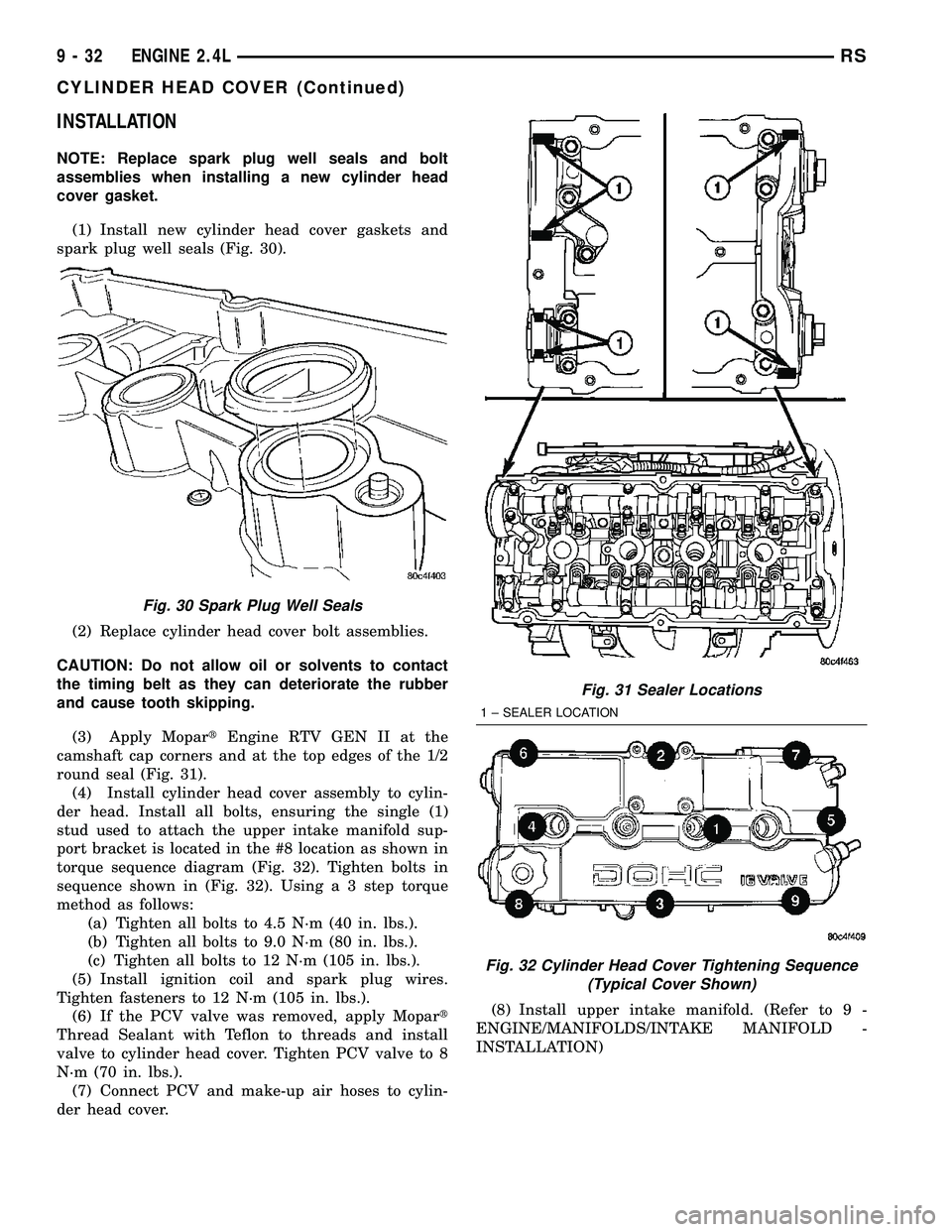

(3) Apply MopartEngine RTV GEN II at the

camshaft cap corners and at the top edges of the 1/2

round seal (Fig. 31).

(4) Install cylinder head cover assembly to cylin-

der head. Install all bolts, ensuring the single (1)

stud used to attach the upper intake manifold sup-

port bracket is located in the #8 location as shown in

torque sequence diagram (Fig. 32). Tighten bolts in

sequence shown in (Fig. 32). Using a 3 step torque

method as follows:

(a) Tighten all bolts to 4.5 N´m (40 in. lbs.).

(b) Tighten all bolts to 9.0 N´m (80 in. lbs.).

(c) Tighten all bolts to 12 N´m (105 in. lbs.).

(5) Install ignition coil and spark plug wires.

Tighten fasteners to 12 N´m (105 in. lbs.).

(6) If the PCV valve was removed, apply Mopart

Thread Sealant with Teflon to threads and install

valve to cylinder head cover. Tighten PCV valve to 8

N´m (70 in. lbs.).

(7) Connect PCV and make-up air hoses to cylin-

der head cover.(8) Install upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION)

Fig. 30 Spark Plug Well Seals

Fig. 31 Sealer Locations

1 ± SEALER LOCATION

Fig. 32 Cylinder Head Cover Tightening Sequence

(Typical Cover Shown)

9 - 32 ENGINE 2.4LRS

CYLINDER HEAD COVER (Continued)

Page 1210 of 2339

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel. They

have chrome plated stems to prevent scuffing. Viton

rubber valve stem seals are integral with the spring

seats. The valves have three-bead lock keepers to

retain springs and to promote valve rotation.

CLEANING

(1) Clean all valves thoroughly and discard

burned, warped and cracked valves.

VALVE SPRINGS & SEALS

REMOVAL

REMOVAL - CYLINDER HEAD ON

(1) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Remove camshafts (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - REMOVAL).

(3) Rotate crankshaft until piston is at TDC on

compression.

(4) With air hose attached to adapter tool installed

in spark plug hole, apply 90-120 psi air pressure.

(5) Using Special Tool MD-998772-A with adapter

6779 (Fig. 33), compress valve springs and remove

valve locks.

(6) Remove valve spring(s).

(7) Remove valve stem seal(s) by a using valve

stem seal tool (Fig. 35).

REMOVAL - CYLINDER HEAD OFF

(1) With cylinder head removed from cylinder

block, compress valve springs using a universal valve

spring compressor.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves, locks and

retainers to insure installation in original location.

(4) Inspect the valves. (Refer to 9 - ENGINE/CYL-

INDER HEAD/VALVE SPRINGS - INSPECTION)

INSPECTION

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested for correct tension. Discard the

springs that do not meet specifications. The following

specifications apply to both intake and exhaust

valves springs:

²Valve Closed Nominal TensionÐ76 lbs. @ 38.0

mm (1.50 in.)

²Valve Open Nominal TensionÐ136 lbs. @ 29.75

mm (1.17 in.)

(2) Inspect each valve spring for squareness with a

steel square and surface plate, test springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

INSTALLATION

INSTALLATION - CYLINDER HEAD ON

(1) Install valve seal/valve spring seat assembly

(Fig. 34). Push the assembly down to seat it onto the

valve guide.

(2) Install valve spring and retainer, use Special

Tool MD-998772-A with adapter 6779 to compress

valve springs only enough to install locks (Fig. 33).

Correct alignment of tool is necessary to avoid nick-

ing valve stems.

(3) Remove air hose and install spark plugs.

(4) Install camshafts (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - INSTALLATION).

(5) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER - INSTALLATION).

INSTALLATION - CYLINDER HEAD OFF

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves

using a valve stem seal tool (Fig. 35). The valve stem

seals should be pushed firmly and squarely over

valve guide.

Fig. 33 Valve Spring - Removal/Installation

1 - VALVE SPRING COMPRESSOR MD 998772A

2 - AIR HOSE

RSENGINE 2.4L9-33