steering wheel adjustment CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 88 of 2339

WHEEL ALIGNMENT

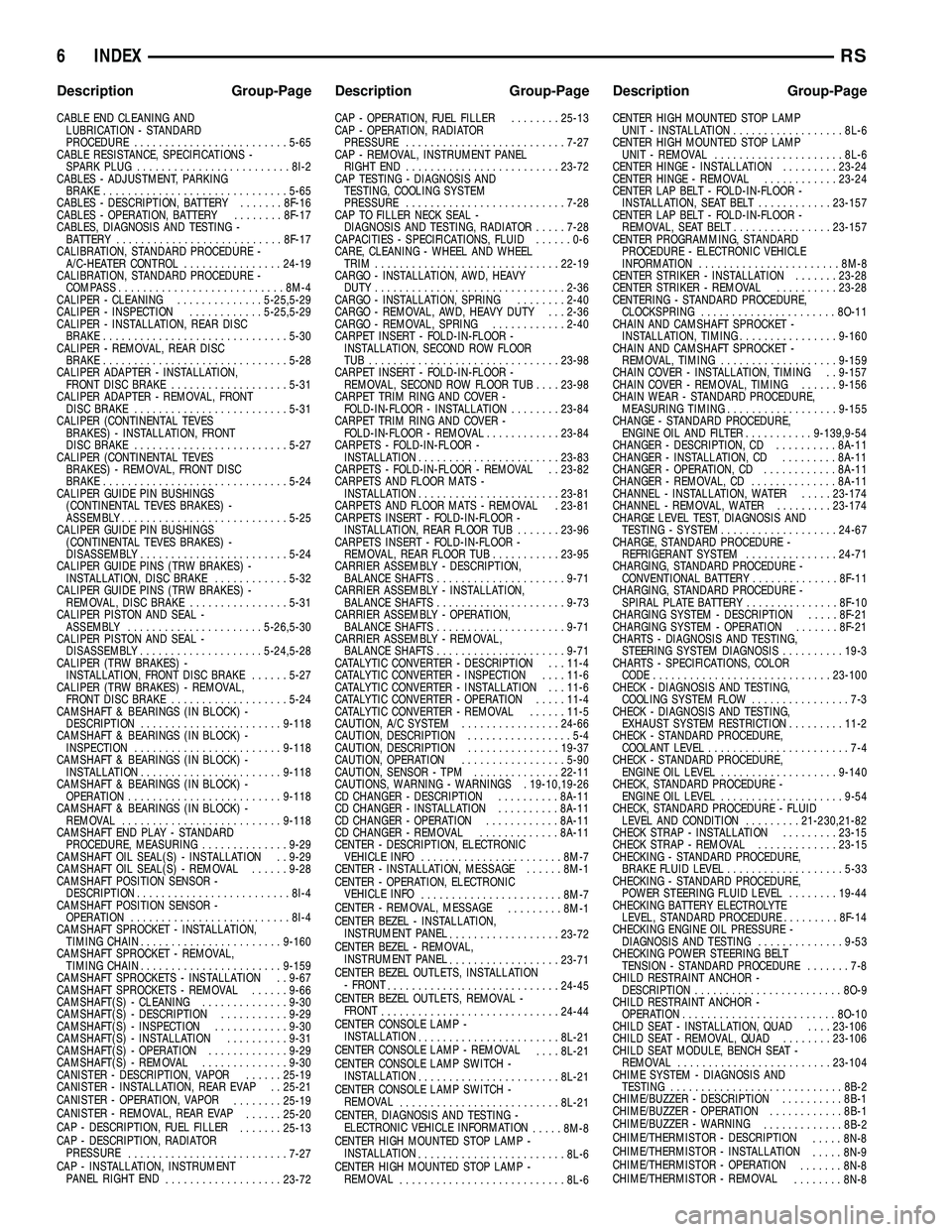

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION - WHEEL ALIGNMENT.......47

DIAGNOSIS AND TESTING - SUSPENSION

AND STEERING......................50

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

ALIGNMENT.........................52STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT......................55

SPECIFICATIONS

WHEEL ALIGNMENT...................56

WHEEL ALIGNMENT

DESCRIPTION - WHEEL ALIGNMENT

Vehicle wheel alignment is the positioning of all

interrelated front and rear suspension angles. These

angles affect the handling and steering of the vehicle

when it is in motion. Proper wheel alignment is

essential for efficient steering, good directional stabil-

ity, and proper tire wear.

The method of checking a vehicle's front and rear

wheel alignment varies depending on the manufac-

turer and type of equipment used. The manufactur-

er's instructions should always be followed to ensure

accuracy of the alignment, except when

DaimlerChrysler Corporation's wheel alignment spec-

ifications differ.

On this vehicle, the suspension angles that can be

adjusted are as follows:

²Front Camber (with camber bolt package and

standard procedure)

²Front Toe

Check the wheel alignment and make all wheel

alignment adjustments with the vehicle standing at

its proper curb height specification. Curb height is

the normal riding height of the vehicle. It is mea-

sured from a certain point on the vehicle to the

ground or a designated area while the vehicle is sit-

ting on a flat, level surface. Refer to Curb Height

Measurement in this section for additional informa-

tion.

Typical wheel alignment angles and measurements

are described in the following paragraphs.

CAMBER

Camber is the inward or outward tilt of the top of

the tire and wheel assembly (Fig. 1). Camber is mea-

sured in degrees of angle relative to a true vertical

line. Camber is a tire wearing angle.

²Excessive negative camber will cause tread wear

at the inside of the tire.²Excessive positive camber will cause tread wear

on the outside of the tire.

Fig. 1 Camber

1 - WHEELS TILTED OUT AT TOP

2 - WHEELS TILTED IN AT TOP

RSWHEEL ALIGNMENT2-47

Page 93 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Lateral Pull 1. Unequal tire pressure 1. Inflate all tires to recommended

pressure

2. Radial tire lead 2. Perform lead correction procedure

3. Incorrect front wheel camber 3. Check and reset front wheel camber

4. Power steering gear imbalance 4. Replace power steering gear

5. Wheel braking 5. Correct braking condition causing

lateral pull

Excessive Steering Free

Play1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to specified

torque

4. Loose or worn steering shaft coupler 4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering pump

drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering coupler 7. Replace steering coupler

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL ALIGNMENT

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment, the following inspection and

necessary corrections must be made to ensure proper

alignment.

(1) Verify that the fuel tank is full of fuel. If the

tank is not full, the reduction in weight will affect

the curb height of the vehicle and the alignment

angles.

(2) The passenger and luggage compartments of

the vehicle should be free of any load that is not fac-

tory equipment.

(3) Check the tires on the vehicle. All tires must be

the same size and in good condition with approxi-

mately the same amount of tread wear. Inflate all

the tires to the recommended air pressure.

(4) Check the front wheel and tire assemblies for

excessive radial runout.(5) Inspect lower ball joints and all steering link-

age for looseness, binding, wear or damage. Repair as

necessary.

(6) Check suspension fasteners for proper torque

and retighten as necessary.

(7) Inspect all suspension component rubber bush-

ings for signs of wear or deterioration. Replace any

faulty bushings or components before aligning the

vehicle.

(8) Check the vehicle's curb height to verify it is

within specifications. Refer to Curb Height Measure-

ment.

WHEEL ALIGNMENT SETUP

(1) Position the vehicle on an alignment rack.

(2) Install all required alignment equipment on

the vehicle per the alignment equipment manufactur-

er's instructions. On this vehicle, a four-wheel align-

ment is recommended.

2 - 52 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

Page 94 of 2339

NOTE: Prior to reading the vehicle's alignment

readouts, the front and rear of vehicle should be

jounced. Induce jounce (rear first, then front) by

grasping the center of the bumper and jouncing

each end of vehicle an equal number of times. The

bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Read the vehicle's current front and rear align-

ment settings. Compare the vehicle's current align-

ment settings to the vehicle specifications for camber,

caster and toe-in. (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - SPECIFICATIONS)

(4) If front camber and caster are not within spec-

ifications, proceed to CAMBER AND CASTER below.

If caster and camber are within specifications, pro-

ceed to TOE which can be found following CAMBER

AND CASTER. Rear camber, caster and toe are not

adjustable. If found not to be within specifications,

reinspect for damaged suspension or body compo-

nents and replace as necessary.

CAMBER AND CASTER

Camber and caster settings on this vehicle are

determined at the time the vehicle is designed, by

the location of the vehicle's suspension components.

This is referred to as NET BUILD. The result is no

required adjustment of camber and caster after the

vehicle is built or when servicing the suspension

components. Thus, when performing a wheel align-

ment, caster and camber are not normally considered

adjustable angles. Camber and caster should be

checked to ensure they meet vehicle specifications.

If front camber is found not to meet alignment

specifications, it can be adjusted using an available

camber adjustment bolt package. Before installing a

camber adjustment bolt package on a vehicle found

to be outside the specifications, inspect the suspen-

sion components for any signs of damage or bending.

CAUTION: Do not attempt to adjust the vehicles

wheel alignment by heating, bending or by perform-

ing any other modification to the vehicle's front

suspension components or body.

If camber readings are not within specifications,

use the following procedure to install the front cam-

ber adjustment bolt package and then adjust front

camber.

CAMBER ADJUSTMENT BOLT PACKAGE INSTALLATION

The camber adjustment bolt package contains 2

flange bolts, 2 cam bolts, 2 dog bone washers, and 4

nuts. This package services both sides of the vehicle.

Use the package to attach the strut clevis bracket to

the steering knuckle after the strut clevis brackethas been modified. To install and adjust the camber

adjustment bolt package, follow the procedure below.

(1) Raise the vehicle until its tires are not support-

ing the weight of the vehicle.

(2) Remove the front tire and wheel assemblies.

CAUTION: When removing the steering knuckle

from the strut clevis bracket, do not put a strain on

the brake flex hose. Also, do not let the weight of

the steering knuckle assembly be supported by the

brake flex hose when removed from the strut

assembly. If necessary use a wire hanger to sup-

port the steering knuckle assembly or if required

remove the brake flex hose from the caliper assem-

bly.

CAUTION: The knuckle to strut assembly attaching

bolt shanks are serrated and must not be turned

during removal. Remove the nuts while holding the

bolts stationary.

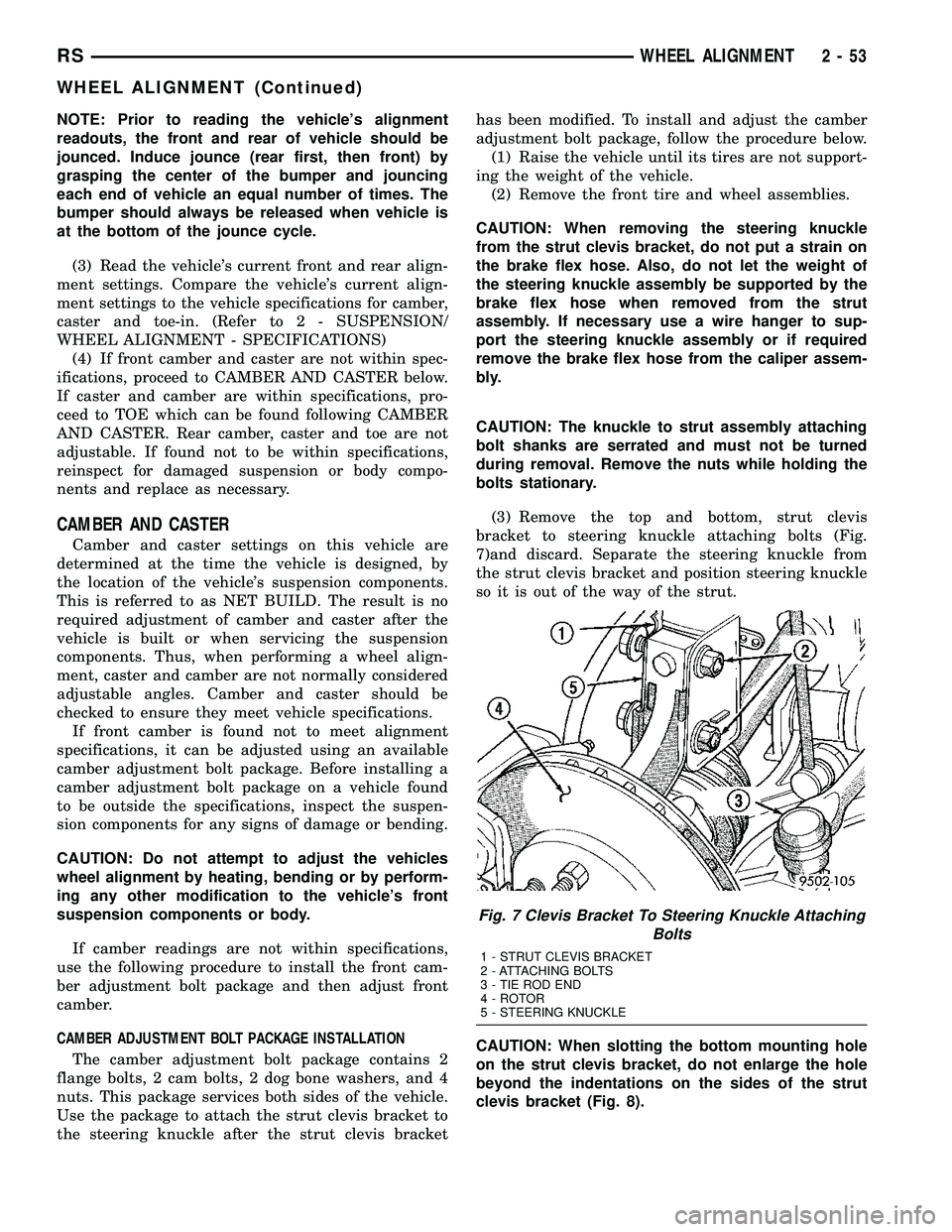

(3) Remove the top and bottom, strut clevis

bracket to steering knuckle attaching bolts (Fig.

7)and discard. Separate the steering knuckle from

the strut clevis bracket and position steering knuckle

so it is out of the way of the strut.

CAUTION: When slotting the bottom mounting hole

on the strut clevis bracket, do not enlarge the hole

beyond the indentations on the sides of the strut

clevis bracket (Fig. 8).

Fig. 7 Clevis Bracket To Steering Knuckle Attaching

Bolts

1 - STRUT CLEVIS BRACKET

2 - ATTACHING BOLTS

3 - TIE ROD END

4 - ROTOR

5 - STEERING KNUCKLE

RSWHEEL ALIGNMENT2-53

WHEEL ALIGNMENT (Continued)

Page 95 of 2339

(4) Using an appropriate grinder and grinding

wheel, slot the bottom hole in both sides of the strut

clevis bracket (Fig. 8).

CAUTION: After slotting the strut clevis bracket

hole, do not install the original attaching bolts when

assembling the steering knuckle to the strut assem-

bly. Only the flange bolts, cam bolts, and dog bone

washers from the service package must be used to

attach the steering knuckle to the strut after the

mounting hole is slotted.

NOTE: The strut clevis-to-knuckle bolts are installed

differently on each side of the vehicle. Left-hand-

side bolts are installed from vehicle rear to front

(Fig. 9). Right-hand-side bolts are installed from

vehicle front to rear.

(5) Position the knuckle back into the strut clevis

bracket. Using the direction indicated in the above

note, install a flanged bolt from the service package

into the upper mounting hole. Using the direction

indicated in the above note, install a cam bolt into

the bottom mounting hole (Fig. 9).

(6) Install a dog bone washer on the steering

knuckle to strut clevis bracket attaching bolts, then

install the nuts onto the bolts from the service pack-

age (Fig. 10). Tighten the bolts just enough to hold

the steering knuckle in position when adjusting cam-

ber, while still allowing the steering knuckle to move

in clevis bracket.

(7) Repeat the procedure to the other side strut

clevis bracket.

(8) Reinstall both front tire and wheel assemblies

and tighten to specifications.(9) Lower the vehicle. Jounce the front and rear of

vehicle an equal amount of times.

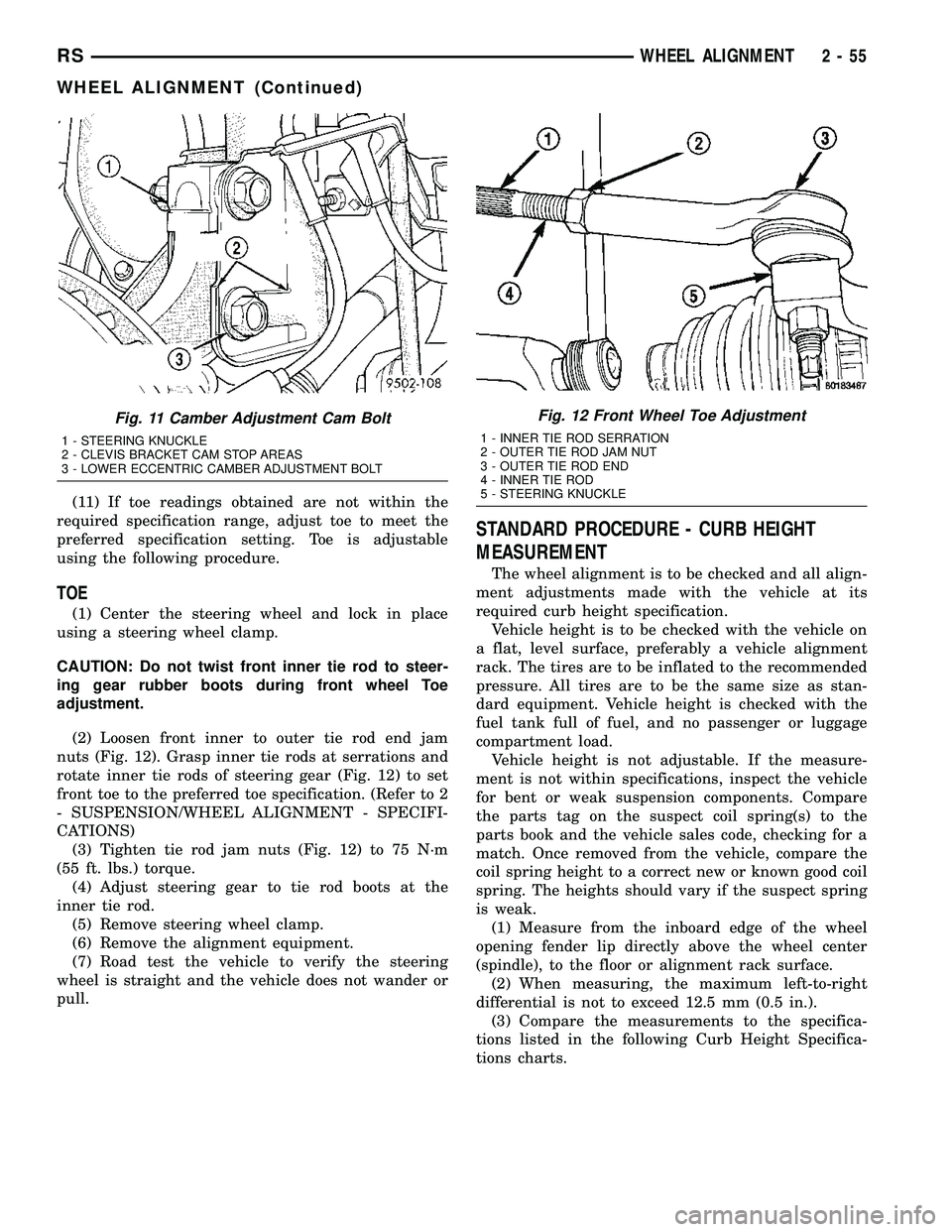

(10) Adjust the front camber to the preferred set-

ting by rotating the lower eccentric cam bolt against

the cam stop areas on the strut clevis bracket (Fig.

11). When camber is set, tighten the upper strut cle-

vis bracket bolt and lower cam bolt. Again jounce

front and rear of vehicle an equal amount of times

and verify front camber setting. Torque both front

strut to steering knuckle attaching bolts to 81 N´m

(60 ft. lbs.) plus an additional 1/4 (90É) turn after the

required torque is met.

Fig. 8 Strut Clevis Bracket Bolt Hole Grinding Area

1 - UPPER STRUT TO STEERING KNUCKLE ATTACHING HOLE

2 - CAMBER ADJUSTMENT SLOT INDENTATION AREA ON

CLEVIS BRACKET

3 - LOWER STRUT TO STEERING KNUCKLE ATTACHING HOLE

4 - STRUT CLEVIS BRACKET

Fig. 9 Package Bolts Correctly Installed

1 - STEERING KNUCKLE

2 - FLANGED BOLT IN TOP HOLE

3 - CAM BOLT IN BOTTOM HOLE

4 - STRUT CLEVIS BRACKET

Fig. 10 Dog Bone Washer And Nuts Installed

1 - STEERING KNUCKLE

2 - DOG BONE WASHER

3 - STRUT CLEVIS BRACKET

4 - ATTACHING NUTS

2 - 54 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

Page 96 of 2339

(11) If toe readings obtained are not within the

required specification range, adjust toe to meet the

preferred specification setting. Toe is adjustable

using the following procedure.

TOE

(1) Center the steering wheel and lock in place

using a steering wheel clamp.

CAUTION: Do not twist front inner tie rod to steer-

ing gear rubber boots during front wheel Toe

adjustment.

(2) Loosen front inner to outer tie rod end jam

nuts (Fig. 12). Grasp inner tie rods at serrations and

rotate inner tie rods of steering gear (Fig. 12) to set

front toe to the preferred toe specification. (Refer to 2

- SUSPENSION/WHEEL ALIGNMENT - SPECIFI-

CATIONS)

(3) Tighten tie rod jam nuts (Fig. 12) to 75 N´m

(55 ft. lbs.) torque.

(4) Adjust steering gear to tie rod boots at the

inner tie rod.

(5) Remove steering wheel clamp.

(6) Remove the alignment equipment.

(7) Road test the vehicle to verify the steering

wheel is straight and the vehicle does not wander or

pull.

STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT

The wheel alignment is to be checked and all align-

ment adjustments made with the vehicle at its

required curb height specification.

Vehicle height is to be checked with the vehicle on

a flat, level surface, preferably a vehicle alignment

rack. The tires are to be inflated to the recommended

pressure. All tires are to be the same size as stan-

dard equipment. Vehicle height is checked with the

fuel tank full of fuel, and no passenger or luggage

compartment load.

Vehicle height is not adjustable. If the measure-

ment is not within specifications, inspect the vehicle

for bent or weak suspension components. Compare

the parts tag on the suspect coil spring(s) to the

parts book and the vehicle sales code, checking for a

match. Once removed from the vehicle, compare the

coil spring height to a correct new or known good coil

spring. The heights should vary if the suspect spring

is weak.

(1) Measure from the inboard edge of the wheel

opening fender lip directly above the wheel center

(spindle), to the floor or alignment rack surface.

(2) When measuring, the maximum left-to-right

differential is not to exceed 12.5 mm (0.5 in.).

(3) Compare the measurements to the specifica-

tions listed in the following Curb Height Specifica-

tions charts.

Fig. 11 Camber Adjustment Cam Bolt

1 - STEERING KNUCKLE

2 - CLEVIS BRACKET CAM STOP AREAS

3 - LOWER ECCENTRIC CAMBER ADJUSTMENT BOLT

Fig. 12 Front Wheel Toe Adjustment

1 - INNER TIE ROD SERRATION

2 - OUTER TIE ROD JAM NUT

3 - OUTER TIE ROD END

4 - INNER TIE ROD

5 - STEERING KNUCKLE

RSWHEEL ALIGNMENT2-55

WHEEL ALIGNMENT (Continued)

Page 1890 of 2339

FRONT SEAT BACK

REMOVAL

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

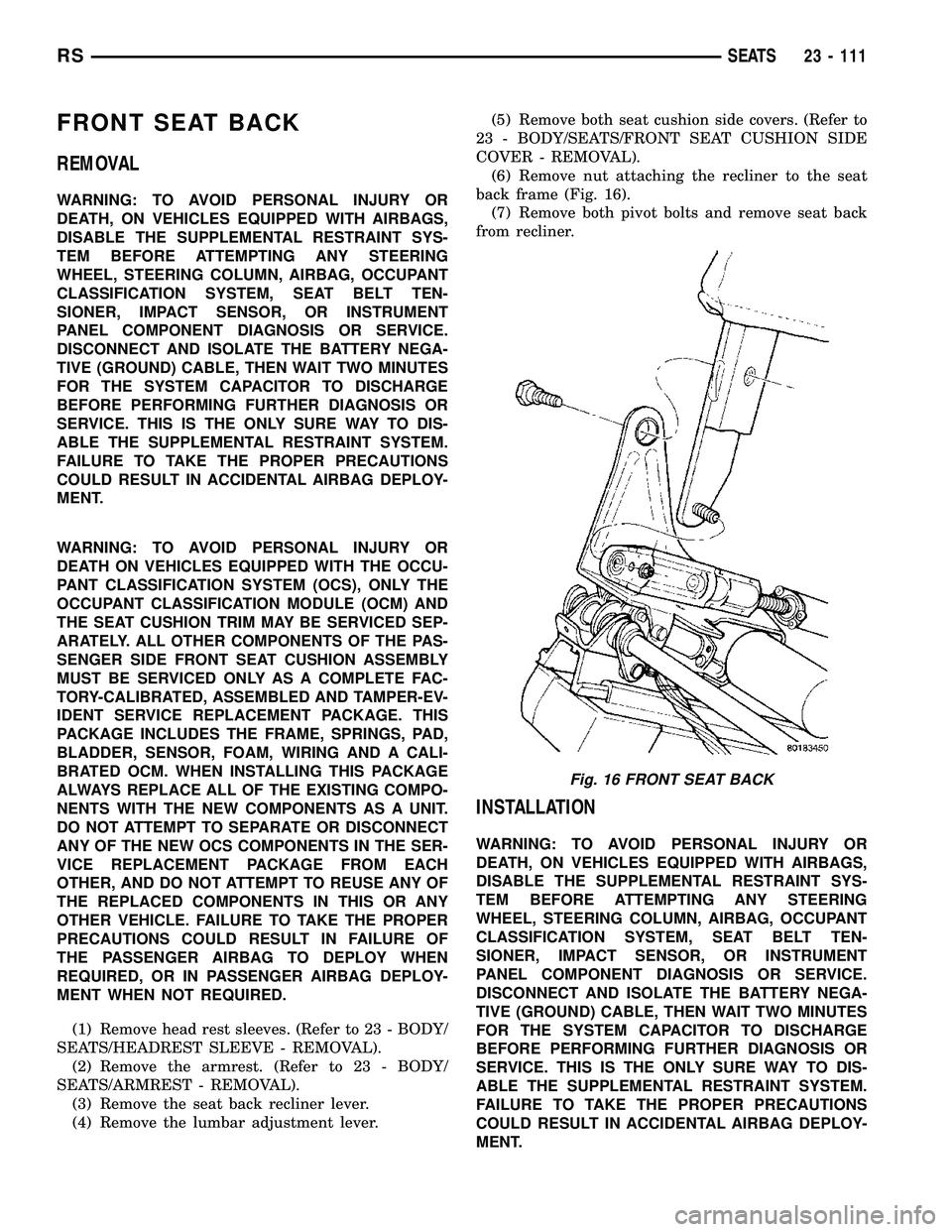

(1) Remove head rest sleeves. (Refer to 23 - BODY/

SEATS/HEADREST SLEEVE - REMOVAL).

(2) Remove the armrest. (Refer to 23 - BODY/

SEATS/ARMREST - REMOVAL).

(3) Remove the seat back recliner lever.

(4) Remove the lumbar adjustment lever.(5) Remove both seat cushion side covers. (Refer to

23 - BODY/SEATS/FRONT SEAT CUSHION SIDE

COVER - REMOVAL).

(6) Remove nut attaching the recliner to the seat

back frame (Fig. 16).

(7) Remove both pivot bolts and remove seat back

from recliner.

INSTALLATION

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

Fig. 16 FRONT SEAT BACK

RSSEATS23 - 111

Page 2304 of 2339

BACKLIGHT (EBL) SYSTEM, DIAGNOSISAND TESTING - ELECTRIC ..............8G-2

BACKSTOW STRAP - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-158

BACKSTOW STRAP - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-158

BAG RETAINER - INSTALLATION, PLASTIC GROCERY .................. 23-149

BAG RETAINER - REMOVAL, PLASTIC GROCERY ......................... 23-149

BALANCE - STANDARD PROCEDURE, TIRE AND WHEEL ..................... 22-5

BALANCE SHAFTS AND CARRIER ASSEMBLY - DESCRIPTION .............9-71

BALANCE SHAFTS AND CARRIER ASSEMBLY - INSTALLATION .............9-73

BALANCE SHAFTS AND CARRIER ASSEMBLY - OPERATION ...............9-71

BALANCE SHAFTS AND CARRIER ASSEMBLY - REMOVAL .................9-71

BALL JOINT - DESCRIPTION, LOWER ......2-10

BALL JOINT - DIAGNOSIS AND TESTING, LOWER ............................. 2-10

BALL JOINT - OPERATION, LOWER .......2-10

BAR - DESCRIPTION, STABILIZER ....2-16,2-44

BAR - DESCRIPTION, TRACK ............2-45

BAR - INSPECTION, STABILIZER ..........2-17

BAR - INSTALLATION, STABILIZER ........2-17

BAR - INSTALLATION, TRACK ............2-46

BAR - OPERATION, STABILIZER ......2-16,2-44

BAR - OPERATION, TRACK ................2-46

BAR - REMOVAL, STABILIZER ...........2-17

BAR - REMOVAL, TRACK ...............2-46

BAR CUSHION - INSTALLATION, STABILIZER ...........................2-4

BAR CUSHION - REMOVAL, STABILIZER ....2-4

BASE BRAKE BLEEDING - STANDARD PROCEDURE ..........................5-8

BASE BRAKE SYSTEM - DIAGNOSIS AND TESTING .............................5-4

BASE BRAKE SYSTEM, SPECIAL TOOLS ....5-10

BASE BRAKES - DESCRIPTION ............5-3

BASE BRAKES - OPERATION ..............5-3

BASE BRAKES (EXPORT) - DESCRIPTION . . . 5-3

BASE COAT/CLEARCOAT FINISH - DESCRIPTION ...................... 23-101

BASE RISER - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-135

BASE RISER - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-134

BASE TRAY - INSTALLATION, FLOOR CONSOLE ........................... 23-89

BASE TRAY - REMOVAL, FLOOR CONSOLE ........................... 23-89

BATTERY - DESCRIPTION ...............8F-7

BATTERY - OPERATION .................8F-9

BATTERY - REMOVAL .................8F-16

BATTERY - SPECIFICATIONS ............8N-24

BATTERY CABLES - DESCRIPTION .......8F-16

BATTERY CABLES - OPERATION .........8F-17

BATTERY CABLES, DIAGNOSIS AND TESTING ........................... 8F-17

BATTERY CHARGING, STANDARD PROCEDURE - CONVENTIONAL ..........8F-11

BATTERY CHARGING, STANDARD PROCEDURE - SPIRAL PLATE ...........8F-10

BATTERY, DIAGNOSIS AND TESTING ......8F-9

BATTERY ELECTROLYTE LEVEL, STANDARD PROCEDURE - CHECKING ....8F-14

BATTERY HOLDDOWN - INSTALLATION . . . 8F-16

BATTERY HOLDDOWN - REMOVAL .......8F-16

BATTERY REPLACEMENT - STANDARD PROCEDURE ........................ 8N-24

BATTERY, SPECIFICATIONS ..............8F-6

BATTERY SYSTEM - DESCRIPTION ........8F-1

BATTERY SYSTEM - OPERATION .........8F-2

BATTERY SYSTEM, DIAGNOSIS AND TESTING ............................ 8F-2

BATTERY SYSTEM SPECIAL TOOLS, SPECIAL TOOLS ...................... 8F-7

BATTERY TEMPERATURE SENSOR - DESCRIPTION ....................... 8F-24

BATTERY TEMPERATURE SENSOR - OPERATION ......................... 8F-24

BATTERY TEMPERATURE SENSOR - REMOVAL .......................... 8F-24

BATTERY TEMPERATURE SENSOR - SPECIFICATIONS ..................... 8F-23BATTERY TESTER, STANDARD

PROCEDURE - MICRO 420 .............8F-15

BATTERY TRAY - DESCRIPTION .........8F-19

BATTERY TRAY - INSTALLATION .........8F-20

BATTERY TRAY - REMOVAL ............8F-19

BEARING - DESCRIPTION, HUB .......2-30,2-5

BEARING - DIAGNOSIS AND TESTING, HUB............................. 2-31,2-5

BEARING - INSTALLATION, HUB .......2-33,2-5

BEARING - OPERATION, HUB .........2-30,2-5

BEARING - REMOVAL, HUB ..........2-31,2-5

BEARING CLEARANCE - STANDARD PROCEDURE, MEASURING

CONNECTING ROD ................... 9-123

BEARING CLEARANCE USING PLASTIGAGE - STANDARD

PROCEDURE, MEASURING ..........9-12,9-86

BEARING FITTING - STANDARD PROCEDURE, MAIN ................... 9-125

BEARING PRELOAD - ADJUSTMENT, DIFFERENTIAL ...................... 21-228

BEARING PRELOAD MEASUREMENT AND ADJUSTMENT, ADJUSTMENTS -

DIFFERENTIAL ....................... 21-79

BEARINGS - INSTALLATION, CRANKSHAFT MAIN .................. 9-127

BEARINGS - REMOVAL, CRANKSHAFT MAIN .............................. 9-127

BEARINGS (IN BLOCK) - DESCRIPTION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - INSPECTION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - INSTALLATION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - OPERATION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - REMOVAL, CAMSHAFT ......................... 9-118

BELLCRANK - INSTALLATION ...........23-35

BELLCRANK - REMOVAL ...............23-35

BELT - DIAGNOSIS AND TESTING, ACCESSORY DRIVE .....................7-7

BELT - FOLD-IN-FLOOR - INSTALLATION, SEAT BELT CENTER LAP ..............23-157

BELT - FOLD-IN-FLOOR - REMOVAL, SEAT BELT CENTER LAP ..............23-157

BELT - INSTALLATION, TIMING ...........9-67

BELT - REMOVAL, TIMING ..............9-65

BELT & RETRACTOR - FIRST ROW - OUTBOARD - INSTALLATION, SEAT ......8O-40

BELT & RETRACTOR - FIRST ROW - OUTBOARD - REMOVAL, SEAT ..........8O-39

BELT & RETRACTOR - OUTBOARD - FRONT - INSTALLATION, SEAT ..........8O-39

BELT & RETRACTOR - OUTBOARD - FRONT - REMOVAL, SEAT ..............8O-38

BELT & RETRACTOR - SECOND ROW - LEFT OUTBOARD - INSTALLATION,

SEAT .............................. 8O-42

BELT & RETRACTOR - SECOND ROW - LEFT OUTBOARD - REMOVAL, SEAT .....8O-42

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD - INSTALLATION,

SEAT .............................. 8O-40

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD - REMOVAL, SEAT ....8O-40

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD WITH REAR HVAC -

LWB - INSTALLATION, SEAT ............8O-41

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD WITH REAR HVAC -

LWB - REMOVAL, SEAT ...............8O-41

BELT BUCKLE - FIRST ROW - BENCH - INSTALLATION, SEAT .................8O-37

BELT BUCKLE - FIRST ROW - BENCH - REMOVAL, SEAT ..................... 8O-36

BELT BUCKLE - FIRST ROW INBOARD - QUAD BUCKET - INSTALLATION, SEAT ....8O-36

BELT BUCKLE - FIRST ROW INBOARD - QUAD BUCKET - REMOVAL, SEAT .......8O-35

BELT BUCKLE - FRONT INBOARD - INSTALLATION, SEAT .................8O-35

BELT BUCKLE - FRONT INBOARD - REMOVAL, SEAT ..................... 8O-35

BELT BUCKLE - SECOND ROW - THREE PASSENGER BENCH - INSTALLATION,

SEAT .............................. 8O-40BELT BUCKLE - SECOND ROW - THREE

PASSENGER BENCH - REMOVAL, SEAT . . . 8O-40

BELT BUCKLE - SECOND ROW INBOARD - 50/50 BENCH - INSTALLATION, SEAT . . . 8O-38

BELT BUCKLE - SECOND ROW INBOARD - 50/50 BENCH - REMOVAL, SEAT .......8O-37

BELT CENTER LAP BELT - FOLD-IN- FLOOR - INSTALLATION, SEAT .........23-157

BELT CENTER LAP BELT - FOLD-IN- FLOOR - REMOVAL, SEAT .............23-157

BELT COVER(S) - INSTALLATION, TIMING ............................. 9-64

BELT COVER(S) - REMOVAL, TIMING ......9-63

BELT HEIGHT ADJUSTE R-BOR

C-PILLAR - INSTALLATION, SEAT ........8O-38

BELT HEIGHT ADJUSTE R-BOR

C-PILLAR - REMOVAL, SEAT ...........8O-38

BELT HEIGHT ADJUSTER KNOB - INSTALLATION, SEAT .................8O-38

BELT HEIGHT ADJUSTER KNOB - REMOVAL, SEAT ..................... 8O-38

BELT MOLDING - INSTALLATION, FRONT DOOR INNER ....................... 23-168

BELT MOLDING - INSTALLATION, FRONT DOOR OUTER ...................... 23-167

BELT MOLDING - REMOVAL, FRONT DOOR INNER ....................... 23-168

BELT MOLDING - REMOVAL, FRONT DOOR OUTER ...................... 23-167

BELT TENSION - STANDARD PROCEDURE, CHECKING POWER

STEERING ............................7-8

BELT TENSION SENSOR - DESCRIPTION . . . 8O-8

BELT TENSION SENSOR - OPERATION .....8O-9

BELT TENSION, SPECIFICATIONS - ACCESSORY DRIVE .....................7-5

BELT TENSIONER - 2.4L - INSTALLATION . . 7-11

BELT TENSIONER - 2.4L - REMOVAL ......7-11

BELT TENSIONER - 3.3/3.8L - INSTALLATION ........................ 7-12

BELT TENSIONER - 3.3/3.8L - REMOVAL . . . 7-12

BELT TENSIONER - DESCRIPTION, SEAT . . 8O-43

BELT TENSIONER - OPERATION, SEAT ....8O-43

BELT TENSIONER & PULLEY - INSTALLATION, TIMING .................9-70

BELT TENSIONER & PULLEY - REMOVAL, TIMING .................... 9-69

BELTS - 2.4L - ADJUSTMENTS, DRIVE .....7-10

BELTS - 2.4L - INSTALLATION, DRIVE ......7-9

BELTS - 2.4L - REMOVAL, DRIVE ..........7-9

BELTS - 3.3/3.8L - INSTALLATION, DRIVE . . 7-12

BELTS - 3.3/3.8L - REMOVAL, DRIVE ......7-11

BELTS - CLEANING, DRIVE ...............7-8

BELTS - INSPECTION, DRIVE .............7-8

BENCH - INSTALLATION, SEAT BACK HINGE COVERS - QUAD BUCKET, 50/50

SPLIT ............................. 23-146

BENCH - INSTALLATION, SEAT BELT BUCKLE - FIRST ROW ................8O-37

BENCH - INSTALLATION, SEAT BELT BUCKLE - SECOND ROW - THREE

PASSENGER ........................ 8O-40

BENCH - INSTALLATION, SEAT BELT BUCKLE - SECOND ROW INBOARD -

50/50 .............................. 8O-38

BENCH - INSTALLATION, SEAT CUSHION COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-144

BENCH - REMOVAL, SEAT BACK HINGE COVERS - QUAD BUCKET, 50/50 SPLIT . . 23-146

BENCH - REMOVAL, SEAT BELT BUCKLE - FIRST ROW ....................... 8O-36

BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW - THREE PASSENGER ....8O-40

BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW INBOARD - 50/50 .......8O-37

BENCH - REMOVAL, SEAT CUSHION COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-144

BENCH SEAT - REMOVAL, CHILD SEAT MODULE .......................... 23-104

BENCH SEAT BACK - INSTALLATION .....23-147

BENCH SEAT BACK - REMOVAL ........23-147

BENCH SEAT BACK COVER - INSTALLATION ...................... 23-148

BENCH SEAT BACK COVER - REMOVAL . . 23-148

BENCH SEAT BACK HINGE - REMOVAL . . 23-146

BENCH SEAT BACK PANEL - INSTALLATION ...................... 23-144

BENCH SEAT BACK PANEL - REMOVAL . . 23-143

RS INDEX3

Description Group-Page Description Group-Page Description Group-Page

Page 2307 of 2339

CABLE END CLEANING ANDLUBRICATION - STANDARD

PROCEDURE ......................... 5-65

CABLE RESISTANCE, SPECIFICATIONS - SPARK PLUG ......................... 8I-2

CABLES - ADJUSTMENT, PARKING BRAKE .............................. 5-65

CABLES - DESCRIPTION, BATTERY .......8F-16

CABLES - OPERATION, BATTERY ........8F-17

CABLES, DIAGNOSIS AND TESTING - BATTERY ........................... 8F-17

CALIBRATION, STANDARD PROCEDURE - A/C-HEATER CONTROL ................24-19

CALIBRATION, STANDARD PROCEDURE - COMPASS ........................... 8M-4

CALIPER - CLEANING ..............5-25,5-29

CALIPER - INSPECTION ............5-25,5-29

CALIPER - INSTALLATION, REAR DISC BRAKE .............................. 5-30

CALIPER - REMOVAL, REAR DISC BRAKE .............................. 5-28

CALIPER ADAPTER - INSTALLATION, FRONT DISC BRAKE ................... 5-31

CALIPER ADAPTER - REMOVAL, FRONT DISC BRAKE ......................... 5-31

CALIPER (CONTINENTAL TEVES BRAKES) - INSTALLATION, FRONT

DISC BRAKE ......................... 5-27

CALIPER (CONTINENTAL TEVES BRAKES) - REMOVAL, FRONT DISC

BRAKE .............................. 5-24

CALIPER GUIDE PIN BUSHINGS (CONTINENTAL TEVES BRAKES) -

ASSEMBLY ............................ 5-25

CALIPER GUIDE PIN BUSHINGS (CONTINENTAL TEVES BRAKES) -

DISASSEMBLY ........................ 5-24

CALIPER GUIDE PINS (TRW BRAKES) - INSTALLATION, DISC BRAKE ............5-32

CALIPER GUIDE PINS (TRW BRAKES) - REMOVAL, DISC BRAKE ................5-31

CALIPER PISTON AND SEAL - ASSEMBLY ...................... 5-26,5-30

CALIPER PISTON AND SEAL - DISASSEMBLY .................... 5-24,5-28

CALIPER (TRW BRAKES) - INSTALLATION, FRONT DISC BRAKE ......5-27

CALIPER (TRW BRAKES) - REMOVAL, FRONT DISC BRAKE ................... 5-24

CAMSHAFT & BEARINGS (IN BLOCK) - DESCRIPTION ....................... 9-118

CAMSHAFT & BEARINGS (IN BLOCK) - INSPECTION ........................ 9-118

CAMSHAFT & BEARINGS (IN BLOCK) - INSTALLATION ....................... 9-118

CAMSHAFT & BEARINGS (IN BLOCK) - OPERATION ......................... 9-118

CAMSHAFT & BEARINGS (IN BLOCK) - REMOVAL .......................... 9-118

CAMSHAFT END PLAY - STANDARD PROCEDURE, MEASURING ..............9-29

CAMSHAFT OIL SEAL(S) - INSTALLATION . . 9-29

CAMSHAFT OIL SEAL(S) - REMOVAL ......9-28

CAMSHAFT POSITION SENSOR - DESCRIPTION ......................... 8I-4

CAMSHAFT POSITION SENSOR - OPERATION .......................... 8I-4

CAMSHAFT SPROCKET - INSTALLATION, TIMING CHAIN ....................... 9-160

CAMSHAFT SPROCKET - REMOVAL, TIMING CHAIN ....................... 9-159

CAMSHAFT SPROCKETS - INSTALLATION . . 9-67

CAMSHAFT SPROCKETS - REMOVAL ......9-66

CAMSHAFT(S) - CLEANING ..............9-30

CAMSHAFT(S) - DESCRIPTION ...........9-29

CAMSHAFT(S) - INSPECTION ............9-30

CAMSHAFT(S) - INSTALLATION ..........9-31

CAMSHAFT(S) - OPERATION .............9-29

CAMSHAFT(S) - REMOVAL ..............9-30

CANISTER - DESCRIPTION, VAPOR ......25-19

CANISTER - INSTALLATION, REAR EVAP . . 25-21

CANISTER - OPERATION, VAPOR ........25-19

CANISTER - REMOVAL, REAR EVAP ......25-20

CAP - DESCRIPTION, FUEL FILLER .......25-13

CAP - DESCRIPTION, RADIATOR PRESSURE .......................... 7-27

CAP - INSTALLATION, INSTRUMENT PANEL RIGHT END ................... 23-72CAP - OPERATION, FUEL FILLER

........25-13

CAP - OPERATION, RADIATOR PRESSURE .......................... 7-27

CAP - REMOVAL, INSTRUMENT PANEL RIGHT END ......................... 23-72

CAP TESTING - DIAGNOSIS AND TESTING, COOLING SYSTEM

PRESSURE .......................... 7-28

CAP TO FILLER NECK SEAL - DIAGNOSIS AND TESTING, RADIATOR .....7-28

CAPACITIES - SPECIFICATIONS, FLUID ......0-6

CARE, CLEANING - WHEEL AND WHEEL TRIM .............................. 22-19

CARGO - INSTALLATION, AWD, HEAVY DUTY ............................... 2-36

CARGO - INSTALLATION, SPRING ........2-40

CARGO - REMOVAL, AWD, HEAVY DUTY . . . 2-36

CARGO - REMOVAL, SPRING ............2-40

CARPET INSERT - FOLD-IN-FLOOR - INSTALLATION, SECOND ROW FLOOR

TUB ............................... 23-98

CARPET INSERT - FOLD-IN-FLOOR - REMOVAL, SECOND ROW FLOOR TUB ....23-98

CARPET TRIM RING AND COVER - FOLD-IN-FLOOR - INSTALLATION ........23-84

CARPET TRIM RING AND COVER - FOLD-IN-FLOOR - REMOVAL ............23-84

CARPETS - FOLD-IN-FLOOR - INSTALLATION ....................... 23-83

CARPETS - FOLD-IN-FLOOR - REMOVAL . . 23-82

CARPETS AND FLOOR MATS - INSTALLATION ....................... 23-81

CARPETS AND FLOOR MATS - REMOVAL . 23-81

CARPETS INSERT - FOLD-IN-FLOOR - INSTALLATION, REAR FLOOR TUB .......23-96

CARPETS INSERT - FOLD-IN-FLOOR - REMOVAL, REAR FLOOR TUB ...........23-95

CARRIER ASSEMBLY - DESCRIPTION, BALANCE SHAFTS ..................... 9-71

CARRIER ASSEMBLY - INSTALLATION, BALANCE SHAFTS ..................... 9-73

CARRIER ASSEMBLY - OPERATION, BALANCE SHAFTS ..................... 9-71

CARRIER ASSEMBLY - REMOVAL, BALANCE SHAFTS ..................... 9-71

CATALYTIC CONVERTER - DESCRIPTION . . . 11-4

CATALYTIC CONVERTER - INSPECTION ....11-6

CATALYTIC CONVERTER - INSTALLATION . . . 11-6

CATALYTIC CONVERTER - OPERATION .....11-4

CATALYTIC CONVERTER - REMOVAL ......11-5

CAUTION, A/C SYSTEM ................24-66

CAUTION, DESCRIPTION .................5-4

CAUTION, DESCRIPTION ...............19-37

CAUTION, OPERATION .................5-90

CAUTION, SENSOR - TPM ..............22-11

CAUTIONS, WARNING - WARNINGS . 19-10,19-26

CD CHANGER - DESCRIPTION ..........8A-11

CD CHANGER - INSTALLATION ..........8A-11

CD CHANGER - OPERATION ............8A-11

CD CHANGER - REMOVAL .............8A-11

CENTER - DESCRIPTION, ELECTRONIC VEHICLE INFO ....................... 8M-7

CENTER - INSTALLATION, MESSAGE ......8M-1

CENTER - OPERATION, ELECTRONIC VEHICLE INFO ....................... 8M-7

CENTER - REMOVAL, MESSAGE .........8M-1

CENTER BEZEL - INSTALLATION, INSTRUMENT PANEL .................. 23-72

CENTER BEZEL - REMOVAL, INSTRUMENT PANEL .................. 23-71

CENTER BEZEL OUTLETS, INSTALLATION - FRONT ............................ 24-45

CENTER BEZEL OUTLETS, REMOVAL - FRONT ............................. 24-44

CENTER CONSOLE LAMP - INSTALLATION ....................... 8L-21

CENTER CONSOLE LAMP - REMOVAL ....8L-21

CENTER CONSOLE LAMP SWITCH - INSTALLATION ....................... 8L-21

CENTER CONSOLE LAMP SWITCH - REMOVAL .......................... 8L-21

CENTER, DIAGNOSIS AND TESTING - ELECTRONIC VEHICLE INFORMATION .....8M-8

CENTER HIGH MOUNTED STOP LAMP - INSTALLATION ........................ 8L-6

CENTER HIGH MOUNTED STOP LAMP - REMOVAL ........................... 8L-6CENTER HIGH MOUNTED STOP LAMP

UNIT - INSTALLATION .................. 8L-6

CENTER HIGH MOUNTED STOP LAMP UNIT - REMOVAL ..................... 8L-6

CENTER HINGE - INSTALLATION .........23-24

CENTER HINGE - REMOVAL ............23-24

CENTER LAP BELT - FOLD-IN-FLOOR - INSTALLATION, SEAT BELT ............23-157

CENTER LAP BELT - FOLD-IN-FLOOR - REMOVAL, SEAT BELT ................23-157

CENTER PROGRAMMING, STANDARD PROCEDURE - ELECTRONIC VEHICLE

INFORMATION ....................... 8M-8

CENTER STRIKER - INSTALLATION .......23-28

CENTER STRIKER - REMOVAL ..........23-28

CENTERING - STANDARD PROCEDURE, CLOCKSPRING ...................... 8O-11

CHAIN AND CAMSHAFT SPROCKET - INSTALLATION, TIMING ................9-160

CHAIN AND CAMSHAFT SPROCKET - REMOVAL, TIMING ................... 9-159

CHAIN COVER - INSTALLATION, TIMING . . 9-157

CHAIN COVER - REMOVAL, TIMING ......9-156

CHAIN WEAR - STANDARD PROCEDURE, MEASURING TIMING .................. 9-155

CHANGE - STANDARD PROCEDURE, ENGINE OIL AND FILTER ...........9-139,9-54

CHANGER - DESCRIPTION, CD ..........8A-11

CHANGER - INSTALLATION, CD .........8A-11

CHANGER - OPERATION, CD ............8A-11

CHANGER - REMOVAL, CD ..............8A-11

CHANNEL - INSTALLATION, WATER .....23-174

CHANNEL - REMOVAL, WATER .........23-174

CHARGE LEVEL TEST, DIAGNOSIS AND TESTING - SYSTEM ................... 24-67

CHARGE, STANDARD PROCEDURE - REFRIGERANT SYSTEM ...............24-71

CHARGING, STANDARD PROCEDURE - CONVENTIONAL BATTERY ..............8F-11

CHARGING, STANDARD PROCEDURE - SPIRAL PLATE BATTERY ...............8F-10

CHARGING SYSTEM - DESCRIPTION .....8F-21

CHARGING SYSTEM - OPERATION .......8F-21

CHARTS - DIAGNOSIS AND TESTING, STEERING SYSTEM DIAGNOSIS ..........19-3

CHARTS - SPECIFICATIONS, COLOR CODE ............................. 23-100

CHECK - DIAGNOSIS AND TESTING, COOLING SYSTEM FLOW ................7-3

CHECK - DIAGNOSIS AND TESTING, EXHAUST SYSTEM RESTRICTION .........11-2

CHECK - STANDARD PROCEDURE, COOLANT LEVEL .......................7-4

CHECK - STANDARD PROCEDURE, ENGINE OIL LEVEL ................... 9-140

CHECK, STANDARD PROCEDURE - ENGINE OIL LEVEL .................... 9-54

CHECK, STANDARD PROCEDURE - FLUID LEVEL AND CONDITION .........21-230,21-82

CHECK STRAP - INSTALLATION .........23-15

CHECK STRAP - REMOVAL .............23-15

CHECKING - STANDARD PROCEDURE, BRAKE FLUID LEVEL ................... 5-33

CHECKING - STANDARD PROCEDURE, POWER STEERING FLUID LEVEL ........19-44

CHECKING BATTERY ELECTROLYTE LEVEL, STANDARD PROCEDURE .........8F-14

CHECKING ENGINE OIL PRESSURE - DIAGNOSIS AND TESTING ..............9-53

CHECKING POWER STEERING BELT TENSION - STANDARD PROCEDURE .......7-8

CHILD RESTRAINT ANCHOR - DESCRIPTION ........................ 8O-9

CHILD RESTRAINT ANCHOR - OPERATION ......................... 8O-10

CHILD SEAT - INSTALLATION, QUAD ....23-106

CHILD SEAT - REMOVAL, QUAD ........23-106

CHILD SEAT MODULE, BENCH SEAT - REMOVAL ......................... 23-104

CHIME SYSTEM - DIAGNOSIS AND TESTING ............................ 8B-2

CHIME/BUZZER - DESCRIPTION ..........8B-1

CHIME/BUZZER - OPERATION ............8B-1

CHIME/BUZZER - WARNING .............8B-2

CHIME/THERMISTOR - DESCRIPTION .....8N-8

CHIME/THERMISTOR - INSTALLATION .....8N-9

CHIME/THERMISTOR - OPERATION .......8N-8

CHIME/THERMISTOR - REMOVAL ........8N-8

6 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2316 of 2339

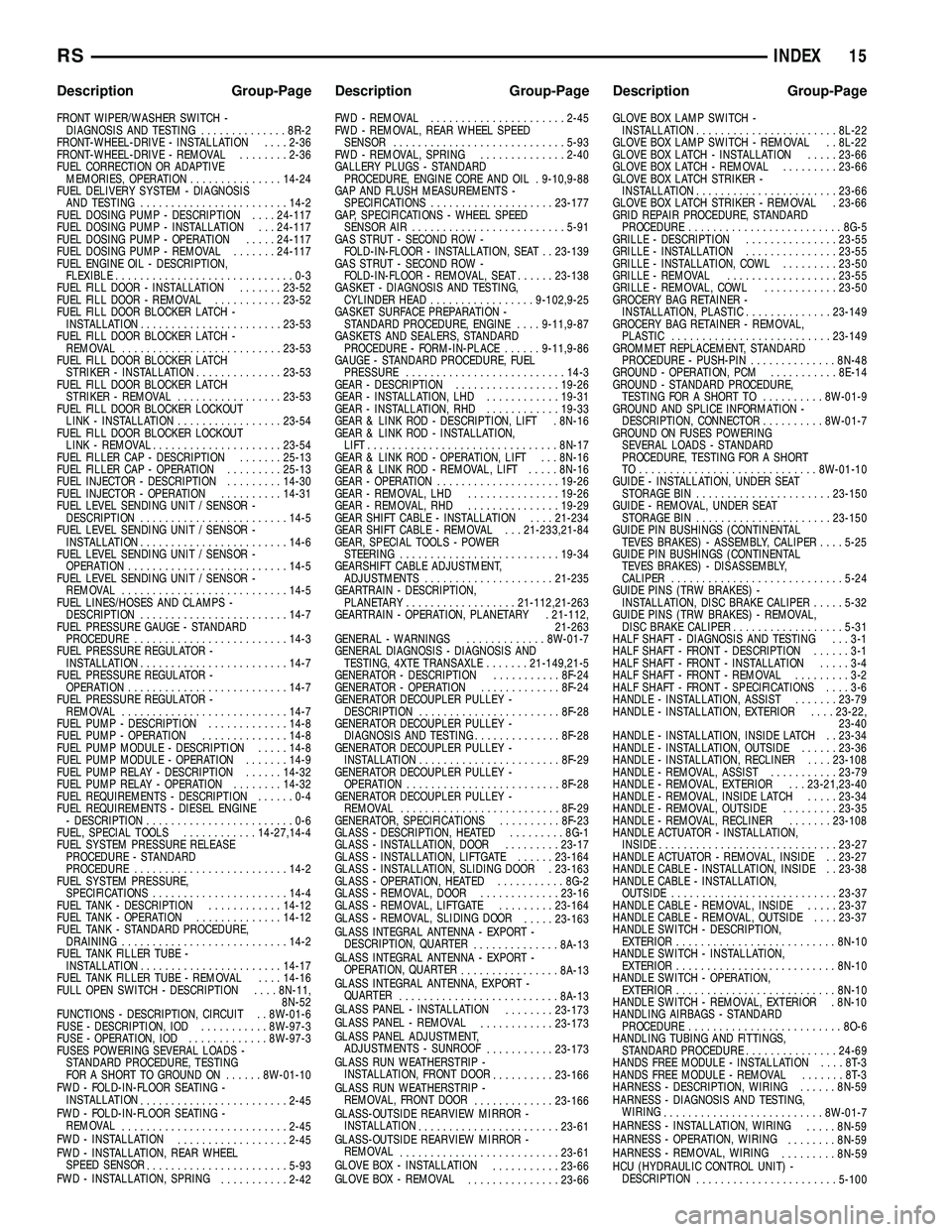

FRONT WIPER/WASHER SWITCH -DIAGNOSIS AND TESTING ..............8R-2

FRONT-WHEEL-DRIVE - INSTALLATION ....2-36

FRONT-WHEEL-DRIVE - REMOVAL ........2-36

FUEL CORRECTION OR ADAPTIVE MEMORIES, OPERATION ...............14-24

FUEL DELIVERY SYSTEM - DIAGNOSIS AND TESTING ........................ 14-2

FUEL DOSING PUMP - DESCRIPTION ....24-117

FUEL DOSING PUMP - INSTALLATION . . . 24-117

FUEL DOSING PUMP - OPERATION .....24-117

FUEL DOSING PUMP - REMOVAL .......24-117

FUEL ENGINE OIL - DESCRIPTION, FLEXIBLE .............................0-3

FUEL FILL DOOR - INSTALLATION .......23-52

FUEL FILL DOOR - REMOVAL ...........23-52

FUEL FILL DOOR BLOCKER LATCH - INSTALLATION ....................... 23-53

FUEL FILL DOOR BLOCKER LATCH - REMOVAL .......................... 23-53

FUEL FILL DOOR BLOCKER LATCH STRIKER - INSTALLATION ..............23-53

FUEL FILL DOOR BLOCKER LATCH STRIKER - REMOVAL .................23-53

FUEL FILL DOOR BLOCKER LOCKOUT LINK - INSTALLATION .................23-54

FUEL FILL DOOR BLOCKER LOCKOUT LINK - REMOVAL ..................... 23-54

FUEL FILLER CAP - DESCRIPTION .......25-13

FUEL FILLER CAP - OPERATION .........25-13

FUEL INJECTOR - DESCRIPTION .........14-30

FUEL INJECTOR - OPERATION ..........14-31

FUEL LEVEL SENDING UNIT / SENSOR - DESCRIPTION ........................ 14-5

FUEL LEVEL SENDING UNIT / SENSOR - INSTALLATION ........................ 14-6

FUEL LEVEL SENDING UNIT / SENSOR - OPERATION .......................... 14-5

FUEL LEVEL SENDING UNIT / SENSOR - REMOVAL ........................... 14-5

FUEL LINES/HOSES AND CLAMPS - DESCRIPTION ........................ 14-7

FUEL PRESSURE GAUGE - STANDARD PROCEDURE ......................... 14-3

FUEL PRESSURE REGULATOR - INSTALLATION ........................ 14-7

FUEL PRESSURE REGULATOR - OPERATION .......................... 14-7

FUEL PRESSURE REGULATOR - REMOVAL ........................... 14-7

FUEL PUMP - DESCRIPTION .............14-8

FUEL PUMP - OPERATION ..............14-8

FUEL PUMP MODULE - DESCRIPTION .....14-8

FUEL PUMP MODULE - OPERATION .......14-9

FUEL PUMP RELAY - DESCRIPTION ......14-32

FUEL PUMP RELAY - OPERATION ........14-32

FUEL REQUIREMENTS - DESCRIPTION ......0-4

FUEL REQUIREMENTS - DIESEL ENGINE - DESCRIPTION ........................0-6

FUEL, SPECIAL TOOLS ............14-27,14-4

FUEL SYSTEM PRESSURE RELEASE PROCEDURE - STANDARD

PROCEDURE ......................... 14-2

FUEL SYSTEM PRESSURE, SPECIFICATIONS ...................... 14-4

FUEL TANK - DESCRIPTION ............14-12

FUEL TANK - OPERATION ..............14-12

FUEL TANK - STANDARD PROCEDURE, DRAINING ........................... 14-2

FUEL TANK FILLER TUBE - INSTALLATION ....................... 14-17

FUEL TANK FILLER TUBE - REMOVAL ....14-16

FULL OPEN SWITCH - DESCRIPTION ....8N-11,

8N-52

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD ...........8W-97-3

FUSE - OPERATION, IOD .............8W-97-3

FUSES POWERING SEVERAL LOADS - STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON ......8W-01-10

FWD - FOLD-IN-FLOOR SEATING - INSTALLATION ........................ 2-45

FWD - FOLD-IN-FLOOR SEATING - REMOVAL ........................... 2-45

FWD - INSTALLATION ..................2-45

FWD - INSTALLATION, REAR WHEEL SPEED SENSOR ....................... 5-93

FWD - INSTALLATION, SPRING ...........2-42FWD - REMOVAL

...................... 2-45

FWD - REMOVAL, REAR WHEEL SPEED SENSOR ............................ 5-93

FWD - REMOVAL, SPRING ..............2-40

GALLERY PLUGS - STANDARD PROCEDURE, ENGINE CORE AND OIL . 9-10,9-88

GAP AND FLUSH MEASUREMENTS - SPECIFICATIONS .................... 23-177

GAP, SPECIFICATIONS - WHEEL SPEED SENSOR AIR ......................... 5-91

GAS STRUT - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-139

GAS STRUT - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-138

GASKET - DIAGNOSIS AND TESTING, CYLINDER HEAD ................. 9-102,9-25

GASKET SURFACE PREPARATION - STANDARD PROCEDURE, ENGINE ....9-11,9-87

GASKETS AND SEALERS, STANDARD PROCEDURE - FORM-IN-PLACE ......9-11,9-86

GAUGE - STANDARD PROCEDURE, FUEL PRESSURE .......................... 14-3

GEAR - DESCRIPTION .................19-26

GEAR - INSTALLATION, LHD ............19-31

GEAR - INSTALLATION, RHD ............19-33

GEAR & LINK ROD - DESCRIPTION, LIFT . 8N-16

GEAR & LINK ROD - INSTALLATION, LIFT ............................... 8N-17

GEAR & LINK ROD - OPERATION, LIFT . . . 8N-16

GEAR & LINK ROD - REMOVAL, LIFT .....8N-16

GEAR - OPERATION .................... 19-26

GEAR - REMOVAL, LHD ...............19-26

GEAR - REMOVAL, RHD ...............19-29

GEAR SHIFT CABLE - INSTALLATION ....21-234

GEAR SHIFT CABLE - REMOVAL . . . 21-233,21-84

GEAR, SPECIAL TOOLS - POWER STEERING .......................... 19-34

GEARSHIFT CABLE ADJUSTMENT, ADJUSTMENTS ..................... 21-235

GEARTRAIN - DESCRIPTION, PLANETARY .................. 21-112,21-263

GEARTRAIN - OPERATION, PLANETARY . 21-112, 21-263

GENERAL - WARNINGS .............8W-01-7

GENERAL DIAGNOSIS - DIAGNOSIS AND TESTING, 4XTE TRANSAXLE .......21-149,21-5

GENERATOR - DESCRIPTION ...........8F-24

GENERATOR - OPERATION .............8F-24

GENERATOR DECOUPLER PULLEY - DESCRIPTION ....................... 8F-28

GENERATOR DECOUPLER PULLEY - DIAGNOSIS AND TESTING ..............8F-28

GENERATOR DECOUPLER PULLEY - INSTALLATION ....................... 8F-29

GENERATOR DECOUPLER PULLEY - OPERATION ......................... 8F-28

GENERATOR DECOUPLER PULLEY - REMOVAL .......................... 8F-29

GENERATOR, SPECIFICATIONS ..........8F-23

GLASS - DESCRIPTION, HEATED .........8G-1

GLASS - INSTALLATION, DOOR .........23-17

GLASS - INSTALLATION, LIFTGATE ......23-164

GLASS - INSTALLATION, SLIDING DOOR . 23-163

GLASS - OPERATION, HEATED ...........8G-2

GLASS - REMOVAL, DOOR .............23-16

GLASS - REMOVAL, LIFTGATE .........23-164

GLASS - REMOVAL, SLIDING DOOR .....23-163

GLASS INTEGRAL ANTENNA - EXPORT - DESCRIPTION, QUARTER ..............8A-13

GLASS INTEGRAL ANTENNA - EXPORT - OPERATION, QUARTER ................8A-13

GLASS INTEGRAL ANTENNA, EXPORT - QUARTER .......................... 8A-13

GLASS PANEL - INSTALLATION ........23-173

GLASS PANEL - REMOVAL ............23-173

GLASS PANEL ADJUSTMENT, ADJUSTMENTS - SUNROOF ...........23-173

GLASS RUN WEATHERSTRIP - INSTALLATION, FRONT DOOR ..........23-166

GLASS RUN WEATHERSTRIP - REMOVAL, FRONT DOOR .............23-166

GLASS-OUTSIDE REARVIEW MIRROR - INSTALLATION ....................... 23-61

GLASS-OUTSIDE REARVIEW MIRROR - REMOVAL .......................... 23-61

GLOVE BOX - INSTALLATION ...........23-66

GLOVE BOX - REMOVAL ...............23-66GLOVE BOX LAMP SWITCH -

INSTALLATION ....................... 8L-22

GLOVE BOX LAMP SWITCH - REMOVAL . . 8L-22

GLOVE BOX LATCH - INSTALLATION .....23-66

GLOVE BOX LATCH - REMOVAL .........23-66

GLOVE BOX LATCH STRIKER - INSTALLATION ....................... 23-66

GLOVE BOX LATCH STRIKER - REMOVAL . 23-66

GRID REPAIR PROCEDURE, STANDARD PROCEDURE ......................... 8G-5

GRILLE - DESCRIPTION ...............23-55

GRILLE - INSTALLATION ...............23-55

GRILLE - INSTALLATION, COWL .........23-50

GRILLE - REMOVAL ..................23-55

GRILLE - REMOVAL, COWL ............23-50

GROCERY BAG RETAINER - INSTALLATION, PLASTIC ..............23-149

GROCERY BAG RETAINER - REMOVAL, PLASTIC .......................... 23-149

GROMMET REPLACEMENT, STANDARD PROCEDURE - PUSH-PIN ..............8N-48

GROUND - OPERATION, PCM ...........8E-14

GROUND - STANDARD PROCEDURE, TESTING FOR A SHORT TO ..........8W-01-9

GROUND AND SPLICE INFORMATION - DESCRIPTION, CONNECTOR ..........8W-01-7

GROUND ON FUSES POWERING SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO.............................8W -01-10

GUIDE - INSTALLATION, UNDER SEAT STORAGE BIN ...................... 23-150

GUIDE - REMOVAL, UNDER SEAT STORAGE BIN ...................... 23-150

GUIDE PIN BUSHINGS (CONTINENTAL TEVES BRAKES) - ASSEMBLY, CALIPER ....5-25

GUIDE PIN BUSHINGS (CONTINENTAL TEVES BRAKES) - DISASSEMBLY,

CALIPER ............................ 5-24

GUIDE PINS (TRW BRAKES) - INSTALLATION, DISC BRAKE CALIPER .....5-32

GUIDE PINS (TRW BRAKES) - REMOVAL, DISC BRAKE CALIPER .................. 5-31

HALF SHAFT - DIAGNOSIS AND TESTING . . . 3-1

HALF SHAFT - FRONT - DESCRIPTION ......3-1

HALF SHAFT - FRONT - INSTALLATION .....3-4

HALF SHAFT - FRONT - REMOVAL .........3-2

HALF SHAFT - FRONT - SPECIFICATIONS ....3-6

HANDLE - INSTALLATION, ASSIST .......23-79

HANDLE - INSTALLATION, EXTERIOR ....23-22,

23-40

HANDLE - INSTALLATION, INSIDE LATCH . . 23-34

HANDLE - INSTALLATION, OUTSIDE ......23-36

HANDLE - INSTALLATION, RECLINER ....23-108

HANDLE - REMOVAL, ASSIST ...........23-79

HANDLE - REMOVAL, EXTERIOR . . . 23-21,23-40

HANDLE - REMOVAL, INSIDE LATCH .....23-34

HANDLE - REMOVAL, OUTSIDE .........23-35

HANDLE - REMOVAL, RECLINER .......23-108

HANDLE ACTUATOR - INSTALLATION, INSIDE ............................. 23-27

HANDLE ACTUATOR - REMOVAL, INSIDE . . 23-27

HANDLE CABLE - INSTALLATION, INSIDE . . 23-38

HANDLE CABLE - INSTALLATION, OUTSIDE ........................... 23-37

HANDLE CABLE - REMOVAL, INSIDE .....23-37

HANDLE CABLE - REMOVAL, OUTSIDE ....23-37

HANDLE SWITCH - DESCRIPTION, EXTERIOR .......................... 8N-10

HANDLE SWITCH - INSTALLATION, EXTERIOR .......................... 8N-10

HANDLE SWITCH - OPERATION, EXTERIOR .......................... 8N-10

HANDLE SWITCH - REMOVAL, EXTERIOR . 8N-10

HANDLING AIRBAGS - STANDARD PROCEDURE ......................... 8O-6

HANDLING TUBING AND FITTINGS, STANDARD PROCEDURE ...............24-69

HANDS FREE MODULE - INSTALLATION ....8T-3

HANDS FREE MODULE - REMOVAL .......8T-3

HARNESS - DESCRIPTION, WIRING ......8N-59

HARNESS - DIAGNOSIS AND TESTING, WIRING ..........................8W -01-7

HARNESS - INSTALLATION, WIRING .....8N-59

HARNESS - OPERATION, WIRING ........8N-59

HARNESS - REMOVAL, WIRING .........8N-59

HCU (HYDRAULIC CONTROL UNIT) - DESCRIPTION ....................... 5-100

RS INDEX15

Description Group-Page Description Group-Page Description Group-Page

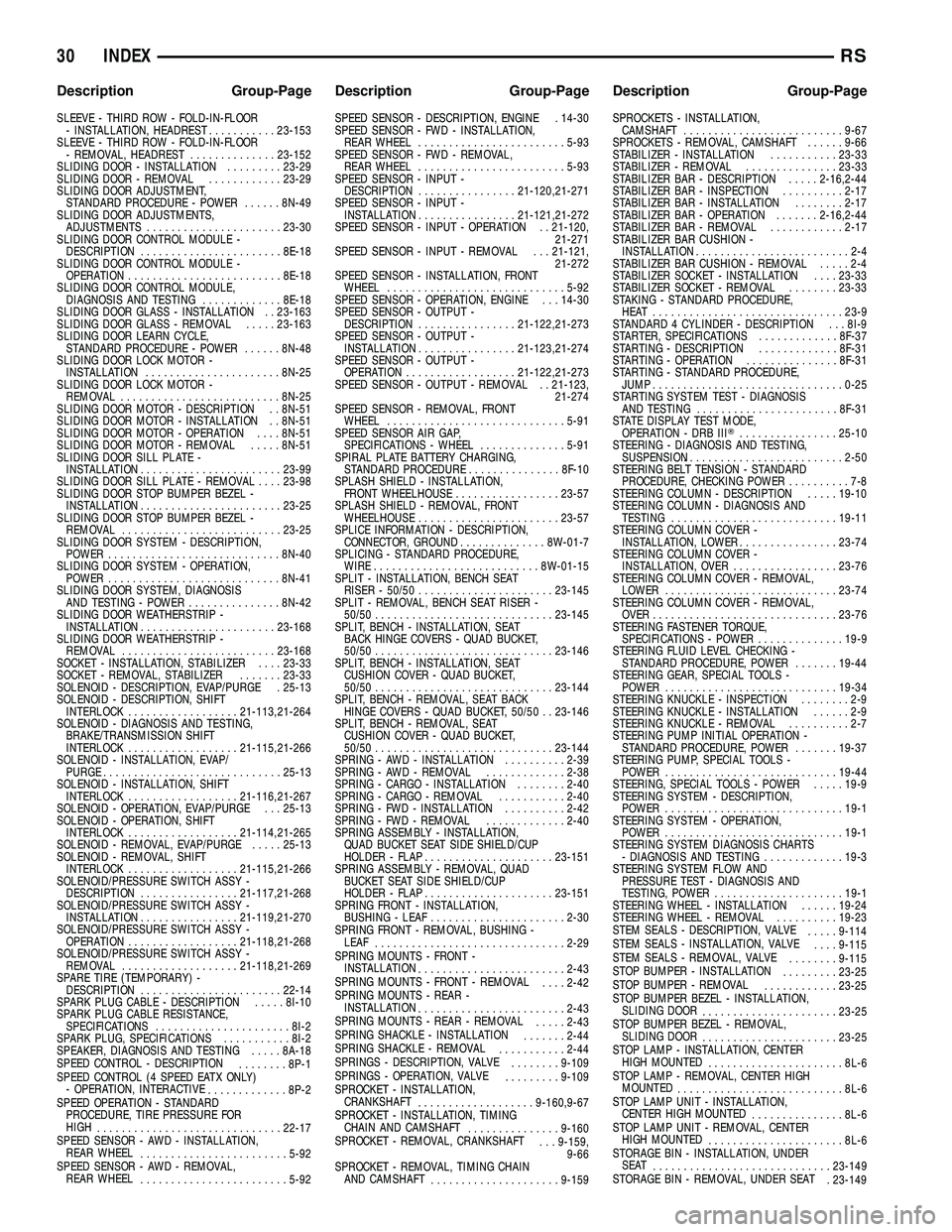

Page 2331 of 2339

SLEEVE - THIRD ROW - FOLD-IN-FLOOR- INSTALLATION, HEADREST ...........23-153

SLEEVE - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, HEADREST ..............23-152

SLIDING DOOR - INSTALLATION .........23-29

SLIDING DOOR - REMOVAL ............23-29

SLIDING DOOR ADJUSTMENT, STANDARD PROCEDURE - POWER ......8N-49

SLIDING DOOR ADJUSTMENTS, ADJUSTMENTS ...................... 23-30

SLIDING DOOR CONTROL MODULE - DESCRIPTION ....................... 8E-18

SLIDING DOOR CONTROL MODULE - OPERATION ......................... 8E-18

SLIDING DOOR CONTROL MODULE, DIAGNOSIS AND TESTING .............8E-18

SLIDING DOOR GLASS - INSTALLATION . . 23-163

SLIDING DOOR GLASS - REMOVAL .....23-163

SLIDING DOOR LEARN CYCLE, STANDARD PROCEDURE - POWER ......8N-48

SLIDING DOOR LOCK MOTOR - INSTALLATION ...................... 8N-25

SLIDING DOOR LOCK MOTOR - REMOVAL .......................... 8N-25

SLIDING DOOR MOTOR - DESCRIPTION . . 8N-51

SLIDING DOOR MOTOR - INSTALLATION . . 8N-51

SLIDING DOOR MOTOR - OPERATION ....8N-51

SLIDING DOOR MOTOR - REMOVAL .....8N-51

SLIDING DOOR SILL PLATE - INSTALLATION ....................... 23-99

SLIDING DOOR SILL PLATE - REMOVAL ....23-98

SLIDING DOOR STOP BUMPER BEZEL - INSTALLATION ....................... 23-25

SLIDING DOOR STOP BUMPER BEZEL - REMOVAL .......................... 23-25

SLIDING DOOR SYSTEM - DESCRIPTION, POWER ............................ 8N-40

SLIDING DOOR SYSTEM - OPERATION, POWER ............................ 8N-41

SLIDING DOOR SYSTEM, DIAGNOSIS AND TESTING - POWER ...............8N-42

SLIDING DOOR WEATHERSTRIP - INSTALLATION ...................... 23-168

SLIDING DOOR WEATHERSTRIP - REMOVAL ......................... 23-168

SOCKET - INSTALLATION, STABILIZER ....23-33

SOCKET - REMOVAL, STABILIZER .......23-33

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-13

SOLENOID - DESCRIPTION, SHIFT INTERLOCK .................. 21-113,21-264

SOLENOID - DIAGNOSIS AND TESTING, BRAKE/TRANSMISSION SHIFT

INTERLOCK .................. 21-115,21-266

SOLENOID - INSTALLATION, EVAP/ PURGE ............................. 25-13

SOLENOID - INSTALLATION, SHIFT INTERLOCK .................. 21-116,21-267

SOLENOID - OPERATION, EVAP/PURGE . . . 25-13

SOLENOID - OPERATION, SHIFT INTERLOCK .................. 21-114,21-265

SOLENOID - REMOVAL, EVAP/PURGE .....25-13

SOLENOID - REMOVAL, SHIFT INTERLOCK .................. 21-115,21-266

SOLENOID/PRESSURE SWITCH ASSY - DESCRIPTION ................ 21-117,21-268

SOLENOID/PRESSURE SWITCH ASSY - INSTALLATION ................ 21-119,21-270

SOLENOID/PRESSURE SWITCH ASSY - OPERATION .................. 21-118,21-268

SOLENOID/PRESSURE SWITCH ASSY - REMOVAL ................... 21-118,21-269

SPARE TIRE (TEMPORARY) - DESCRIPTION ....................... 22-14

SPARK PLUG CABLE - DESCRIPTION .....8I-10

SPARK PLUG CABLE RESISTANCE, SPECIFICATIONS ...................... 8I-2

SPARK PLUG, SPECIFICATIONS ...........8I-2

SPEAKER, DIAGNOSIS AND TESTING .....8A-18

SPEED CONTROL - DESCRIPTION ........8P-1

SPEED CONTROL (4 SPEED EATX ONLY) - OPERATION, INTERACTIVE .............8P-2

SPEED OPERATION - STANDARD PROCEDURE, TIRE PRESSURE FOR

HIGH .............................. 22-17

SPEED SENSOR - AWD - INSTALLATION, REAR WHEEL ........................ 5-92

SPEED SENSOR - AWD - REMOVAL, REAR WHEEL ........................ 5-92SPEED SENSOR - DESCRIPTION, ENGINE . 14-30

SPEED SENSOR - FWD - INSTALLATION,

REAR WHEEL ........................ 5-93

SPEED SENSOR - FWD - REMOVAL, REAR WHEEL ........................ 5-93

SPEED SENSOR - INPUT - DESCRIPTION ................ 21-120,21-271

SPEED SENSOR - INPUT - INSTALLATION ................ 21-121,21-272

SPEED SENSOR - INPUT - OPERATION . . 21-120, 21-271

SPEED SENSOR - INPUT - REMOVAL . . . 21-121, 21-272

SPEED SENSOR - INSTALLATION, FRONT WHEEL ............................. 5-92

SPEED SENSOR - OPERATION, ENGINE . . . 14-30

SPEED SENSOR - OUTPUT - DESCRIPTION ................ 21-122,21-273

SPEED SENSOR - OUTPUT - INSTALLATION ................ 21-123,21-274

SPEED SENSOR - OUTPUT - OPERATION .................. 21-122,21-273

SPEED SENSOR - OUTPUT - REMOVAL . . 21-123, 21-274

SPEED SENSOR - REMOVAL, FRONT WHEEL ............................. 5-91

SPEED SENSOR AIR GAP, SPECIFICATIONS - WHEEL ..............5-91

SPIRAL PLATE BATTERY CHARGING, STANDARD PROCEDURE ...............8F-10

SPLASH SHIELD - INSTALLATION, FRONT WHEELHOUSE .................23-57

SPLASH SHIELD - REMOVAL, FRONT WHEELHOUSE ....................... 23-57

SPLICE INFORMATION - DESCRIPTION, CONNECTOR, GROUND ..............8W-01-7

SPLICING - STANDARD PROCEDURE, WIRE ...........................8W -01-15

SPLIT - INSTALLATION, BENCH SEAT RISER - 50/50 ...................... 23-145

SPLIT - REMOVAL, BENCH SEAT RISER - 50/50 ............................. 23-145

SPLIT, BENCH - INSTALLATION, SEAT BACK HINGE COVERS - QUAD BUCKET,

50/50 ............................. 23-146

SPLIT, BENCH - INSTALLATION, SEAT CUSHION COVER - QUAD BUCKET,

50/50 ............................. 23-144

SPLIT, BENCH - REMOVAL, SEAT BACK HINGE COVERS - QUAD BUCKET, 50/50 . . 23-146

SPLIT, BENCH - REMOVAL, SEAT CUSHION COVER - QUAD BUCKET,

50/50 ............................. 23-144

SPRING - AWD - INSTALLATION ..........2-39

SPRING - AWD - REMOVAL .............2-38

SPRING - CARGO - INSTALLATION ........2-40

SPRING - CARGO - REMOVAL ...........2-40

SPRING - FWD - INSTALLATION ..........2-42

SPRING - FWD - REMOVAL .............2-40

SPRING ASSEMBLY - INSTALLATION, QUAD BUCKET SEAT SIDE SHIELD/CUP

HOLDER - FLAP ..................... 23-151

SPRING ASSEMBLY - REMOVAL, QUAD BUCKET SEAT SIDE SHIELD/CUP

HOLDER - FLAP ..................... 23-151

SPRING FRONT - INSTALLATION, BUSHING - LEAF ...................... 2-30

SPRING FRONT - REMOVAL, BUSHING - LEAF ............................... 2-29

SPRING MOUNTS - FRONT - INSTALLATION ........................ 2-43

SPRING MOUNTS - FRONT - REMOVAL ....2-42

SPRING MOUNTS - REAR - INSTALLATION ........................ 2-43

SPRING MOUNTS - REAR - REMOVAL .....2-43

SPRING SHACKLE - INSTALLATION .......2-44

SPRING SHACKLE - REMOVAL ...........2-44

SPRINGS - DESCRIPTION, VALVE ........9-109

SPRINGS - OPERATION, VALVE .........9-109

SPROCKET - INSTALLATION, CRANKSHAFT ................... 9-160,9-67

SPROCKET - INSTALLATION, TIMING CHAIN AND CAMSHAFT ...............9-160

SPROCKET - REMOVAL, CRANKSHAFT . . . 9-159,

9-66

SPROCKET - REMOVAL, TIMING CHAIN AND CAMSHAFT ..................... 9-159SPROCKETS - INSTALLATION,

CAMSHAFT .......................... 9-67

SPROCKETS - REMOVAL, CAMSHAFT ......9-66

STABILIZER - INSTALLATION ...........23-33

STABILIZER - REMOVAL ...............23-33

STABILIZER BAR - DESCRIPTION .....2-16,2-44

STABILIZER BAR - INSPECTION ..........2-17

STABILIZER BAR - INSTALLATION ........2-17

STABILIZER BAR - OPERATION .......2-16,2-44

STABILIZER BAR - REMOVAL ............2-17

STABILIZER BAR CUSHION - INSTALLATION .........................2-4

STABILIZER BAR CUSHION - REMOVAL .....2-4

STABILIZER SOCKET - INSTALLATION ....23-33

STABILIZER SOCKET - REMOVAL ........23-33

STAKING - STANDARD PROCEDURE, HEAT ............................... 23-9

STANDARD 4 CYLINDER - DESCRIPTION . . . 8I-9

STARTER, SPECIFICATIONS .............8F-37

STARTING - DESCRIPTION .............8F-31

STARTING - OPERATION ...............8F-31

STARTING - STANDARD PROCEDURE, JUMP ............................... 0-25

STARTING SYSTEM TEST - DIAGNOSIS AND TESTING ....................... 8F-31

STATE DISPLAY TEST MODE, OPERATION - DRB III T................ 25-10

STEERING - DIAGNOSIS AND TESTING, SUSPENSION .......................... 2-50

STEERING BELT TENSION - STANDARD PROCEDURE, CHECKING POWER ..........7-8

STEERING COLUMN - DESCRIPTION .....19-10

STEERING COLUMN - DIAGNOSIS AND TESTING ........................... 19-11

STEERING COLUMN COVER - INSTALLATION, LOWER ................23-74

STEERING COLUMN COVER - INSTALLATION, OVER .................23-76

STEERING COLUMN COVER - REMOVAL, LOWER ............................ 23-74

STEERING COLUMN COVER - REMOVAL, OVER .............................. 23-76

STEERING FASTENER TORQUE, SPECIFICATIONS - POWER ..............19-9

STEERING FLUID LEVEL CHECKING - STANDARD PROCEDURE, POWER .......19-44

STEERING GEAR, SPECIAL TOOLS - POWER ............................ 19-34

STEERING KNUCKLE - INSPECTION ........2-9

STEERING KNUCKLE - INSTALLATION ......2-9

STEERING KNUCKLE - REMOVAL ..........2-7

STEERING PUMP INITIAL OPERATION - STANDARD PROCEDURE, POWER .......19-37

STEERING PUMP, SPECIAL TOOLS - POWER ............................ 19-44

STEERING, SPECIAL TOOLS - POWER .....19-9

STEERING SYSTEM - DESCRIPTION, POWER ............................. 19-1

STEERING SYSTEM - OPERATION, POWER ............................. 19-1

STEERING SYSTEM DIAGNOSIS CHARTS - DIAGNOSIS AND TESTING .............19-3

STEERING SYSTEM FLOW AND PRESSURE TEST - DIAGNOSIS AND

TESTING, POWER ..................... 19-1

STEERING WHEEL - INSTALLATION ......19-24

STEERING WHEEL - REMOVAL ..........19-23

STEM SEALS - DESCRIPTION, VALVE .....9-114

STEM SEALS - INSTALLATION, VALVE ....9-115

STEM SEALS - REMOVAL, VALVE ........9-115

STOP BUMPER - INSTALLATION .........23-25

STOP BUMPER - REMOVAL ............23-25

STOP BUMPER BEZEL - INSTALLATION, SLIDING DOOR ...................... 23-25

STOP BUMPER BEZEL - REMOVAL, SLIDING DOOR ...................... 23-25

STOP LAMP - INSTALLATION, CENTER HIGH MOUNTED ...................... 8L-6

STOP LAMP - REMOVAL, CENTER HIGH MOUNTED ........................... 8L-6

STOP LAMP UNIT - INSTALLATION, CENTER HIGH MOUNTED ...............8L-6

STOP LAMP UNIT - REMOVAL, CENTER HIGH MOUNTED ...................... 8L-6

STORAGE BIN - INSTALLATION, UNDER SEAT ............................. 23-149

STORAGE BIN - REMOVAL, UNDER SEAT . 23-149

30 INDEXRS

Description Group-Page Description Group-Page Description Group-Page