radiator CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1839 of 1938

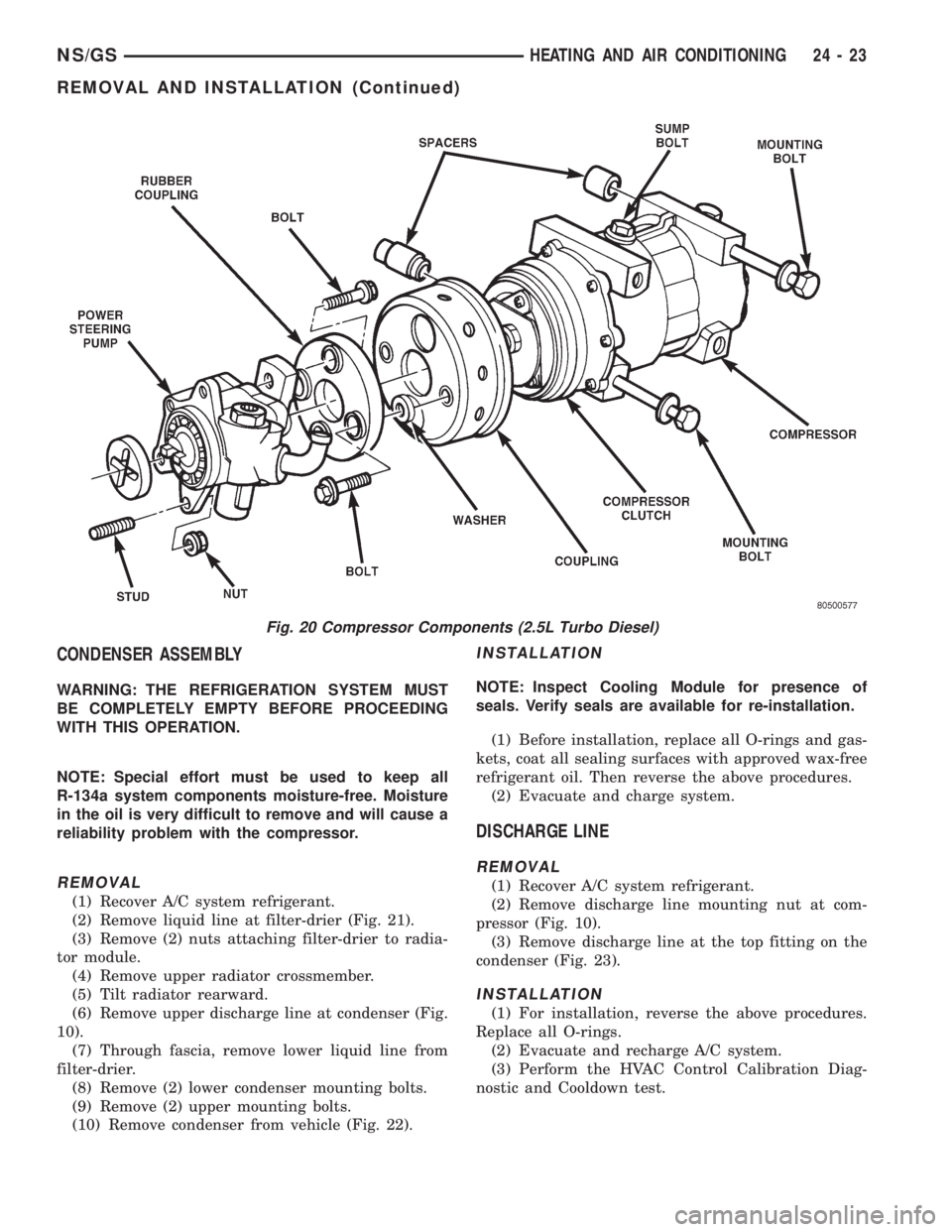

COMPRESSOR

REMOVAL

WARNING: REFER TO REFRIGERANT SERVICE

PROCEDURES FOR INFORMATION REGARDING

PROPER RECOVERY OF THE REFRIGERANT

BEFORE ATTEMPTING TO REMOVE THE COM-

PRESSOR.

(1) Disconnect negative battery cable.

(2) Pinch off coolant lines to rear Heat unit (if

equipped). Drain engine coolant.

(3) Remove upper radiator hose.

(4) Remove drive belt (refer to Group 7, Cooling

System). Disconnect compressor clutch wire lead.

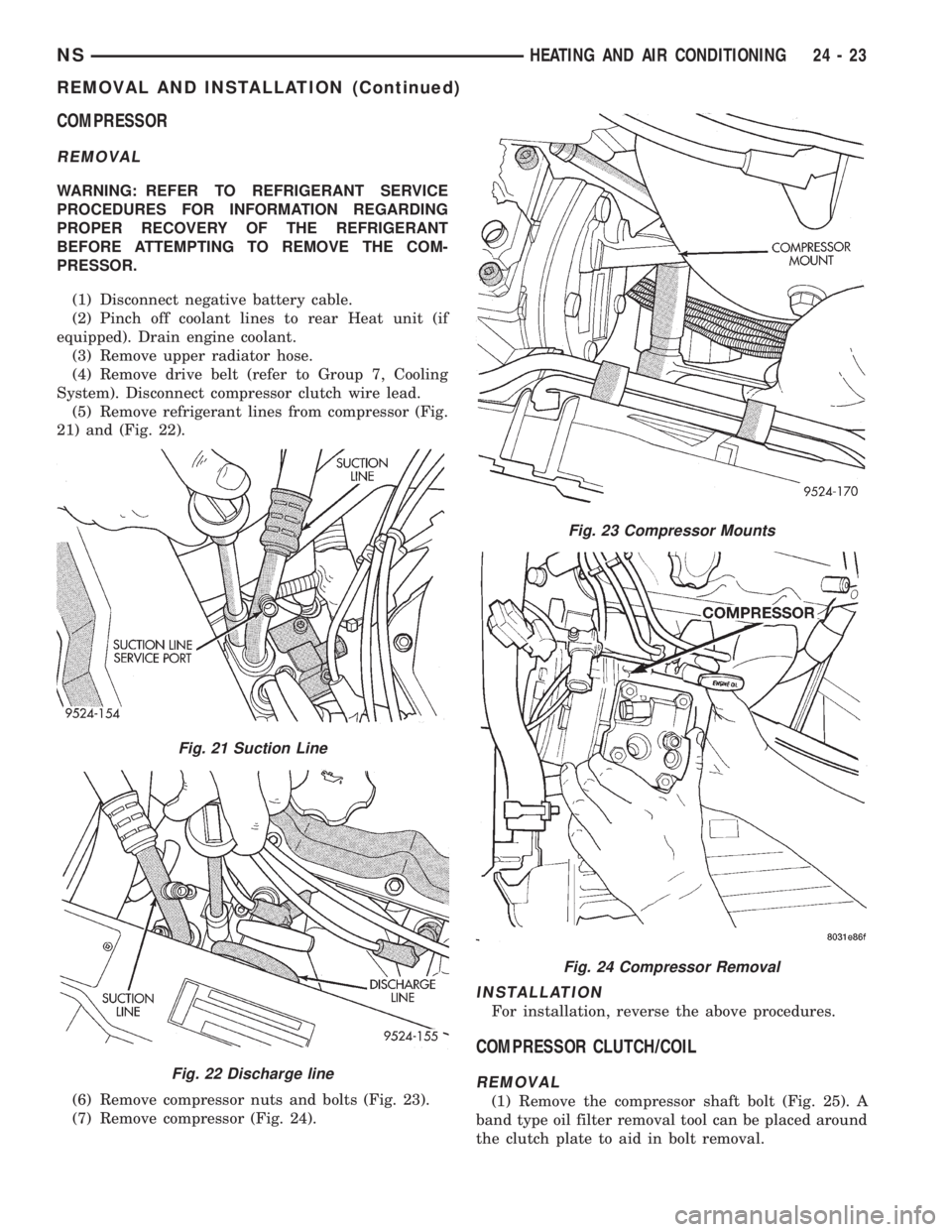

(5) Remove refrigerant lines from compressor (Fig.

21) and (Fig. 22).

(6) Remove compressor nuts and bolts (Fig. 23).

(7) Remove compressor (Fig. 24).

INSTALLATION

For installation, reverse the above procedures.

COMPRESSOR CLUTCH/COIL

REMOVAL

(1) Remove the compressor shaft bolt (Fig. 25). A

band type oil filter removal tool can be placed around

the clutch plate to aid in bolt removal.

Fig. 21 Suction Line

Fig. 22 Discharge line

Fig. 23 Compressor Mounts

Fig. 24 Compressor Removal

NSHEATING AND AIR CONDITIONING 24 - 23

REMOVAL AND INSTALLATION (Continued)

Page 1841 of 1938

CAUTION: The clutch pulley and the front plate

were mated at the factory by a burnishing opera-

tion. No attempt should be made to separately

replace either part. This will result in clutch slip-

page due to insufficient contact area.

INSTALLATION

(1) Align pin in back of field coil with hole in com-

pressor end housing, and position field coil into place.

Make sure that lead wires are properly routed, and

fasten with the wire clip screw.

(2) Install field coil retaining snap ring with snap

ring pliers. The bevel side of the snap ring facing

outward. Also both snap ring eyelets must be to the

right or left of the pin on compressor. Press snap ring

to make sure it is properly seated in the groove.

CAUTION: If snap ring is not fully seated it will

vibrate out, resulting in a clutch failure and severe

damage to the front face of the compressor.

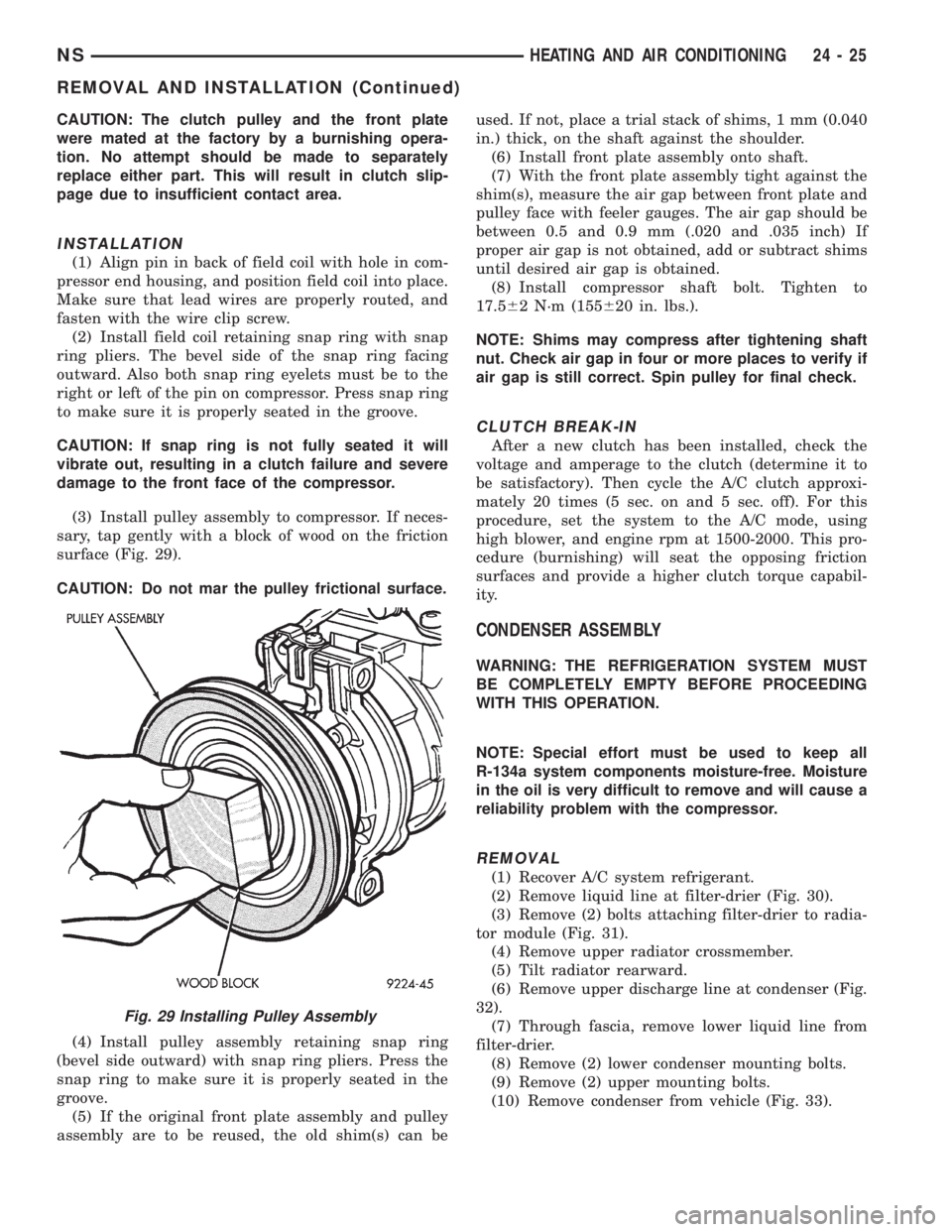

(3) Install pulley assembly to compressor. If neces-

sary, tap gently with a block of wood on the friction

surface (Fig. 29).

CAUTION: Do not mar the pulley frictional surface.

(4) Install pulley assembly retaining snap ring

(bevel side outward) with snap ring pliers. Press the

snap ring to make sure it is properly seated in the

groove.

(5) If the original front plate assembly and pulley

assembly are to be reused, the old shim(s) can beused. If not, place a trial stack of shims, 1 mm (0.040

in.) thick, on the shaft against the shoulder.

(6) Install front plate assembly onto shaft.

(7) With the front plate assembly tight against the

shim(s), measure the air gap between front plate and

pulley face with feeler gauges. The air gap should be

between 0.5 and 0.9 mm (.020 and .035 inch) If

proper air gap is not obtained, add or subtract shims

until desired air gap is obtained.

(8) Install compressor shaft bolt. Tighten to

17.562 N´m (155620 in. lbs.).

NOTE: Shims may compress after tightening shaft

nut. Check air gap in four or more places to verify if

air gap is still correct. Spin pulley for final check.

CLUTCH BREAK-IN

After a new clutch has been installed, check the

voltage and amperage to the clutch (determine it to

be satisfactory). Then cycle the A/C clutch approxi-

mately 20 times (5 sec. on and 5 sec. off). For this

procedure, set the system to the A/C mode, using

high blower, and engine rpm at 1500-2000. This pro-

cedure (burnishing) will seat the opposing friction

surfaces and provide a higher clutch torque capabil-

ity.

CONDENSER ASSEMBLY

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

REMOVAL

(1) Recover A/C system refrigerant.

(2) Remove liquid line at filter-drier (Fig. 30).

(3) Remove (2) bolts attaching filter-drier to radia-

tor module (Fig. 31).

(4) Remove upper radiator crossmember.

(5) Tilt radiator rearward.

(6) Remove upper discharge line at condenser (Fig.

32).

(7) Through fascia, remove lower liquid line from

filter-drier.

(8) Remove (2) lower condenser mounting bolts.

(9) Remove (2) upper mounting bolts.

(10) Remove condenser from vehicle (Fig. 33).

Fig. 29 Installing Pulley Assembly

NSHEATING AND AIR CONDITIONING 24 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1845 of 1938

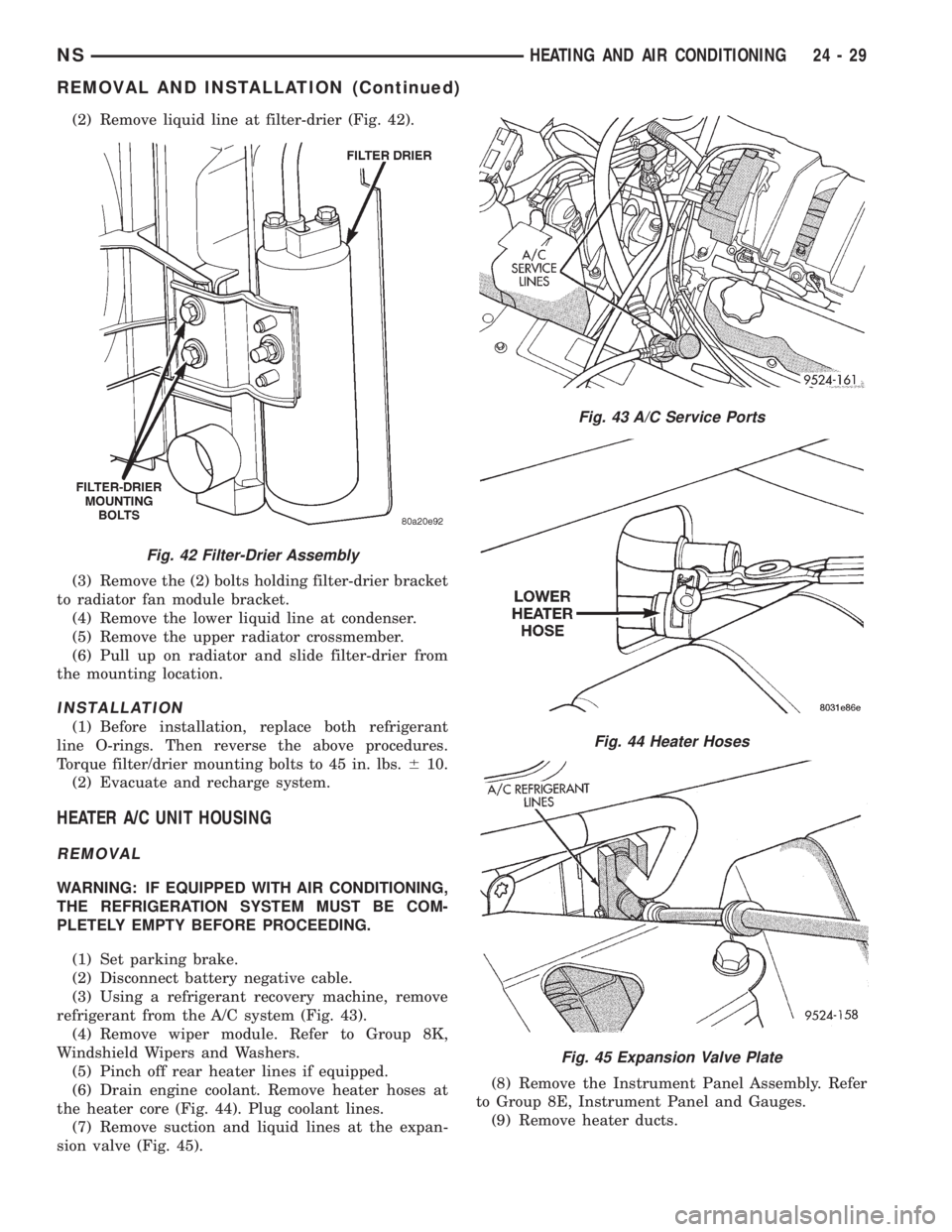

(2) Remove liquid line at filter-drier (Fig. 42).

(3) Remove the (2) bolts holding filter-drier bracket

to radiator fan module bracket.

(4) Remove the lower liquid line at condenser.

(5) Remove the upper radiator crossmember.

(6) Pull up on radiator and slide filter-drier from

the mounting location.

INSTALLATION

(1) Before installation, replace both refrigerant

line O-rings. Then reverse the above procedures.

Torque filter/drier mounting bolts to 45 in. lbs.610.

(2) Evacuate and recharge system.

HEATER A/C UNIT HOUSING

REMOVAL

WARNING: IF EQUIPPED WITH AIR CONDITIONING,

THE REFRIGERATION SYSTEM MUST BE COM-

PLETELY EMPTY BEFORE PROCEEDING.

(1) Set parking brake.

(2) Disconnect battery negative cable.

(3) Using a refrigerant recovery machine, remove

refrigerant from the A/C system (Fig. 43).

(4) Remove wiper module. Refer to Group 8K,

Windshield Wipers and Washers.

(5) Pinch off rear heater lines if equipped.

(6) Drain engine coolant. Remove heater hoses at

the heater core (Fig. 44). Plug coolant lines.

(7) Remove suction and liquid lines at the expan-

sion valve (Fig. 45).(8) Remove the Instrument Panel Assembly. Refer

to Group 8E, Instrument Panel and Gauges.

(9) Remove heater ducts.

Fig. 42 Filter-Drier Assembly

Fig. 43 A/C Service Ports

Fig. 44 Heater Hoses

Fig. 45 Expansion Valve Plate

NSHEATING AND AIR CONDITIONING 24 - 29

REMOVAL AND INSTALLATION (Continued)

Page 1848 of 1938

CAUTION: When removing hoses from heater core

inlet or outlet nipples, do not use excessive force.

Heater core may become damaged and leak engine

coolant.

(3) Carefully rotate hose back and forth while tug-

ging slightly away from connector nipple. If the hose

will not come off, slice the hose at the connector nip-

ple and peel off heater hose. This method will require

heater hose replacement.

INSTALLATION

For installation, reverse the above procedures.

LIQUID LINE

REMOVAL

(1) Disconnect the battery negative cable.

(2) Recover A/C system refrigerant.

(3) Remove the accessory drive belt.

(4) Remove upper generator bracket.

(5) Remove ground wire at dash panel.

(6) Remove the nut retaining the refrigerant line

sealing plate to the expansion valve (Fig. 39).

(7) Remove the stud from the expansion valve (Fig.

40).

(8) Remove liquid line from expansion valve.

(9) Cover the openings to prevent contamination.

(10) Disconnect wire connector at pressure trans-

ducer.

(11) Remove liquid line mounting bracket at right

frame rail.

(12) Using access slot between radiator crossmem-

ber and grille, loosen liquid line mounting plate at

filter-drier. Remove liquid line from filter-drier. It

may be necessary to bend liquid line in half to

remove line. The replacement line is a two-piece

assembly.

(13) Remove the old O-rings.

INSTALLATION

For installation, reverse the above procedures.

²Install the stud to the evaporator sealing plate

and tighten 7 to 11 N´m (64 to 96 in. lbs.) torque.

²Install new O-rings.

²Install two-piece line in place of original part.

²A

ssemble line halves after it is installed on vehicle.²Evacuate and recharge A/C system.

MODE DOOR ACTUATOR

REMOVAL

(1) Remove the lower left side steering column

cover. Refer to Group 8E, Instrument Panel and Sys-

tems.

(2) Remove ABS control module (Fig. 56).

(3) Remove mode actuator connector (Fig. 57).

(4) Remove mode door actuator (Fig. 58).

INSTALLATION

(1) For installation, reverse the above procedures.

Fig. 55 Lower Heater Hose

Fig. 56 ABS Control Module

Fig. 57 Mode Door Actuator Connector

24 - 32 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1861 of 1938

CAUTION: Do not damage the evaporator insulation

liner during installation.

(3) Carefully install the evaporator and expansion

valve straight into the unit. Do not scratch the seal-

ing surfaces with the plumbing extension tube pilots.

(4) Determine the amount of old refrigerant oil

drained from the evaporator. Add this amount (of

clean refrigerant oil) back into the system.

(5) Carefully align the expansion valve onto the

pilot tubes of the plumbing extension (do not scratch

the sealing surface). Install the bolt through the

plumbing plate into the unit sealing plate. Tighten

bolts to 2363 N´m (200630 inch pounds) torque.

(6) Install evaporator cover and blower scroll.

(7) Install quarter trim panel, evacuate/charge sys-

tem, and perform the performance test.

REAR AIR CONDITIONING LINES

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

REMOVAL

(1) Hoist vehicle

(2) Remove compression fittings to the suction and

liquid lines located on the right, outboard side of the

underbody, rearward of the front crossmember. (Fig.

2)

(3) remove (1) bolt securing a/c lines to block

located on the right, outboard side of the underbody,

rearward of the rear wheel and tire. (Fig. 5)

(4) Remove (3) straps securing underbody lines.

(Fig. 1)

(5) Separate and remove a/c lines from vehicle.

INSTALLATION

(1) Before installation, replace all O-rings and gas-

kets. Coat all sealing surfaces with approved wax-

free refrigerant oil. Then, reverse the above

procedures.

(2) Evacuate and recharge system.

REAR HEATER A/C AIR OUTLETS

REMOVAL

Separate barrel from bezel by pulling outward.

INSTALLATION

For installation, push the outlet firmly into the

opening until it locks into place.

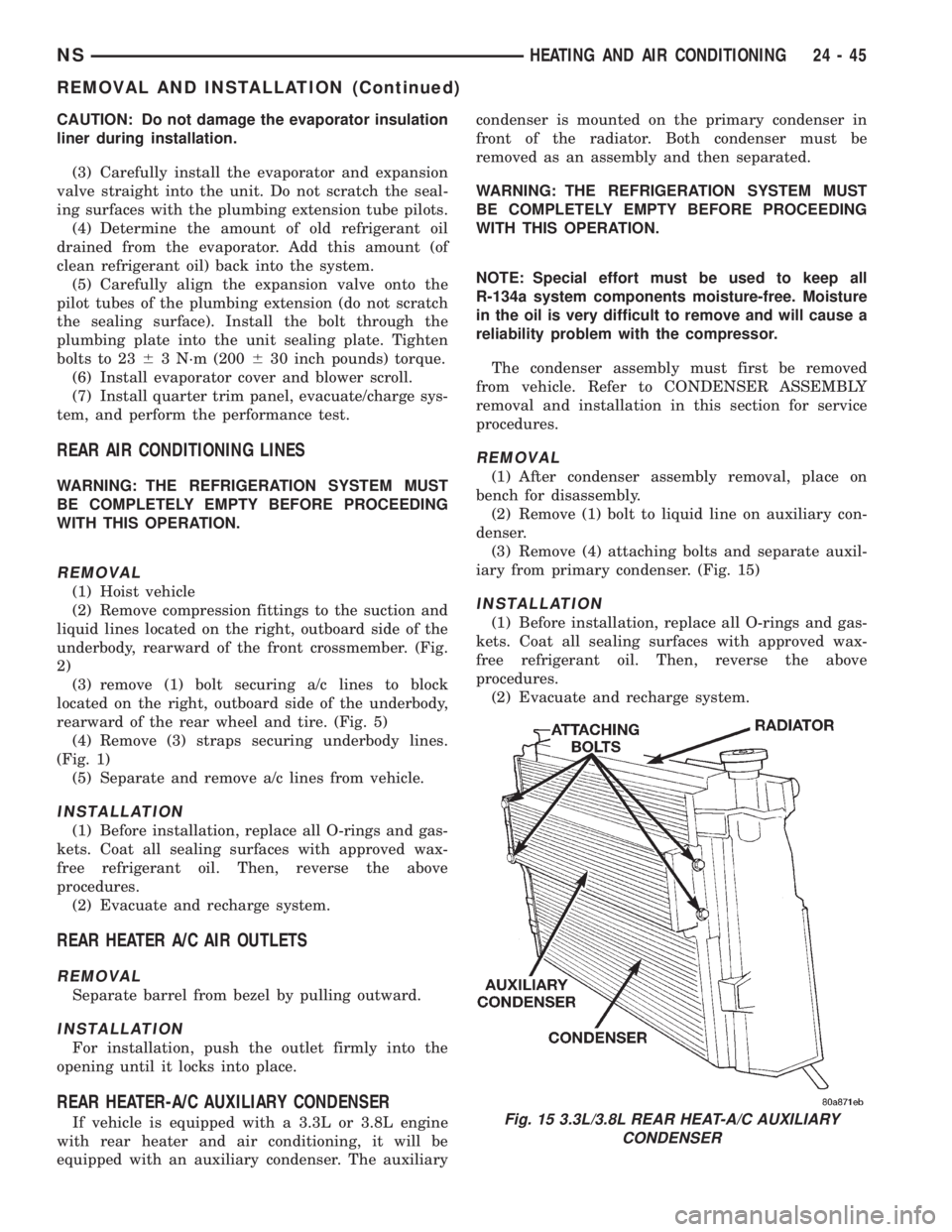

REAR HEATER-A/C AUXILIARY CONDENSER

If vehicle is equipped with a 3.3L or 3.8L engine

with rear heater and air conditioning, it will be

equipped with an auxiliary condenser. The auxiliarycondenser is mounted on the primary condenser in

front of the radiator. Both condenser must be

removed as an assembly and then separated.

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

The condenser assembly must first be removed

from vehicle. Refer to CONDENSER ASSEMBLY

removal and installation in this section for service

procedures.

REMOVAL

(1) After condenser assembly removal, place on

bench for disassembly.

(2) Remove (1) bolt to liquid line on auxiliary con-

denser.

(3) Remove (4) attaching bolts and separate auxil-

iary from primary condenser. (Fig. 15)

INSTALLATION

(1) Before installation, replace all O-rings and gas-

kets. Coat all sealing surfaces with approved wax-

free refrigerant oil. Then, reverse the above

procedures.

(2) Evacuate and recharge system.

Fig. 15 3.3L/3.8L REAR HEAT-A/C AUXILIARY

CONDENSER

NSHEATING AND AIR CONDITIONING 24 - 45

REMOVAL AND INSTALLATION (Continued)

Page 1864 of 1938

NOTE: If the heater core was emptied and was not

prefilled, it is necessary to thermal cycle the vehicle

TWICE. The heater core is positioned higher than

the radiator fill cap. Therefore the heater core will

not gravity fill to level. To thermal cycle the vehicle,

it must be operated till the thermostat opens, then

turned off and allowed to cool. In order to verify

that the auxiliary unit is filled completely, the follow-

ing procedure can be used:

²Vehicle at room temperature.

²Engine is brought up to operating temperature.

²Front unit is OFF, temperature slides are at full

HEAT position.

²Engine is at idle.

²With rear blower motor ON HIGH.

²Discharge air temperature, measured at the

dual register located on the C-pillar base, is between

135É and 145É F.

REAR HEATER CORE

REMOVAL

(1) Remove the lower right quarter trim panel.

Refer to Group 23, Body.

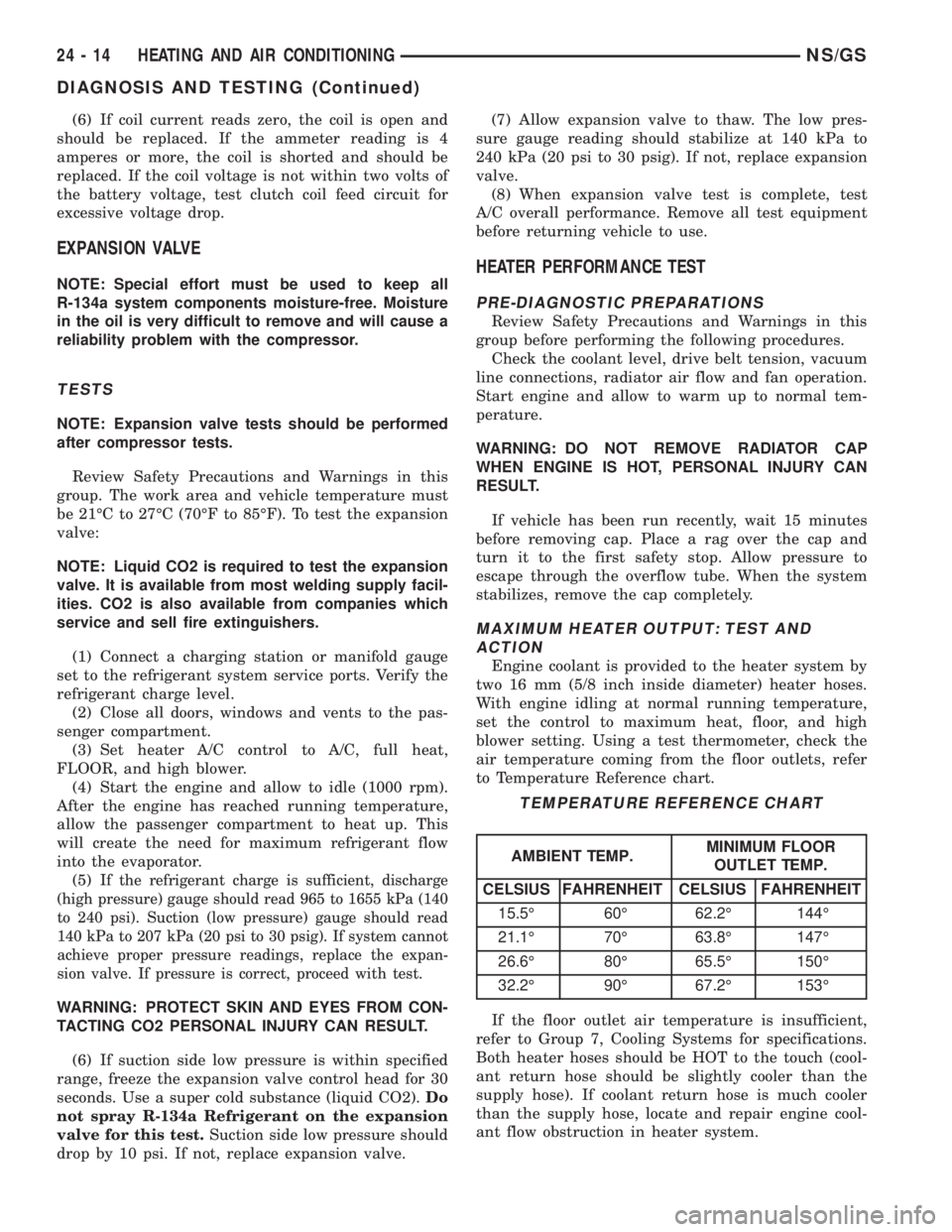

(2) Isolate and disconnect lines from heater core

(Fig. 27).

(3) Remove heater core retaining screws.

(4) Carefully pull the heater core and tubes up and

straight out of the unit.

INSTALLATION

For installation, reverse the above procedures. Pre-

fill the heater core (Fig. 26). Test for leaks and over-

all performance.

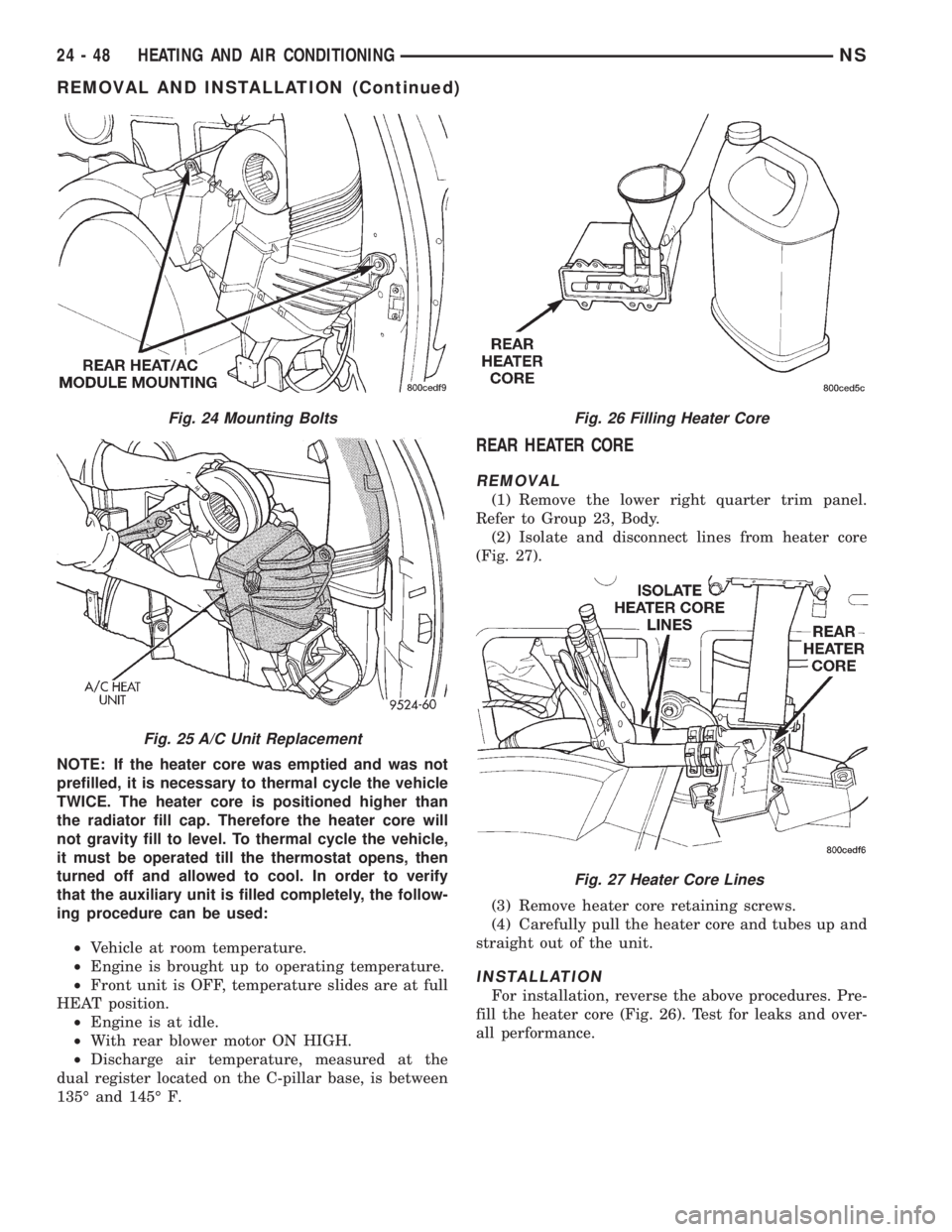

Fig. 24 Mounting Bolts

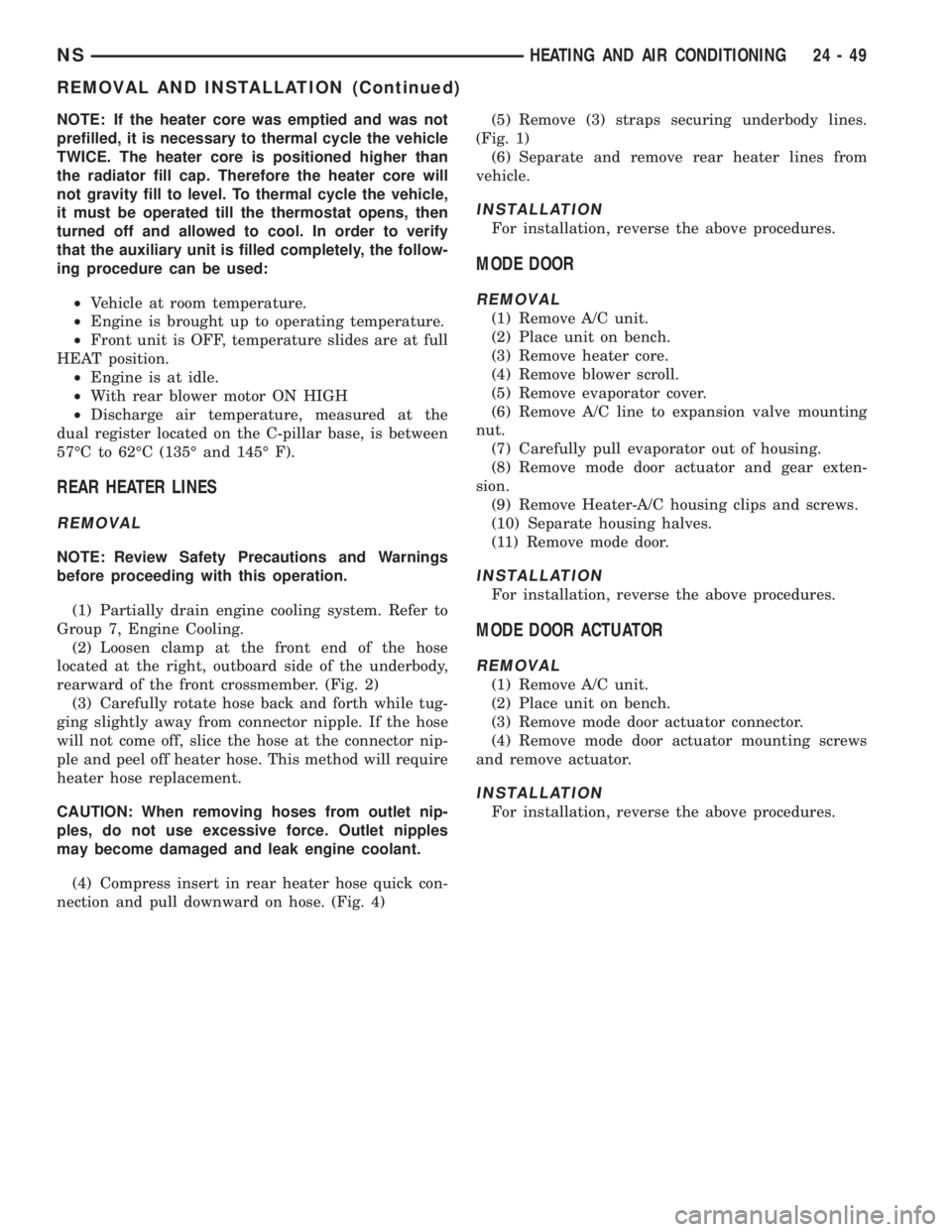

Fig. 25 A/C Unit Replacement

Fig. 26 Filling Heater Core

Fig. 27 Heater Core Lines

24 - 48 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1865 of 1938

NOTE: If the heater core was emptied and was not

prefilled, it is necessary to thermal cycle the vehicle

TWICE. The heater core is positioned higher than

the radiator fill cap. Therefore the heater core will

not gravity fill to level. To thermal cycle the vehicle,

it must be operated till the thermostat opens, then

turned off and allowed to cool. In order to verify

that the auxiliary unit is filled completely, the follow-

ing procedure can be used:

²Vehicle at room temperature.

²Engine is brought up to operating temperature.

²Front unit is OFF, temperature slides are at full

HEAT position.

²Engine is at idle.

²With rear blower motor ON HIGH

²Discharge air temperature, measured at the

dual register located on the C-pillar base, is between

57ÉC to 62ÉC (135É and 145É F).

REAR HEATER LINES

REMOVAL

NOTE: Review Safety Precautions and Warnings

before proceeding with this operation.

(1) Partially drain engine cooling system. Refer to

Group 7, Engine Cooling.

(2) Loosen clamp at the front end of the hose

located at the right, outboard side of the underbody,

rearward of the front crossmember. (Fig. 2)

(3) Carefully rotate hose back and forth while tug-

ging slightly away from connector nipple. If the hose

will not come off, slice the hose at the connector nip-

ple and peel off heater hose. This method will require

heater hose replacement.

CAUTION: When removing hoses from outlet nip-

ples, do not use excessive force. Outlet nipples

may become damaged and leak engine coolant.

(4) Compress insert in rear heater hose quick con-

nection and pull downward on hose. (Fig. 4)(5) Remove (3) straps securing underbody lines.

(Fig. 1)

(6) Separate and remove rear heater lines from

vehicle.

INSTALLATION

For installation, reverse the above procedures.

MODE DOOR

REMOVAL

(1) Remove A/C unit.

(2) Place unit on bench.

(3) Remove heater core.

(4) Remove blower scroll.

(5) Remove evaporator cover.

(6) Remove A/C line to expansion valve mounting

nut.

(7) Carefully pull evaporator out of housing.

(8) Remove mode door actuator and gear exten-

sion.

(9) Remove Heater-A/C housing clips and screws.

(10) Separate housing halves.

(11) Remove mode door.

INSTALLATION

For installation, reverse the above procedures.

MODE DOOR ACTUATOR

REMOVAL

(1) Remove A/C unit.

(2) Place unit on bench.

(3) Remove mode door actuator connector.

(4) Remove mode door actuator mounting screws

and remove actuator.

INSTALLATION

For installation, reverse the above procedures.

NSHEATING AND AIR CONDITIONING 24 - 49

REMOVAL AND INSTALLATION (Continued)

Page 1880 of 1938

(6) If coil current reads zero, the coil is open and

should be replaced. If the ammeter reading is 4

amperes or more, the coil is shorted and should be

replaced. If the coil voltage is not within two volts of

the battery voltage, test clutch coil feed circuit for

excessive voltage drop.

EXPANSION VALVE

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

TESTS

NOTE: Expansion valve tests should be performed

after compressor tests.

Review Safety Precautions and Warnings in this

group. The work area and vehicle temperature must

be 21ÉC to 27ÉC (70ÉF to 85ÉF). To test the expansion

valve:

NOTE: Liquid CO2 is required to test the expansion

valve. It is available from most welding supply facil-

ities. CO2 is also available from companies which

service and sell fire extinguishers.

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set heater A/C control to A/C, full heat,

FLOOR, and high blower.

(4) Start the engine and allow to idle (1000 rpm).

After the engine has reached running temperature,

allow the passenger compartment to heat up. This

will create the need for maximum refrigerant flow

into the evaporator.

(5) I

f the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 1655 kPa (140

to 240 psi). Suction (low pressure) gauge should read

140 kPa to 207 kPa (20 psi to 30 psig). If system cannot

achieve proper pressure readings, replace the expan-

sion valve. If pressure is correct, proceed with test.

WARNING: PROTECT SKIN AND EYES FROM CON-

TACTING CO2 PERSONAL INJURY CAN RESULT.

(6) If suction side low pressure is within specified

range, freeze the expansion valve control head for 30

seconds. Use a super cold substance (liquid CO2).Do

not spray R-134a Refrigerant on the expansion

valve for this test.Suction side low pressure should

drop by 10 psi. If not, replace expansion valve.(7) Allow expansion valve to thaw. The low pres-

sure gauge reading should stabilize at 140 kPa to

240 kPa (20 psi to 30 psig). If not, replace expansion

valve.

(8) When expansion valve test is complete, test

A/C overall performance. Remove all test equipment

before returning vehicle to use.

HEATER PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings in this

group before performing the following procedures.

Check the coolant level, drive belt tension, vacuum

line connections, radiator air flow and fan operation.

Start engine and allow to warm up to normal tem-

perature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to

escape through the overflow tube. When the system

stabilizes, remove the cap completely.

MAXIMUM HEATER OUTPUT: TEST AND

ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference chart.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

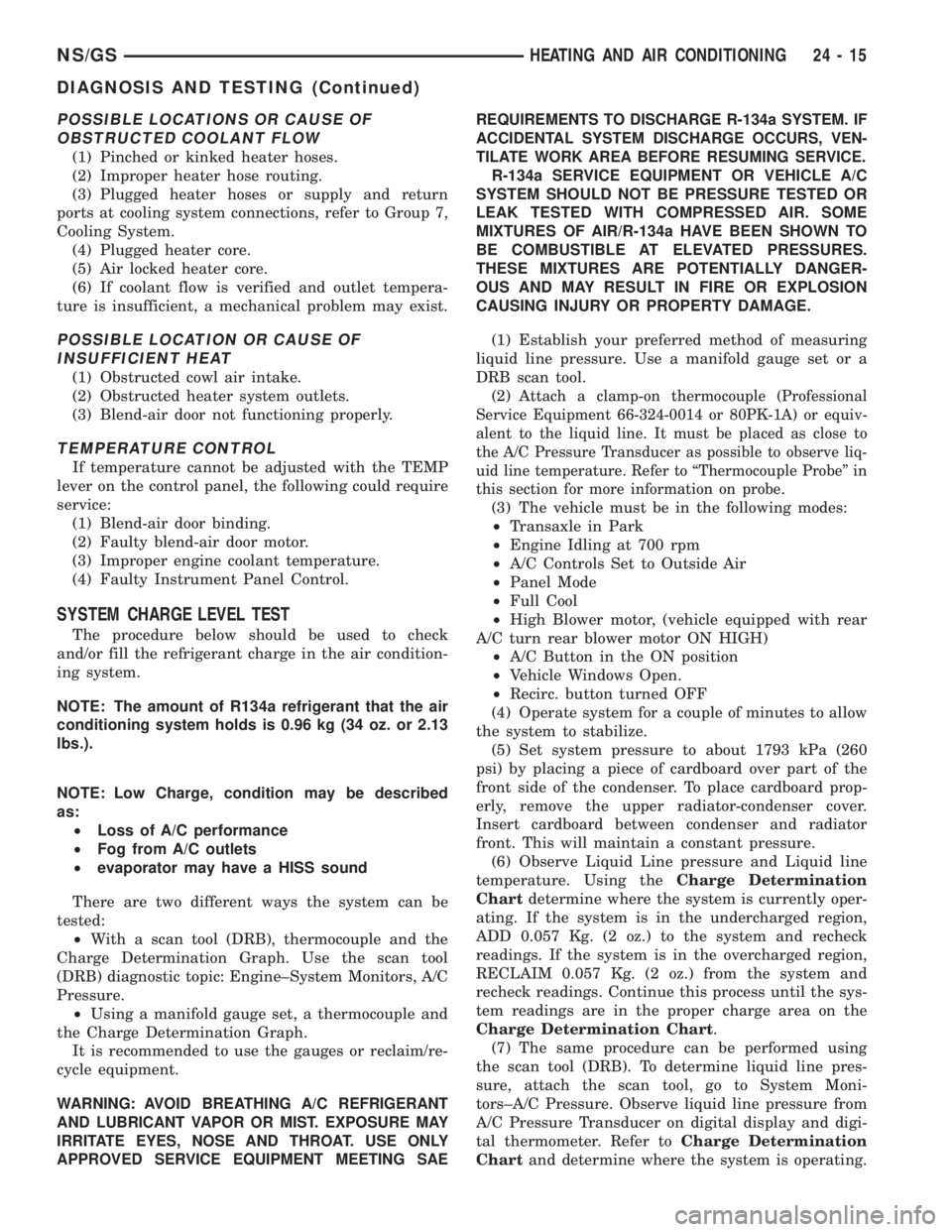

TEMPERATURE REFERENCE CHART

AMBIENT TEMP.MINIMUM FLOOR

OUTLET TEMP.

CELSIUS FAHRENHEIT CELSIUS FAHRENHEIT

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

24 - 14 HEATING AND AIR CONDITIONINGNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1881 of 1938

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.

(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF

INSUFFICIENT HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door motor.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

NOTE: The amount of R134a refrigerant that the air

conditioning system holds is 0.96 kg (34 oz. or 2.13

lbs.).

NOTE: Low Charge, condition may be described

as:

²Loss of A/C performance

²Fog from A/C outlets

²evaporator may have a HISS sound

There are two different ways the system can be

tested:

²With a scan tool (DRB), thermocouple and the

Charge Determination Graph. Use the scan tool

(DRB) diagnostic topic: Engine±System Monitors, A/C

Pressure.

²Using a manifold gauge set, a thermocouple and

the Charge Determination Graph.

It is recommended to use the gauges or reclaim/re-

cycle equipment.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAEREQUIREMENTS TO DISCHARGE R-134a SYSTEM. IF

ACCIDENTAL SYSTEM DISCHARGE OCCURS, VEN-

TILATE WORK AREA BEFORE RESUMING SERVICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. SOME

MIXTURES OF AIR/R-134a HAVE BEEN SHOWN TO

BE COMBUSTIBLE AT ELEVATED PRESSURES.

THESE MIXTURES ARE POTENTIALLY DANGER-

OUS AND MAY RESULT IN FIRE OR EXPLOSION

CAUSING INJURY OR PROPERTY DAMAGE.

(1) Establish your preferred method of measuring

liquid line pressure. Use a manifold gauge set or a

DRB scan tool.

(2) A

ttach a clamp-on thermocouple (Professional

Service Equipment 66-324-0014 or 80PK-1A) or equiv-

alent to the liquid line. It must be placed as close to

the A/C Pressure Transducer as possible to observe liq-

uid line temperature. Refer to ªThermocouple Probeº in

this section for more information on probe.

(3) The vehicle must be in the following modes:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set to Outside Air

²Panel Mode

²Full Cool

²High Blower motor, (vehicle equipped with rear

A/C turn rear blower motor ON HIGH)

²A/C Button in the ON position

²Vehicle Windows Open.

²Recirc. button turned OFF

(4) Operate system for a couple of minutes to allow

the system to stabilize.

(5) Set system pressure to about 1793 kPa (260

psi) by placing a piece of cardboard over part of the

front side of the condenser. To place cardboard prop-

erly, remove the upper radiator-condenser cover.

Insert cardboard between condenser and radiator

front. This will maintain a constant pressure.

(6) Observe Liquid Line pressure and Liquid line

temperature. Using theCharge Determination

Chartdetermine where the system is currently oper-

ating. If the system is in the undercharged region,

ADD 0.057 Kg. (2 oz.) to the system and recheck

readings. If the system is in the overcharged region,

RECLAIM 0.057 Kg. (2 oz.) from the system and

recheck readings. Continue this process until the sys-

tem readings are in the proper charge area on the

Charge Determination Chart.

(7) The same procedure can be performed using

the scan tool (DRB). To determine liquid line pres-

sure, attach the scan tool, go to System Moni-

tors±A/C Pressure. Observe liquid line pressure from

A/C Pressure Transducer on digital display and digi-

tal thermometer. Refer toCharge Determination

Chartand determine where the system is operating.

NS/GSHEATING AND AIR CONDITIONING 24 - 15

DIAGNOSIS AND TESTING (Continued)

Page 1889 of 1938

CONDENSER ASSEMBLY

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

REMOVAL

(1) Recover A/C system refrigerant.

(2) Remove liquid line at filter-drier (Fig. 21).

(3) Remove (2) nuts attaching filter-drier to radia-

tor module.

(4) Remove upper radiator crossmember.

(5) Tilt radiator rearward.

(6) Remove upper discharge line at condenser (Fig.

10).

(7) Through fascia, remove lower liquid line from

filter-drier.

(8) Remove (2) lower condenser mounting bolts.

(9) Remove (2) upper mounting bolts.

(10) Remove condenser from vehicle (Fig. 22).

INSTALLATION

NOTE: Inspect Cooling Module for presence of

seals. Verify seals are available for re-installation.

(1) Before installation, replace all O-rings and gas-

kets, coat all sealing surfaces with approved wax-free

refrigerant oil. Then reverse the above procedures.

(2) Evacuate and charge system.

DISCHARGE LINE

REMOVAL

(1) Recover A/C system refrigerant.

(2) Remove discharge line mounting nut at com-

pressor (Fig. 10).

(3) Remove discharge line at the top fitting on the

condenser (Fig. 23).

INSTALLATION

(1) For installation, reverse the above procedures.

Replace all O-rings.

(2) Evacuate and recharge A/C system.

(3) Perform the HVAC Control Calibration Diag-

nostic and Cooldown test.

Fig. 20 Compressor Components (2.5L Turbo Diesel)

NS/GSHEATING AND AIR CONDITIONING 24 - 23

REMOVAL AND INSTALLATION (Continued)