radiator CHRYSLER VOYAGER 1996 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1400 of 1938

FUEL INJECTION SYSTEMÐ2.0L ENGINE

INDEX

page page

GENERAL INFORMATION

INTRODUCTIONÐ2.0L ENGINE............ 32

MODES OF OPERATIONÐ2.0L ENGINE..... 32

DESCRIPTION AND OPERATION

AIR CONDITIONING (A/C) RELAYÐPCM

OUTPUTÐ2.0L ENGINE................ 35

AIR CONDITIONING PRESSURE

TRANSDUCERÐPCM INPUTÐ

2.0L ENGINE......................... 33

AIR CONDITIONING SWITCH SENSEÐ

PCM INPUTÐ2.0L ENGINE.............. 33

AUTOMATIC SHUTDOWN (ASD) SENSEÐ

PCM INPUTÐ2.0L ENGINE.............. 33

AUTOMATIC SHUTDOWN RELAYÐ

PCM OUTPUTÐ2.0L ENGINE............ 35

BATTERY VOLTAGEÐPCM INPUTÐ

2.0L ENGINE......................... 33

CAMSHAFT POSITION SENSORÐ

PCM INPUTÐ2.0L ENGINE.............. 33

CRANKSHAFT POSITION SENSORÐ

PCM INPUTÐ2.0L ENGINE.............. 33

DATA LINK CONNECTORÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

ELECTRONIC EGR TRANSDUCERÐ

PCM OUTPUTÐ2.0L ENGINE............ 35

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUTÐ2.0L ENGINE.............. 33

FUEL INJECTORSÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

FUEL PUMP RELAYÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

GENERATOR FIELDÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

HEATED OXYGEN SENSORÐPCM INPUTÐ

2.0L ENGINE......................... 33

IDLE AIR CONTROL MOTORÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

IGNITION COILÐPCM OUTPUTÐ

2.0L ENGINE......................... 36KNOCK SENSORÐPCM INPUTÐ

2.0L ENGINE......................... 34

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUTÐ2.0L ENGINE...... 36

MANIFOLD ABSOLUTE PRESSURE

(MAP SENSOR)ÐPCM INPUTÐ

2.0L ENGINE......................... 34

POWERTRAIN CONTROL MODULEÐ

2.0L ENGINE......................... 33

RADIATOR FAN CONTROL MODULEÐ

PCM OUTPUTÐ2.0L ENGINE............ 36

SPEED CONTROL SOLENOIDSÐ

PCM OUTPUTÐ2.0L ENGINE............ 36

SPEED CONTROLÐPCM INPUTÐ

2.0L ENGINE......................... 34

STARTER RELAYÐPCM OUTPUTÐ

2.0L ENGINE......................... 35

SYSTEM DIAGNOSISÐ2.0L ENGINE........ 33

TACHOMETERÐPCM OUTPUTÐ

2.0L ENGINE......................... 36

THROTTLE BODYÐ2.0L ENGINE.......... 36

THROTTLE POSITION SENSOR/ IDLE AIR

CONTROL MOTORÐPCM INPUTÐ

2.0L ENGINE......................... 35

DIAGNOSIS AND TESTING

ASD AND FUEL PUMP RELAYSÐ

2.0L ENGINE......................... 39

CAMSHAFT AND CRANKSHAFT

POSITION SENSOR................... 40

ENGINE COOLANT TEMPERATURE

SENSOR............................ 40

KNOCK SENSORÐ2.0L ENGINE........... 40

MANIFOLD ABSOLUTE PRESSURE

(MAP) SENSORÐ2.0L ENGINE........... 39

THROTTLE BODY MINIMUM AIR FLOW..... 41

THROTTLE POSITION SENSOR........... 40

VISUAL INSPECTIONÐSOHC............. 36

SPECIFICATIONS

TORQUE............................. 42

GENERAL INFORMATION

INTRODUCTIONÐ2.0L ENGINE

Refer to the Introduction for 2.4/3.0/3.3/3.8L

engines under General Information in the Fuel Injec-

tion System section of group 14 for more information.

MODES OF OPERATIONÐ2.0L ENGINE

Refer to the Modes of Operation for 2.4/3.0/3.3/3.8L

engines under General Information in the Fuel Injec-

tion System section of group 14 for more information.

14 - 32 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

Page 1404 of 1938

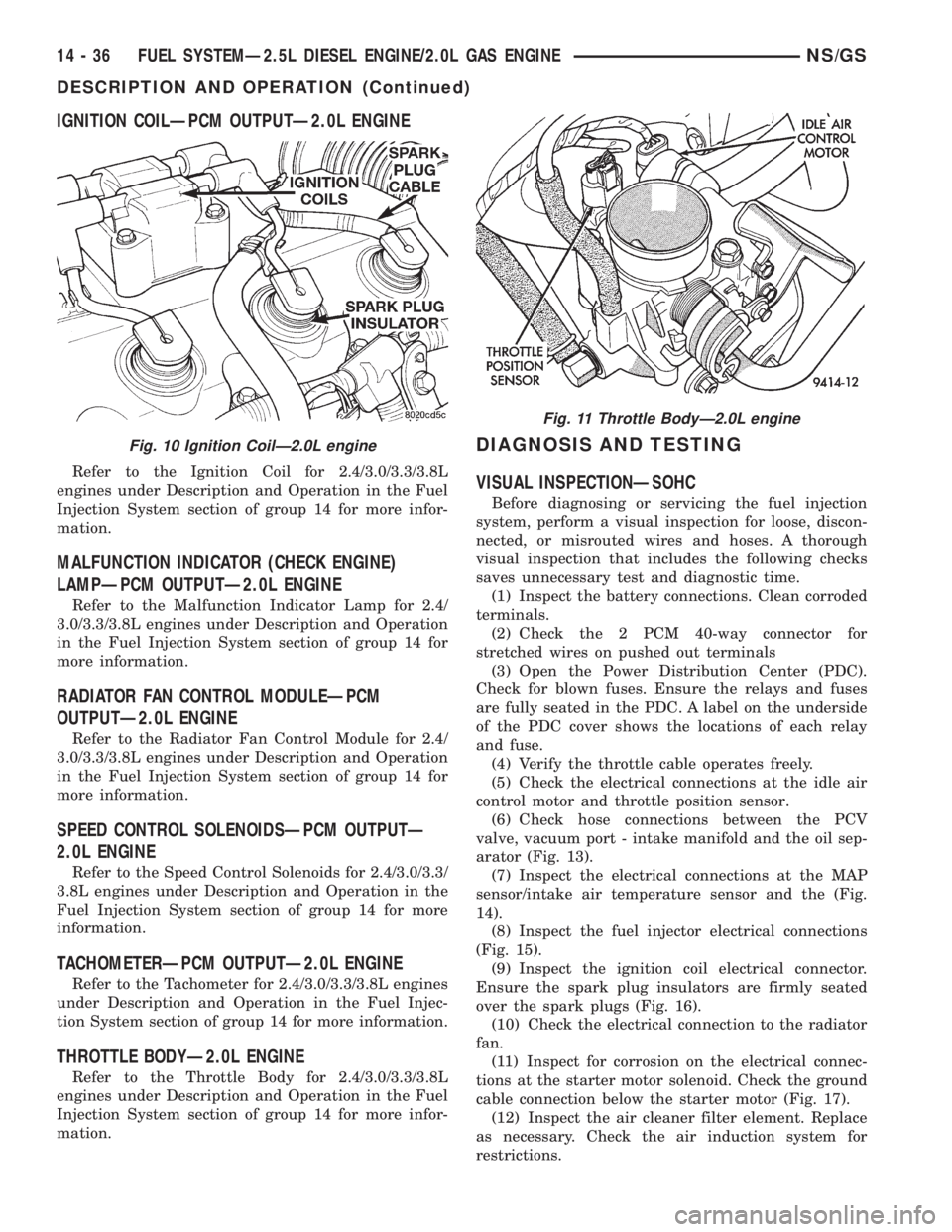

IGNITION COILÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Ignition Coil for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Malfunction Indicator Lamp for 2.4/

3.0/3.3/3.8L engines under Description and Operation

in the Fuel Injection System section of group 14 for

more information.

RADIATOR FAN CONTROL MODULEÐPCM

OUTPUTÐ2.0L ENGINE

Refer to the Radiator Fan Control Module for 2.4/

3.0/3.3/3.8L engines under Description and Operation

in the Fuel Injection System section of group 14 for

more information.

SPEED CONTROL SOLENOIDSÐPCM OUTPUTÐ

2.0L ENGINE

Refer to the Speed Control Solenoids for 2.4/3.0/3.3/

3.8L engines under Description and Operation in the

Fuel Injection System section of group 14 for more

information.

TACHOMETERÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Tachometer for 2.4/3.0/3.3/3.8L engines

under Description and Operation in the Fuel Injec-

tion System section of group 14 for more information.

THROTTLE BODYÐ2.0L ENGINE

Refer to the Throttle Body for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

DIAGNOSIS AND TESTING

VISUAL INSPECTIONÐSOHC

Before diagnosing or servicing the fuel injection

system, perform a visual inspection for loose, discon-

nected, or misrouted wires and hoses. A thorough

visual inspection that includes the following checks

saves unnecessary test and diagnostic time.

(1) Inspect the battery connections. Clean corroded

terminals.

(2) Check the 2 PCM 40-way connector for

stretched wires on pushed out terminals

(3) Open the Power Distribution Center (PDC).

Check for blown fuses. Ensure the relays and fuses

are fully seated in the PDC. A label on the underside

of the PDC cover shows the locations of each relay

and fuse.

(4) Verify the throttle cable operates freely.

(5) Check the electrical connections at the idle air

control motor and throttle position sensor.

(6) Check hose connections between the PCV

valve, vacuum port - intake manifold and the oil sep-

arator (Fig. 13).

(7) Inspect the electrical connections at the MAP

sensor/intake air temperature sensor and the (Fig.

14).

(8) Inspect the fuel injector electrical connections

(Fig. 15).

(9) Inspect the ignition coil electrical connector.

Ensure the spark plug insulators are firmly seated

over the spark plugs (Fig. 16).

(10) Check the electrical connection to the radiator

fan.

(11) Inspect for corrosion on the electrical connec-

tions at the starter motor solenoid. Check the ground

cable connection below the starter motor (Fig. 17).

(12) Inspect the air cleaner filter element. Replace

as necessary. Check the air induction system for

restrictions.

Fig. 10 Ignition CoilÐ2.0L engine

Fig. 11 Throttle BodyÐ2.0L engine

14 - 36 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1476 of 1938

GENERAL INFORMATION

31TH TRANSAXLE

NOTE: Safety goggles should be worn at all times

when working on these transaxles.

This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system. The identifica-

tion markings and usage of the transaxle are charted

in Diagnosis and Tests.

NOTE: Transaxle operation requirements are differ-

ent for each vehicle and engine combination. Some

internal parts will be different to provide for this.

Therefore, when replacing parts, refer to the seven

digit part number stamped on rear of the transaxle

oil pan flange.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

(4) Center distances between the main rotating

parts in these three areas are held precise to main-

tain a low noise level.

(5) The torque converter, transaxle area, and dif-

ferential are housed in an integral aluminum die

casting.The differential oil sump is common

with the transaxle sump. Separate filling of the

differential is NOT necessary.

(6) The torque converter is attached to the crank-

shaft through a flexible driving plate. Cooling of the

converter is accomplished by circulating the tran-

saxle fluid through a remote cooler. There are two

types of coolers used. An oil-to-water type cooler

located in the radiator side tank and/or an oil-to air

heat exchanger. The torque converter assembly is a

sealed unit that cannot be disassembled.

(7) The transaxle fluid is filtered by an internal fil-

ter attached to the lower side of the valve body

assembly.

(8) Engine torque is transmitted to the torque con-

verter then, through the input shaft to multiple-disc

clutches in the transaxle. The power flow depends on

the application of the clutches and bands. Refer to

Elements in Use Chart in Diagnosis and Tests sec-

tion.

(9) The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The drive shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump, and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor of the

final drive (axle) ratio. The shaft also carries the gov-

ernor and parking sprag. An integral helical gear on

the transfer shaft drives the differential ring gear.

The final drive gearing is completed with one of two

gear ratios of 2.98 or 3.19 depending on model and

application.

FLUID LEVEL AND CONDITION

NOTE: The transmission and differential sump have

a common oil sump with a communicating opening

between the two.

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground. This will assure complete oil level sta-

bilization between differential and transmis-

sion.The fluid should be at normal operating

temperature (approximately 82 C. or 180 F.). The

fluid level is correct if it is in the HOT region (cross-

hatched area) on the dipstick.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, the air bubbles can cause overheat-

ing, fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and servo operation.

Foaming can also result in fluid escaping from the

transaxle dipstick where it may be mistaken for a

leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed.

Be sure to examine the fluid on the dipstick closely.

21 - 2 TRANSAXLE AND POWER TRANSFER UNITNS

Page 1752 of 1938

BODY COMPONENT SERVICE

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 23

WIND NOISE........................... 24

SERVICE PROCEDURES

HEAT STAKING......................... 24

REMOVAL AND INSTALLATION

A-PILLAR LOWER EXTENSION TRIM........ 25

A-PILLAR TRIM PANEL................... 25

COWL COVER.......................... 25

COWL TRIM............................ 25

FLOOR CARPET........................ 26

FRONT DOOR APPLIQUE................. 28

FRONT DOOR CHECK STRAP.............. 28

FRONT DOOR FRAME CLOSEOUT MOLDINGS . 29

FRONT DOOR GLASS RUN WEATHER-STRIP . . 30

FRONT DOOR GLASS.................... 29

FRONT DOOR HINGE.................... 30

FRONT DOOR INNER BELT MOLDING....... 31

FRONT DOOR LATCH STRIKER............ 32

FRONT DOOR LATCH.................... 31

FRONT DOOR LOCK CYLINDER............ 32

FRONT DOOR OUTER BELT MOLDING....... 33

FRONT DOOR OUTSIDE HANDLE........... 33

FRONT DOOR REFLECTOR............... 34

FRONT DOOR SILL PLATE................ 34

FRONT DOOR TRIM PANEL................ 34

FRONT DOOR WEATHER-STRIP............ 36

FRONT DOOR WINDOW CRANK............ 36

FRONT DOOR WINDOW REGULATOR....... 36

FRONT DOOR.......................... 27

FRONT SEAT........................... 37

FRONT WHEELHOUSE SPLASH SHIELD..... 37

FUEL FILL DOOR BLOCKER LATCH STRIKER . . 38

FUEL FILL DOOR BLOCKER LATCH......... 38

FUEL FILL DOOR BLOCKER LOCKOUT LINK . . 38

FUEL FILLER HOUSING ± WITH BLOCKER

LATCH .............................. 39

GRILLE............................... 39

HEADLINING........................... 39

HOOD HINGE.......................... 41

HOOD LATCH STRIKER................... 42

HOOD LATCH.......................... 41

HOOD RELEASE CABLE.................. 42

HOOD RELEASE HANDLE................. 42

HOOD................................ 40

JACK STORAGE COVER.................. 43

LEFT D-PILLAR TRIM PANEL............... 43

LEFT QUARTER TRIM PANEL.............. 44

LIFTGATE CHMSL ACCESS PANEL.......... 47

LIFTGATE HINGE........................ 47LIFTGATE LATCH STRIKER................ 47

LIFTGATE LATCH........................ 47

LIFTGATE LOCK CYLINDER............... 48

LIFTGATE OUTSIDE HANDLE.............. 48

LIFTGATE PROP ASSEMBLY............... 49

LIFTGATE SILL PLATE.................... 49

LIFTGATE STABILIZER WEDGE STRIKER..... 49

LIFTGATE STABILIZER WEDGE............. 49

LIFTGATE TRIM PANEL................... 50

LIFTGATE UPPER FRAME MOLDING........ 50

LIFTGATE UPPER FRAME SIDE MOLDINGS . . . 51

LIFTGATE............................. 46

LOWER B-PILLAR TRIM COVER............ 51

LUGGAGE RACK CROSSBAR.............. 51

LUGGAGE RACK RISER COVER............ 52

LUGGAGE RACK SIDE RAIL............... 52

OVERHEAD GRAB-HANDLES.............. 52

QUARTER GLASS....................... 52

QUARTER TRIM BOLSTER................ 53

RADIATOR CLOSURE PANEL CROSSMEMBER . 53

RAIL LAMP MODULE..................... 54

REAR HEADER TRIM..................... 55

REAR HVAC LOUVER AND BEZEL.......... 55

RIGHT D-PILLAR TRIM PANEL.............. 55

RIGHT QUARTER TRIM PANEL............. 56

ROOF APERTURE (RAP) MOLDING.......... 57

SEAT BELT BUCKLE FIRST REAR QUAD

BUCKET............................. 58

SEAT BELT BUCKLE FIRST REAR ± TWO

PASSENGER BENCH................... 58

SEAT BELT BUCKLE SECOND REAR ± THREE

PASSENGER BENCH................... 59

SEAT BELT BUCKLE ± FRONT INBOARD..... 57

SEAT BELT FIRST REAR ANCHOR BRACKET ±

LWB ................................ 59

SEAT BELT FIRST REAR OUTBOARD ± LWB

FOUR DOOR.......................... 60

SEAT BELT FIRST REAR OUTBOARD ± SWB

FOUR DOOR.......................... 60

SEAT BELT LEFT FIRST REAR OUTBOARD ±

LWB THREE DOOR..................... 61

SEAT BELT LEFT FIRST REAR OUTBOARD ±

SWB THREE DOOR.................... 61

SEAT BELT SECOND REAR OUTBOARD ±

SWB ................................ 61

SEAT BELT SECOND RIGHT REAR OUTBOARD

±LWB ............................... 62

SEAT BELT ± OUTBOARD FRONT........... 59

SECOND RIGHT REAR OUTBOARD SEAT BELT

± LWB W/REAR HVAC................... 62

23 - 22 BODYNS

Page 1771 of 1938

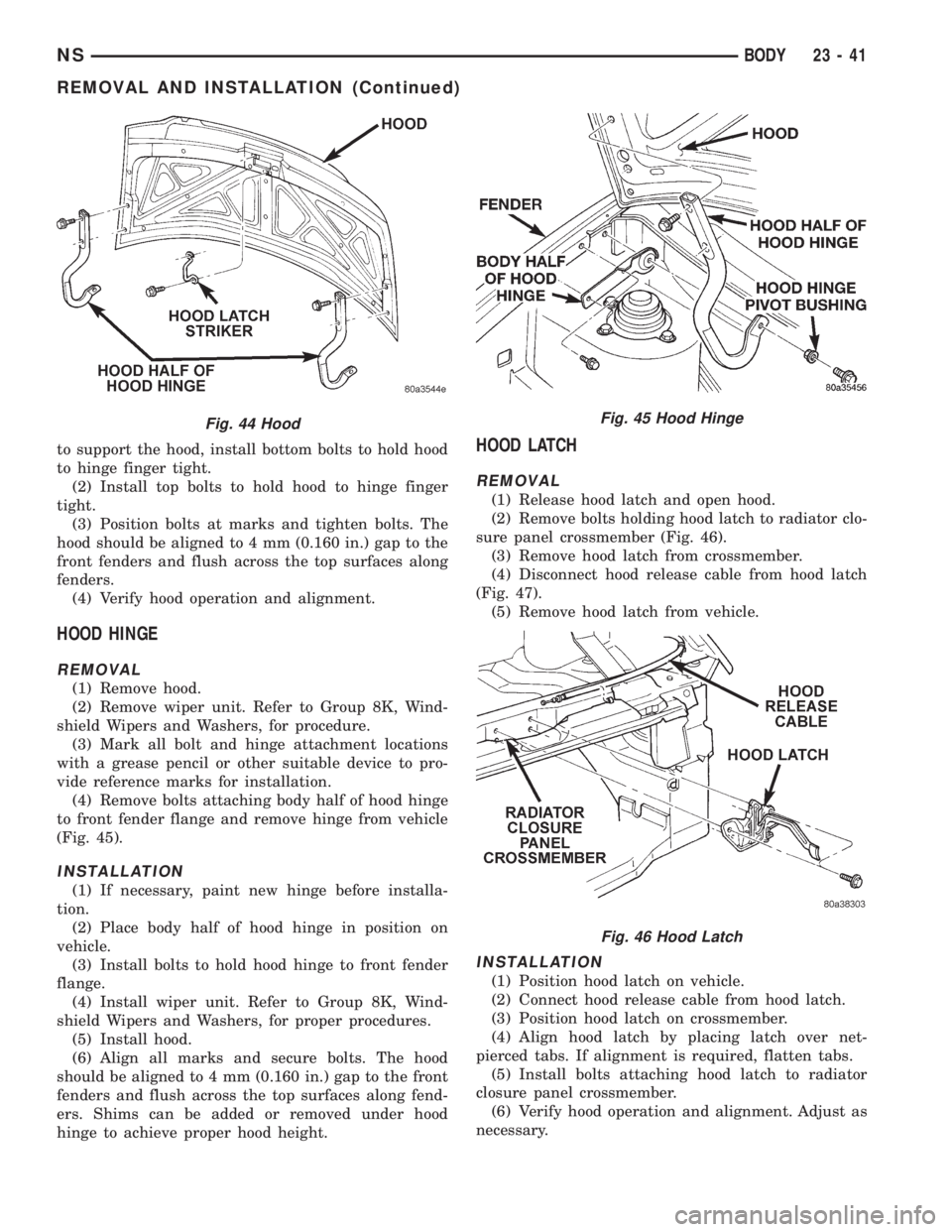

to support the hood, install bottom bolts to hold hood

to hinge finger tight.

(2) Install top bolts to hold hood to hinge finger

tight.

(3) Position bolts at marks and tighten bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders.

(4) Verify hood operation and alignment.

HOOD HINGE

REMOVAL

(1) Remove hood.

(2) Remove wiper unit. Refer to Group 8K, Wind-

shield Wipers and Washers, for procedure.

(3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation.

(4) Remove bolts attaching body half of hood hinge

to front fender flange and remove hinge from vehicle

(Fig. 45).

INSTALLATION

(1) If necessary, paint new hinge before installa-

tion.

(2) Place body half of hood hinge in position on

vehicle.

(3) Install bolts to hold hood hinge to front fender

flange.

(4) Install wiper unit. Refer to Group 8K, Wind-

shield Wipers and Washers, for proper procedures.

(5) Install hood.

(6) Align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. Shims can be added or removed under hood

hinge to achieve proper hood height.

HOOD LATCH

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts holding hood latch to radiator clo-

sure panel crossmember (Fig. 46).

(3) Remove hood latch from crossmember.

(4) Disconnect hood release cable from hood latch

(Fig. 47).

(5) Remove hood latch from vehicle.

INSTALLATION

(1) Position hood latch on vehicle.

(2) Connect hood release cable from hood latch.

(3) Position hood latch on crossmember.

(4) Align hood latch by placing latch over net-

pierced tabs. If alignment is required, flatten tabs.

(5) Install bolts attaching hood latch to radiator

closure panel crossmember.

(6) Verify hood operation and alignment. Adjust as

necessary.

Fig. 44 HoodFig. 45 Hood Hinge

Fig. 46 Hood Latch

NSBODY 23 - 41

REMOVAL AND INSTALLATION (Continued)

Page 1772 of 1938

(7) Tighten attaching bolts to 11 to 16 N´m (100 to

140 in. lbs.) torque.

HOOD LATCH STRIKER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts holding striker to inside of hood

(Fig. 44).

(3) Remove hood latch striker from vehicle.

INSTALLATION

(1) Position hood latch striker on vehicle.

(2) Install bolts to hold hood latch striker to hood.

(3) Align hood latch striker to engage smoothly

into hood latch.

(4) Verify hood operation and alignment. Adjust as

necessary.

(5) Tighten attaching bolts to 11 to 16 N´m (100 to

140 in. lbs.) torque.

HOOD RELEASE CABLE

REMOVAL

(1) Remove hood latch.

(2) Disengage cable end from hood latch locking

mechanism.

(3) Slide cable case end sideways in keyhole slot of

hood latch while pinching barb on cable case closed.

(4) Remove cable from latch (Fig. 47).

(5) Remove hood release handle from instrument

panel.

(6) Disengage rubber grommet cable insulator

from hole in dash panel.

(7) Attach a suitable length of mechanic's wire to

latch end of cable to assist cable installation.

(8) Route cable back from latch through engine

compartment toward dash panel near power brake

booster (Fig. 48).

(9) Remove attaching clips from cable case.

(10) From inside vehicle, pull cable through dash

panel until mechanic's wire is exposed.

(11) Disconnect cable from mechanic's wire.(12) Remove hood release cable from vehicle.

INSTALLATION

(1) Place hood release cable in position under

instrument panel.

(2) Attach latch end of hood release cable to

mechanic's wire protruding through dash panel.

(3) Route cable forward through engine compart-

ment toward latch by pulling on mechanic's wire

(Fig. 48).

(4) Disconnect mechanic's wire from cable.

(5) Engage rubber grommet cable insulator into

hole in dash panel.

(6) Install hood release handle into instrument

panel.

(7) Place cable in position on latch.

(8) Slide cable case end sideways into keyhole slot

of hood latch.

(9) Engage cable end into hood latch locking mech-

anism.

(10) Install hood latch.

(11) Install attaching clips to cable case and install

clips into original holes in strut tower, fender, head-

lamp area, and radiator closure panel crossmember.

HOOD RELEASE HANDLE

REMOVAL

(1) Remove lower steering column cover and knee

blocker reinforcement. Refer to Group 8E, Instru-

ment Panel and Systems for proper procedures.

(2) Remove hood latch cable.

(3) Remove screws holding hood latch release han-

dle to instrument panel brace (Fig. 49).

(4) Remove hood latch release handle from vehicle.

INSTALLATION

(1) Position hood latch release handle on vehicle.

(2) Install screws to hold hood latch release handle

to instrument panel brace.

Fig. 47 Hood Release Cable End Attachment

Fig. 48 Hood Release Cable Routing

23 - 42 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1783 of 1938

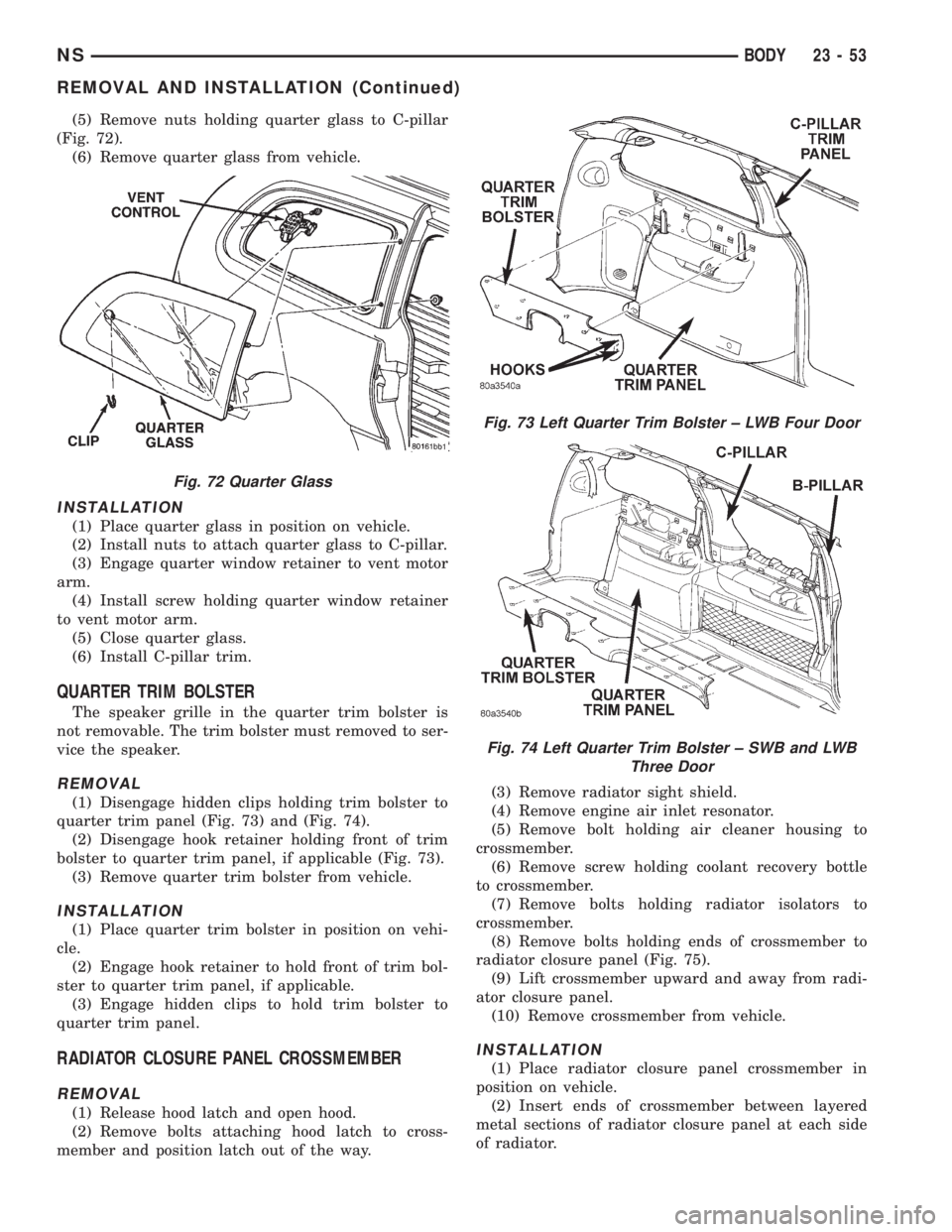

(5) Remove nuts holding quarter glass to C-pillar

(Fig. 72).

(6) Remove quarter glass from vehicle.

INSTALLATION

(1) Place quarter glass in position on vehicle.

(2) Install nuts to attach quarter glass to C-pillar.

(3) Engage quarter window retainer to vent motor

arm.

(4) Install screw holding quarter window retainer

to vent motor arm.

(5) Close quarter glass.

(6) Install C-pillar trim.

QUARTER TRIM BOLSTER

The speaker grille in the quarter trim bolster is

not removable. The trim bolster must removed to ser-

vice the speaker.

REMOVAL

(1) Disengage hidden clips holding trim bolster to

quarter trim panel (Fig. 73) and (Fig. 74).

(2) Disengage hook retainer holding front of trim

bolster to quarter trim panel, if applicable (Fig. 73).

(3) Remove quarter trim bolster from vehicle.

INSTALLATION

(1) Place quarter trim bolster in position on vehi-

cle.

(2) Engage hook retainer to hold front of trim bol-

ster to quarter trim panel, if applicable.

(3) Engage hidden clips to hold trim bolster to

quarter trim panel.

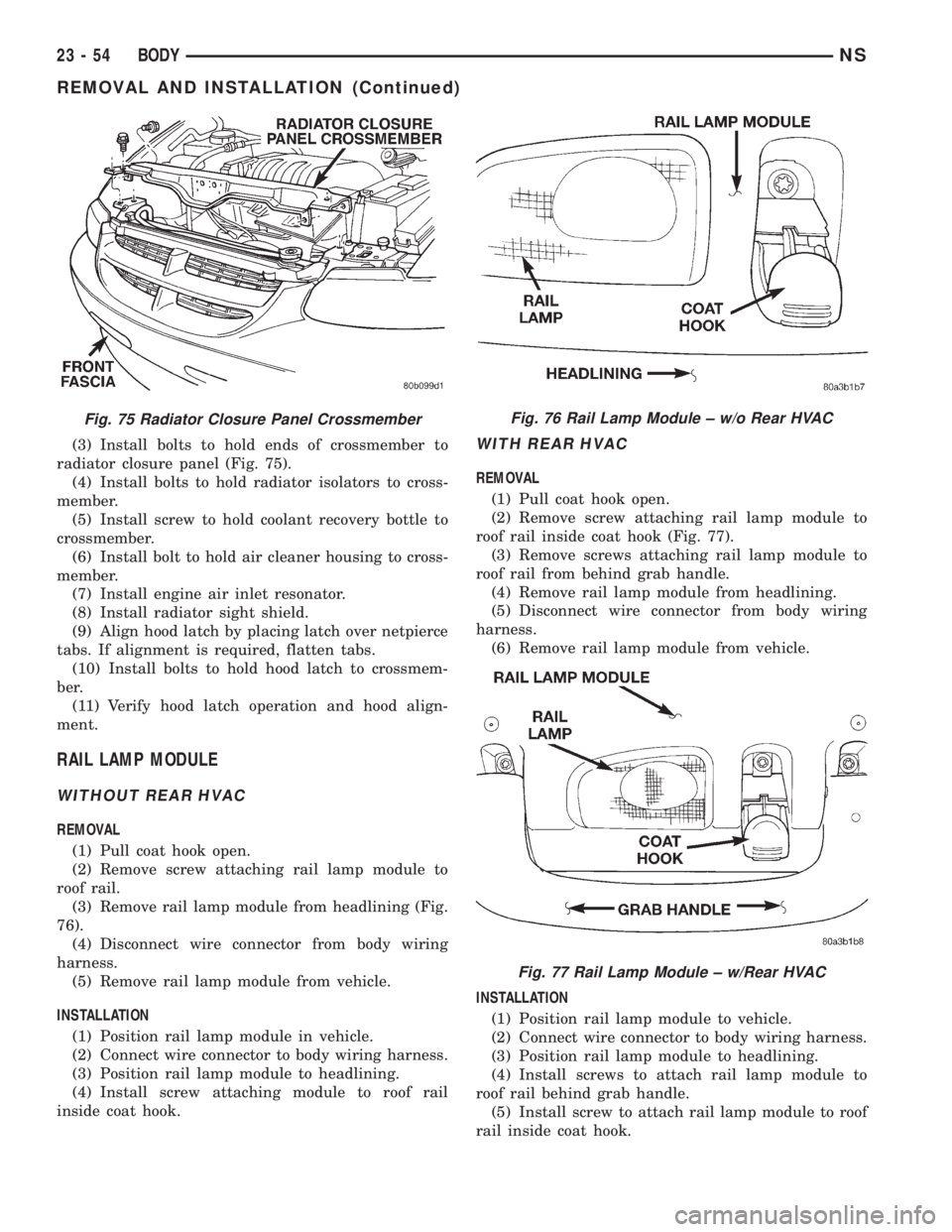

RADIATOR CLOSURE PANEL CROSSMEMBER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to cross-

member and position latch out of the way.(3) Remove radiator sight shield.

(4) Remove engine air inlet resonator.

(5) Remove bolt holding air cleaner housing to

crossmember.

(6) Remove screw holding coolant recovery bottle

to crossmember.

(7) Remove bolts holding radiator isolators to

crossmember.

(8) Remove bolts holding ends of crossmember to

radiator closure panel (Fig. 75).

(9) Lift crossmember upward and away from radi-

ator closure panel.

(10) Remove crossmember from vehicle.

INSTALLATION

(1) Place radiator closure panel crossmember in

position on vehicle.

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

Fig. 72 Quarter Glass

Fig. 73 Left Quarter Trim Bolster ± LWB Four Door

Fig. 74 Left Quarter Trim Bolster ± SWB and LWB

Three Door

NSBODY 23 - 53

REMOVAL AND INSTALLATION (Continued)

Page 1784 of 1938

(3) Install bolts to hold ends of crossmember to

radiator closure panel (Fig. 75).

(4) Install bolts to hold radiator isolators to cross-

member.

(5) Install screw to hold coolant recovery bottle to

crossmember.

(6) Install bolt to hold air cleaner housing to cross-

member.

(7) Install engine air inlet resonator.

(8) Install radiator sight shield.

(9) Align hood latch by placing latch over netpierce

tabs. If alignment is required, flatten tabs.

(10) Install bolts to hold hood latch to crossmem-

ber.

(11) Verify hood latch operation and hood align-

ment.

RAIL LAMP MODULE

WITHOUT REAR HVAC

REMOVAL

(1) Pull coat hook open.

(2) Remove screw attaching rail lamp module to

roof rail.

(3) Remove rail lamp module from headlining (Fig.

76).

(4) Disconnect wire connector from body wiring

harness.

(5) Remove rail lamp module from vehicle.

INSTALLATION

(1) Position rail lamp module in vehicle.

(2) Connect wire connector to body wiring harness.

(3) Position rail lamp module to headlining.

(4) Install screw attaching module to roof rail

inside coat hook.

WITH REAR HVAC

REMOVAL

(1) Pull coat hook open.

(2) Remove screw attaching rail lamp module to

roof rail inside coat hook (Fig. 77).

(3) Remove screws attaching rail lamp module to

roof rail from behind grab handle.

(4) Remove rail lamp module from headlining.

(5) Disconnect wire connector from body wiring

harness.

(6) Remove rail lamp module from vehicle.

INSTALLATION

(1) Position rail lamp module to vehicle.

(2) Connect wire connector to body wiring harness.

(3) Position rail lamp module to headlining.

(4) Install screws to attach rail lamp module to

roof rail behind grab handle.

(5) Install screw to attach rail lamp module to roof

rail inside coat hook.

Fig. 75 Radiator Closure Panel CrossmemberFig. 76 Rail Lamp Module ± w/o Rear HVAC

Fig. 77 Rail Lamp Module ± w/Rear HVAC

23 - 54 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1831 of 1938

be 21ÉC to 27ÉC (70ÉF to 85ÉF). To test the expansion

valve:

NOTE: Liquid CO2 is required to test the expansion

valve. It is available from most welding supply facil-

ities. CO2 is also available from companies which

service and sell fire extinguishers.

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set heater A/C control to A/C, full heat,

FLOOR, and high blower.

(4) Start the engine and allow to idle (1000 rpm).

After the engine has reached running temperature,

allow the passenger compartment to heat up. This

will create the need for maximum refrigerant flow

into the evaporator.

(5) If the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 1655 kPa

(140 to 240 psi). Suction (low pressure) gauge should

read 140 kPa to 207 kPa (20 psi to 30 psig). If system

cannot achieve proper pressure readings, replace the

expansion valve. If pressure is correct, proceed with

test.

WARNING: PROTECT SKIN AND EYES FROM CON-

TACTING CO2 PERSONAL INJURY CAN RESULT.

(6) If suction side low pressure is within specified

range, freeze the expansion valve control head for 30

seconds. Use a super cold substance (liquid CO2).Do

not spray R-134a or R-12 Refrigerant on the

expansion valve for this test.Suction side low

pressure should drop by 10 psi. If not, replace expan-

sion valve.

(7) Allow expansion valve to thaw. The low pres-

sure gauge reading should stabilize at 140 kPa to

240 kPa (20 psi to 30 psig). If not, replace expansion

valve.

(8) When expansion valve test is complete, test

A/C overall performance. Remove all test equipment

before returning vehicle to use.

HEATER PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings in this

group before performing the following procedures.

Check the coolant level, drive belt tension, vacuum

line connections, radiator air flow and fan operation.

Start engine and allow to warm up to normal tem-

perature.WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to

escape through the overflow tube. When the system

stabilizes, remove the cap completely.

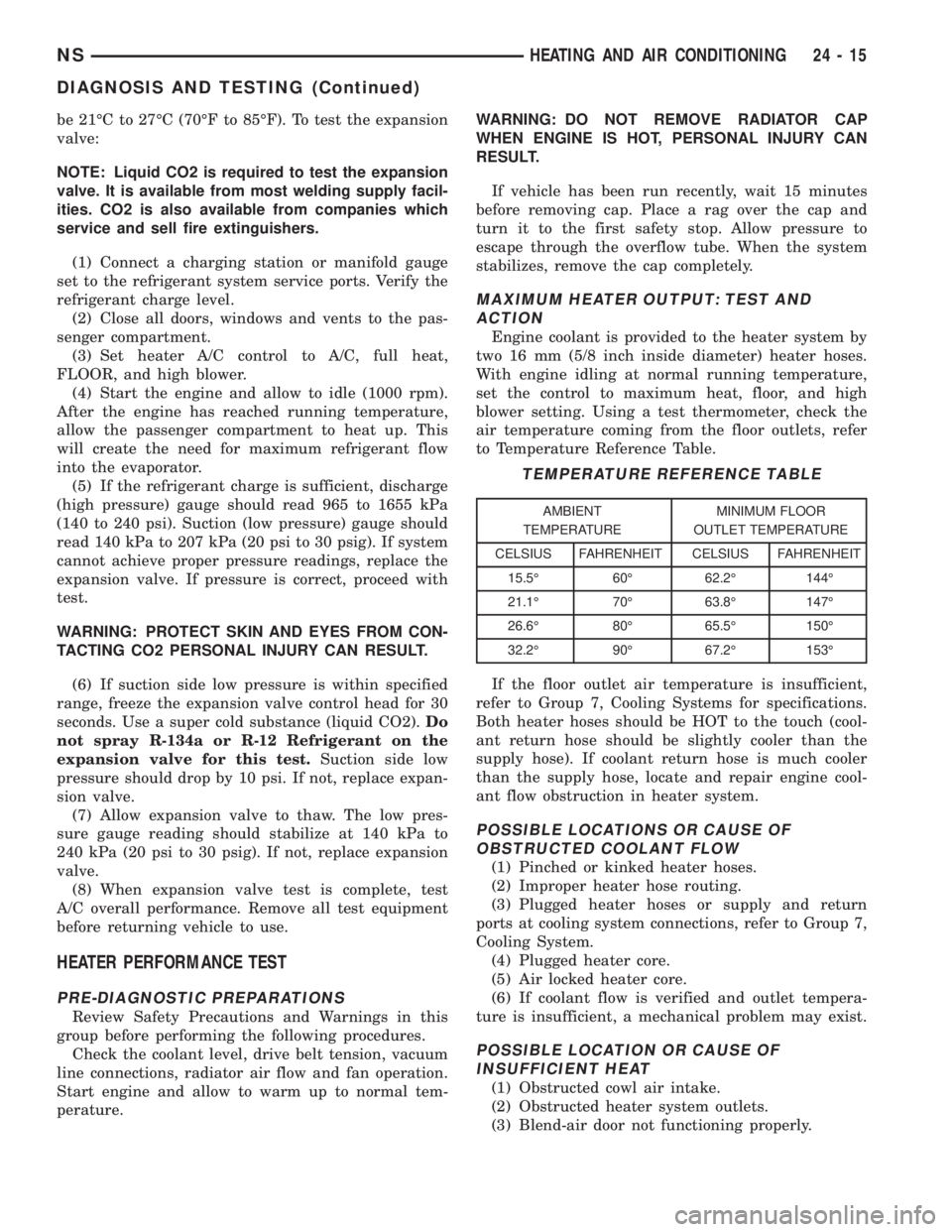

MAXIMUM HEATER OUTPUT: TEST AND

ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference Table.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.

(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF

INSUFFICIENT HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE REFERENCE TABLE

AMBIENT

TEMPERATUREMINIMUM FLOOR

OUTLET TEMPERATURE

CELSIUS FAHRENHEIT CELSIUS FAHRENHEIT

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

NSHEATING AND AIR CONDITIONING 24 - 15

DIAGNOSIS AND TESTING (Continued)

Page 1832 of 1938

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door motor.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

NOTE: The amount of R134a refrigerant that the air

conditioning system holds is:

²Without rear A/C± .96 kg (34 oz. or 2.13 lbs.)

²With Rear A/C± 1.36 kg (48 oz. or 3.00 lbs.)

NOTE: Low Charge, condition may be described

as:

²Loss of A/C performance

²Fog from A/C outlets

²evaporator may have a HISS sound

There are two different ways the system can be

tested:

²With a scan tool (DRB), thermocouple and the

Charge Determination Graph. Use the scan tool

(DRB) diagnostic topic: Engine±System Monitors, A/C

Pressure.

²Using a manifold gauge set, a thermocouple and

the Charge Determination Graph.

It is recommended to use the gauges or reclaim/re-

cycle equipment.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. SOME

MIXTURES OF AIR/R-134a HAVE BEEN SHOWN TO

BE COMBUSTIBLE AT ELEVATED PRESSURES.

THESE MIXTURES ARE POTENTIALLY DANGER-

OUS AND MAY RESULT IN FIRE OR EXPLOSION

CAUSING INJURY OR PROPERTY DAMAGE.

(1) Establish your preferred method of measuring

liquid line pressure. Use a manifold gauge set or a

DRB scan tool.(2) Attach a clamp-on thermocouple (P.S.E. 66-324-

0014 or 80PK-1A) or equivalent to the liquid line. It

must be placed as close to the A/C Pressure Trans-

ducer as possible to observe liquid line temperature.

Refer to ªThermocouple Probeº in this section for

more information on probe.

(3) The vehicle must be in the following modes:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set to Outside Air

²Panel Mode

²Full Cool

²High Blower motor, (vehicle equipped with rear

A/C turn rear blower motor ON HIGH)

²A/C Button in the ON position

²Vehicle Windows Open.

²Recirc. button turned OFF

(4) Operate system for a couple of minutes to allow

the system to stabilize.

(5) Set system pressure to about 1793 kPa (260

psi) by placing a piece of cardboard over part of the

front side of the condenser. To place cardboard prop-

erly, remove the upper radiator-condenser cover.

Insert cardboard between condenser and radiator

front. This will maintain a constant pressure.

(6) Observe Liquid Line pressure and Liquid line

temperature. Using theCharge Determination

Chartdetermine where the system is currently oper-

ating. If the system is in the undercharged region,

ADD 0.057 Kg. (2 oz.) to the system and recheck

readings. If the system is in the overcharged region,

RECLAIM 0.057 Kg. (2 oz.) from the system and

recheck readings. Continue this process until the sys-

tem readings are in the proper charge area on the

Charge Determination Chart.

(7) The same procedure can be performed using

the scan tool (DRB). To determine liquid line pres-

sure, attach the scan tool, go to System Moni-

tors±A/C Pressure. Observe liquid line pressure from

A/C Pressure Transducer on digital display and digi-

tal thermometer. Refer toCharge Determination

Chartand determine where the system is operating.

SERVICE PROCEDURES

R-134a REFRIGERANT

This vehicle uses a new type of refrigerant called

R-134a. It is a non-toxic, non-flammable, clear color-

less liquefied gas.

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 in a R-134a system could cause

compressor failure, refrigerant oil to sludge and/or

poor performance.Never add any other type of

refrigerant to a system designed to use R-134a

refrigerant. System failure will occur.

24 - 16 HEATING AND AIR CONDITIONINGNS

DIAGNOSIS AND TESTING (Continued)