wheel CHRYSLER VOYAGER 1996 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 143 of 1938

145).(12) Remove the rotor from the hub/bearing.

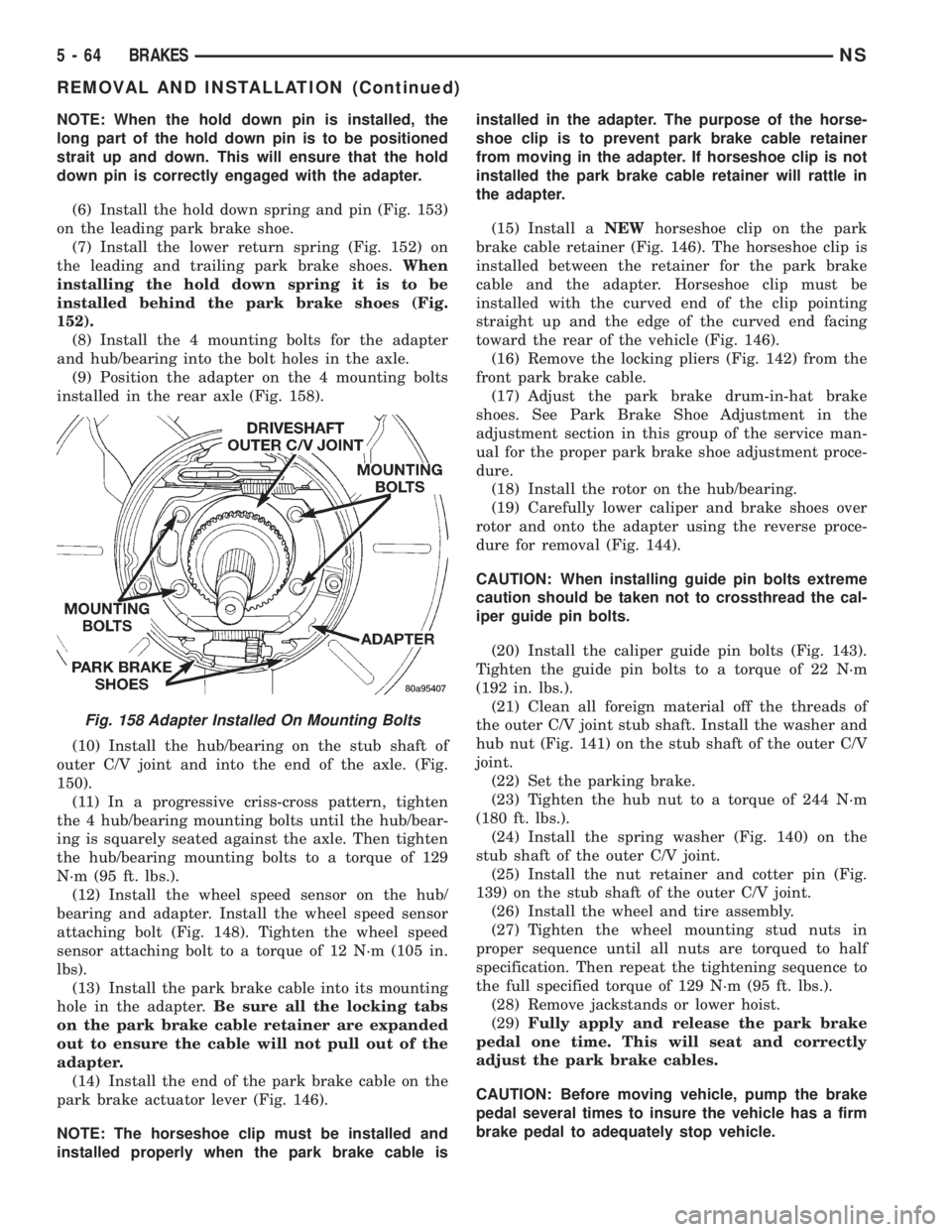

(13) Remove the horseshoe clip (Fig. 146) from the

retainer on the end of the park brake cable.

(14) Remove the end of the park brake cable from

the actuator lever on the adapter (Fig. 146).

(15) Remove the end of the park brake cable from

the adapter. Park brake cable is removed from

adapter using a 1/2 wrench slipped over the park

brake cable retainer as show in (Fig. 147) to com-

press the locking tabs on the park brake cable

retainer.

(16) Remove the attaching bolt from the wheel

speed sensor (Fig. 148). Then remove wheel speed

sensor from hub/bearing and adapter.

(17) Remove the hub/bearing to axle mounting

bolts (Fig. 149).

(18) Remove the hub/bearing from the axle and the

stub shaft of the outer C/V joint (Fig. 150).

(19) Remove the adapter from the rear axle.

(20) Mount the adapter in a vise using the anchor

boss for the park brake cable (Fig. 151).

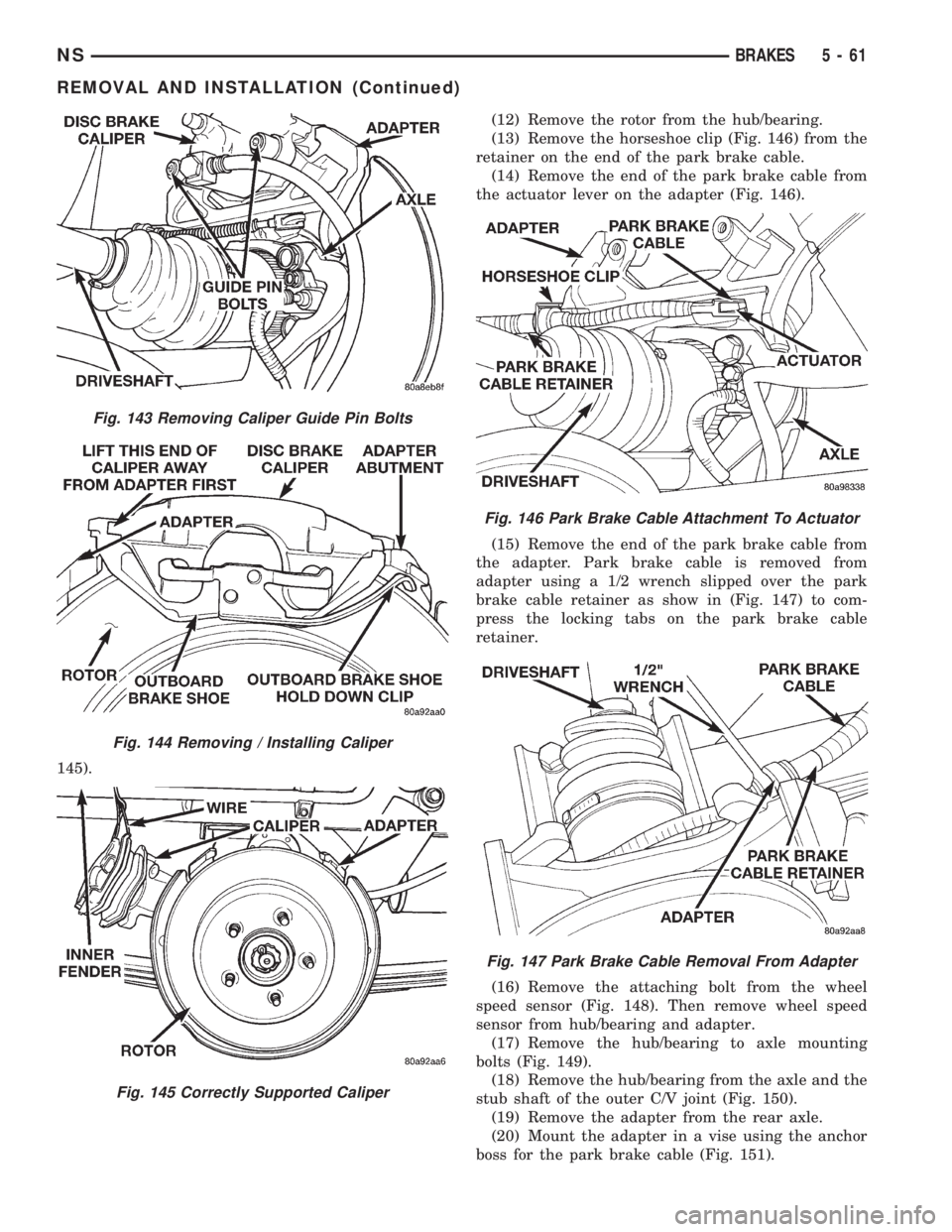

Fig. 143 Removing Caliper Guide Pin Bolts

Fig. 144 Removing / Installing Caliper

Fig. 145 Correctly Supported Caliper

Fig. 146 Park Brake Cable Attachment To Actuator

Fig. 147 Park Brake Cable Removal From Adapter

NSBRAKES 5 - 61

REMOVAL AND INSTALLATION (Continued)

Page 146 of 1938

NOTE: When the hold down pin is installed, the

long part of the hold down pin is to be positioned

strait up and down. This will ensure that the hold

down pin is correctly engaged with the adapter.

(6) Install the hold down spring and pin (Fig. 153)

on the leading park brake shoe.

(7) Install the lower return spring (Fig. 152) on

the leading and trailing park brake shoes.When

installing the hold down spring it is to be

installed behind the park brake shoes (Fig.

152).

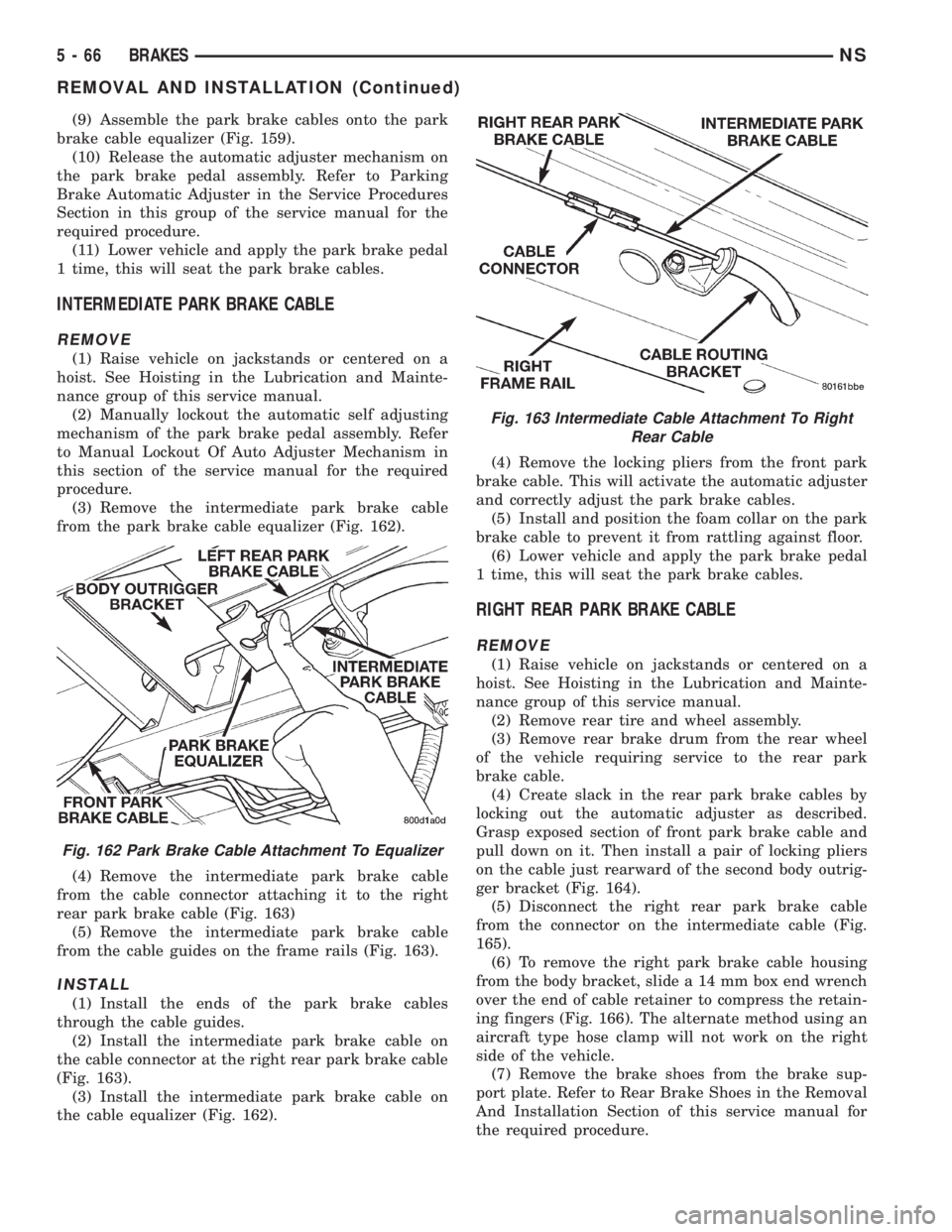

(8) Install the 4 mounting bolts for the adapter

and hub/bearing into the bolt holes in the axle.

(9) Position the adapter on the 4 mounting bolts

installed in the rear axle (Fig. 158).

(10) Install the hub/bearing on the stub shaft of

outer C/V joint and into the end of the axle. (Fig.

150).

(11) In a progressive criss-cross pattern, tighten

the 4 hub/bearing mounting bolts until the hub/bear-

ing is squarely seated against the axle. Then tighten

the hub/bearing mounting bolts to a torque of 129

N´m (95 ft. lbs.).

(12) Install the wheel speed sensor on the hub/

bearing and adapter. Install the wheel speed sensor

attaching bolt (Fig. 148). Tighten the wheel speed

sensor attaching bolt to a torque of 12 N´m (105 in.

lbs).

(13) Install the park brake cable into its mounting

hole in the adapter.Be sure all the locking tabs

on the park brake cable retainer are expanded

out to ensure the cable will not pull out of the

adapter.

(14) Install the end of the park brake cable on the

park brake actuator lever (Fig. 146).

NOTE: The horseshoe clip must be installed and

installed properly when the park brake cable isinstalled in the adapter. The purpose of the horse-

shoe clip is to prevent park brake cable retainer

from moving in the adapter. If horseshoe clip is not

installed the park brake cable retainer will rattle in

the adapter.

(15) Install aNEWhorseshoe clip on the park

brake cable retainer (Fig. 146). The horseshoe clip is

installed between the retainer for the park brake

cable and the adapter. Horseshoe clip must be

installed with the curved end of the clip pointing

straight up and the edge of the curved end facing

toward the rear of the vehicle (Fig. 146).

(16) Remove the locking pliers (Fig. 142) from the

front park brake cable.

(17) Adjust the park brake drum-in-hat brake

shoes. See Park Brake Shoe Adjustment in the

adjustment section in this group of the service man-

ual for the proper park brake shoe adjustment proce-

dure.

(18) Install the rotor on the hub/bearing.

(19) Carefully lower caliper and brake shoes over

rotor and onto the adapter using the reverse proce-

dure for removal (Fig. 144).

CAUTION: When installing guide pin bolts extreme

caution should be taken not to crossthread the cal-

iper guide pin bolts.

(20) Install the caliper guide pin bolts (Fig. 143).

Tighten the guide pin bolts to a torque of 22 N´m

(192 in. lbs.).

(21) Clean all foreign material off the threads of

the outer C/V joint stub shaft. Install the washer and

hub nut (Fig. 141) on the stub shaft of the outer C/V

joint.

(22) Set the parking brake.

(23) Tighten the hub nut to a torque of 244 N´m

(180 ft. lbs.).

(24) Install the spring washer (Fig. 140) on the

stub shaft of the outer C/V joint.

(25) Install the nut retainer and cotter pin (Fig.

139) on the stub shaft of the outer C/V joint.

(26) Install the wheel and tire assembly.

(27) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 129 N´m (95 ft. lbs.).

(28) Remove jackstands or lower hoist.

(29)Fully apply and release the park brake

pedal one time. This will seat and correctly

adjust the park brake cables.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop vehicle.

Fig. 158 Adapter Installed On Mounting Bolts

5 - 64 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 148 of 1938

(9) Assemble the park brake cables onto the park

brake cable equalizer (Fig. 159).

(10) Release the automatic adjuster mechanism on

the park brake pedal assembly. Refer to Parking

Brake Automatic Adjuster in the Service Procedures

Section in this group of the service manual for the

required procedure.

(11) Lower vehicle and apply the park brake pedal

1 time, this will seat the park brake cables.

INTERMEDIATE PARK BRAKE CABLE

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Manually lockout the automatic self adjusting

mechanism of the park brake pedal assembly. Refer

to Manual Lockout Of Auto Adjuster Mechanism in

this section of the service manual for the required

procedure.

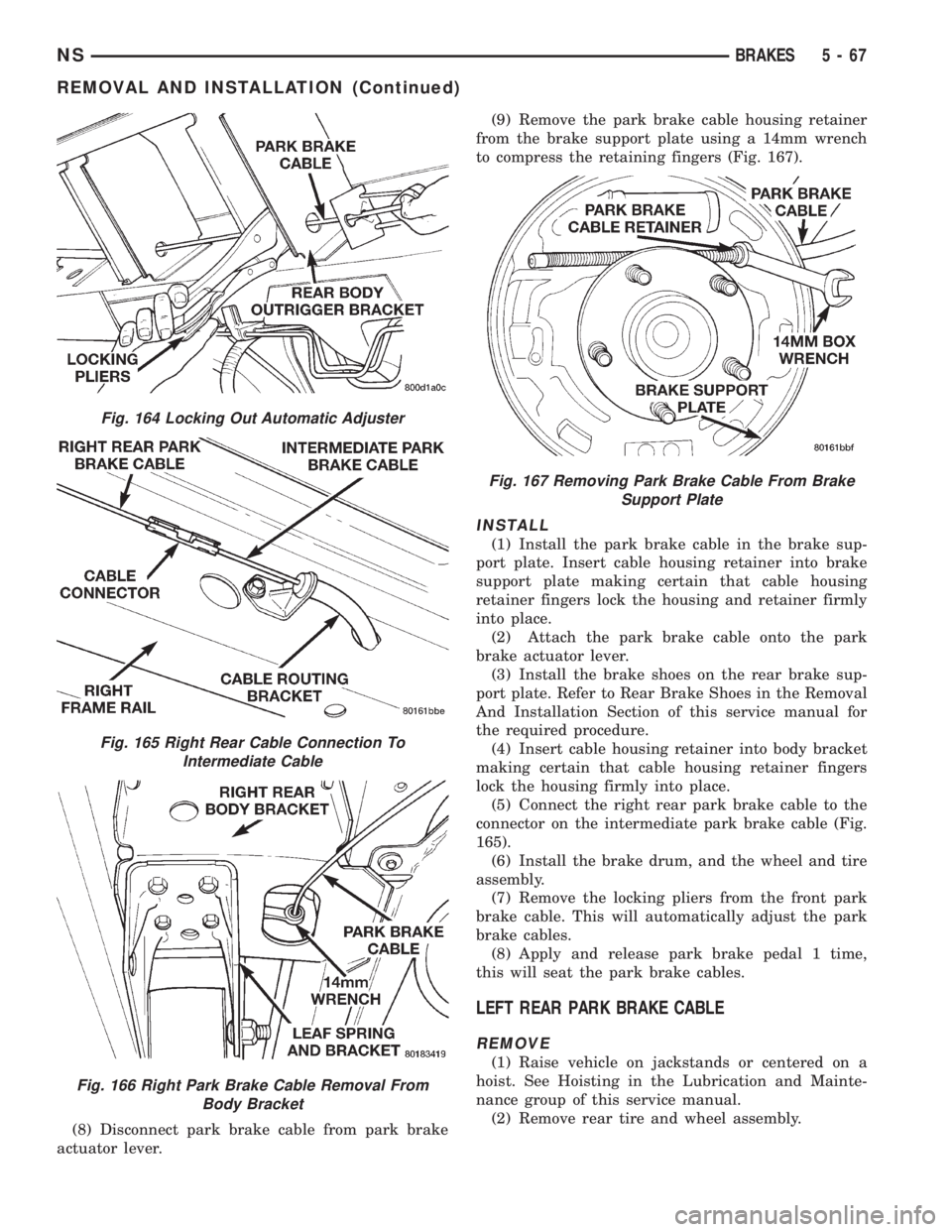

(3) Remove the intermediate park brake cable

from the park brake cable equalizer (Fig. 162).

(4) Remove the intermediate park brake cable

from the cable connector attaching it to the right

rear park brake cable (Fig. 163)

(5) Remove the intermediate park brake cable

from the cable guides on the frame rails (Fig. 163).

INSTALL

(1) Install the ends of the park brake cables

through the cable guides.

(2) Install the intermediate park brake cable on

the cable connector at the right rear park brake cable

(Fig. 163).

(3) Install the intermediate park brake cable on

the cable equalizer (Fig. 162).(4) Remove the locking pliers from the front park

brake cable. This will activate the automatic adjuster

and correctly adjust the park brake cables.

(5) Install and position the foam collar on the park

brake cable to prevent it from rattling against floor.

(6) Lower vehicle and apply the park brake pedal

1 time, this will seat the park brake cables.

RIGHT REAR PARK BRAKE CABLE

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Remove rear tire and wheel assembly.

(3) Remove rear brake drum from the rear wheel

of the vehicle requiring service to the rear park

brake cable.

(4) Create slack in the rear park brake cables by

locking out the automatic adjuster as described.

Grasp exposed section of front park brake cable and

pull down on it. Then install a pair of locking pliers

on the cable just rearward of the second body outrig-

ger bracket (Fig. 164).

(5) Disconnect the right rear park brake cable

from the connector on the intermediate cable (Fig.

165).

(6) To remove the right park brake cable housing

from the body bracket, slide a 14 mm box end wrench

over the end of cable retainer to compress the retain-

ing fingers (Fig. 166). The alternate method using an

aircraft type hose clamp will not work on the right

side of the vehicle.

(7) Remove the brake shoes from the brake sup-

port plate. Refer to Rear Brake Shoes in the Removal

And Installation Section of this service manual for

the required procedure.

Fig. 162 Park Brake Cable Attachment To Equalizer

Fig. 163 Intermediate Cable Attachment To Right

Rear Cable

5 - 66 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 149 of 1938

(8) Disconnect park brake cable from park brake

actuator lever.(9) Remove the park brake cable housing retainer

from the brake support plate using a 14mm wrench

to compress the retaining fingers (Fig. 167).

INSTALL

(1) Install the park brake cable in the brake sup-

port plate. Insert cable housing retainer into brake

support plate making certain that cable housing

retainer fingers lock the housing and retainer firmly

into place.

(2) Attach the park brake cable onto the park

brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. Refer to Rear Brake Shoes in the Removal

And Installation Section of this service manual for

the required procedure.

(4) Insert cable housing retainer into body bracket

making certain that cable housing retainer fingers

lock the housing firmly into place.

(5) Connect the right rear park brake cable to the

connector on the intermediate park brake cable (Fig.

165).

(6) Install the brake drum, and the wheel and tire

assembly.

(7) Remove the locking pliers from the front park

brake cable. This will automatically adjust the park

brake cables.

(8) Apply and release park brake pedal 1 time,

this will seat the park brake cables.

LEFT REAR PARK BRAKE CABLE

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Remove rear tire and wheel assembly.

Fig. 164 Locking Out Automatic Adjuster

Fig. 165 Right Rear Cable Connection To

Intermediate Cable

Fig. 166 Right Park Brake Cable Removal From

Body Bracket

Fig. 167 Removing Park Brake Cable From Brake

Support Plate

NSBRAKES 5 - 67

REMOVAL AND INSTALLATION (Continued)

Page 150 of 1938

(3) Remove rear brake drum from the rear wheel

of the vehicle requiring service to the rear park

brake cable.

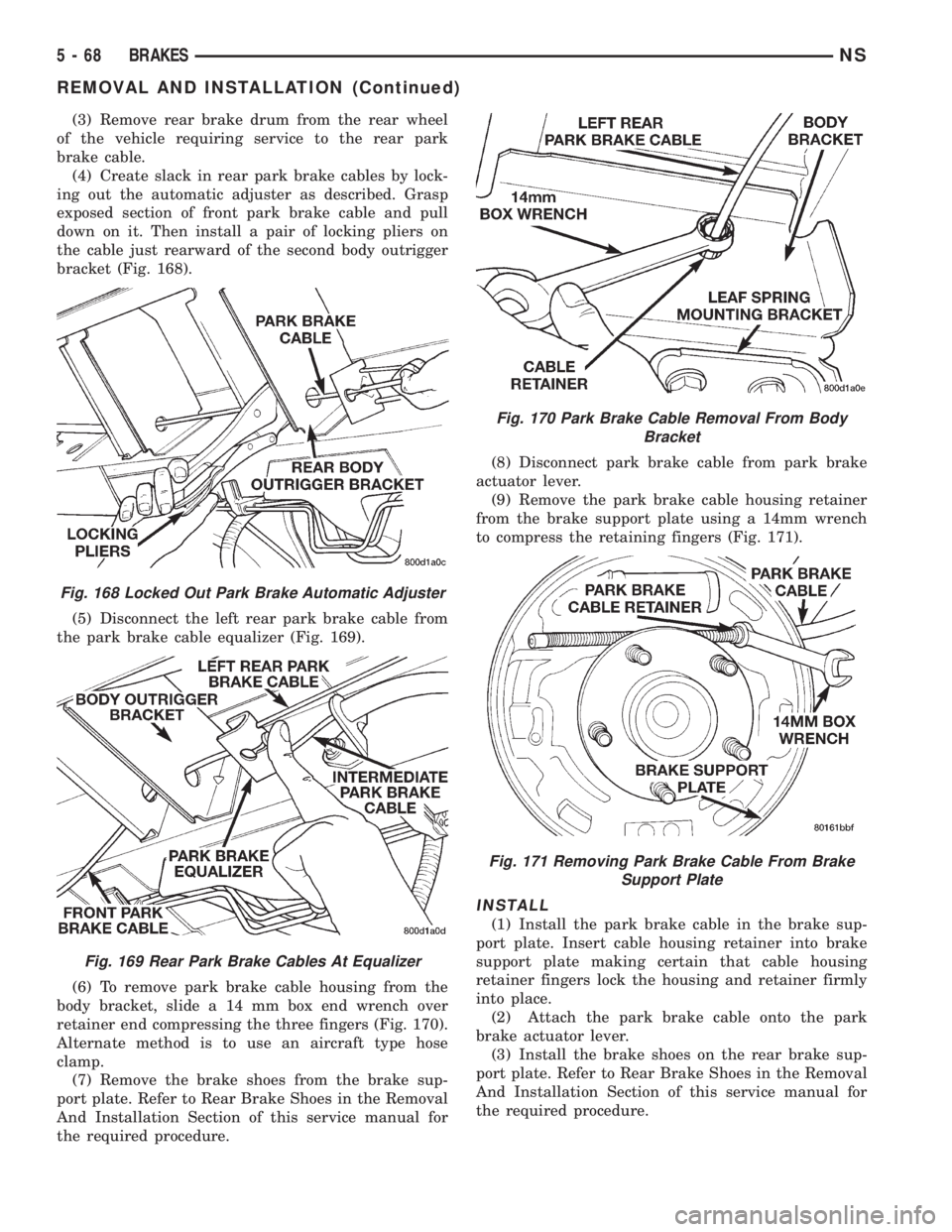

(4) Create slack in rear park brake cables by lock-

ing out the automatic adjuster as described. Grasp

exposed section of front park brake cable and pull

down on it. Then install a pair of locking pliers on

the cable just rearward of the second body outrigger

bracket (Fig. 168).

(5) Disconnect the left rear park brake cable from

the park brake cable equalizer (Fig. 169).

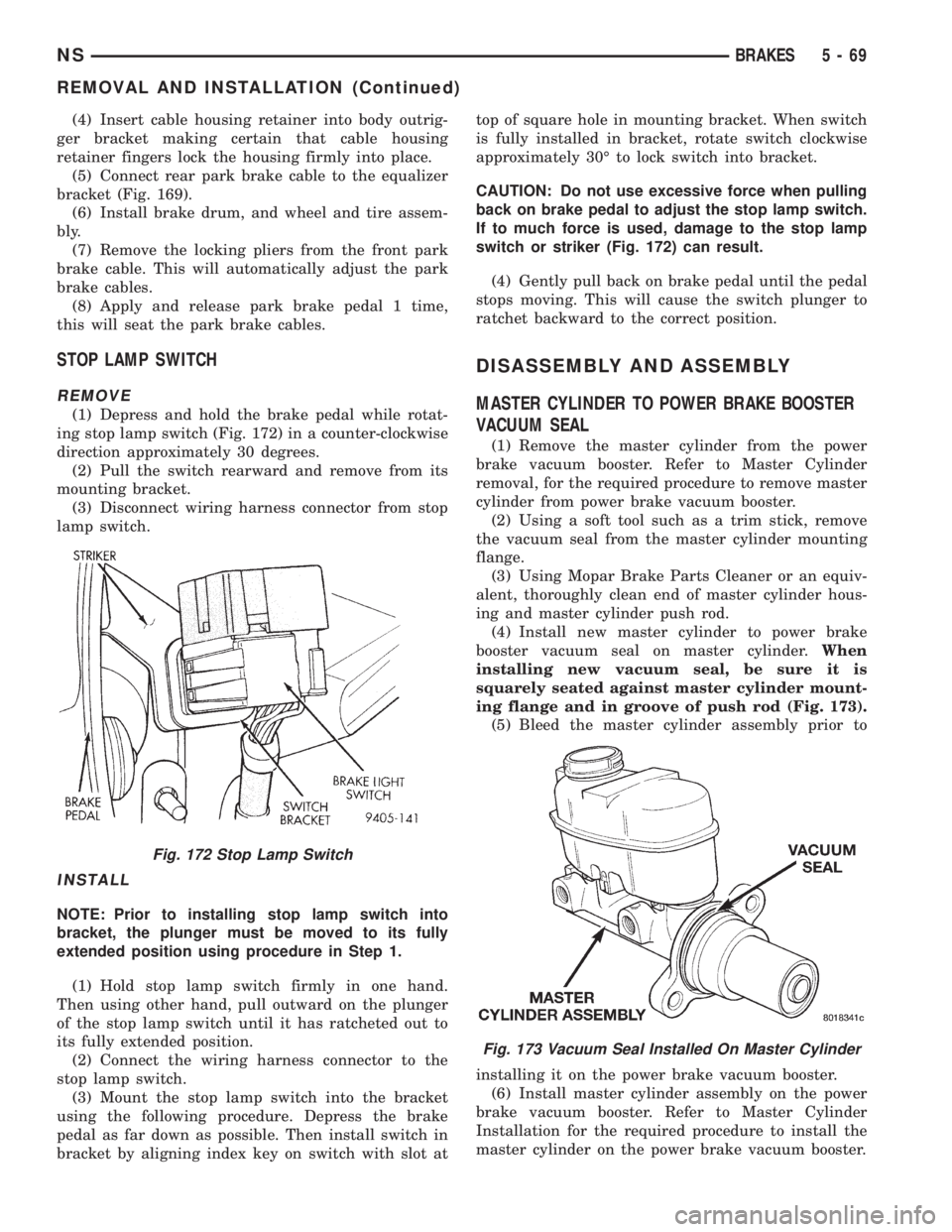

(6) To remove park brake cable housing from the

body bracket, slide a 14 mm box end wrench over

retainer end compressing the three fingers (Fig. 170).

Alternate method is to use an aircraft type hose

clamp.

(7) Remove the brake shoes from the brake sup-

port plate. Refer to Rear Brake Shoes in the Removal

And Installation Section of this service manual for

the required procedure.(8) Disconnect park brake cable from park brake

actuator lever.

(9) Remove the park brake cable housing retainer

from the brake support plate using a 14mm wrench

to compress the retaining fingers (Fig. 171).

INSTALL

(1) Install the park brake cable in the brake sup-

port plate. Insert cable housing retainer into brake

support plate making certain that cable housing

retainer fingers lock the housing and retainer firmly

into place.

(2) Attach the park brake cable onto the park

brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. Refer to Rear Brake Shoes in the Removal

And Installation Section of this service manual for

the required procedure.

Fig. 168 Locked Out Park Brake Automatic Adjuster

Fig. 169 Rear Park Brake Cables At Equalizer

Fig. 170 Park Brake Cable Removal From Body

Bracket

Fig. 171 Removing Park Brake Cable From Brake

Support Plate

5 - 68 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 151 of 1938

(4) Insert cable housing retainer into body outrig-

ger bracket making certain that cable housing

retainer fingers lock the housing firmly into place.

(5) Connect rear park brake cable to the equalizer

bracket (Fig. 169).

(6) Install brake drum, and wheel and tire assem-

bly.

(7) Remove the locking pliers from the front park

brake cable. This will automatically adjust the park

brake cables.

(8) Apply and release park brake pedal 1 time,

this will seat the park brake cables.

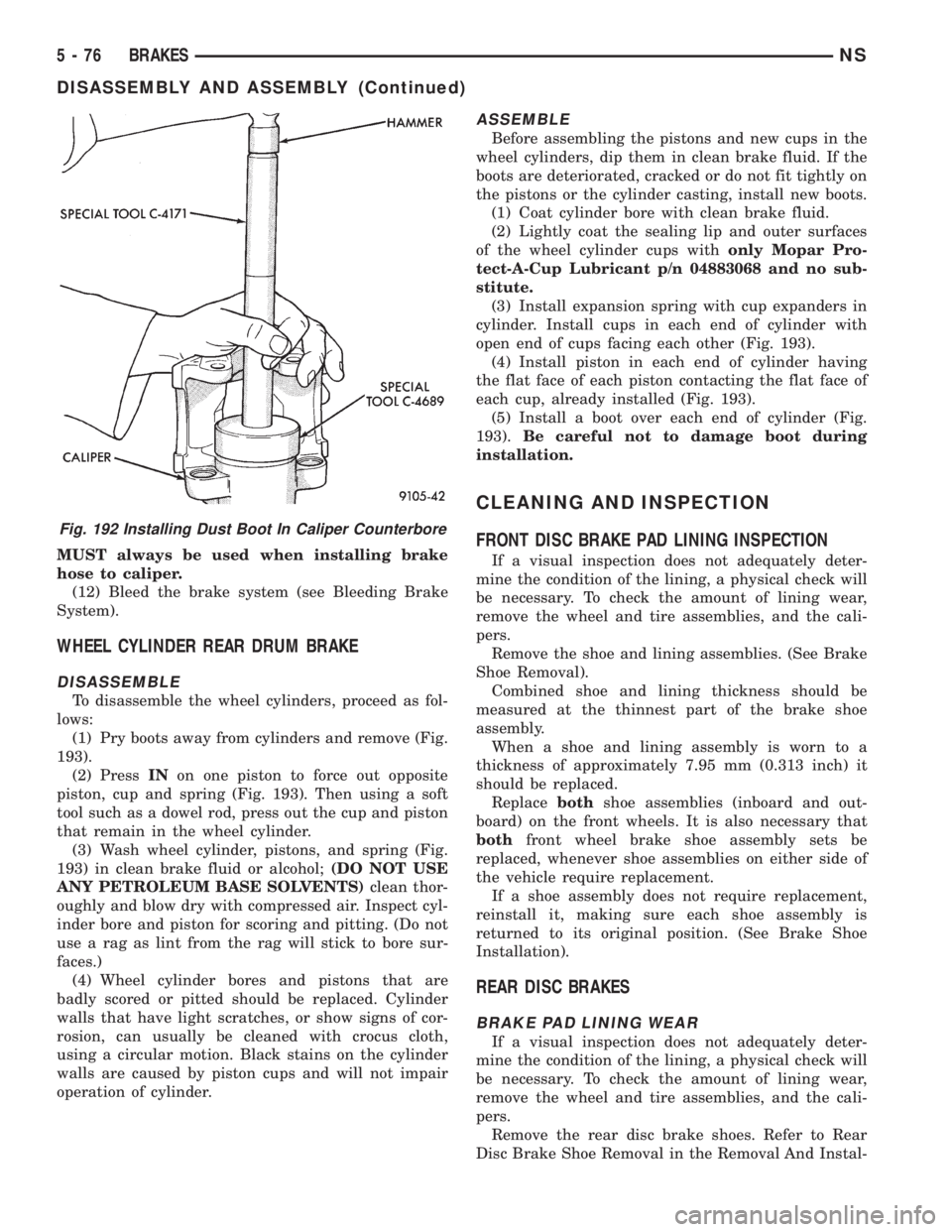

STOP LAMP SWITCH

REMOVE

(1) Depress and hold the brake pedal while rotat-

ing stop lamp switch (Fig. 172) in a counter-clockwise

direction approximately 30 degrees.

(2) Pull the switch rearward and remove from its

mounting bracket.

(3) Disconnect wiring harness connector from stop

lamp switch.

INSTALL

NOTE: Prior to installing stop lamp switch into

bracket, the plunger must be moved to its fully

extended position using procedure in Step 1.

(1) Hold stop lamp switch firmly in one hand.

Then using other hand, pull outward on the plunger

of the stop lamp switch until it has ratcheted out to

its fully extended position.

(2) Connect the wiring harness connector to the

stop lamp switch.

(3) Mount the stop lamp switch into the bracket

using the following procedure. Depress the brake

pedal as far down as possible. Then install switch in

bracket by aligning index key on switch with slot attop of square hole in mounting bracket. When switch

is fully installed in bracket, rotate switch clockwise

approximately 30É to lock switch into bracket.

CAUTION: Do not use excessive force when pulling

back on brake pedal to adjust the stop lamp switch.

If to much force is used, damage to the stop lamp

switch or striker (Fig. 172) can result.

(4) Gently pull back on brake pedal until the pedal

stops moving. This will cause the switch plunger to

ratchet backward to the correct position.

DISASSEMBLY AND ASSEMBLY

MASTER CYLINDER TO POWER BRAKE BOOSTER

VACUUM SEAL

(1) Remove the master cylinder from the power

brake vacuum booster. Refer to Master Cylinder

removal, for the required procedure to remove master

cylinder from power brake vacuum booster.

(2) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(3) Using Mopar Brake Parts Cleaner or an equiv-

alent, thoroughly clean end of master cylinder hous-

ing and master cylinder push rod.

(4) Install new master cylinder to power brake

booster vacuum seal on master cylinder.When

installing new vacuum seal, be sure it is

squarely seated against master cylinder mount-

ing flange and in groove of push rod (Fig. 173).

(5) Bleed the master cylinder assembly prior to

installing it on the power brake vacuum booster.

(6) Install master cylinder assembly on the power

brake vacuum booster. Refer to Master Cylinder

Installation for the required procedure to install the

master cylinder on the power brake vacuum booster.

Fig. 172 Stop Lamp Switch

Fig. 173 Vacuum Seal Installed On Master Cylinder

NSBRAKES 5 - 69

REMOVAL AND INSTALLATION (Continued)

Page 158 of 1938

MUST always be used when installing brake

hose to caliper.

(12) Bleed the brake system (see Bleeding Brake

System).

WHEEL CYLINDER REAR DRUM BRAKE

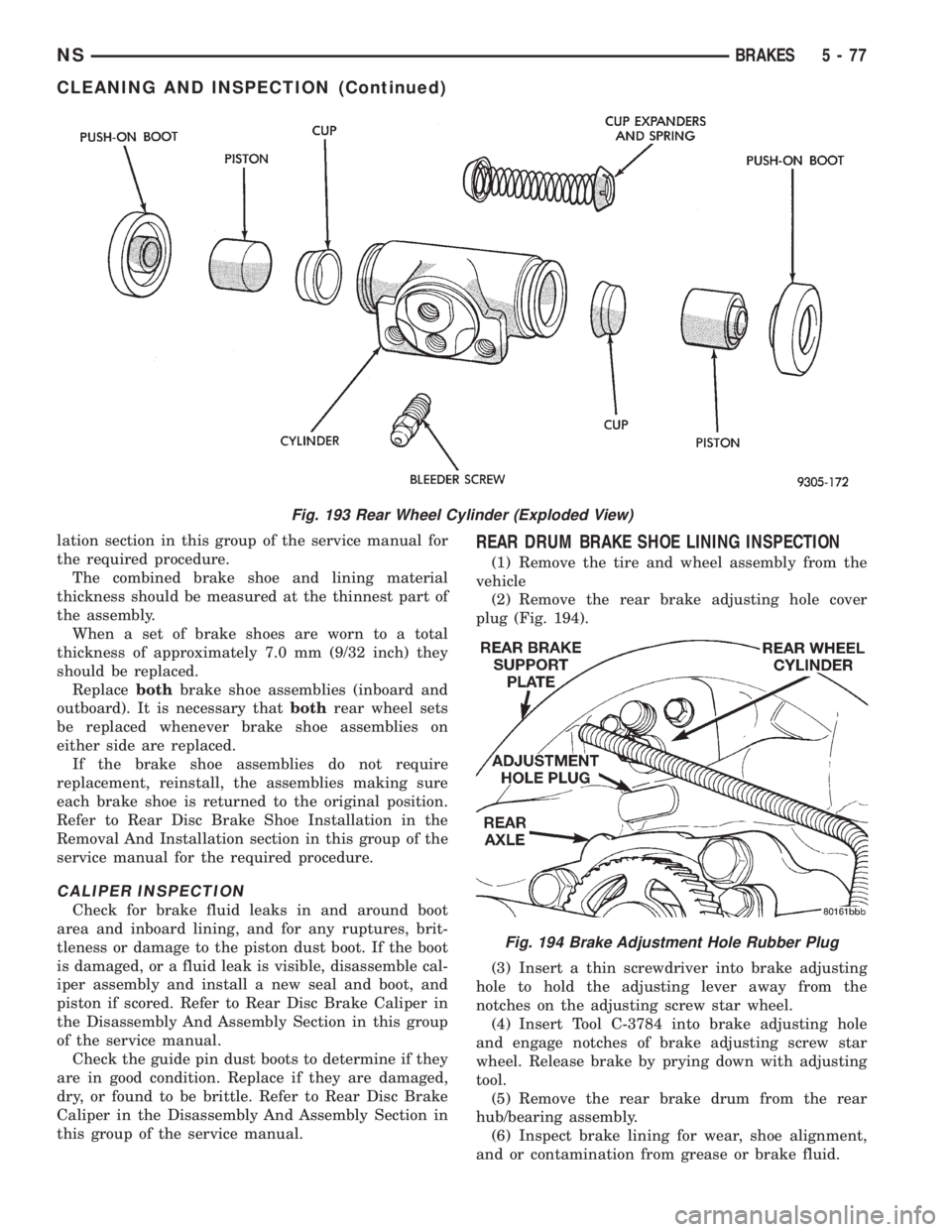

DISASSEMBLE

To disassemble the wheel cylinders, proceed as fol-

lows:

(1) Pry boots away from cylinders and remove (Fig.

193).

(2) PressINon one piston to force out opposite

piston, cup and spring (Fig. 193). Then using a soft

tool such as a dowel rod, press out the cup and piston

that remain in the wheel cylinder.

(3) Wash wheel cylinder, pistons, and spring (Fig.

193) in clean brake fluid or alcohol;(DO NOT USE

ANY PETROLEUM BASE SOLVENTS)clean thor-

oughly and blow dry with compressed air. Inspect cyl-

inder bore and piston for scoring and pitting. (Do not

use a rag as lint from the rag will stick to bore sur-

faces.)

(4) Wheel cylinder bores and pistons that are

badly scored or pitted should be replaced. Cylinder

walls that have light scratches, or show signs of cor-

rosion, can usually be cleaned with crocus cloth,

using a circular motion. Black stains on the cylinder

walls are caused by piston cups and will not impair

operation of cylinder.

ASSEMBLE

Before assembling the pistons and new cups in the

wheel cylinders, dip them in clean brake fluid. If the

boots are deteriorated, cracked or do not fit tightly on

the pistons or the cylinder casting, install new boots.

(1) Coat cylinder bore with clean brake fluid.

(2) Lightly coat the sealing lip and outer surfaces

of the wheel cylinder cups withonly Mopar Pro-

tect-A-Cup Lubricant p/n 04883068 and no sub-

stitute.

(3) Install expansion spring with cup expanders in

cylinder. Install cups in each end of cylinder with

open end of cups facing each other (Fig. 193).

(4) Install piston in each end of cylinder having

the flat face of each piston contacting the flat face of

each cup, already installed (Fig. 193).

(5) Install a boot over each end of cylinder (Fig.

193).Be careful not to damage boot during

installation.

CLEANING AND INSPECTION

FRONT DISC BRAKE PAD LINING INSPECTION

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary. To check the amount of lining wear,

remove the wheel and tire assemblies, and the cali-

pers.

Remove the shoe and lining assemblies. (See Brake

Shoe Removal).

Combined shoe and lining thickness should be

measured at the thinnest part of the brake shoe

assembly.

When a shoe and lining assembly is worn to a

thickness of approximately 7.95 mm (0.313 inch) it

should be replaced.

Replacebothshoe assemblies (inboard and out-

board) on the front wheels. It is also necessary that

bothfront wheel brake shoe assembly sets be

replaced, whenever shoe assemblies on either side of

the vehicle require replacement.

If a shoe assembly does not require replacement,

reinstall it, making sure each shoe assembly is

returned to its original position. (See Brake Shoe

Installation).

REAR DISC BRAKES

BRAKE PAD LINING WEAR

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary. To check the amount of lining wear,

remove the wheel and tire assemblies, and the cali-

pers.

Remove the rear disc brake shoes. Refer to Rear

Disc Brake Shoe Removal in the Removal And Instal-

Fig. 192 Installing Dust Boot In Caliper Counterbore

5 - 76 BRAKESNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 159 of 1938

lation section in this group of the service manual for

the required procedure.

The combined brake shoe and lining material

thickness should be measured at the thinnest part of

the assembly.

When a set of brake shoes are worn to a total

thickness of approximately 7.0 mm (9/32 inch) they

should be replaced.

Replacebothbrake shoe assemblies (inboard and

outboard). It is necessary thatbothrear wheel sets

be replaced whenever brake shoe assemblies on

either side are replaced.

If the brake shoe assemblies do not require

replacement, reinstall, the assemblies making sure

each brake shoe is returned to the original position.

Refer to Rear Disc Brake Shoe Installation in the

Removal And Installation section in this group of the

service manual for the required procedure.

CALIPER INSPECTION

Check for brake fluid leaks in and around boot

area and inboard lining, and for any ruptures, brit-

tleness or damage to the piston dust boot. If the boot

is damaged, or a fluid leak is visible, disassemble cal-

iper assembly and install a new seal and boot, and

piston if scored. Refer to Rear Disc Brake Caliper in

the Disassembly And Assembly Section in this group

of the service manual.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to Rear Disc Brake

Caliper in the Disassembly And Assembly Section in

this group of the service manual.

REAR DRUM BRAKE SHOE LINING INSPECTION

(1) Remove the tire and wheel assembly from the

vehicle

(2) Remove the rear brake adjusting hole cover

plug (Fig. 194).

(3) Insert a thin screwdriver into brake adjusting

hole to hold the adjusting lever away from the

notches on the adjusting screw star wheel.

(4) Insert Tool C-3784 into brake adjusting hole

and engage notches of brake adjusting screw star

wheel. Release brake by prying down with adjusting

tool.

(5) Remove the rear brake drum from the rear

hub/bearing assembly.

(6) Inspect brake lining for wear, shoe alignment,

and or contamination from grease or brake fluid.

Fig. 193 Rear Wheel Cylinder (Exploded View)

Fig. 194 Brake Adjustment Hole Rubber Plug

NSBRAKES 5 - 77

CLEANING AND INSPECTION (Continued)

Page 160 of 1938

REAR DRUM BRAKE WHEEL CYLINDER

With brake drums removed, inspect the wheel cyl-

inder boots for evidence of a brake fluid leak. Visu-

ally check the boots for cuts, tears, or heat cracks. If

any of these conditions exist, the wheel cylinders

should be completely cleaned, inspected and new

parts installed.

If a wheel cylinder is leaking and the brake lining

material is saturated with brake fluid, the brake

shoes must be replaced.

BRAKE HOSE AND BRAKE LINES INSPECTION

Flexible rubber hose is used at both front brakes

and at the rear axle. Inspection of brake hoses

should be performed whenever the brake system is

serviced and every 7,500 miles or 12 months, which-

ever comes first (every engine oil change). Inspect

hydraulic brake hoses for surface cracking, scuffing,

or worn spots. If the fabric casing of the rubber hose

becomes exposed due to cracks or abrasions in the

rubber hose cover, the hose should be replaced imme-

diately. Eventual deterioration of the hose can take

place with possible burst failure. Faulty installation

can cause twisting, resulting in wheel, tire, or chassis

interference.

The steel brake tubing should be inspected period-

ically for evidence of physical damage or contact with

moving or hot components.

The flexible brake tube sections used on this vehi-

cle in the primary and secondary tubes from the

master cylinder to the ABS hydraulic control unit

connections and the chassis brake tubes between the

hydraulic control unit and the proportioning valve

must also be inspected. This flexible tubing must be

inspected for kinks, fraying and its contact with

other components of the vehicle or contact with the

body of the vehicle.

REAR WHEEL HUB AND BEARING ASSEMBLY

The rear hub and bearing assembly is designed for

the life of the vehicle and should require no mainte-

nance. The following procedure may be used for eval-

uation of bearing condition.

With wheel and brake drum removed, rotate

flanged outer ring of hub. Excessive roughness, lat-

eral play or resistance to rotation may indicate dirt

intrusion or bearing failure. If the rear wheel bear-

ings exhibit these conditions during inspection, the

hub and bearing assembly should be replaced.

Damaged bearing seals and resulting excessive

grease loss may also require bearing replacement.

Moderate grease loss from bearing is considered nor-

mal and should not require replacement of the hub

and bearing assembly.

ADJUSTMENTS

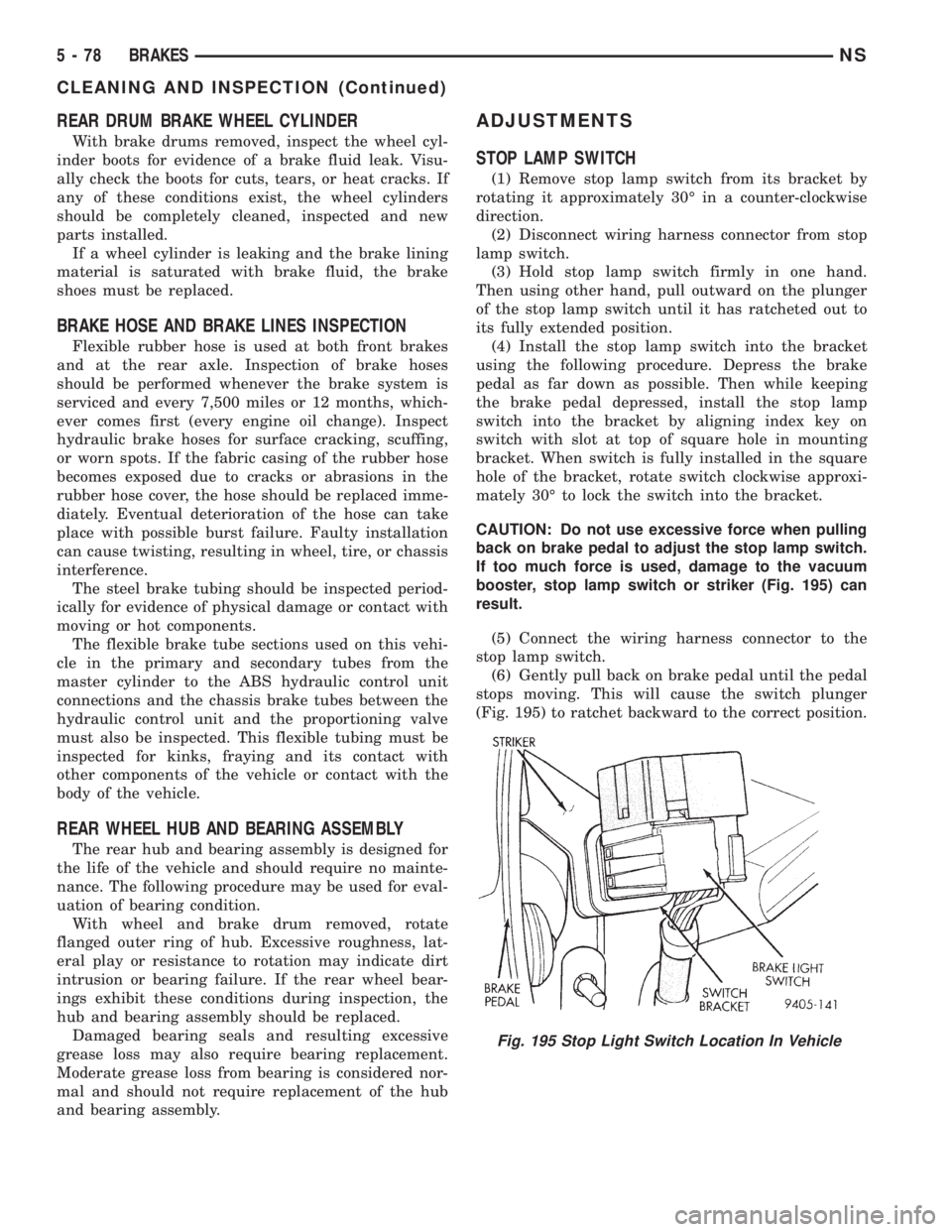

STOP LAMP SWITCH

(1) Remove stop lamp switch from its bracket by

rotating it approximately 30É in a counter-clockwise

direction.

(2) Disconnect wiring harness connector from stop

lamp switch.

(3) Hold stop lamp switch firmly in one hand.

Then using other hand, pull outward on the plunger

of the stop lamp switch until it has ratcheted out to

its fully extended position.

(4) Install the stop lamp switch into the bracket

using the following procedure. Depress the brake

pedal as far down as possible. Then while keeping

the brake pedal depressed, install the stop lamp

switch into the bracket by aligning index key on

switch with slot at top of square hole in mounting

bracket. When switch is fully installed in the square

hole of the bracket, rotate switch clockwise approxi-

mately 30É to lock the switch into the bracket.

CAUTION: Do not use excessive force when pulling

back on brake pedal to adjust the stop lamp switch.

If too much force is used, damage to the vacuum

booster, stop lamp switch or striker (Fig. 195) can

result.

(5) Connect the wiring harness connector to the

stop lamp switch.

(6) Gently pull back on brake pedal until the pedal

stops moving. This will cause the switch plunger

(Fig. 195) to ratchet backward to the correct position.

Fig. 195 Stop Light Switch Location In Vehicle

5 - 78 BRAKESNS

CLEANING AND INSPECTION (Continued)

Page 161 of 1938

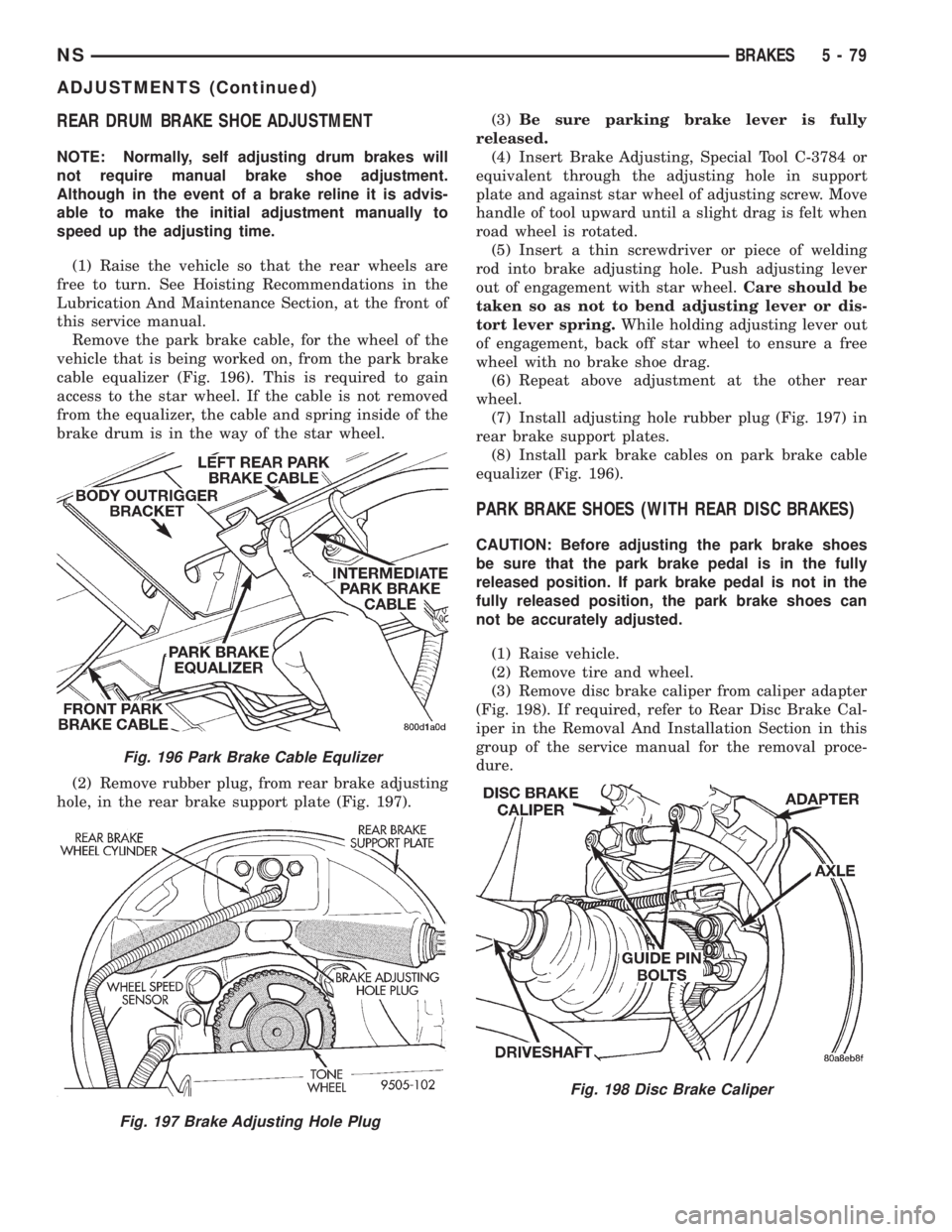

REAR DRUM BRAKE SHOE ADJUSTMENT

NOTE: Normally, self adjusting drum brakes will

not require manual brake shoe adjustment.

Although in the event of a brake reline it is advis-

able to make the initial adjustment manually to

speed up the adjusting time.

(1) Raise the vehicle so that the rear wheels are

free to turn. See Hoisting Recommendations in the

Lubrication And Maintenance Section, at the front of

this service manual.

Remove the park brake cable, for the wheel of the

vehicle that is being worked on, from the park brake

cable equalizer (Fig. 196). This is required to gain

access to the star wheel. If the cable is not removed

from the equalizer, the cable and spring inside of the

brake drum is in the way of the star wheel.

(2) Remove rubber plug, from rear brake adjusting

hole, in the rear brake support plate (Fig. 197).(3)Be sure parking brake lever is fully

released.

(4) Insert Brake Adjusting, Special Tool C-3784 or

equivalent through the adjusting hole in support

plate and against star wheel of adjusting screw. Move

handle of tool upward until a slight drag is felt when

road wheel is rotated.

(5) Insert a thin screwdriver or piece of welding

rod into brake adjusting hole. Push adjusting lever

out of engagement with star wheel.Care should be

taken so as not to bend adjusting lever or dis-

tort lever spring.While holding adjusting lever out

of engagement, back off star wheel to ensure a free

wheel with no brake shoe drag.

(6) Repeat above adjustment at the other rear

wheel.

(7) Install adjusting hole rubber plug (Fig. 197) in

rear brake support plates.

(8) Install park brake cables on park brake cable

equalizer (Fig. 196).

PARK BRAKE SHOES (WITH REAR DISC BRAKES)

CAUTION: Before adjusting the park brake shoes

be sure that the park brake pedal is in the fully

released position. If park brake pedal is not in the

fully released position, the park brake shoes can

not be accurately adjusted.

(1) Raise vehicle.

(2) Remove tire and wheel.

(3) Remove disc brake caliper from caliper adapter

(Fig. 198). If required, refer to Rear Disc Brake Cal-

iper in the Removal And Installation Section in this

group of the service manual for the removal proce-

dure.

Fig. 196 Park Brake Cable Equlizer

Fig. 197 Brake Adjusting Hole Plug

Fig. 198 Disc Brake Caliper

NSBRAKES 5 - 79

ADJUSTMENTS (Continued)