tow CHRYSLER VOYAGER 1996 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 880 of 1938

Component Page

Seat Belt Switch.....................8W-80-83

Sentry Key Immobilizer Module.........8W-80-83

Speed Control Dimming Module.........8W-80-83

Stop Lamp Switch....................8W-80-83

Throttle Position Sensor (2.0L)..........8W-80-84

Throttle Position Sensor (Except 2.0L). . . .8W-80-84

Traction Control Switch................8W-80-84

Trailer Tow Connector.................8W-80-84

Transmission Control Module...........8W-80-85Component Page

Transmission Control Solenoids..........8W-80-86

Transmission Range Sensor.............8W-80-86

Turbine Speed Sensor.................8W-80-87

Turbo Boost Pressure Sensor............8W-80-87

Upstream Heated Oxygen Sensor........8W-80-87

Vehicle Speed Control Servo............8W-80-87

Vehicle Speed Sensor..................8W-80-88

Wiper Module (Built-Up-Export).........8W-80-88

Wiper Module (Except Built-Up-Export) . . .8W-80-88

8W - 80 - 4 8W - 80 CONNECTOR PIN-OUTSNS/GS

Page 890 of 1938

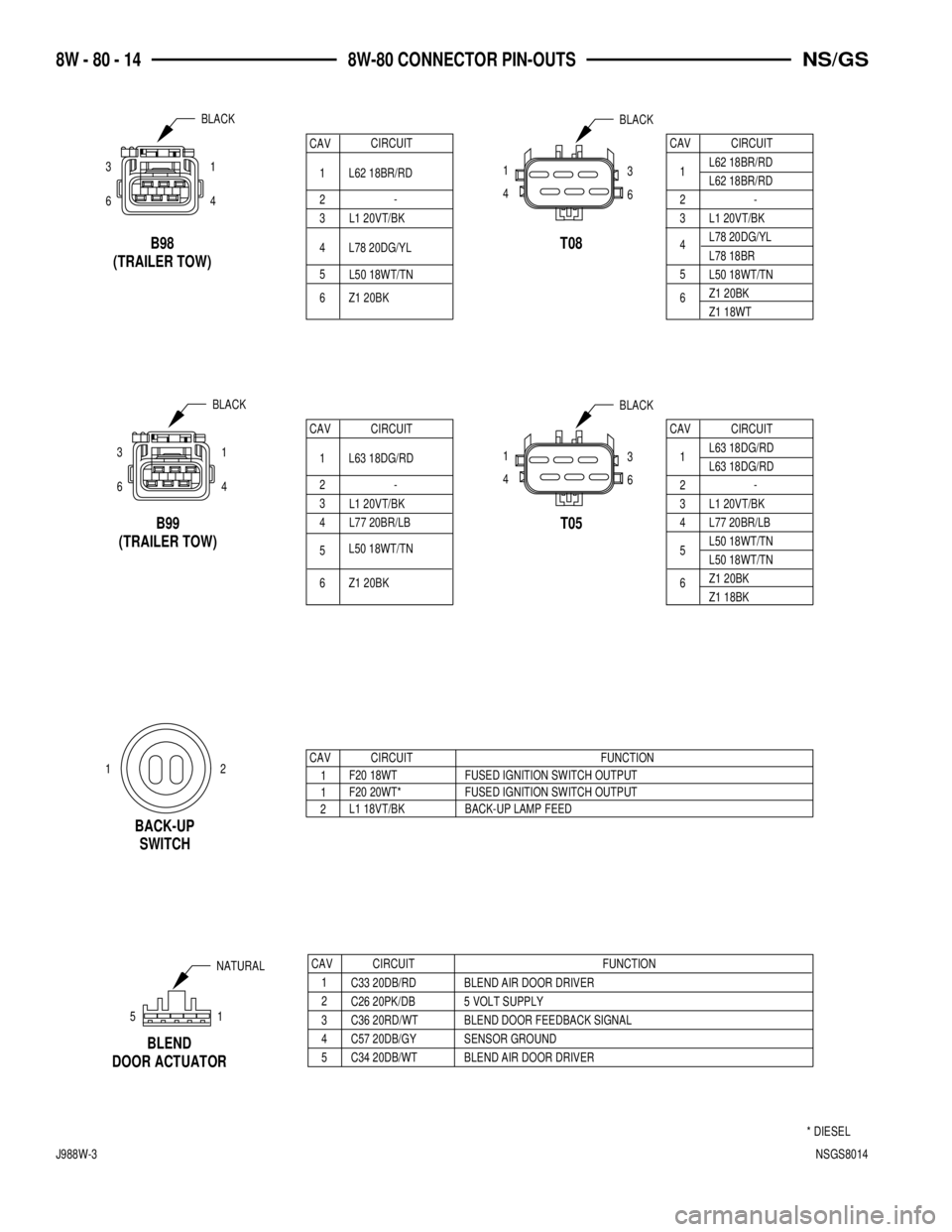

Z1 20BK

L50 18WT/TN 3

61

4

BLACKBLACK

4 1

6 3

L63 18DG/RD

6 5 1Z1 18BK Z1 20BK L50 18WT/TN

L50 18WT/TN L77 20BR/LB L1 20VT/BK L63 18DG/RD L63 18DG/RD

4 3 2 CAV

- CIRCUIT

6 5 1

L77 20BR/LB L1 20VT/BK

4 3

2 CAV

- CIRCUIT

3

61

4

BLACKBLACK

4 1

6 3

Z1 20BK L78 20DG/YL L62 18BR/RD

6 4 1Z1 18WT Z1 20BK L50 18WT/TN L78 18BR

L78 20DG/YL L1 20VT/BK L62 18BR/RD L62 18BR/RD

5 3 2 CAV

- CIRCUIT

6 4 1

L50 18WT/TN L1 20VT/BK

5 3 2 CAV

- CIRCUIT

B99

(TRAILER TOW) (TRAILER TOW)B98 T08

T05

DOOR ACTUATORBLEND

2 1

BACK-UP

SWITCH

BACK-UP LAMP FEED L1 18VT/BK

2F20 20WT* FUSED IGNITION SWITCH OUTPUTFUSED IGNITION SWITCH OUTPUT F20 18WT

1 1

CAV FUNCTION CIRCUIT

* DIESEL FUNCTION

CIRCUIT

BLEND AIR DOOR DRIVER

5 VOLT SUPPLY

BLEND DOOR FEEDBACK SIGNAL

SENSOR GROUND

BLEND AIR DOOR DRIVERCAV

1

2

3

4

5C33 20DB/RD

C26 20PK/DB

C36 20RD/WT

C57 20DB/GY

C34 20DB/WTNATURAL

1 5

8W - 80 - 14 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8014

Page 924 of 1938

LAMP KEY-IN HALO

WHITE

1 2

1

M11 20PK/LB Z1 20BK

2 CAV COURTESY LAMP SWITCH OUTPUT GROUND CIRCUIT

FUNCTION

(PREMIUM)SPEAKER LEFT DOOR

LEFT INSTRUMENT PANEL SPEAKER (-)

X55 20BR/RD LEFT FRONT SPEAKER (-)RADIO CHOKE OUTPUT X13 16RD/DG

6

5

3 6

4

1 BLACK

X156 20VT/WT* X53 20DG X15 16BK/DG X154 20WT/VT*

4 3 2 1 CAV

LEFT FRONT SPEAKER (+) AMPLIFIED SPEAKER GROUND LEFT INSTRUMENT PANEL SPEAKER (+)FUNCTION CIRCUIT

RELAY LEFT COMBINATION

4

2

3 5 1BLACK

GROUND

3 2

L615 18OR L50 18WT/TN

L50 18WT/TN Z1 18BK Z1 18BK

L63 18DG/RD

5 4 1 CAV LEFT COMBINATION RELAY OUTPUT

STOP LAMP SWITCH OUTPUT

STOP LAMP SWITCH OUTPUT LEFT TURN SIGNAL

- CIRCUIT

- FUNCTION

(2.0L/2.4L/3.8L) KNOCK SENSOR

21

GRAY

K4 18BK/LB K42 18DB/LG

2 1 CAV SENSOR GROUND KNOCK SENSOR SIGNAL CIRCUIT

FUNCTION

SWITCHKEY-IN

1 2GREEN

Z1 20BK G26 20LB

2 1 CAV GROUND KEY-IN IGNITION SWITCH SENSE CIRCUIT

FUNCTION

(TRAILER TOW)

X153 20WT/BR** LEFT INSTRUMENT PANEL SPEAKER (+)

X155 20BR/WT**

LEFT INSTRUMENT PANEL SPEAKER (-)

** LHD* RHD

8W - 80 - 48 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8048

Page 929 of 1938

MIRROR LAMPS LEFT VISOR/VANITY

ABBLACK

F41 20PK/VT M20 20BR

B A CAV FUSED B (+) COURTESY LAMP GROUND FUNCTION CIRCUIT

SIGNAL RELAY LEFT STOP/TURN

1 4

2

3 5

BLACK

LEFT COMBINATION RELAY OUTPUT LEFT STOP/TURN SIGNAL OUTPUT 1

4 2L615 18OR L63 18DG/RD L63 18DG/RD L73 18YL

Z1 18BK Z1 18BK

L50 18WT/TN L50 18WT/TN

5 3 CAV

LEFT REAR TURN SIGNAL GROUND STOP LAMP SWITCH OUTPUT CIRCUIT

FUNCTION

GRAY

GROUND Z1 18BK

2

1L63 18DG/RD CAV FUNCTION CIRCUIT

LEFT REPEATER LAMP SIGNAL

1 2

SENSOR WHEEL SPEEDLEFT REAR

GRAY

21

B4 18LG B3 18LG/DB

2 1 CAV LEFT REAR WHEEL SPEED SENSOR (+) LEFT REAR WHEEL SPEED SENSOR (-) FUNCTION CIRCUIT

LEFT REAR VENT MOTOR (OPEN) Q24 18DG

3

31NATURAL

LEFT REAR

VENT MOTOR

(RHD)

LEFT REAR VENT MOTOR (CLOSE) Q14 18GY

2

1- CAV FUNCTION CIRCUIT

-

LEFT REPEATER

LAMP

(BUILT-UP-EXPORT)

(TRAILER TOW)

NS/GS8W-80 CONNECTOR PIN-OUTS 8W - 80 - 53

NSGS8053J988W-3

Page 954 of 1938

RELAY RIGHT COMBINATION- -

BLACK4

2

3 5

RIGHT TURN SIGNAL

1

L605 18DG L50 18WT/TN Z1 18BK L62 18BR/RD

L62 18BR/RD

5 4 3 2 CAV RIGHT TURN SIGNAL STOP LAMP SWITCH OUTPUT GROUND CIRCUIT

FUNCTION

(EXCEPT BUILT-UP-EXPORT)FOG LAMPRIGHT

FOG LAMP RELAY OUTPUT L39 18LB**

GRAY*

1 PURPLE**

2

Z39 20BK L39 18VT/RD*

2 1 CAV FOG LAMP SWITCHED GROUND FOG LAMP RELAY OUTPUT CIRCUIT

FUNCTION BLACK

FOG LAMP SWITCHED GROUND Z39 20BK

2

1F39 18PK/LG CAV FUNCTION CIRCUIT

FUSED PARK LAMP RELAY OUTPUT

RIGHT

FOG LAMP

(BUILT-UP-EXPORT)

1 2

(PREMIUM)SPEAKER RIGHT DOOR

X56 20DB/RD RIGHT FRONT SPEAKER (-)RADIO CHOKE OUTPUT X13 16RD/DG

65

3 6

4

1 BLACK

X155 20BR/WT X54 20VT X15 16BK/DG X153 20WT/BR

4 3 2 1 CAV RIGHT FRONT I/P SPEAKER (-) RIGHT FRONT SPEAKER (+) AMPLIFIED SPEAKER GROUND RIGHT I/P SPEAKER (+)FUNCTION CIRCUIT

PANEL SPEAKERRIGHT FRONT3

4X153 20WT/BR-

RIGHT FRONT I/P SPEAKER (+)-

BLACK

4

1

- X155 20BR/WT

2 1 CAV - RIGHT FRONT I/P SPEAKER (-) CIRCUIT

FUNCTION

(TRAILER TOW)

(PREMIUM)

RHD

LHD

DIESEL

* DODGE/PLYMOUTH

** CHRYSLER X154 20WT/VT RIGHT FRONT I/P SPEAKER (+)

X156 20VT/WT

RIGHT FRONT I/P SPEAKER (-)

GRAY

X156 20VT/WT RIGHT FRONT I/P SPEAKER (-)

X154 20WT/VT RIGHT I/P SPEAKER (+)

8W - 80 - 78 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8078

Page 959 of 1938

SWITCH STOP LAMP

1

6 GRAY

F32 18PK/DB L50 18WT/TN

V30 20DB/RD* V32 20YL/RD* Z1 20BK

K29 20WT/PK

6 5 4

3 2 1 CAV FUSED B(+)

STOP LAMP SWITCH OUTPUT SPEED CONTROL BRAKE SWITCH OUTPUT SPEED CONTROL ON/OFF SWITCH SENSE

GROUND STOP LAMP SWITCH SENSE FUNCTION CIRCUIT

* GAS

DIMMING MODULESPEED CONTROL

4BLACK1

V32 20YL/RD V38 20LB/RD L97 29PK/DB

4 3 2 1 CAV SPEED CONTROL ON/OFF SWITCH SENSE

SPEED CONTROL RELAY CONTROL PARK LAMP RELAY CONTROL

- FUNCTION

- CIRCUIT

BLACK

(BUILT-UP-EXPORT)

6 1

MODULE IMMOBILIZERSENTRY KEY

CAV CIRCUIT FUNCTION

1 F41 20PK/VT FUSED B(+)

2 Z2 20BK GROUND

3 F87 20WT/BK FUSED IGNITION (ST-RUN)

4- -

5 D2 20WT/BK CCD BUS (-)

6 D1 20VT/BR CCD BUS (+)

SWITCH SEAT BELT

2 1BLACK

Z1 20BK G10 18LG/RD

2 1 CAV GROUND SEAT BELT SWITCH SENSE FUNCTION CIRCUIT

VANITY MIRROR LAMPSRIGHT VISOR/

ABBLACK

F41 20PK/VT M20 20BR

B A CAV FUSED B(+) COURTESY LAMP GROUND FUNCTION CIRCUIT

SIGNAL RELAYSTOP/TURNRIGHT

BLACK4

2

3 5

2 1

GROUND STOP LAMP SWITCH OUTPUT

L605 18DG L62 18BR/RD L74 18LG Z1 18BK

Z1 18BK L50 18WT/TN L50 18WT/TN

5 4

3 CAV RIGHT COMBINATION RELAY OUTPUT RIGHT TURN SIGNAL STOP LAMP SWITCH OUTPUTFUNCTION CIRCUIT

(TRAILER TOW)

NS/GS8W-80 CONNECTOR PIN-OUTS 8W - 80 - 83

NSGS8083J988W-3

Page 960 of 1938

CONNECTOR TRAILER TOW

CAP

L73 18YL Z1 18WT

L78 18BR

L74 18LG

4 3 2 1 CAV STOP LAMP SWITCH OUTPUT

GROUND

FUSED B(+) STOP LAMP SWITCH OUTPUT CIRCUIT

FUNCTION

SWITCH TRACTION CONTROL

E2 20OR B27 20RD/YL Z1 20BK

3 2

1 CAV PANEL LAMP FEED

TRACTION CONTROL SWITCH SENSE GROUND CIRCUIT

FUNCTION

3 1BLACK

(EXCEPT 2.0L) POSITION SENSORTHROTTLE

K4 18BK/LB

SENSOR GROUND 1

3

CAV CIRCUIT FUNCTION

1

K22 18OR/DB THROTTLE POSITION SENSOR SIGNAL 2

K6 18VT/WT 5 VOLT SUPPLY

3

CIRCUIT FUNCTION

CAV

1

2K4 18BK/LB CRANK POSITION SENSOR

THROTTLE POSITION SENSOR SIGNAL K22 18OR/DB

3K6 18VT/WT 5V SUPPLY

(2.0L) SENSOR THROTTLE POSITION

WHITE

31

WHITE

8W - 80 - 84 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8084

Page 970 of 1938

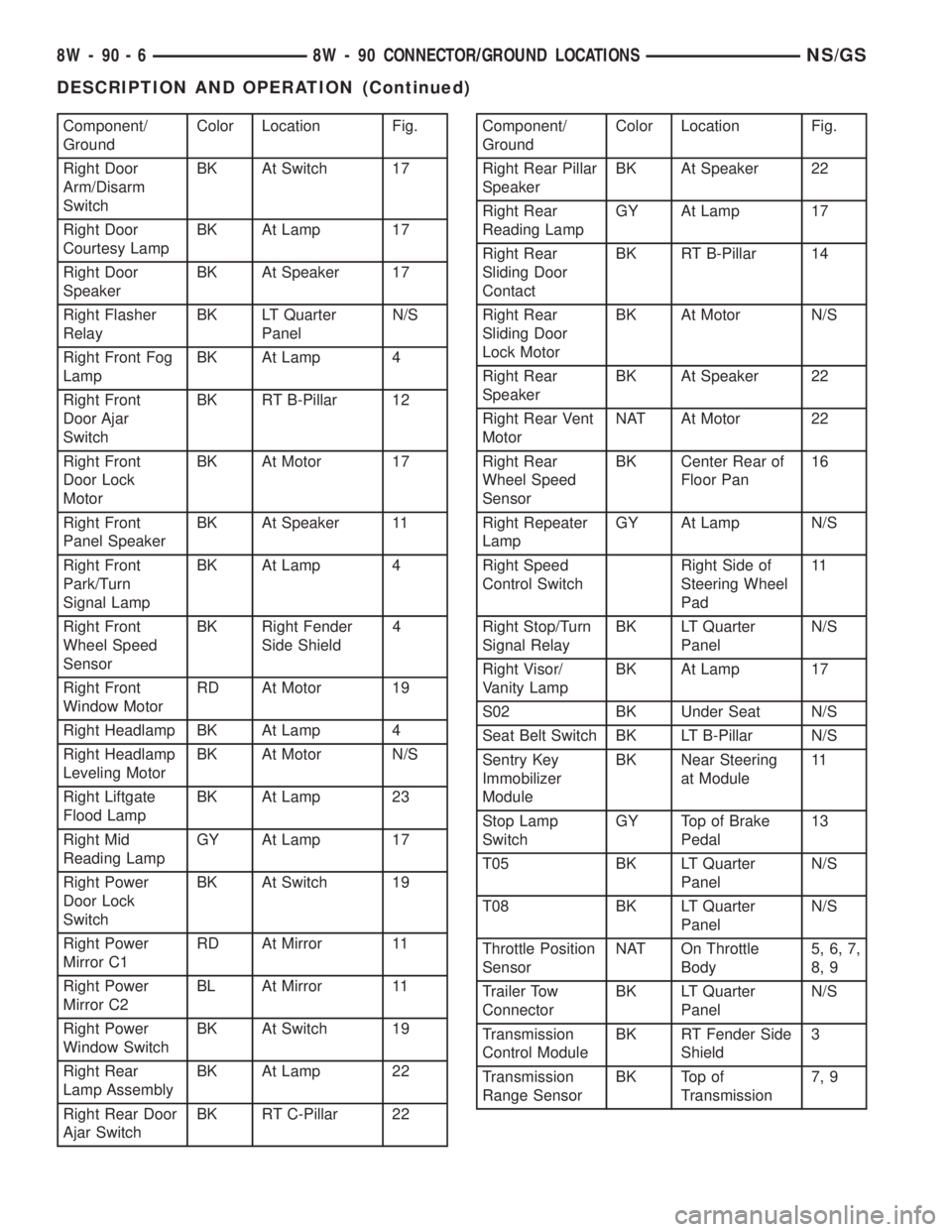

Component/

GroundColor Location Fig.

Right Door

Arm/Disarm

SwitchBK At Switch 17

Right Door

Courtesy LampBK At Lamp 17

Right Door

SpeakerBK At Speaker 17

Right Flasher

RelayBK LT Quarter

PanelN/S

Right Front Fog

LampBK At Lamp 4

Right Front

Door Ajar

SwitchBK RT B-Pillar 12

Right Front

Door Lock

MotorBK At Motor 17

Right Front

Panel SpeakerBK At Speaker 11

Right Front

Park/Turn

Signal LampBK At Lamp 4

Right Front

Wheel Speed

SensorBK Right Fender

Side Shield4

Right Front

Window MotorRD At Motor 19

Right Headlamp BK At Lamp 4

Right Headlamp

Leveling MotorBK At Motor N/S

Right Liftgate

Flood LampBK At Lamp 23

Right Mid

Reading LampGY At Lamp 17

Right Power

Door Lock

SwitchBK At Switch 19

Right Power

Mirror C1RD At Mirror 11

Right Power

Mirror C2BL At Mirror 11

Right Power

Window SwitchBK At Switch 19

Right Rear

Lamp AssemblyBK At Lamp 22

Right Rear Door

Ajar SwitchBK RT C-Pillar 22Component/

GroundColor Location Fig.

Right Rear Pillar

SpeakerBK At Speaker 22

Right Rear

Reading LampGY At Lamp 17

Right Rear

Sliding Door

ContactBK RT B-Pillar 14

Right Rear

Sliding Door

Lock MotorBK At Motor N/S

Right Rear

SpeakerBK At Speaker 22

Right Rear Vent

MotorNAT At Motor 22

Right Rear

Wheel Speed

SensorBK Center Rear of

Floor Pan16

Right Repeater

LampGY At Lamp N/S

Right Speed

Control SwitchRight Side of

Steering Wheel

Pad11

Right Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Right Visor/

Vanity LampBK At Lamp 17

S02 BK Under Seat N/S

Seat Belt Switch BK LT B-Pillar N/S

Sentry Key

Immobilizer

ModuleBK Near Steering

at Module11

Stop Lamp

SwitchGY Top of Brake

Pedal13

T05 BK LT Quarter

PanelN/S

T08 BK LT Quarter

PanelN/S

Throttle Position

SensorNAT On Throttle

Body5, 6, 7,

8, 9

Trailer Tow

ConnectorBK LT Quarter

PanelN/S

Transmission

Control ModuleBK RT Fender Side

Shield3

Transmission

Range SensorBK Top of

Transmission7, 9

8W - 90 - 6 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1000 of 1938

Component/

GroundColor Location Fig.

Right Rear

Sliding Door

ContactBK RT B-Pillar 14

Right Rear

Sliding Door

Lock MotorBK At Motor N/S

Right Rear

SpeakerBK At Speaker 22

Right Rear Vent

MotorNAT At Motor 22

Right Rear

Wheel Speed

SensorGY Center Rear of

Floor Pan16

Right Repeater

LampGY At Lamp N/S

Right Speed

Control SwitchRight Side of

Steering Wheel

Pad11

Right Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Right Visor/

Vanity LampBK At Lamp 17

S02 BK Under Seat N/S

Seat Belt Switch BK RT B-Pillar N/S

Sentry Key

Immobilizer

ModuleBK Near Steering

Column at

Module11

Stop Lamp

SwitchGY Top of Brake

Pedal12

T05 BK LT Quarter

PanelN/S

T08 BK RT Quarter

PanelN/SComponent/

GroundColor Location Fig.

Throttle Position

SensorNAT On Throttle

Body5, 6, 7,

8, 9

Trailer Tow

ConnectorBK LT Quarter

PanelN/S

Transmission

Control ModuleBK RT Fender Side

Shield3

Transmission

Range SensorBK Top of

Transmission7. 9

Transmission

Control

SolenoidsBK Front of

Transmission7, 9

Turbine Speed

SensorGY Front of

Transmission7, 9

Turn Signal/

Hazard SwitchBK Part of

Multifunction

Switch11

Upstream

Heated Oxygen

SensorGY Rear of Engine 5, 6, 7,

8, 9

Vehicle Speed

Control ServoBK LT Rear of

Engine

Compartment5, 6, 7,

8, 9

Vehicle Speed

SensorBK Rear of

Transmission5, 6, 8

Windshield

Wiper SwitchBK Part of

Multifunction

Switch11

Wiper Module BK LT Side of

Engine2

8W - 90 - 36 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1052 of 1938

made to seal the area between the bedplate and cyl-

inder block without disturbing the bearing clearance

or alignment of these components.

GASKET DISASSEMBLY

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some

instances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper

may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

SURFACE PREPARATION

Scrape clean or wire brush all gasket surfaces to

remove all loose material. Inspect stamped parts to

ensure gasket rails are flat. Gasket surfaces must be

free of oil and dirt. Make sure old gasket material is

removed from blind attaching holes.

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing the material off location.

TheMopartSilicone Rubber Adhesive Sealant

gasket material or equivalent should be applied in a

continuous bead approximately 3 mm (0.120 in.) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 in.) drop

is placed in the center of the gasket contact area.

Uncured sealant may be removed with a shop towels.

Components should be torqued in place while the

sealant is still wet to the touch (within 10 minutes).

The usage of a locating dowel is recommended during

assembly to prevent smearing of material off loca-

tion.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

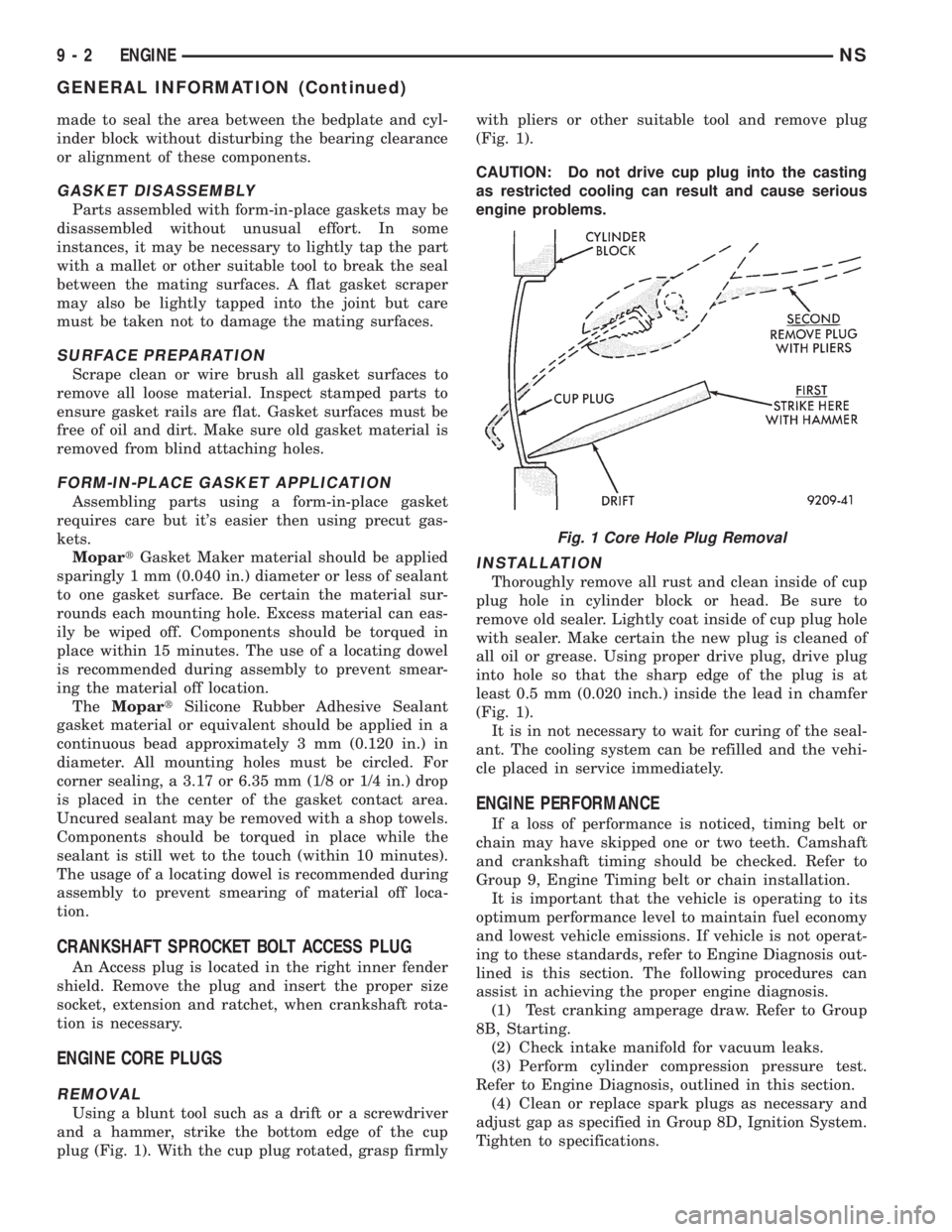

ENGINE CORE PLUGS

REMOVAL

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 1). With the cup plug rotated, grasp firmlywith pliers or other suitable tool and remove plug

(Fig. 1).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly remove all rust and clean inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with sealer. Make certain the new plug is cleaned of

all oil or grease. Using proper drive plug, drive plug

into hole so that the sharp edge of the plug is at

least 0.5 mm (0.020 inch.) inside the lead in chamfer

(Fig. 1).

It is in not necessary to wait for curing of the seal-

ant. The cooling system can be refilled and the vehi-

cle placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-

ing to these standards, refer to Engine Diagnosis out-

lined is this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis, outlined in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

Fig. 1 Core Hole Plug Removal

9 - 2 ENGINENS

GENERAL INFORMATION (Continued)