heater CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1831 of 1938

be 21ÉC to 27ÉC (70ÉF to 85ÉF). To test the expansion

valve:

NOTE: Liquid CO2 is required to test the expansion

valve. It is available from most welding supply facil-

ities. CO2 is also available from companies which

service and sell fire extinguishers.

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set heater A/C control to A/C, full heat,

FLOOR, and high blower.

(4) Start the engine and allow to idle (1000 rpm).

After the engine has reached running temperature,

allow the passenger compartment to heat up. This

will create the need for maximum refrigerant flow

into the evaporator.

(5) If the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 1655 kPa

(140 to 240 psi). Suction (low pressure) gauge should

read 140 kPa to 207 kPa (20 psi to 30 psig). If system

cannot achieve proper pressure readings, replace the

expansion valve. If pressure is correct, proceed with

test.

WARNING: PROTECT SKIN AND EYES FROM CON-

TACTING CO2 PERSONAL INJURY CAN RESULT.

(6) If suction side low pressure is within specified

range, freeze the expansion valve control head for 30

seconds. Use a super cold substance (liquid CO2).Do

not spray R-134a or R-12 Refrigerant on the

expansion valve for this test.Suction side low

pressure should drop by 10 psi. If not, replace expan-

sion valve.

(7) Allow expansion valve to thaw. The low pres-

sure gauge reading should stabilize at 140 kPa to

240 kPa (20 psi to 30 psig). If not, replace expansion

valve.

(8) When expansion valve test is complete, test

A/C overall performance. Remove all test equipment

before returning vehicle to use.

HEATER PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings in this

group before performing the following procedures.

Check the coolant level, drive belt tension, vacuum

line connections, radiator air flow and fan operation.

Start engine and allow to warm up to normal tem-

perature.WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to

escape through the overflow tube. When the system

stabilizes, remove the cap completely.

MAXIMUM HEATER OUTPUT: TEST AND

ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference Table.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.

(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF

INSUFFICIENT HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

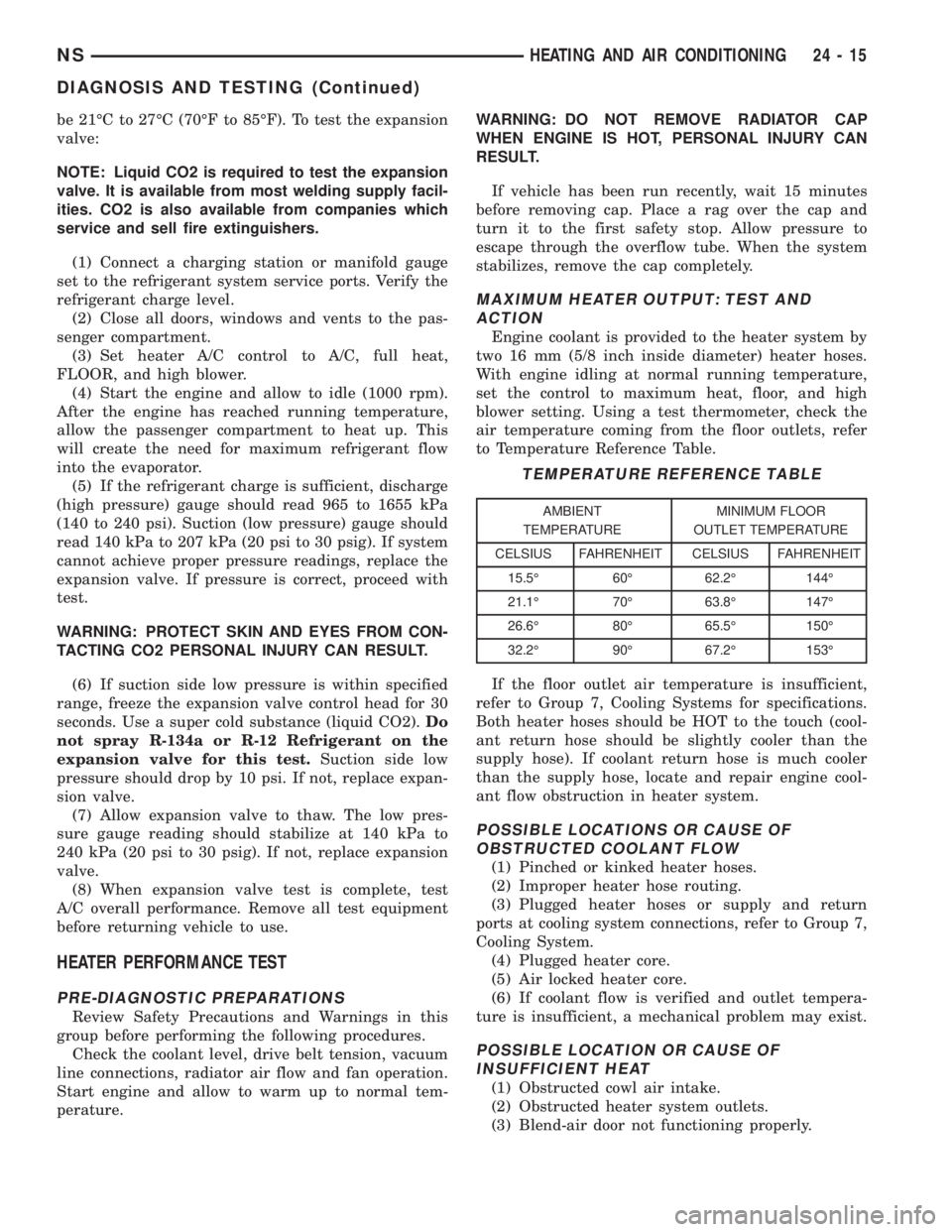

TEMPERATURE REFERENCE TABLE

AMBIENT

TEMPERATUREMINIMUM FLOOR

OUTLET TEMPERATURE

CELSIUS FAHRENHEIT CELSIUS FAHRENHEIT

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

NSHEATING AND AIR CONDITIONING 24 - 15

DIAGNOSIS AND TESTING (Continued)

Page 1845 of 1938

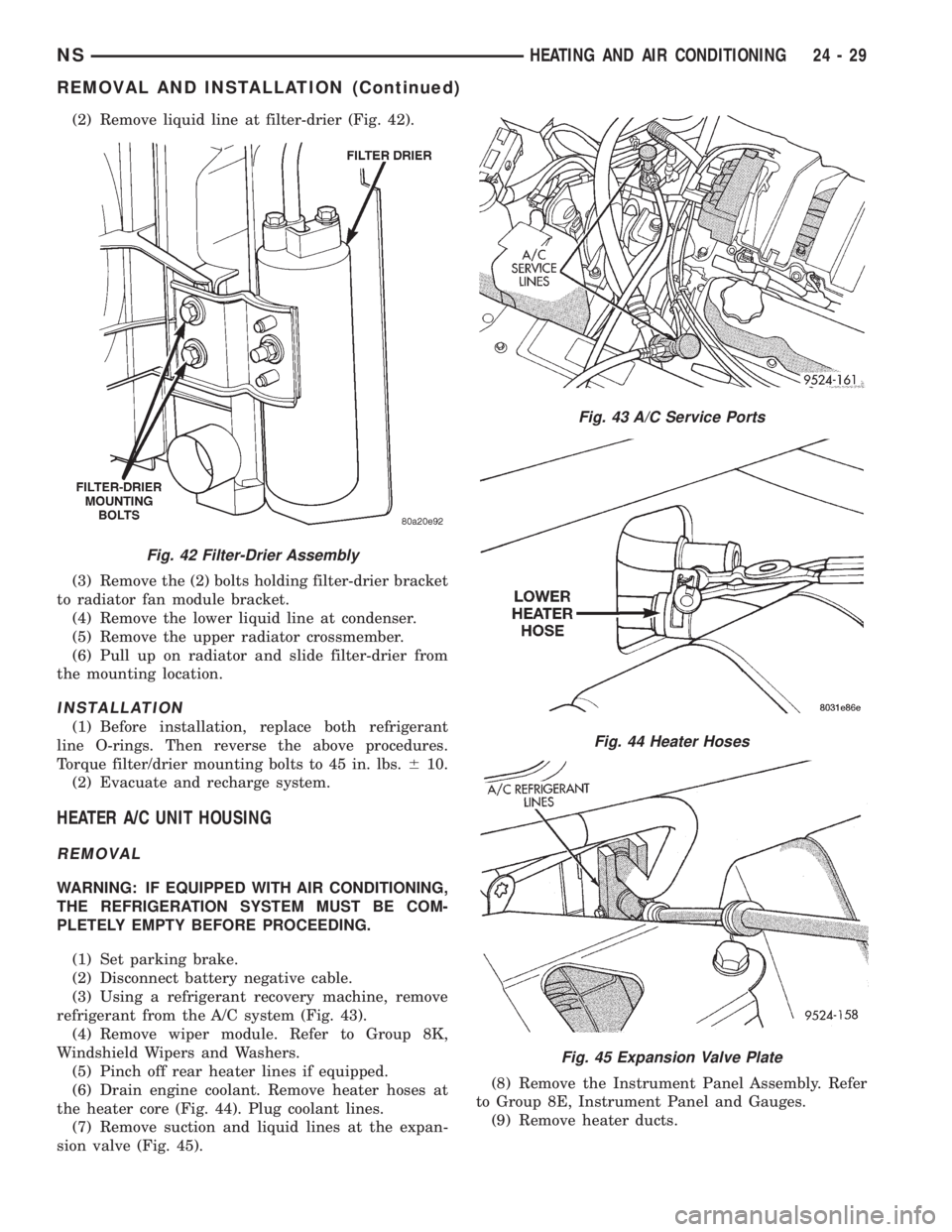

(2) Remove liquid line at filter-drier (Fig. 42).

(3) Remove the (2) bolts holding filter-drier bracket

to radiator fan module bracket.

(4) Remove the lower liquid line at condenser.

(5) Remove the upper radiator crossmember.

(6) Pull up on radiator and slide filter-drier from

the mounting location.

INSTALLATION

(1) Before installation, replace both refrigerant

line O-rings. Then reverse the above procedures.

Torque filter/drier mounting bolts to 45 in. lbs.610.

(2) Evacuate and recharge system.

HEATER A/C UNIT HOUSING

REMOVAL

WARNING: IF EQUIPPED WITH AIR CONDITIONING,

THE REFRIGERATION SYSTEM MUST BE COM-

PLETELY EMPTY BEFORE PROCEEDING.

(1) Set parking brake.

(2) Disconnect battery negative cable.

(3) Using a refrigerant recovery machine, remove

refrigerant from the A/C system (Fig. 43).

(4) Remove wiper module. Refer to Group 8K,

Windshield Wipers and Washers.

(5) Pinch off rear heater lines if equipped.

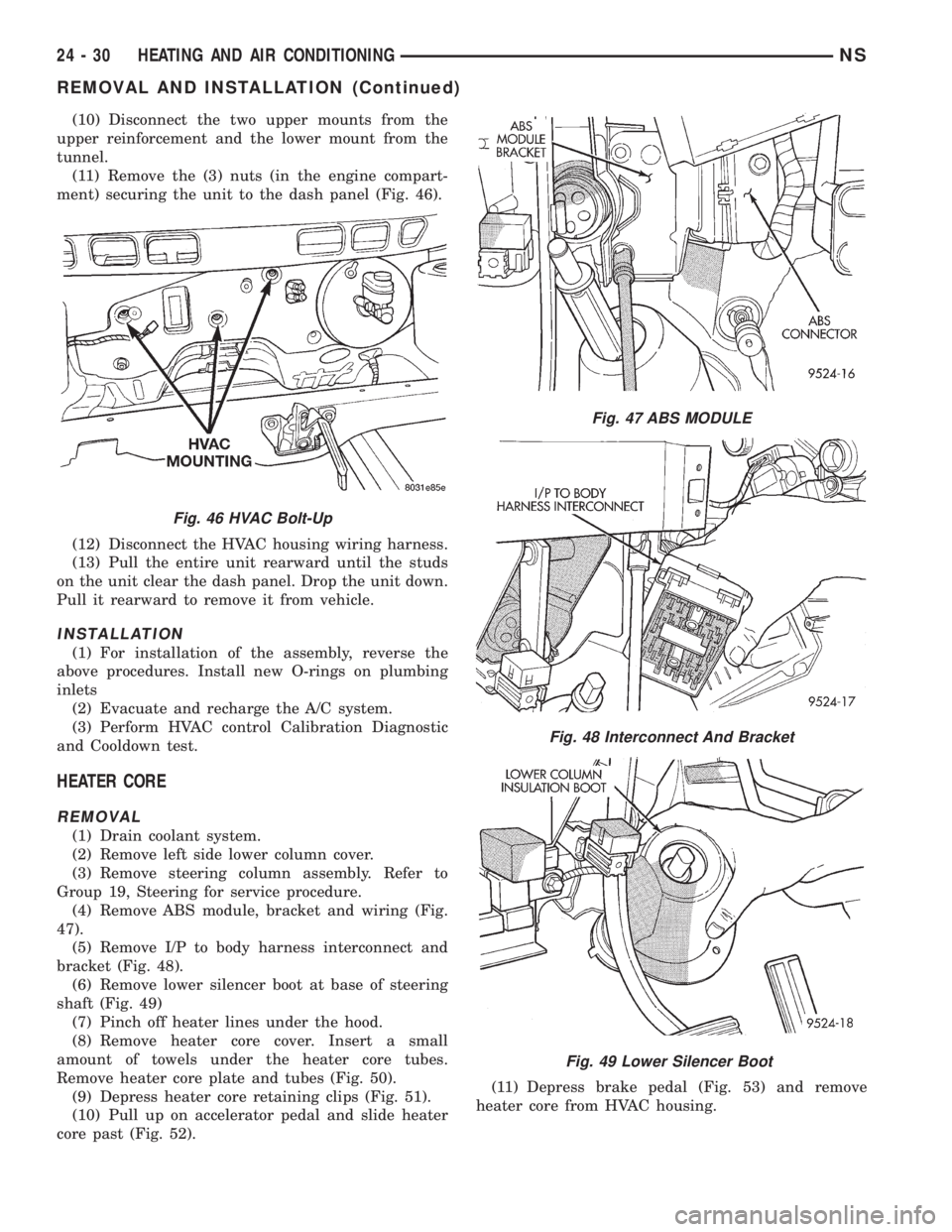

(6) Drain engine coolant. Remove heater hoses at

the heater core (Fig. 44). Plug coolant lines.

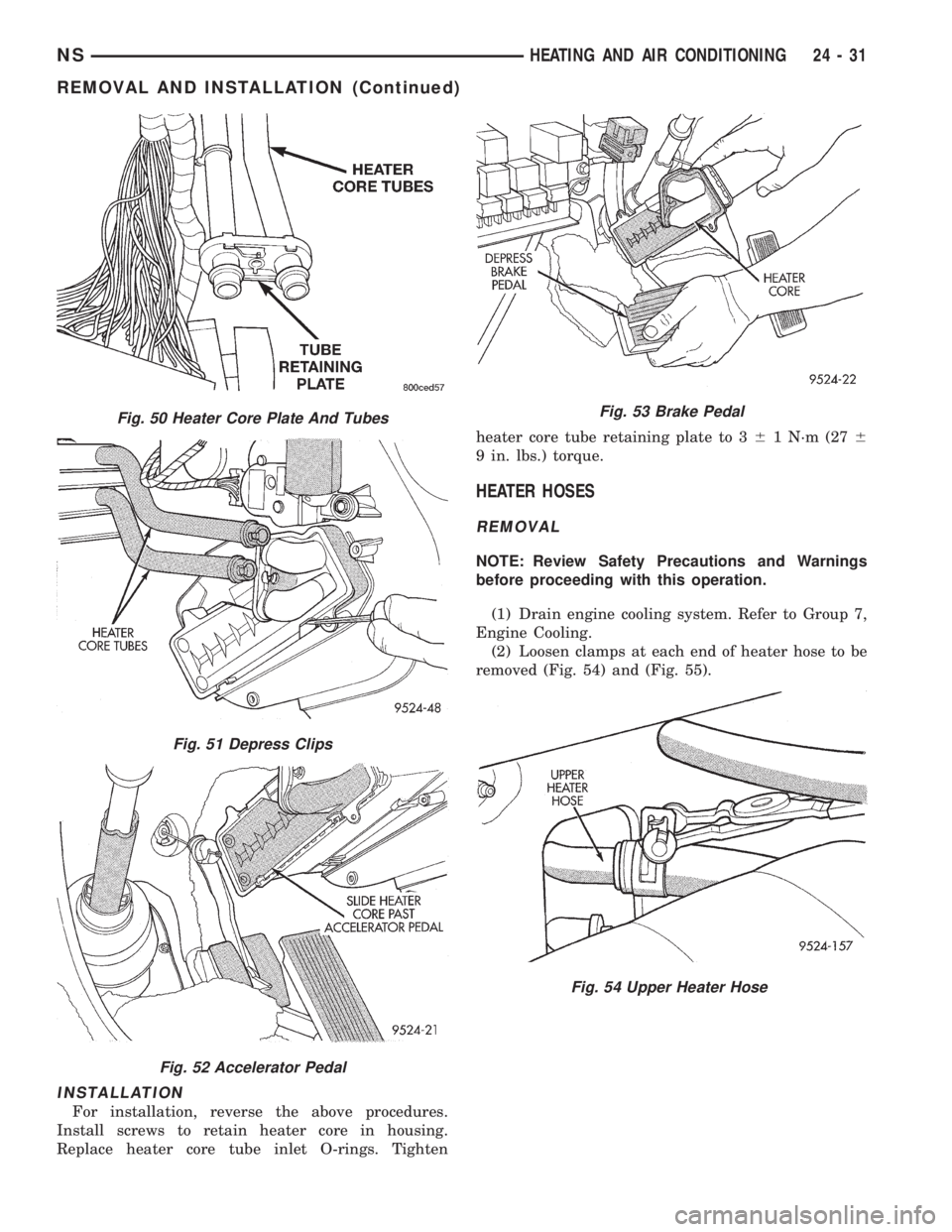

(7) Remove suction and liquid lines at the expan-

sion valve (Fig. 45).(8) Remove the Instrument Panel Assembly. Refer

to Group 8E, Instrument Panel and Gauges.

(9) Remove heater ducts.

Fig. 42 Filter-Drier Assembly

Fig. 43 A/C Service Ports

Fig. 44 Heater Hoses

Fig. 45 Expansion Valve Plate

NSHEATING AND AIR CONDITIONING 24 - 29

REMOVAL AND INSTALLATION (Continued)

Page 1846 of 1938

(10) Disconnect the two upper mounts from the

upper reinforcement and the lower mount from the

tunnel.

(11) Remove the (3) nuts (in the engine compart-

ment) securing the unit to the dash panel (Fig. 46).

(12) Disconnect the HVAC housing wiring harness.

(13) Pull the entire unit rearward until the studs

on the unit clear the dash panel. Drop the unit down.

Pull it rearward to remove it from vehicle.

INSTALLATION

(1) For installation of the assembly, reverse the

above procedures. Install new O-rings on plumbing

inlets

(2) Evacuate and recharge the A/C system.

(3) Perform HVAC control Calibration Diagnostic

and Cooldown test.

HEATER CORE

REMOVAL

(1) Drain coolant system.

(2) Remove left side lower column cover.

(3) Remove steering column assembly. Refer to

Group 19, Steering for service procedure.

(4) Remove ABS module, bracket and wiring (Fig.

47).

(5) Remove I/P to body harness interconnect and

bracket (Fig. 48).

(6) Remove lower silencer boot at base of steering

shaft (Fig. 49)

(7) Pinch off heater lines under the hood.

(8) Remove heater core cover. Insert a small

amount of towels under the heater core tubes.

Remove heater core plate and tubes (Fig. 50).

(9) Depress heater core retaining clips (Fig. 51).

(10) Pull up on accelerator pedal and slide heater

core past (Fig. 52).(11) Depress brake pedal (Fig. 53) and remove

heater core from HVAC housing.

Fig. 46 HVAC Bolt-Up

Fig. 47 ABS MODULE

Fig. 48 Interconnect And Bracket

Fig. 49 Lower Silencer Boot

24 - 30 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1847 of 1938

INSTALLATION

For installation, reverse the above procedures.

Install screws to retain heater core in housing.

Replace heater core tube inlet O-rings. Tightenheater core tube retaining plate to 361 N´m (276

9 in. lbs.) torque.

HEATER HOSES

REMOVAL

NOTE: Review Safety Precautions and Warnings

before proceeding with this operation.

(1) Drain engine cooling system. Refer to Group 7,

Engine Cooling.

(2) Loosen clamps at each end of heater hose to be

removed (Fig. 54) and (Fig. 55).

Fig. 50 Heater Core Plate And Tubes

Fig. 51 Depress Clips

Fig. 52 Accelerator Pedal

Fig. 53 Brake Pedal

Fig. 54 Upper Heater Hose

NSHEATING AND AIR CONDITIONING 24 - 31

REMOVAL AND INSTALLATION (Continued)

Page 1848 of 1938

CAUTION: When removing hoses from heater core

inlet or outlet nipples, do not use excessive force.

Heater core may become damaged and leak engine

coolant.

(3) Carefully rotate hose back and forth while tug-

ging slightly away from connector nipple. If the hose

will not come off, slice the hose at the connector nip-

ple and peel off heater hose. This method will require

heater hose replacement.

INSTALLATION

For installation, reverse the above procedures.

LIQUID LINE

REMOVAL

(1) Disconnect the battery negative cable.

(2) Recover A/C system refrigerant.

(3) Remove the accessory drive belt.

(4) Remove upper generator bracket.

(5) Remove ground wire at dash panel.

(6) Remove the nut retaining the refrigerant line

sealing plate to the expansion valve (Fig. 39).

(7) Remove the stud from the expansion valve (Fig.

40).

(8) Remove liquid line from expansion valve.

(9) Cover the openings to prevent contamination.

(10) Disconnect wire connector at pressure trans-

ducer.

(11) Remove liquid line mounting bracket at right

frame rail.

(12) Using access slot between radiator crossmem-

ber and grille, loosen liquid line mounting plate at

filter-drier. Remove liquid line from filter-drier. It

may be necessary to bend liquid line in half to

remove line. The replacement line is a two-piece

assembly.

(13) Remove the old O-rings.

INSTALLATION

For installation, reverse the above procedures.

²Install the stud to the evaporator sealing plate

and tighten 7 to 11 N´m (64 to 96 in. lbs.) torque.

²Install new O-rings.

²Install two-piece line in place of original part.

²A

ssemble line halves after it is installed on vehicle.²Evacuate and recharge A/C system.

MODE DOOR ACTUATOR

REMOVAL

(1) Remove the lower left side steering column

cover. Refer to Group 8E, Instrument Panel and Sys-

tems.

(2) Remove ABS control module (Fig. 56).

(3) Remove mode actuator connector (Fig. 57).

(4) Remove mode door actuator (Fig. 58).

INSTALLATION

(1) For installation, reverse the above procedures.

Fig. 55 Lower Heater Hose

Fig. 56 ABS Control Module

Fig. 57 Mode Door Actuator Connector

24 - 32 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1850 of 1938

²Install two-piece line in place of original part.

²Assemble line halves after it is installed on vehi-

cle.

²Evacuate and recharge A/C system.

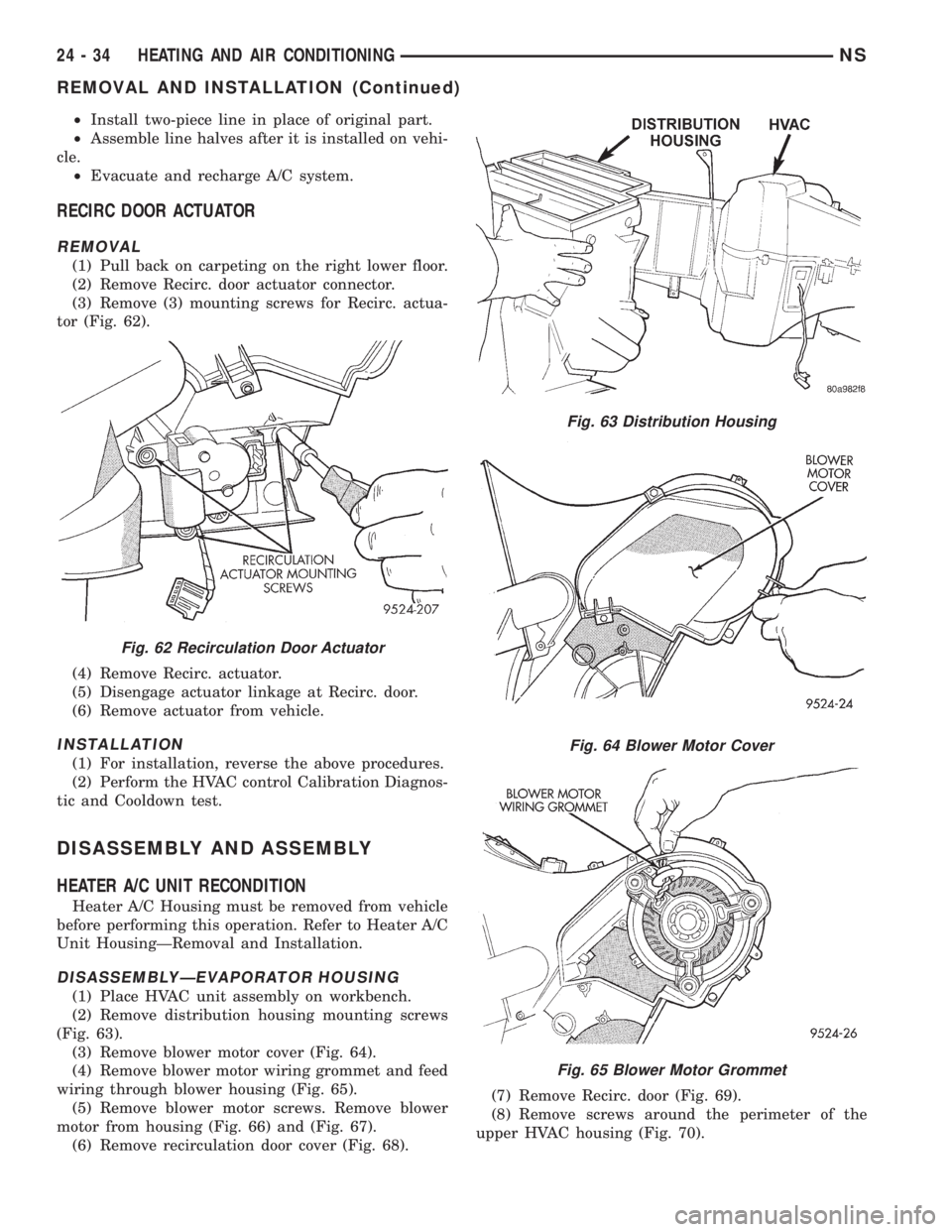

RECIRC DOOR ACTUATOR

REMOVAL

(1) Pull back on carpeting on the right lower floor.

(2) Remove Recirc. door actuator connector.

(3) Remove (3) mounting screws for Recirc. actua-

tor (Fig. 62).

(4) Remove Recirc. actuator.

(5) Disengage actuator linkage at Recirc. door.

(6) Remove actuator from vehicle.

INSTALLATION

(1) For installation, reverse the above procedures.

(2) Perform the HVAC control Calibration Diagnos-

tic and Cooldown test.

DISASSEMBLY AND ASSEMBLY

HEATER A/C UNIT RECONDITION

Heater A/C Housing must be removed from vehicle

before performing this operation. Refer to Heater A/C

Unit HousingÐRemoval and Installation.

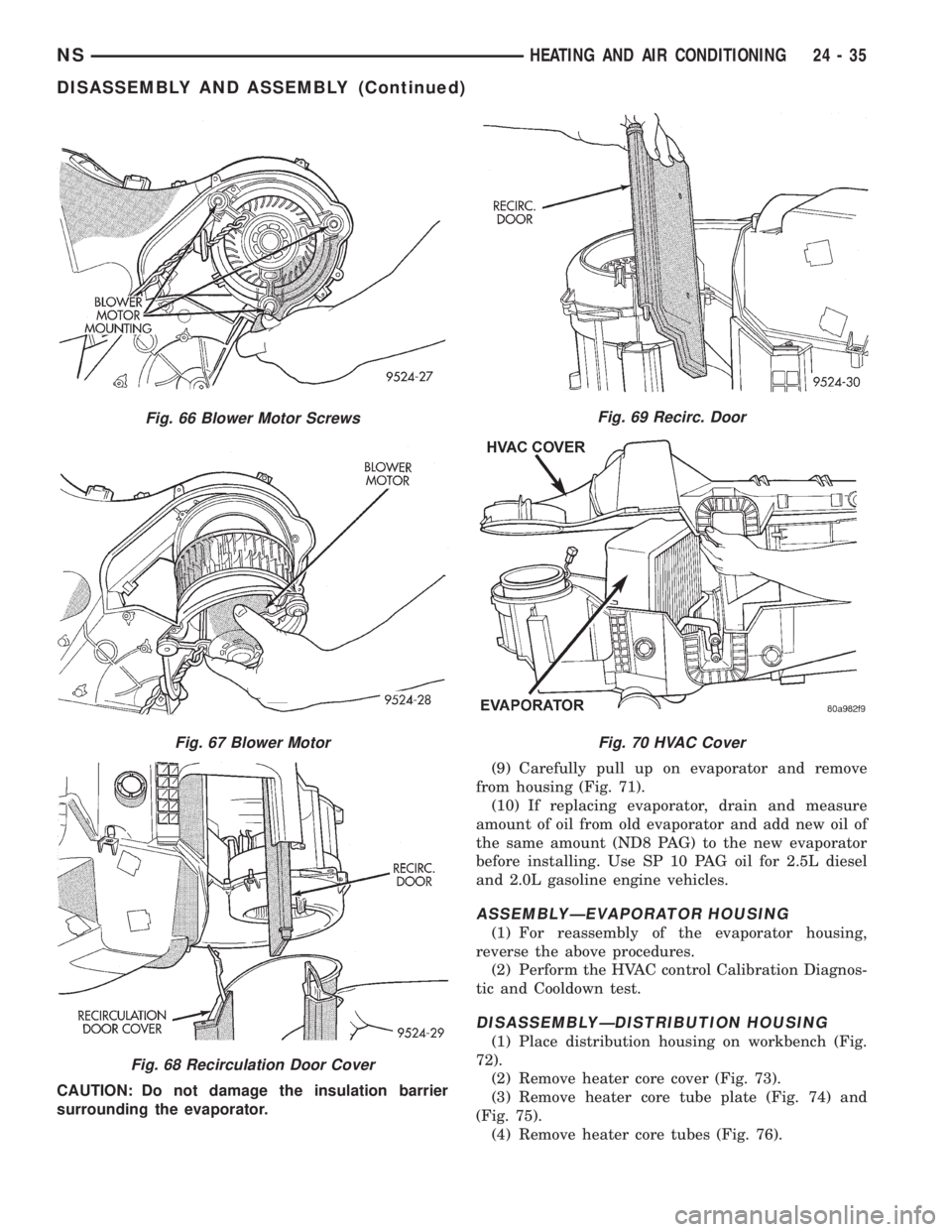

DISASSEMBLYÐEVAPORATOR HOUSING

(1) Place HVAC unit assembly on workbench.

(2) Remove distribution housing mounting screws

(Fig. 63).

(3) Remove blower motor cover (Fig. 64).

(4) Remove blower motor wiring grommet and feed

wiring through blower housing (Fig. 65).

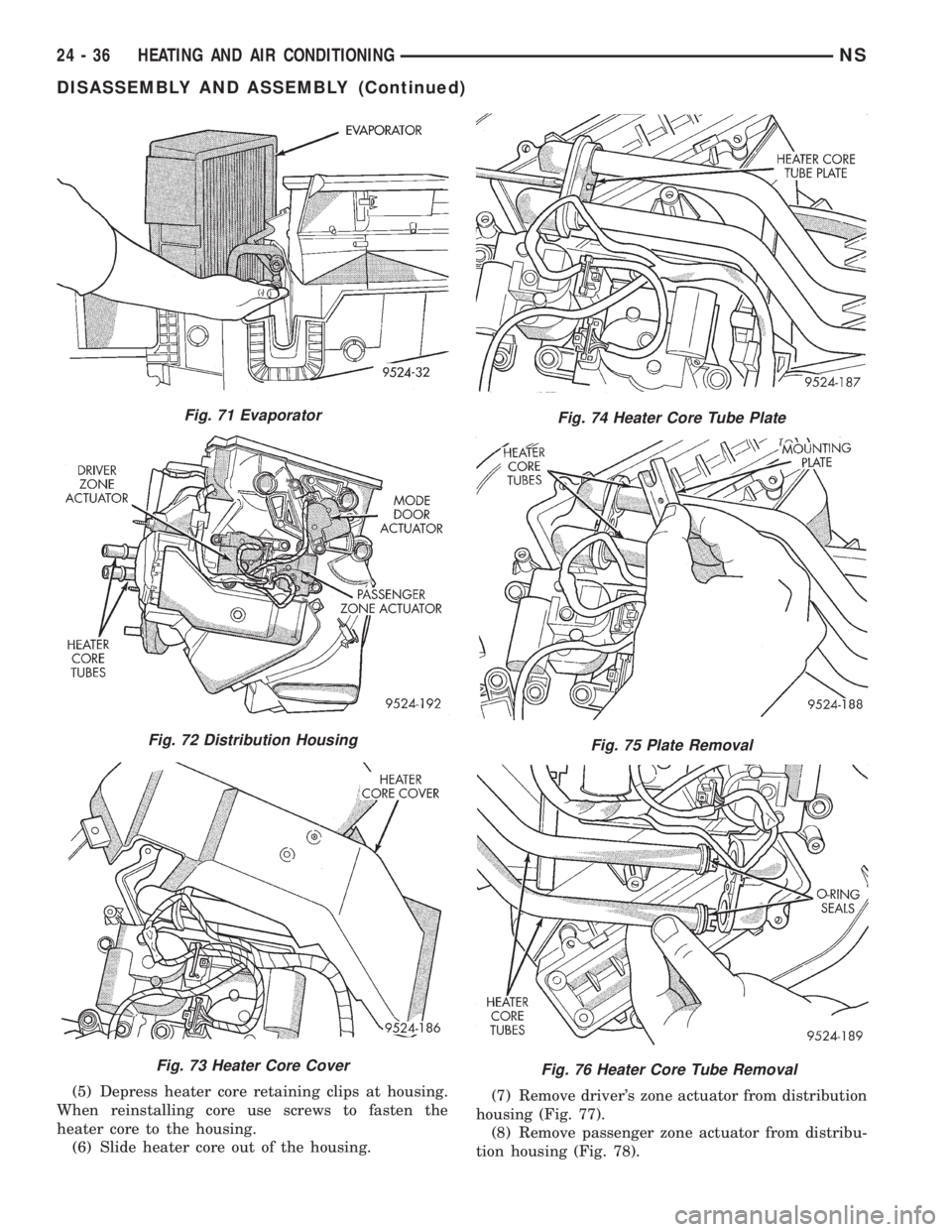

(5) Remove blower motor screws. Remove blower

motor from housing (Fig. 66) and (Fig. 67).

(6) Remove recirculation door cover (Fig. 68).(7) Remove Recirc. door (Fig. 69).

(8) Remove screws around the perimeter of the

upper HVAC housing (Fig. 70).

Fig. 62 Recirculation Door Actuator

Fig. 63 Distribution Housing

Fig. 64 Blower Motor Cover

Fig. 65 Blower Motor Grommet

24 - 34 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1851 of 1938

CAUTION: Do not damage the insulation barrier

surrounding the evaporator.(9) Carefully pull up on evaporator and remove

from housing (Fig. 71).

(10) If replacing evaporator, drain and measure

amount of oil from old evaporator and add new oil of

the same amount (ND8 PAG) to the new evaporator

before installing. Use SP 10 PAG oil for 2.5L diesel

and 2.0L gasoline engine vehicles.

ASSEMBLYÐEVAPORATOR HOUSING

(1) For reassembly of the evaporator housing,

reverse the above procedures.

(2) Perform the HVAC control Calibration Diagnos-

tic and Cooldown test.

DISASSEMBLYÐDISTRIBUTION HOUSING

(1) Place distribution housing on workbench (Fig.

72).

(2) Remove heater core cover (Fig. 73).

(3) Remove heater core tube plate (Fig. 74) and

(Fig. 75).

(4) Remove heater core tubes (Fig. 76).

Fig. 66 Blower Motor Screws

Fig. 67 Blower Motor

Fig. 68 Recirculation Door Cover

Fig. 69 Recirc. Door

Fig. 70 HVAC Cover

NSHEATING AND AIR CONDITIONING 24 - 35

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1852 of 1938

(5) Depress heater core retaining clips at housing.

When reinstalling core use screws to fasten the

heater core to the housing.

(6) Slide heater core out of the housing.(7) Remove driver's zone actuator from distribution

housing (Fig. 77).

(8) Remove passenger zone actuator from distribu-

tion housing (Fig. 78).

Fig. 71 Evaporator

Fig. 72 Distribution Housing

Fig. 73 Heater Core Cover

Fig. 74 Heater Core Tube Plate

Fig. 75 Plate Removal

Fig. 76 Heater Core Tube Removal

24 - 36 HEATING AND AIR CONDITIONINGNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1857 of 1938

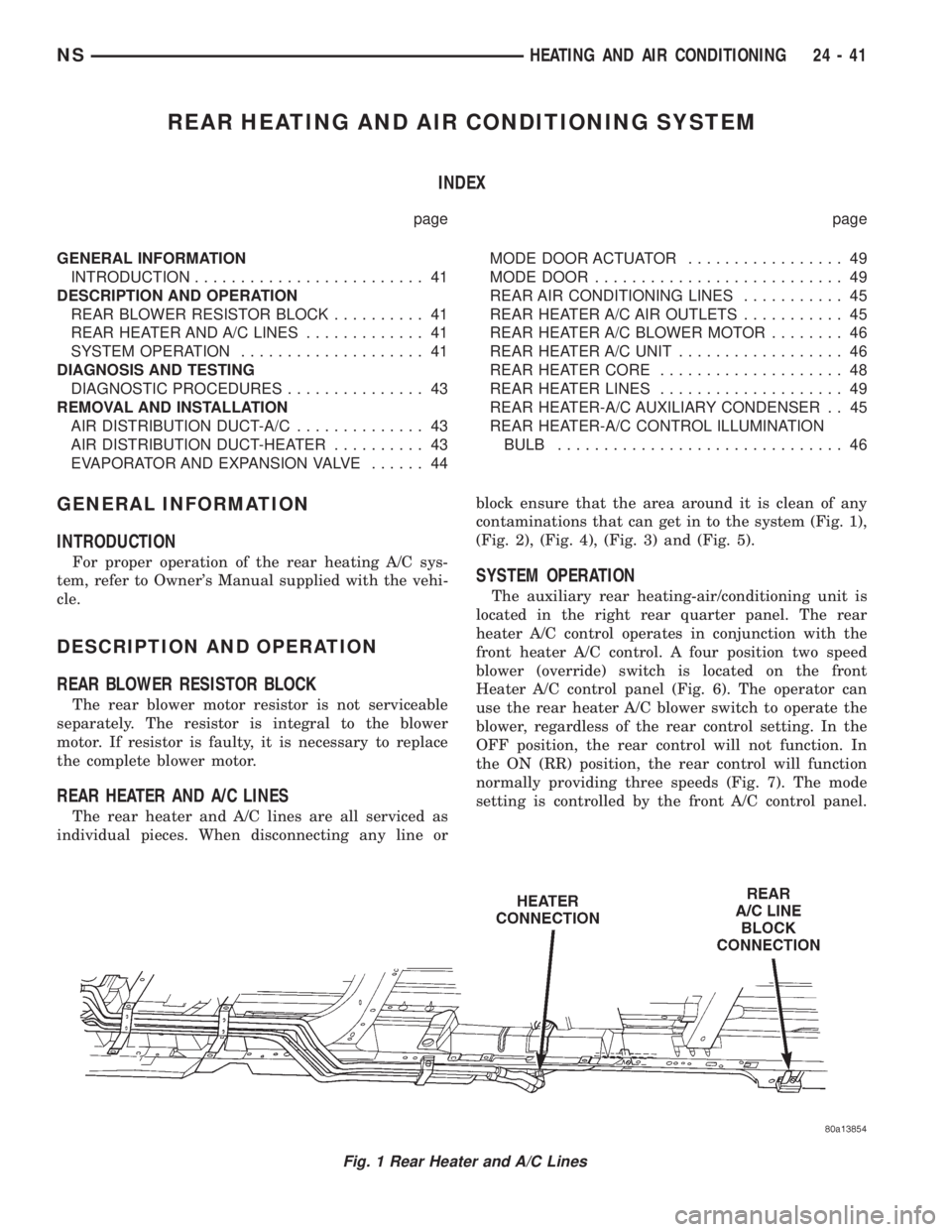

REAR HEATING AND AIR CONDITIONING SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 41

DESCRIPTION AND OPERATION

REAR BLOWER RESISTOR BLOCK.......... 41

REAR HEATER AND A/C LINES............. 41

SYSTEM OPERATION.................... 41

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES............... 43

REMOVAL AND INSTALLATION

AIR DISTRIBUTION DUCT-A/C.............. 43

AIR DISTRIBUTION DUCT-HEATER.......... 43

EVAPORATOR AND EXPANSION VALVE...... 44MODE DOOR ACTUATOR................. 49

MODE DOOR........................... 49

REAR AIR CONDITIONING LINES........... 45

REAR HEATER A/C AIR OUTLETS........... 45

REAR HEATER A/C BLOWER MOTOR........ 46

REAR HEATER A/C UNIT.................. 46

REAR HEATER CORE.................... 48

REAR HEATER LINES.................... 49

REAR HEATER-A/C AUXILIARY CONDENSER . . 45

REAR HEATER-A/C CONTROL ILLUMINATION

BULB............................... 46

GENERAL INFORMATION

INTRODUCTION

For proper operation of the rear heating A/C sys-

tem, refer to Owner's Manual supplied with the vehi-

cle.

DESCRIPTION AND OPERATION

REAR BLOWER RESISTOR BLOCK

The rear blower motor resistor is not serviceable

separately. The resistor is integral to the blower

motor. If resistor is faulty, it is necessary to replace

the complete blower motor.

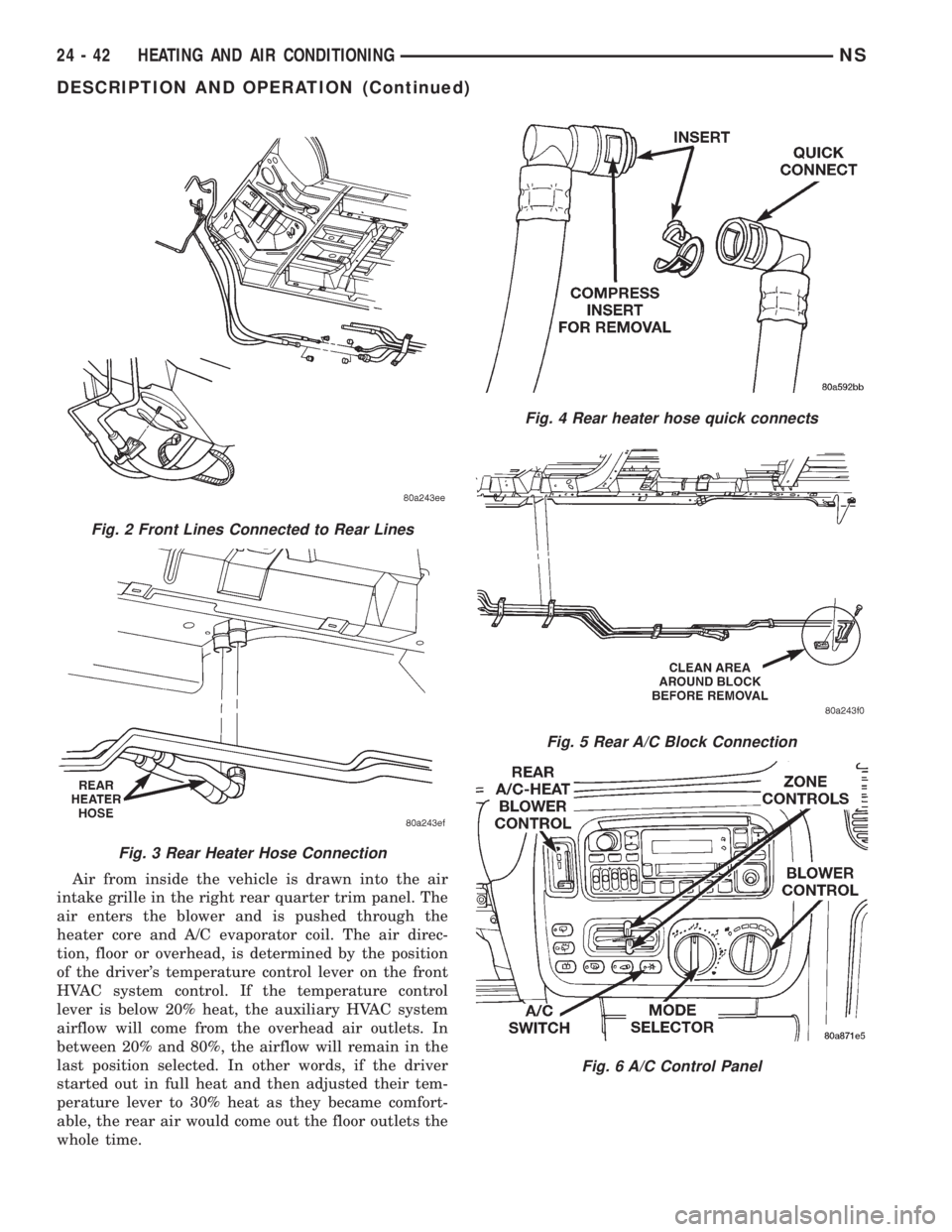

REAR HEATER AND A/C LINES

The rear heater and A/C lines are all serviced as

individual pieces. When disconnecting any line orblock ensure that the area around it is clean of any

contaminations that can get in to the system (Fig. 1),

(Fig. 2), (Fig. 4), (Fig. 3) and (Fig. 5).

SYSTEM OPERATION

The auxiliary rear heating-air/conditioning unit is

located in the right rear quarter panel. The rear

heater A/C control operates in conjunction with the

front heater A/C control. A four position two speed

blower (override) switch is located on the front

Heater A/C control panel (Fig. 6). The operator can

use the rear heater A/C blower switch to operate the

blower, regardless of the rear control setting. In the

OFF position, the rear control will not function. In

the ON (RR) position, the rear control will function

normally providing three speeds (Fig. 7). The mode

setting is controlled by the front A/C control panel.

Fig. 1 Rear Heater and A/C Lines

NSHEATING AND AIR CONDITIONING 24 - 41

Page 1858 of 1938

Air from inside the vehicle is drawn into the air

intake grille in the right rear quarter trim panel. The

air enters the blower and is pushed through the

heater core and A/C evaporator coil. The air direc-

tion, floor or overhead, is determined by the position

of the driver's temperature control lever on the front

HVAC system control. If the temperature control

lever is below 20% heat, the auxiliary HVAC system

airflow will come from the overhead air outlets. In

between 20% and 80%, the airflow will remain in the

last position selected. In other words, if the driver

started out in full heat and then adjusted their tem-

perature lever to 30% heat as they became comfort-

able, the rear air would come out the floor outlets the

whole time.

Fig. 2 Front Lines Connected to Rear Lines

Fig. 3 Rear Heater Hose Connection

Fig. 4 Rear heater hose quick connects

Fig. 5 Rear A/C Block Connection

Fig. 6 A/C Control Panel

24 - 42 HEATING AND AIR CONDITIONINGNS

DESCRIPTION AND OPERATION (Continued)