heater CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1872 of 1938

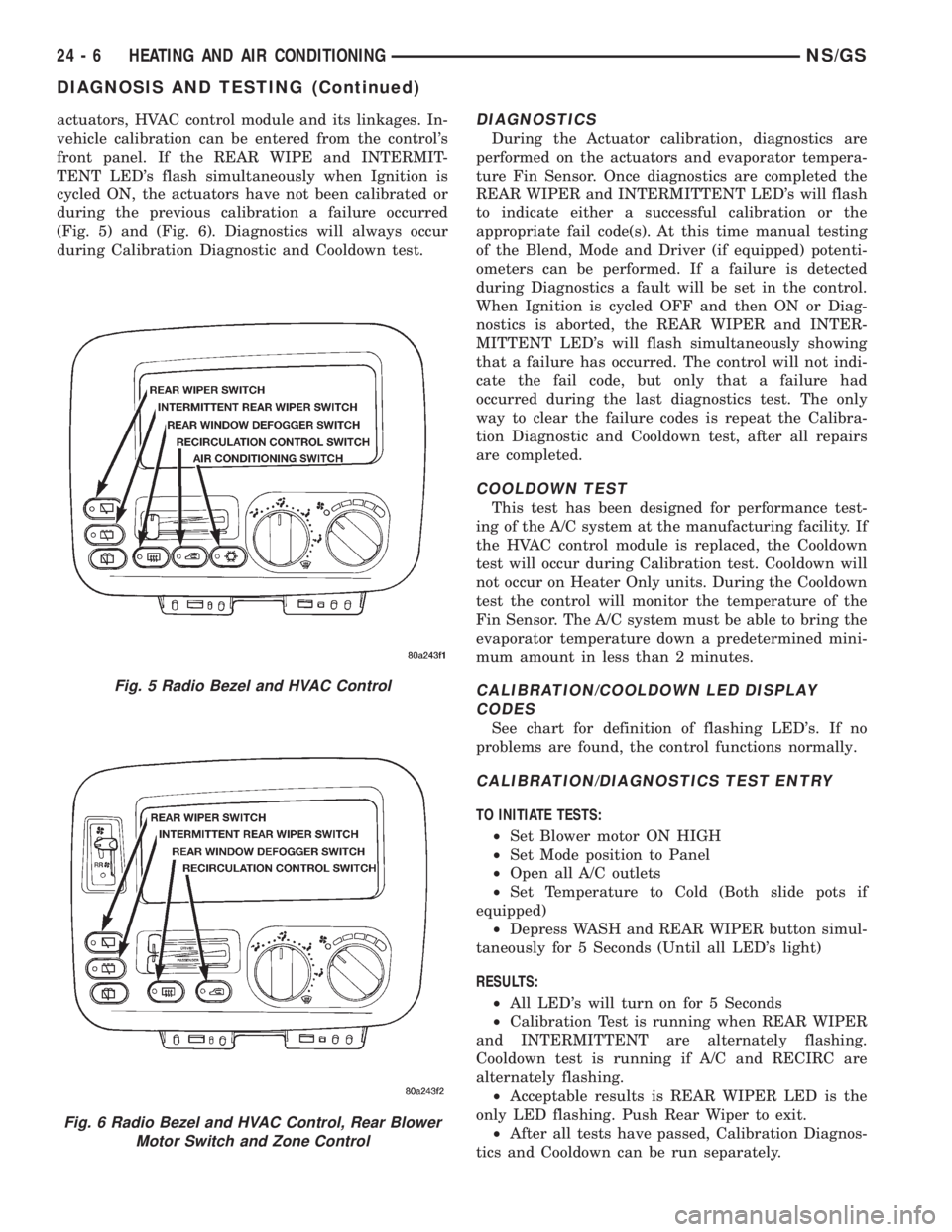

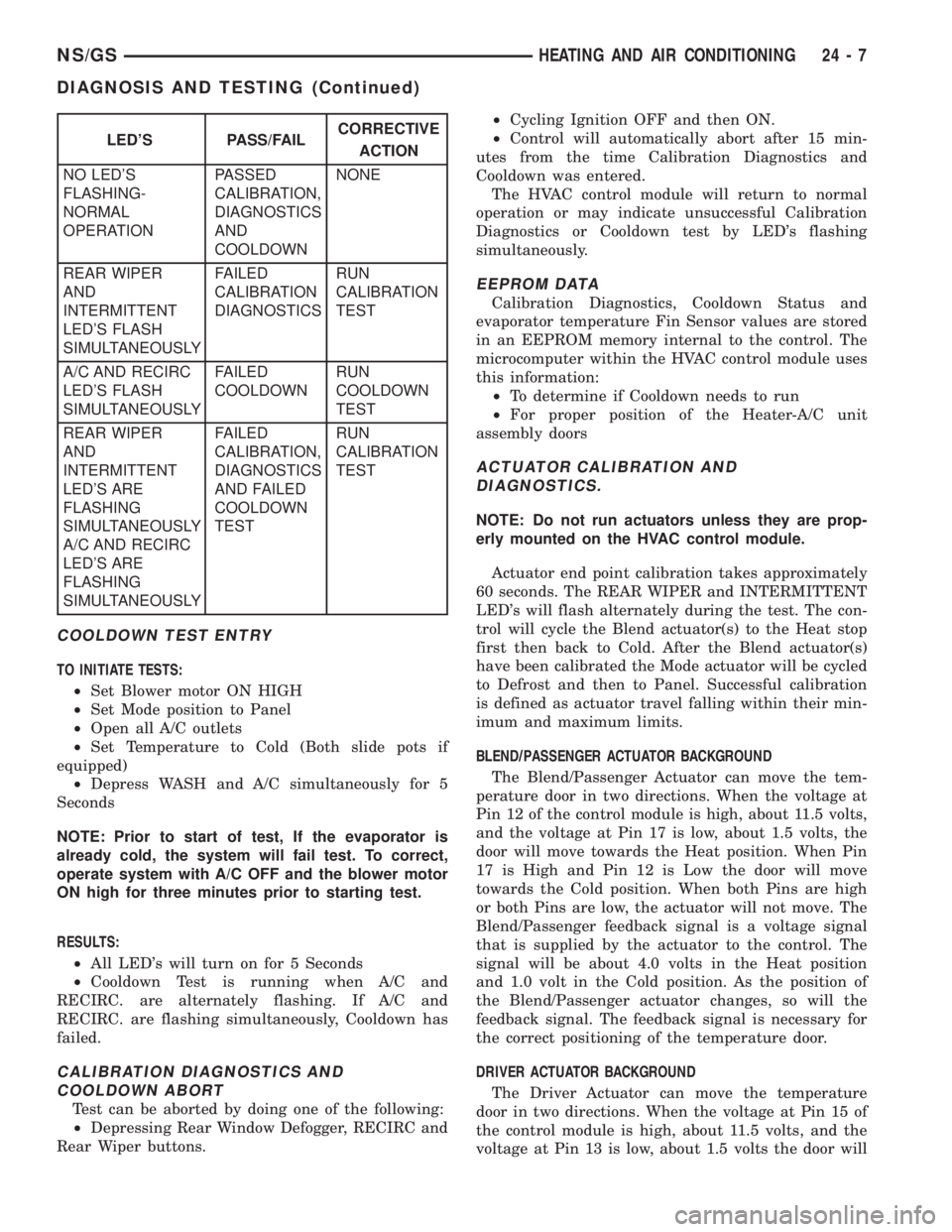

actuators, HVAC control module and its linkages. In-

vehicle calibration can be entered from the control's

front panel. If the REAR WIPE and INTERMIT-

TENT LED's flash simultaneously when Ignition is

cycled ON, the actuators have not been calibrated or

during the previous calibration a failure occurred

(Fig. 5) and (Fig. 6). Diagnostics will always occur

during Calibration Diagnostic and Cooldown test.DIAGNOSTICS

During the Actuator calibration, diagnostics are

performed on the actuators and evaporator tempera-

ture Fin Sensor. Once diagnostics are completed the

REAR WIPER and INTERMITTENT LED's will flash

to indicate either a successful calibration or the

appropriate fail code(s). At this time manual testing

of the Blend, Mode and Driver (if equipped) potenti-

ometers can be performed. If a failure is detected

during Diagnostics a fault will be set in the control.

When Ignition is cycled OFF and then ON or Diag-

nostics is aborted, the REAR WIPER and INTER-

MITTENT LED's will flash simultaneously showing

that a failure has occurred. The control will not indi-

cate the fail code, but only that a failure had

occurred during the last diagnostics test. The only

way to clear the failure codes is repeat the Calibra-

tion Diagnostic and Cooldown test, after all repairs

are completed.

COOLDOWN TEST

This test has been designed for performance test-

ing of the A/C system at the manufacturing facility. If

the HVAC control module is replaced, the Cooldown

test will occur during Calibration test. Cooldown will

not occur on Heater Only units. During the Cooldown

test the control will monitor the temperature of the

Fin Sensor. The A/C system must be able to bring the

evaporator temperature down a predetermined mini-

mum amount in less than 2 minutes.

CALIBRATION/COOLDOWN LED DISPLAY

CODES

See chart for definition of flashing LED's. If no

problems are found, the control functions normally.

CALIBRATION/DIAGNOSTICS TEST ENTRY

TO INITIATE TESTS:

²Set Blower motor ON HIGH

²Set Mode position to Panel

²Open all A/C outlets

²Set Temperature to Cold (Both slide pots if

equipped)

²Depress WASH and REAR WIPER button simul-

taneously for 5 Seconds (Until all LED's light)

RESULTS:

²All LED's will turn on for 5 Seconds

²Calibration Test is running when REAR WIPER

and INTERMITTENT are alternately flashing.

Cooldown test is running if A/C and RECIRC are

alternately flashing.

²Acceptable results is REAR WIPER LED is the

only LED flashing. Push Rear Wiper to exit.

²After all tests have passed, Calibration Diagnos-

tics and Cooldown can be run separately.

Fig. 5 Radio Bezel and HVAC Control

Fig. 6 Radio Bezel and HVAC Control, Rear Blower

Motor Switch and Zone Control

24 - 6 HEATING AND AIR CONDITIONINGNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1873 of 1938

COOLDOWN TEST ENTRY

TO INITIATE TESTS:

²Set Blower motor ON HIGH

²Set Mode position to Panel

²Open all A/C outlets

²Set Temperature to Cold (Both slide pots if

equipped)

²Depress WASH and A/C simultaneously for 5

Seconds

NOTE: Prior to start of test, If the evaporator is

already cold, the system will fail test. To correct,

operate system with A/C OFF and the blower motor

ON high for three minutes prior to starting test.

RESULTS:

²All LED's will turn on for 5 Seconds

²Cooldown Test is running when A/C and

RECIRC. are alternately flashing. If A/C and

RECIRC. are flashing simultaneously, Cooldown has

failed.

CALIBRATION DIAGNOSTICS AND

COOLDOWN ABORT

Test can be aborted by doing one of the following:

²Depressing Rear Window Defogger, RECIRC and

Rear Wiper buttons.²Cycling Ignition OFF and then ON.

²Control will automatically abort after 15 min-

utes from the time Calibration Diagnostics and

Cooldown was entered.

The HVAC control module will return to normal

operation or may indicate unsuccessful Calibration

Diagnostics or Cooldown test by LED's flashing

simultaneously.

EEPROM DATA

Calibration Diagnostics, Cooldown Status and

evaporator temperature Fin Sensor values are stored

in an EEPROM memory internal to the control. The

microcomputer within the HVAC control module uses

this information:

²To determine if Cooldown needs to run

²For proper position of the Heater-A/C unit

assembly doors

ACTUATOR CALIBRATION AND

DIAGNOSTICS.

NOTE: Do not run actuators unless they are prop-

erly mounted on the HVAC control module.

Actuator end point calibration takes approximately

60 seconds. The REAR WIPER and INTERMITTENT

LED's will flash alternately during the test. The con-

trol will cycle the Blend actuator(s) to the Heat stop

first then back to Cold. After the Blend actuator(s)

have been calibrated the Mode actuator will be cycled

to Defrost and then to Panel. Successful calibration

is defined as actuator travel falling within their min-

imum and maximum limits.

BLEND/PASSENGER ACTUATOR BACKGROUND

The Blend/Passenger Actuator can move the tem-

perature door in two directions. When the voltage at

Pin 12 of the control module is high, about 11.5 volts,

and the voltage at Pin 17 is low, about 1.5 volts, the

door will move towards the Heat position. When Pin

17 is High and Pin 12 is Low the door will move

towards the Cold position. When both Pins are high

or both Pins are low, the actuator will not move. The

Blend/Passenger feedback signal is a voltage signal

that is supplied by the actuator to the control. The

signal will be about 4.0 volts in the Heat position

and 1.0 volt in the Cold position. As the position of

the Blend/Passenger actuator changes, so will the

feedback signal. The feedback signal is necessary for

the correct positioning of the temperature door.

DRIVER ACTUATOR BACKGROUND

The Driver Actuator can move the temperature

door in two directions. When the voltage at Pin 15 of

the control module is high, about 11.5 volts, and the

voltage at Pin 13 is low, about 1.5 volts the door will

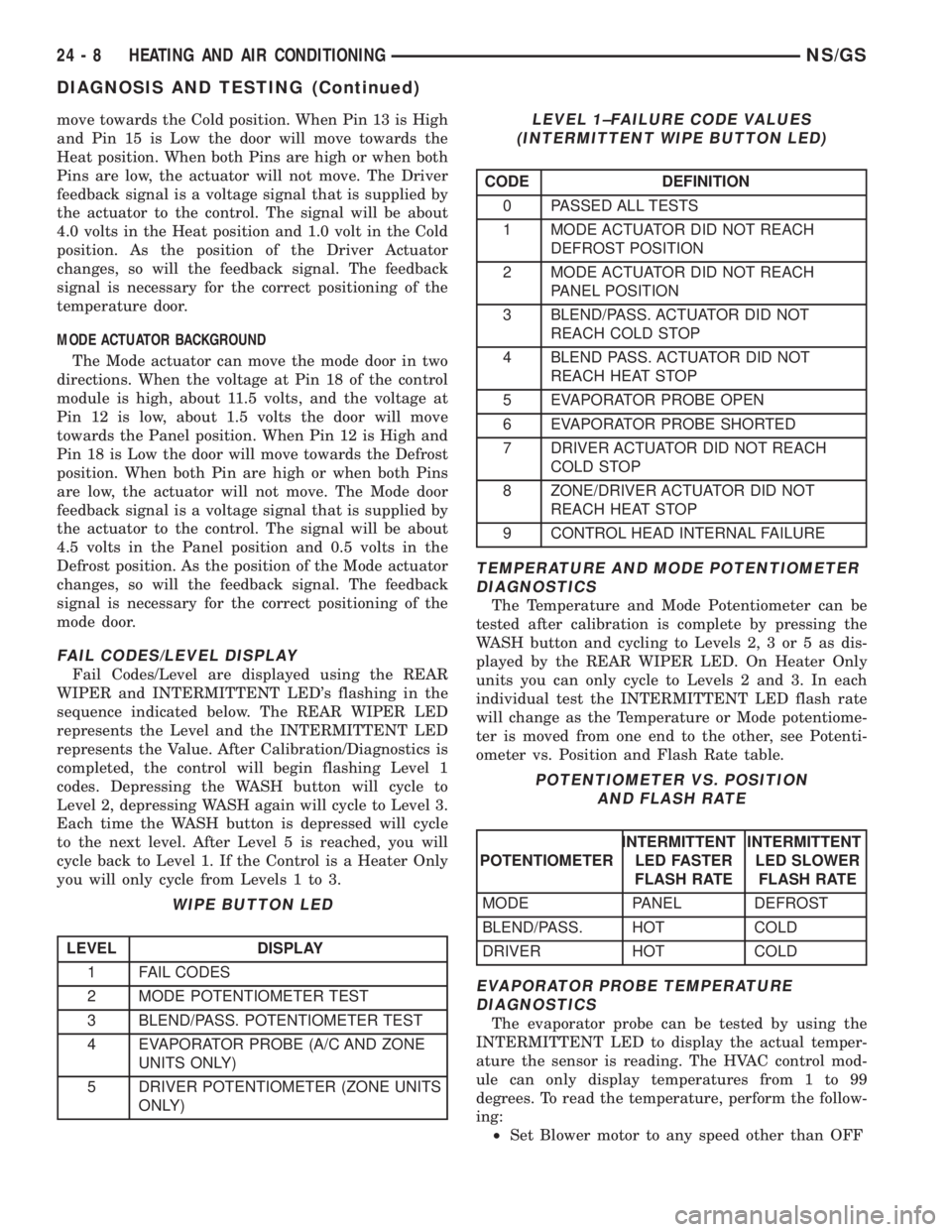

LED'S PASS/FAILCORRECTIVE

ACTION

NO LED'S

FLASHING-

NORMAL

OPERATIONPASSED

CALIBRATION,

DIAGNOSTICS

AND

COOLDOWNNONE

REAR WIPER

AND

INTERMITTENT

LED'S FLASH

SIMULTANEOUSLYFAILED

CALIBRATION

DIAGNOSTICSRUN

CALIBRATION

TEST

A/C AND RECIRC

LED'S FLASH

SIMULTANEOUSLYFAILED

COOLDOWNRUN

COOLDOWN

TEST

REAR WIPER

AND

INTERMITTENT

LED'S ARE

FLASHING

SIMULTANEOUSLY

A/C AND RECIRC

LED'S ARE

FLASHING

SIMULTANEOUSLYFAILED

CALIBRATION,

DIAGNOSTICS

AND FAILED

COOLDOWN

TESTRUN

CALIBRATION

TEST

NS/GSHEATING AND AIR CONDITIONING 24 - 7

DIAGNOSIS AND TESTING (Continued)

Page 1874 of 1938

move towards the Cold position. When Pin 13 is High

and Pin 15 is Low the door will move towards the

Heat position. When both Pins are high or when both

Pins are low, the actuator will not move. The Driver

feedback signal is a voltage signal that is supplied by

the actuator to the control. The signal will be about

4.0 volts in the Heat position and 1.0 volt in the Cold

position. As the position of the Driver Actuator

changes, so will the feedback signal. The feedback

signal is necessary for the correct positioning of the

temperature door.

MODE ACTUATOR BACKGROUND

The Mode actuator can move the mode door in two

directions. When the voltage at Pin 18 of the control

module is high, about 11.5 volts, and the voltage at

Pin 12 is low, about 1.5 volts the door will move

towards the Panel position. When Pin 12 is High and

Pin 18 is Low the door will move towards the Defrost

position. When both Pin are high or when both Pins

are low, the actuator will not move. The Mode door

feedback signal is a voltage signal that is supplied by

the actuator to the control. The signal will be about

4.5 volts in the Panel position and 0.5 volts in the

Defrost position. As the position of the Mode actuator

changes, so will the feedback signal. The feedback

signal is necessary for the correct positioning of the

mode door.

FAIL CODES/LEVEL DISPLAY

Fail Codes/Level are displayed using the REAR

WIPER and INTERMITTENT LED's flashing in the

sequence indicated below. The REAR WIPER LED

represents the Level and the INTERMITTENT LED

represents the Value. After Calibration/Diagnostics is

completed, the control will begin flashing Level 1

codes. Depressing the WASH button will cycle to

Level 2, depressing WASH again will cycle to Level 3.

Each time the WASH button is depressed will cycle

to the next level. After Level 5 is reached, you will

cycle back to Level 1. If the Control is a Heater Only

you will only cycle from Levels 1 to 3.

TEMPERATURE AND MODE POTENTIOMETER

DIAGNOSTICS

The Temperature and Mode Potentiometer can be

tested after calibration is complete by pressing the

WASH button and cycling to Levels 2, 3 or 5 as dis-

played by the REAR WIPER LED. On Heater Only

units you can only cycle to Levels 2 and 3. In each

individual test the INTERMITTENT LED flash rate

will change as the Temperature or Mode potentiome-

ter is moved from one end to the other, see Potenti-

ometer vs. Position and Flash Rate table.

EVAPORATOR PROBE TEMPERATURE

DIAGNOSTICS

The evaporator probe can be tested by using the

INTERMITTENT LED to display the actual temper-

ature the sensor is reading. The HVAC control mod-

ule can only display temperatures from 1 to 99

degrees. To read the temperature, perform the follow-

ing:

²Set Blower motor to any speed other than OFF

WIPE BUTTON LED

LEVEL DISPLAY

1 FAIL CODES

2 MODE POTENTIOMETER TEST

3 BLEND/PASS. POTENTIOMETER TEST

4 EVAPORATOR PROBE (A/C AND ZONE

UNITS ONLY)

5 DRIVER POTENTIOMETER (ZONE UNITS

ONLY)

LEVEL 1±FAILURE CODE VALUES

(INTERMITTENT WIPE BUTTON LED)

CODE DEFINITION

0 PASSED ALL TESTS

1 MODE ACTUATOR DID NOT REACH

DEFROST POSITION

2 MODE ACTUATOR DID NOT REACH

PANEL POSITION

3 BLEND/PASS. ACTUATOR DID NOT

REACH COLD STOP

4 BLEND PASS. ACTUATOR DID NOT

REACH HEAT STOP

5 EVAPORATOR PROBE OPEN

6 EVAPORATOR PROBE SHORTED

7 DRIVER ACTUATOR DID NOT REACH

COLD STOP

8 ZONE/DRIVER ACTUATOR DID NOT

REACH HEAT STOP

9 CONTROL HEAD INTERNAL FAILURE

POTENTIOMETER VS. POSITION

AND FLASH RATE

POTENTIOMETERINTERMITTENT

LED FASTER

FLASH RATEINTERMITTENT

LED SLOWER

FLASH RATE

MODE PANEL DEFROST

BLEND/PASS. HOT COLD

DRIVER HOT COLD

24 - 8 HEATING AND AIR CONDITIONINGNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1877 of 1938

²No charge

²Compressor not operating

Verify that the test was done with the evaporator

at room temperature. The test consists of starting

the compressor and measuring the time it takes for

the evaporator temperature to fall 7ÉC (20ÉF). If the

compressor has been running, the evaporator is cold

already and will not be capable of falling 7ÉC (20ÉF).

If the test was run with a cold evaporator, turn A/C

off and turn the blower motor switch to high position

for 3 to 5 minutes till the evaporator is to room tem-

perature. Then repeat the Calibration Diagnostic and

Cooldown test.

If refrigerant system is performing properly and

the system will not pass test. Repeat the Calibration

Diagnostic and Cooldown test to determine if the

evaporator temperature FIN sensor has developed an

open or a short circuit. If the HVAC control module

still passes Calibration test, verify Cooldown test

manually with a pocket thermometer. The outlet air

temperature must drop at least 7ÉC (20ÉF) within

two minutes. If the vehicle passes with the manual

thermometer, take HVAC control to level 4 (evapora-

tor probe temperature readout) and repeat the

Cooldown test. Ensure the evaporator is at room tem-

perature before starting test. Check if evaporator

probe will drop the temperature 7ÉC (20ÉF) in two

minutes. If the Evaporator Probe is found to be

faulty, check that the sensor is positioned in the

evaporator fins properly. If not, correct and repeat

test. If OK, replace the evaporator probe.

Once the repairs are completed, repeat the Calibra-

tion Diagnostic and Cooldown test. Repeating the

test is necessary to clear the fault codes.

A/C PERFORMANCE TEST

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

heater A/C unit, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to RECIRC, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, A/C performance levels rise.

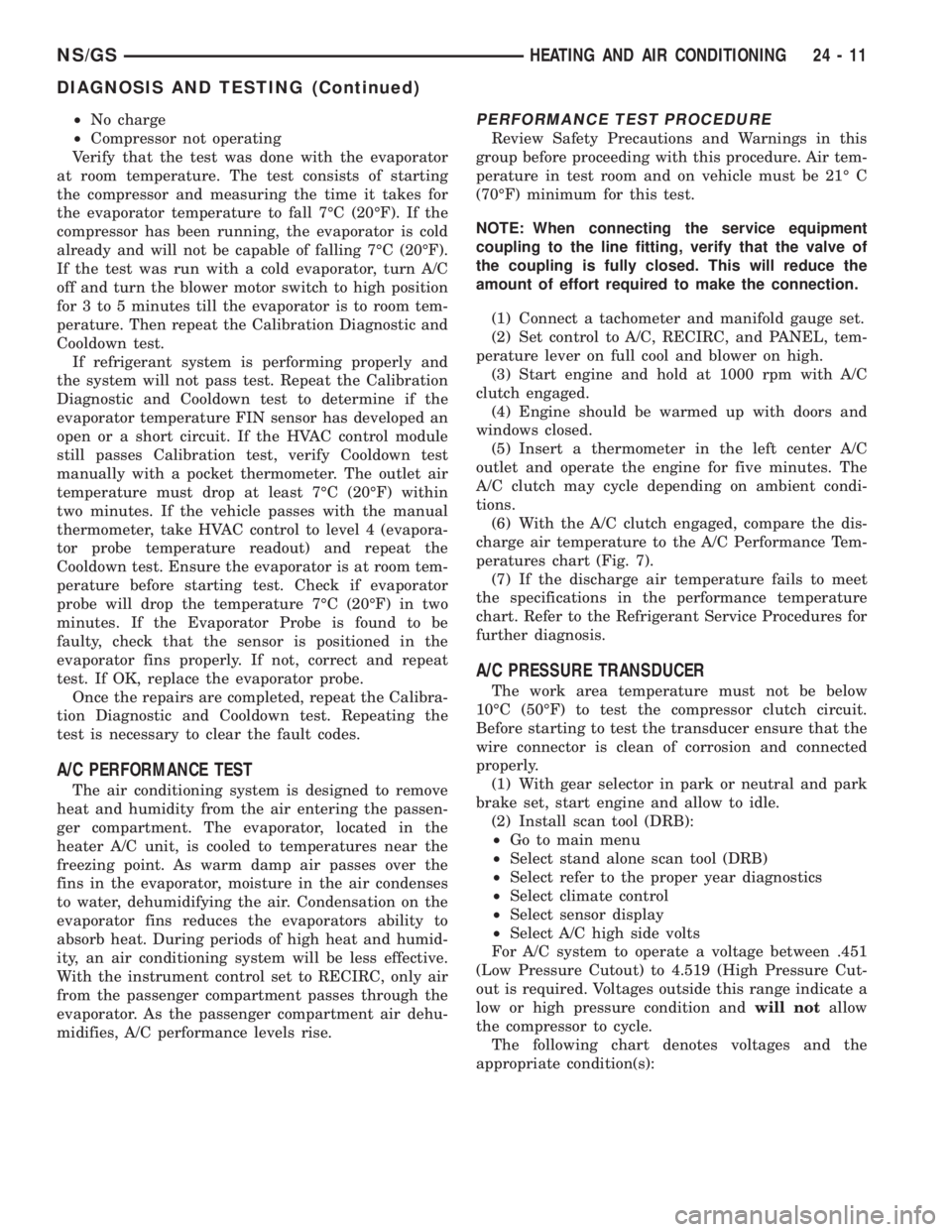

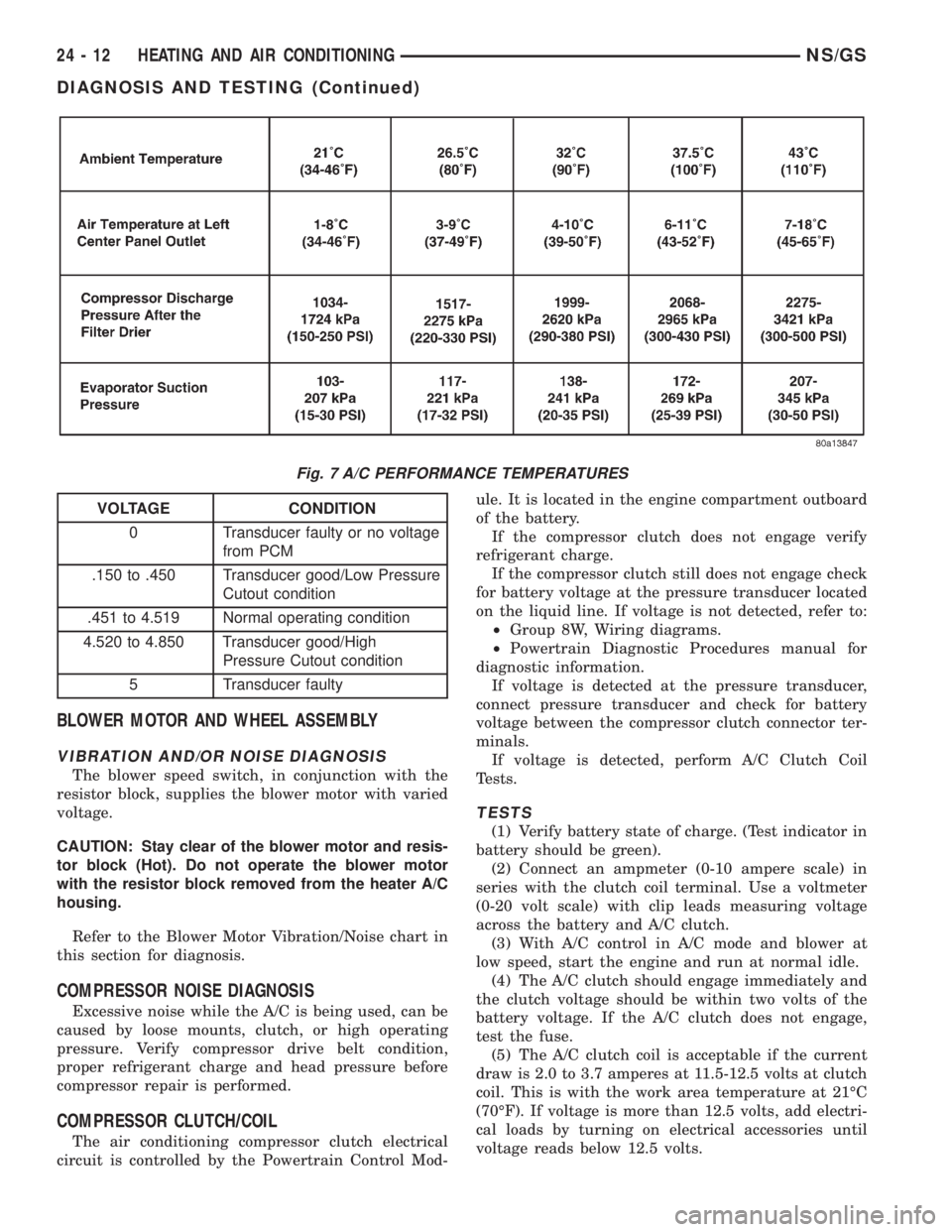

PERFORMANCE TEST PROCEDURE

Review Safety Precautions and Warnings in this

group before proceeding with this procedure. Air tem-

perature in test room and on vehicle must be 21É C

(70ÉF) minimum for this test.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer and manifold gauge set.

(2) Set control to A/C, RECIRC, and PANEL, tem-

perature lever on full cool and blower on high.

(3) Start engine and hold at 1000 rpm with A/C

clutch engaged.

(4) Engine should be warmed up with doors and

windows closed.

(5) Insert a thermometer in the left center A/C

outlet and operate the engine for five minutes. The

A/C clutch may cycle depending on ambient condi-

tions.

(6) With the A/C clutch engaged, compare the dis-

charge air temperature to the A/C Performance Tem-

peratures chart (Fig. 7).

(7) If the discharge air temperature fails to meet

the specifications in the performance temperature

chart. Refer to the Refrigerant Service Procedures for

further diagnosis.

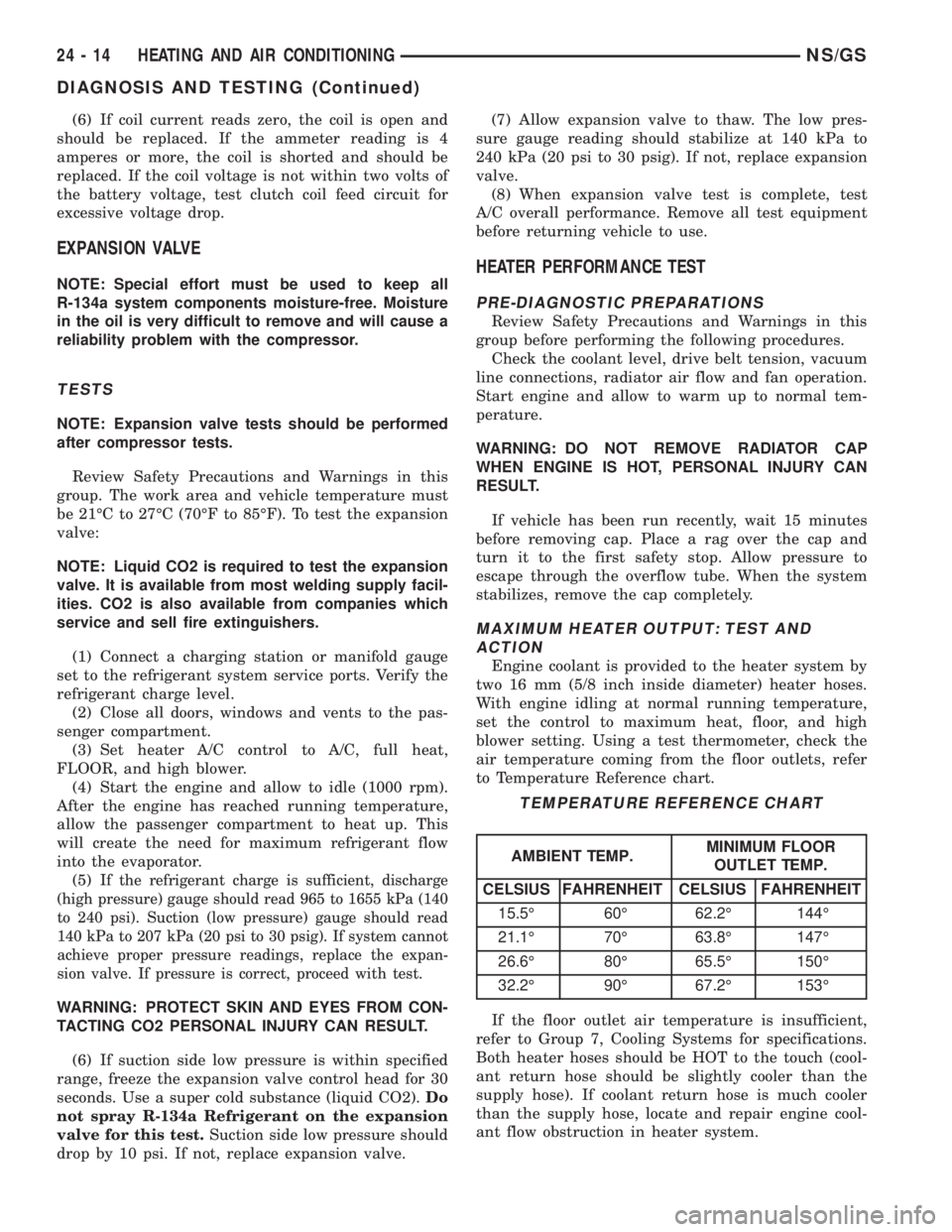

A/C PRESSURE TRANSDUCER

The work area temperature must not be below

10ÉC (50ÉF) to test the compressor clutch circuit.

Before starting to test the transducer ensure that the

wire connector is clean of corrosion and connected

properly.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Install scan tool (DRB):

²Go to main menu

²Select stand alone scan tool (DRB)

²Select refer to the proper year diagnostics

²Select climate control

²Select sensor display

²Select A/C high side volts

For A/C system to operate a voltage between .451

(Low Pressure Cutout) to 4.519 (High Pressure Cut-

out is required. Voltages outside this range indicate a

low or high pressure condition andwill notallow

the compressor to cycle.

The following chart denotes voltages and the

appropriate condition(s):

NS/GSHEATING AND AIR CONDITIONING 24 - 11

DIAGNOSIS AND TESTING (Continued)

Page 1878 of 1938

BLOWER MOTOR AND WHEEL ASSEMBLY

VIBRATION AND/OR NOISE DIAGNOSIS

The blower speed switch, in conjunction with the

resistor block, supplies the blower motor with varied

voltage.

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater A/C

housing.

Refer to the Blower Motor Vibration/Noise chart in

this section for diagnosis.

COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the A/C is being used, can be

caused by loose mounts, clutch, or high operating

pressure. Verify compressor drive belt condition,

proper refrigerant charge and head pressure before

compressor repair is performed.

COMPRESSOR CLUTCH/COIL

The air conditioning compressor clutch electrical

circuit is controlled by the Powertrain Control Mod-ule. It is located in the engine compartment outboard

of the battery.

If the compressor clutch does not engage verify

refrigerant charge.

If the compressor clutch still does not engage check

for battery voltage at the pressure transducer located

on the liquid line. If voltage is not detected, refer to:

²Group 8W, Wiring diagrams.

²Powertrain Diagnostic Procedures manual for

diagnostic information.

If voltage is detected at the pressure transducer,

connect pressure transducer and check for battery

voltage between the compressor clutch connector ter-

minals.

If voltage is detected, perform A/C Clutch Coil

Tests.

TESTS

(1) Verify battery state of charge. (Test indicator in

battery should be green).

(2) Connect an ampmeter (0-10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch.

(3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle.

(4) The A/C clutch should engage immediately and

the clutch voltage should be within two volts of the

battery voltage. If the A/C clutch does not engage,

test the fuse.

(5) The A/C clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5-12.5 volts at clutch

coil. This is with the work area temperature at 21ÉC

(70ÉF). If voltage is more than 12.5 volts, add electri-

cal loads by turning on electrical accessories until

voltage reads below 12.5 volts.

Fig. 7 A/C PERFORMANCE TEMPERATURES

VOLTAGE CONDITION

0 Transducer faulty or no voltage

from PCM

.150 to .450 Transducer good/Low Pressure

Cutout condition

.451 to 4.519 Normal operating condition

4.520 to 4.850 Transducer good/High

Pressure Cutout condition

5 Transducer faulty

24 - 12 HEATING AND AIR CONDITIONINGNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1880 of 1938

(6) If coil current reads zero, the coil is open and

should be replaced. If the ammeter reading is 4

amperes or more, the coil is shorted and should be

replaced. If the coil voltage is not within two volts of

the battery voltage, test clutch coil feed circuit for

excessive voltage drop.

EXPANSION VALVE

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

TESTS

NOTE: Expansion valve tests should be performed

after compressor tests.

Review Safety Precautions and Warnings in this

group. The work area and vehicle temperature must

be 21ÉC to 27ÉC (70ÉF to 85ÉF). To test the expansion

valve:

NOTE: Liquid CO2 is required to test the expansion

valve. It is available from most welding supply facil-

ities. CO2 is also available from companies which

service and sell fire extinguishers.

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set heater A/C control to A/C, full heat,

FLOOR, and high blower.

(4) Start the engine and allow to idle (1000 rpm).

After the engine has reached running temperature,

allow the passenger compartment to heat up. This

will create the need for maximum refrigerant flow

into the evaporator.

(5) I

f the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 1655 kPa (140

to 240 psi). Suction (low pressure) gauge should read

140 kPa to 207 kPa (20 psi to 30 psig). If system cannot

achieve proper pressure readings, replace the expan-

sion valve. If pressure is correct, proceed with test.

WARNING: PROTECT SKIN AND EYES FROM CON-

TACTING CO2 PERSONAL INJURY CAN RESULT.

(6) If suction side low pressure is within specified

range, freeze the expansion valve control head for 30

seconds. Use a super cold substance (liquid CO2).Do

not spray R-134a Refrigerant on the expansion

valve for this test.Suction side low pressure should

drop by 10 psi. If not, replace expansion valve.(7) Allow expansion valve to thaw. The low pres-

sure gauge reading should stabilize at 140 kPa to

240 kPa (20 psi to 30 psig). If not, replace expansion

valve.

(8) When expansion valve test is complete, test

A/C overall performance. Remove all test equipment

before returning vehicle to use.

HEATER PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings in this

group before performing the following procedures.

Check the coolant level, drive belt tension, vacuum

line connections, radiator air flow and fan operation.

Start engine and allow to warm up to normal tem-

perature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to

escape through the overflow tube. When the system

stabilizes, remove the cap completely.

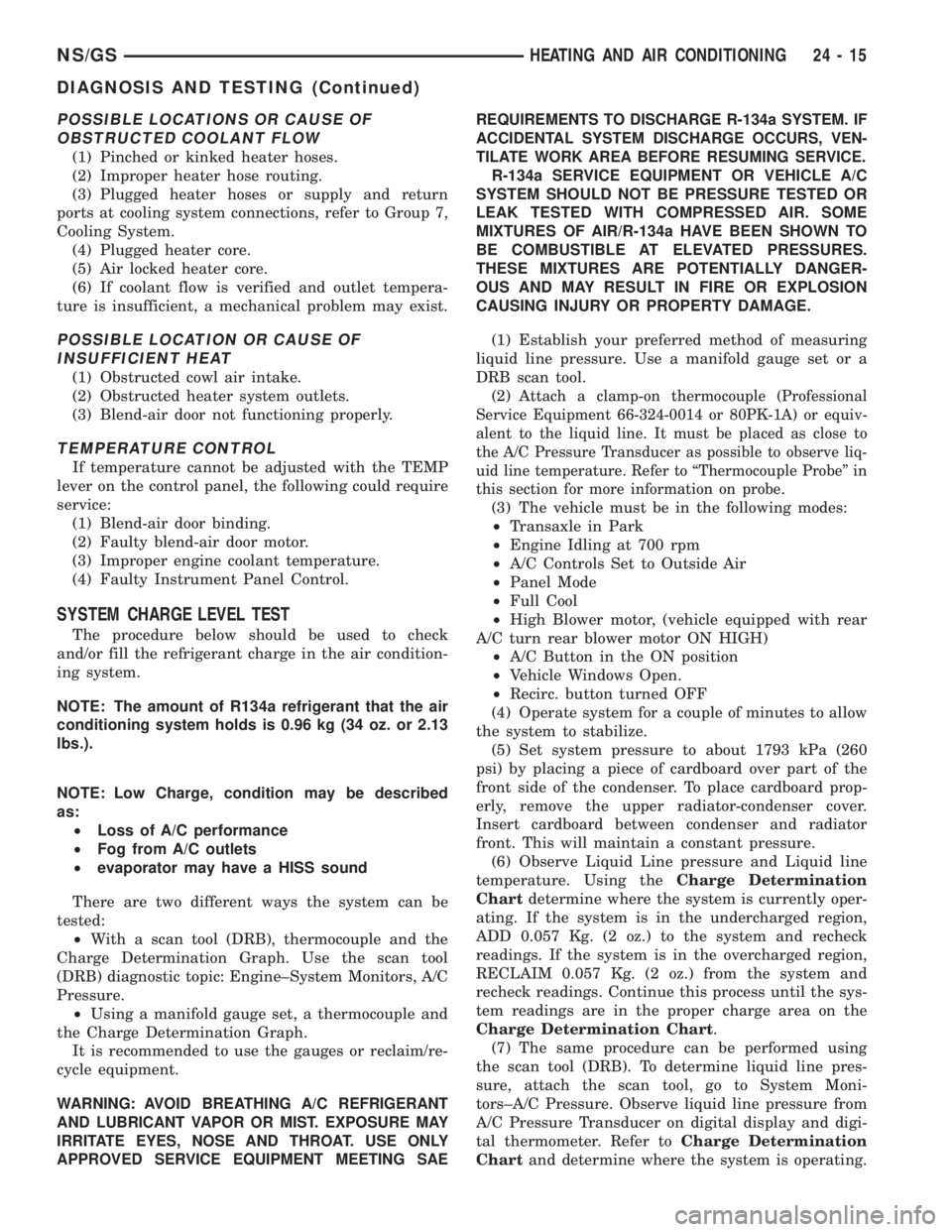

MAXIMUM HEATER OUTPUT: TEST AND

ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference chart.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

TEMPERATURE REFERENCE CHART

AMBIENT TEMP.MINIMUM FLOOR

OUTLET TEMP.

CELSIUS FAHRENHEIT CELSIUS FAHRENHEIT

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

24 - 14 HEATING AND AIR CONDITIONINGNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1881 of 1938

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.

(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF

INSUFFICIENT HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door motor.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

NOTE: The amount of R134a refrigerant that the air

conditioning system holds is 0.96 kg (34 oz. or 2.13

lbs.).

NOTE: Low Charge, condition may be described

as:

²Loss of A/C performance

²Fog from A/C outlets

²evaporator may have a HISS sound

There are two different ways the system can be

tested:

²With a scan tool (DRB), thermocouple and the

Charge Determination Graph. Use the scan tool

(DRB) diagnostic topic: Engine±System Monitors, A/C

Pressure.

²Using a manifold gauge set, a thermocouple and

the Charge Determination Graph.

It is recommended to use the gauges or reclaim/re-

cycle equipment.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAEREQUIREMENTS TO DISCHARGE R-134a SYSTEM. IF

ACCIDENTAL SYSTEM DISCHARGE OCCURS, VEN-

TILATE WORK AREA BEFORE RESUMING SERVICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. SOME

MIXTURES OF AIR/R-134a HAVE BEEN SHOWN TO

BE COMBUSTIBLE AT ELEVATED PRESSURES.

THESE MIXTURES ARE POTENTIALLY DANGER-

OUS AND MAY RESULT IN FIRE OR EXPLOSION

CAUSING INJURY OR PROPERTY DAMAGE.

(1) Establish your preferred method of measuring

liquid line pressure. Use a manifold gauge set or a

DRB scan tool.

(2) A

ttach a clamp-on thermocouple (Professional

Service Equipment 66-324-0014 or 80PK-1A) or equiv-

alent to the liquid line. It must be placed as close to

the A/C Pressure Transducer as possible to observe liq-

uid line temperature. Refer to ªThermocouple Probeº in

this section for more information on probe.

(3) The vehicle must be in the following modes:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set to Outside Air

²Panel Mode

²Full Cool

²High Blower motor, (vehicle equipped with rear

A/C turn rear blower motor ON HIGH)

²A/C Button in the ON position

²Vehicle Windows Open.

²Recirc. button turned OFF

(4) Operate system for a couple of minutes to allow

the system to stabilize.

(5) Set system pressure to about 1793 kPa (260

psi) by placing a piece of cardboard over part of the

front side of the condenser. To place cardboard prop-

erly, remove the upper radiator-condenser cover.

Insert cardboard between condenser and radiator

front. This will maintain a constant pressure.

(6) Observe Liquid Line pressure and Liquid line

temperature. Using theCharge Determination

Chartdetermine where the system is currently oper-

ating. If the system is in the undercharged region,

ADD 0.057 Kg. (2 oz.) to the system and recheck

readings. If the system is in the overcharged region,

RECLAIM 0.057 Kg. (2 oz.) from the system and

recheck readings. Continue this process until the sys-

tem readings are in the proper charge area on the

Charge Determination Chart.

(7) The same procedure can be performed using

the scan tool (DRB). To determine liquid line pres-

sure, attach the scan tool, go to System Moni-

tors±A/C Pressure. Observe liquid line pressure from

A/C Pressure Transducer on digital display and digi-

tal thermometer. Refer toCharge Determination

Chartand determine where the system is operating.

NS/GSHEATING AND AIR CONDITIONING 24 - 15

DIAGNOSIS AND TESTING (Continued)

Page 1892 of 1938

(2) Hand-start the stud into the expansion valve

and torque to7-11N´m(64-96in.lbs.).

(3) Carefully install the expansion valve to the

sealing plate. Install the two screws and tighten 8 to

14 N´m (70 to 130 in. lbs.) torque.

(4) Carefully install the refrigerant lines and seal-

ing plate to the expansion valve. Install the nut and

tighten 20 to 26 N´m (170 to 230 in. lbs.) torque.

(5) Install the ground wire at dash panel.

(6) Pull generator back into the proper position for

bracket mounting.

(7) Install generator field wire connector.

(8) Install the upper generator bracket.

(9) Install accessory drive belt.

(10) Evacuate and recharge system.

(11) After expansion valve is installed, the system

is charged, and leaks have checked repeat the A/C

performance check.

FILTER-DRIER ASSEMBLY

REMOVAL

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

(1) Recover A/C system refrigerant.

(2) Remove liquid line at filter-drier (Fig. 21).

(3) Remove the (2) bolts holding filter-drier bracket

to radiator fan module bracket.

(4) Remove the lower liquid line at condenser.

(5) Remove the upper radiator crossmember.

(6) Pull up on radiator and slide filter-drier from

the mounting location.

INSTALLATION

(1) Before installation, replace both refrigerant

line O-rings. Then reverse the above procedures.

(2) Evacuate and recharge system.

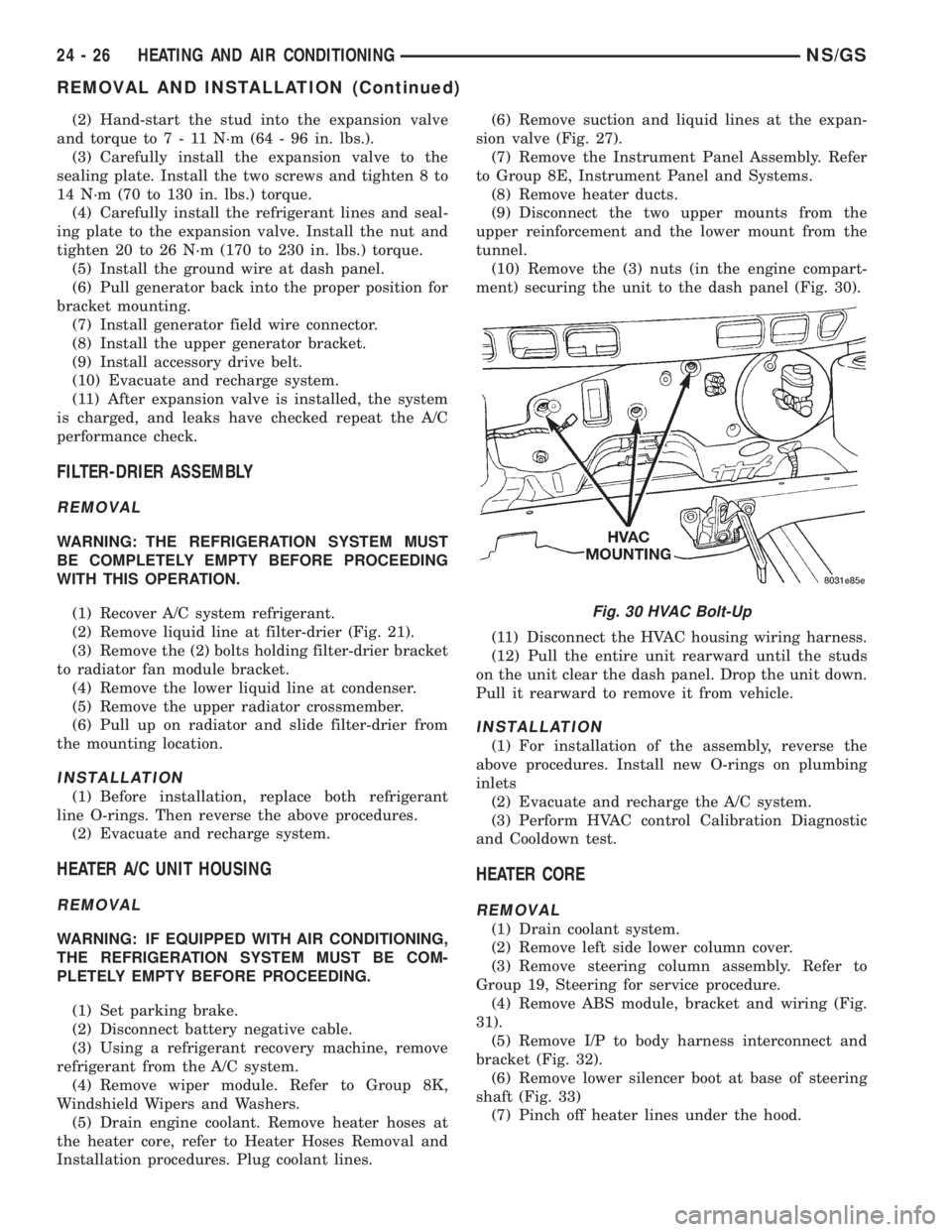

HEATER A/C UNIT HOUSING

REMOVAL

WARNING: IF EQUIPPED WITH AIR CONDITIONING,

THE REFRIGERATION SYSTEM MUST BE COM-

PLETELY EMPTY BEFORE PROCEEDING.

(1) Set parking brake.

(2) Disconnect battery negative cable.

(3) Using a refrigerant recovery machine, remove

refrigerant from the A/C system.

(4) Remove wiper module. Refer to Group 8K,

Windshield Wipers and Washers.

(5) Drain engine coolant. Remove heater hoses at

the heater core, refer to Heater Hoses Removal and

Installation procedures. Plug coolant lines.(6) Remove suction and liquid lines at the expan-

sion valve (Fig. 27).

(7) Remove the Instrument Panel Assembly. Refer

to Group 8E, Instrument Panel and Systems.

(8) Remove heater ducts.

(9) Disconnect the two upper mounts from the

upper reinforcement and the lower mount from the

tunnel.

(10) Remove the (3) nuts (in the engine compart-

ment) securing the unit to the dash panel (Fig. 30).

(11) Disconnect the HVAC housing wiring harness.

(12) Pull the entire unit rearward until the studs

on the unit clear the dash panel. Drop the unit down.

Pull it rearward to remove it from vehicle.

INSTALLATION

(1) For installation of the assembly, reverse the

above procedures. Install new O-rings on plumbing

inlets

(2) Evacuate and recharge the A/C system.

(3) Perform HVAC control Calibration Diagnostic

and Cooldown test.

HEATER CORE

REMOVAL

(1) Drain coolant system.

(2) Remove left side lower column cover.

(3) Remove steering column assembly. Refer to

Group 19, Steering for service procedure.

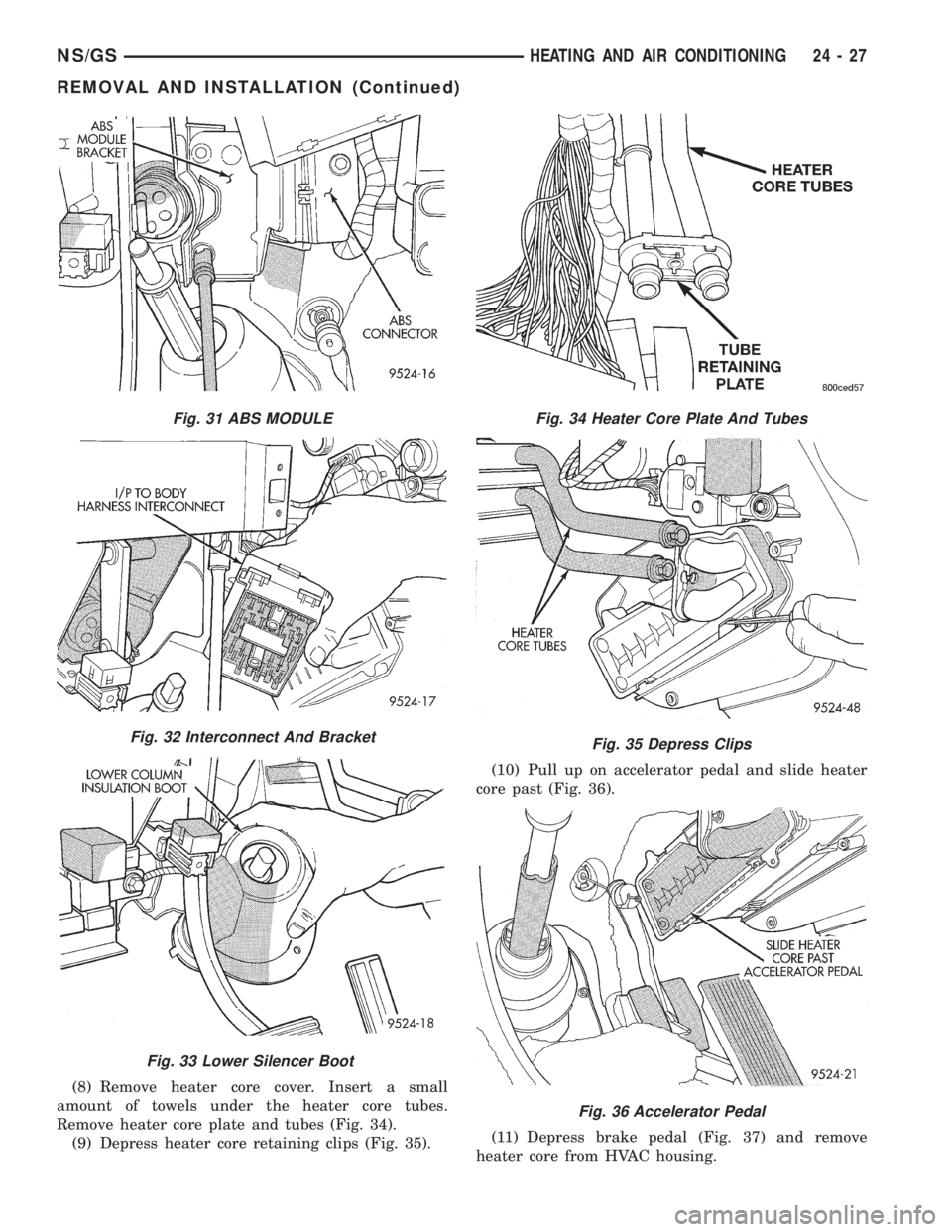

(4) Remove ABS module, bracket and wiring (Fig.

31).

(5) Remove I/P to body harness interconnect and

bracket (Fig. 32).

(6) Remove lower silencer boot at base of steering

shaft (Fig. 33)

(7) Pinch off heater lines under the hood.

Fig. 30 HVAC Bolt-Up

24 - 26 HEATING AND AIR CONDITIONINGNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1893 of 1938

(8) Remove heater core cover. Insert a small

amount of towels under the heater core tubes.

Remove heater core plate and tubes (Fig. 34).

(9) Depress heater core retaining clips (Fig. 35).(10) Pull up on accelerator pedal and slide heater

core past (Fig. 36).

(11) Depress brake pedal (Fig. 37) and remove

heater core from HVAC housing.

Fig. 31 ABS MODULE

Fig. 32 Interconnect And Bracket

Fig. 33 Lower Silencer Boot

Fig. 34 Heater Core Plate And Tubes

Fig. 35 Depress Clips

Fig. 36 Accelerator Pedal

NS/GSHEATING AND AIR CONDITIONING 24 - 27

REMOVAL AND INSTALLATION (Continued)

Page 1894 of 1938

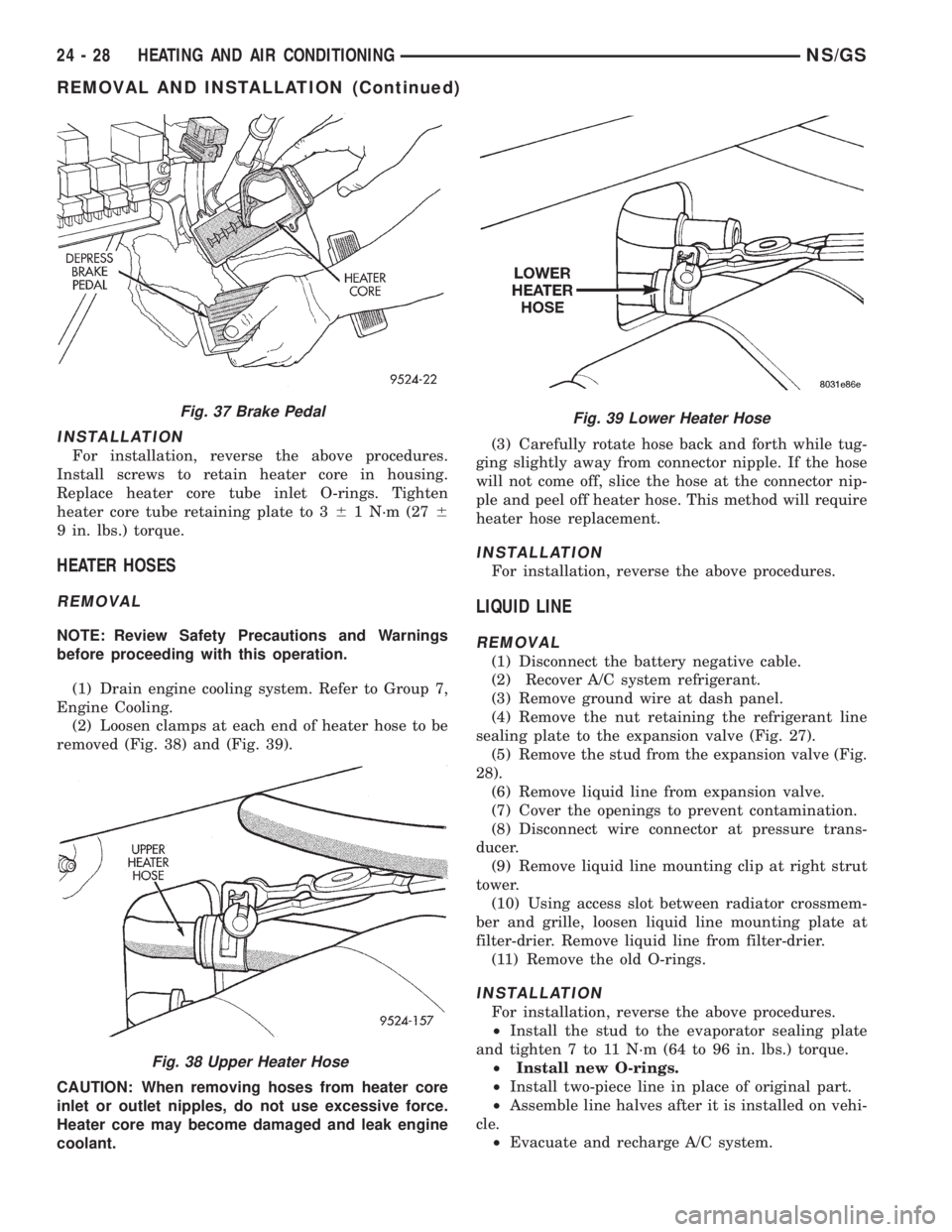

INSTALLATION

For installation, reverse the above procedures.

Install screws to retain heater core in housing.

Replace heater core tube inlet O-rings. Tighten

heater core tube retaining plate to 361 N´m (276

9 in. lbs.) torque.

HEATER HOSES

REMOVAL

NOTE: Review Safety Precautions and Warnings

before proceeding with this operation.

(1) Drain engine cooling system. Refer to Group 7,

Engine Cooling.

(2) Loosen clamps at each end of heater hose to be

removed (Fig. 38) and (Fig. 39).

CAUTION: When removing hoses from heater core

inlet or outlet nipples, do not use excessive force.

Heater core may become damaged and leak engine

coolant.(3) Carefully rotate hose back and forth while tug-

ging slightly away from connector nipple. If the hose

will not come off, slice the hose at the connector nip-

ple and peel off heater hose. This method will require

heater hose replacement.

INSTALLATION

For installation, reverse the above procedures.

LIQUID LINE

REMOVAL

(1) Disconnect the battery negative cable.

(2) Recover A/C system refrigerant.

(3) Remove ground wire at dash panel.

(4) Remove the nut retaining the refrigerant line

sealing plate to the expansion valve (Fig. 27).

(5) Remove the stud from the expansion valve (Fig.

28).

(6) Remove liquid line from expansion valve.

(7) Cover the openings to prevent contamination.

(8) Disconnect wire connector at pressure trans-

ducer.

(9) Remove liquid line mounting clip at right strut

tower.

(10) Using access slot between radiator crossmem-

ber and grille, loosen liquid line mounting plate at

filter-drier. Remove liquid line from filter-drier.

(11) Remove the old O-rings.

INSTALLATION

For installation, reverse the above procedures.

²Install the stud to the evaporator sealing plate

and tighten 7 to 11 N´m (64 to 96 in. lbs.) torque.

²Install new O-rings.

²Install two-piece line in place of original part.

²Assemble line halves after it is installed on vehi-

cle.

²Evacuate and recharge A/C system.

Fig. 37 Brake Pedal

Fig. 38 Upper Heater Hose

Fig. 39 Lower Heater Hose

24 - 28 HEATING AND AIR CONDITIONINGNS/GS

REMOVAL AND INSTALLATION (Continued)