heater CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1896 of 1938

(7) Remove suction line mounting nut at compres-

sor (Fig. 10).

(8) Remove suction line mounting bracket.

(9) Remove suction line.

INSTALLATION

For installation, reverse the above procedures.

²Install the stud to the evaporator sealing plate

and tighten 7 to 11 N´m (64 to 96 in. lbs.) torque.

²Install new O-rings.

²Install two-piece line in place of original part.

²Assemble line halves after it is installed on vehi-

cle.

²Evacuate and recharge A/C system.

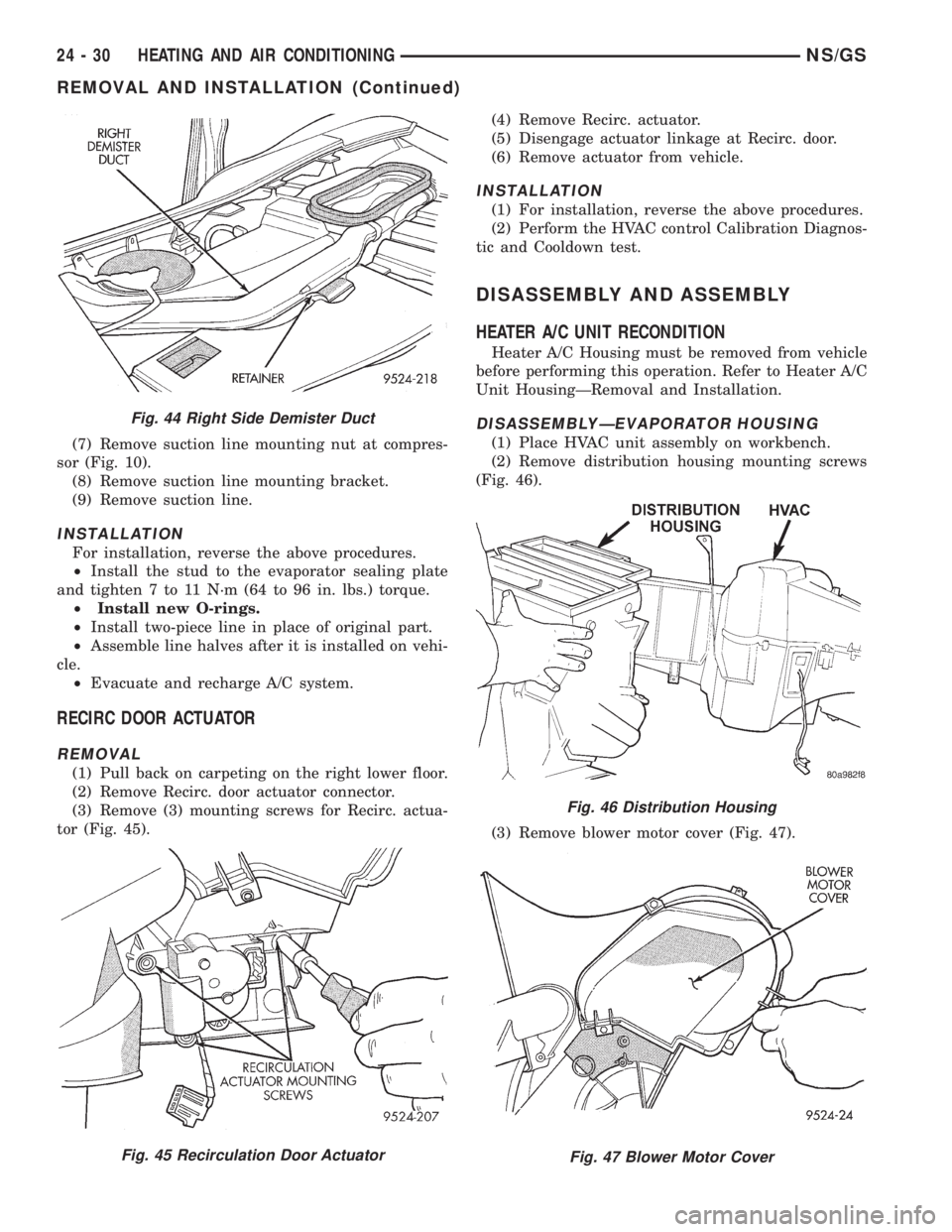

RECIRC DOOR ACTUATOR

REMOVAL

(1) Pull back on carpeting on the right lower floor.

(2) Remove Recirc. door actuator connector.

(3) Remove (3) mounting screws for Recirc. actua-

tor (Fig. 45).(4) Remove Recirc. actuator.

(5) Disengage actuator linkage at Recirc. door.

(6) Remove actuator from vehicle.

INSTALLATION

(1) For installation, reverse the above procedures.

(2) Perform the HVAC control Calibration Diagnos-

tic and Cooldown test.

DISASSEMBLY AND ASSEMBLY

HEATER A/C UNIT RECONDITION

Heater A/C Housing must be removed from vehicle

before performing this operation. Refer to Heater A/C

Unit HousingÐRemoval and Installation.

DISASSEMBLYÐEVAPORATOR HOUSING

(1) Place HVAC unit assembly on workbench.

(2) Remove distribution housing mounting screws

(Fig. 46).

(3) Remove blower motor cover (Fig. 47).

Fig. 44 Right Side Demister Duct

Fig. 45 Recirculation Door Actuator

Fig. 46 Distribution Housing

Fig. 47 Blower Motor Cover

24 - 30 HEATING AND AIR CONDITIONINGNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1898 of 1938

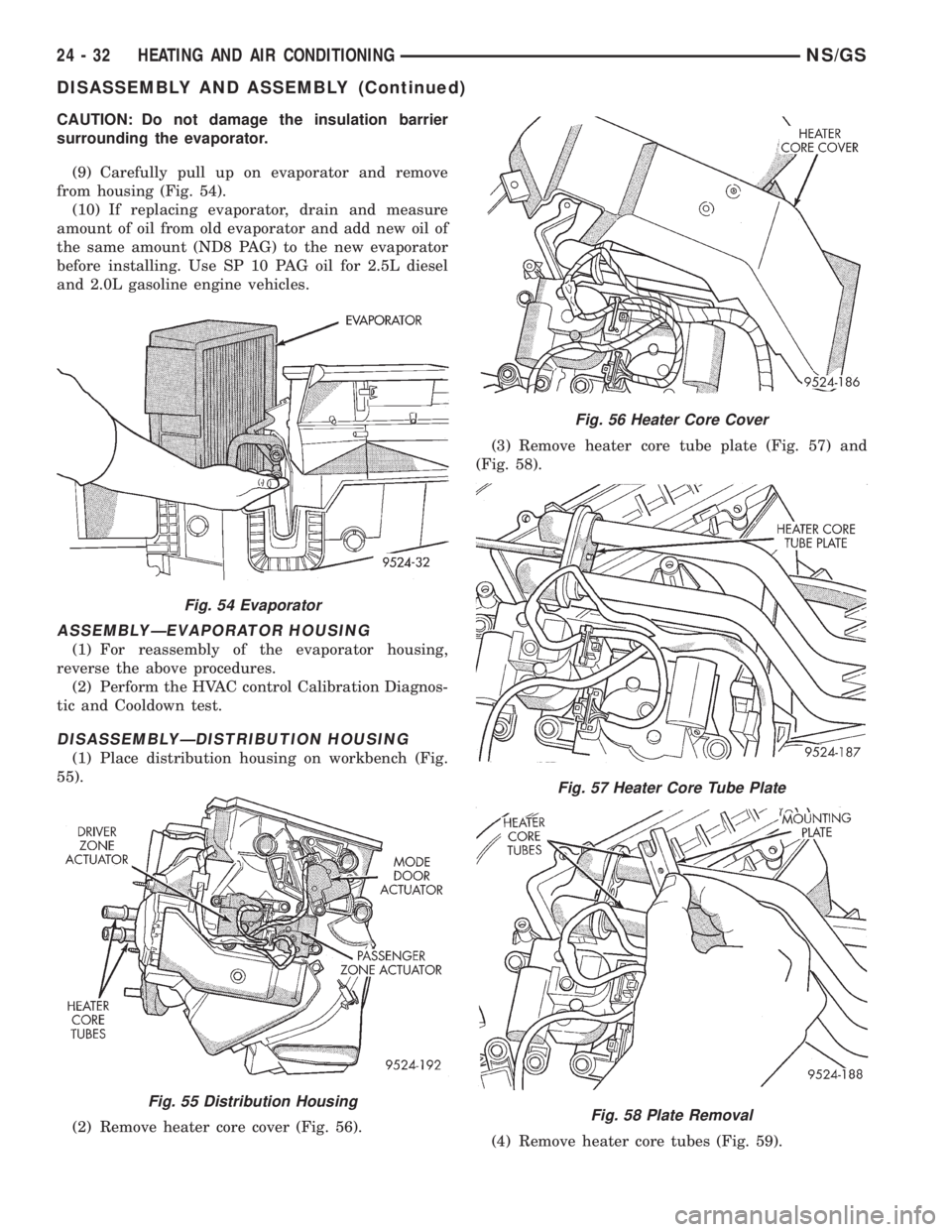

CAUTION: Do not damage the insulation barrier

surrounding the evaporator.

(9) Carefully pull up on evaporator and remove

from housing (Fig. 54).

(10) If replacing evaporator, drain and measure

amount of oil from old evaporator and add new oil of

the same amount (ND8 PAG) to the new evaporator

before installing. Use SP 10 PAG oil for 2.5L diesel

and 2.0L gasoline engine vehicles.

ASSEMBLYÐEVAPORATOR HOUSING

(1) For reassembly of the evaporator housing,

reverse the above procedures.

(2) Perform the HVAC control Calibration Diagnos-

tic and Cooldown test.

DISASSEMBLYÐDISTRIBUTION HOUSING

(1) Place distribution housing on workbench (Fig.

55).

(2) Remove heater core cover (Fig. 56).(3) Remove heater core tube plate (Fig. 57) and

(Fig. 58).

(4) Remove heater core tubes (Fig. 59).

Fig. 54 Evaporator

Fig. 55 Distribution Housing

Fig. 56 Heater Core Cover

Fig. 57 Heater Core Tube Plate

Fig. 58 Plate Removal

24 - 32 HEATING AND AIR CONDITIONINGNS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1899 of 1938

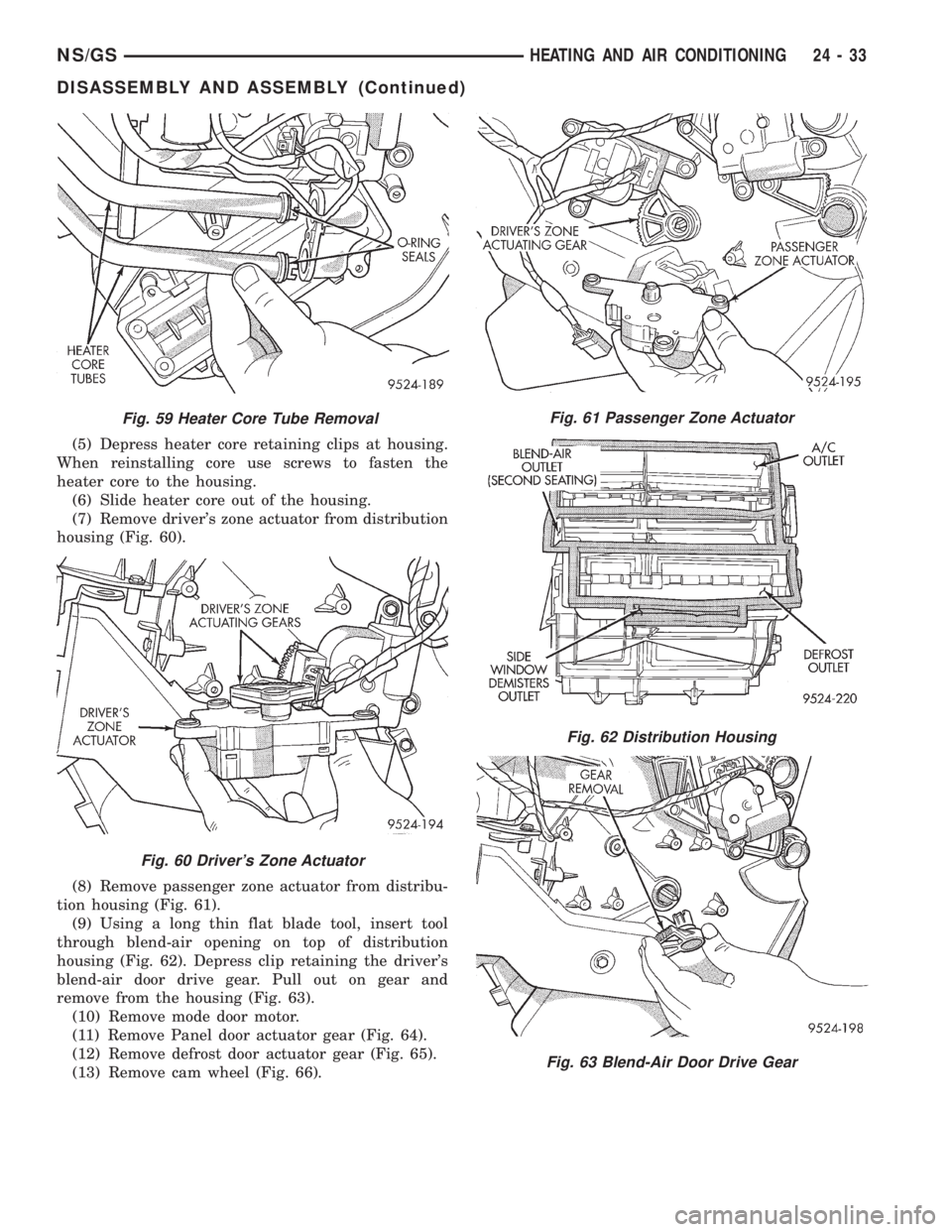

(5) Depress heater core retaining clips at housing.

When reinstalling core use screws to fasten the

heater core to the housing.

(6) Slide heater core out of the housing.

(7) Remove driver's zone actuator from distribution

housing (Fig. 60).

(8) Remove passenger zone actuator from distribu-

tion housing (Fig. 61).

(9) Using a long thin flat blade tool, insert tool

through blend-air opening on top of distribution

housing (Fig. 62). Depress clip retaining the driver's

blend-air door drive gear. Pull out on gear and

remove from the housing (Fig. 63).

(10) Remove mode door motor.

(11) Remove Panel door actuator gear (Fig. 64).

(12) Remove defrost door actuator gear (Fig. 65).

(13) Remove cam wheel (Fig. 66).

Fig. 59 Heater Core Tube Removal

Fig. 60 Driver's Zone Actuator

Fig. 61 Passenger Zone Actuator

Fig. 62 Distribution Housing

Fig. 63 Blend-Air Door Drive Gear

NS/GSHEATING AND AIR CONDITIONING 24 - 33

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1910 of 1938

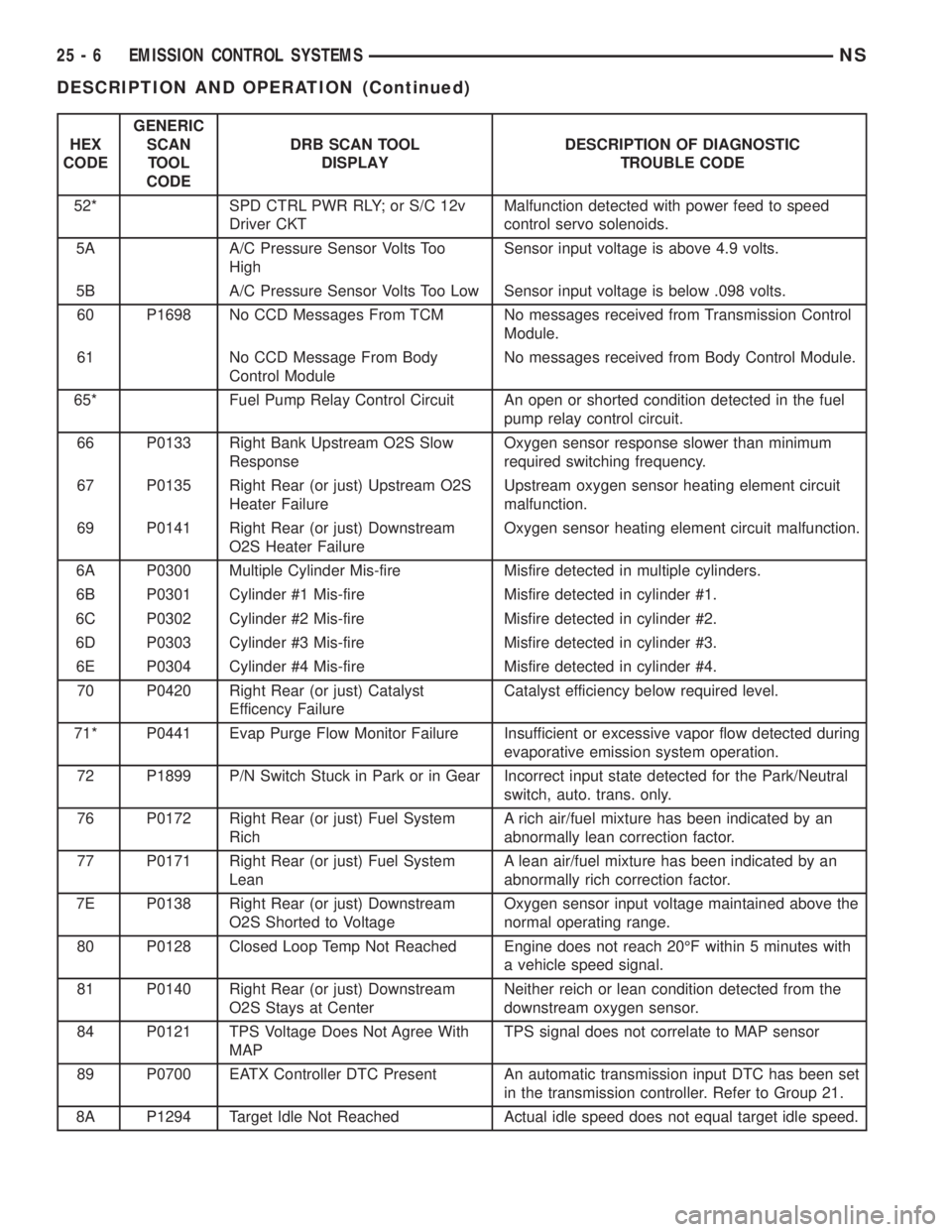

HEX

CODEGENERIC

SCAN

TOOL

CODEDRB SCAN TOOL

DISPLAYDESCRIPTION OF DIAGNOSTIC

TROUBLE CODE

52* SPD CTRL PWR RLY; or S/C 12v

Driver CKTMalfunction detected with power feed to speed

control servo solenoids.

5A A/C Pressure Sensor Volts Too

HighSensor input voltage is above 4.9 volts.

5B A/C Pressure Sensor Volts Too Low Sensor input voltage is below .098 volts.

60 P1698 No CCD Messages From TCM No messages received from Transmission Control

Module.

61 No CCD Message From Body

Control ModuleNo messages received from Body Control Module.

65* Fuel Pump Relay Control Circuit An open or shorted condition detected in the fuel

pump relay control circuit.

66 P0133 Right Bank Upstream O2S Slow

ResponseOxygen sensor response slower than minimum

required switching frequency.

67 P0135 Right Rear (or just) Upstream O2S

Heater FailureUpstream oxygen sensor heating element circuit

malfunction.

69 P0141 Right Rear (or just) Downstream

O2S Heater FailureOxygen sensor heating element circuit malfunction.

6A P0300 Multiple Cylinder Mis-fire Misfire detected in multiple cylinders.

6B P0301 Cylinder #1 Mis-fire Misfire detected in cylinder #1.

6C P0302 Cylinder #2 Mis-fire Misfire detected in cylinder #2.

6D P0303 Cylinder #3 Mis-fire Misfire detected in cylinder #3.

6E P0304 Cylinder #4 Mis-fire Misfire detected in cylinder #4.

70 P0420 Right Rear (or just) Catalyst

Efficency FailureCatalyst efficiency below required level.

71* P0441 Evap Purge Flow Monitor Failure Insufficient or excessive vapor flow detected during

evaporative emission system operation.

72 P1899 P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral

switch, auto. trans. only.

76 P0172 Right Rear (or just) Fuel System

RichA rich air/fuel mixture has been indicated by an

abnormally lean correction factor.

77 P0171 Right Rear (or just) Fuel System

LeanA lean air/fuel mixture has been indicated by an

abnormally rich correction factor.

7E P0138 Right Rear (or just) Downstream

O2S Shorted to VoltageOxygen sensor input voltage maintained above the

normal operating range.

80 P0128 Closed Loop Temp Not Reached Engine does not reach 20ÉF within 5 minutes with

a vehicle speed signal.

81 P0140 Right Rear (or just) Downstream

O2S Stays at CenterNeither reich or lean condition detected from the

downstream oxygen sensor.

84 P0121 TPS Voltage Does Not Agree With

MAPTPS signal does not correlate to MAP sensor

89 P0700 EATX Controller DTC Present An automatic transmission input DTC has been set

in the transmission controller. Refer to Group 21.

8A P1294 Target Idle Not Reached Actual idle speed does not equal target idle speed.

25 - 6 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 1912 of 1938

MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the check engine lamp or a scan tool.

The following is a list of the system monitors:

²EGR Monitor

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Evaporative System Leak Detection Monitor

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

HEX 66, and 7AÐOXYGEN SENSOR (O2S)

MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 air fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrous oxide (NOx) from

the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate

²Reduced output voltage

²Dynamic shift

²Shorted or open circuitsResponse rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richer

than optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt. A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

HEX 67, 69, 7C, and 7DÐOXYGEN SENSOR

HEATER MONITOR

If there is an oxygen sensor (O2S) DTC as well as

a O2S heater DTC, the O2S fault MUST be repaired

first. After the O2S fault is repaired, verify that the

heater circuit is operating correctly.

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572 Éto 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The O2S circuit is monitored for a drop in voltage.

The sensor output is used to test the heater by iso-

lating the effect of the heater element on the O2S

output voltage from the other effects.

HEX 2EÐEGR MONITOR

The Powertrain Control Module (PCM) performs

an on-board diagnostic check of the EGR system.

The EGR system consists of two main components:

a vacuum solenoid and a vacuum operated valve with

a back pressure transducer. The EGR monitor is used

to test whether the EGR system is operating within

specifications. The diagnostic check activates only

during selected engine/driving conditions. When the

25 - 8 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)