airbag CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 439 of 1938

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH

WARNING: BEFORE SERVICING A STEERING COL-

UMN EQUIPPED WITH AN AIRBAG REFER TO

GROUP 8M, RESTRAINT SYSTEMS FOR PROPER

AND SAFE SERVICE PROCEDURES.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect and isolate battery negative cable.

(3) Remove upper and lower steering column

shrouds, refer to Group 19, Steering for proper pro-

cedures.

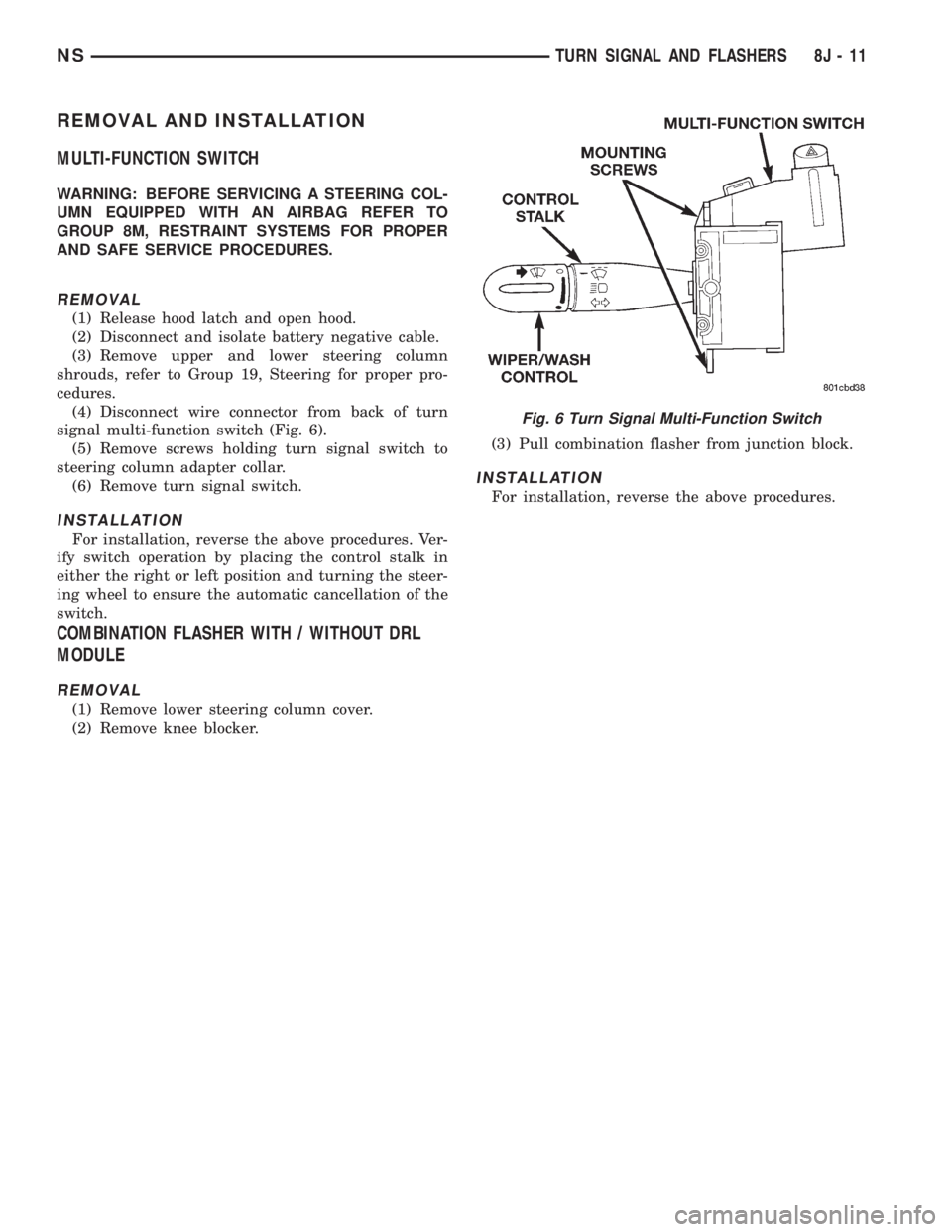

(4) Disconnect wire connector from back of turn

signal multi-function switch (Fig. 6).

(5) Remove screws holding turn signal switch to

steering column adapter collar.

(6) Remove turn signal switch.

INSTALLATION

For installation, reverse the above procedures. Ver-

ify switch operation by placing the control stalk in

either the right or left position and turning the steer-

ing wheel to ensure the automatic cancellation of the

switch.

COMBINATION FLASHER WITH / WITHOUT DRL

MODULE

REMOVAL

(1) Remove lower steering column cover.

(2) Remove knee blocker.(3) Pull combination flasher from junction block.

INSTALLATION

For installation, reverse the above procedures.

Fig. 6 Turn Signal Multi-Function Switch

NSTURN SIGNAL AND FLASHERS 8J - 11

Page 441 of 1938

WINDSHIELD WIPERS AND WASHERS

CONTENTS

page page

REAR WIPER AND WASHER................ 9WINDSHIELD WIPERS AND WASHER......... 1

WINDSHIELD WIPERS AND WASHER

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES................ 1

FAILED PARK SWITCH.................... 2

MULTI-FUNCTION SWITCH................. 4

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH................. 4

WINDSHIELD WASHER BOTTLE............. 4

WINDSHIELD WIPER BLADE ELEMENT....... 6WINDSHIELD WIPER BLADE................ 5

WINDSHIELD WIPER MOTOR............... 6

WIPER ARM............................. 7

WIPER LINKAGE......................... 7

WIPER UNIT............................ 7

CLEANING AND INSPECTION

WIPER BLADES.......................... 8

ADJUSTMENTS

WIPER ARM ALIGNMENT.................. 8

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

SAFETY PRECAUTIONS. DISCONNECT THE NEGA-

TIVE CABLE FROM THE BATTERY BEFORE SER-

VICING COMPONENTS INVOLVING THE AIRBAG

SYSTEM. ACCIDENTAL DEPLOYMENT OF AIRBAG

AND PERSONAL INJURY CAN RESULT.

The windshield wipers can be operated with the

windshield wiper switch when the ignition switch is

in the RUN or ACCESSORY positions. The wind-

shield wiper system is protected by a 40 amp fuse (9)

located in the Power Distribution Center (PDC) in

the engine compartment. The windshield washer cir-

cuit is protected by a 6 amp fuse (9) located in the

Junction Block. The wiper motor has permanent

magnetic fields. The speeds are determined by cur-

rent flow to the appropriate set of brushes inside the

motor. The current flow is controlled by the multi-

function switch stalk mounted wiper switch, high

speed/low speed relays located in the PDC. The speed

sensitive intermittent wiper is controlled by the BodyControl Module (BCM). The intermittent mode, with

the vehicle traveling greater than 10.4 mph, has a

range of 0.5 to 18 seconds. With the vehicle traveling

less than 10.4 mph, and the time delay is not

adjusted, time delay doubles to a range of 1 to 36

seconds. The wiper arms will park at the base of the

windshield just above the cowl cover after the wiper

switch is turned OFF.

The windshield wiper motor and linkage is located

in an integral wiper unit at the rear of the engine

compartment. The wiper unit must be removed to

gain access to the wiper motor.

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES

The windshield wiper system operates in several

modes:

²Low and high speed normal wipe

²Speed sensitive intermittent wipe

²Wipe after wash

²Pulse wipe

²Park (switch OFF)

The windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-

NSWINDSHIELD WIPERS AND WASHERS 8K - 1

Page 444 of 1938

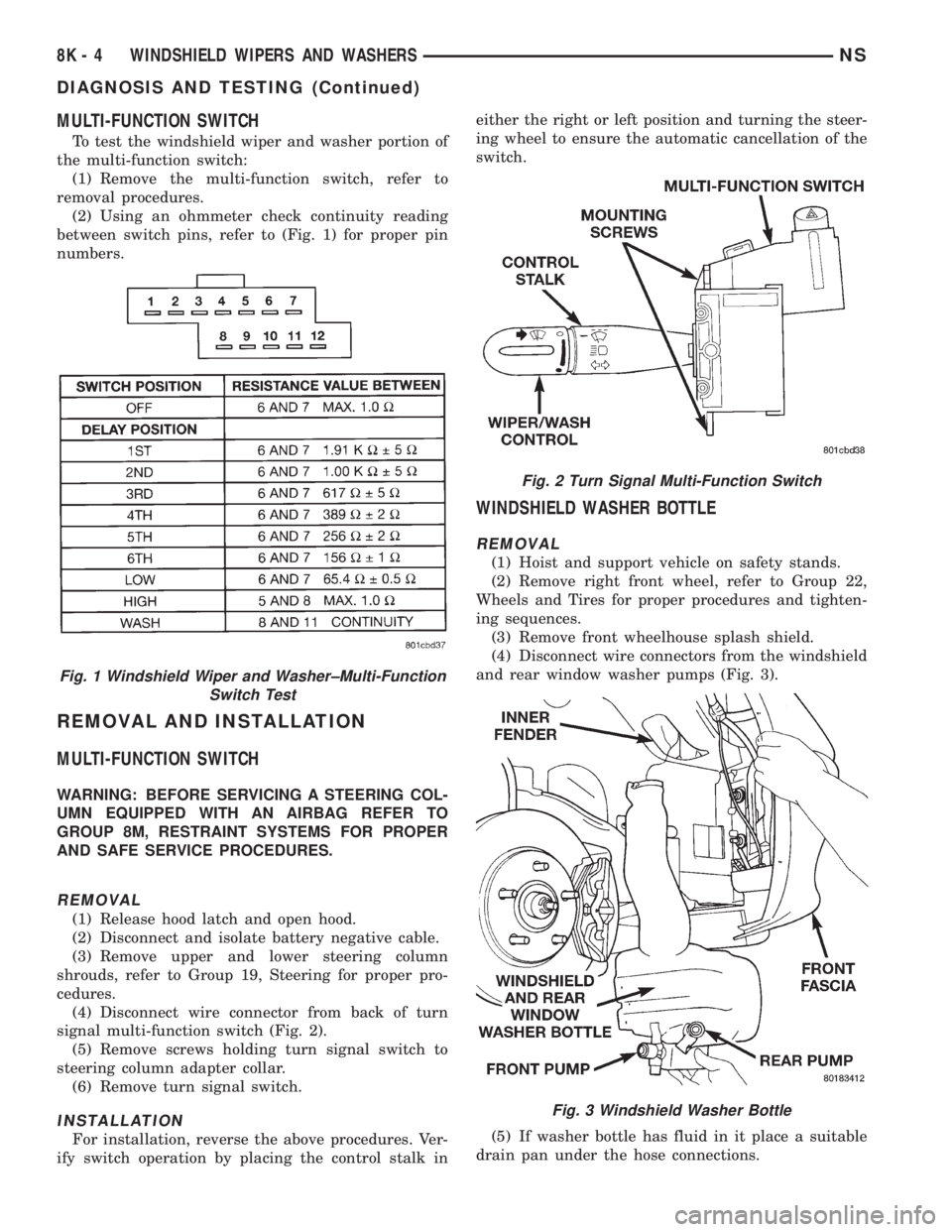

MULTI-FUNCTION SWITCH

To test the windshield wiper and washer portion of

the multi-function switch:

(1) Remove the multi-function switch, refer to

removal procedures.

(2) Using an ohmmeter check continuity reading

between switch pins, refer to (Fig. 1) for proper pin

numbers.

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH

WARNING: BEFORE SERVICING A STEERING COL-

UMN EQUIPPED WITH AN AIRBAG REFER TO

GROUP 8M, RESTRAINT SYSTEMS FOR PROPER

AND SAFE SERVICE PROCEDURES.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect and isolate battery negative cable.

(3) Remove upper and lower steering column

shrouds, refer to Group 19, Steering for proper pro-

cedures.

(4) Disconnect wire connector from back of turn

signal multi-function switch (Fig. 2).

(5) Remove screws holding turn signal switch to

steering column adapter collar.

(6) Remove turn signal switch.

INSTALLATION

For installation, reverse the above procedures. Ver-

ify switch operation by placing the control stalk ineither the right or left position and turning the steer-

ing wheel to ensure the automatic cancellation of the

switch.

WINDSHIELD WASHER BOTTLE

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove right front wheel, refer to Group 22,

Wheels and Tires for proper procedures and tighten-

ing sequences.

(3) Remove front wheelhouse splash shield.

(4) Disconnect wire connectors from the windshield

and rear window washer pumps (Fig. 3).

(5) If washer bottle has fluid in it place a suitable

drain pan under the hose connections.

Fig. 1 Windshield Wiper and Washer±Multi-Function

Switch Test

Fig. 2 Turn Signal Multi-Function Switch

Fig. 3 Windshield Washer Bottle

8K - 4 WINDSHIELD WIPERS AND WASHERSNS

DIAGNOSIS AND TESTING (Continued)

Page 477 of 1938

BULB APPLICATION

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 25SPECIFICATIONS

EXTERIOR LAMP BULBS.................. 25

INTERIOR LAMP BULBS.................. 25

GENERAL INFORMATION

INTRODUCTION

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

SPECIFICATIONS

EXTERIOR LAMP BULBS

LAMP BULB

Back-up...............................3057

CHMSL................................921

Fog Lamp...............................H3

FogLamp±T&C ........................9040

Headlamp..............................9007

Headlamp high beam ± T&C...............9005

Headlamp low beam ± T&C............9005 SLL

License Plate............................168

Parking/Turn Signal/Front Side Marker. . . .3157NA

Parking/Turn Signal ± T&C............4157NAK

Tail, Stop, Turn Signal and Side Marker......3057

Front Side Marker......................194NA

INTERIOR LAMP BULBS

LAMP BULB

ABS.................................PC194

AirBag ..............................PC194

Alarm Set (Security)....................PC194

Brake Warning.........................PC194

Center/Rear Reading Lamps.................578

Center/Rear Dome Lamps...................579

Check Engine Ind.......................PC194

Front Door Courtesy.......................567

Door Ajar Ind..........................PC194

Front Header Reading Lamp................567

Glove Box Lamp..........................194

High Beam Ind.........................PC194

Instrument Cluster.....................PC194

IP Bin/Ash Tray..........................161

Liftgate Flood Lamps......................567

Liftgate Ajar Ind.........................PC74

Low Fuel Ind..........................PC194

Oil Pressure Ind........................PC194

O/H Console Reading Lamps................579

Seat Belt Ind...........................PC74

Engine Temp Ind.......................PC194

Turn Signal...........................PC194

Engine Compartment Lamps................579

Visor Vanity Lamp....................6501966

Low Washer Fluid.......................PC74

Low Volts Warning.......................PC74

Cruise Indicator........................PC194

NSLAMPS 8L - 25

Page 495 of 1938

BULB APPLICATION

INDEX

page page

GENERAL INFORMATION

INTRODUCTION....................... 17

CLEANING AND INSPECTION

HEADLAMP CLEANING.................. 17SPECIFICATIONS

EXTERIOR LAMP BULBS................. 17

INTERIOR LAMP BULBS................. 17

GENERAL INFORMATION

INTRODUCTION

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

CLEANING AND INSPECTION

HEADLAMP CLEANING

This vehicle is equipped with plastic headlights

that are lighter and less susceptible to stone break-

age than glass headlights.

This plastic is not as scratch resistant as glass and

therefore a different lens cleaning procedures must

be followed.

To minimize the possibility of scratching the lenses

and reducing light output, avoid wiping with a dry

cloth. To remove road dirt, wash with a mild soap

solution followed by rinsing with water.

Do not use abrasive cleaning components, solvents,

steel wool or other aggressive material to clean the

lenses.

SPECIFICATIONS

EXTERIOR LAMP BULBS

LAMP BULB

Back-up.............................P21W

CHMSL (Non-Solar Tint)................P21W

CHMSL (Solar Tint)....................R10WLAMP BULB

Fog Lamp..............................H3

Headlamp..............................H4

License Plate..........................C5W

Front Turn Signal....................PY21W

Citylight..............................T4W

Front Side Repeater.....................T4W

Tail, Stop...........................P21/5W

Rear Turn Signal......................P21W

Rear Fog Lamp........................P21W

INTERIOR LAMP BULBS

LAMP BULB

ABS ................................PC194

AirBag .............................PC194

Alarm Set (Security/Immobilzer)..........PC194

Brake Warning.......................PC194

Center/Rear Reading Lamps...............578

Center/Rear Dome Lamps.................579

Cruise Indicator.......................PC194

Door Ajar Indicator....................PC194

Engine Compartment Lamps...............579

Engine Temp Indicator.................PC194

Front Door Courtesy......................567

Glove Box Lamp.........................194

Glow Plug Indicator (Diesel Engine Only) . . . PC194

High Beam Indicator...................PC194

Instrument Cluster....................PC194

IP/Ash Tray (Left Hand Drive Only).........161

Liftgate Flood Lamps.....................567

Liftgate Ajar Indicator...................PC74

Low Coolant Level (Diesel Engine Only).....PC74

Low Fuel Indicator....................PC194

Low Volts Warning.....................PC74

Low Washer Fluid......................PC74

Oil Pressure Indicator..................PC194

O/H Console Reading Lamps...............579

Seat Belt Indicator (Except Diesel).........PC74

Service Engine Soon...................PC194

Turn Signal..........................PC194

Visor Vanity Lamp...................6501966

NS/GSLAMPS 8L - 17

Page 497 of 1938

RESTRAINT SYSTEM

CONTENTS

page page

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS............ 1

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE (ACM)......... 1

CLOCKSPRING.......................... 2

DRIVER AND PASSENGER

AIRBAG MODULES..................... 2

DIAGNOSIS AND TESTING

AIRBAG SYSTEM TEST................... 2

SERVICE PROCEDURES

CLEANUP PROCEDURE................... 3HANDLING AIRBAG MODULE.............. 3

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE............... 3

CLOCKSPRING.......................... 5

DRIVER AIRBAG MODULE................. 5

PASSENGER AIRBAG..................... 6

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE..... 7

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO±MECHANICAL UNIT. DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE CABLE

BEFORE BEGINNING AIRBAG SYSTEM COMPO-

NENT REMOVAL OR INSTALLATION PROCEDURES.

THIS WILL DISABLE THE AIRBAG SYSTEM. FAIL-

URE TO DISCONNECT THE BATTERY COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR TWO MINUTES BEFORE REMOVING AIRBAG

COMPONENTS.

DO NOT PLACE AN INTACT UNDEPLOYED AIR-

BAG FACE DOWN ON A SOLID SURFACE, THE AIR-

BAG WILL PROPEL INTO THE AIR IF

ACCIDENTALLY DEPLOYED AND COULD RESULT

IN PERSONAL INJURY. WHEN CARRYING OR HAN-

DLING AN UNDEPLOYED AIRBAG MODULE, THE

TRIM SIDE OF THE AIRBAG SHOULD BE POINTING

AWAY FROM THE BODY TO MINIMIZE POSSIBILITY

OF INJURY IF ACCIDENTAL DEPLOYMENT

OCCURS.

REPLACE AIRBAG SYSTEM COMPONENTS WITH

MOPARTREPLACEMENT PARTS. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN INFE-

RIOR OCCUPANT PROTECTION.

WEAR SAFETY GLASSES, RUBBER GLOVES,

AND LONG SLEEVED CLOTHING WHEN CLEANING

POWDER RESIDUE FROM VEHICLE AFTER AIRBAG

DEPLOYMENT. SODIUM HYDROXIDE POWDERRESIDUE EMITTED FROM A DEPLOYED AIRBAG

CAN CAUSE SKIN IRRITATION. FLUSH AFFECTED

AREA WITH COOL WATER IF IRRITATION IS EXPE-

RIENCED. IF NASAL OR THROAT IRRITATION IS

EXPERIENCED, EXIT THE VEHICLE FOR FRESH AIR

UNTIL THE IRRITATION CEASES. IF IRRITATION

CONTINUES, SEE A PHYSICIAN.

DO NOT USE A REPLACEMENT AIRBAG THAT IS

NOT IN THE ORIGINAL PACKAGING, IMPROPER

DEPLOYMENT AND PERSONAL INJURY CAN

RESULT.

THE FACTORY INSTALLED FASTENERS,

SCREWS AND BOLTS USED TO FASTEN AIRBAG

COMPONENTS HAVE A SPECIAL COATING AND

ARE SPECIFICALLY DESIGNED FOR THE AIRBAG

SYSTEM. DO NOT USE SUBSTITUTE FASTENERS,

USE ONLY ORIGINAL EQUIPMENT FASTENERS

LISTED IN THE PARTS CATALOG WHEN FASTENER

REPLACEMENT IS REQUIRED.

NOTE: Airbags should be stored in a cool dry loca-

tion away from excessive heat and static electrical

activity with the fabric airbag facing UP, or a prema-

ture deployment can result.

If the Driver/Passenger Airbag Module is defective

and not deployed, refer to Chrysler Corporation cur-

rent return list for proper handling procedures.

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE (ACM)

The Airbag Control Module (ACM) contains the

impact sensor and energy reserve capacitor. The

NSRESTRAINT SYSTEM 8M - 1

Page 498 of 1938

ACM monitors the system to determine the system

readiness. The ACM contains on-board diagnostics

and will light the AIRBAG warning lamp in the mes-

sage center when a problem occurs.

The driver and passenger airbag system is a safety

device designed to reduce the risk of fatality or seri-

ous injury, caused by a frontal impact of the vehicle.

The impact sensor provides verification of the

direction and severity of the impact. One impact sen-

sor is used. It is located inside the Airbag Control

Module (ACM) which is mounted on a bracket, just

forward of the center console. The impact sensor is

an accelerometer that senses deceleration. The decel-

eration pulses are sent to a microprocessor which

contains a decision algorithm. When an impact is

severe enough to require airbag protection, the ACM

micro processor sends a signal that completes the

electrical circuit to the driver and passenger airbags.

The sensor is calibrated for the specific vehicle and

reacts to the severity and direction of the impact.

CLOCKSPRING

The clockspring is snapped into a plastic mounting

platform on the steering column behind the steering

wheel. The clockspring is used to maintain a contin-

uous electrical circuit between the wiring harness

and the driver's airbag module. This assembly con-

sists of a flat ribbon like electrically conductive tape

which winds and unwinds with the steering wheel

rotation.

DRIVER AND PASSENGER AIRBAG MODULES

The Driver Airbag Module is located in the center

of the steering wheel. The Passenger Airbag Module

is located in the instrument panel above the glove

box (Fig. 1). The Driver Airbag Module cover contains

the horn switch, inflator device, and a fabric bag. The

airbag cover/horn switch is serviced separately from

the inflator and bag components. Refer to Group 8G,

Horns for proper service procedure for horn switch.

The Passenger Airbag Module is serviced as an

assembly.

WARNING: WHEN THE AIRBAG SYSTEM IS

DEPLOYED BECAUSE OF A COLLISION, THE FOL-

LOWING MUST BE REPLACED:

²COMPLETE STEERING COLUMN ASSEMBLY

²LOWER STEERING COUPLER

²STEERING WHEEL

²STEERING COLUMN CLOCKSPRING

²DRIVER AIRBAG COVER/HORN SWITCH

²DRIVER AIRBAG MODULE

²PASSENGER AIRBAG MODULE

²UPPER INSTRUMENT PANEL WITH PAD

DIAGNOSIS AND TESTING

AIRBAG SYSTEM TEST

(1) Disconnect and isolate the battery negative

cable.

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

(2) Connect scan tool (DRB) to Data Link connec-

tor, located at left side of the steering column and at

the lower edge of the lower instrument panel.

(3) Turn the ignition key to ON position. Exit vehi-

cle with scan tool. Use the latest version of the

proper cartridge.

(4) After checking that no one is inside the vehicle,

connect the battery negative terminal.

(5) Using the scan tool, read and record active

diagnostic code data.

(6) Read and record any stored diagnostic codes.

(7) Refer to the proper Body Diagnostic Procedures

Manual if any diagnostic codes are found in Step 5 or

Step 6.

(8) Erase stored diagnostic codes if there are no

active diagnostic codes. If problems remain, diagnos-

tic codes will not erase. Refer to the Passive

Restraint Diagnostic Test Manual to diagnose the

problem.If airbag warning lamp either fails to

light, or goes on and stays on, there is a system

malfunction. Refer to the proper Body Diagnos-

tic Procedures Manual to diagnose the problem.

Fig. 1 Airbag Module Locations

8M - 2 RESTRAINT SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 499 of 1938

SERVICE PROCEDURES

CLEANUP PROCEDURE

Roll or fold the passenger airbag towards the

instrument panel surface and close the door over the

folded bag. Then tape the door shut.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well (Fig.

2). If HVAC was in RECIRC mode at time of airbag

deployment, operate HVAC blower on low speed/heat

and vacuum powder residue expelled from the heat

outlets. Multiple vacuum cleaning may to necessary

to decontaminate the interior of the vehicle.

NOTE: Dispose deployed airbag properly, contact

dealer or government agency for disposal recom-

mendations.

SERVICE OF DEPLOYED AIRBAG MODULE

DRIVER AIRBAG

If a Driver Airbag Module has been deployed, but

not due to a collision, replace the following:

²Driver Airbag Module

²Clockspring assembly

²Driver airbag cover/horn switch

The components above must be replaced because

they cannot be reused. Replace any other driver air-

bag system components if damaged.

PASSENGER AIRBAG

If a Passenger Airbag Module has been deployed,

but not due to a collision, replace the following:

²Passenger Airbag Module

²Upper instrument panel with pad

The component above must be replaced because

they cannot be reused. Inspect the heat duct near the

passenger airbag for any damage replace as neces-sary. Replace any other passenger airbag system

components if damaged.

HANDLING AIRBAG MODULE

DEPLOYED MODULE

The vehicle interior may contain a very small

amount of sodium hydroxide powder, a by-product of

airbag deployment. Sodium hydroxide powder can

irritate the skin, eyes, nose and throat. Wear safety

glasses, rubber gloves, and long sleeved clothing

when cleaning any of the powder residue from the

vehicle.

If you find that the cleanup is irritating your skin,

run cool water over the affected area. Also, if you

experience nasal or throat irritation, exit the vehicle

for fresh air until the irritation ceases. If irritation

continues, see a physician.

UNDEPLOYED

The airbag modules must be stored in its original

special container until used for service. At no time

should a source of electricity be permitted near the

inflator on the back of an airbag module. When car-

rying or handling an undeployed airbag module, the

trim side of the airbag should be pointing away from

the body to minimize possibility of injury if acciden-

tal deployment occurs. Do not place undeployed air-

bag face down on a solid surface, the airbag will

propel into the air if accidentally deployment occurs.

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE

WARNING: THE ACM CONTAINS THE IMPACT

SENSOR WHICH ENABLES THE SYSTEM TO

DEPLOY THE AIRBAGS. TO AVOID ACCIDENTAL

DEPLOYMENT, NEVER CONNECT ACM ELECTRI-

CALLY TO THE SYSTEM WHILE VEHICLE BATTERY

IS CONNECTED. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE BEFORE BEGINNING

ANY AIRBAG SYSTEM COMPONENT SERVICE PRO-

CEDURES. THIS WILL DISABLE THE AIRBAG SYS-

TEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

REMOVAL

(1) Disconnect and isolate battery negative cable.

Allow at least two minutes for the reserve capacitor

in the Airbag Control Module (ACM) to discharge.

Fig. 2 Vacuum Heater and A/C Outlets

NSRESTRAINT SYSTEM 8M - 3

Page 500 of 1938

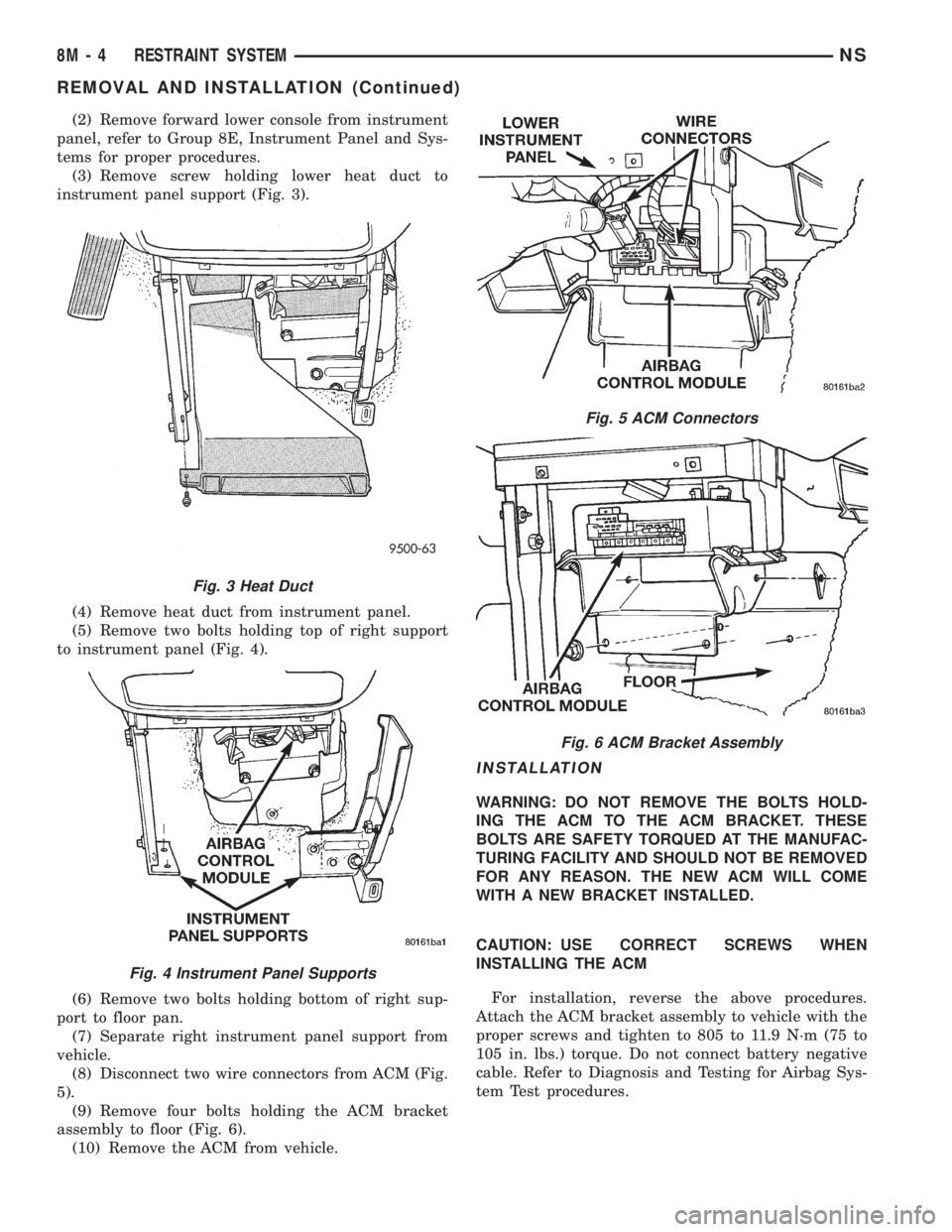

(2) Remove forward lower console from instrument

panel, refer to Group 8E, Instrument Panel and Sys-

tems for proper procedures.

(3) Remove screw holding lower heat duct to

instrument panel support (Fig. 3).

(4) Remove heat duct from instrument panel.

(5) Remove two bolts holding top of right support

to instrument panel (Fig. 4).

(6) Remove two bolts holding bottom of right sup-

port to floor pan.

(7) Separate right instrument panel support from

vehicle.

(8) Disconnect two wire connectors from ACM (Fig.

5).

(9) Remove four bolts holding the ACM bracket

assembly to floor (Fig. 6).

(10) Remove the ACM from vehicle.

INSTALLATION

WARNING: DO NOT REMOVE THE BOLTS HOLD-

ING THE ACM TO THE ACM BRACKET. THESE

BOLTS ARE SAFETY TORQUED AT THE MANUFAC-

TURING FACILITY AND SHOULD NOT BE REMOVED

FOR ANY REASON. THE NEW ACM WILL COME

WITH A NEW BRACKET INSTALLED.

CAUTION: USE CORRECT SCREWS WHEN

INSTALLING THE ACM

For installation, reverse the above procedures.

Attach the ACM bracket assembly to vehicle with the

proper screws and tighten to 805 to 11.9 N´m (75 to

105 in. lbs.) torque. Do not connect battery negative

cable. Refer to Diagnosis and Testing for Airbag Sys-

tem Test procedures.

Fig. 3 Heat Duct

Fig. 4 Instrument Panel Supports

Fig. 5 ACM Connectors

Fig. 6 ACM Bracket Assembly

8M - 4 RESTRAINT SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 501 of 1938

CLOCKSPRING

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

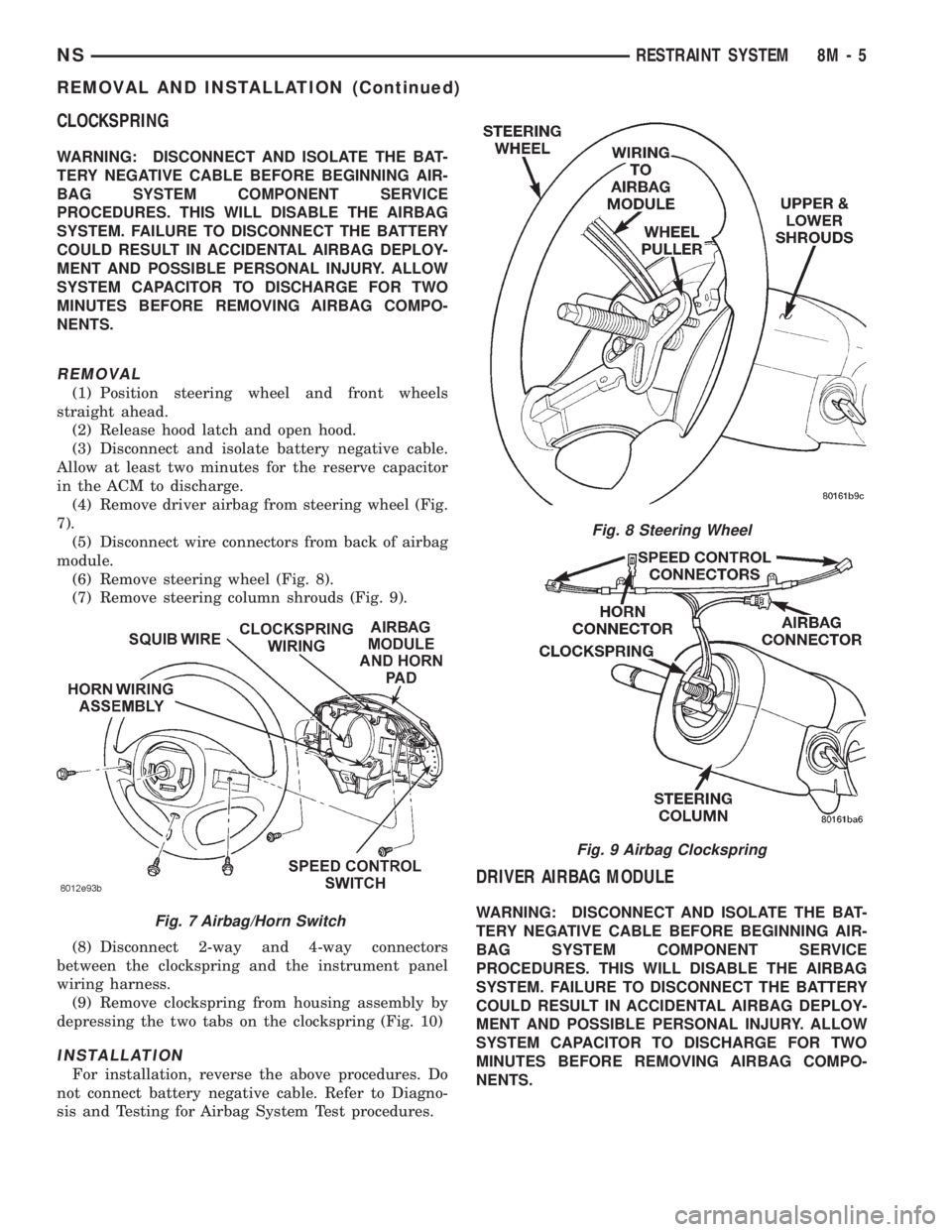

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood.

(3) Disconnect and isolate battery negative cable.

Allow at least two minutes for the reserve capacitor

in the ACM to discharge.

(4) Remove driver airbag from steering wheel (Fig.

7).

(5) Disconnect wire connectors from back of airbag

module.

(6) Remove steering wheel (Fig. 8).

(7) Remove steering column shrouds (Fig. 9).

(8) Disconnect 2-way and 4-way connectors

between the clockspring and the instrument panel

wiring harness.

(9) Remove clockspring from housing assembly by

depressing the two tabs on the clockspring (Fig. 10)

INSTALLATION

For installation, reverse the above procedures. Do

not connect battery negative cable. Refer to Diagno-

sis and Testing for Airbag System Test procedures.

DRIVER AIRBAG MODULE

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.Fig. 7 Airbag/Horn Switch

Fig. 8 Steering Wheel

Fig. 9 Airbag Clockspring

NSRESTRAINT SYSTEM 8M - 5

REMOVAL AND INSTALLATION (Continued)