display CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 339 of 1938

CLUSTER CALIBRATION TABLE

Speedometer Calibration Point

1 ............................0mph(0Km/h)

2 ..........................20mph(40Km/h)

3 ..........................55mph(80Km/h)

4 .........................75mph(120 Km/h)

Tachometer Calibration Point

1....................................0rpm

2 .................................1000 rpm

3 .................................3000 rpm

4 .................................6000 rpm

Fuel Gauge Calibration Point

1.................................Empty (E)

2 .................................1/8 Filled

3 .................................1/4 Filled

4...................................Full (F)

Temperature Gauge Calibration Point

1 ..................................Cold (C)

2...............................Low Normal

3 ..............................High Normal

4...................................Hot (H)

CALIBRATION TEST

When CHEC-1 is displayed in the odometer win-

dow, each of the cluster's gauge pointers will move

sequentially through each calibration point. The Cal-

ibration Table contains the proper calibration points

for each gauge. If the gauge pointers are not cali-

brated, a problem exists in the cluster. If any gauge

is out of calibration it will have to be calibrated using

a scan tool (DRB III). Refer to the proper Body Diag-

nostic Procedure Manual for calibration procedures.

ODOMETER SEGMENT TEST

When CHEC-2 is displayed in the odometer win-

dow, each digit of the odometer will illuminate

sequentially. If a segment in the odometer does not

illuminate normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE

INDICATOR SEGMENT TEST

When CHEC-3 is displayed in the odometer win-

dow, each segment of the transmission range indica-

tor will illuminate sequentially. If a segment in the

transmission range indicator does not illuminate nor-

mally, a problem exists in the display board.

CONDITIONS

Refer to the following tables:

²Instrument Cluster

²Speedometer

²Tachometer

²Fuel Gauge

²Temperature Gauge

²Odometer

²Electronic Transmission Range Indicator

(PRND3L)

²Mechanical Transmission Range Indicator

(PRND21)

for possible/problems/causes and corrections.

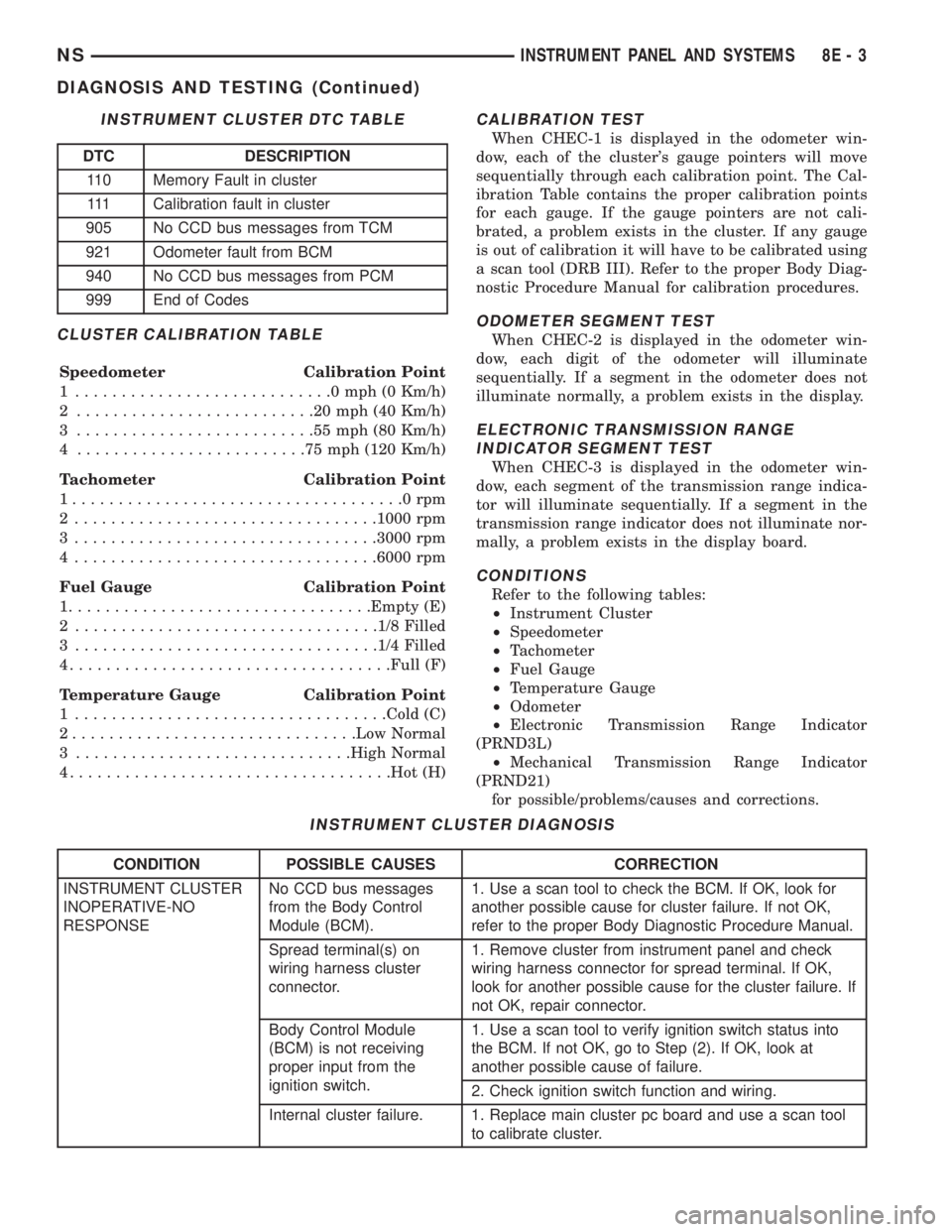

INSTRUMENT CLUSTER DTC TABLE

DTC DESCRIPTION

110 Memory Fault in cluster

111 Calibration fault in cluster

905 No CCD bus messages from TCM

921 Odometer fault from BCM

940 No CCD bus messages from PCM

999 End of Codes

INSTRUMENT CLUSTER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

INSTRUMENT CLUSTER

INOPERATIVE-NO

RESPONSENo CCD bus messages

from the Body Control

Module (BCM).1. Use a scan tool to check the BCM. If OK, look for

another possible cause for cluster failure. If not OK,

refer to the proper Body Diagnostic Procedure Manual.

Spread terminal(s) on

wiring harness cluster

connector.1. Remove cluster from instrument panel and check

wiring harness connector for spread terminal. If OK,

look for another possible cause for the cluster failure. If

not OK, repair connector.

Body Control Module

(BCM) is not receiving

proper input from the

ignition switch.1. Use a scan tool to verify ignition switch status into

the BCM. If not OK, go to Step (2). If OK, look at

another possible cause of failure.

2. Check ignition switch function and wiring.

Internal cluster failure. 1. Replace main cluster pc board and use a scan tool

to calibrate cluster.

NSINSTRUMENT PANEL AND SYSTEMS 8E - 3

DIAGNOSIS AND TESTING (Continued)

Page 340 of 1938

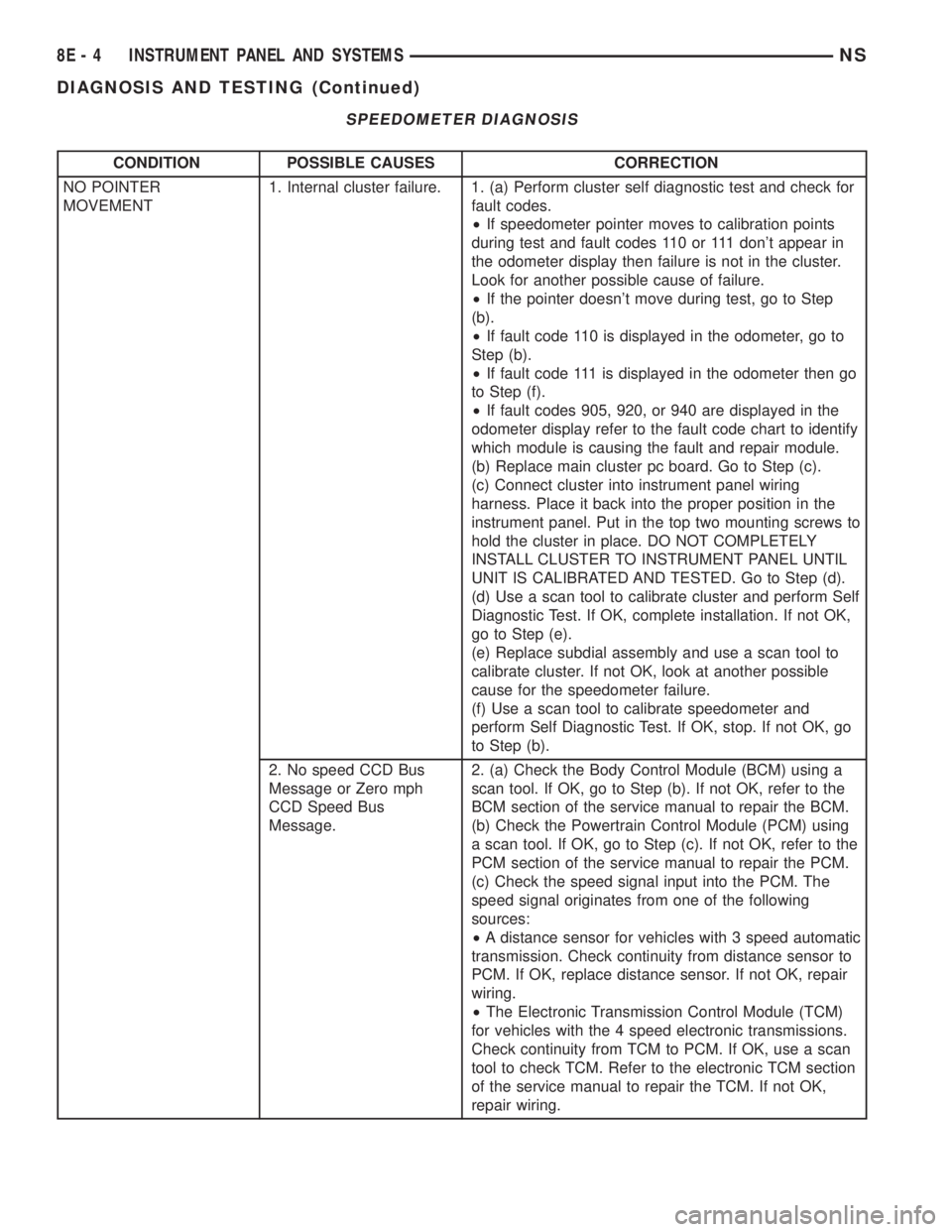

SPEEDOMETER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT1. Internal cluster failure. 1. (a) Perform cluster self diagnostic test and check for

fault codes.

²If speedometer pointer moves to calibration points

during test and fault codes 110 or 111 don't appear in

the odometer display then failure is not in the cluster.

Look for another possible cause of failure.

²If the pointer doesn't move during test, go to Step

(b).

²If fault code 110 is displayed in the odometer, go to

Step (b).

²If fault code 111 is displayed in the odometer then go

to Step (f).

²If fault codes 905, 920, or 940 are displayed in the

odometer display refer to the fault code chart to identify

which module is causing the fault and repair module.

(b) Replace main cluster pc board. Go to Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place. DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) Use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, complete installation. If not OK,

go to Step (e).

(e) Replace subdial assembly and use a scan tool to

calibrate cluster. If not OK, look at another possible

cause for the speedometer failure.

(f) Use a scan tool to calibrate speedometer and

perform Self Diagnostic Test. If OK, stop. If not OK, go

to Step (b).

2. No speed CCD Bus

Message or Zero mph

CCD Speed Bus

Message.2. (a) Check the Body Control Module (BCM) using a

scan tool. If OK, go to Step (b). If not OK, refer to the

BCM section of the service manual to repair the BCM.

(b) Check the Powertrain Control Module (PCM) using

a scan tool. If OK, go to Step (c). If not OK, refer to the

PCM section of the service manual to repair the PCM.

(c) Check the speed signal input into the PCM. The

speed signal originates from one of the following

sources:

²A distance sensor for vehicles with 3 speed automatic

transmission. Check continuity from distance sensor to

PCM. If OK, replace distance sensor. If not OK, repair

wiring.

²The Electronic Transmission Control Module (TCM)

for vehicles with the 4 speed electronic transmissions.

Check continuity from TCM to PCM. If OK, use a scan

tool to check TCM. Refer to the electronic TCM section

of the service manual to repair the TCM. If not OK,

repair wiring.

8E - 4 INSTRUMENT PANEL AND SYSTEMSNS

DIAGNOSIS AND TESTING (Continued)

Page 341 of 1938

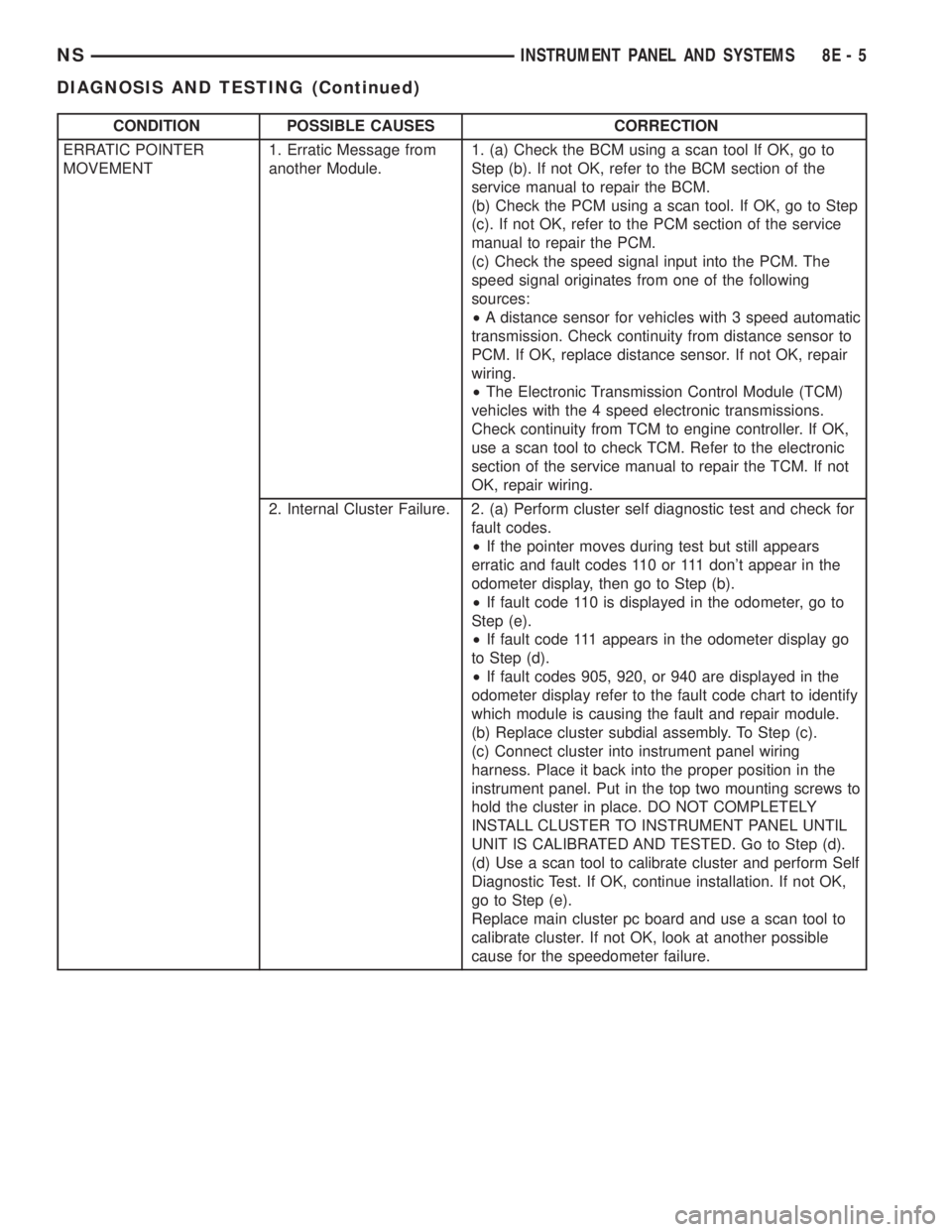

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT1. Erratic Message from

another Module.1. (a) Check the BCM using a scan tool If OK, go to

Step (b). If not OK, refer to the BCM section of the

service manual to repair the BCM.

(b) Check the PCM using a scan tool. If OK, go to Step

(c). If not OK, refer to the PCM section of the service

manual to repair the PCM.

(c) Check the speed signal input into the PCM. The

speed signal originates from one of the following

sources:

²A distance sensor for vehicles with 3 speed automatic

transmission. Check continuity from distance sensor to

PCM. If OK, replace distance sensor. If not OK, repair

wiring.

²The Electronic Transmission Control Module (TCM)

vehicles with the 4 speed electronic transmissions.

Check continuity from TCM to engine controller. If OK,

use a scan tool to check TCM. Refer to the electronic

section of the service manual to repair the TCM. If not

OK, repair wiring.

2. Internal Cluster Failure. 2. (a) Perform cluster self diagnostic test and check for

fault codes.

²If the pointer moves during test but still appears

erratic and fault codes 110 or 111 don't appear in the

odometer display, then go to Step (b).

²If fault code 110 is displayed in the odometer, go to

Step (e).

²If fault code 111 appears in the odometer display go

to Step (d).

²If fault codes 905, 920, or 940 are displayed in the

odometer display refer to the fault code chart to identify

which module is causing the fault and repair module.

(b) Replace cluster subdial assembly. To Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place. DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) Use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go to Step (e).

Replace main cluster pc board and use a scan tool to

calibrate cluster. If not OK, look at another possible

cause for the speedometer failure.

NSINSTRUMENT PANEL AND SYSTEMS 8E - 5

DIAGNOSIS AND TESTING (Continued)

Page 343 of 1938

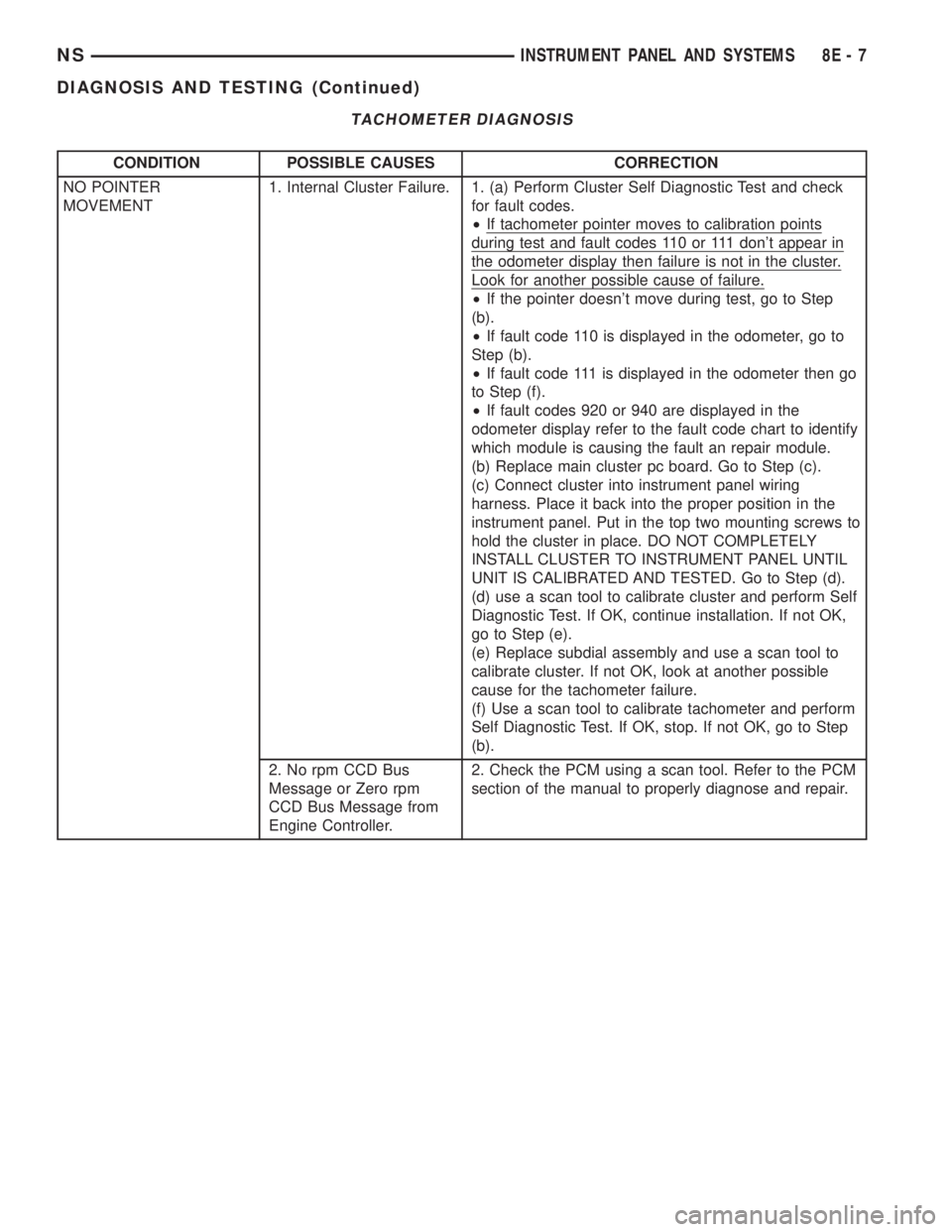

TACHOMETER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT1. Internal Cluster Failure. 1. (a) Perform Cluster Self Diagnostic Test and check

for fault codes.

²If tachometer pointer moves to calibration points

during test and fault codes 110 or 111 don't appear in

the odometer display then failure is not in the cluster.

Look for another possible cause of failure.

²If the pointer doesn't move during test, go to Step

(b).

²If fault code 110 is displayed in the odometer, go to

Step (b).

²If fault code 111 is displayed in the odometer then go

to Step (f).

²If fault codes 920 or 940 are displayed in the

odometer display refer to the fault code chart to identify

which module is causing the fault an repair module.

(b) Replace main cluster pc board. Go to Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place. DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go to Step (e).

(e) Replace subdial assembly and use a scan tool to

calibrate cluster. If not OK, look at another possible

cause for the tachometer failure.

(f) Use a scan tool to calibrate tachometer and perform

Self Diagnostic Test. If OK, stop. If not OK, go to Step

(b).

2. No rpm CCD Bus

Message or Zero rpm

CCD Bus Message from

Engine Controller.2. Check the PCM using a scan tool. Refer to the PCM

section of the manual to properly diagnose and repair.

NSINSTRUMENT PANEL AND SYSTEMS 8E - 7

DIAGNOSIS AND TESTING (Continued)

Page 344 of 1938

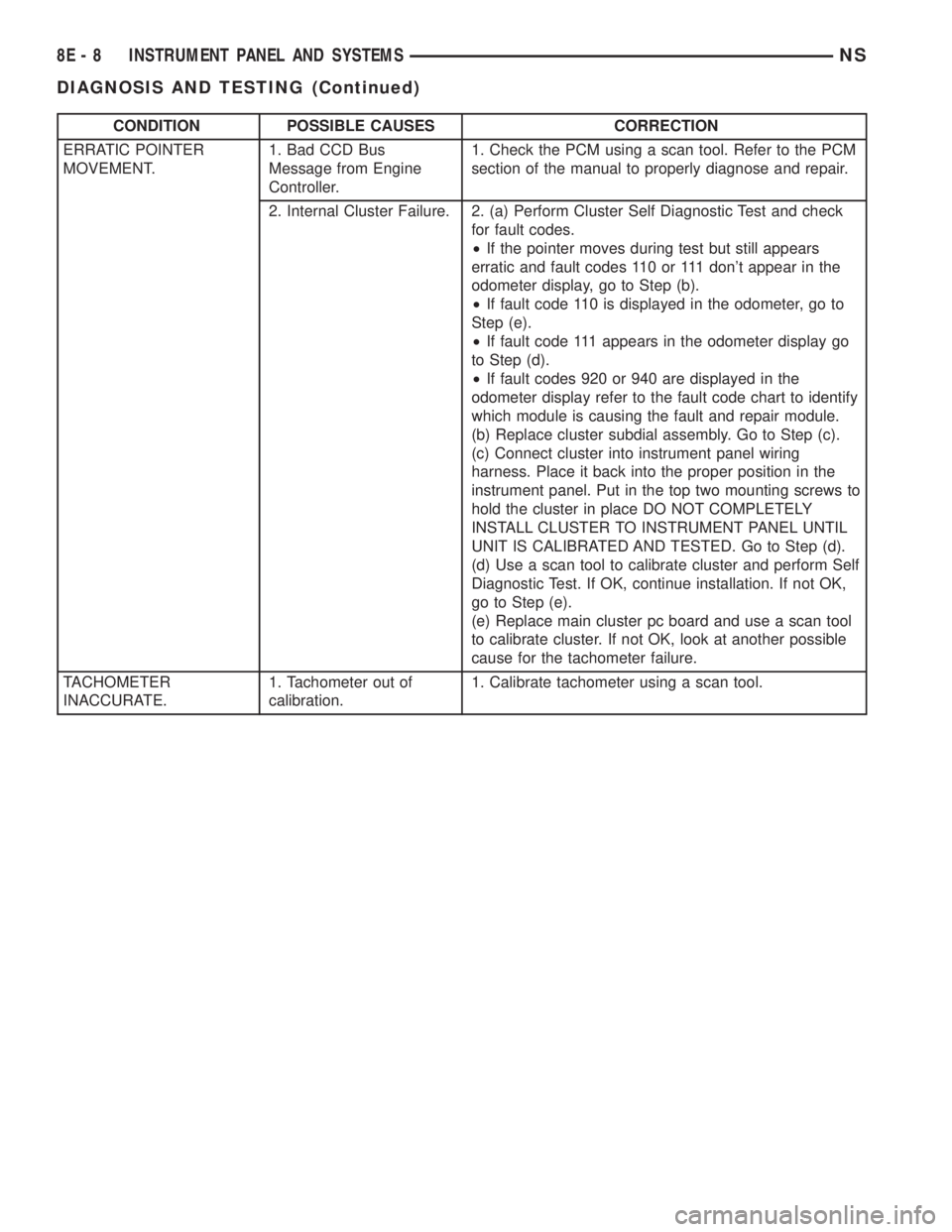

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. Bad CCD Bus

Message from Engine

Controller.1. Check the PCM using a scan tool. Refer to the PCM

section of the manual to properly diagnose and repair.

2. Internal Cluster Failure. 2. (a) Perform Cluster Self Diagnostic Test and check

for fault codes.

²If the pointer moves during test but still appears

erratic and fault codes 110 or 111 don't appear in the

odometer display, go to Step (b).

²If fault code 110 is displayed in the odometer, go to

Step (e).

²If fault code 111 appears in the odometer display go

to Step (d).

²If fault codes 920 or 940 are displayed in the

odometer display refer to the fault code chart to identify

which module is causing the fault and repair module.

(b) Replace cluster subdial assembly. Go to Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) Use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go to Step (e).

(e) Replace main cluster pc board and use a scan tool

to calibrate cluster. If not OK, look at another possible

cause for the tachometer failure.

TACHOMETER

INACCURATE.1. Tachometer out of

calibration.1. Calibrate tachometer using a scan tool.

8E - 8 INSTRUMENT PANEL AND SYSTEMSNS

DIAGNOSIS AND TESTING (Continued)

Page 345 of 1938

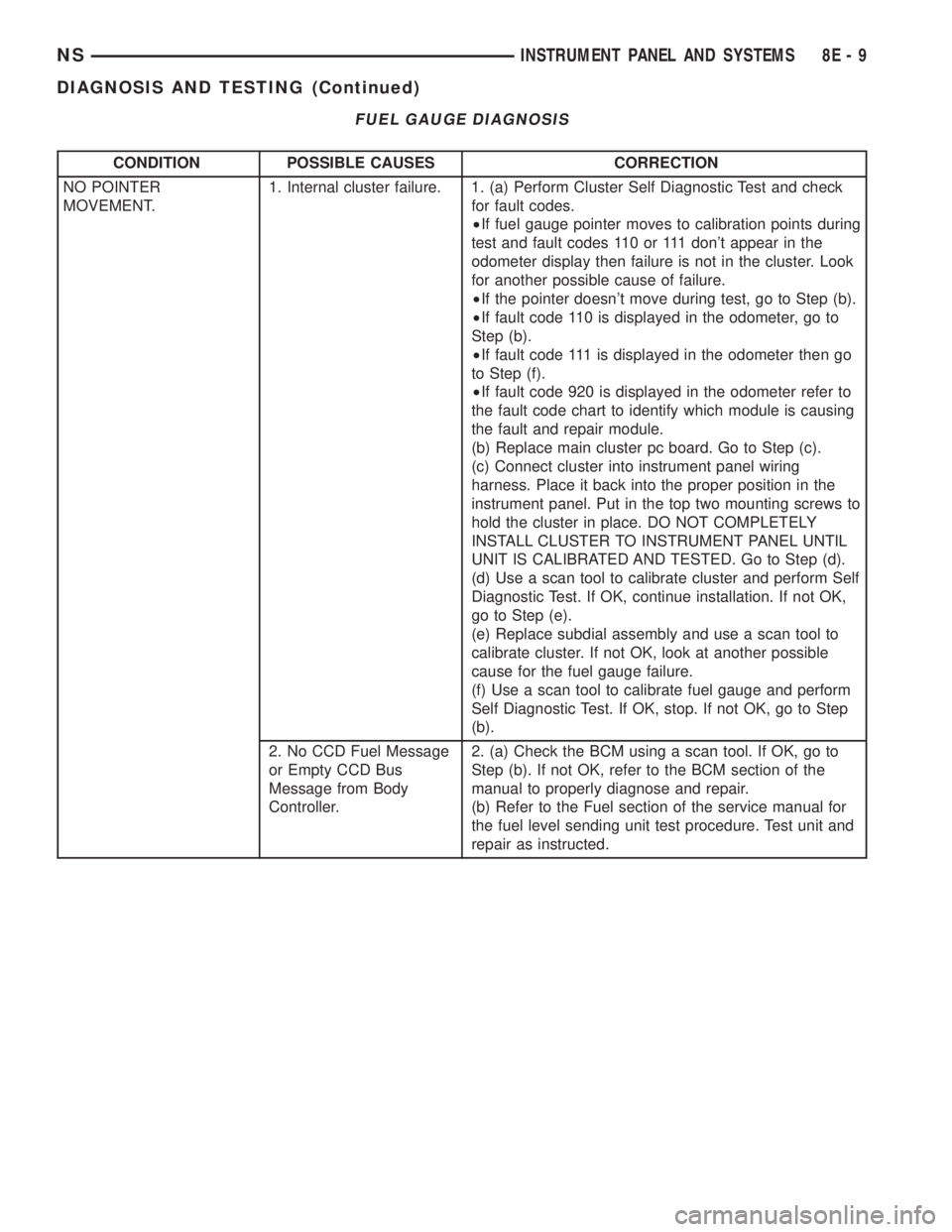

FUEL GAUGE DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT.1. Internal cluster failure. 1. (a) Perform Cluster Self Diagnostic Test and check

for fault codes.

²If fuel gauge pointer moves to calibration points during

test and fault codes 110 or 111 don't appear in the

odometer display then failure is not in the cluster. Look

for another possible cause of failure.

²If the pointer doesn't move during test, go to Step (b).

²If fault code 110 is displayed in the odometer, go to

Step (b).

²If fault code 111 is displayed in the odometer then go

to Step (f).

²If fault code 920 is displayed in the odometer refer to

the fault code chart to identify which module is causing

the fault and repair module.

(b) Replace main cluster pc board. Go to Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place. DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) Use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go to Step (e).

(e) Replace subdial assembly and use a scan tool to

calibrate cluster. If not OK, look at another possible

cause for the fuel gauge failure.

(f) Use a scan tool to calibrate fuel gauge and perform

Self Diagnostic Test. If OK, stop. If not OK, go to Step

(b).

2. No CCD Fuel Message

or Empty CCD Bus

Message from Body

Controller.2. (a) Check the BCM using a scan tool. If OK, go to

Step (b). If not OK, refer to the BCM section of the

manual to properly diagnose and repair.

(b) Refer to the Fuel section of the service manual for

the fuel level sending unit test procedure. Test unit and

repair as instructed.

NSINSTRUMENT PANEL AND SYSTEMS 8E - 9

DIAGNOSIS AND TESTING (Continued)

Page 346 of 1938

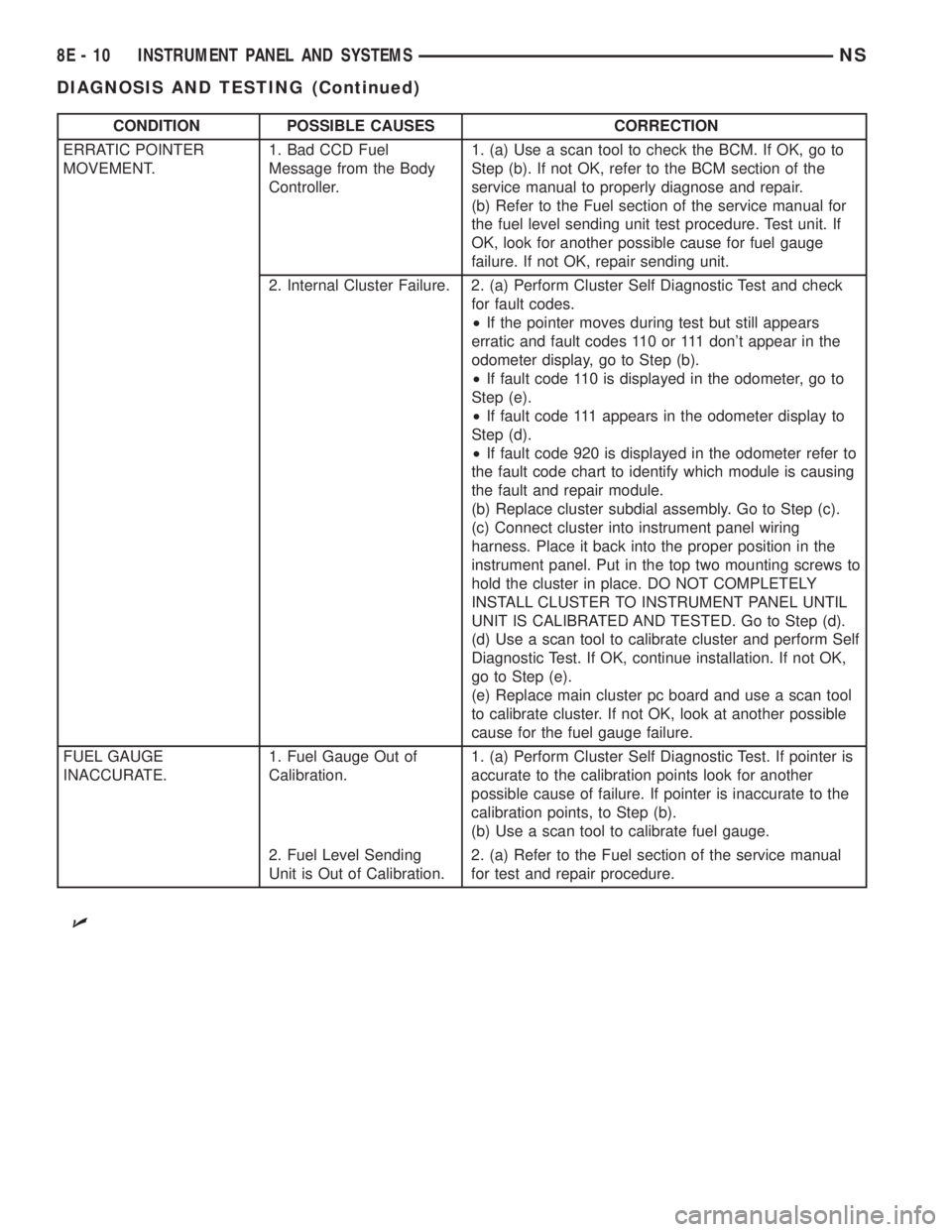

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. Bad CCD Fuel

Message from the Body

Controller.1. (a) Use a scan tool to check the BCM. If OK, go to

Step (b). If not OK, refer to the BCM section of the

service manual to properly diagnose and repair.

(b) Refer to the Fuel section of the service manual for

the fuel level sending unit test procedure. Test unit. If

OK, look for another possible cause for fuel gauge

failure. If not OK, repair sending unit.

2. Internal Cluster Failure. 2. (a) Perform Cluster Self Diagnostic Test and check

for fault codes.

²If the pointer moves during test but still appears

erratic and fault codes 110 or 111 don't appear in the

odometer display, go to Step (b).

²If fault code 110 is displayed in the odometer, go to

Step (e).

²If fault code 111 appears in the odometer display to

Step (d).

²If fault code 920 is displayed in the odometer refer to

the fault code chart to identify which module is causing

the fault and repair module.

(b) Replace cluster subdial assembly. Go to Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place. DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) Use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go to Step (e).

(e) Replace main cluster pc board and use a scan tool

to calibrate cluster. If not OK, look at another possible

cause for the fuel gauge failure.

FUEL GAUGE

INACCURATE.1. Fuel Gauge Out of

Calibration.1. (a) Perform Cluster Self Diagnostic Test. If pointer is

accurate to the calibration points look for another

possible cause of failure. If pointer is inaccurate to the

calibration points, to Step (b).

(b) Use a scan tool to calibrate fuel gauge.

2. Fuel Level Sending

Unit is Out of Calibration.2. (a) Refer to the Fuel section of the service manual

for test and repair procedure.

U

8E - 10 INSTRUMENT PANEL AND SYSTEMSNS

DIAGNOSIS AND TESTING (Continued)

Page 347 of 1938

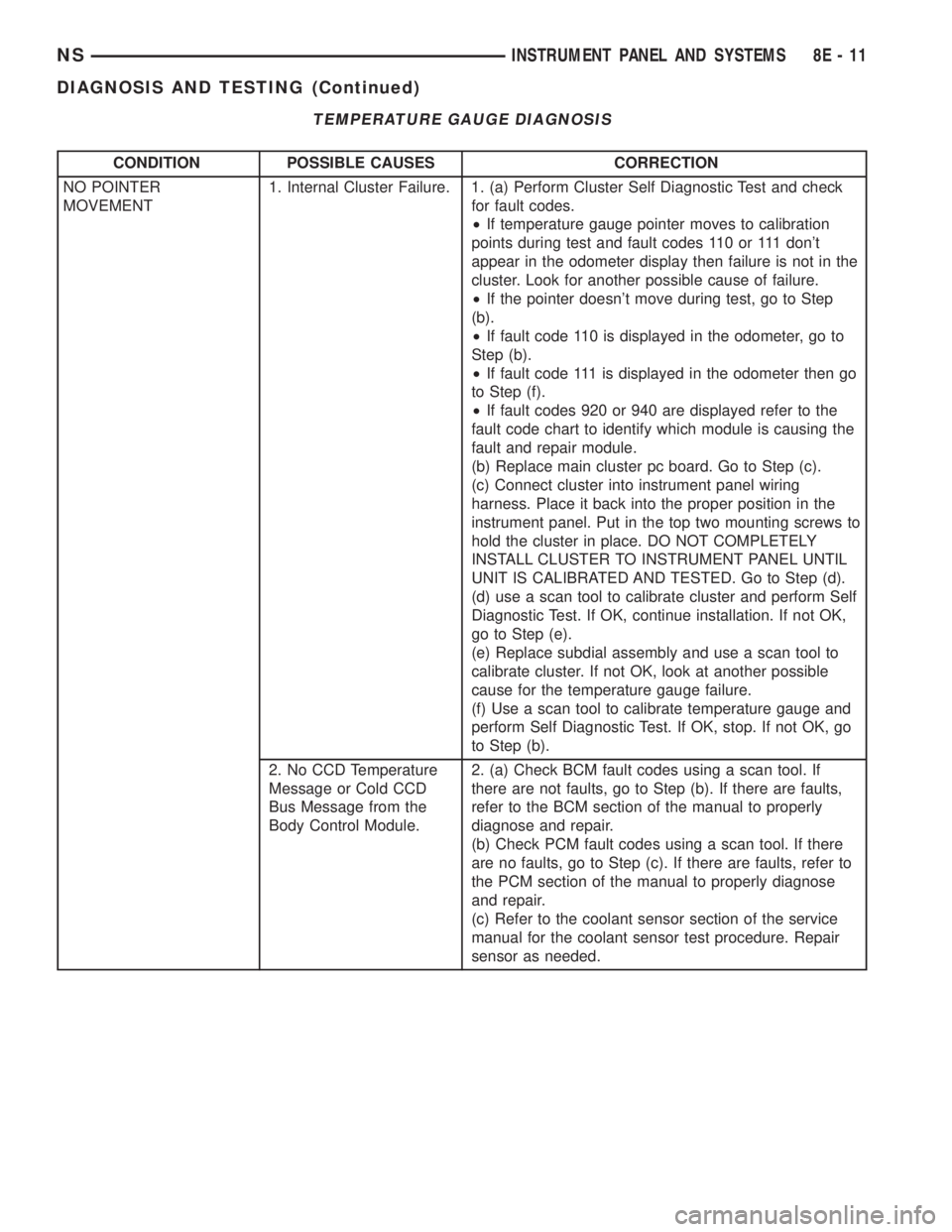

TEMPERATURE GAUGE DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT1. Internal Cluster Failure. 1. (a) Perform Cluster Self Diagnostic Test and check

for fault codes.

²If temperature gauge pointer moves to calibration

points during test and fault codes 110 or 111 don't

appear in the odometer display then failure is not in the

cluster. Look for another possible cause of failure.

²If the pointer doesn't move during test, go to Step

(b).

²If fault code 110 is displayed in the odometer, go to

Step (b).

²If fault code 111 is displayed in the odometer then go

to Step (f).

²If fault codes 920 or 940 are displayed refer to the

fault code chart to identify which module is causing the

fault and repair module.

(b) Replace main cluster pc board. Go to Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place. DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go to Step (e).

(e) Replace subdial assembly and use a scan tool to

calibrate cluster. If not OK, look at another possible

cause for the temperature gauge failure.

(f) Use a scan tool to calibrate temperature gauge and

perform Self Diagnostic Test. If OK, stop. If not OK, go

to Step (b).

2. No CCD Temperature

Message or Cold CCD

Bus Message from the

Body Control Module.2. (a) Check BCM fault codes using a scan tool. If

there are not faults, go to Step (b). If there are faults,

refer to the BCM section of the manual to properly

diagnose and repair.

(b) Check PCM fault codes using a scan tool. If there

are no faults, go to Step (c). If there are faults, refer to

the PCM section of the manual to properly diagnose

and repair.

(c) Refer to the coolant sensor section of the service

manual for the coolant sensor test procedure. Repair

sensor as needed.

NSINSTRUMENT PANEL AND SYSTEMS 8E - 11

DIAGNOSIS AND TESTING (Continued)

Page 348 of 1938

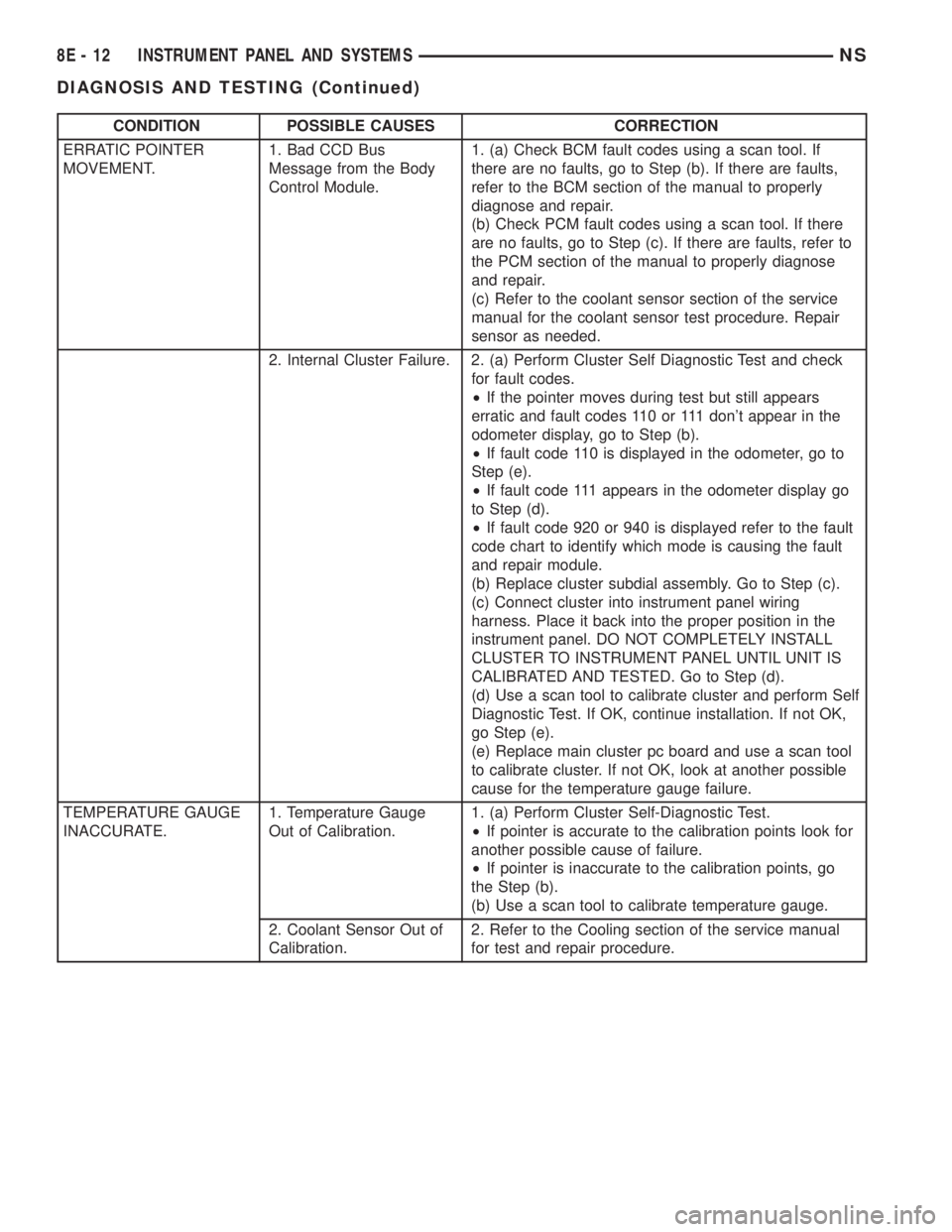

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. Bad CCD Bus

Message from the Body

Control Module.1. (a) Check BCM fault codes using a scan tool. If

there are no faults, go to Step (b). If there are faults,

refer to the BCM section of the manual to properly

diagnose and repair.

(b) Check PCM fault codes using a scan tool. If there

are no faults, go to Step (c). If there are faults, refer to

the PCM section of the manual to properly diagnose

and repair.

(c) Refer to the coolant sensor section of the service

manual for the coolant sensor test procedure. Repair

sensor as needed.

2. Internal Cluster Failure. 2. (a) Perform Cluster Self Diagnostic Test and check

for fault codes.

²If the pointer moves during test but still appears

erratic and fault codes 110 or 111 don't appear in the

odometer display, go to Step (b).

²If fault code 110 is displayed in the odometer, go to

Step (e).

²If fault code 111 appears in the odometer display go

to Step (d).

²If fault code 920 or 940 is displayed refer to the fault

code chart to identify which mode is causing the fault

and repair module.

(b) Replace cluster subdial assembly. Go to Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. DO NOT COMPLETELY INSTALL

CLUSTER TO INSTRUMENT PANEL UNTIL UNIT IS

CALIBRATED AND TESTED. Go to Step (d).

(d) Use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go Step (e).

(e) Replace main cluster pc board and use a scan tool

to calibrate cluster. If not OK, look at another possible

cause for the temperature gauge failure.

TEMPERATURE GAUGE

INACCURATE.1. Temperature Gauge

Out of Calibration.1. (a) Perform Cluster Self-Diagnostic Test.

²If pointer is accurate to the calibration points look for

another possible cause of failure.

²If pointer is inaccurate to the calibration points, go

the Step (b).

(b) Use a scan tool to calibrate temperature gauge.

2. Coolant Sensor Out of

Calibration.2. Refer to the Cooling section of the service manual

for test and repair procedure.

8E - 12 INSTRUMENT PANEL AND SYSTEMSNS

DIAGNOSIS AND TESTING (Continued)

Page 349 of 1938

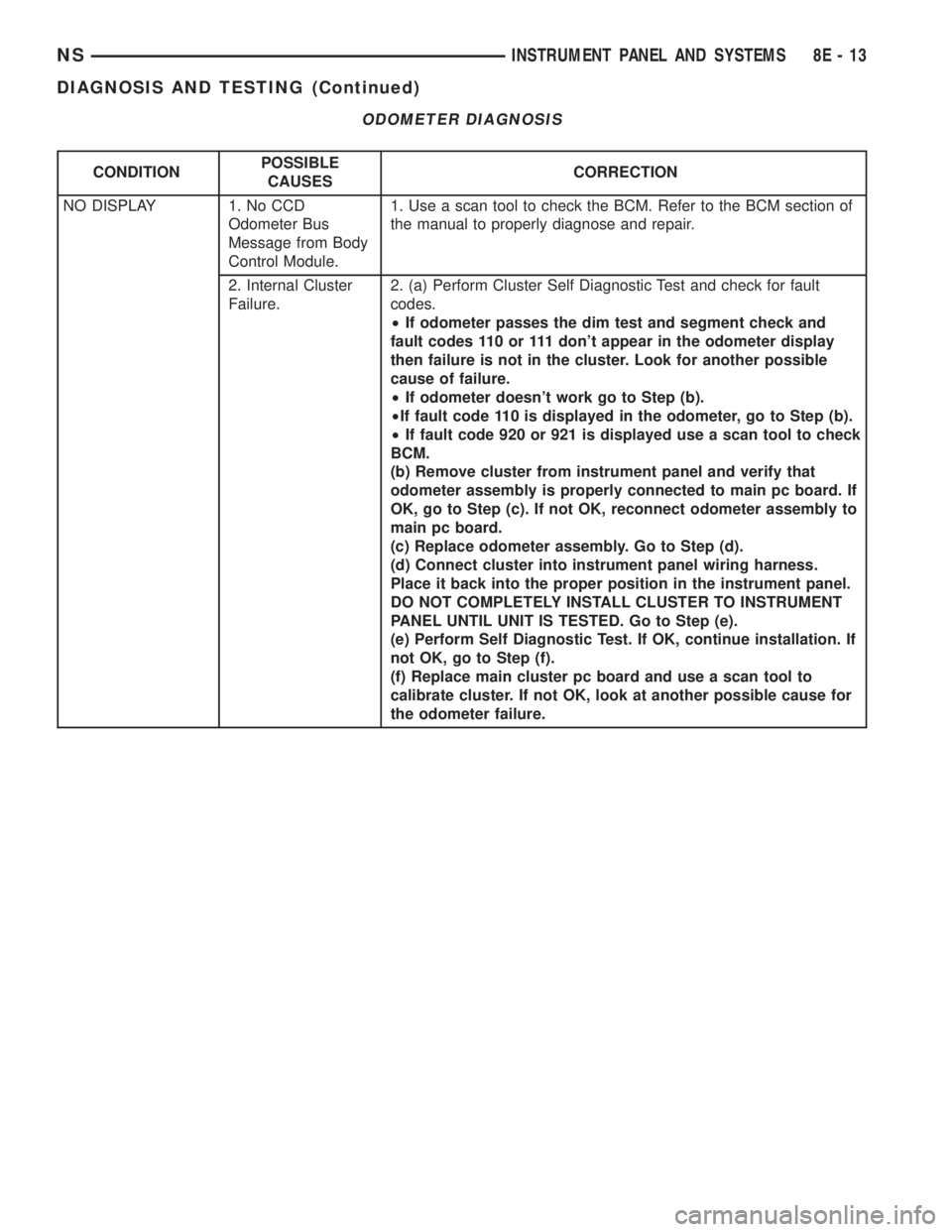

ODOMETER DIAGNOSIS

CONDITIONPOSSIBLE

CAUSESCORRECTION

NO DISPLAY 1. No CCD

Odometer Bus

Message from Body

Control Module.1. Use a scan tool to check the BCM. Refer to the BCM section of

the manual to properly diagnose and repair.

2. Internal Cluster

Failure.2. (a) Perform Cluster Self Diagnostic Test and check for fault

codes.

²If odometer passes the dim test and segment check and

fault codes 110 or 111 don't appear in the odometer display

then failure is not in the cluster. Look for another possible

cause of failure.

²If odometer doesn't work go to Step (b).

²If fault code 110 is displayed in the odometer, go to Step (b).

²If fault code 920 or 921 is displayed use a scan tool to check

BCM.

(b) Remove cluster from instrument panel and verify that

odometer assembly is properly connected to main pc board. If

OK, go to Step (c). If not OK, reconnect odometer assembly to

main pc board.

(c) Replace odometer assembly. Go to Step (d).

(d) Connect cluster into instrument panel wiring harness.

Place it back into the proper position in the instrument panel.

DO NOT COMPLETELY INSTALL CLUSTER TO INSTRUMENT

PANEL UNTIL UNIT IS TESTED. Go to Step (e).

(e) Perform Self Diagnostic Test. If OK, continue installation. If

not OK, go to Step (f).

(f) Replace main cluster pc board and use a scan tool to

calibrate cluster. If not OK, look at another possible cause for

the odometer failure.

NSINSTRUMENT PANEL AND SYSTEMS 8E - 13

DIAGNOSIS AND TESTING (Continued)