heater CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 228 of 1938

RADIATOR COOLANT FLOW TEST

To determine whether coolant is flowing through

the cooling system, use the following procedure:

(1) If engine is cold, idle engine until normal oper-

ating temperature is reached. Then feel the upper

radiator hose. If it is hot, coolant is circulating.

WARNING: DO NOT REMOVE RADIATOR PRES-

SURE CAP WITH THE SYSTEM HOT AND UNDER

PRESSURE BECAUSE SERIOUS BURNS FROM

COOLANT CAN OCCUR.

(2) Remove radiator pressure cap when engine is

cold, idle engine until thermostat opens, you should

observe coolant flow while looking down the filler

neck. Once flow is detected install radiator pressure

cap.

RADIATOR FAN CONTROL

Fan control is accomplished two ways. A pressure

transducer on the compressor discharge line sends a

signal to the Powertrain Control Module (PCM)

which will activate the fan. In addition to this con-

trol, the fan is turned on by the temperature of the

coolant which is sensed by the coolant temperature

sensor which sends the message to the PCM. The fan

will not run during cranking until the engine starts

no matter what the coolant temperature is.

CAUTION: The solid state fan relay is attached to

the left frame rail near the lower radiator support.

The relay bracket, and fastener are used to dissi-

pate heat from the relay. Ensure the relay is prop-

erly attached to prevent the following:

²Intermittent engine overheating.

²Relay ªthermalº shutdown, or relay damage.

ELECTRIC FAN MOTOR TEST

Refer to Powertrain Diagnostic Manual for proce-

dure.

TESTING COOLING SYSTEM FOR LEAKS

With engine not running, wipe the radiator filler

neck sealing seat clean. The radiator should be full.

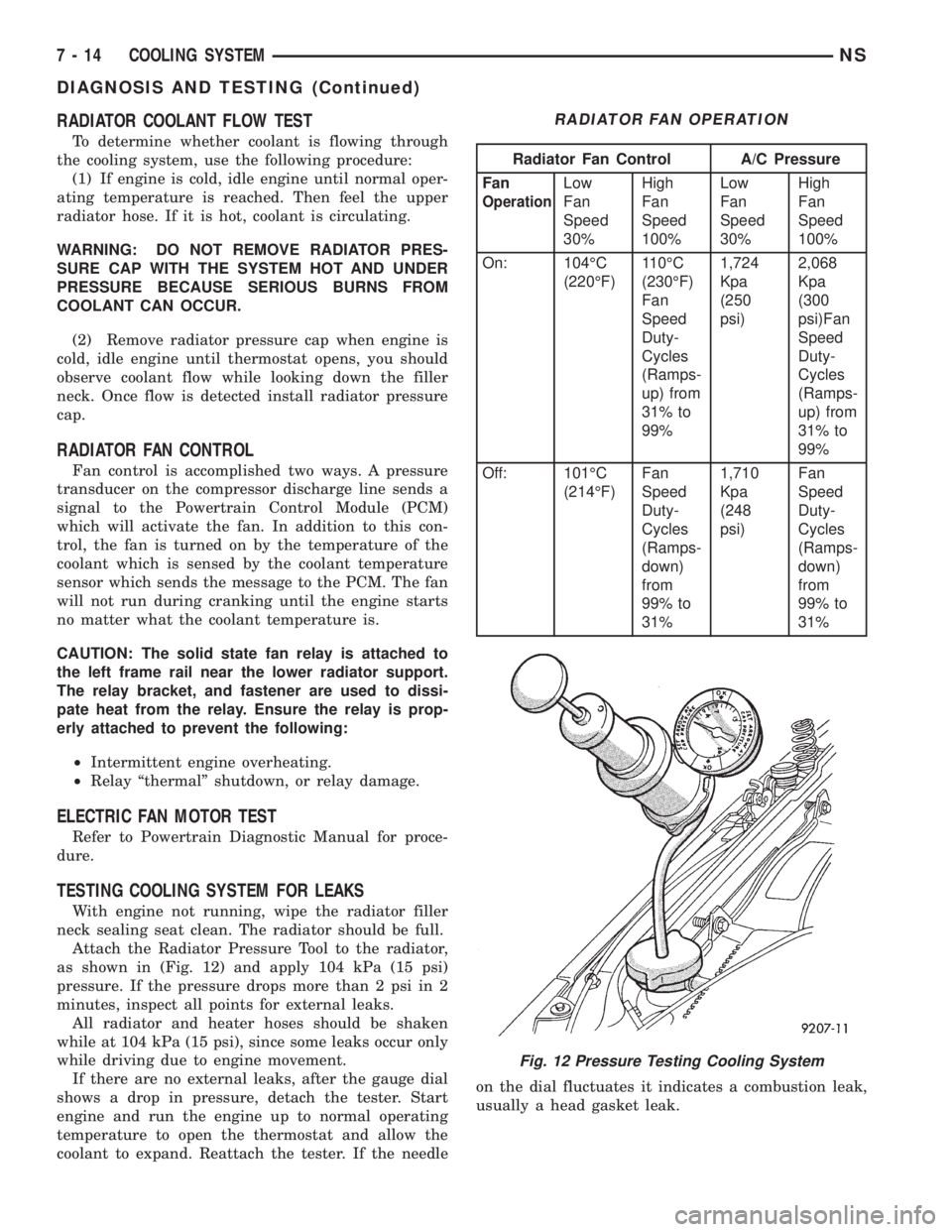

Attach the Radiator Pressure Tool to the radiator,

as shown in (Fig. 12) and apply 104 kPa (15 psi)

pressure. If the pressure drops more than 2 psi in 2

minutes, inspect all points for external leaks.

All radiator and heater hoses should be shaken

while at 104 kPa (15 psi), since some leaks occur only

while driving due to engine movement.

If there are no external leaks, after the gauge dial

shows a drop in pressure, detach the tester. Start

engine and run the engine up to normal operating

temperature to open the thermostat and allow the

coolant to expand. Reattach the tester. If the needleon the dial fluctuates it indicates a combustion leak,

usually a head gasket leak.

RADIATOR FAN OPERATION

Radiator Fan Control A/C Pressure

Fan

Operation

Low

Fan

Speed

30%High

Fan

Speed

100%Low

Fan

Speed

30%High

Fan

Speed

100%

On: 104ÉC

(220ÉF)110ÉC

(230ÉF)

Fan

Speed

Duty-

Cycles

(Ramps-

up) from

31% to

99%1,724

Kpa

(250

psi)2,068

Kpa

(300

psi)Fan

Speed

Duty-

Cycles

(Ramps-

up) from

31% to

99%

Off: 101ÉC

(214ÉF)Fan

Speed

Duty-

Cycles

(Ramps-

down)

from

99% to

31%1,710

Kpa

(248

psi)Fan

Speed

Duty-

Cycles

(Ramps-

down)

from

99% to

31%

Fig. 12 Pressure Testing Cooling System

7 - 14 COOLING SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 230 of 1938

at running operating temperature the high pressure

inlet tank runs full and the low pressure outlet tank

drops:

²Transmission oil will become hotter.

²High reading shown on the temperature gauge.

²Air in the coolant can cause loss of flow through

the heater.

²Exhaust gas leaks into the coolant also can

cause the same problems.

DEAERATION

Air can only be removed from the system by gath-

ering under the pressure cap. On the next heat up it

will be pushed past the pressure cap into the CRS

tank by thermal expansion of the coolant. It then

escapes to the atmosphere in the CRS tank and is

replaced with solid coolant on cool down.

TEMPERATURE GAUGE INDICATION

At idle with Air Conditioning off the temperature

gauge will rise slowly to about 5/8 gauge travel, the

fan will come on and the gauge will quickly drop to

about 1/2 gauge travel. This is normal.

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE

Do not remove radiator cap for routine cool-

ant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the radiator cap.With the engine cold

and not running,simply observe the level of the

coolant in the reserve tank (Fig. 3). The coolant level

should be between the minimum and maximum

marks.

COOLANTÐADDING ADDITIONAL

The radiator cap should not be removed.

When additional coolant is needed to maintain this

level, it should be added to the coolant reserve tank.

Use only 50/50 mix of ethylene glycol type antifreeze

and water.

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended.

COOLANT LEVEL SERVICE

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator.

When servicing requires a coolant level check in

the radiator, the engine must beoffandnotunder

pressure. Drain several ounces of coolant from the

radiator draincock while observing the CoolantRecovery System (CRS) Tank. Coolant level in the

CRS tank should drop slightly. Then remove the radi-

ator cap. The radiator should be full to the top. If

not, and the coolant level in the CRS tank is at the

MIN mark there is an air leak in the CRS system.

Check hose or hose connections to the CRS tank,

radiator filler neck or the pressure cap seal to the

radiator filler neck for leaks.

COOLING SYSTEMÐDRAINING

Without removing radiator pressure cap and

with system not under pressure,shut engine off

and open draincock. The coolant reserve tank should

empty first, then remove radiator pressure cap. (if

not, see Testing Cooling System for leaks). To vent

2.4L engine remove the coolant temperature sensor

located above water outlet housing (Fig. 15). The 3.0/

3.3/3.8L engines have an air bleed vent on the ther-

mostat.

Removal of a sensor is required because the ther-

mostat does not have an air vent. Sensor removal

allows an air bleed for coolant to drain from the

engine block.

COOLING SYSTEMÐREFILLING

First clean system to remove old coolant, see Cool-

ing System Cleaning.

Fill the system, using the correct antifreeze as

described in the Coolant Section. Fill the system to

50 percent of its capacity with 100 percent glycol.

Then complete filling system with water. The 2.4L

engine requires venting by removal of the coolant

sensor on top of the water outlet connector (Fig. 15).

When coolant reaches this hole:

²Install coolant sensor and tighten to 7 N´m (60

in. lbs.) for 2.4L Engines.

Fig. 15 Coolant Temperature SensorÐ2.4L Engine

Drain/Fill

7 - 16 COOLING SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 231 of 1938

Continue filling system until full, this provides bet-

ter heater performance.Be careful not to spill

coolant on drive belts or the generator.

Fill coolant reserve system to at least the MAX

mark with 50/50 solution. It may be necessary to add

coolant to the reserve tank after three or four warm

up/cool down cycles to maintain coolant level between

the MAX and MIN mark. This will allow trapped air

to be removed from the system.

REMOVAL AND INSTALLATION

WATER PUMPÐ2.4L ENGINE

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on a hoist. Remove right inner

splash shield.

(3) Remove accessory drive belts. Refer to Acces-

sory Drive Belt service in this section.

(4) Drain cooling system. Refer to Cooling System

Draining in this section.

(5) Support engine from the bottom and remove

right engine mount.

(6) Remove right engine mount bracket.

(7) Remove timing belt. Refer to Group 9, Engine

for procedure.

(8) Remove timing belt idler pulley.

(9) Hold camshaft sprocket with Special tool

C-4687 and adaptor C-4687-1 while removing bolt.

Remove both cam sprockets.

(10) Remove rear timing belt cover.

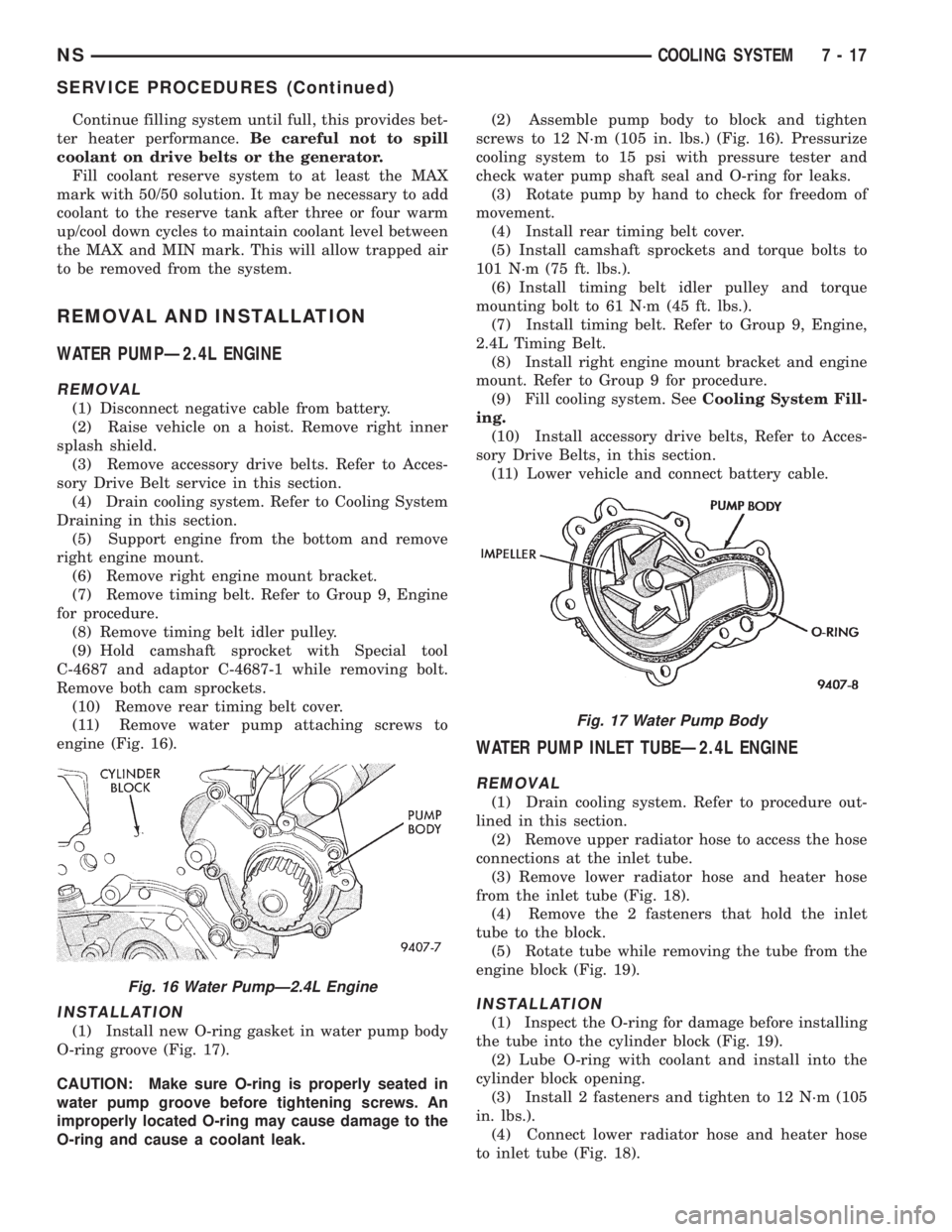

(11) Remove water pump attaching screws to

engine (Fig. 16).

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring groove (Fig. 17).

CAUTION: Make sure O-ring is properly seated in

water pump groove before tightening screws. An

improperly located O-ring may cause damage to the

O-ring and cause a coolant leak.(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.) (Fig. 16). Pressurize

cooling system to 15 psi with pressure tester and

check water pump shaft seal and O-ring for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install rear timing belt cover.

(5) Install camshaft sprockets and torque bolts to

101 N´m (75 ft. lbs.).

(6) Install timing belt idler pulley and torque

mounting bolt to 61 N´m (45 ft. lbs.).

(7) Install timing belt. Refer to Group 9, Engine,

2.4L Timing Belt.

(8) Install right engine mount bracket and engine

mount. Refer to Group 9 for procedure.

(9) Fill cooling system. SeeCooling System Fill-

ing.

(10) Install accessory drive belts, Refer to Acces-

sory Drive Belts, in this section.

(11) Lower vehicle and connect battery cable.

WATER PUMP INLET TUBEÐ2.4L ENGINE

REMOVAL

(1) Drain cooling system. Refer to procedure out-

lined in this section.

(2) Remove upper radiator hose to access the hose

connections at the inlet tube.

(3) Remove lower radiator hose and heater hose

from the inlet tube (Fig. 18).

(4) Remove the 2 fasteners that hold the inlet

tube to the block.

(5) Rotate tube while removing the tube from the

engine block (Fig. 19).

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 19).

(2) Lube O-ring with coolant and install into the

cylinder block opening.

(3) Install 2 fasteners and tighten to 12 N´m (105

in. lbs.).

(4) Connect lower radiator hose and heater hose

to inlet tube (Fig. 18).

Fig. 16 Water PumpÐ2.4L Engine

Fig. 17 Water Pump Body

NSCOOLING SYSTEM 7 - 17

SERVICE PROCEDURES (Continued)

Page 235 of 1938

INSTALLATION

(1) Place a new gasket (dipped in water) on the

thermostat housing surface, center thermostat into

opening in the intake manifold water box.

(2) Place housing and gasket over the thermostat,

making sure thermostat is in the recess provided

(Fig. 28).

(3) Bolt housing to intake manifold, tighten bolts

to 28 N´m (250 in. lbs.).

(4) Refill the cooling system to the proper level.

Refer to Cooling System Refilling outlined in this sec-

tion for procedure.

RADIATOR

REMOVAL

(1) Disconnect negative cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(2) Drain cooling system. Refer to Draining Cool-

ing System of this section.

(3) Remove air intake resonator.

(4) Remove coolant reserve system tank to filler

neck tube hose.

(5) Disconnect fans from the connector located on

the left side of the fan module.

(6) Remove the Coolant Recovery System (CRS)

tank retaining screw from the upper radiator closure

panel crossmember.

(7) Disconnect the upper radiator mounting

screws from the crossmember. Disconnect the engine

block heater wire if equipped.

(8) Remove the upper radiator closure panel

crossmember. Refer to Group 23 Body for procedure.

(9) Remove air cleaner assembly.

(10) Disconnect automatic transmission oil cooler

lines at radiator and plug.

(11) Disconnect inlet and outlet hoses from the

radiator. Remove the lower hose clip from the fan

module.

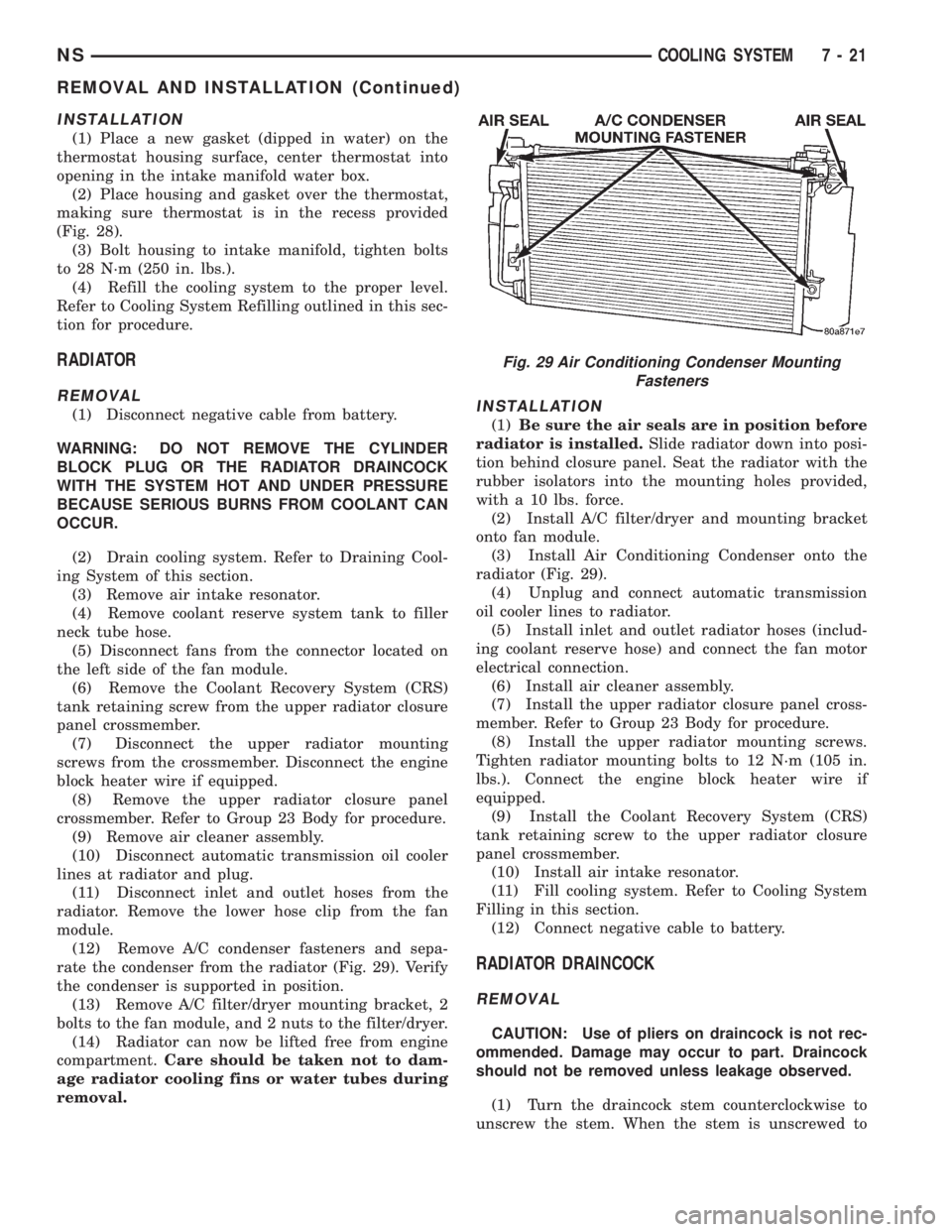

(12) Remove A/C condenser fasteners and sepa-

rate the condenser from the radiator (Fig. 29). Verify

the condenser is supported in position.

(13) Remove A/C filter/dryer mounting bracket, 2

bolts to the fan module, and 2 nuts to the filter/dryer.

(14) Radiator can now be lifted free from engine

compartment.Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.INSTALLATION

(1)Be sure the air seals are in position before

radiator is installed.Slide radiator down into posi-

tion behind closure panel. Seat the radiator with the

rubber isolators into the mounting holes provided,

with a 10 lbs. force.

(2) Install A/C filter/dryer and mounting bracket

onto fan module.

(3) Install Air Conditioning Condenser onto the

radiator (Fig. 29).

(4) Unplug and connect automatic transmission

oil cooler lines to radiator.

(5) Install inlet and outlet radiator hoses (includ-

ing coolant reserve hose) and connect the fan motor

electrical connection.

(6) Install air cleaner assembly.

(7) Install the upper radiator closure panel cross-

member. Refer to Group 23 Body for procedure.

(8) Install the upper radiator mounting screws.

Tighten radiator mounting bolts to 12 N´m (105 in.

lbs.). Connect the engine block heater wire if

equipped.

(9) Install the Coolant Recovery System (CRS)

tank retaining screw to the upper radiator closure

panel crossmember.

(10) Install air intake resonator.

(11) Fill cooling system. Refer to Cooling System

Filling in this section.

(12) Connect negative cable to battery.

RADIATOR DRAINCOCK

REMOVAL

CAUTION: Use of pliers on draincock is not rec-

ommended. Damage may occur to part. Draincock

should not be removed unless leakage observed.

(1) Turn the draincock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

Fig. 29 Air Conditioning Condenser Mounting

Fasteners

NSCOOLING SYSTEM 7 - 21

REMOVAL AND INSTALLATION (Continued)

Page 237 of 1938

(13) Raise the vehicle. Install the lower auxiliary

transmission cooler lines to the retaining clips on the

fan module shroud, if equipped.

(14) Install outlet hose retainer clip to the shroud.

Install the radiator outlet hose to the retaining clip.

(15) Lower the vehicle.

ENGINE BLOCK HEATER

REMOVAL

(1) Drain coolant from radiator and cylinder block.

Refer to Cooling System Drain, Clean, Flush and

Refill of this section for procedure.

(2) Remove power cord plug from heater.

(3) Loosen screw in center of heater. Remove

heater assembly.

INSTALLATION

(1) Thoroughly clean core hole and heater seat.

(2) Insert heater assembly with element loop posi-

tionedupward.

(3) With heater seated, tighten center screw

securely to assure a positive seal.

(4) Fill cooling system with coolant to the proper

level, vent air, and inspect for leaks. Pressurize sys-

tem with Radiator Pressure Tool before looking for

leaks.

(5) Install power cord plug to heater.

ACCESSORY DRIVE BELTSÐ2.4L

REMOVAL/INSTALLATION-ADJUST

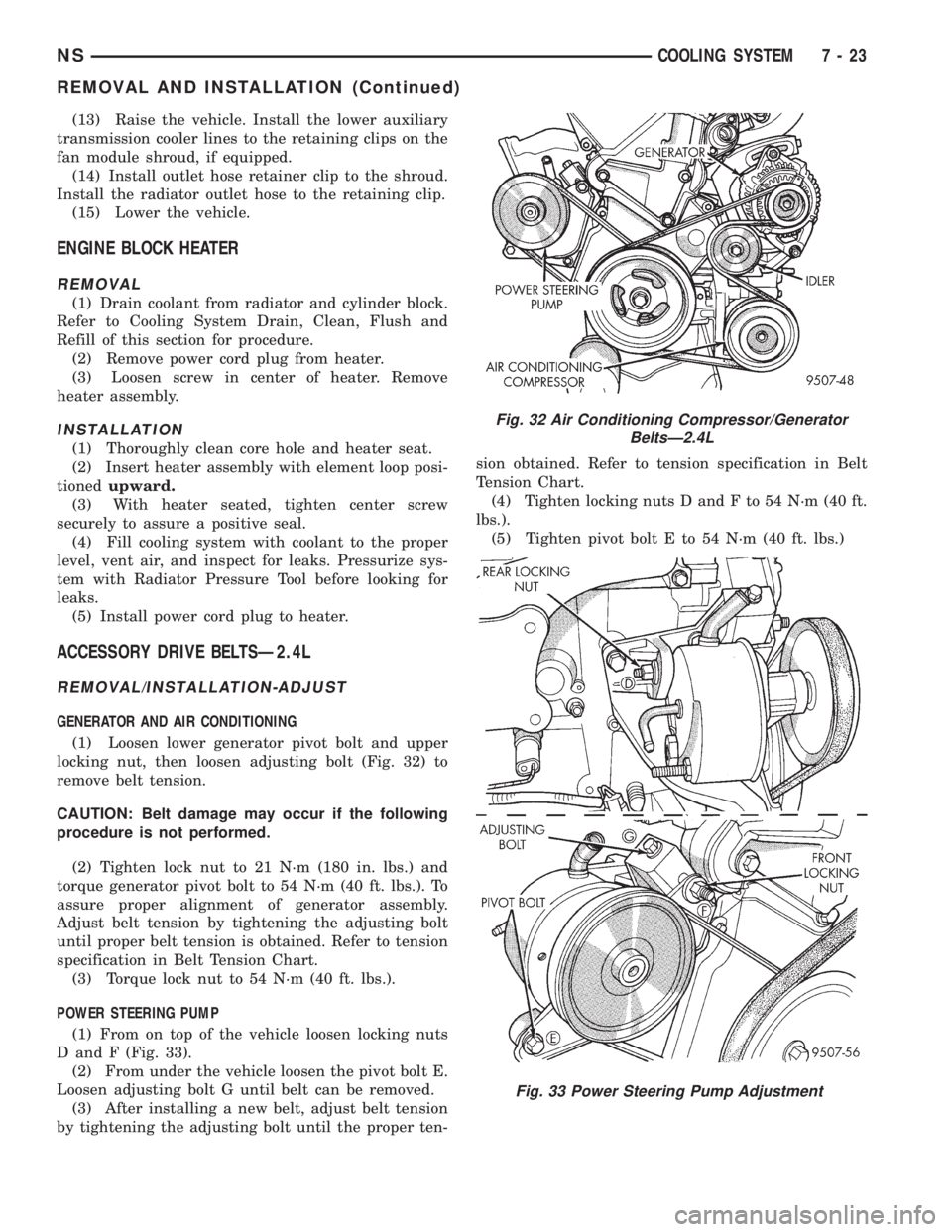

GENERATOR AND AIR CONDITIONING

(1) Loosen lower generator pivot bolt and upper

locking nut, then loosen adjusting bolt (Fig. 32) to

remove belt tension.

CAUTION: Belt damage may occur if the following

procedure is not performed.

(2) Tighten lock nut to 21 N´m (180 in. lbs.) and

torque generator pivot bolt to 54 N´m (40 ft. lbs.). To

assure proper alignment of generator assembly.

Adjust belt tension by tightening the adjusting bolt

until proper belt tension is obtained. Refer to tension

specification in Belt Tension Chart.

(3) Torque lock nut to 54 N´m (40 ft. lbs.).

POWER STEERING PUMP

(1) From on top of the vehicle loosen locking nuts

D and F (Fig. 33).

(2) From under the vehicle loosen the pivot bolt E.

Loosen adjusting bolt G until belt can be removed.

(3) After installing a new belt, adjust belt tension

by tightening the adjusting bolt until the proper ten-sion obtained. Refer to tension specification in Belt

Tension Chart.

(4) Tighten locking nuts D and F to 54 N´m (40 ft.

lbs.).

(5) Tighten pivot bolt E to 54 N´m (40 ft. lbs.)

Fig. 32 Air Conditioning Compressor/Generator

BeltsÐ2.4L

Fig. 33 Power Steering Pump Adjustment

NSCOOLING SYSTEM 7 - 23

REMOVAL AND INSTALLATION (Continued)

Page 240 of 1938

and the remove the splash shield to gain access to

the drive belts.

BELT TENSION GAUGE METHOD

Use belt tensioning Special Tool Kit C-4162 for:

CAUTION: The Burroughs gauge for the Poly-V

belt is not to be used on the V-belt. These gauges

are not interchangeable.

²For conventional V-belts affix the Burroughs

gauge (Special Tool C-4162) to the belt. Adjust the

belt tension for New or Used belt as prescribed in the

Belt Tension Chart.

²For a Poly-V belt affix the Poly-V Burroughs

gauge to the belt and then apply specified tension to

the belt as prescribed in the Belt Tension Chart

Adjust belt tension for aNeworUsedbelt as pre-

scribed in the Belt Tension Chart.

BELT TENSION CHARTSPECIFICATIONS

COOLING SYSTEM CAPACITY

TORQUE CHART

DESCRIPTION TORQUE

Thermostat Housing

BoltsÐ2.4L & 3.3/3.8L......28N´m(250 in. lbs.)

BoltsÐ3.0L...............12N´m(105 in. lbs.)

Water Pump Mounting

BoltsÐ2.4L & 3.3/3.8L......12N´m(250 in. lbs.)

BoltsÐ3.0L...............27N´m(240 in. lbs.)

Water Pump Inlet Tube

BoltsÐ2.4L...............12N´m(250 in. lbs.)

BoltsÐ3.0L................11N´m(94in.lbs.)

Water Pump Pulley

BoltsÐ3.3/3.8L............28N´m(250 in. lbs.)

Transaxle Oil Cooler Hose

ClampsÐAll Engines.........2N´m(18in.lbs.)

Radiator Mounting Upper Bracket

NutÐAll Engines..........12N´m(105 in. lbs.)

SPECIAL TOOLS

COOLING

ACCESSORY DRIVE

BELTGAUGE

2.4L ENGINE

A/C COMPRESSOR /

GENERATORNEW 190 LB.

USED 115 LB.

POWER STEERING NEW 140 LB.

USED 90 LB.

3.0L ENGINE

A/C COMPRESSOR NEW 150 LB.

USED 80 LB.

GENERATOR / POWER

STEERINGDYNAMIC TENSIONER

3.3/3.8L ENGINES

A/C COMPRESSOR DYNAMIC TENSIONER

GENERATOR / WATER

PUMP / POWER

STEERINGDYNAMIC TENSIONER

Engine Standard Duty Trailer Tow or

Heavy Duty

Front

HeaterRear

HeaterFront

HeaterRear

Heater

2.4L 10.6

liters*

(11.23

qts.)*N/A N/A N/A

3.0L 12.3

liters*

(13.0

qts.)*N/A N/A 15.0

liters*

(15.9

qts.)*

3.3/3.8L 12.5

liters*15.26

liters*12.5

liters*15.26

liters*

(13.23

qts.)*(16.13

qts.)*(13.23

qts.)*(16.13

qts)*

*Includes Heater and Coolant Recovery Tank Filled to

Max Level.

Belt Tension Gauge C-4162

7 - 26 COOLING SYSTEMNS

ADJUSTMENTS (Continued)

Page 241 of 1938

COOLING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

COOLANT PRESSURE BOTTLE............ 1

COOLING SYSTEM Ð 2.0L GASOLINE...... 1

COOLING SYSTEM Ð 2.5L VM DIESEL..... 1

LOW COOLANT LEVEL SENSOR........... 1

RADIATOR............................ 2

DESCRIPTION AND OPERATION

AUTOMATIC BELT TENSIONER............ 6

BELT TENSION......................... 5

COOLANT PERFORMANCE............... 5

PRESSURE/VENT CAP................... 4

THERMOSTAT OPERATION............... 4

THERMOSTAT......................... 6

WATER PUMP......................... 3

SERVICE PROCEDURES

ADDING ADDITIONAL COOLANT........... 7

DRAINING COOLING SYSTEM............. 7

REFILLING COOLING SYSTEM............ 7

REMOVAL AND INSTALLATION

ENGINE THERMOSTATÐ 2.0L GASOLINE . . . 9GENERATOR/POWER STEERING BELT Ð 2.5L

VM DIESEL......................... 10

RADIATOR Ð 2.5L VM DIESEL........... 9

THERMOSTAT Ð 2.5L VM DIESEL......... 9

WATER PUMP BELT Ð 2.5L VM DIESEL . . . 10

WATER PUMP Ð 2.0L GASOLINE......... 7

WATER PUMP Ð 2.5L VM DIESEL........ 8

CLEANING AND INSPECTION

WATER PUMP........................ 10

ADJUSTMENTS

BELT TENSION CHART................. 11

BELT TENSION GAUGE METHOD......... 11

SPECIFICATIONS

COOLING SYSTEM CAPACITY............ 12

TORQUE CHART...................... 12

SPECIAL TOOLS

COOLING............................ 12

GENERAL INFORMATION

COOLING SYSTEM Ð 2.0L GASOLINE

The 2.0L gasoline engine cooling system consists of

an engine cooling module, thermostat, coolant, a

water pump to circulate the coolant. The engine cool-

ing module may consist of a radiator, electric fan

motors, fan, shroud, coolant reserve system, hoses,

clamps, air condition condenser.

²When the Engine is cold: The thermostat is

closed; the cooling system has no flow through the

radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open;

the cooling system has flow through radiator, engine,

heater system and bypass.

COOLING SYSTEM Ð 2.5L VM DIESEL

The cooling system has a radiator, coolant, electric

fan motors, shroud, pressure cap, thermostat, coolant

pressure bottle, hoses, a water pump to circulate the

coolant, to complete the circuit. Coolant flow for the

VM diesel engine is shown in (Fig. 1).

COOLANT PRESSURE BOTTLE

2.5L VM DIESEL

This system works with the pressure cap to use

thermal expansion and contraction of the coolant to

keep the coolant free of trapped air. It provides some

reserve coolant to cover minor leaks and evaporation

or boiling losses. The coolant pressure bottle location

for 2.5L diesel is above the cylinder head cover (Fig.

2).

LOW COOLANT LEVEL SENSOR

The low coolant level sensor checks for low coolant

level in the coolant tank. A signal will be sent from

this sensor to the Body Control Module (BCM). When

the BCM determines low coolant level for 30 contin-

uous seconds, the instrument panel mounted low

coolant level warning lamp will be illuminated. The

sensor is located on the front side of the coolant tank

(Fig. 4). For information, refer to Group 8E, Instru-

ment Panel and Gauges.

If this lamp is illuminated, it indicates the need to

fill the coolant tank and check for leaks.

NS/GSCOOLING SYSTEM 7 - 1

Page 246 of 1938

Initial belt adjustment is done with a adjustable

tensioner pulley. After the initial adjustment is per-

formed, an automatic belt tensioner is used to main-

tain correct belt tension at all times. Do not attempt

to check belt tension with a belt tension gauge on

vehicles equipped with an automatic belt tensioner.

Refer to Automatic Belt Tensioner in this group.

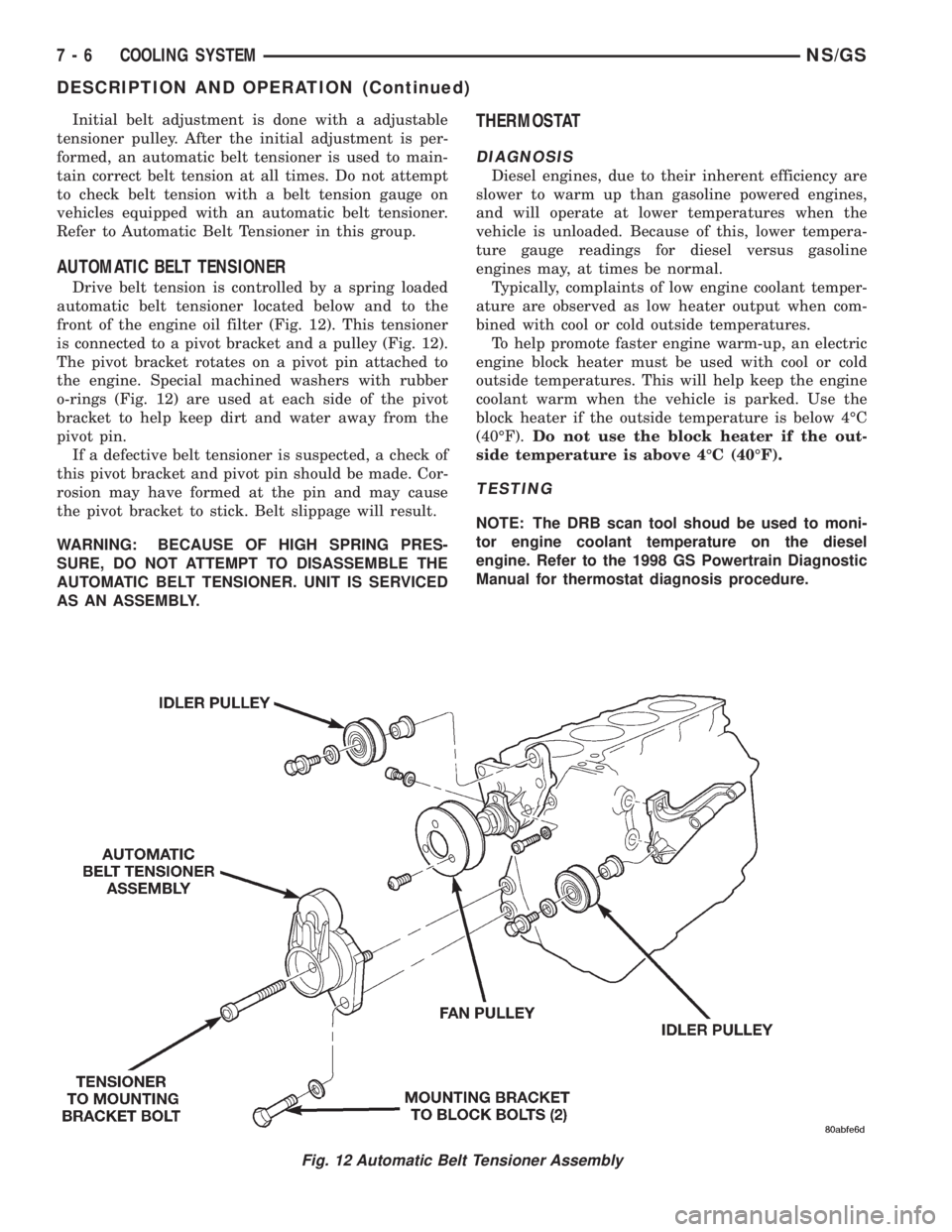

AUTOMATIC BELT TENSIONER

Drive belt tension is controlled by a spring loaded

automatic belt tensioner located below and to the

front of the engine oil filter (Fig. 12). This tensioner

is connected to a pivot bracket and a pulley (Fig. 12).

The pivot bracket rotates on a pivot pin attached to

the engine. Special machined washers with rubber

o-rings (Fig. 12) are used at each side of the pivot

bracket to help keep dirt and water away from the

pivot pin.

If a defective belt tensioner is suspected, a check of

this pivot bracket and pivot pin should be made. Cor-

rosion may have formed at the pin and may cause

the pivot bracket to stick. Belt slippage will result.

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE THE

AUTOMATIC BELT TENSIONER. UNIT IS SERVICED

AS AN ASSEMBLY.

THERMOSTAT

DIAGNOSIS

Diesel engines, due to their inherent efficiency are

slower to warm up than gasoline powered engines,

and will operate at lower temperatures when the

vehicle is unloaded. Because of this, lower tempera-

ture gauge readings for diesel versus gasoline

engines may, at times be normal.

Typically, complaints of low engine coolant temper-

ature are observed as low heater output when com-

bined with cool or cold outside temperatures.

To help promote faster engine warm-up, an electric

engine block heater must be used with cool or cold

outside temperatures. This will help keep the engine

coolant warm when the vehicle is parked. Use the

block heater if the outside temperature is below 4ÉC

(40ÉF).Do not use the block heater if the out-

side temperature is above 4ÉC (40ÉF).

TESTING

NOTE: The DRB scan tool shoud be used to moni-

tor engine coolant temperature on the diesel

engine. Refer to the 1998 GS Powertrain Diagnostic

Manual for thermostat diagnosis procedure.

Fig. 12 Automatic Belt Tensioner Assembly

7 - 6 COOLING SYSTEMNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 247 of 1938

SERVICE PROCEDURES

ADDING ADDITIONAL COOLANT

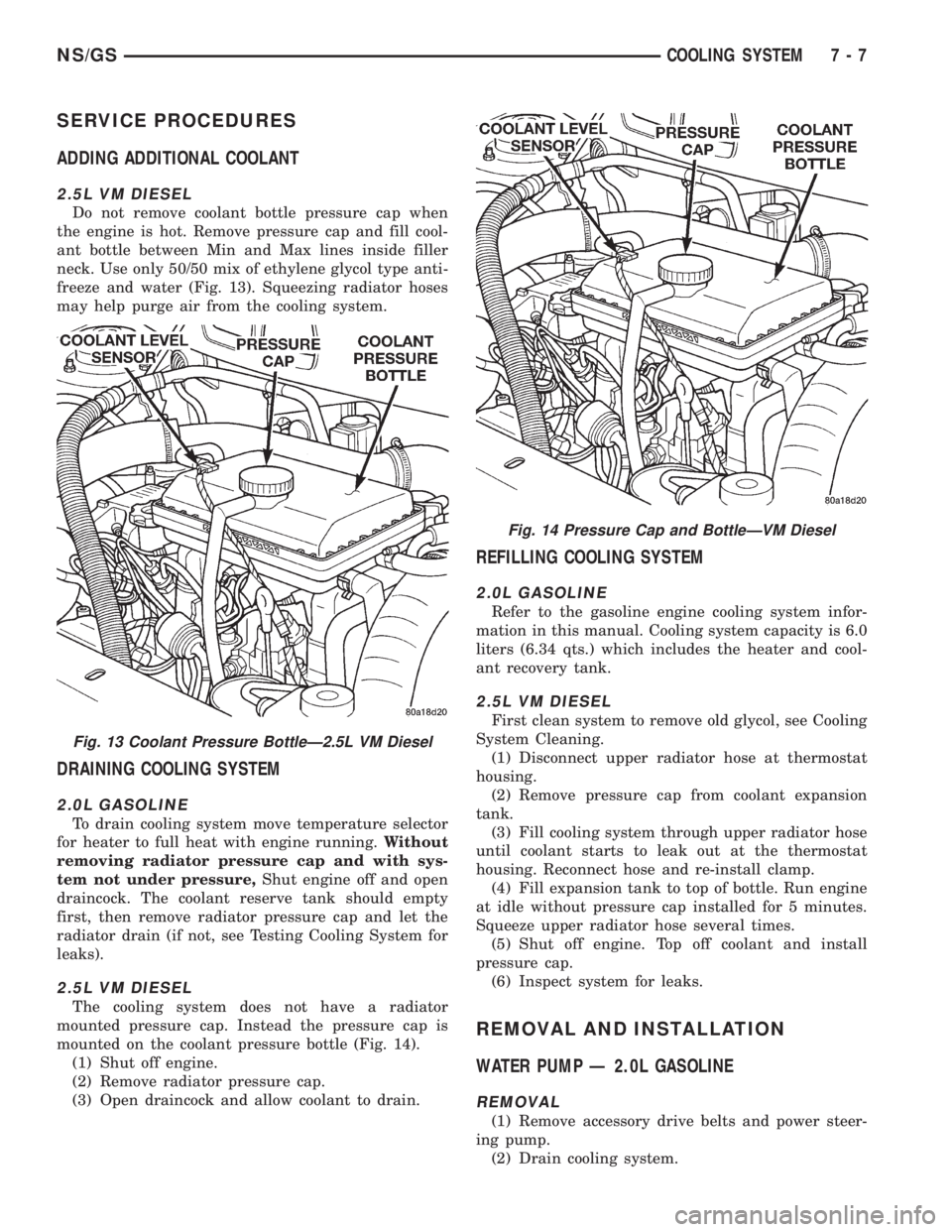

2.5L VM DIESEL

Do not remove coolant bottle pressure cap when

the engine is hot. Remove pressure cap and fill cool-

ant bottle between Min and Max lines inside filler

neck. Use only 50/50 mix of ethylene glycol type anti-

freeze and water (Fig. 13). Squeezing radiator hoses

may help purge air from the cooling system.

DRAINING COOLING SYSTEM

2.0L GASOLINE

To drain cooling system move temperature selector

for heater to full heat with engine running.Without

removing radiator pressure cap and with sys-

tem not under pressure,Shut engine off and open

draincock. The coolant reserve tank should empty

first, then remove radiator pressure cap and let the

radiator drain (if not, see Testing Cooling System for

leaks).

2.5L VM DIESEL

The cooling system does not have a radiator

mounted pressure cap. Instead the pressure cap is

mounted on the coolant pressure bottle (Fig. 14).

(1) Shut off engine.

(2) Remove radiator pressure cap.

(3) Open draincock and allow coolant to drain.

REFILLING COOLING SYSTEM

2.0L GASOLINE

Refer to the gasoline engine cooling system infor-

mation in this manual. Cooling system capacity is 6.0

liters (6.34 qts.) which includes the heater and cool-

ant recovery tank.

2.5L VM DIESEL

First clean system to remove old glycol, see Cooling

System Cleaning.

(1) Disconnect upper radiator hose at thermostat

housing.

(2) Remove pressure cap from coolant expansion

tank.

(3) Fill cooling system through upper radiator hose

until coolant starts to leak out at the thermostat

housing. Reconnect hose and re-install clamp.

(4) Fill expansion tank to top of bottle. Run engine

at idle without pressure cap installed for 5 minutes.

Squeeze upper radiator hose several times.

(5) Shut off engine. Top off coolant and install

pressure cap.

(6) Inspect system for leaks.

REMOVAL AND INSTALLATION

WATER PUMP Ð 2.0L GASOLINE

REMOVAL

(1) Remove accessory drive belts and power steer-

ing pump.

(2) Drain cooling system.

Fig. 13 Coolant Pressure BottleÐ2.5L VM Diesel

Fig. 14 Pressure Cap and BottleÐVM Diesel

NS/GSCOOLING SYSTEM 7 - 7

Page 252 of 1938

SPECIFICATIONS

COOLING SYSTEM CAPACITY

TORQUE CHART

SPECIAL TOOLS

COOLING

2.0L Gasoline *10.6 liters (11 qts.)

2.5L VM Diesel *10.0 liters (10.6 qts.)

*Includes Heater and Coolant recovery/pressure Tank.

COMPONENT 2.0L

GASOLINE2.5L VM

Thermostat

Cover Bolts105 in-lbs 10.8 N´m (96 in.

lbs.)

Water Pump

Mounting Bolts12 N´m (105 in.

lbs.)22.6 N´m (204

in. lbs.)

Water Pump

Pulley BoltsN/A 27.5 N´m (240

in. lbs.)

Upper Radiator

Mounting

Bracket Bolts12 N´m (105 in.

lbs.)12 N´m (105 in.

lbs.)

Turbocharger

Oil Supply LineN/A 24.5 N´m (215

in. lbs.)

Turbocharger

Oil Return LineN/A 10.8 N´m (96 in.

lbs.)

Water Pump

Housing NutsN/A 9.5 N´m (84 in.

lbs.)

Water Manifold

BoltsN/A 11.2 N´m (96 in.

lbs.)

Coolant Bottle

Bolts2.0 N´m (18 in.

lbs.)10.8 N´m (96 in.

lbs.)

Belt Tension Gauge C-4162

7 - 12 COOLING SYSTEMNS/GS