heater CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 290 of 1938

CHARGING SYSTEM RESISTANCE TESTS

These tests will show the amount of voltage drop

across the generator output wire from the generator

output (B+) terminal to the battery positive post.

They will also show the amount of voltage drop from

the ground (-) terminal on the generator or case

ground (Fig. 1) to the battery negative post.

A voltmeter with a 0±18 volt DC scale should be

used for these tests. By repositioning the voltmeter

test leads, the point of high resistance (voltage drop)

can easily be found.

PREPARATION

(1) Before starting test, make sure battery is in

good condition and is fully-charged. See Group 8A,

Battery for more information.

(2) Check condition of battery cables at battery.

Clean if necessary.

(3) Start the engine and allow it to reach normal

operating temperature.

(4) Shut engine off.

(5) Connect an engine tachometer.

(6) Fully engage the parking brake.

TEST

(1) Start engine.

(2) Place heater blower in high position.

(3) Turn on headlamps and place in high-beam

position.

(4) Turn rear window defogger on.

(5) Bring engine speed up to 2400 rpm and hold.

(6) Testing (+ positive) circuitry:

(a) Touch the negative lead of voltmeter directly

to battery positivePOST(Fig. 2).

(b) Touch the positive lead of voltmeter to the

B+ output terminal stud on the generator (not the

terminal mounting nut). Voltage should be no

higher than 0.6 volts. If voltage is higher than 0.6

volts, touch test lead to terminal mounting stud

nut and then to the wiring connector. If voltage is

now below 0.6 volts, look for dirty, loose or poor

connection at this point. Also check condition of the

generator output wire-to-battery bullet connector.

Refer to Group 8, Wiring for connector location. A

voltage drop test may be performed at each (-

ground) connection in this circuit to locate the

excessive resistance.

(7) Testing (- ground) circuitry:

(a) Touch the positive lead of voltmeter directly

to battery negativePOST.

(b) Touch the negative lead of voltmeter to the

generator case. Voltage should be no higher than

0.3 volts. If voltage is higher than 0.3 volts, touch

test lead to generator case and then to the engine

block. If voltage is now below 0.3 volts, look for

dirty, loose or poor connection at this point. A volt-

age drop test may be performed at each connectionin this circuit to locate the excessive resistance.

This test can also be performed between the gener-

ator case and the engine. If test voltage is higher

than 0.3 volts, check for corrosion at generator

mounting points or loose generator mounting.

CURRENT OUTPUT TEST

The current output test will determine if the

charging system can deliver its minimum test cur-

rent (amperage) output. Refer to the Specifications

section at the end of this group for minimum test

current (amperage) requirements.

The first part of this test will determine the com-

bined amperage output of both the generator and the

Electronic Voltage Regulator (EVR) circuitry.

PREPARATION

(1) Determine if any Diagnostic Trouble Codes

(DTC) exist. To determine a DTC, refer to On-Board

Diagnostics in this group. For repair, refer to the

appropriate Powertrain Diagnostic Procedures man-

ual.

(2) Before starting test, make sure battery is in

good condition and is fully-charged. See Group 8A,

Battery for more information.

(3) Check condition of battery cables at battery.

Clean if necessary.

(4) Perform the Voltage Drop Test. This will

ensure clean and tight generator/battery electrical

connections.

(5) Be sure the generator drive belt is properly

tensioned. Refer to Group 7, Cooling System for

information.

(6) A volt/amp tester equipped with both a battery

load control (carbon pile rheostat) and an inductive-

type pickup clamp (ammeter probe) will be used for

this test. Refer to operating instructions supplied

with tester. When using a tester equipped with an

inductive-type clamp, removal of wiring at the gener-

ator will not be necessary.

(7) Start the engine and allow it to reach operating

temperature.

(8) Shut engine off.

(9) Turn off all electrical accessories and all vehicle

lighting.

(10) Connect the volt/amp tester leads to the bat-

tery. Be sure the carbon pile rheostat control is in the

OPEN or OFF position before connecting leads. See

Load Test in Group 8A, Battery for more information.

Also refer to the operating instructions supplied with

test equipment.

(11) Connect the inductive clamp (ammeter probe).

Refer to the operating instructions supplied with test

equipment.

(12) If volt/amp tester is not equipped with an

engine tachometer, connect a separate tachometer to

the engine.

8C - 4 CHARGING SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 302 of 1938

Clean Spark Plug cables with a cloth moistened

with a non-flammable solvent. Wipe the cables dry.

Check for brittle or cracked insulation.

SPARK PLUG CABLESÐ3.3/3.8L

The spark plug cables and spark plug boots are

made from high temperature silicone materials. The

spark plug boots utilize metal heat shields for ther-

mal protection from the exhaust manifold. The heat

shields slide over the spark plug boots. The notches

on the heat shields ensure the spark plug boot and

shield twist together during spark plug boot removal.

They also identify proper heat shield installation on

the boot for service.Refer to 3.3/3.8L Spark Plug

Cable removal and installation.All spark plug

cable leads are properly identified with cylinder num-

bers. The inside of the spark plug boot is coated with

a special high temperature silicone grease for greater

sealing and to minimize boot bonding to the spark

plug insulator. The convoluted tubing on the rear

plug cables are made of a high temperature plastic

material. Under normal driving conditions, the spark

plug cables have a recommended service life of a

100,000 miles. The spark plugs have a recommended

service life of 75,000 miles for severe driving condi-

tions per schedule B in this manual.

The spark plug heat shield can be reused if an

ignition cable is replaced due to failure. Never reuse

heat shield's that have heat shield anti-twist, side or

spark plug attachment tabs bent or missing. Ensure

that the heat shield is properly attached to the spark

plug to avoid RFI problems. The bottom of the spark

plug heat shield must make contact with the spark

plug hex.

The front ignition cables must not make contact

with the oil dip stick tube and #5 cable must not

touch the coil mounting bolt to avoid abrasion/dielec-

tric failures.

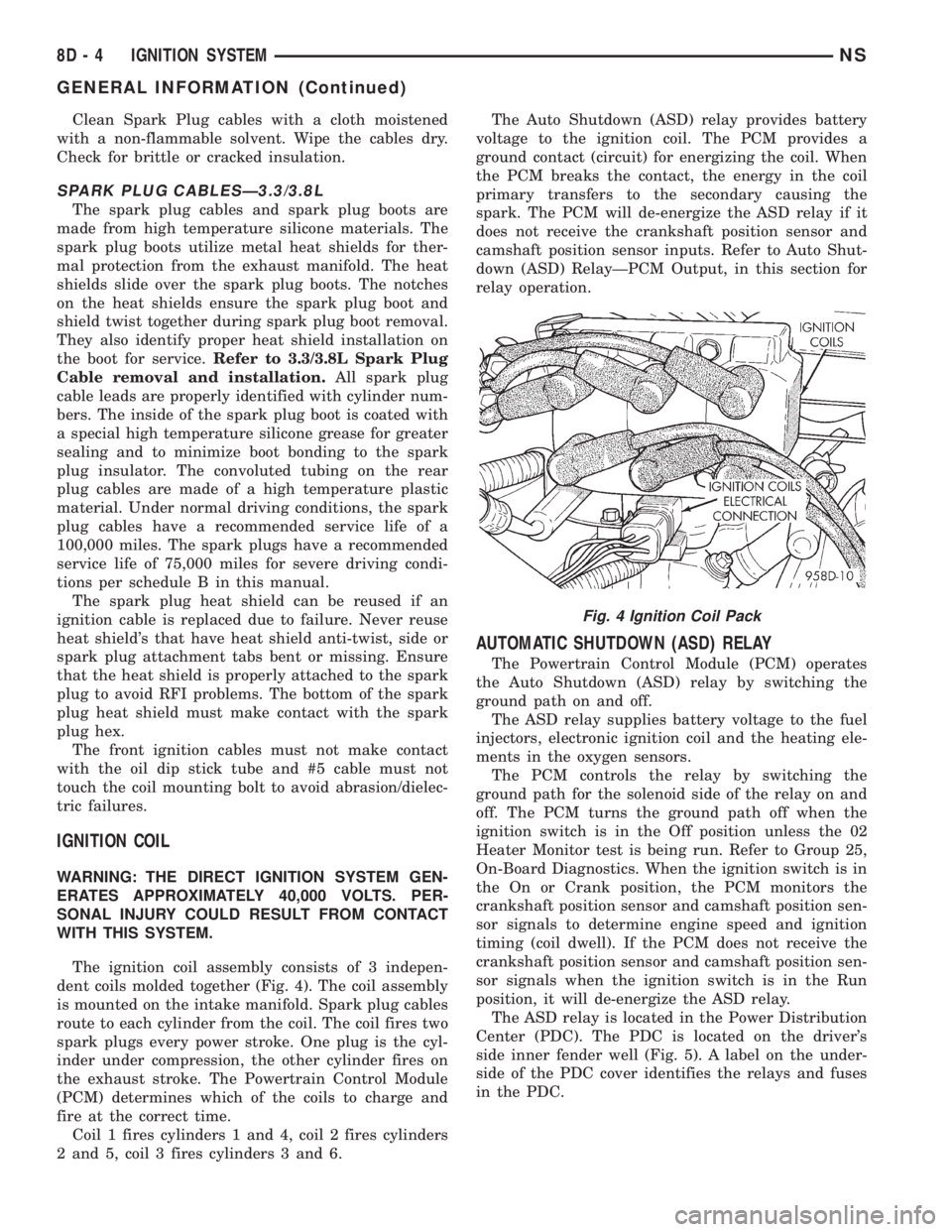

IGNITION COIL

WARNING: THE DIRECT IGNITION SYSTEM GEN-

ERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

The ignition coil assembly consists of 3 indepen-

dent coils molded together (Fig. 4). The coil assembly

is mounted on the intake manifold. Spark plug cables

route to each cylinder from the coil. The coil fires two

spark plugs every power stroke. One plug is the cyl-

inder under compression, the other cylinder fires on

the exhaust stroke. The Powertrain Control Module

(PCM) determines which of the coils to charge and

fire at the correct time.

Coil 1 fires cylinders 1 and 4, coil 2 fires cylinders

2 and 5, coil 3 fires cylinders 3 and 6.The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) RelayÐPCM Output, in this section for

relay operation.

AUTOMATIC SHUTDOWN (ASD) RELAY

The Powertrain Control Module (PCM) operates

the Auto Shutdown (ASD) relay by switching the

ground path on and off.

The ASD relay supplies battery voltage to the fuel

injectors, electronic ignition coil and the heating ele-

ments in the oxygen sensors.

The PCM controls the relay by switching the

ground path for the solenoid side of the relay on and

off. The PCM turns the ground path off when the

ignition switch is in the Off position unless the 02

Heater Monitor test is being run. Refer to Group 25,

On-Board Diagnostics. When the ignition switch is in

the On or Crank position, the PCM monitors the

crankshaft position sensor and camshaft position sen-

sor signals to determine engine speed and ignition

timing (coil dwell). If the PCM does not receive the

crankshaft position sensor and camshaft position sen-

sor signals when the ignition switch is in the Run

position, it will de-energize the ASD relay.

The ASD relay is located in the Power Distribution

Center (PDC). The PDC is located on the driver's

side inner fender well (Fig. 5). A label on the under-

side of the PDC cover identifies the relays and fuses

in the PDC.

Fig. 4 Ignition Coil Pack

8D - 4 IGNITION SYSTEMNS

GENERAL INFORMATION (Continued)

Page 337 of 1938

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

INSTRUMENT CLUSTER................... 1

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES................ 2

HEADLAMP SWITCH..................... 2

SELF DIAGNOSTIC TEST.................. 2

TRACTION CONTROL SWITCH............. 17

REMOVAL AND INSTALLATION

BODY CONTROL MODULE (BCM).......... 18

CONVENIENCE BIN - CUP HOLDER......... 17

CONVENIENCE BIN LAMP................ 17

CONVENIENCE BIN TRACK............... 18

GLOVE BOX LAMP AND SWITCH.......... 19

GLOVE BOX LOCK STRIKER.............. 20

GLOVE BOX........................... 19

HEADLAMP SWITCH LAMP(S)............ 21

HEADLAMP SWITCH.................... 20

HVAC CONTROL LAMP.................. 21

INSTRUMENT CLUSTER BACK PANEL...... 21

INSTRUMENT CLUSTER BEZEL............ 21

INSTRUMENT CLUSTER ELECTRONIC

ODOMETER AND TRANSMISSION RANGE

INDICATOR.......................... 19

INSTRUMENT CLUSTER LAMPS........... 22

INSTRUMENT CLUSTER LENS - MECHANICAL

TRANSMISSION RANGE INDICATOR

(PRND21)........................... 19

INSTRUMENT CLUSTER LENS............. 22INSTRUMENT CLUSTER PRINTED CIRCUIT

BOARD.............................. 23

INSTRUMENT CLUSTER SUBDIAL.......... 23

INSTRUMENT CLUSTER SUBDIALÐ

MECHANICAL TRANSMISSION RANGE

INDICATOR.......................... 23

INSTRUMENT CLUSTER WITH ELECTRONIC

TRANSMISSION RANGE INDICATOR...... 23

INSTRUMENT CLUSTER WITH MECHANICAL

TRANSMISSION RANGE INDICATOR...... 24

INSTRUMENT PANEL LEFT END COVER..... 27

INSTRUMENT PANEL LOUVERS........... 27

INSTRUMENT PANEL RIGHT END COVER.... 29

INSTRUMENT PANEL TOP COVER.......... 29

INSTRUMENT PANEL.................... 25

JUNCTION BLOCK...................... 30

KNEE BLOCKER REINFORCEMENT......... 30

LOWER CONSOLE...................... 30

LOWER INSTRUMENT PANEL............. 31

LOWER STEERING COLUMN COVER........ 31

MECHANICAL TRANSMISSION RANGE

INDICATOR.......................... 32

MESSAGE CENTER LAMP................ 32

MESSAGE CENTER...................... 32

OUTLET (12 VOLT) BASE................. 32

OVER STEERING COLUMN BEZEL.......... 32

POWER MIRROR SWITCH LAMP.......... 34

POWER MIRROR SWITCH................ 34

RADIO BEZEL AND HVAC CONTROL........ 34

REAR HEATER-A/C SWITCH LAMP......... 35

REAR HEATER-A/C SWITCH............... 35

TRACTION CONTROL SWITCH............. 35

GENERAL INFORMATION

INTRODUCTION

The instrumentation gauges on NS vehicles are

contained in a subdial assemblies within the instru-

ment cluster. The individual gauges are not serviced

separately. If one of the cluster gauges becomes

faulty the entire subdial would require replacement

and all gauges will have to be calibrated. Refer to the

proper Body Diagnostic Procedure Manual for cali-

bration procedures.

DESCRIPTION AND OPERATION

INSTRUMENT CLUSTER

The mechanical instrument cluster with a tachom-

eter is equipped with a electronic vacuum fluorescent

transmission range indicator (PRND3L), odometer,

and trip odometer display.

The mechanical instrument cluster without a

tachometer is equipped with a cable operated trans-

mission range indicator (PRND21).

NSINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 371 of 1938

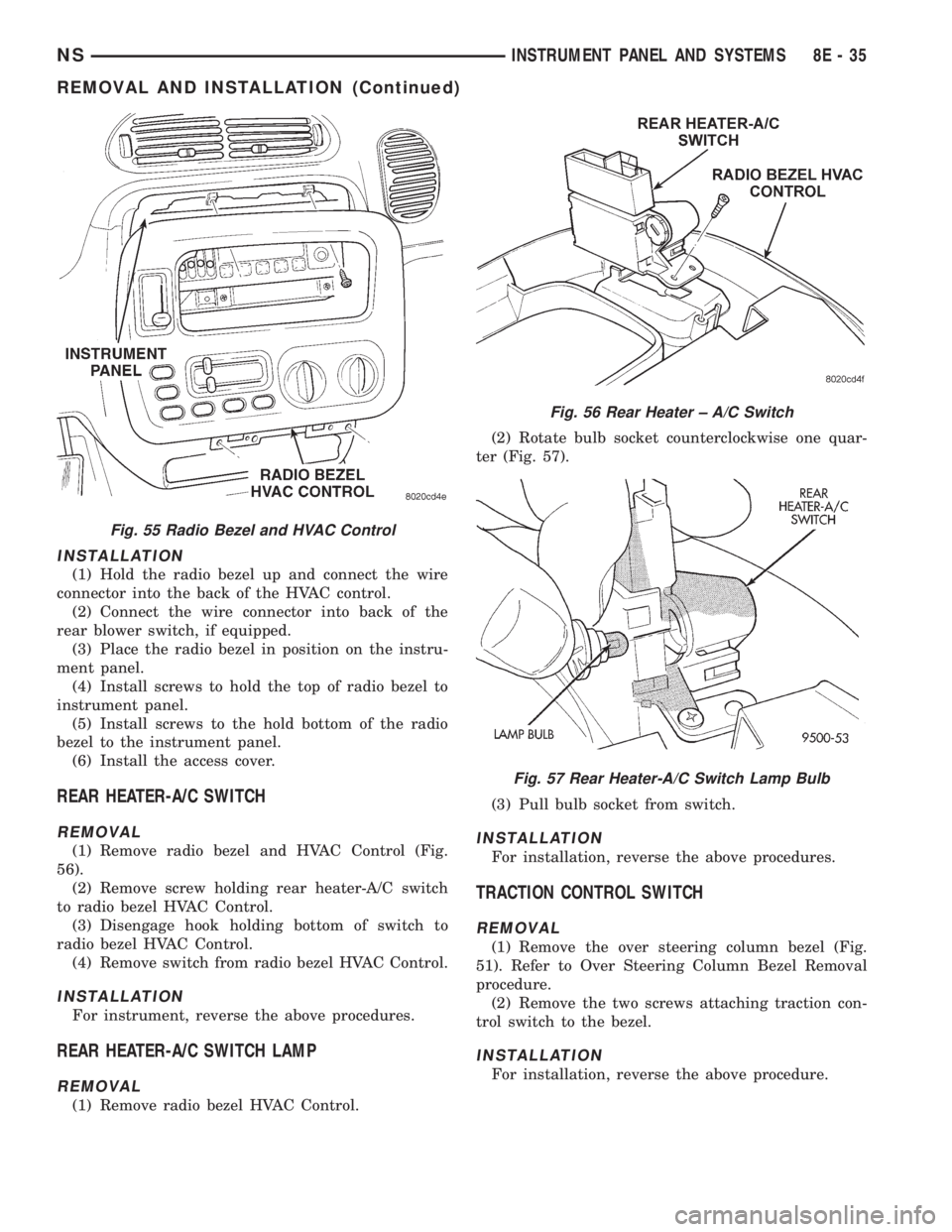

INSTALLATION

(1) Hold the radio bezel up and connect the wire

connector into the back of the HVAC control.

(2) Connect the wire connector into back of the

rear blower switch, if equipped.

(3) Place the radio bezel in position on the instru-

ment panel.

(4) Install screws to hold the top of radio bezel to

instrument panel.

(5) Install screws to the hold bottom of the radio

bezel to the instrument panel.

(6) Install the access cover.

REAR HEATER-A/C SWITCH

REMOVAL

(1) Remove radio bezel and HVAC Control (Fig.

56).

(2) Remove screw holding rear heater-A/C switch

to radio bezel HVAC Control.

(3) Disengage hook holding bottom of switch to

radio bezel HVAC Control.

(4) Remove switch from radio bezel HVAC Control.

INSTALLATION

For instrument, reverse the above procedures.

REAR HEATER-A/C SWITCH LAMP

REMOVAL

(1) Remove radio bezel HVAC Control.(2) Rotate bulb socket counterclockwise one quar-

ter (Fig. 57).

(3) Pull bulb socket from switch.

INSTALLATION

For installation, reverse the above procedures.

TRACTION CONTROL SWITCH

REMOVAL

(1) Remove the over steering column bezel (Fig.

51). Refer to Over Steering Column Bezel Removal

procedure.

(2) Remove the two screws attaching traction con-

trol switch to the bezel.

INSTALLATION

For installation, reverse the above procedure.

Fig. 55 Radio Bezel and HVAC Control

Fig. 56 Rear Heater ± A/C Switch

Fig. 57 Rear Heater-A/C Switch Lamp Bulb

NSINSTRUMENT PANEL AND SYSTEMS 8E - 35

REMOVAL AND INSTALLATION (Continued)

Page 373 of 1938

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION........................ 1

DESCRIPTION AND OPERATION

HEADLAMP AND POWER MIRROR

SWITCH LAMP(S)..................... 1

INSTRUMENT CLUSTER................. 2

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES.............. 2

HEADLAMP SWITCH.................... 2

SELF DIAGNOSTIC TEST................. 3

REMOVAL AND INSTALLATION

ASH RECEIVER ± CONVENIENCE

BIN LAMP MODULE.................. 15

BODY CONTROL MODULE (BCM)......... 16

CIGAR LIGHTER BASE.................. 16

CONVENIENCE BIN.................... 15

CONVENIENCE BIN - CUP HOLDER....... 15

GLOVE BOX.......................... 17

GLOVE BOX LAMP AND SWITCH......... 17

GLOVE BOX LOCK STRIKER............. 17

HEADLAMP SWITCH................... 18

HEADLAMP SWITCH LAMP(S)........... 18

HVAC CONTROL LAMP................. 18

INSTRUMENT CLUSTER................ 20INSTRUMENT CLUSTER BACK PANEL..... 18

INSTRUMENT CLUSTER BEZEL.......... 18

INSTRUMENT CLUSTER LENS........... 19

INSTRUMENT CLUSTER PRINTED

CIRCUIT BOARD..................... 19

INSTRUMENT CLUSTER SUBDIAL........ 20

INSTRUMENT PANEL................... 20

INSTRUMENT PANEL LEFT END COVER.... 22

INSTRUMENT PANEL LOUVERS.......... 22

INSTRUMENT PANEL RIGHT END COVER . . 25

INSTRUMENT PANEL TOP COVER........ 24

JUNCTION BLOCK..................... 25

KNEE BLOCKER REINFORCEMENT........ 25

LOWER CONSOLE..................... 26

LOWER INSTRUMENT PANEL............ 26

LOWER STEERING COLUMN COVER...... 27

MESSAGE CENTER.................... 27

OVER STEERING COLUMN BEZEL........ 28

POWER MIRROR SWITCH.............. 28

POWER MIRROR SWITCH LAMP......... 28

RADIO BEZEL AND HVAC CONTROL....... 29

REAR HEATER-A/C SWITCH............. 29

REAR HEATER-A/C SWITCH LAMP........ 29

GENERAL INFORMATION

INTRODUCTION

The instrumentation gauges on GS vehicles are

contained in a subdial assemblies within the instru-

ment cluster. The individual gauges are not serviced

separately. If one of the cluster gauges becomes

faulty the entire subdial would require replacement

and all gauges will have to be calibrated. Refer to the

proper Body Diagnostic Procedure Manual for cali-

bration procedures.

DESCRIPTION AND OPERATION

HEADLAMP AND POWER MIRROR SWITCH

LAMP(S)

The Headlamp Switch and Power Mirror Switch

lamps are shown in (Fig. 1). For replacement of the

lamp(s) refer to Headlamp Switch Lamp(s) Removal

and Installation procedures below. Refer to Group 8T,

Power Mirrors for mirror test procedures.

NS/GSINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 401 of 1938

INSTALLATION

For installation, reverse the above procedures.

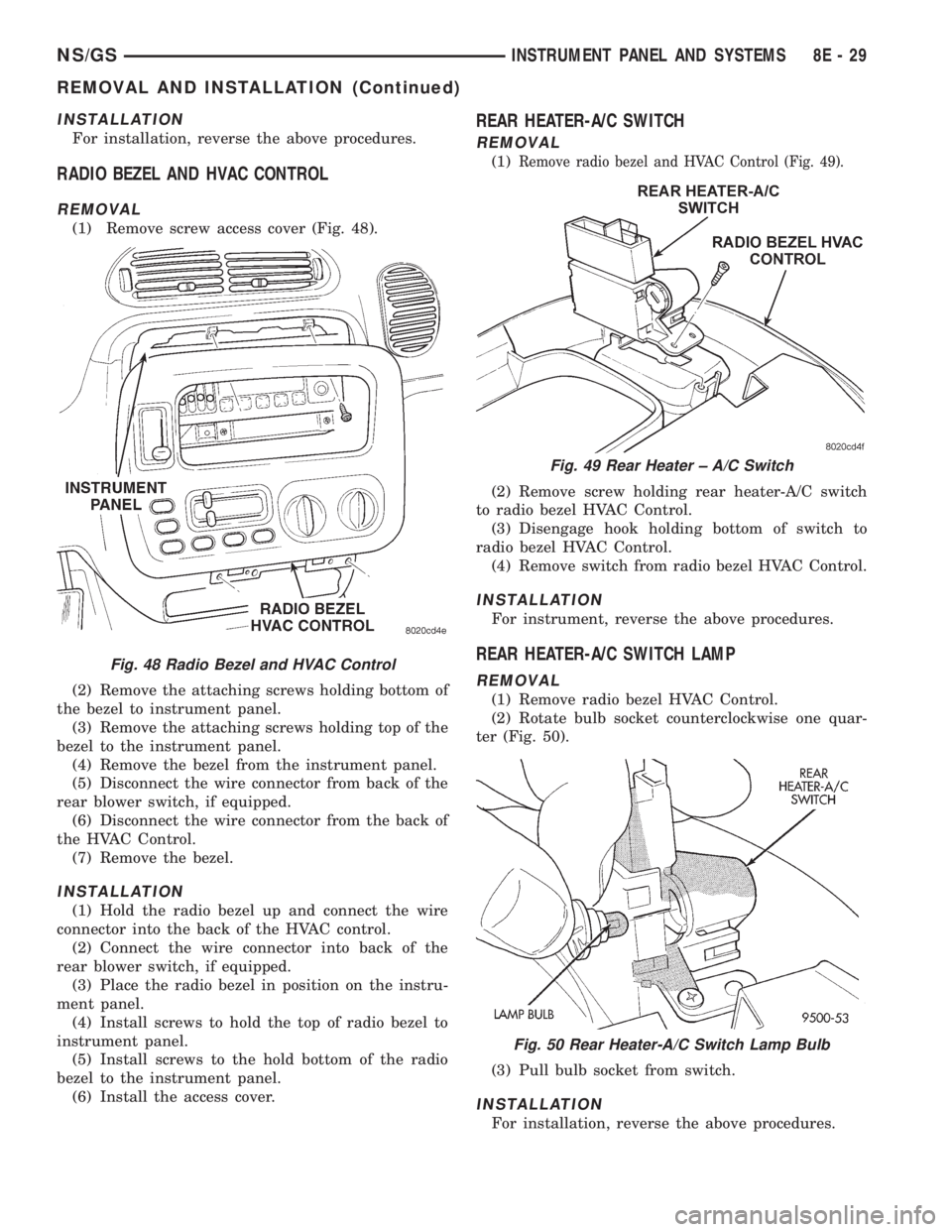

RADIO BEZEL AND HVAC CONTROL

REMOVAL

(1) Remove screw access cover (Fig. 48).

(2) Remove the attaching screws holding bottom of

the bezel to instrument panel.

(3) Remove the attaching screws holding top of the

bezel to the instrument panel.

(4) Remove the bezel from the instrument panel.

(5) Disconnect the wire connector from back of the

rear blower switch, if equipped.

(6) Disconnect the wire connector from the back of

the HVAC Control.

(7) Remove the bezel.

INSTALLATION

(1) Hold the radio bezel up and connect the wire

connector into the back of the HVAC control.

(2) Connect the wire connector into back of the

rear blower switch, if equipped.

(3) Place the radio bezel in position on the instru-

ment panel.

(4) Install screws to hold the top of radio bezel to

instrument panel.

(5) Install screws to the hold bottom of the radio

bezel to the instrument panel.

(6) Install the access cover.

REAR HEATER-A/C SWITCH

REMOVAL

(1)Remove radio bezel and HVAC Control (Fig. 49).

(2) Remove screw holding rear heater-A/C switch

to radio bezel HVAC Control.

(3) Disengage hook holding bottom of switch to

radio bezel HVAC Control.

(4) Remove switch from radio bezel HVAC Control.

INSTALLATION

For instrument, reverse the above procedures.

REAR HEATER-A/C SWITCH LAMP

REMOVAL

(1) Remove radio bezel HVAC Control.

(2) Rotate bulb socket counterclockwise one quar-

ter (Fig. 50).

(3) Pull bulb socket from switch.

INSTALLATION

For installation, reverse the above procedures.

Fig. 48 Radio Bezel and HVAC Control

Fig. 49 Rear Heater ± A/C Switch

Fig. 50 Rear Heater-A/C Switch Lamp Bulb

NS/GSINSTRUMENT PANEL AND SYSTEMS 8E - 29

REMOVAL AND INSTALLATION (Continued)

Page 499 of 1938

SERVICE PROCEDURES

CLEANUP PROCEDURE

Roll or fold the passenger airbag towards the

instrument panel surface and close the door over the

folded bag. Then tape the door shut.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well (Fig.

2). If HVAC was in RECIRC mode at time of airbag

deployment, operate HVAC blower on low speed/heat

and vacuum powder residue expelled from the heat

outlets. Multiple vacuum cleaning may to necessary

to decontaminate the interior of the vehicle.

NOTE: Dispose deployed airbag properly, contact

dealer or government agency for disposal recom-

mendations.

SERVICE OF DEPLOYED AIRBAG MODULE

DRIVER AIRBAG

If a Driver Airbag Module has been deployed, but

not due to a collision, replace the following:

²Driver Airbag Module

²Clockspring assembly

²Driver airbag cover/horn switch

The components above must be replaced because

they cannot be reused. Replace any other driver air-

bag system components if damaged.

PASSENGER AIRBAG

If a Passenger Airbag Module has been deployed,

but not due to a collision, replace the following:

²Passenger Airbag Module

²Upper instrument panel with pad

The component above must be replaced because

they cannot be reused. Inspect the heat duct near the

passenger airbag for any damage replace as neces-sary. Replace any other passenger airbag system

components if damaged.

HANDLING AIRBAG MODULE

DEPLOYED MODULE

The vehicle interior may contain a very small

amount of sodium hydroxide powder, a by-product of

airbag deployment. Sodium hydroxide powder can

irritate the skin, eyes, nose and throat. Wear safety

glasses, rubber gloves, and long sleeved clothing

when cleaning any of the powder residue from the

vehicle.

If you find that the cleanup is irritating your skin,

run cool water over the affected area. Also, if you

experience nasal or throat irritation, exit the vehicle

for fresh air until the irritation ceases. If irritation

continues, see a physician.

UNDEPLOYED

The airbag modules must be stored in its original

special container until used for service. At no time

should a source of electricity be permitted near the

inflator on the back of an airbag module. When car-

rying or handling an undeployed airbag module, the

trim side of the airbag should be pointing away from

the body to minimize possibility of injury if acciden-

tal deployment occurs. Do not place undeployed air-

bag face down on a solid surface, the airbag will

propel into the air if accidentally deployment occurs.

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE

WARNING: THE ACM CONTAINS THE IMPACT

SENSOR WHICH ENABLES THE SYSTEM TO

DEPLOY THE AIRBAGS. TO AVOID ACCIDENTAL

DEPLOYMENT, NEVER CONNECT ACM ELECTRI-

CALLY TO THE SYSTEM WHILE VEHICLE BATTERY

IS CONNECTED. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE BEFORE BEGINNING

ANY AIRBAG SYSTEM COMPONENT SERVICE PRO-

CEDURES. THIS WILL DISABLE THE AIRBAG SYS-

TEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

REMOVAL

(1) Disconnect and isolate battery negative cable.

Allow at least two minutes for the reserve capacitor

in the Airbag Control Module (ACM) to discharge.

Fig. 2 Vacuum Heater and A/C Outlets

NSRESTRAINT SYSTEM 8M - 3

Page 561 of 1938

WIRING DIAGRAMS

CONTENTS

page page

AIR CONDITIONING-HEATER.......... 8W-42-1

AIRBAG SYSTEM................... 8W-43-1

ANTI-LOCK BRAKES................. 8W-35-1

AUDIO SYSTEM.................... 8W-47-1

BODY CONTROL MODULE............ 8W-45-1

CHARGING SYSTEM................. 8W-20-1

COMPONENT INDEX................. 8W-02-1

CONNECTOR/GROUND LOCATIONS..... 8W-90-1

CONNECTOR PIN-OUTS.............. 8W-80-1

FRONT LIGHTING................... 8W-50-1

FUEL/IGNITION SYSTEM............. 8W-30-1

GENERAL INFORMATION............. 8W-01-1

GROUND DISTRIBUTION............. 8W-15-1

HORN/CIGAR LIGHTER/POWER OUTLET . 8W-41-1

INSTRUMENT CLUSTER.............. 8W-40-1

INTERIOR LIGHTING................. 8W-44-1

JUNCTION BLOCK................... 8W-12-1

MESSAGE CENTER.................. 8W-46-1OVERHEAD CONSOLE................ 8W-49-1

POWER DISTRIBUTION.............. 8W-10-1

POWER DOOR LOCKS............... 8W-61-1

POWER MIRRORS.................. 8W-62-1

POWER SEAT...................... 8W-63-1

POWER WINDOWS.................. 8W-60-1

REAR LIGHTING.................... 8W-51-1

SPLICE INFORMATION............... 8W-70-1

SPLICE LOCATIONS................. 8W-95-1

STARTING SYSTEM................. 8W-21-1

TRAILER TOW...................... 8W-54-1

TRANSMISSION CONTROL SYSTEM.... 8W-31-1

TURN SIGNALS..................... 8W-52-1

VEHICLE SPEED CONTROL........... 8W-33-1

VEHICLE THEFT SECURITY SYSTEM.... 8W-39-1

WINDOW DEFOGGERS............... 8W-48-1

WIPERS........................... 8W-53-1

NS/GSWIRING DIAGRAMS 8W - 1

Page 577 of 1938

8W-02 COMPONENT INDEX

Component Page

2-4 Pressure Switch.....................8W-31

2-4 Solenoid...........................8W-31

A/C Compressor Clutch..................8W-42

A/C Compressor Clutch Relay...........8W-10, 42

A/C Heater Control.....................8W-42

A/C On Indicator.......................8W-42

A/C Pressure Transducer..............8W-30, 42

A/C Switch............................8W-42

A/C Zone Door Actuator..................8W-42

ABS Warning Lamp..................8W-35, 46

Accelerator Pedal Position Sensor..........8W-30

Airbag Control Module...................8W-43

Airbag Indicator Lamp...................8W-43

Airbag Warning Lamp...................8W-46

All Wheel Drive Solenoid.................8W-31

Ambient Air Temperature Sensor...........8W-49

Ash Receiver Lamp.....................8W-44

Automatic Day/Night Mirror..............8W-44

Automatic Shut Down Relay............8W-10, 30

Splice Information......................8W-70

Back-Up Lamp.........................8W-51

Back-Up Switch.....................8W-44, 51

Battery...............................8W-20

Blend Door Actuator.....................8W-42

Body Control Module....................8W-45

Brake Pressure Switch...................8W-46

Brake Warning Lamp....................8W-46

Camshaft Position Sensor................8W-30

Center Dome Lamp.....................8W-44

Center High Mounted Stop Lamp..........8W-51

Cigar/Accessory Relay...................8W-41

Clockspring.......8W-10, 15, 30, 33, 39, 40, 41, 43

Cluster Illumination Lamps...............8W-40

Clutch Interlock Switch...............8W-12, 21

Clutch Interlock Switch Jumper......8W-12, 21, 31

Clutch Switch.......................8W-30, 33

Combination Flasher/DRL Module. . . .8W-50, 51, 52

Combination Relays.....................8W-54

Compass/Mini-Trip Computer..............8W-49

Control Sleeve Sensor....................8W-30

Controller Anti-Lock Brake...............8W-35

Courtesy Lamp Relay...........8W-10, 12, 44, 50

Crank Case Heater......................8W-30

Crankshaft Position Sensor...............8W-30

Cruise Indicator Lamp...................8W-40

Data Link Connector....................8W-30

Diesel Power Relay...................8W-10, 30

Dome Lamp Switch.....................8W-50

Door Ajar Indicator Lamp................8W-40

Door Ajar Switches................8W-39, 40, 44

Door Lock Relay........................8W-61

Speakers..............................8W-47Component Page

Door Unlock Relay......................8W-61

Oxygen Sensors........................8W-30

Door Ajar Switches.............8W-39, 40, 44, 45

Door Arm/Disarm Switches.............8W-39, 61

Door Courtesy Lamps....................8W-44

Door Lock Motors.......................8W-61

Door Lock Switches.....................8W-61

Door Unlock Relays.....................8W-61

Heated Seat Backs......................8W-63

Heated Seat Cushions...................8W-63

Heated Seat Modules....................8W-63

Heated Seat Switches....................8W-63

Power Mirrors.........................8W-62

Power Seat Switches....................8W-63

Power Window Switches..................8W-60

Seat Motors...........................8W-63

Window Motors........................8W-60

Radiator Fans.........................8W-42

Dump Solenoid.........................8W-33

EGR Solenoid..........................8W-30

Electric Wiper De-Icer...................8W-48

Electronic PRNDL Indicator...............8W-40

Engine Coolant Temperature Gauge.........8W-40

Engine Coolant Temperature Lamp.........8W-46

Engine Coolant Temperature Sensor........8W-30

Engine Oil Pressure Switch...............8W-46

Engine Speed Sensor....................8W-30

Engine Starter Motor....................8W-21

Engine Starter Motor Relay............8W-10, 21

Evap Leak Detection Pump...............8W-30

Evap/Purge Solenoid....................8W-30

Evaporator Temperature Sensor............8W-42

Express Down Module...................8W-60

Flexible Fuel Sensor.....................8W-30

Fog Lamps............................8W-50

Fog Lamp Relay........................8W-50

Front Blower Motor.....................8W-42

Front Blower Motor Relay.............8W-10, 42

Front Blower Motor Resistor Block.........8W-42

Front Cigar Lighter/Power Outlet..........8W-41

Front Reading Lamp Defeat Switch.........8W-44

Front Reading Lamps/Switch..............8W-44

Front Washer Motor.....................8W-53

Front Wiper Switch.....................8W-53

Fuel Gauge............................8W-40

Fuel Heater...........................8W-30

Fuel Heater Relay...................8W-10, 30

Fuel Injectors..........................8W-30

Fuel Pump Module......................8W-30

Fuel Pump Relay....................8W-10, 30

Fuel Quantity Actuator..................8W-30

Fuel Shutdown Solenoid..................8W-30

NS/GS8W - 02 COMPONENT INDEX 8W - 02 - 1

Page 578 of 1938

Component Page

Fuel Tank Module...................8W-30, 45

Fuel Temperature Sensor.................8W-30

Fuel Timing Solenoid....................8W-30

Fuses (JB)............................8W-12

Fuses (PDC)...........................8W-10

Fusible Link.....................8W-20, 21, 63

Fusible Link A0........................8W-30

Fusible Link A11.......................8W-10

Fusible Link A54.......................8W-10

Grounds..............................8W-15

Generator.............................8W-20

Glove Box Lamp........................8W-44

Glow Plug Lamp.....................8W-30, 46

Glow Plugs............................8W-30

Glow Plug Relay........................8W-30

Headlamps............................8W-50

Headlamp Dimmer Switch..........8W-10, 46, 50

Headlamp Leveling Motors...............8W-50

Headlamp Switch.......................8W-50

Headlamp Washer......................8W-53

High Beam Indicator....................8W-46

High Beam Relay....................8W-10, 50

Headlamps............................8W-50

Horns................................8W-41

Hood Ajar Switch....................8W-39, 44

Horn Relay.........................8W-39, 41

Horn Switch.....................8W-10, 39, 41

HVAC Control.........................8W-42

Idle Air Control Motor...................8W-30

Ignition Coil Pack.......................8W-30

Ignition Switch.........................8W-10

Instrument Cluster.....................8W-40

Intake Air Temperature Sensor............8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor.....................8W-30

Interior Lamps On Switch................8W-44

Junction Block.........................8W-12

Key-In Halo Lamp......................8W-44

Knock Sensor..........................8W-30

Lamp Assemblies.......................8W-51

License Lamp..........................8W-51

Liftgate Ajar Indicator Lamp..............8W-40

Liftgate Ajar Switch...............8W-39, 40, 44

Liftgate Arm/Disarm Switch............8W-39, 61

Liftgate Flood Lamps....................8W-44

Liftgate Lock Motor.....................8W-61

Low Beam Relay.....................8W-10, 50

Low Coolant Level Switch................8W-45

Low Fuel Warning Indicator Lamp..........8W-40

Low Oil Pressure Lamp..................8W-46

Low Washer Fluid Level Indicator Lamp.....8W-40

Low Washer Fluid Switch.................8W-53

Low/Reverse Pressure Switch..............8W-31

Low/Reverse Solenoid....................8W-31Component Page

Manifold Absolute Pressure Sensor.........8W-30

Memory Power Seat Switch...............8W-63

Seat Sensors...........................8W-63

Memory Seat/Mirror Module...........8W-62, 63

Memory Set Switch..................8W-62, 63

Message Center........................8W-46

Mid Reading Lamps.....................8W-44

Mode Door Actuator.....................8W-42

Name Brand Speaker Relay...............8W-47

Needle Movement Sensor.................8W-30

Odometer.............................8W-40

Output Shaft Speed Sensor...............8W-31

Overdrive Pressure Switch................8W-31

Overdrive Solenoid......................8W-31

Overhead Console.......................8W-49

Park Brake Switch...................8W-46, 50

Park Lamp Relay.........8W-10, 12, 44, 50, 51, 54

Park/Turn Signal Lamps.................8W-50

Airbag Squibs..........................8W-43

Power Distribution Center................8W-10

Power Folding Mirror Switch..............8W-62

Power Mirror Fold Relay.................8W-62

Power Mirror Switch....................8W-62

Power Mirror Unfold Relay...............8W-62

Power Seat Circuit Breaker............8W-62, 63

Powertrain Control Module...............8W-30

PTCs (JB).............................8W-12

Radiator Fan Disconnect.................8W-42

Radiator Fan Relays.....................8W-42

Radio................................8W-47

Radio Choke...........................8W-47

Reading Lamps........................8W-44

Rear A/C Heater Unit....................8W-42

Rear Blower Control Switches.............8W-42

Rear Cigar Lighter/Power Outlet...........8W-41

Rear Defogger On Indicator...............8W-42

Rear Dome Lamp.......................8W-44

Rear Fog Lamp.........................8W-51

Rear Fog Lamp Indicator.................8W-51

Rear Washer Motor.....................8W-53

Rear Washer Switch..................8W-42, 53

Rear Window Defogger...................8W-48

Rear Window Defogger Relay..............8W-48

Rear Window Defogger Switch..........8W-42, 48

Rear Wiper Delay On Indicator.........8W-42, 53

Rear Wiper Delay Switch..............8W-42, 53

Rear Wiper Motor.......................8W-53

Rear Wiper On Indicator..............8W-42, 53

Rear Wiper On Switch................8W-42, 53

Recirculate Mode Indicator................8W-42

Recirculate Mode Switch.................8W-42

Recirculation Door Actuator...............8W-42

Remote Keyless Entry Module.............8W-61

Repeater Lamps.....................8W-51, 52

8W - 02 - 2 8W - 02 COMPONENT INDEXNS/GS