change time CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1166 of 1938

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

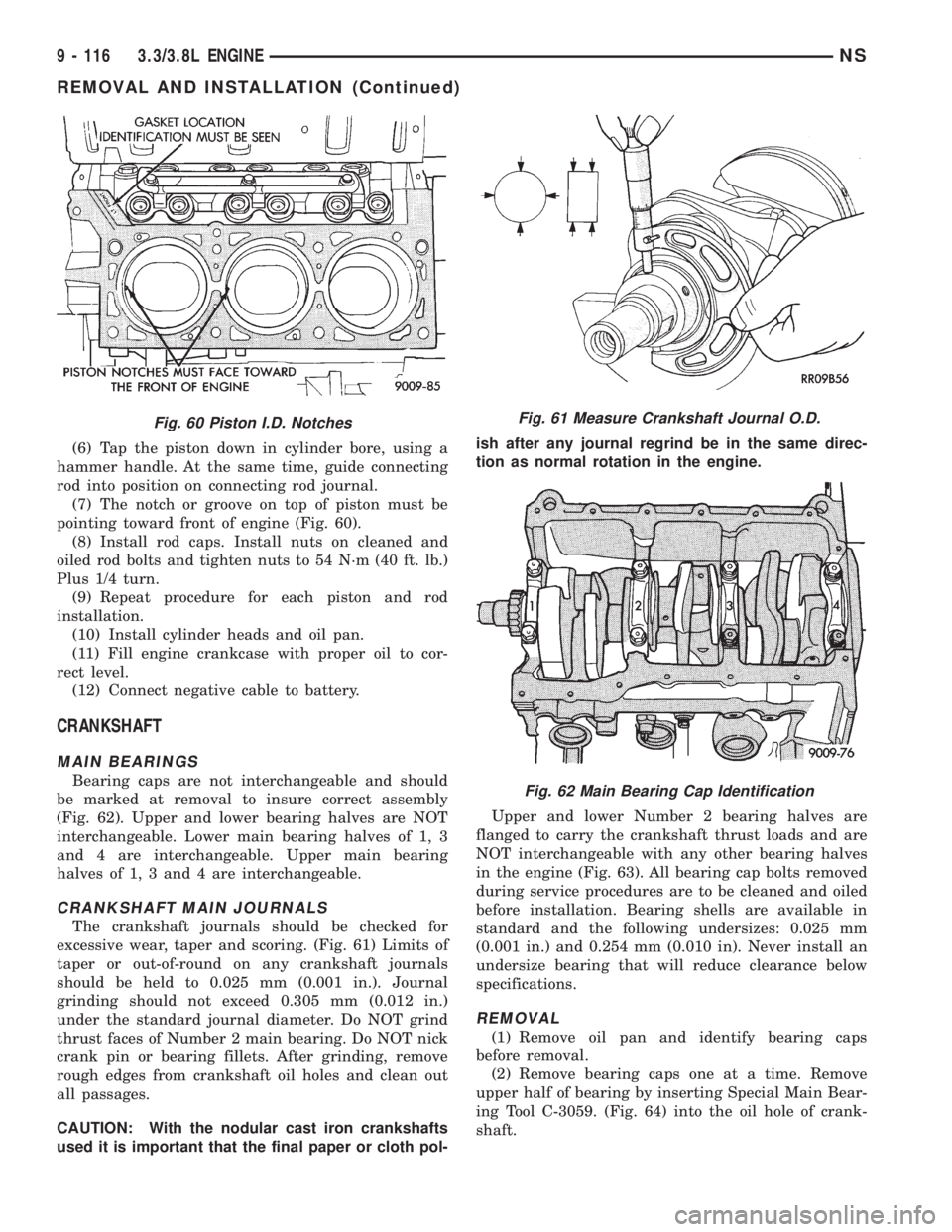

(7) The notch or groove on top of piston must be

pointing toward front of engine (Fig. 60).

(8) Install rod caps. Install nuts on cleaned and

oiled rod bolts and tighten nuts to 54 N´m (40 ft. lb.)

Plus 1/4 turn.

(9) Repeat procedure for each piston and rod

installation.

(10) Install cylinder heads and oil pan.

(11) Fill engine crankcase with proper oil to cor-

rect level.

(12) Connect negative cable to battery.

CRANKSHAFT

MAIN BEARINGS

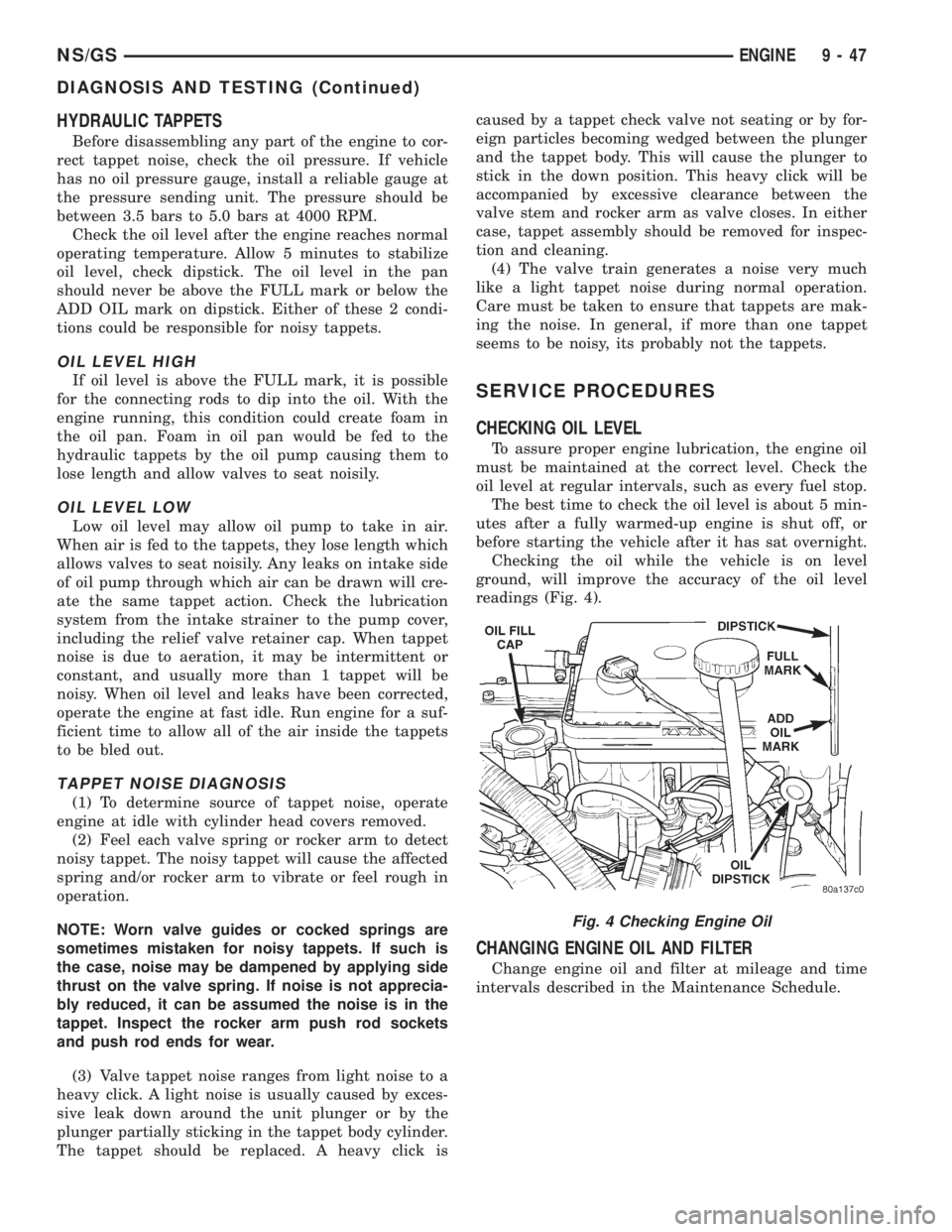

Bearing caps are not interchangeable and should

be marked at removal to insure correct assembly

(Fig. 62). Upper and lower bearing halves are NOT

interchangeable. Lower main bearing halves of 1, 3

and 4 are interchangeable. Upper main bearing

halves of 1, 3 and 4 are interchangeable.

CRANKSHAFT MAIN JOURNALS

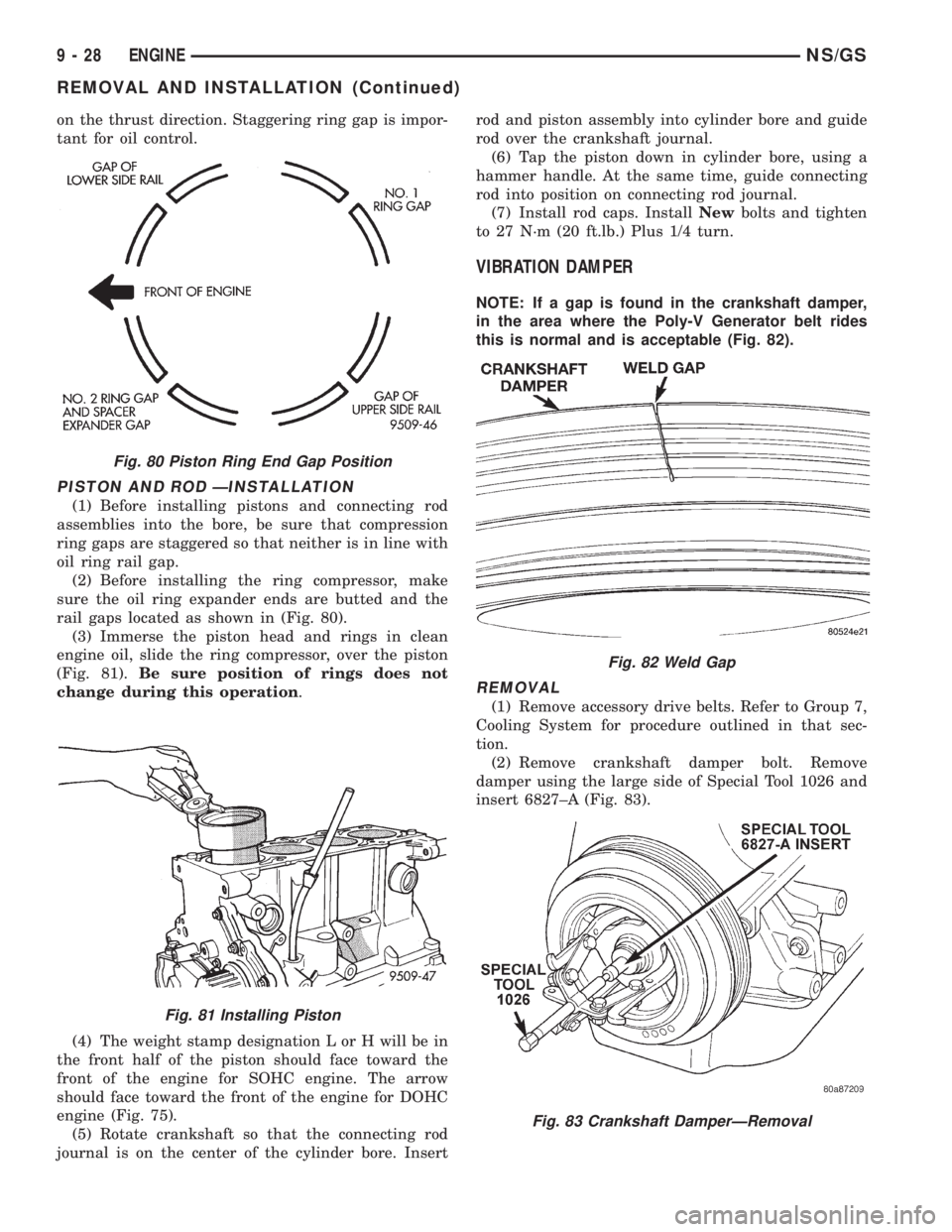

The crankshaft journals should be checked for

excessive wear, taper and scoring. (Fig. 61) Limits of

taper or out-of-round on any crankshaft journals

should be held to 0.025 mm (0.001 in.). Journal

grinding should not exceed 0.305 mm (0.012 in.)

under the standard journal diameter. Do NOT grind

thrust faces of Number 2 main bearing. Do NOT nick

crank pin or bearing fillets. After grinding, remove

rough edges from crankshaft oil holes and clean out

all passages.

CAUTION: With the nodular cast iron crankshafts

used it is important that the final paper or cloth pol-ish after any journal regrind be in the same direc-

tion as normal rotation in the engine.

Upper and lower Number 2 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 63). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersizes: 0.025 mm

(0.001 in.) and 0.254 mm (0.010 in). Never install an

undersize bearing that will reduce clearance below

specifications.

REMOVAL

(1) Remove oil pan and identify bearing caps

before removal.

(2) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059. (Fig. 64) into the oil hole of crank-

shaft.

Fig. 60 Piston I.D. NotchesFig. 61 Measure Crankshaft Journal O.D.

Fig. 62 Main Bearing Cap Identification

9 - 116 3.3/3.8L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1206 of 1938

on the thrust direction. Staggering ring gap is impor-

tant for oil control.

PISTON AND ROD ÐINSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 80).

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston

(Fig. 81).Be sure position of rings does not

change during this operation.

(4) The weight stamp designation L or H will be in

the front half of the piston should face toward the

front of the engine for SOHC engine. The arrow

should face toward the front of the engine for DOHC

engine (Fig. 75).

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insertrod and piston assembly into cylinder bore and guide

rod over the crankshaft journal.

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(7) Install rod caps. InstallNewbolts and tighten

to 27 N´m (20 ft.lb.) Plus 1/4 turn.

VIBRATION DAMPER

NOTE: If a gap is found in the crankshaft damper,

in the area where the Poly-V Generator belt rides

this is normal and is acceptable (Fig. 82).

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure outlined in that sec-

tion.

(2) Remove crankshaft damper bolt. Remove

damper using the large side of Special Tool 1026 and

insert 6827±A (Fig. 83).

Fig. 80 Piston Ring End Gap Position

Fig. 81 Installing Piston

Fig. 82 Weld Gap

Fig. 83 Crankshaft DamperÐRemoval

9 - 28 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1225 of 1938

HYDRAULIC TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, check the oil pressure. If vehicle

has no oil pressure gauge, install a reliable gauge at

the pressure sending unit. The pressure should be

between 3.5 bars to 5.0 bars at 4000 RPM.

Check the oil level after the engine reaches normal

operating temperature. Allow 5 minutes to stabilize

oil level, check dipstick. The oil level in the pan

should never be above the FULL mark or below the

ADD OIL mark on dipstick. Either of these 2 condi-

tions could be responsible for noisy tappets.

OIL LEVEL HIGH

If oil level is above the FULL mark, it is possible

for the connecting rods to dip into the oil. With the

engine running, this condition could create foam in

the oil pan. Foam in oil pan would be fed to the

hydraulic tappets by the oil pump causing them to

lose length and allow valves to seat noisily.

OIL LEVEL LOW

Low oil level may allow oil pump to take in air.

When air is fed to the tappets, they lose length which

allows valves to seat noisily. Any leaks on intake side

of oil pump through which air can be drawn will cre-

ate the same tappet action. Check the lubrication

system from the intake strainer to the pump cover,

including the relief valve retainer cap. When tappet

noise is due to aeration, it may be intermittent or

constant, and usually more than 1 tappet will be

noisy. When oil level and leaks have been corrected,

operate the engine at fast idle. Run engine for a suf-

ficient time to allow all of the air inside the tappets

to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak down around the unit plunger or by the

plunger partially sticking in the tappet body cylinder.

The tappet should be replaced. A heavy click iscaused by a tappet check valve not seating or by for-

eign particles becoming wedged between the plunger

and the tappet body. This will cause the plunger to

stick in the down position. This heavy click will be

accompanied by excessive clearance between the

valve stem and rocker arm as valve closes. In either

case, tappet assembly should be removed for inspec-

tion and cleaning.

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. In general, if more than one tappet

seems to be noisy, its probably not the tappets.

SERVICE PROCEDURES

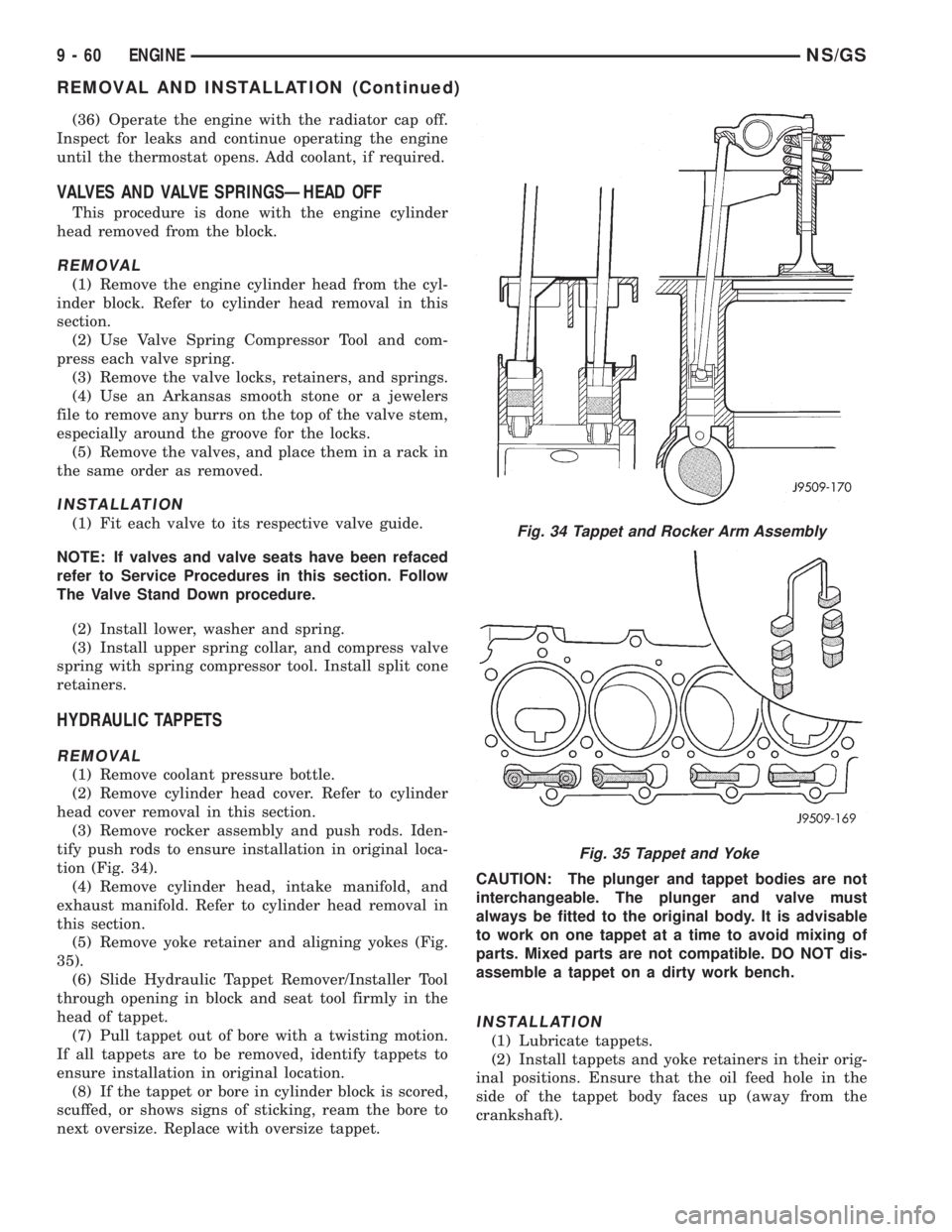

CHECKING OIL LEVEL

To assure proper engine lubrication, the engine oil

must be maintained at the correct level. Check the

oil level at regular intervals, such as every fuel stop.

The best time to check the oil level is about 5 min-

utes after a fully warmed-up engine is shut off, or

before starting the vehicle after it has sat overnight.

Checking the oil while the vehicle is on level

ground, will improve the accuracy of the oil level

readings (Fig. 4).

CHANGING ENGINE OIL AND FILTER

Change engine oil and filter at mileage and time

intervals described in the Maintenance Schedule.

Fig. 4 Checking Engine Oil

NS/GSENGINE 9 - 47

DIAGNOSIS AND TESTING (Continued)

Page 1238 of 1938

(36) Operate the engine with the radiator cap off.

Inspect for leaks and continue operating the engine

until the thermostat opens. Add coolant, if required.

VALVES AND VALVE SPRINGSÐHEAD OFF

This procedure is done with the engine cylinder

head removed from the block.

REMOVAL

(1) Remove the engine cylinder head from the cyl-

inder block. Refer to cylinder head removal in this

section.

(2) Use Valve Spring Compressor Tool and com-

press each valve spring.

(3) Remove the valve locks, retainers, and springs.

(4) Use an Arkansas smooth stone or a jewelers

file to remove any burrs on the top of the valve stem,

especially around the groove for the locks.

(5) Remove the valves, and place them in a rack in

the same order as removed.

INSTALLATION

(1) Fit each valve to its respective valve guide.

NOTE: If valves and valve seats have been refaced

refer to Service Procedures in this section. Follow

The Valve Stand Down procedure.

(2) Install lower, washer and spring.

(3) Install upper spring collar, and compress valve

spring with spring compressor tool. Install split cone

retainers.

HYDRAULIC TAPPETS

REMOVAL

(1) Remove coolant pressure bottle.

(2) Remove cylinder head cover. Refer to cylinder

head cover removal in this section.

(3) Remove rocker assembly and push rods. Iden-

tify push rods to ensure installation in original loca-

tion (Fig. 34).

(4) Remove cylinder head, intake manifold, and

exhaust manifold. Refer to cylinder head removal in

this section.

(5) Remove yoke retainer and aligning yokes (Fig.

35).

(6) Slide Hydraulic Tappet Remover/Installer Tool

through opening in block and seat tool firmly in the

head of tappet.

(7) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed, identify tappets to

ensure installation in original location.

(8) If the tappet or bore in cylinder block is scored,

scuffed, or shows signs of sticking, ream the bore to

next oversize. Replace with oversize tappet.CAUTION: The plunger and tappet bodies are not

interchangeable. The plunger and valve must

always be fitted to the original body. It is advisable

to work on one tappet at a time to avoid mixing of

parts. Mixed parts are not compatible. DO NOT dis-

assemble a tappet on a dirty work bench.

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets and yoke retainers in their orig-

inal positions. Ensure that the oil feed hole in the

side of the tappet body faces up (away from the

crankshaft).

Fig. 34 Tappet and Rocker Arm Assembly

Fig. 35 Tappet and Yoke

9 - 60 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1324 of 1938

THROTTLE BODY....................... 64

THROTTLE POSITION SENSOR............ 65

UPSTREAM OXYGEN SENSOR............. 68

SPECIFICATIONS

TORQUE.............................. 72SPECIAL TOOLS

FUEL................................. 72

GENERAL INFORMATION

INTRODUCTION

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCMprogramming. Input from the oxygen (O2S) sensor is

not monitored during OPEN LOOP modes.

During CLOSED LOOP modes the PCM does mon-

itor the O2S sensor input. This input indicates to the

PCM whether or not the calculated injector pulse

width results in the ideal air/fuel ratio of 14.7 parts

air to 1 part fuel. By monitoring the exhaust oxygen

content through the O2S sensor, the PCM can fine

tune the injector pulse width. Fine tuning injector

pulse width allows the PCM to achieve optimum fuel

economy combined with low emissions.

The multi-port fuel injection system has the follow-

ing modes of operation:

²Ignition switch ON (zero RPM)

²Engine start-up

²Engine warm-up

²Cruise (Idle)

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

The engine start-up (crank), engine warm-up, and

wide open throttle modes are OPEN LOOP modes.

Under most operating conditions, the acceleration,

deceleration, and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the multi-port fuel injection system is acti-

vated by the ignition switch, the following actions

occur:

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the coolant temperature sen-

sor and throttle position sensor input. The PCM mod-

ifies fuel strategy based on this input.

When the key is in the ON position and the engine

is not running (zero rpm), the Automatic Shutdown

(ASD) relay and fuel pump relay are not energized.

Therefore battery voltage is not supplied to the fuel

pump, ignition coil, fuel injectors or oxygen sensor

heating element.

ENGINE START-UP MODE

This is an OPEN LOOP mode. The following

actions occur when the starter motor is engaged.

If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the ASD relay and fuel pump relay. These relays sup-

ply battery voltage to the fuel pump, fuel injectors,

14 - 30 FUEL SYSTEMNS

SPECIFICATIONS (Continued)

Page 1327 of 1938

²Engine coolant temperature

²Engine speed (crankshaft position sensor)

²Intake air temperature (2.4L only)

²Manifold absolute pressure

²Throttle position

²Transaxle gear selection (park/neutral switch)

The PCM also adjusts engine idle speed through

the idle air control motor based on the following

inputs.

²Air conditioning select switch head pressure

²Brake switch

²Engine coolant temperature

²Engine speed (crankshaft position sensor)

²Manifold absolute pressure

²Throttle position

²Transaxle gear selection (park/neutral switch)

²Vehicle distance (speed)

The Automatic Shutdown (ASD) and fuel pump

relays are located in the Power Distribution Center

(PDC).

The camshaft position sensor (distributor pick-up

signal 3.0L) and crankshaft position sensor signals

are sent to the PCM. If the PCM does not receive

both signals within approximately one second of

engine cranking, it deactivates the ASD relay and

fuel pump relay. When these relays are deactivated,

power is shut off to the fuel injectors, ignition coil,

oxygen sensor heating element and fuel pump.

The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts to

power the camshaft position sensor, crankshaft posi-

tion sensor and vehicle speed sensor. The PCM also

provides a 5.0 volt supply for the manifold absolute

pressure sensor, throttle position sensor and engine

coolant temperature sensor.

AIR CONDITIONING PRESSURE TRANSDUCERÐ

PCM INPUT

The Powertrain Control Module (PCM) monitors

the A/C compressor discharge (high side) pressure

through the air conditioning pressure transducer.

The transducer supplies an input to the PCM. The

PCM engages the A/C compressor clutch if pressure

is sufficient for A/C system operation.

AIR CONDITIONING SWITCH SENSEÐPCM INPUT

When the air conditioning or defrost switch is put

in the ON position and the low pressure switch, com-

bination valve, and high pressure switch close, the

PCM receives an A/C input. After receiving this

input, the PCM activates the A/C compressor clutch

by grounding the A/C clutch relay. The PCM also

adjusts idle speed to a scheduled RPM to compensate

for increased engine load.

AUTOMATIC SHUTDOWN (ASD) SENSEÐPCM

INPUT

The ASD sense circuit informs the PCM when the

ASD relay energizes. A 12 volt signal at this input

indicates to the PCM that the ASD has been acti-

vated. This input is used only to sense that the ASD

relay is energized.

When energized, the ASD relay supplies battery

voltage to the fuel injectors, ignition coils and the

heating element in each oxygen sensor. If the PCM

does not receive 12 volts from this input after

grounding the ASD relay, it sets a Diagnostic Trouble

Code (DTC).

BATTERY VOLTAGEÐPCM INPUT

The PCM monitors the battery voltage input to

determine fuel injector pulse width and generator

field control.

If battery voltage is low the PCM will increase

injector pulse width (period of time that the injector

is energized).

BRAKE SWITCHÐPCM INPUT

When the brake switch is activated, the PCM

receives an input indicating that the brakes are

being applied. After receiving this input the PCM

maintains idle speed to a scheduled RPM through

control of the idle air control motor. The brake switch

is mounted on the brake pedal support bracket.

CAMSHAFT POSITION SENSORÐPCM INPUT

The PCM determines fuel injection synchronization

and cylinder identification from inputs provided by

the camshaft position sensor and crankshaft position

sensor. From the two inputs, the PCM determines

crankshaft position.

3.3/3.8L

The sensor generates pulses as groups of notches

on the camshaft sprocket pass underneath it (Fig. 2).

The PCM keeps track of crankshaft rotation and

identifies each cylinder by the pulses generated by

the notches on the camshaft sprocket. Four crank-

shaft pulses follow each group of camshaft pulses.

When the PCM receives two camshaft pulses fol-

lowed by the long flat spot on the camshaft sprocket,

it knows that the crankshaft timing marks for cylin-

der one are next (on driveplate). When the PCM

receives one camshaft pulse after the long flat spot

on the sprocket, cylinder number two crankshaft tim-

ing marks are next. After 3 camshaft pulses, the

PCM knows cylinder four crankshaft timing marks

follow. One camshaft pulse after the three pulses

indicates cylinder five. The two camshaft pulses after

cylinder 5 signals cylinder six (Fig. 3). The PCM can

synchronize on cylinders 1 or 4.

NSFUEL SYSTEM 14 - 33

DESCRIPTION AND OPERATION (Continued)

Page 1330 of 1938

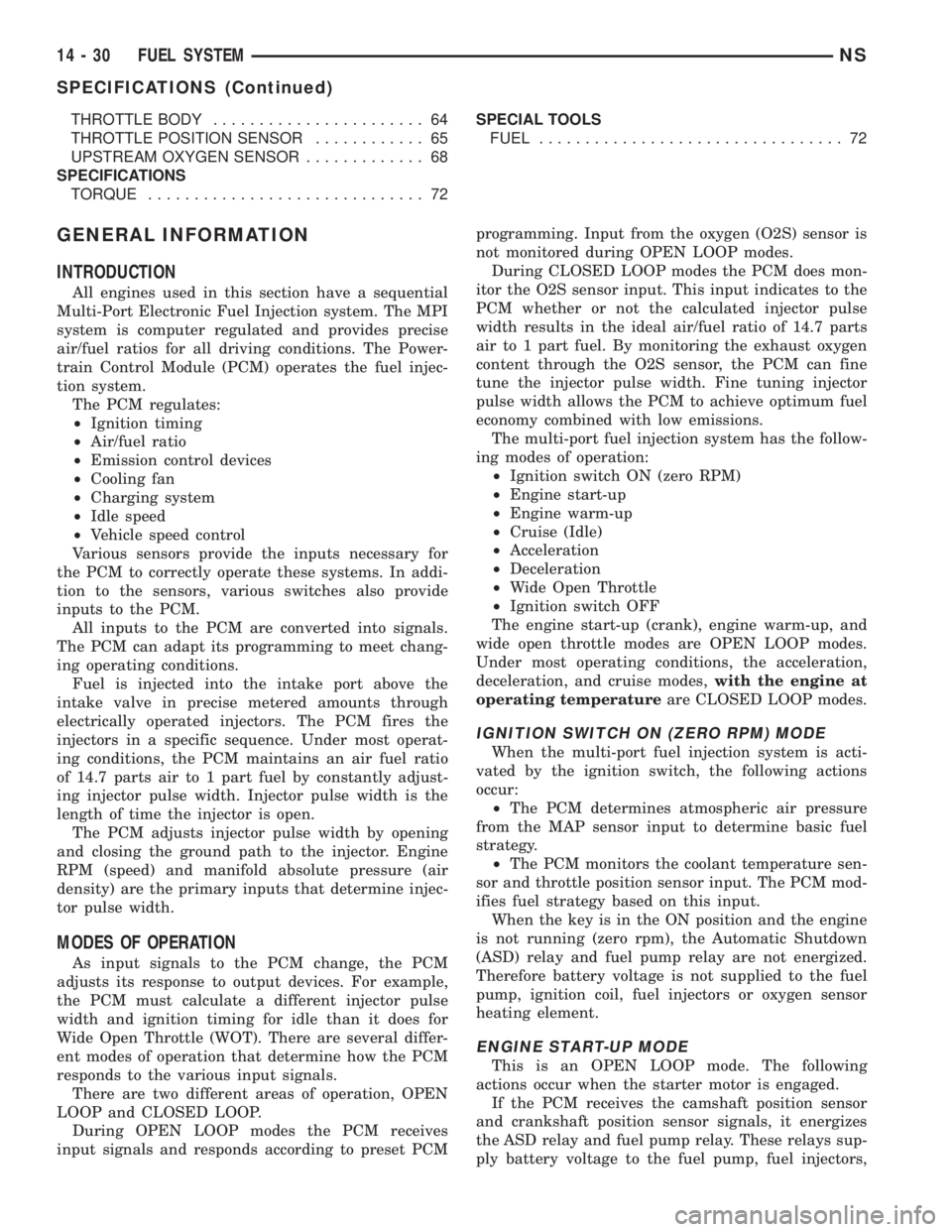

The crankshaft position sensor is located in the

transaxle housing, above the vehicle speed sensor

(Fig. 10). The bottom of the sensor is positioned next

to the drive plate.The distance between the bot-

tom of sensor and the drive plate is critical to

the operation of the system. When servicing the

crankshaft position sensor, refer to the appro-

priate Multi-Port Fuel Injection Service Proce-

dures section in this Group.

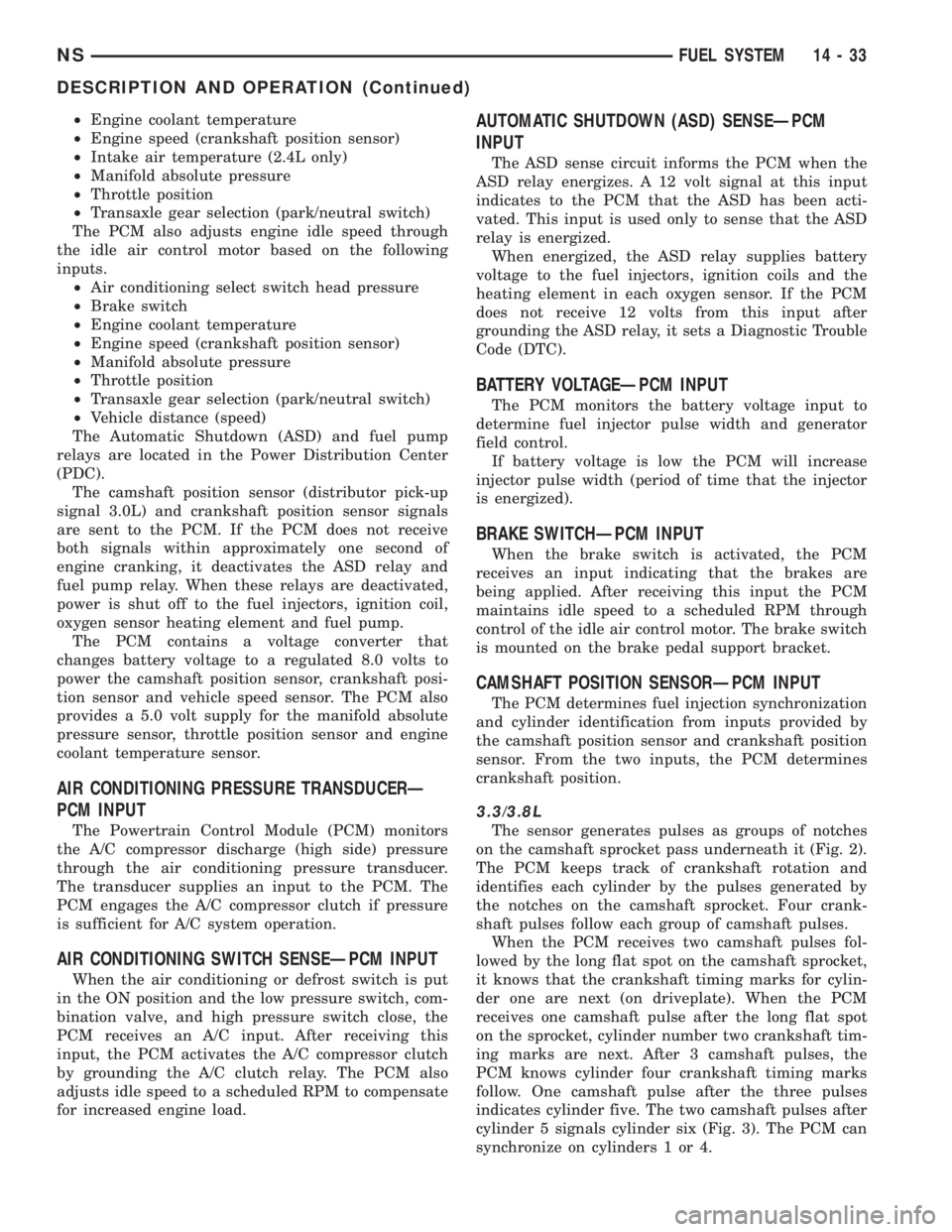

2.4L

The second crankshaft counterweight has

machined into it two sets of four timing reference

notches and a 60 degree signature notch (Fig. 11).

From the crankshaft position sensor input the PCM

determines engine speed and crankshaft angle (posi-

tion).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltagegoes low (less than 0.3 volts). When a notch aligns

with the sensor, voltage spikes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulse. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined to a

uniform width representing 13.6 degrees of crank-

shaft rotation. From the voltage pulse width the

PCM tells the difference between the timing refer-

ence notches and the 60 degree signature notch. The

60 degree signature notch produces a longer pulse

width than the smaller timing reference notches. If

the camshaft position sensor input switches from

high to low when the 60 degree signature notch

passes under the crankshaft position sensor, the

PCM knows cylinder number one is the next cylinder

at TDC.

The crankshaft position sensor mounts to the

engine block behind the generator, just above the oil

filter (Fig. 12).

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The engine coolant temperature sensor is a vari-

able resistor with a range of -40ÉC to 129ÉC (-40ÉF to

265ÉF).

The engine coolant temperature sensor provides an

input voltage to the PCM. As coolant temperature

varies, the sensor resistance changes resulting in a

different input voltage to the PCM.

When the engine is cold, the PCM will demand

slightly richer air/fuel mixtures and higher idle

speeds until normal operating temperatures are

reached.

The engine coolant sensor is also used for cooling

fan control.

Fig. 10 Crankshaft Position Sensor LocationÐ3.0/

3.3/3.8L

Fig. 11 Timing Reference Notches

14 - 36 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1334 of 1938

a fixed vehicle speed has been selected. The speed

control RESUME voltage indicates the previous fixed

speed is requested. The speed control CANCEL volt-

age tells the PCM to deactivate but retain set speed

in memory (same as depressing the brake pedal). The

speed control OFF voltage tells the PCM that the

speed control system has deactivated. Refer to Group

8H for more speed control information.

TRANSAXLE PARK/NEUTRAL SWITCHÐPCM

INPUT

The park/neutral switch is located on the transaxle

housing (Fig. 25). It provides an input to the PCM

indicating whether the automatic transaxle is in

Park or Neutral. This input is used to determine idlespeed (varying with gear selection) and ignition tim-

ing advance. The park neutral switch is sometimes

referred to as the neutral safety switch.

THROTTLE POSITION SENSOR (TPS)ÐPCM INPUT

The TPS is mounted on the throttle body and con-

nected to the throttle blade shaft (Fig. 26) or (Fig.

27) or (Fig. 28). The TPS is a variable resistor that

provides the (PCM) with an input signal (voltage)

representing throttle blade position. As the position

of the throttle blade changes, the resistance of the

TPS changes.

Fig. 23 MAP SensorÐ3.0L

Fig. 24 MAP SensorÐ2.4L

Fig. 25 Park Neutral SwitchÐ4-Speed Electronic

Automatic TransaxleÐTypical

Fig. 26 Throttle Position SensorÐ3.3/3.8L

14 - 40 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1337 of 1938

(brake, park/neutral, air conditioning). Deceleration

die out is also prevented by increasing airflow when

the throttle is closed quickly after a driving (speed)

condition.

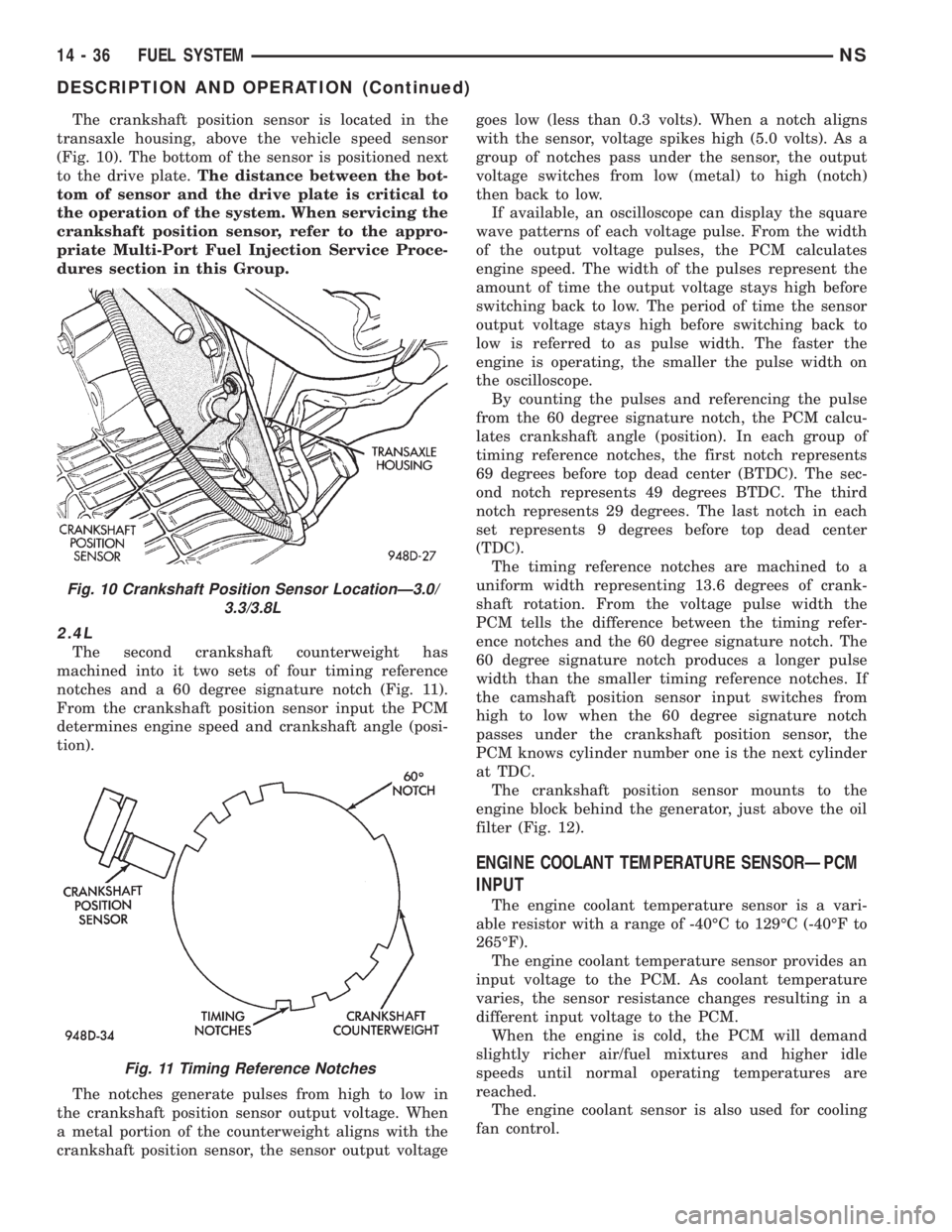

DUTY CYCLE EVAP CANISTER PURGE

SOLENOIDÐPCM OUTPUT

The duty cycle EVAP purge solenoid regulates the

rate of vapor flow from the EVAP canister to the

throttle body. The PCM operates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM ener-

gizes and de-energizes the solenoid 5 or 10 times per

second, depending upon operating conditions. The

PCM varies the vapor flow rate by changing solenoid

pulse width. Pulse width is the amount of time the

solenoid energizes.

A rubber boot covers the duty cycle EVAP purge

solenoid. The solenoid attaches to a bracket mounted

to the right engine mount (Fig. 31). The top of the

solenoid has the word TOP on it. The solenoid will

not operate properly unless it is installed correctly.

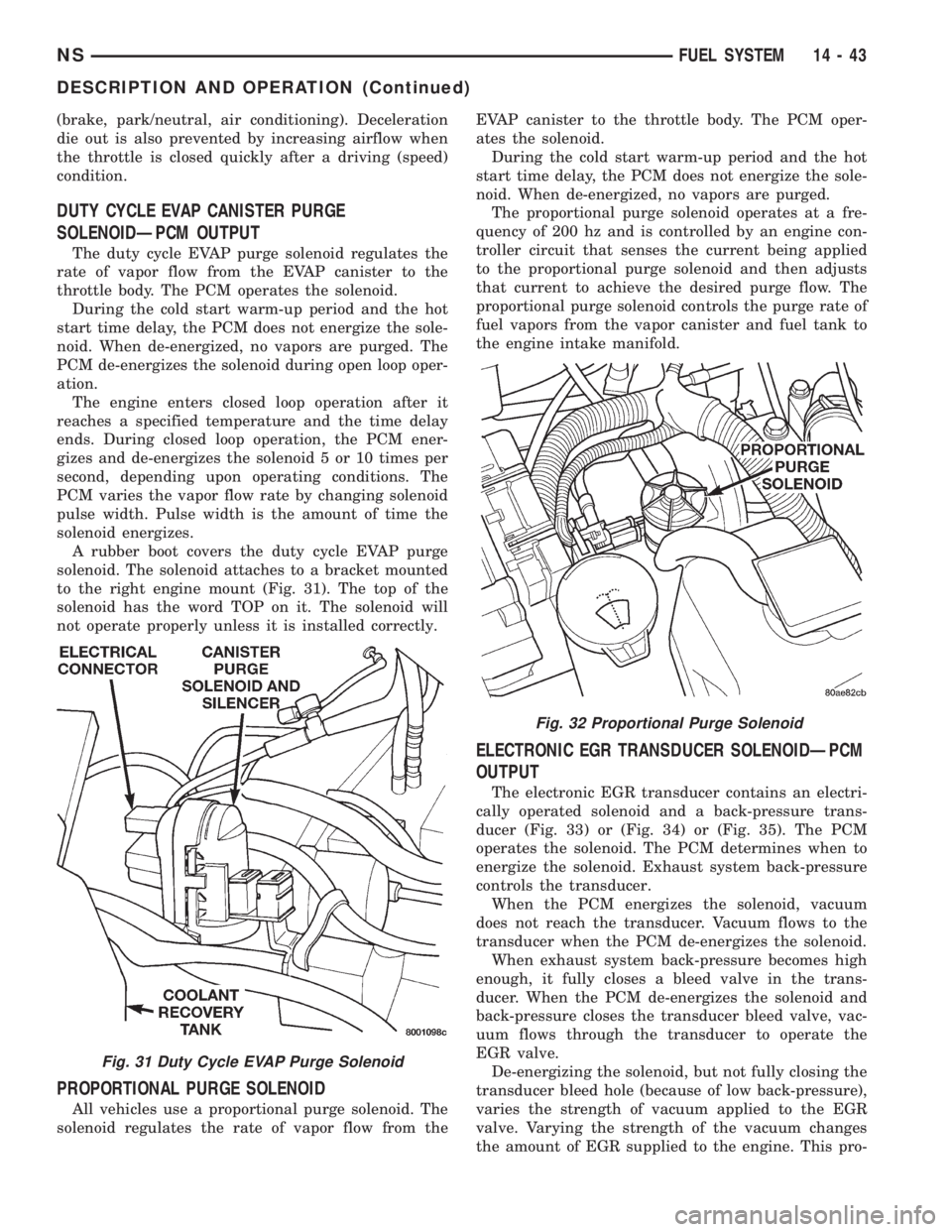

PROPORTIONAL PURGE SOLENOID

All vehicles use a proportional purge solenoid. The

solenoid regulates the rate of vapor flow from theEVAP canister to the throttle body. The PCM oper-

ates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid and then adjusts

that current to achieve the desired purge flow. The

proportional purge solenoid controls the purge rate of

fuel vapors from the vapor canister and fuel tank to

the engine intake manifold.

ELECTRONIC EGR TRANSDUCER SOLENOIDÐPCM

OUTPUT

The electronic EGR transducer contains an electri-

cally operated solenoid and a back-pressure trans-

ducer (Fig. 33) or (Fig. 34) or (Fig. 35). The PCM

operates the solenoid. The PCM determines when to

energize the solenoid. Exhaust system back-pressure

controls the transducer.

When the PCM energizes the solenoid, vacuum

does not reach the transducer. Vacuum flows to the

transducer when the PCM de-energizes the solenoid.

When exhaust system back-pressure becomes high

enough, it fully closes a bleed valve in the trans-

ducer. When the PCM de-energizes the solenoid and

back-pressure closes the transducer bleed valve, vac-

uum flows through the transducer to operate the

EGR valve.

De-energizing the solenoid, but not fully closing the

transducer bleed hole (because of low back-pressure),

varies the strength of vacuum applied to the EGR

valve. Varying the strength of the vacuum changes

the amount of EGR supplied to the engine. This pro-

Fig. 31 Duty Cycle EVAP Purge Solenoid

Fig. 32 Proportional Purge Solenoid

NSFUEL SYSTEM 14 - 43

DESCRIPTION AND OPERATION (Continued)

Page 1340 of 1938

Shutdown (ASD) RelayÐPCM Output in this section

for relay operation.

TORQUE CONVERTER CLUTCH SOLENOIDÐPCM

OUTPUT

Three-speed automatic transaxles use a torque con-

verter clutch solenoid. The PCM controls the engage-

ment of the torque converter clutch through the

solenoid. The torque converter clutch is engaged only

in direct drive mode. Refer to Group 21 for transaxle

information.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

The PCM supplies the malfunction indicator (check

engine) lamp on/off signal to the instrument panel

through the CCD Bus. The CCD Bus is a communi-

cations port. Various modules use the CCD Bus to

exchange information.

The Check Engine lamp comes on each time the

ignition key is turned ON and stays on for 3 seconds

as a bulb test.

The Malfunction Indicator Lamp (MIL) stays on

continuously, when the PCM has entered a Limp-In

mode or identified a failed emission component. Dur-

ing Limp-in Mode, the PCM attempts to keep the

system operational. The MIL signals the need for

immediate service. In limp-in mode, the PCM com-

pensates for the failure of certain components that

send incorrect signals. The PCM substitutes for the

incorrect signals with inputs from other sensors.

If the PCM detects active engine misfire severe

enough to cause catalyst damage, it flashes the MIL.

At the same time the PCM also sets a Diagnostic

Trouble Code (DTC).

For signals that can trigger the MIL (Check

Engine Lamp) refer to Group 25, On-Board

Dianostics.

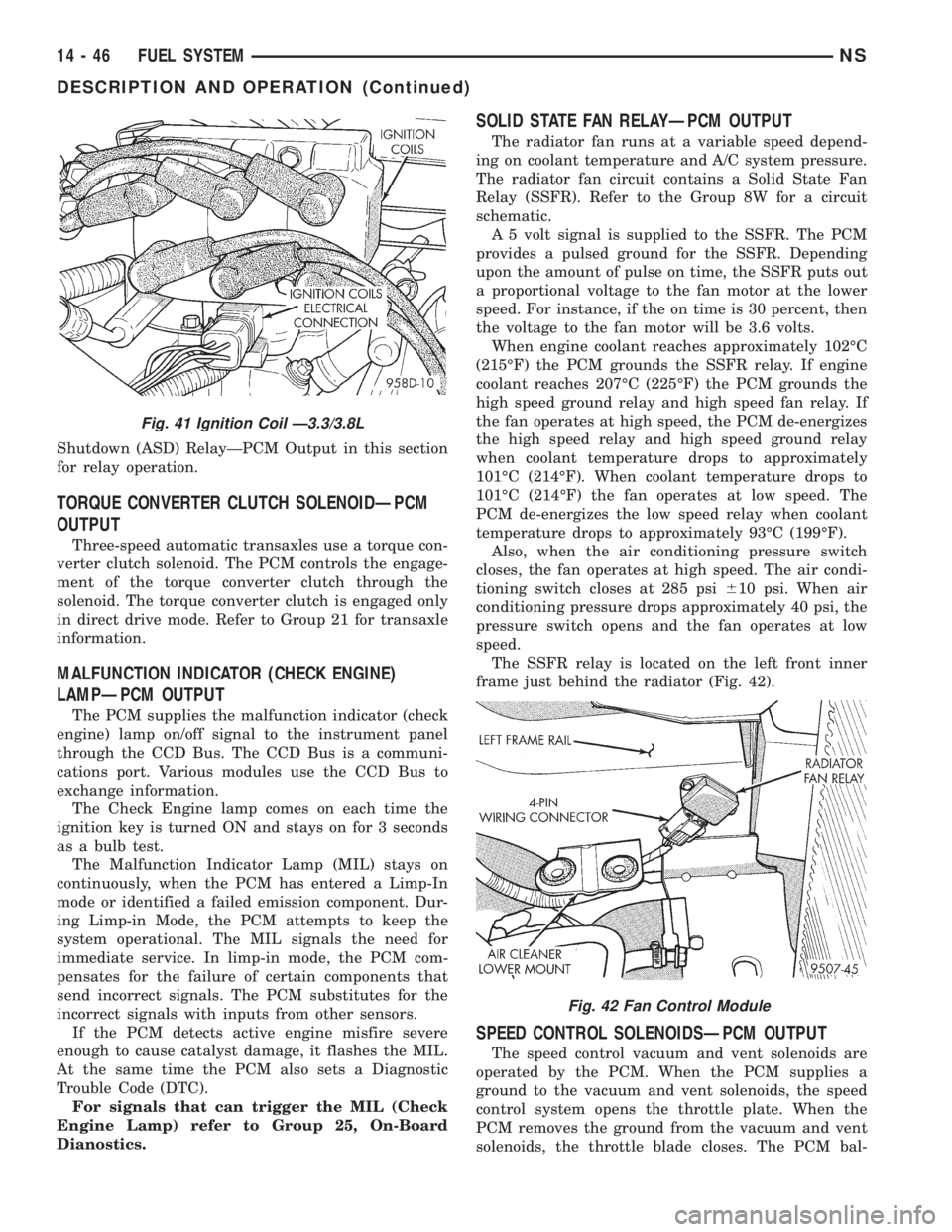

SOLID STATE FAN RELAYÐPCM OUTPUT

The radiator fan runs at a variable speed depend-

ing on coolant temperature and A/C system pressure.

The radiator fan circuit contains a Solid State Fan

Relay (SSFR). Refer to the Group 8W for a circuit

schematic.

A 5 volt signal is supplied to the SSFR. The PCM

provides a pulsed ground for the SSFR. Depending

upon the amount of pulse on time, the SSFR puts out

a proportional voltage to the fan motor at the lower

speed. For instance, if the on time is 30 percent, then

the voltage to the fan motor will be 3.6 volts.

When engine coolant reaches approximately 102ÉC

(215ÉF) the PCM grounds the SSFR relay. If engine

coolant reaches 207ÉC (225ÉF) the PCM grounds the

high speed ground relay and high speed fan relay. If

the fan operates at high speed, the PCM de-energizes

the high speed relay and high speed ground relay

when coolant temperature drops to approximately

101ÉC (214ÉF). When coolant temperature drops to

101ÉC (214ÉF) the fan operates at low speed. The

PCM de-energizes the low speed relay when coolant

temperature drops to approximately 93ÉC (199ÉF).

Also, when the air conditioning pressure switch

closes, the fan operates at high speed. The air condi-

tioning switch closes at 285 psi610 psi. When air

conditioning pressure drops approximately 40 psi, the

pressure switch opens and the fan operates at low

speed.

The SSFR relay is located on the left front inner

frame just behind the radiator (Fig. 42).

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a

ground to the vacuum and vent solenoids, the speed

control system opens the throttle plate. When the

PCM removes the ground from the vacuum and vent

solenoids, the throttle blade closes. The PCM bal-

Fig. 41 Ignition Coil Ð3.3/3.8L

Fig. 42 Fan Control Module

14 - 46 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)